Page 1

Manitowoc

QM20/QM30/QM45

SM50

Q130/Q170/Q210/Q270

Undercounter

Ice Machines

Technician’s

Handbook

This manual is updated as new information and models are

released. Visit our website for the latest manual.

America’s #1 Selling Ice Machine

Part Number 80-01111-9 7/10

www.manitowocice.com

Page 2

Page 3

Safety Notices

!

Warning

!

Caution

Important

As you work on Manitowoc equipment, be sure to pay

close attention to the safety notices in this handbook.

Disregarding the notices may lead to serious injury

and/or damage to the equipment.

Throughout this handbook, you will see the following

types of

safety notices:

Text in a W arning box alerts you to a potentia l

personal inju ry situation. Be sure to re ad th e

Warning st atement be fore procee ding, an d work

carefully.

Text in a Ca ution box alerts you to a si tuation i n

which you could damage the equipment. Be sure

to read the Caution statement before proceeding,

and work carefully.

Procedural Notices

As you work on Manitowoc equipment, be sure to read

the procedural notices in this handbook. These notices

supply helpful information which may assist you as

you work.

Throughout this handbook, you will see the following

es of procedural notices:

typ

Text in an Imp ortant box provide s you with

information that may help you pe rform a

procedure more e fficiently. Di sregarding this

information will not cause damage or in jury, but it

may slow you down as you work.

NOTE: Text set off as a Note provides you with simple,

but useful, extra information about the procedure you

are performing.

Page 4

Read These Before Proceeding:

!

Caution

Important

! Warning

! Warning

We reserve the right to make product

improvements at any time. Specifications and

design are subject to change without notice.

Proper inst allation, care and maintenance are

essential for maxi mum performance and troublefree ope ration of your Manitowoc equ ipment. If

you encounter pro blems n ot covere d b y this

handbook, do n ot procee d, cont act Mani towoc

Foodservice Grou p. We will be happy to provide

assistance.

Routine a djustments an d mai ntenance

procedures ou tlined in this h andbook a re not

covered by the warranty.

PERSONAL INJURY POTENTIAL

Do not operate equipment that has been misused,

abused, neglected, damaged, or altered/modified

from that of original manufactured specifications.

POTENTIAL PERSONAL INJURY

SITUATION

This ice machin e con tains re frigerant ch arge.

Installation an d b razing of the line set s must b e

performed by a prope rly trained refri geration

technician aware of the Dangers of dealing with

refrigerant charged e quipment. T he technician

must also be US Government Environment al

Protection Agen cy (EP A) certified in prop er

refrigerant handling and servicing procedures.

Page 5

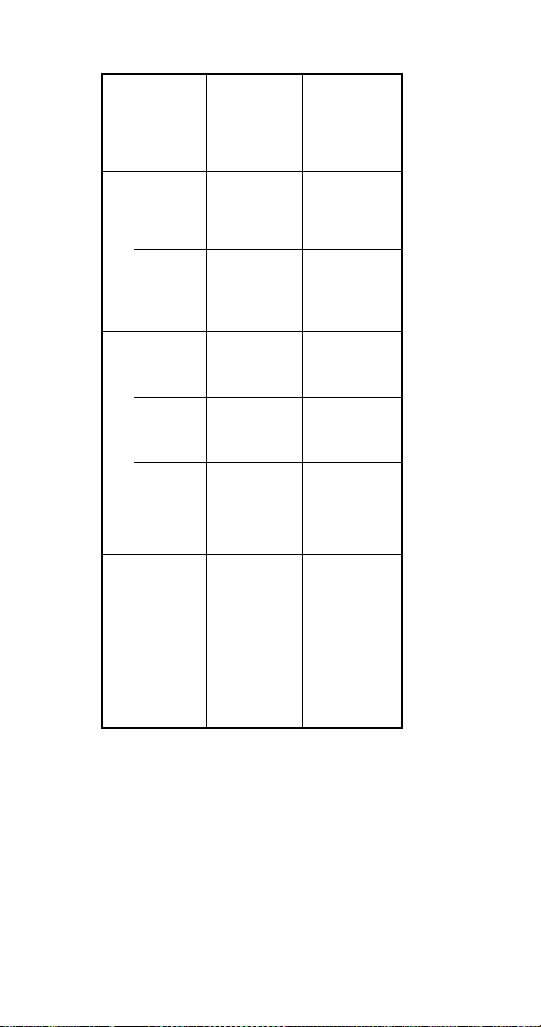

Table of Contents

GENERAL INFORMATION

Model Numbers . . . . . . . . . . . . . . . . . . . . . 11

How to Read a Model Number . . . . . . . . . 12

Accessories . . . . . . . . . . . . . . . . . . . . . . . 12

Bin Caster . . . . . . . . . . . . . . . . . . . . . . 12

Manitowoc Cleaner and Sanitizer . . . . 12

Model/Serial Number Location . . . . . . . . 14

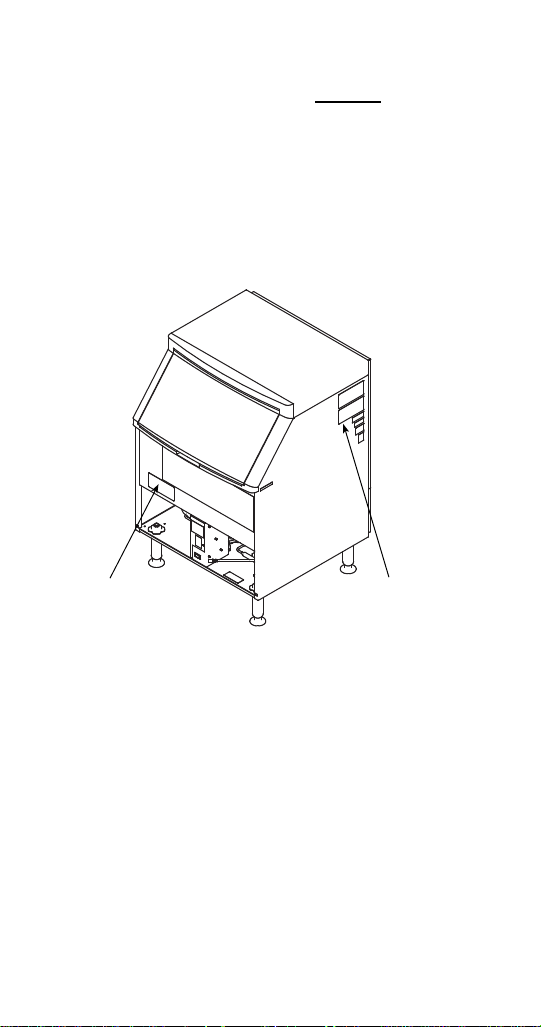

Q130/Q170/Q210/Q270 . . . . . . . . . . . 14

QM20/QM30 . . . . . . . . . . . . . . . . . . . . 15

QM45 . . . . . . . . . . . . . . . . . . . . . . . . . 15

Ice Machine Warranty Information . . . . . 17

Owner Warranty Registration Card . . . 17

Commercial Warranty Coverage . . . . . 17

Residential Warranty Coverage . . . . . 20

INSTALLATION

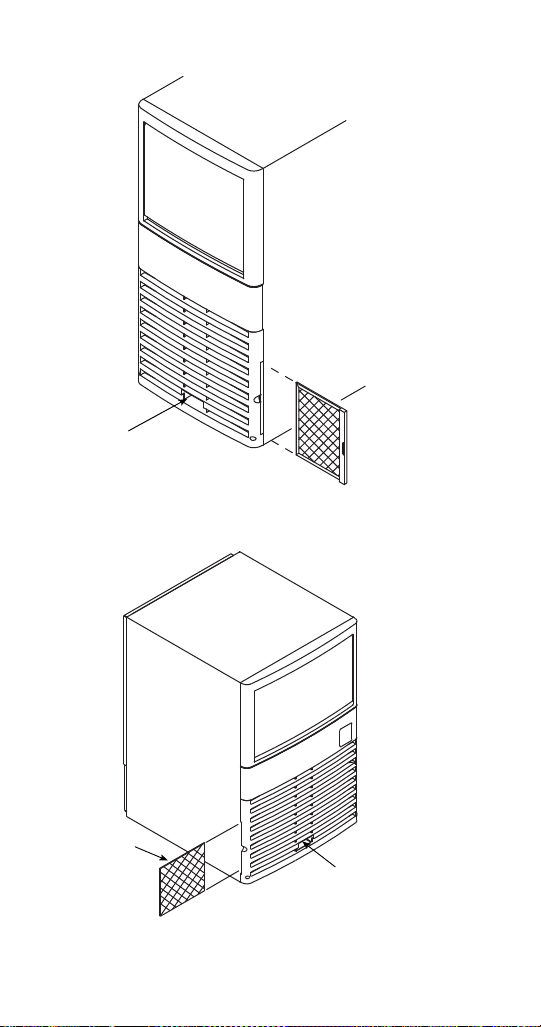

Location of Ice Machine . . . . . . . . . . . . . . 23

Ice Machine Clearance Requirements . . 24

Ice Machine Heat of Rejection . . . . . . . . . 24

Leveling the Ice Machine . . . . . . . . . . . . . 25

QM45/Q130/Q170/Q210/Q270 . . . . . . 25

SM50/QM20/QM30 . . . . . . . . . . . . . . . 26

Electrical Requirements . . . . . . . . . . . . . . 27

Voltage . . . . . . . . . . . . . . . . . . . . . . . . 27

Electrical Specifications . . . . . . . . . . . . . 28

Water Service/Drains . . . . . . . . . . . . . . . . 31

Water Supply . . . . . . . . . . . . . . . . . . . . 31

Water Inlet Lines . . . . . . . . . . . . . . . . . 31

Drain Connections . . . . . . . . . . . . . . . . 31

Cooling Tower Applications . . . . . . . . . 32

COMPONENT IDENTIFICATION

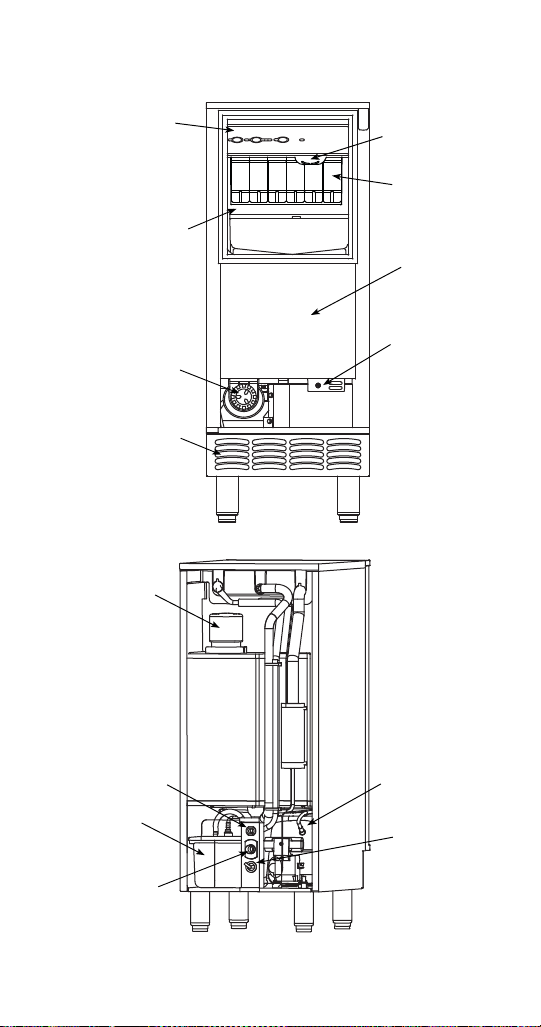

QM45/Q130/Q170/Q210/Q270 . . . . . . . . . 37

QM20/QM30 . . . . . . . . . . . . . . . . . . . . . . . .39

SM50 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

MAINTENANCE

Ice Machine Inspection . . . . . . . . . . . . . . 43

Exterior Cleaning . . . . . . . . . . . . . . . . . . .43

Part Number 80-01111-9 7/10 5

Page 6

Cleaning the Condenser . . . . . . . . . . . . . 43

Air-cooled Condenser . . . . . . . . . . . . . 44

Water-cooled Condenser and

Water Regulating Valve . . . . . . . . . . . 44

QM45/Q130/Q170/Q210/Q270 . . . . . . . . . 45

Interior Cleaning and Sanitizing . . . . . 45

QM20/QM30 . . . . . . . . . . . . . . . . . . . . . . . 60

Cleaning and Sanitizing Procedure . . 60

SM50 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Cleaning Procedure . . . . . . . . . . . . . . 67

Sanitizing Procedure . . . . . . . . . . . . . 68

Removal of Parts for Cleaning and

Sanitizing . . . . . . . . . . . . . . . . . . . . . . 69

Removal from Service/Winterization . . . 77

General . . . . . . . . . . . . . . . . . . . . . . . . 77

Air-cooled Ice Machines . . . . . . . . . . . 77

Water-cooled Ice Machines . . . . . . . . 78

OPERATION

QM45/Q130/Q170/Q210/Q270 . . . . . . . . . 79

Initial Start-up or Start-up After

Automatic Shut-off . . . . . . . . . . . . . . . 79

Freeze Sequence . . . . . . . . . . . . . . . . 79

Harvest Sequence . . . . . . . . . . . . . . . 80

Automatic Shut-off . . . . . . . . . . . . . . . 80

Energized Parts Chart . . . . . . . . . . . . 81

QM20/QM30 . . . . . . . . . . . . . . . . . . . . . . . 83

Initial Start-up or Start-up After

Automatic Shut-off . . . . . . . . . . . . . . . 83

Freeze Sequence . . . . . . . . . . . . . . . . 83

Harvest Sequence . . . . . . . . . . . . . . . 84

Automatic Shut-off . . . . . . . . . . . . . . . 84

Energized Parts Chart . . . . . . . . . . . . 85

SM50 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Initial Start-up or Start-up After

Automatic Shut-off . . . . . . . . . . . . . . . 86

Energized Parts Chart . . . . . . . . . . . . 88

Operational Checks . . . . . . . . . . . . . . . . . 89

QM45/Q130/Q170/Q210/Q270 . . . . . 89

QM20/QM30 . . . . . . . . . . . . . . . . . . . . 92

SM50 . . . . . . . . . . . . . . . . . . . . . . . . . 95

6 Part Number 80-01111-9 7/10

Page 7

TROUBLESHOOTING

QM45/Q130/Q170/Q210/Q270 . . . . . . . . . 99

Diagnosing an Ice Machine

that Will Not Run . . . . . . . . . . . . . . . . . 99

Diagnosing Ice Thickness Control

Circuitry . . . . . . . . . . . . . . . . . . . . . . . . 100

Ice Production Check . . . . . . . . . . . . . 103

Installation and Visual Inspection

Checklist . . . . . . . . . . . . . . . . . . . . . . . 104

Water System Checklist . . . . . . . . . . . 105

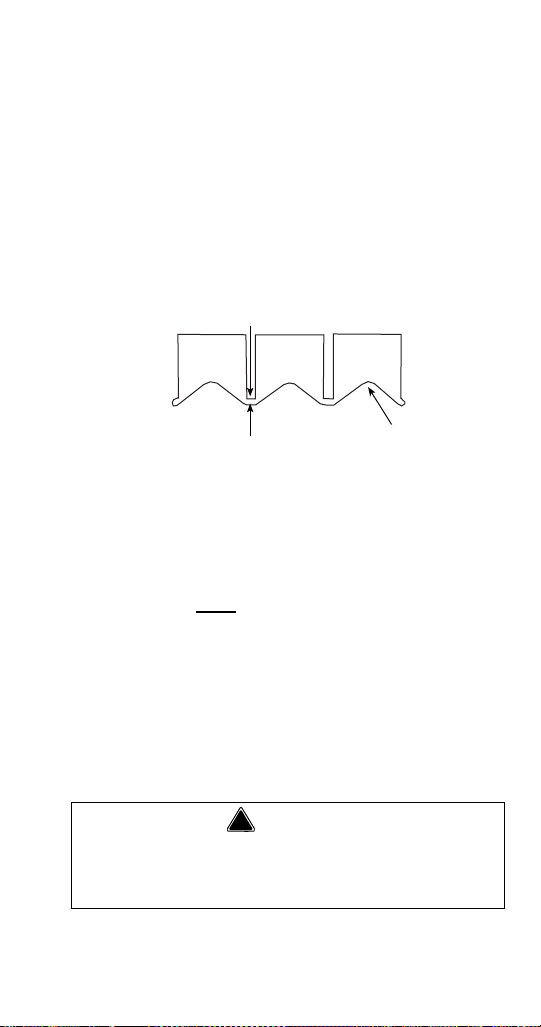

Ice Formation Pattern . . . . . . . . . . . . . 106

Safety Limit Feature . . . . . . . . . . . . . . 108

Analyzing Discharge Pressure . . . . . . 115

Analyzing Suction Pressure . . . . . . . . 117

Hot Gas Valve . . . . . . . . . . . . . . . . . . . 121

Comparing Evaporator Inlet/Outlet

Temperatures . . . . . . . . . . . . . . . . . . . 125

Discharge Line Temperature Analysis 126

Refrigeration Component Diagnostic

Chart . . . . . . . . . . . . . . . . . . . . . . . . . . 128

Final Analysis . . . . . . . . . . . . . . . . . . .130

Refrigeration Component Diagnostic Chart

131

QM20/QM30 . . . . . . . . . . . . . . . . . . . . . . . .134

Diagnosing an Ice Machine

that Will Not Run . . . . . . . . . . . . . . . . . 134

Refrigeration Diagnostics . . . . . . . . . . 135

Ice Formation Pattern . . . . . . . . . . . . . 137

QM45 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .139

Electrical . . . . . . . . . . . . . . . . . . . . . . . 139

Refrigeration Diagnostics . . . . . . . . . . 140

Flooding Expansion Valve . . . . . . . . . . 143

Starving Expansion Valve/

Low Refrigerant Charge . . . . . . . . . . . 143

Overcharged System . . . . . . . . . . . . . 143

SM50 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

Diagnosing an Ice Machine

that Will Not Run . . . . . . . . . . . . . . . . . 144

Ice Machine Will Not Harvest . . . . . . . 145

Ice Quality Is Poor — Cubes are

Shallow, Incomplete or White . . . . . . . 146

Part Number 80-01111-9 7/10 7

Page 8

Freeze Cycle Is Long, Low Ice

Production . . . . . . . . . . . . . . . . . . . . . 147

Ice Machine Runs and No Ice

Is Produced . . . . . . . . . . . . . . . . . . . . 148

Analyzing Discharge Pressure . . . . . . 149

Discharge Pressure High Checklist . . 150

Freeze Cycle Discharge Pressure Low

Checklist . . . . . . . . . . . . . . . . . . . . . . . 150

Analyzing Suction Pressure . . . . . . . . 151

Hot Gas Valve . . . . . . . . . . . . . . . . . . 154

COMPONENT CHECK PROCEDURES

Main Fuse . . . . . . . . . . . . . . . . . . . . . . . . . 159

Function . . . . . . . . . . . . . . . . . . . . . . . 159

Specifications . . . . . . . . . . . . . . . . . . . 159

Check Procedure . . . . . . . . . . . . . . . . 159

Bin Switch . . . . . . . . . . . . . . . . . . . . . . . . 160

QM45/Q130/Q170/Q210/Q270 . . . . . 160

Bin Thermostat . . . . . . . . . . . . . . . . . . . . 164

QM20/QM30 . . . . . . . . . . . . . . . . . . . . 164

SM50 . . . . . . . . . . . . . . . . . . . . . . . . . 166

Liquid Line Thermistor . . . . . . . . . . . . . . 169

QM20/QM30/SM50 . . . . . . . . . . . . . . . 169

Diagnosing Start Components . . . . . . . . 171

Capacitor . . . . . . . . . . . . . . . . . . . . . . 171

Relay . . . . . . . . . . . . . . . . . . . . . . . . . 171

ON/OFF/WASH Toggle Switch . . . . . . . . 172

Function . . . . . . . . . . . . . . . . . . . . . . . 172

Specifications . . . . . . . . . . . . . . . . . . . 172

Check Procedure . . . . . . . . . . . . . . . . 172

QM45/Q130/Q170/Q210/Q270 . . . . . 173

QM20/QM30 . . . . . . . . . . . . . . . . . . . . 173

Ice Thickness Probe . . . . . . . . . . . . . . . . 174

QM45/Q130/Q170/Q210/Q270 . . . . . 174

Ice Thickness Check . . . . . . . . . . . . . 175

Compressor Electrical Diagnostics . . . . 176

Check Resistance (Ohm) Values . . . . 176

Single Phase Compressors . . . . . . . . 176

Check Motor Windings to Ground . . . 176

Compressor Drawing Locked Rotor . . 177

Compressor Drawing High Amps . . . . 177

Fan Cycle Control . . . . . . . . . . . . . . . . . . 178

QM45/Q130/Q170/Q210/Q270 . . . . . 178

8 Part Number 80-01111-9 7/10

Page 9

High Pressure Cutout (HPCO) Control . . 179

QM45/Q130/Q170/Q210/Q270 . . . . . . 179

Filter-Driers . . . . . . . . . . . . . . . . . . . . . . . . 180

Liquid Line Filter Drier . . . . . . . . . . . . . 180

Refrigerant Recovery/Evacuation . . . . . . 181

Definitions . . . . . . . . . . . . . . . . . . . . . . 181

Refrigerant Re-use Policy . . . . . . . . . . 182

Recovery and Recharging . . . . . . . . . . 184

System Contamination Cleanup . . . . . . . 190

General . . . . . . . . . . . . . . . . . . . . . . . . 190

Determining Severity of Contamination 190

Mild System Contamination Cleanup

Procedure . . . . . . . . . . . . . . . . . . . . . . 192

Severe System Contamination Cleanup

Procedure . . . . . . . . . . . . . . . . . . . . . . 193

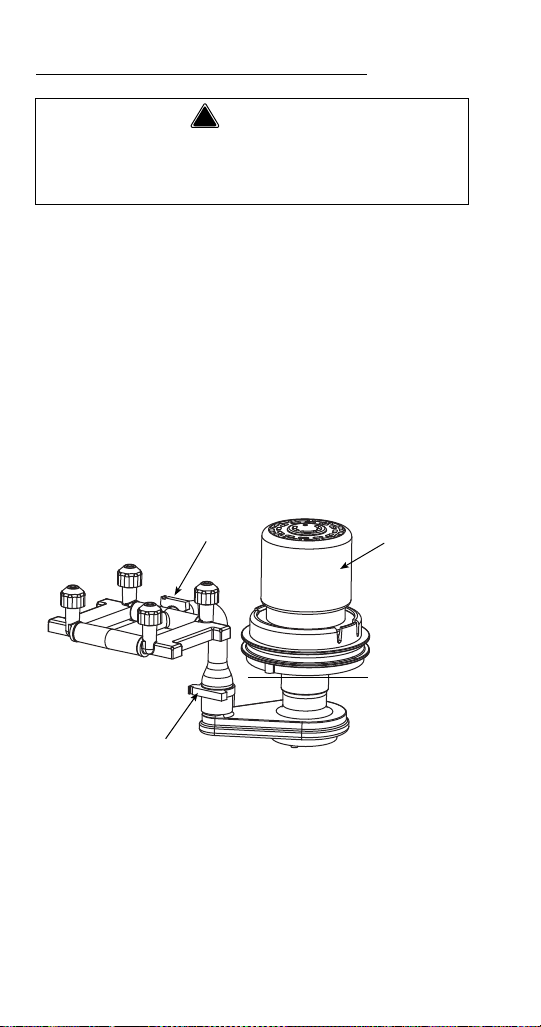

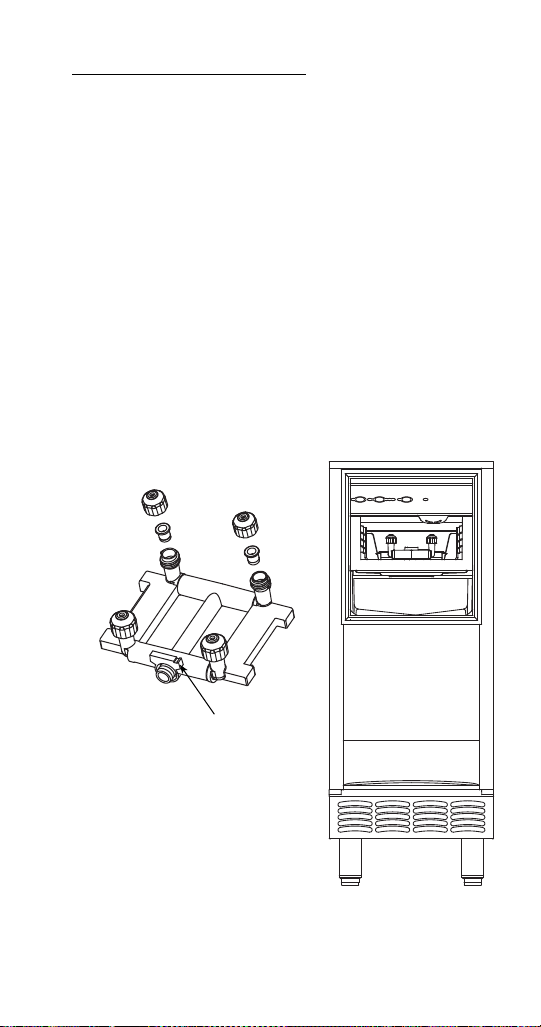

Replacing Pressure Controls without

Removing Refrigerant Charge . . . . . . . 194

Q270 Condenser Fan Motor

Replacement . . . . . . . . . . . . . . . . . . . . . . . 196

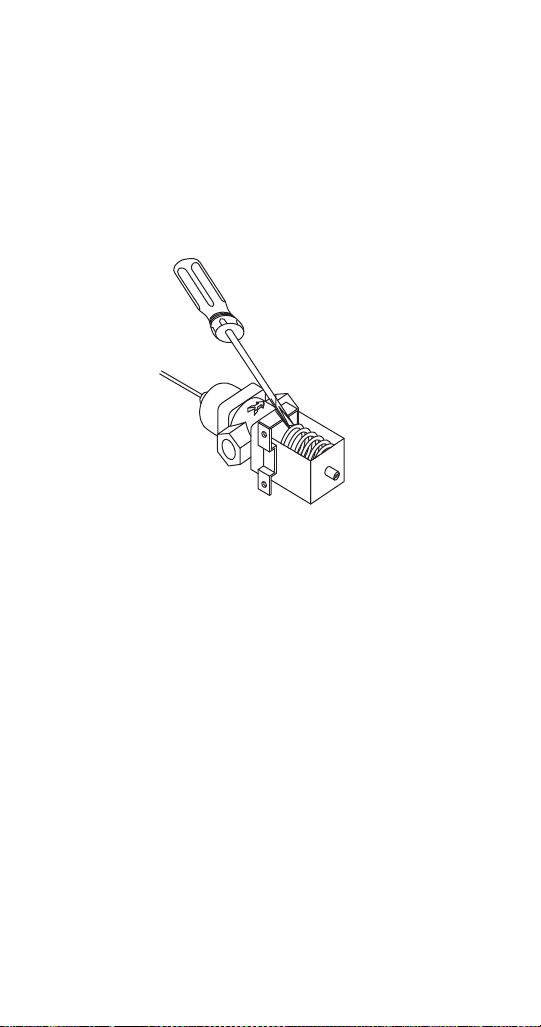

Brazing Procedures for Danfoss Solenoid

Valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . 197

COMPONENT SPECIFICATIONS

Main Fuse . . . . . . . . . . . . . . . . . . . . . . . . . 199

Bin Switch . . . . . . . . . . . . . . . . . . . . . . . . . 199

QM45/Q130/Q170/Q210/Q270 . . . . . . 199

Bin Thermostat . . . . . . . . . . . . . . . . . . . . . 199

QM20/QM30/SM50 . . . . . . . . . . . . . . . 199

ON/OFF/WASH Toggle Switch . . . . . . . . . 199

Fan Control Cycle . . . . . . . . . . . . . . . . . . . 199

QM45/Q130/Q170/Q210/Q270 . . . . . . 199

High Pressure Cutout (HPCO) Control . . 200

Filter-Driers . . . . . . . . . . . . . . . . . . . . . . . . 200

Liquid Line Thermistor . . . . . . . . . . . . . . . 200

QM20/QM30/SM50 . . . . . . . . . . . . . . . 200

Total System Refrigerant Charge . . . . . . 201

Part Number 80-01111-9 7/10 9

Page 10

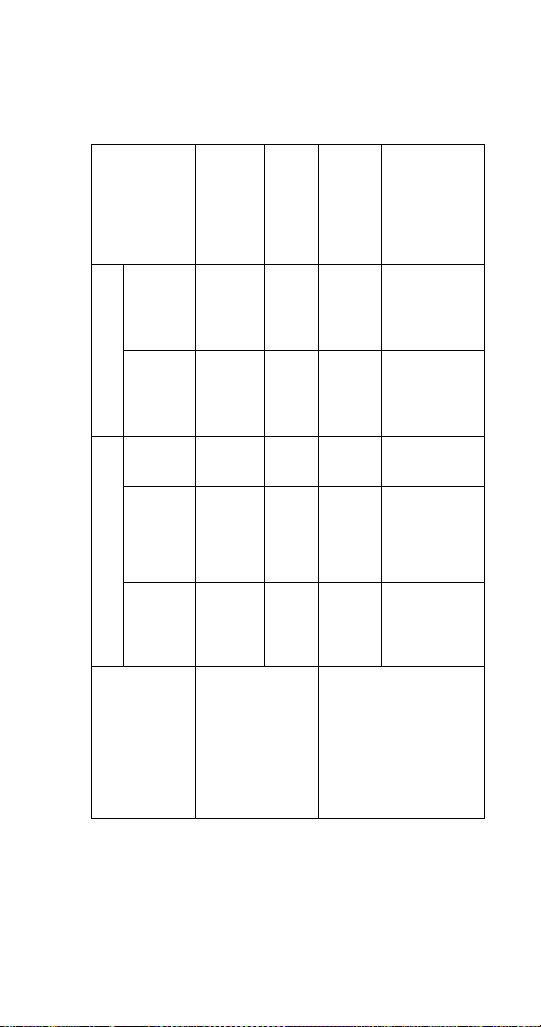

CHARTS

Cycle Times, 24 Hr. Ice Production and

Refrigerant Pressure Charts . . . . . . . . . . 203

QM20 Self-contained Air-cooled . . . . . 204

QM30 Self-contained Air-cooled . . . . . 205

QM45 Self-contained Air-cooled . . . . . 206

QM45 Operating Temperatures . . . . . 207

SM50 Self-contained Air-cooled . . . . . 208

Q130 Self-contained Air-cooled

(Before Serial Number 310047287) . . 209

Q130 Self-contained Air-cooled

(After Serial Number 310047287) . . . . 210

Q130 Self-contained Water-cooled . . 211

Q170 Self-contained Air-cooled . . . . . 212

Q210 Self-contained Air-cooled . . . . . 213

Q210 Self-contained Water-cooled . . 214

Q270 Self-contained Air-cooled . . . . . 215

Q270 Self-contained Water-cooled . . 216

DIAGRAMS

Wiring Diagrams . . . . . . . . . . . . . . . . . . . 217

QM20 . . . . . . . . . . . . . . . . . . . . . . . . . 218

QM30 . . . . . . . . . . . . . . . . . . . . . . . . . 219

QM30 . . . . . . . . . . . . . . . . . . . . . . . . . 220

QM45 . . . . . . . . . . . . . . . . . . . . . . . . . 221

SM50 . . . . . . . . . . . . . . . . . . . . . . . . . 222

Q130/Q210 . . . . . . . . . . . . . . . . . . . . . 223

Q130/Q170/Q210 . . . . . . . . . . . . . . . . 224

Q270 . . . . . . . . . . . . . . . . . . . . . . . . . . 225

Q270 . . . . . . . . . . . . . . . . . . . . . . . . . . 226

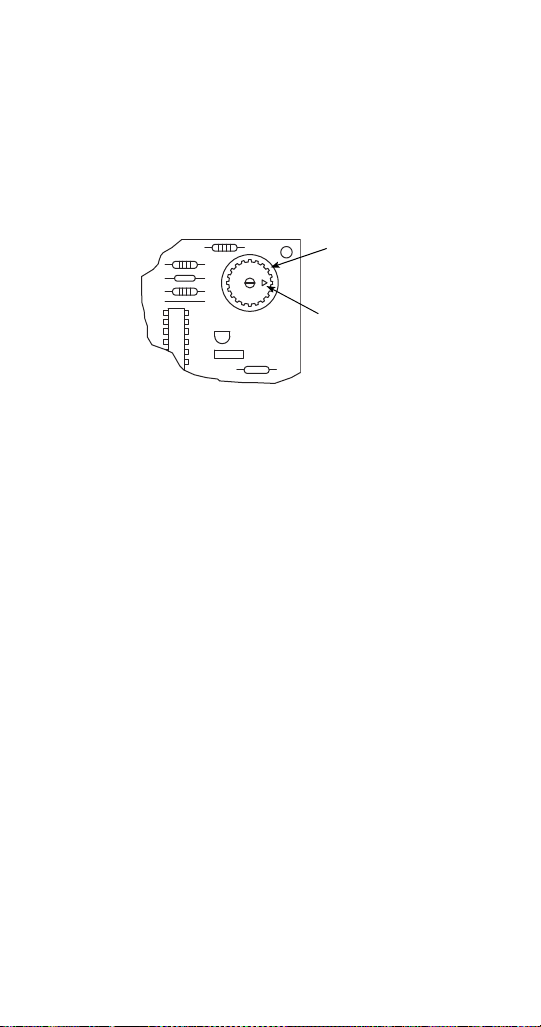

Electronic Control Boards . . . . . . . . . . . 227

Tubing Schematics . . . . . . . . . . . . . . . . . 230

10 Part Number 80-01111-9 7/10

Page 11

General Information

! Warning

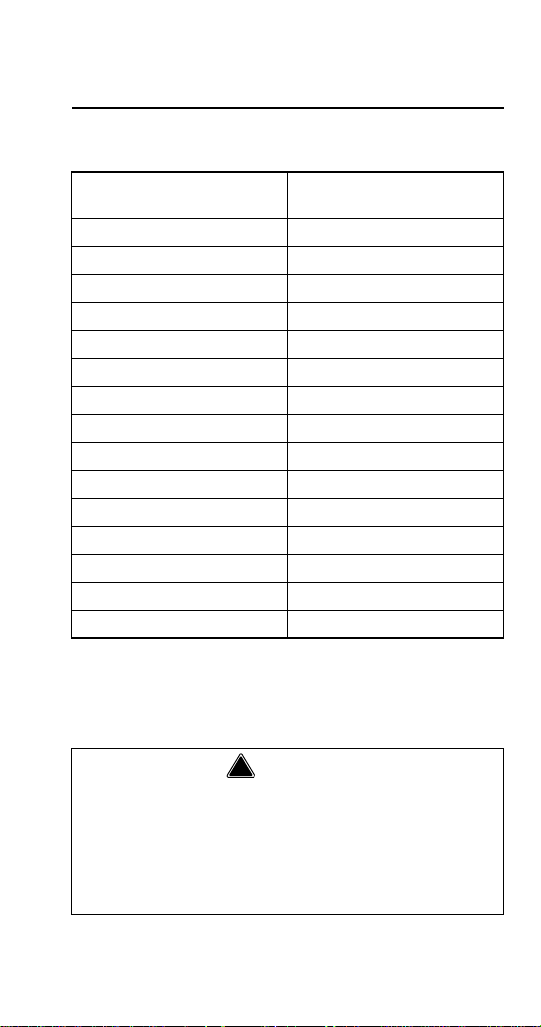

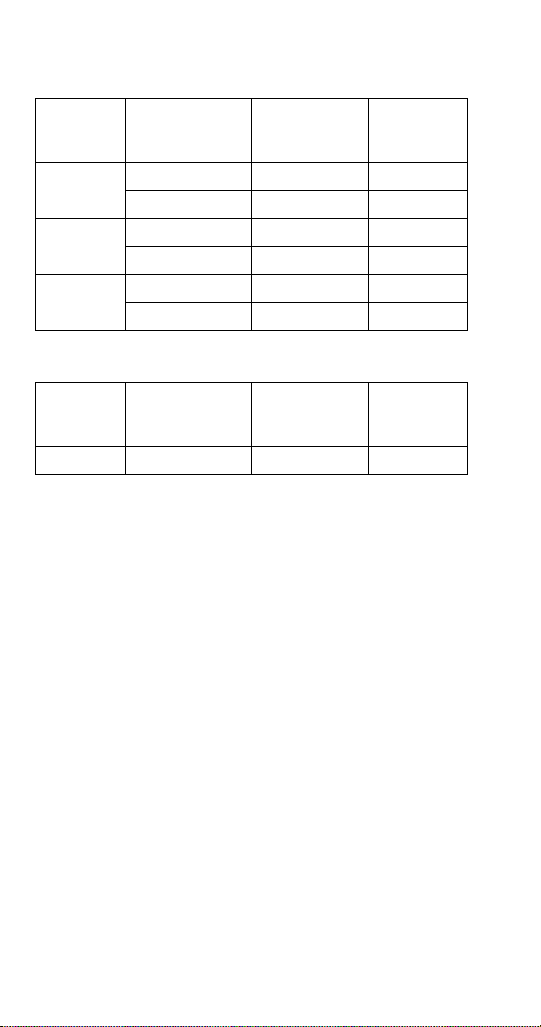

Model Numbers

This manual covers the following models:

Self-contained

Air-cooled

QM20A* N/A

QM30A* N/A

QM45A* N/A

SM50A N/A

QR0130A QR0131W

QD0132A QD0133W

QY0134A QY0135W

QD0172A N/A

QY0174A N/A

QR0210A QR0211W

QD0212A QD0213W

QY0214A QY0215W

QR0270A QR0271W

QD0272A QD0273W

QY0274A QY0275W

*QM Models – the suffix E represents 230 volt/1 ph/50 hz machine.

Self-contained

Water-cooled

An ice machin e con tains h igh voltage electricity

and refri gerant ch arge. Rep airs are to b e

performed by properly trained refri geration

technicians a ware of the dangers of d ealing with

high vol tage e lectricity and refrigera nt und er

pressure.

Part Number 80-01111-9 7/10 11

Page 12

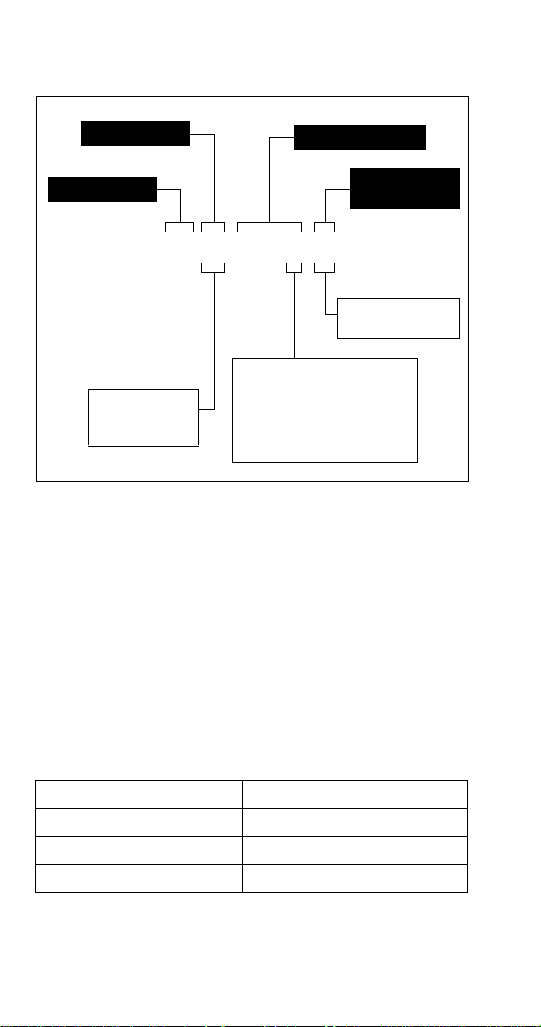

How to Read a Model Number

A - Air-cooled

W - Water-cooled

0 - Regular, Air-cooled

1 - Regular, Water-cooled

2 - Dice, Air-cooled

3 - Dice, Water-cooled

4 - Half-dice, Air-cooled

5 - Half-dice, Water-cooled

Series

Condenser

Type

Capacity

Q R 0130 A

R - Regular

D - Dice

Y - Half-dice

Cube Size

Accessories

Contact your Manitowoc distributor for these optional

accessories:

BIN CASTER

Replaces standard legs.

MANITOWOC CLEANER AND SANITIZER

Manitowoc Ice Machine Cleaner and Sanitizer are

available in convenient 16 oz. (473 ml) and 1 gal

(3.78 l) bottles. These are the only cleaner and

sanitizer approved for use with Manitowoc products.

Cleaner Part Number Sanitizer Part Number

16 oz 94-0456-3 16 oz 94-0565-3

*16 oz 000000084

1 Gallon 4-0580-3 1 Gallon 94-0581-3

* This cleaner must be used with all SM50 ice machines. Evaporator

damage will result with repeated use or high concentrations of P/N

94-0565-3 cleaner with SM50 ice machines.

12 Part Number 80-01111-9 7/10

Page 13

!

Caution

Use only Ma nitowoc app roved Ice Machine

Cleaner (part nu mber 9 4-0546-3 original gre en

ice machin e cleaner or 000 000084 clea r met al

safe ice ma chine clea ner) a nd San itizer (p art

number 94-0565-3). It is a viola tion of Federal

law to use th ese so lutions in a manner

inconsistent with thei r l abeling. Re ad a nd

understand all lab els printed on bottles before

use.

NOTE: The Manitowoc Automatic Cleaning System

®

(AuCS

ice machines SM50, QM20, QM30, QM45, Q130,

Q170, Q210, or Q270.

QM20, QM30, QM45 ice machines do not have a

water curtain covering the evaporator. Q130, Q210,

Q170, Q270 have an ice damper that performs the

functions of the water curtain see Ice Damper

Removal/Installation for Details.

) accessory cannot be used with Undercounter

Part Number 80-01111-9 7/10 13

Page 14

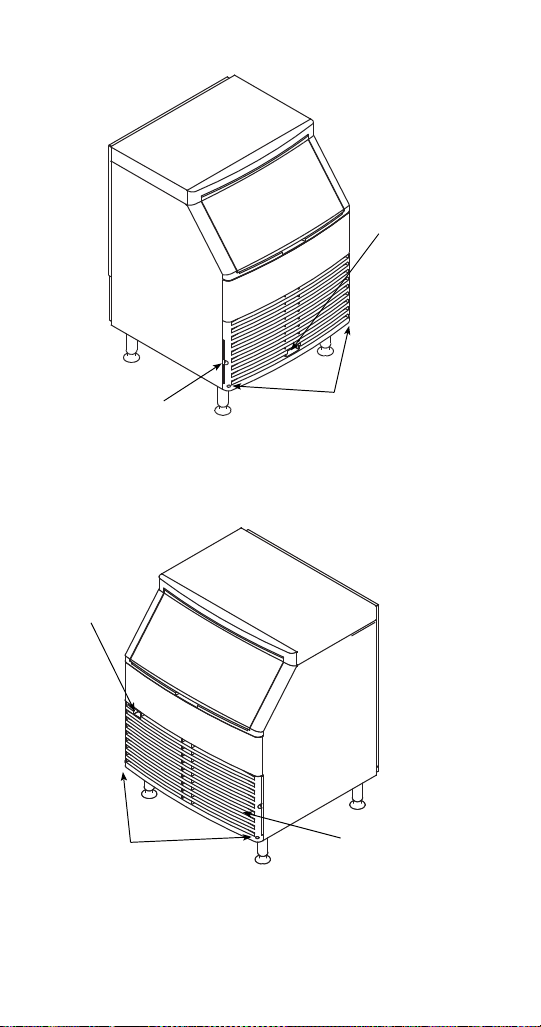

Model/Serial Number Location

MODEL/SERIAL

NUMBER PLATE

MODEL/SERIAL

NUMBER PLATE

SV1687G

The model and serial numbers are required when

requesting information from your local Manitowoc

distributor, service representative, or Manitowoc Ice.

The model and serial number are listed on the

OWNER WARRANTY REGISTRATION CARD. They

are also listed on the MODEL/SERIAL NUMBER

DECAL affixed to the ice machine.

Q130/Q170/Q210/Q270

Model/Serial Number Location

14 Part Number 80-01111-9 7/10

Page 15

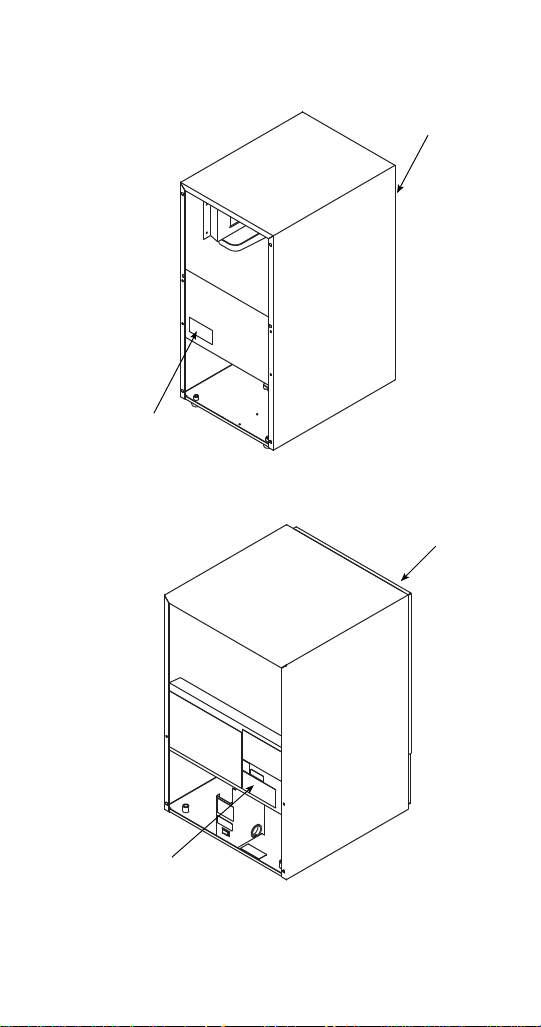

QM20/QM30

MODEL/SERIAL

NUMBER PLATE

MODEL/SERIAL

NUMBER PLATE

SV1599

MODEL/SERIAL

NUMBER

PLATE

MODEL/SERIAL

NUMBER PLATE

SV1732

QM45

Part Number 80-01111-9 7/10 15

Page 16

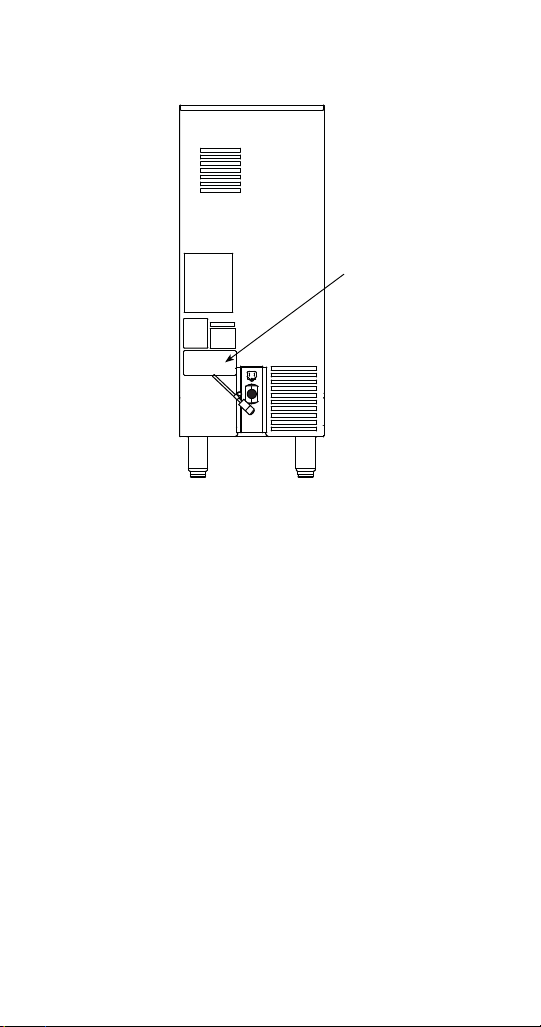

SM50

MODEL/SERIAL

NUMBER PLATE

16 Part Number 80-01111-9 7/10

Page 17

Ice Machine Warranty Information

Important

OWNER WARRANTY REGISTRATION CARD

General

Warranty coverage begins the day the ice machine is

installed.

Complete and mail the OWNER W ARRANTYREGISTRATION C ARD as soo n as p ossible to

validate the installation date.

If the OWNER WARRANTY REGISTRATION CARD is

not returned, Manitowoc will use the date of sale to the

Manitowoc Distributor as the first day of warranty

coverage for your new ice machine.

COMMERCIAL WARRANTY COVERAGE

General

The following Warranty outline is provided for your

convenience. For a detailed explanation, read the

warranty bond shipped with each product.

Contact your local Manitowoc representative or

Manitowoc Ice, if you need further warranty

information.

Parts

Q130/Q170/Q210/Q270

1. Manitowoc warrants the ice machine against

defects in materials and workmanship, under

normal use and service for three (3) years from

the date of original installation.

2. The evaporator and compressor are covered by

an additional two (2) year (five years total)

warranty beginning on the date of the original

installation.

SM50/QM20/QM30/QM45

1. Manitowoc warrants the ice machine against

defects in materials and workmanship, under

normal use and service for three (3) years from

the date of original installation.

Part Number 80-01111-9 7/10 17

Page 18

Labor

Q130/Q170/Q210/Q270

1. Labor required to repair or replace defective

components is covered for three (3) years from

the date of original installation.

2. The evaporator is covered by an additional two(2) year (five years total) labor warranty beginning

on the date of the original installation (Q130/

Q170/Q210/Q270 only).

SM50/QM20/QM30/QM45

1. Labor required to repair or replace defective

components is covered for three (3) years from

the date of original installation.

Exclusions

The following items are not included in the ice

machine’s warranty coverage:

1. Normal maintenance, adjustments and cleaning

as outlined in this manual.

2. Repairs due to unauthorized modifications to the

ice machine or use of non-standard parts without

prior written approval from Manitowoc Ice.

3. Damage caused by improper installation of the ice

machine, electrical supply, water supply or

drainage, or damage caused by floods, storms, or

other acts of God.

4. Premium labor rates due to holidays, overtime,

etc.; travel time; flat rate service call charges;

mileage and miscellaneous tools and material

charges not listed on the payment schedule.

Additional labor charges resulting from the

inaccessibility of equipment are also excluded.

5. Parts or assemblies subjected to misuse, abuse,

neglect or accidents.

6. Damage or problems caused by installation,

cleaning and/or maintenance procedures

inconsistent with the technical instructions

provided in this manual.

7. This warranty is intended exclusively for

commercial application. No warranty is extended

for personal, family, or household purposes.

18 Part Number 80-01111-9 7/10

Page 19

Authorized Warranty Service

To comply with the provisions of the warranty, a

refrigeration service company qualified and authorized

by your Manitowoc distributor, or a Contracted Service

Representative must perform the warranty repair.

Service Calls

Normal maintenance, adjustments and cleaning as

outlined in this manual are not covered by the

warranty.

Part Number 80-01111-9 7/10 19

Page 20

RESIDENTIAL WARRANTY COVERAGE

What Does this Limited Warranty Cover?

Subject to the exclusions and limitations below,

Manitowoc Ice (“Manitowoc”) warrants to the original

consumer that any new ice machine manufactured by

Manitowoc (the “Product”) shall be free of defects in

material or workmanship for the warranty period

outlined below under normal use and maintenance,

and upon proper installation and start-up in

accordance with the instruction manual supplied with

the Product.

How Long Does this Limited Warranty Last?

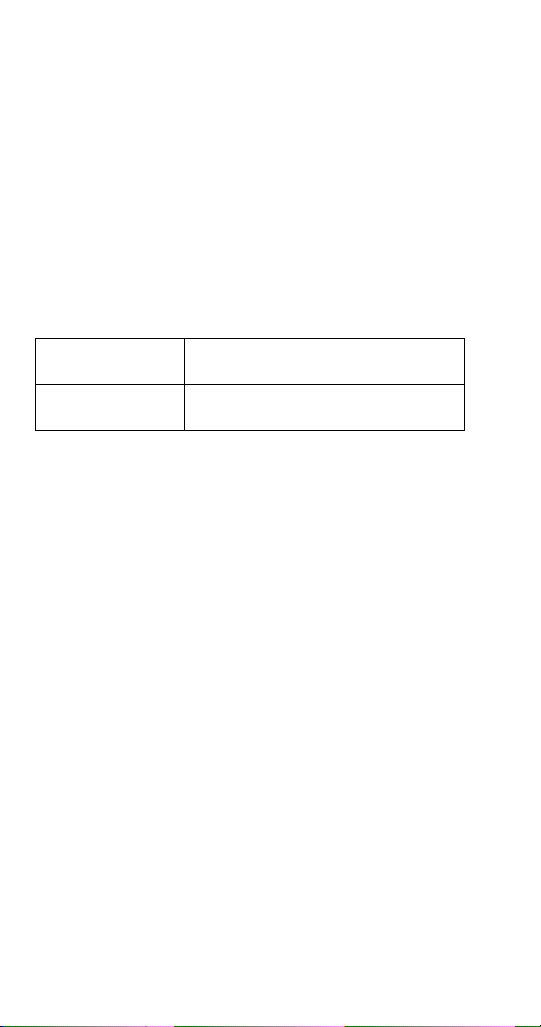

Product Covered Warranty Period

Ice Machine Twelve (12) months

from the sale date

Who is Covered by this Limited Warranty?

This limited warranty only applies to the original

consumer of the Product and is not transferable.

What are MANITOWOC ICE’S Obligations Under this Limited Warranty?

If a defect arises and Manitowoc receives a valid

warranty claim prior to the expiration of the warranty

period, Manitowoc shall, at its option: (1) repair the

Product at Manitowoc’s cost, including standard

straight time labor charges, (2) replace the Product

with one that is new or at least as functionally

equivalent as the original, or (3) refund the purchase

price for the Product. Replacement parts are

warranted for 90 days or the balance of the original

warranty period, whichever is longer. The foregoing

constitutes Manitowoc’s sole obligation and the

consumer’s exclusive remedy for any breach of this

limited warranty. Manitowoc’s liability under this limited

warranty is limited to the purchase price of Product.

Additional expenses including, without limitation,

service travel time, overtime or premium labor

charges, accessing or removing the Product, or

shipping are the responsibility of the consumer.

20 Part Number 80-01111-9 7/10

Page 21

What Is Not Covered?

This limited warranty does cover, and you are solely

responsible for the costs of: (1) periodic or routine

maintenance, (2) repair or replacement of the Product

or parts due to normal wear and tear, (3) defects or

damage to the Product or parts resulting from misuse,

abuse, neglect, or accidents, (4) defects or damage to

the Product or parts resulting from improper or

unauthorized alterations, modifications, or changes;

and (5) defects or damage to any Product that has not

been installed and/or maintained in accordance with

the instruction manual or technical instructions

provided by Manitowoc. To the extent that warranty

exclusions are not permitted under some state laws,

these exclusions may not apply to you.

EXCEPT AS STATED IN THE FOLLOWING SENTENCE,

THIS LIMITED WARRANTY IS THE SOLE AND EXCLUSIVE

WARRANTY OF MANITOWOC WITH REGARD TO THE

PRODUCT. ALL IMPLIED WARRANTIES ARE STRICTLY

LIMITED TO THE DURATION OF THE LIMITED

WARRANTY APPLICABLE TO THE PRODUCTS AS

STATED ABOVE, INCLUDING BUT NOT LIMITED TO, ANY

WARRANTY OF MERCHANTABILITY OR OF FITNESS

FOR A PARTICULAR PURPOSE.

Some states do not

allow limitations on how long an implied warranty lasts,

so the above limitation may not apply to you.

IN NO EVENT SHALL MANITOWOC OR ANY OF ITS

AFFILIATES BE LIABLE TO THE CONSUMER OR ANY

OTHER PERSON FOR ANY INCIDENTAL,

CONSEQUENTIAL OR SPECIAL DAMAGES OF ANY KIND

(INCLUDING, WITHOUT LIMITATION, LOSS OF PROFITS,

REVENUE OR BUSINESS) ARISING FROM OR IN ANY

MANNER CONNECTED WITH THE PRODUCT, ANY

BREACH OF THIS LIMITED WARRANTY, OR ANY OTHER

CAUSE WHATSOEVER, WHETHER BASED ON

CONTRACT, TORT OR ANY OTHER THEORY OF

LIABILITY.

Some states do not allow the exclusion or

limitation of incidental or consequential damages, so

the above limitation or exclusion may not apply to you.

Part Number 80-01111-9 7/10 21

Page 22

How State Law Applies

This limited warranty gives you specific legal rights,

and you may also have rights that vary from state to

state or from one jurisdiction to another.

Registration Card

To secure prompt and continuing warranty service, this

warranty registration card must be completed and sent

to Manitowoc within thirty (30) days from the sale date.

Complete the following registration card and send it to

Manitowoc at the address shown above. Retain a copy

for your records.

HOW TO OBTAIN WARRANTY SERVICE

To obtain warranty service or information regarding

your Product, please contact us at:

MANITOWOC ICE

2110 S. 26

th

St.,

P.O. Box 1720

Manitowoc, WI 54221-1720

Telephone: 920-682-0161 Fax: 920-683-7585

www.manitowocice.com

22 Part Number 80-01111-9 7/10

Page 23

Installation

Location of Ice Machine

The location selected for the ice machine must meet

the following criteria. If any of these criteria are not

met, select another location.

• The location must be indoors.

• The location must be free of airborne and other

contaminants.

• Air temperature:

• Q130/Q170/Q210/Q270/QM45 must be at

least 40°F (4°C) but must not exceed 110°F

(43.4°C).

• QM20/QM30 must be at least 50°F (10°C) but

must not exceed 113°F (45°C).

• SM50 must be at least 50°F (10°C) but must

not exceed 110°F (43°C).

• The location must not be near heat-generating

equipment or in direct sunlight.

• The location must be capable of supporting the

weight of the ice machine and a full bin of ice.

• The location must allow enough clearance for

water, drain, and electrical connections in the rear

of the ice machine.

• The location must not obstruct airflow through or

around the ice machine (condenser airflow is in

and out the front). Refer to the chart below for

clearance requirements.

• The ice machine must be protected if it will be

subjected to temperatures below 32°F (0°C).

Failure caused by exposure to freezing

temperatures is not covered by the warranty.

Part Number 80-01111-9 7/10 23

Page 24

Ice Machine Clearance Requirements

Self-contained

Air-cooled

Top/Sides 5" (127 mm)* 5" (127 mm)*

Back 5" (127 mm)* 5" (127 mm)*

*NOTE: The ice machine may be built into a cabinet.

Self-contained

Water-cooled

There is no minimum clearance requirement for the

top or left and right sides of the ice machine. The listed

values are recommended for efficient operation and

servicing only.

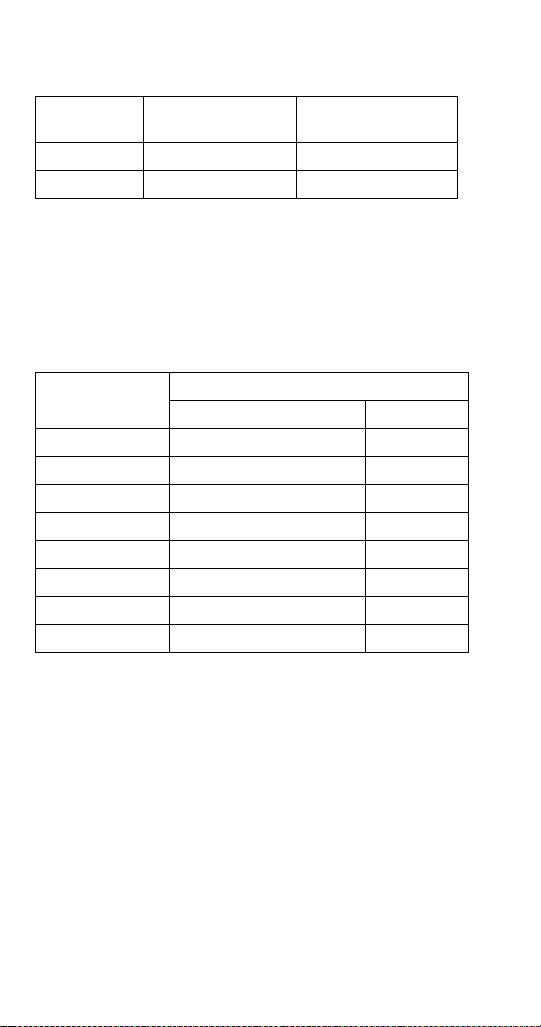

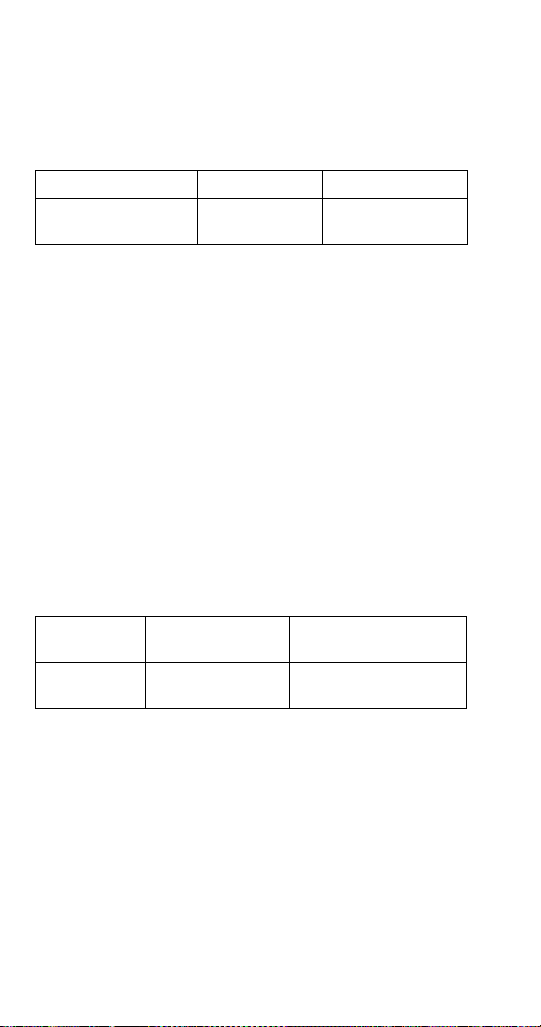

Ice Machine Heat of Rejection

Series

Ice Machine

SM50 1145 2300

QM20 1450 2100

QM30 1600 2350

QM45 1750 2600

Q130 2100 3300

Q170 2200 2600

Q210 2400 3400

Q270 3800 6000

* B.T.U./Hour

** Because the heat of rejection varies during the ice making cycle,

the figure shown is an average.

Ice machines, like other refrigeration equipment, reject

heat through the condenser. It is helpful to know the

amount of heat rejected by the ice machine when

sizing air conditioning equipment where self-contained

air-cooled ice machines are installed.

Heat of Rejection*

Air Conditioning** Peak

24 Part Number 80-01111-9 7/10

Page 25

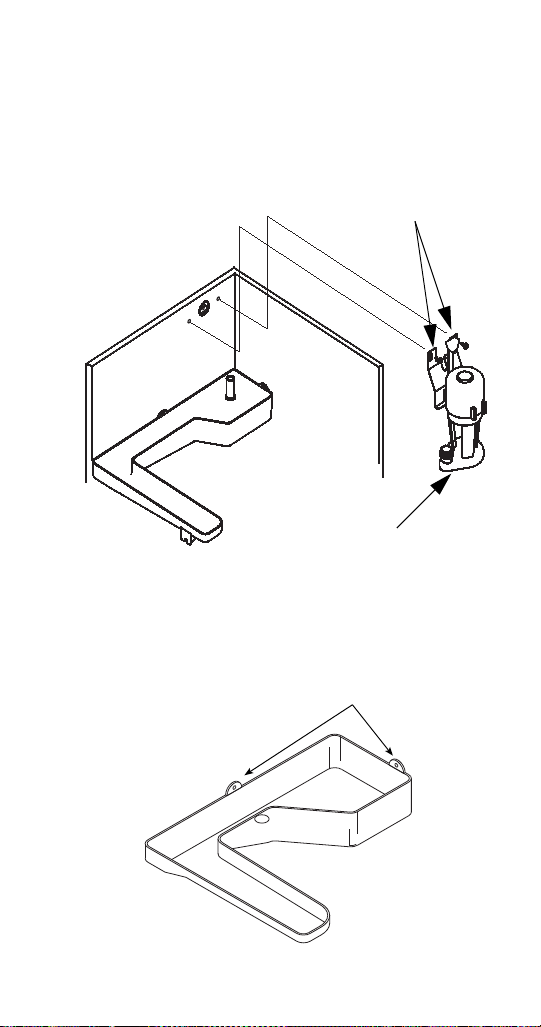

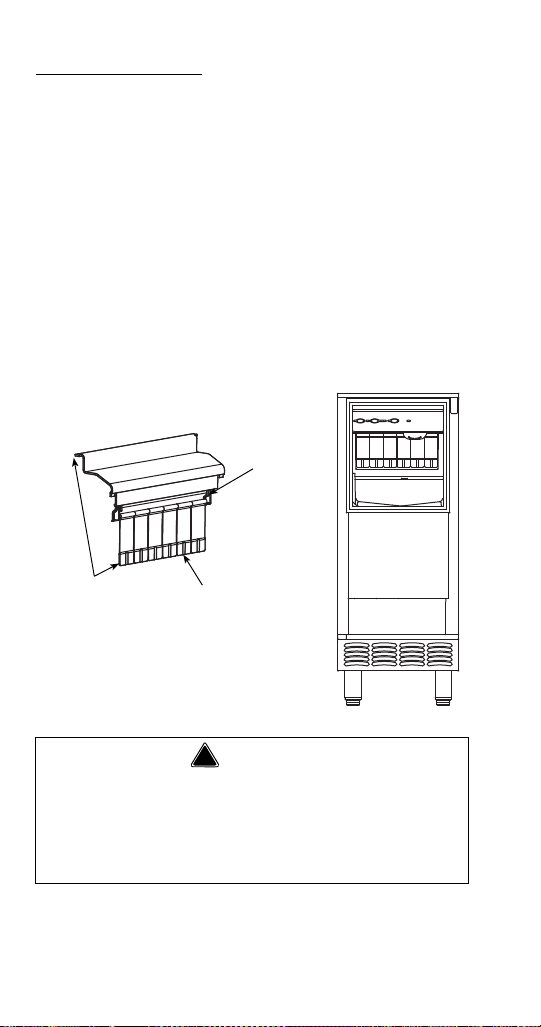

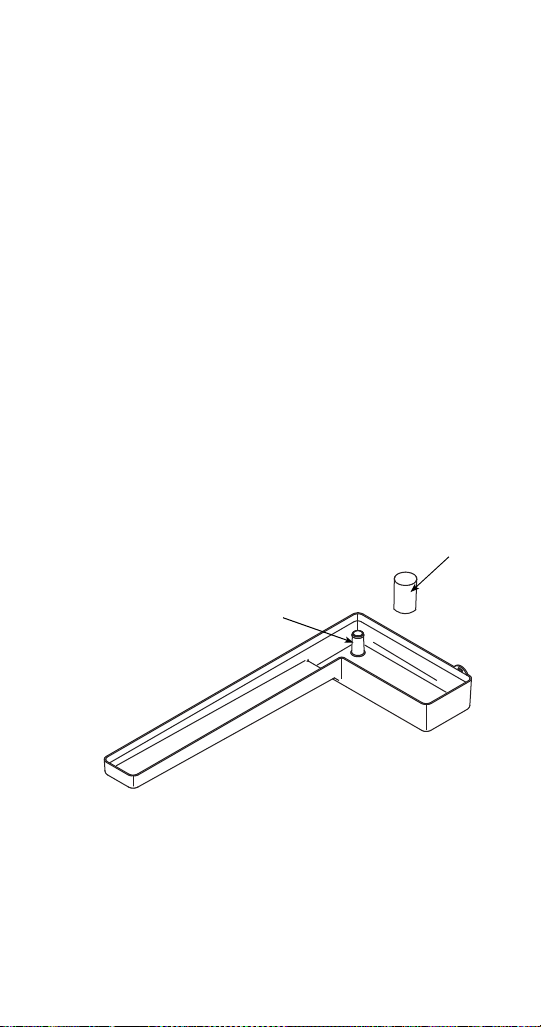

Leveling the Ice Machine

!

Caution

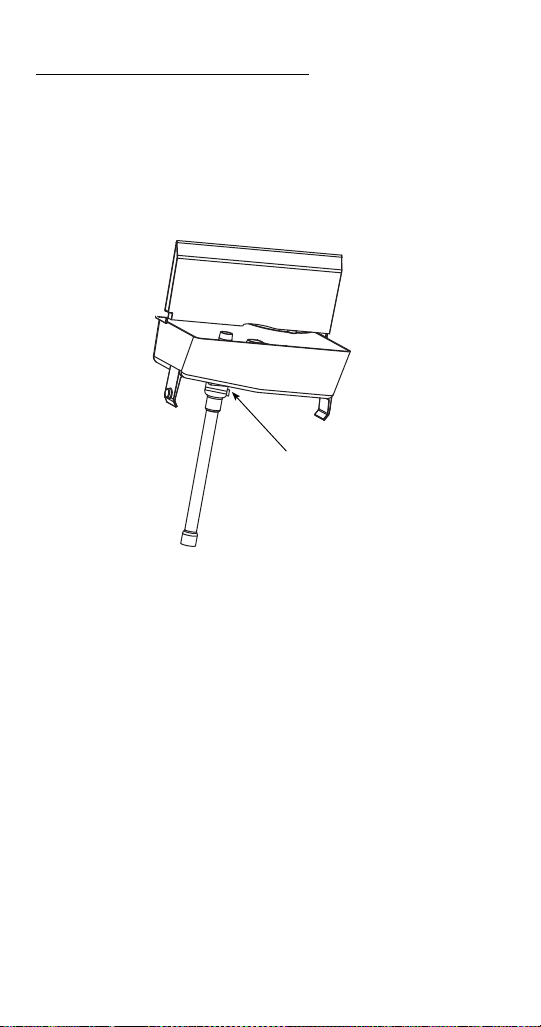

THREAD

LEVELING LEG

INTO BASE OF

CABINET

THREAD “FOOT”

IN AS FAR AS

POSSIBLE

SV1606

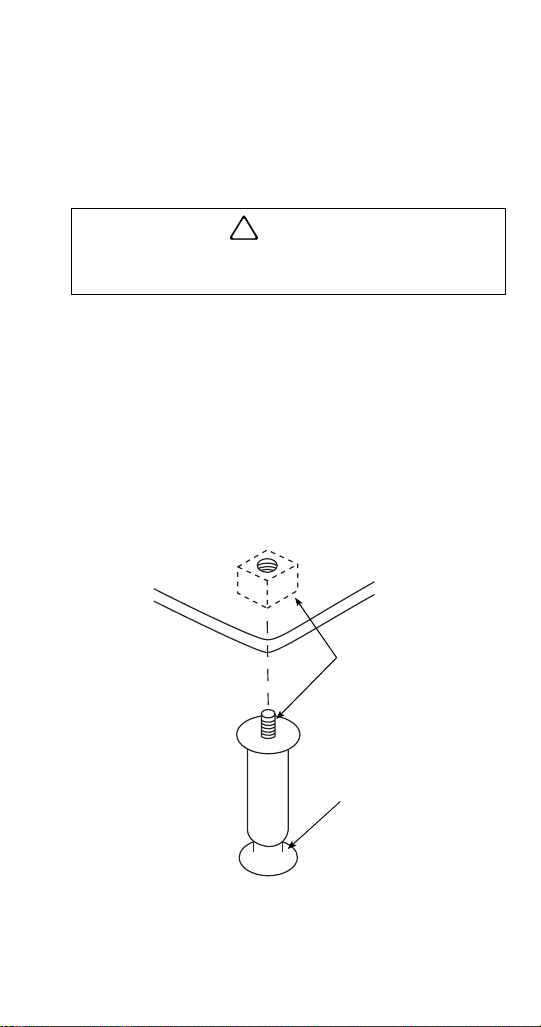

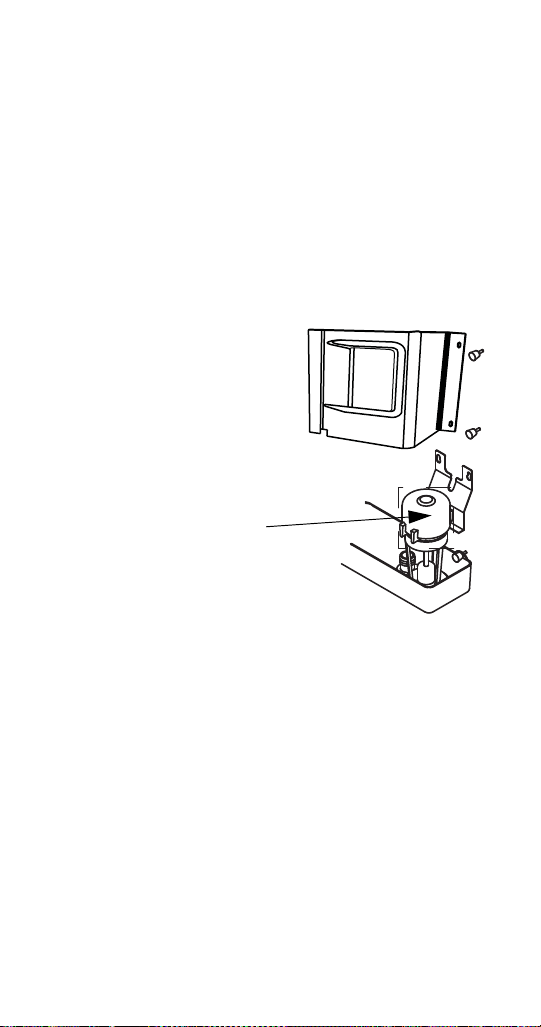

QM45/Q130/Q170/Q210/Q270

1. Screw the leveling legs onto the bottom of the ice

machine.

2. Screw the foot of each leg in as far as possible.

The leg s must be screwe d in tightly to preven t

them from bending.

3. Move the ice machine into its final position.

4. Level the ice machine to ensure that the siphon

system functions correctly. Use a level on top of

the ice machine. Turn each foot as necessary to

level the ice machine from front to back and side

to side.

NOTE: An optional 2-1/2" (6.35 cm) caster assembly is

available for use in place of the legs on the Q130,

Q170, Q210, Q270, or QM45. Installation instructions

are supplied with the casters.

Leg Installation

Part Number 80-01111-9 7/10 25

Page 26

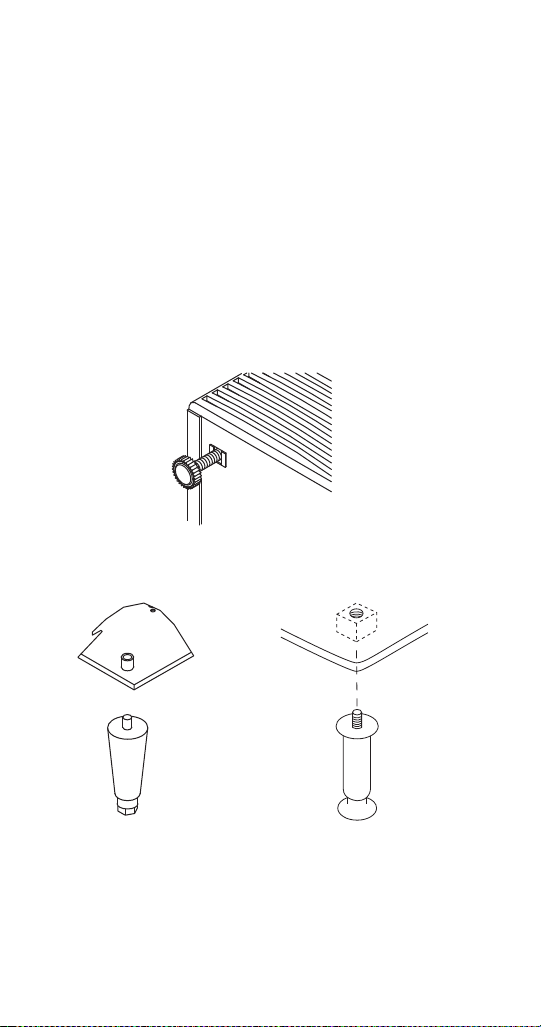

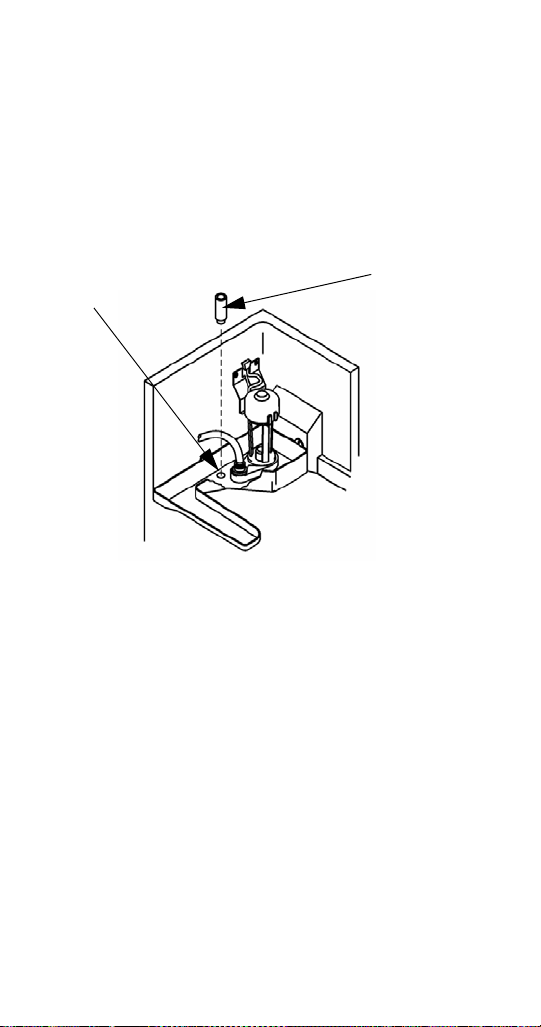

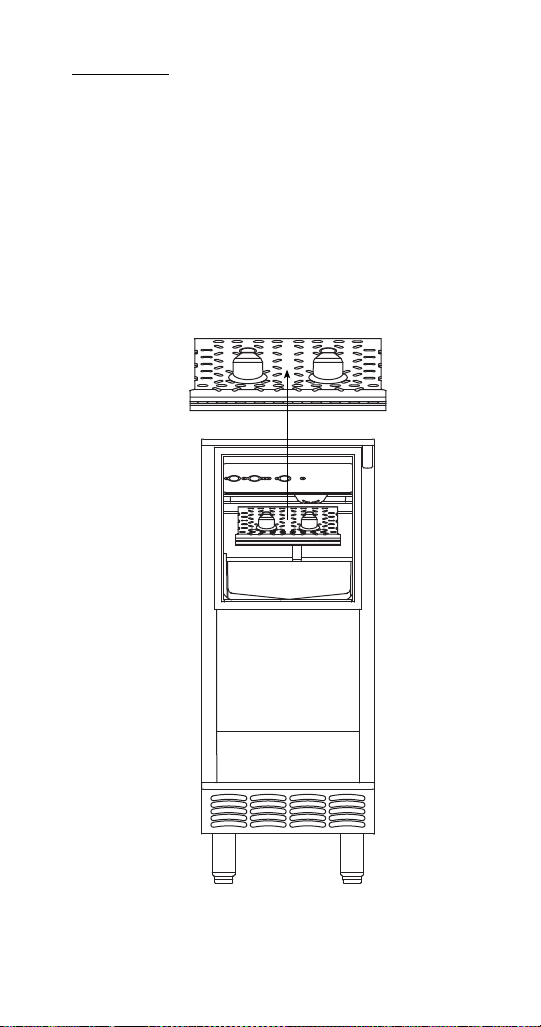

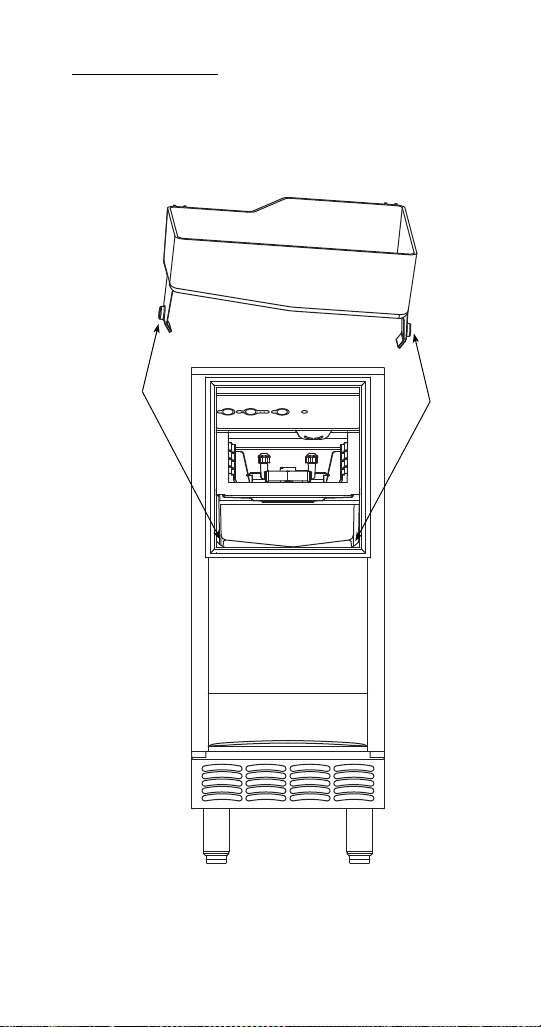

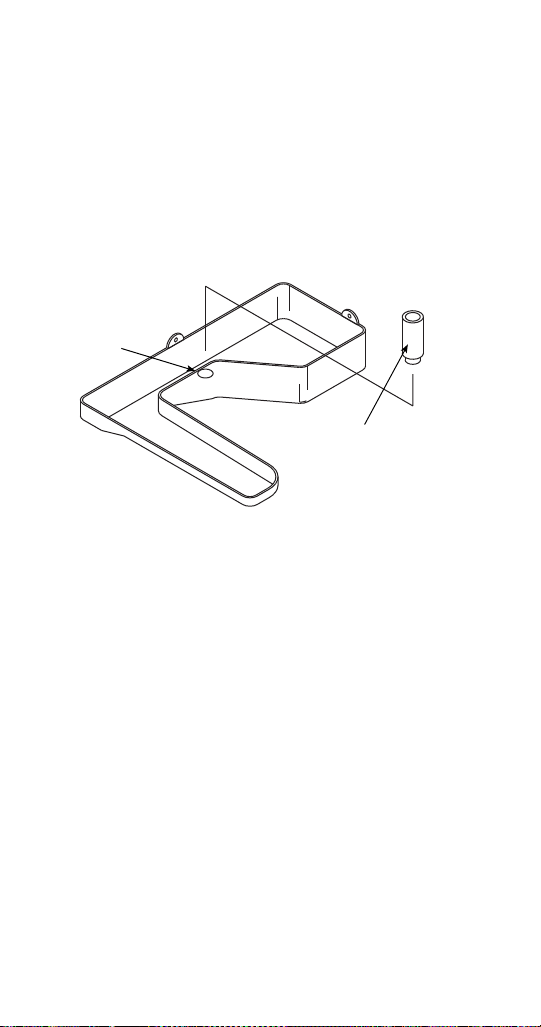

SM50/QM20/QM30

SV1705

SV1606SV1679B

After moving the ice machine into the installation

location, it must be leveled for proper operation.

Follow these steps to level the ice machine:

1. Use a level to check the levelness of the ice

machine from front to back and from side to side.

2. If the ice machine is not level, adjust the leveling

glides or legs on each corner of the base of the

ice machine as necessary.

3. Check the levelness of the ice machine after each

adjustment.

4. Repeat steps 2 and 3 until the ice machine is level

from front to back and from side to side.

Levelers

Legs

26 Part Number 80-01111-9 7/10

Page 27

Electrical Requirements

VOLTAGE

The maximum allowable voltage variation is ±10% of

the rated voltage on the ice machine model/serial

number plate at start-up (when the electrical load is

highest).

The 115/1/60 ice machines are factory pre-wired with

a 6' (1.8 m) power cord, and NEMA 5-15P-plug

configuration.

The 208-230/1/60 and 230/1/50 ice machines are

factory pre-wired with a power cord only, no plug is

supplied.

FUSE/CIRCUIT BREAKER

A separate fuse/circuit breaker must be provided for

each ice machine. Circuit breakers must be H.A.C.R.

rated (does not apply in Canada).

TOTAL CIRCUIT AMPACITY

The total circuit ampacity is used to help select the

wire size of the electrical supply.

The wire size (or gauge) is also dependent upon

location, materials used, length of run, etc., so it must

be determined by a qualified electrician.

Part Number 80-01111-9 7/10 27

Page 28

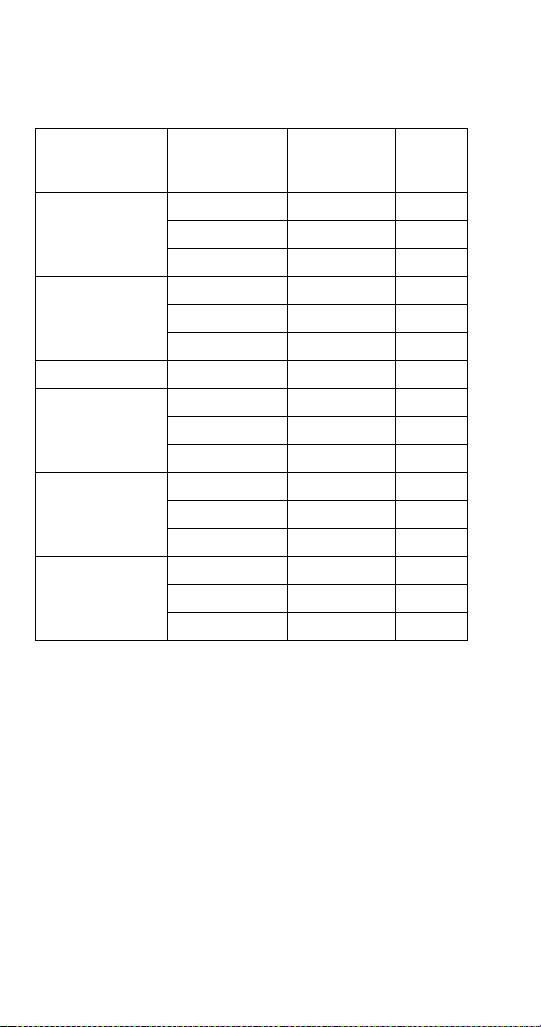

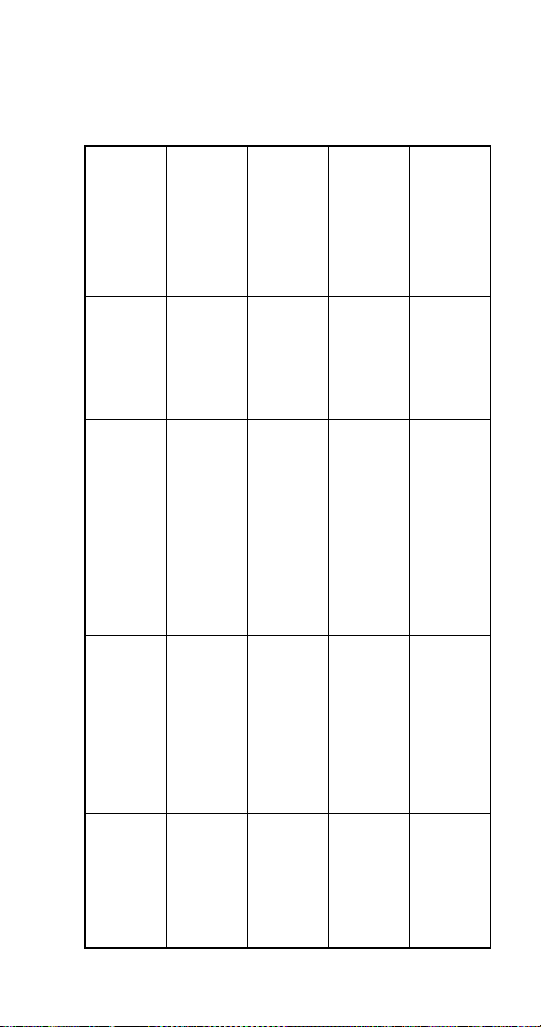

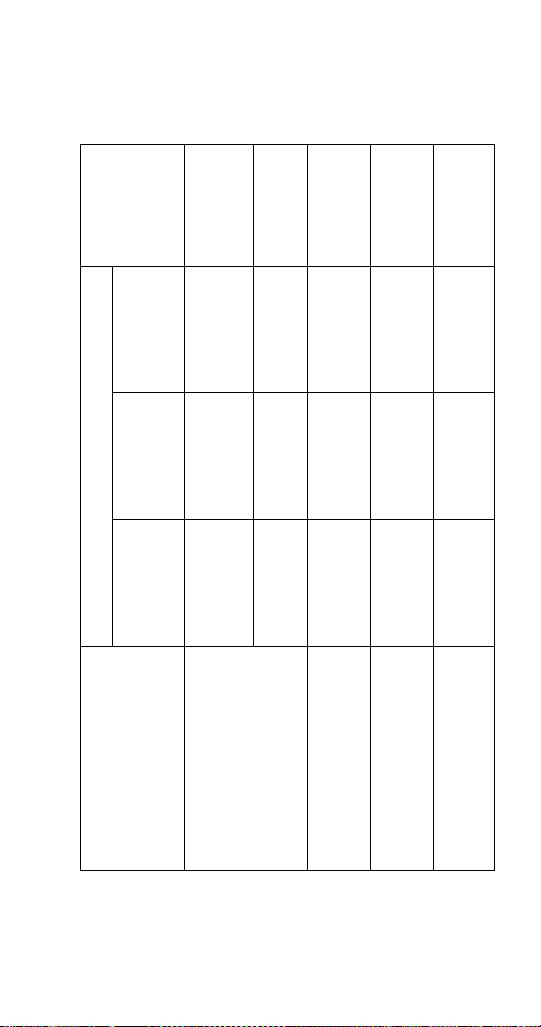

Electrical Specifications

Q130/Q170/Q210/Q270 Air-cooled Ice Machine

Ice Machine

Q130

(Before

Serial Number

310047287)

Q130

(After

Serial Number

310047287)

Q170 115/1/60 15 amp 7.0

Q210

Q270

Danfoss

Q270

Tecumseh

Voltage

Phase Cycle

115/1/60 15 amp 7.6

208-230/1/60 15 amp 3.3

230/1/50 15 amp 3.3

115/1/60 15 amp 7.0

208/1/60 15 amp 3.1

230/1/50 15 amp 3.0

115/1/60 15 amp 6.5

208-230/1/60 15 amp 3.6

230/1/50 15 amp 3.6

115/1/60 15 amp 10.7

208-230/1/60 15 amp 5.2

230/1/50 15 amp 5.2

115/1/60 15 amp 8.5

208-230/1/60 15 amp 4.5

230/1/50 15 amp 4.5

Max. Fuse/

Circuit

Breaker

Total

Amps

28 Part Number 80-01111-9 7/10

Page 29

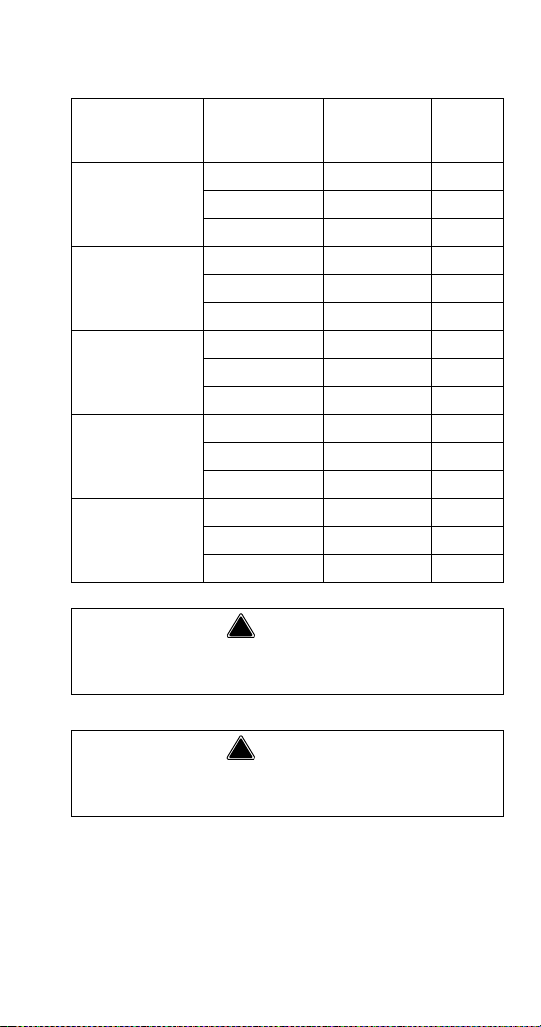

Q130/Q210/Q270 Water-cooled Ice Machine

!

Warning

! Warning

Ice Machine

Q130

(Before

Serial Number

310047287)

Q130

(After

Serial Number

310047287)

Q210

Q270

Danfoss

Q270

Tecumseh

Voltage

Phase Cycle

115/1/60 15 amp 6.8

208-230/1/60 15 amp 2.8

230/1/50 15 amp 2.8

115/1/60 15 amp 6.3

208/1/60 15 amp 2.6

230/1/50 15 amp 2.5

115/1/60 15 amp 6.1

208-230/1/60 15 amp 3.1

230/1/50 15 amp 3.1

115/1/60 15 amp 9.9

208-230/1/60 15 amp 4.7

230/1/50 15 amp 4.7

115/1/60 15 amp 7.7

208-230/1/60 15 amp 4.0

230/1/50 15 amp 4.0

Max. Fuse/

Circuit

Breaker

Total

Amps

All wiring must conform to local, state and national

codes.

The ice machine must be grounded in accordance

with national and local electrical code.

Part Number 80-01111-9 7/10 29

Page 30

QM20/QM30/QM45 Air-cooled Ice Machine

Ice

Machine

QM20

QM30

QM45

Volt age Phase

Cycle

115/1/60 15 amp 3.5

230/1/50 15 amp 1.5

115/1/60 15 amp 5.3

230/1/50 15 amp 2.6

115/1/60 15 amp 5.2

230/1/50 15 amp 2.6

Max. Fuse/

Circuit

Breaker

SM50 Air-cooled Ice Machine

Ice

Machine

SM50 115/1/60 15 amp 4.1

Volt age Phase

Cycle

Max. Fuse/

Circuit

Breaker

Total

Amps

Total

Amps

30 Part Number 80-01111-9 7/10

Page 31

Water Service/Drains

Important

WATER SUPPLY

Local water conditions may require treatment of the

water to inhibit scale formation, filter sediment, and

remove chlorine odor and taste.

If yo u are inst alling a Man itowoc w ater filter

system, refer to t he Installation Inst ructions

supplied with the filter system for ice making

water inlet connections.

WATER INLET LINES

Follow these guidelines to install water inlet lines:

• Do not connect the ice machine to a hot water

supply. Be sure all hot water restrictors installed for

other equipment are working. (Check valves on

sink faucets, dishwashers, etc.)

• If water pressure exceeds the maximum

recommended pressure, 80 psig (5.5 bar) obtain a

water pressure regulator from your Manitowoc

distributor.

• Install a water shut-off valve for ice making potable

water.

• Insulate water inlet lines to prevent condensation.

DRAIN CONNECTIONS

Follow these guidelines when installing drain lines to

prevent drain water from flowing back into the ice

machine and storage bin:

• Drain lines must have a 1.5-inch drop per 5 feet of

run (2.5 cm per meter), and must not create traps.

• The floor drain must be large enough to

accommodate drainage from all drains.

• Run separate bin and ice machine drain lines.

Insulate them to prevent condensation.

• Vent the bin and ice machine drain to the

atmosphere.

Part Number 80-01111-9 7/10 31

Page 32

COOLING TOWER APPLICATIONS

!

Caution

Water Cooled Models Only

A water-cooling tower installation does not require

modification of the ice machine. The water regulator

valve for the condenser continues to control the

refrigeration discharge pressure.

It is necessary to know the amount of heat rejected,

and the pressure drop through the condenser and

water valves (inlet to outlet) when using a cooling

tower on an ice machine.

• Water entering the condenser must not exceed

90°F (32.2°C).

• Water flow through the condenser must not

exceed 5 gallons (19 liters) per minute.

• Allow for a pressure drop of 7 psig (.48 bar)

between the condenser water inlet and the outlet

of the ice machine.

• Water exiting the condenser must not exceed

110°F (43.3°C).

Plumbing must conform to state and local codes

32 Part Number 80-01111-9 7/10

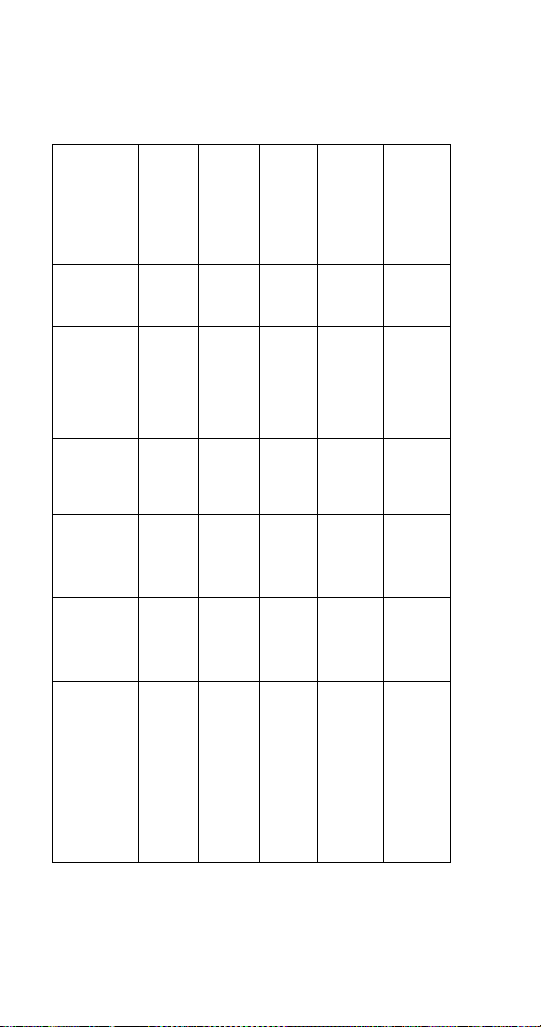

Page 33

WATER SUPPLY AND DRAIN LINE SIZING/

CONNECTIONS

QM45/Q130/Q170/Q210/Q270

Ice Machine

Tubing Size Up to

Ice Machine

Water

Water

Fitting

Fitting

Pressure

Temperature

inside diameter

3/8" (9.5 mm) min.

3/8" Female

Pipe Thread

80 psi (5.5 bar) max.

20 psi (1.38 bar) min.

33°F (0.6°C) min.

90°F (32.2°C) max.

inside diameter

3/8" (9.5 mm) min.

3/8" Female

Pipe Thread

20 psi (1.38 bar) min.

150 psi (10.3 bar) max.

33°F (0.6°C) min.

90°F (32.2°C) max.

inside diameter

3/8" (9.5 mm) min.

3/8" Female

Pipe Thread

—

—

diameter

min. inside

1/2" (12.7 mm)

1/2" Female

Pipe Thread

—

—

Location

Part Number 80-01111-9 7/10 33

Water Inlet

Ice Making

Water Inlet

Condenser

Condenser

Water Drain

Bin Drain

Page 34

QM20/QM30

Fitting

Ice Machine

Tubing Size Up to

inside diameter

3/8" (.95 cm) min.

5/8" (1.59 cm) min.

inside diameter

Ice Machine

Water

Water

Location

Fitting

Pressure

Temperature

3/4" Male

Connection

34.8 psi (2.4 bar) min.

89.9 psi (6.2 bar) max.

50°F (10°C) min.

86°F (30°C) max.

Water Inlet

Ice Making

5/8" (1.59 cm)

inside

diameter

flexible hose

—

—

Bin Drain

34 Part Number 80-01111-9 7/10

Page 35

SM50

Fitting

Ice Machine

Tubing Size Up to

inside diameter

1/4" (.64 cm) min.

inside diameter

3/4" (1.9 cm) min.

inside diameter

3/8" (.96 cm) min.

Ice Machine

Water

Water

Location

Fitting

Pressure

Temperature

ID Copper

1/4" (.64 cm)

20 psi (1.38 bar) min.

50°F (10°C) min.

Ice Making

Tubing

80 psi (5.5 bar) max.

90°F (32.2°C) max.

Water Inlet

Hose Barb

3/4" (1.9 cm)

—

—

Bin Drain

Hose

3/8" (.96 cm)

—

than 50°F (10°C).

—

Note: If air temperature is less than 60°F (15.5°C) water temperature must be equal or greater

Drain Pump

Part Number 80-01111-9 7/10 35

Page 36

36 Part Number 80-01111-9 7/10

This Page Intentionally Left Blan k

Page 37

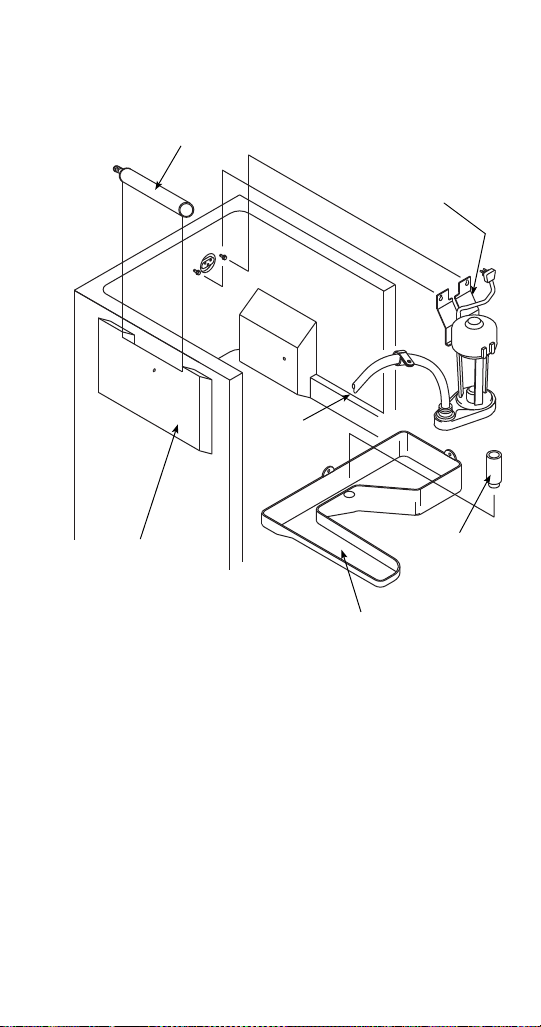

Component Identification

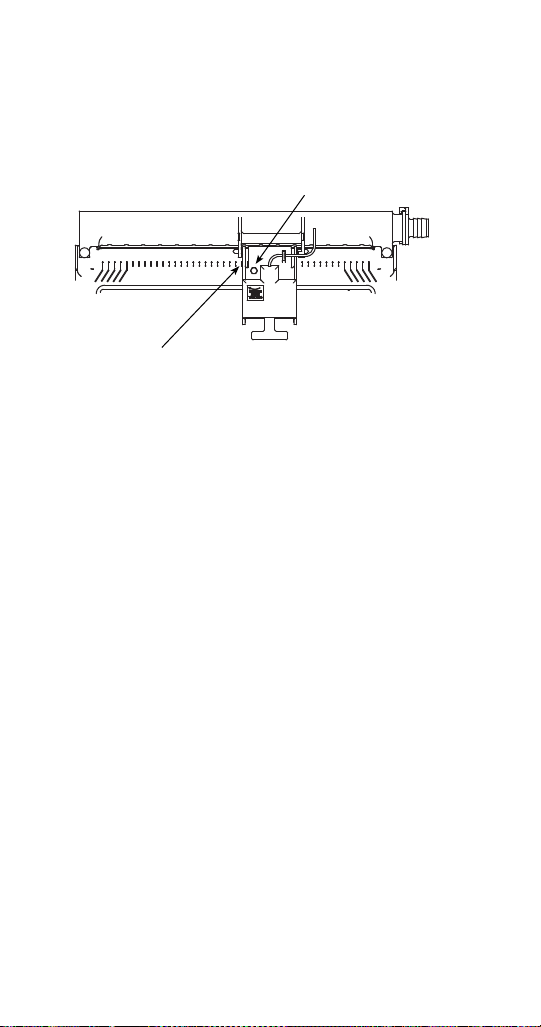

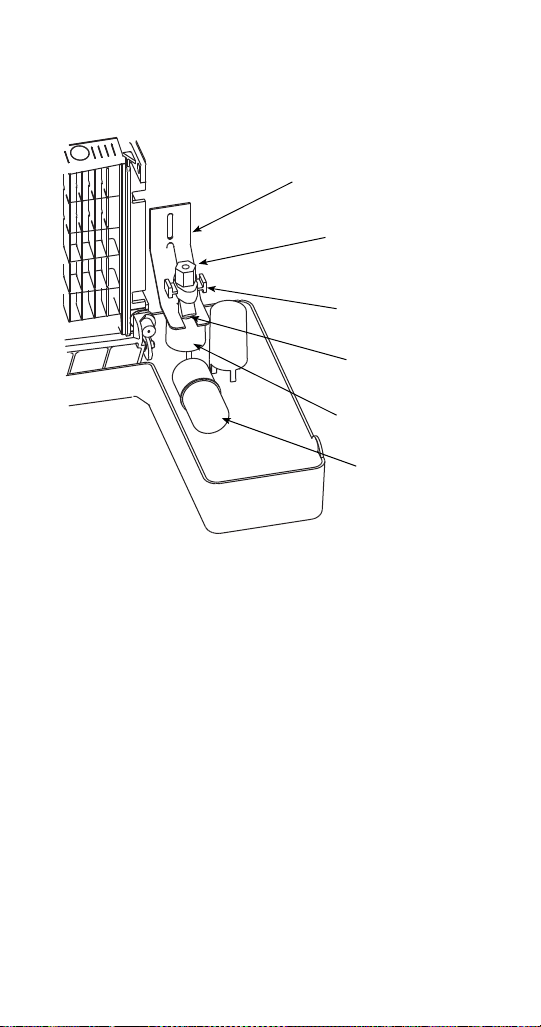

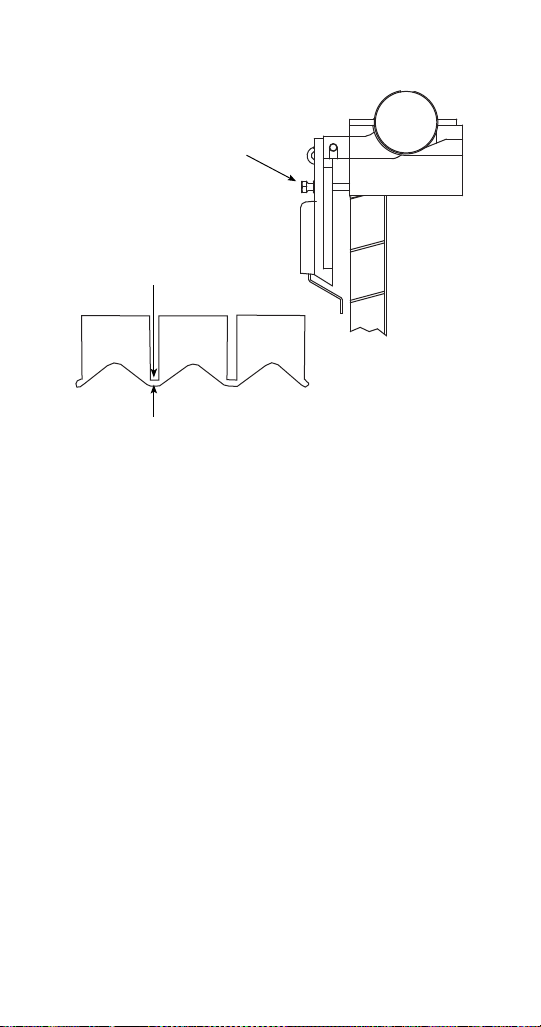

ICE THICKNESS

PROBE

DISTRIBUTION

TUBE (Q210/Q270

SHOWN)

EVAPORATOR

(Q210/Q270

SHOWN)

WATER

TROUGH

ICE

DAMPER

WATER

PUMP

SV1694A

FLOAT VALVE

BIN SWITCH

MAGNET

SIPHON CAP

SV1695A

QM45/Q130/Q170/Q210/Q270

Part Number 80-01111-9 7/10 37

Evaporator Compartment

Page 38

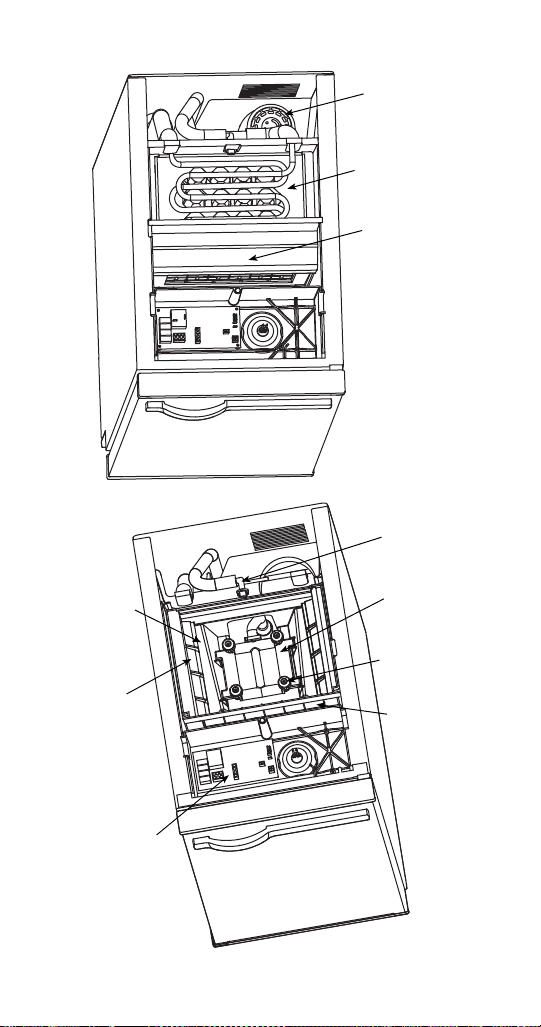

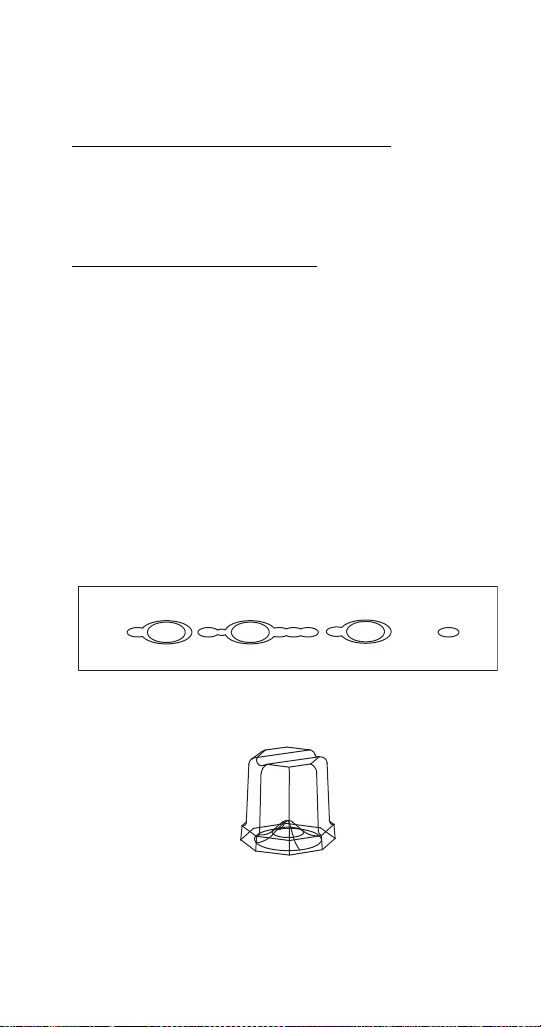

QM45/Q130/Q170/Q210 Ice Machines

ON/OFF/WASH

TO GG L E

SWITCH

CONDENSER AIR

FILTER

COMPRESSOR

COMPARTMENT

ACCESS SCREWS

SV1686G

CONDENSER AIR FILTER

ON/OFF/WASH

TOGGLE

SWITCH

COMPRESSOR

COMPARTMENT ACCESS

SCREWS

PT1288

Q270 Ice Machines

38 Part Number 80-01111-9 7/10

Page 39

QM20/QM30

WATER

DISTRIBUTION

TUBE

WATE R

PUMP

OUTLET

HOSE

WATE R PUM P

AND

BRACKET

ASSEMBLY

EVAPORATOR

ASSEMBLY

WATER

TROUGH

OVERFLOW

TUBE

SV1716A

Part Number 80-01111-9 7/10 39

Page 40

QM20 Ice Machines

SV1711

ON/OFF/WASH

TO GG L E

SWITCH

SV1681A

ON/OFF/WASH

TO GG L E

SWITCH

CONDENSER

AIR FILTER

40 Part Number 80-01111-9 7/10

QM30 Ice Machines

Page 41

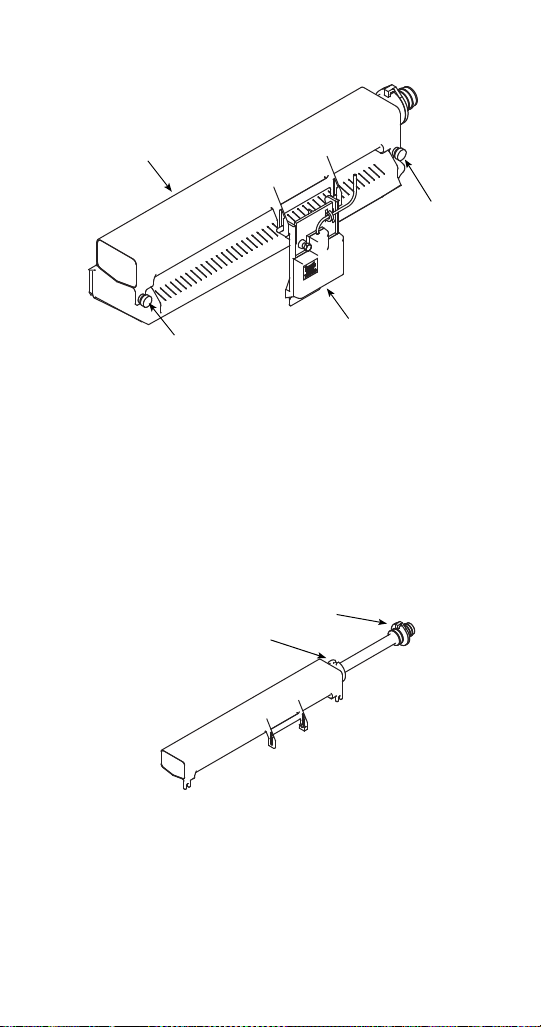

SM50

CONTROL

PANEL

EVAPORATOR

COMPARTMENT

WATER

FILTER

GRILL

BIN LIGHT

WATER

SHUTTERS

BIN

THERMOSTAT

BIN

WATER

PUMP

ELECTRICAL

DRAIN

PUMP

DRAIN

WATER

INLET

REFRIGERATION

COMPRESSOR

Part Number 80-01111-9 7/10 41

Page 42

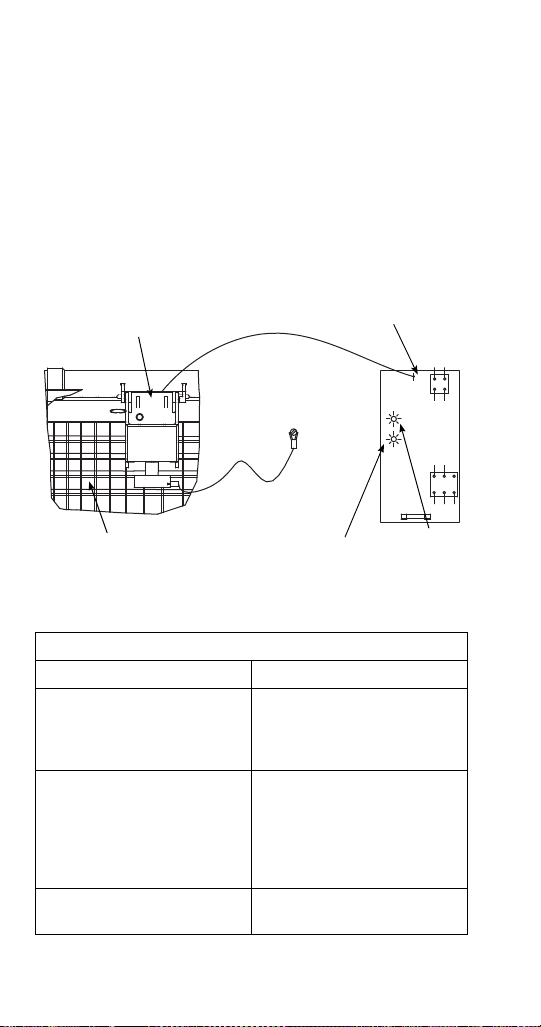

WATER

PUMP

EVAPORATOR

WATER

SHUTTER

ASSEMBLY

NOTE:

EVAPORATOR

REMOVED

FOR CLARITY

EVAPORATOR

BUCKET

CONTROL

BOARD

WATER

SHUTTERS

SPRAY

NOZZLES

SPRAY

BAR

WATER

SUPPLY

LINE

42 Part Number 80-01111-9 7/10

Page 43

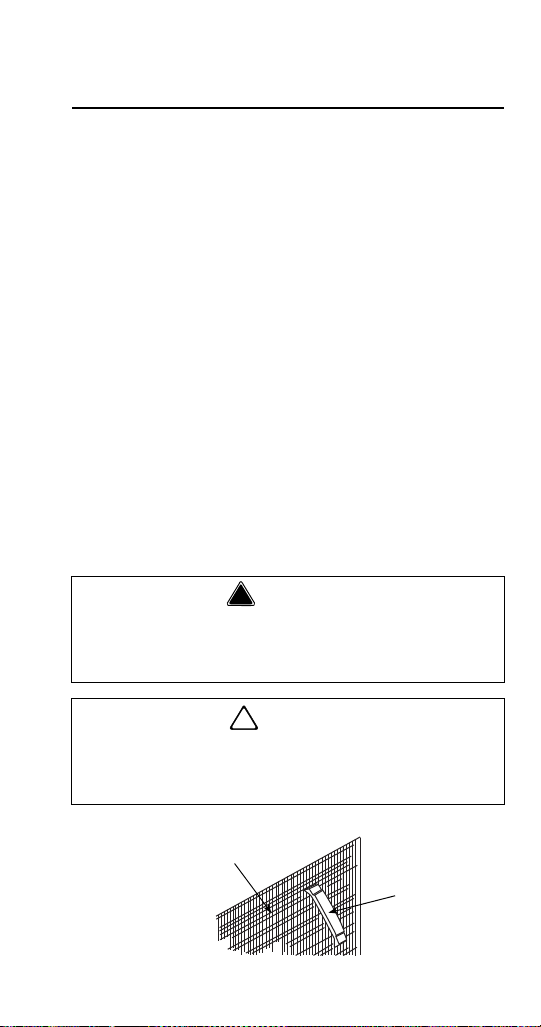

Maintenance

! Warning

!

Caution

CONDENSER

COMB

DOWN

ONLY

FIN COMB

Ice Machine Inspection

Check all water fittings and lines for leaks. Also, make

sure the refrigeration tubing is not rubbing or vibrating

against other tubing, panels, etc.

Do not put anything (boxes, etc.) in front of the ice

machine. There must be adequate airflow through and

around the ice machine to maximize ice production

and ensure long component life.

Exterior Cleaning

Clean the area around the ice machine as often as

necessary to maintain cleanliness and efficient

operation.

Sponge any dust and dirt off the outside of the ice

machine with mild soap and water. Wipe dry with a

clean, soft cloth.

A commercial grade stainless steel cleaner/polish can

be used as necessary.

Cleaning the Condenser

Disconnect electric powe r to the ice machine a t

the e lectric service s witch before clean ing the

condenser.

If you are clea ning the condenser fan blades with

water, cover the fan motor to prev ent water

damage.

Part Number 80-01111-9 7/10 43

Page 44

AIR-COOLED CONDENSER

! Warning

A dirty condenser restricts airflow, resulting in excessively

high operating temperatures. This reduces ice production

and shortens component life. Clean the condenser at least

every six months. Follow the steps below.

The conde nser fi ns are sharp. Use care whe n

cleaning them.

1. The washable aluminum filter on self-contained aircooled ice machines is designed to catch dust, dirt, lint

and grease. This helps keep the condenser clean.

Clean the filter with a mild soap and water solution.

2. Clean the outside of the condenser with a soft brush or a

vacuum with a brush attachment. Clean from top to

bottom, not side to side. Be careful not to bend the

condenser fins.

3. Shine a flashlight through the condenser to check for dirt

between the fins. If dirt remains:

A. Blow compressed air through the condenser fins

from the inside. Be careful not to bend the fan

blades.

B. Use a commercial condenser coil cleaner. Follow

the directions and cautions supplied with the

cleaner.

4. Straighten any bent condenser fins with a fin comb.

5. Carefully wipe off the fan blades and motor with a soft

cloth. Do not bend the fan blades. If the fan blades are

excessively dirty, wash with warm, soapy water and

rinse thoroughly.

WATER-COOLED CONDENSER AND WATER REGULATING VALVE

The water-cooled condenser and water regulating valve may

require cleaning due to scale build-up.

Low ice production, high water consumption and high

operating temperatures and pressures all may be symptoms

of restrictions in the condenser water circuit.

Because the cleaning procedures require special pumps and

cleaning solutions, they must be performed by qualified

maintenance or service personnel.

44 Part Number 80-01111-9 7/10

Page 45

QM45/Q130/Q170/Q210/Q270

!

Caution

!

Caution

! Warning

INTERIOR CLEANING AND SANITIZING

General

Clean and sanitize the ice machine every six months

for efficient operation. If the ice machine requires more

frequent cleaning and sanitizing, consult a qualified

service company to test the water quality and

recommend appropriate water treatment.

The ice machine must be taken apart for cleaning and

sanitizing.

Use only Ma nitowoc app roved Ice Machine

Cleaner (p art number 94-0 546-3) and

Sanitizer (p art n umber 94 -0565-3). It is a

violation of F ederal law to u se th ese

solutions in a manner inconsistent with their

labeling. Read and unde rstand all lab els

printed on bottles before use.

Cleaning and Sanitizing Procedure

Do no t mix Ice Machi ne Cle aner an d

Sanitizer solutions together. It is a violation of

Federal l aw to u se the se solutions i n a

manner inconsistent with their labeling.

Wear rubb er glo ves and safe ty g oggles

(and/or face sh ield) when h andling Ice

Machine Cleaner or Sanitizer.

Ice machine cleaner is used to remove lime scale and

mineral deposits. Ice machine sanitizer disinfects and

removes algae and slime.

Part Number 80-01111-9 7/10 45

Page 46

Step 1 Set the toggle switch to the OFF position after

!

Caution

! Warning

ice falls from the evaporator at the end of a Harvest

cycle. Or, set the switch to the OFF position and allow

the ice to melt off the evaporator.

Never use a nything to force ice fro m the

evaporator. Damage may result.

Step 2 Remove all ice from the bin.

Step 3 To start a cleaning cycle, move the toggle

switch to the WASH position.

Step 4 Add the proper amount of Manitowoc Ice

Machine Cleaner to the water trough.

Model Amount of Cleaner

QM45 1.5 ounce (45 ml)

Q130 1 ounce (30 ml)

Q170 2 ounces (60 ml)

Q210 2 ounces (60 ml)

Q270 2 ounces (60 ml)

Step 5 Wait until the clean cycle is complete

(approximately 22 minutes) then place the toggle

switch in the OFF position, disconnect power and

water supplies to the ice machine.

Disconnect electric power to the ice machine

at the electric switch box before proceeding.

46 Part Number 80-01111-9 7/10

Page 47

Step 6 Remove parts for cleaning.

DO NOT SOAK

WATER PUMP MOTOR IN

CLEANER OR SANITIZER

SOLUTIONS

WHEN USED- REMOVE

THUMBSCREWS AND

WATER PUMP COVER

A. Remove Two Thumbsc r ew s a nd Water

Pump Cover (When Used).

B. Remove the Vinyl Hose Connecting the

Water Pump and Water Distribution Tube

C. Remove Water Pump

• Disconnect the water pump power cord

• Loosen the screws securing the pumpmounting bracket to the bulkhead

• Lift the pump and bracket assembly off

the mounting screws.

Water Pump Removal

Part Number 80-01111-9 7/10 47

Page 48

D. Remove the Ice Thickness Probe

SV1138A

ICE

THICKNESS

PROBE

COMPRESS SIDES OF ICE

THICKNESS PROBE

• Compress the side of the ice thickness probe

near the top hinge pin and remove it from the

bracket.

Ice Thickness Probe Removal

NOTE: At this point, the ice thickness probe can easily

be cleaned. If complete removal is desired follow the

ice thickness probe wire to the bulkhead grommet (exit

point) in the back wall. Pop the bulkhead grommet out

of the back wall by inserting fingernails or a flat object

between the back wall and the grommet and prying

forward. Pull the bulkhead grommet and wire forward

until the connector is accessible, then disconnect the

wire lead from the connector.

Ice Thickness Probe Cleaning

• Mix a solution of Manitowoc ice machine cleaner

and water (2 ounces of cleaner to 16 ounces of

water) in a container.

• Soak the ice thickness probe a minimum of 10

minutes.

Clean all ice thickness probe surfaces and verify the

ice thickness probe cavity is clean. Rinse thoroughly

with clean water, then dry completely. Incomplete

rinsing and drying of the ice thickness probe can

cause premature harvest.

48 Part Number 80-01111-9 7/10

Page 49

E. Remove the Water Distribution Tube

!

Caution

SV1630

DISTRIBUTION

TUBE

THUMB

SCREW

1. LIFT UP

2. SLIDE BACK

3. SLIDE TO RIGHT

THUMB

SCREW

1

3

2

Q170/Q210/Q270 Models

Water Distribution Tube Removal

Q170/Q210/Q270

• Loosen the two thumbscrews, which secure the

distribution tube.

• Lift the right side of the distribution tube up off the

locating pin, then slide it back and to the right.

Do not force this removal. Be sure the

locating pin is clear of the hole before sliding

the distribution tube out.

Part Number 80-01111-9 7/10 49

Page 50

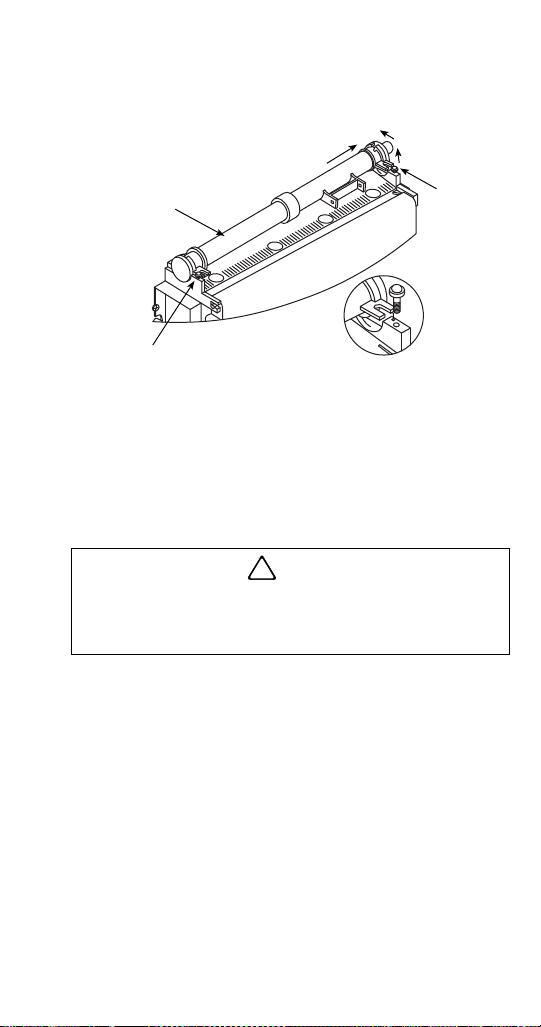

Disassembly

SV1211

INNER

TUBE

TA B

KEYWAY

INNER

TUBE

• Twist both of the inner tube ends until the tabs line

up with the keyways.

• Pull the inner tube ends outward.

Q210/Q270 Water Distribution Tube Disassembly

50 Part Number 80-01111-9 7/10

Page 51

Q130 Models

SV1731C

THUMBSCREW

REMOVE ICE

THICKNESS PROBE

THUMBSCREW

DISTRIBUTION

TUBE

SV1741

KEYWAY

TAB

Q130 Water Distribution Tube Removal

• Loosen the two thumbscrews, which secure

the distribution tube.

• Lift the distribution tube up off the

thumbscrews.

Disassembly

• Twist the barbed end until the tab lines up with

the keyway.

• Pull the inner tube end outward.

Q130 Water Distribution Tube Disassembly

Part Number 80-01111-9 7/10 51

Page 52

F. Remove the Float Valve

SV1695-2

FLOAT VALVE

BRACKET

COMPRESSION

FITTING

CAP AND FILTER

SCREEN

SPLASH

SHIELD

SHUT-OFF

VAL VE

FLOAT

• Turn the splash shield counterclockwise one or

two turns.

FLOAT VALVE REMOVAL

• Pull the float valve forward and off the mounting

bracket.

• Disconnect the water inlet tube from the float valve

at the compression fitting.

• Remove the cap and filter screen for cleaning.

52 Part Number 80-01111-9 7/10

Page 53

G. Remove the Water T rough

SV1689-1

UPPER

THUMBSCREW

SV1689-2

LOWER

THUMBSCREWS

REMOVE

SIPHON

TUBE

• Apply downward pressure on the siphon tube and

remove from the bottom of the water trough.

• Remove the upper thumbscrew.

• While supporting the water trough remove the two

thumbscrews from beneath the water trough.

• Remove the water trough from the bin area.

Part Number 80-01111-9 7/10 53

Page 54

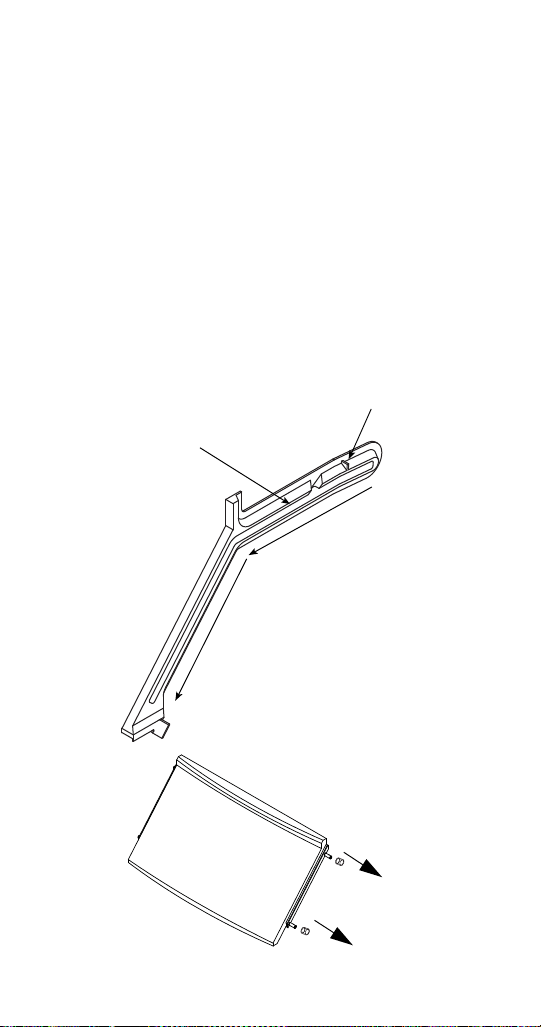

H. Remove the ice damper.

SV1731F

STEP 1

STEP 2

SV1731G

STEP 2

STEP 1

Q130

• Grasp left side of ice damper and apply

ressure against the right-hand ice damper

p

mounting bracket.

• Pull forward on the ice damper until the leftand mounting pin disengages.

h

Installation

• Grasp the right side of ice damper and place

ft hand pin in the mounting bracket.

le

• While applying pressure against the left-hand

unting bracket push the damper until the

mo

right-hand mounting pin engages.

Q170/Q210/Q270

54 Part Number 80-01111-9 7/10

Page 55

• Grasp ice damper and apply pressure toward

SV1742A

STEP 2

STEP 1

STEP 3

SV1742H

STEP 2

STEP 1

STEP 3

the left hand mounting bracket.

• Apply pressure to the right hand mounting

ket with thumb.

brac

• Pull ice damper forward when the right hand

mper pin disengages.

ice da

Installation

• Place ice damper pin in left hand mounting

b

racket and apply pressure toward the left

hand mounting bracket.

• Apply pressure to the right hand mounting

ket with thumb.

brac

• Push ice damper toward evaporator until right

and damper pin engages.

h

Part Number 80-01111-9 7/10 55

Page 56

I. Remove the Bin Door

STOP TAB

TRACK SLOT

SLIDE DOOR

FORWARD

SV1748

• Grasp the rear of the bin door and pull bin door

forward approximately 5".

• Slide bin door to the rear while applying upward

pressure (The rear door pins will ride up into the track

slot and slide backward to the stop tab).

• While applying pressure against the bin door pull

down on the rear of each bin door track until the door

pins clear the stop tabs.

• Slide the rear door pins off the end and then below

the door track. Slide bin door forward allowing the

back of the door to lower into the bin. Continue

forward with the bin door until the front pins bottom

out in the track.

• Lift right side of door until the front pins clear the

track, then remove door from bin.

• Remove rollers (4) from all door pins.

56 Part Number 80-01111-9 7/10

Page 57

Step 7 Mix a solution of cleaner and warm water.

Depending on the amount of mineral buildup, a larger

quantity of solution may be required. Use the ratio in

the table below to mix enough solution to thoroughly

clean all parts.

Solution

Type

Cleaner 1 gal. (4 l) 16 oz (500 ml) cleaner

Water Mixed with

Step 8 Use ½ of the cleaner/water solution to clean

all components. The cleaner solution will foam when it

contacts lime scale and mineral deposits; once the

foaming stops use a soft bristle brush, sponge or cloth

(not a wire brush) to carefully clean the parts. Soak the

parts for 5 minutes (15 – 20 minutes for heavily scaled

parts). Rinse all components with clean water.

Step 9 While components are soaking, use ½ of the

cleaner/water solution to clean all foodzone surfaces

of the ice machine and bin. Use a nylon brush or cloth

to thoroughly clean the following ice machine areas:

• Evaporator plastic parts – including top, bottom

and sides

• Bin bottom, sides and top

Rinse all areas thoroughly with clean water.

Step 10 Mix a solution of sanitizer and warm water.

Solution

Type

Sanitizer 6 gal. (23 l) 4 oz (120 ml) sanitizer

Step 11 Use 1/2 of

Water Mixed With

the sanitizer/water solution to

sanitize all removed components. Use a cloth or

sponge to liberally apply the solution to all surfaces of

the removed parts or soak the removed parts in the

sanitizer/water solution. Do not rinse parts after

sanitizing.

Part Number 80-01111-9 7/10 57

Page 58

Step 12 Use 1/2 of the sanitizer/water solution to

! Warning

sanitize all foodzone surfaces of the ice machine and

bin. Use a cloth or sponge to liberally apply the

solution. When sanitizing, pay particular attention to

the following areas:

• Evaporator plastic parts - including top, bottom and

sides

• Bin bottom, sides and top

Do not rinse the sanitized areas.

Step 13 Replace all removed components.

Step 14 Reapply power and water to the ice machine

and place the toggle switch in the WASH position.

Add the proper amount of Manitowoc Ice Machine

Sanitizer to the water trough.

Model Amount of Sanitizer

QM45 1.5 ounces (45 ml)

Q130 1.6 ounces (48 ml)

Q170 2.2 ounces (66 ml)

Q210 2.2 ounces (66 ml)

Q270 1.9 ounces (57 ml)

Step 15 Wait until the sanitize cycle is complete

(approximately 22 minutes) then place the toggle

switch in the OFF position, disconnect power and

water supplies to the ice machine.

Disconnect el ectric po wer to the i ce

machine at th e electric sw itch box before

proceeding.

Step 16 Repeat step 6 to remove parts for hand

sanitizing.

Step 17 Mix a solution of sanitizer and warm water.

Solution

Type

Sanitizer 6 gal. (23 l) 4 oz (120 ml) sanitizer

58 Part Number 80-01111-9 7/10

Water Mixed With

Page 59

Step 18 Use 1/2 of the sanitizer/water solution to

sanitize all removed components. Use a cloth or

sponge to liberally apply the solution to all surfaces of

the removed parts or soak the removed parts in the

sanitizer/water solution. Do not rinse parts after

sanitizing.

Step 19 Use 1/2 of the sanitizer/water solution to

sanitize all foodzone surfaces of the ice machine and

bin. Use a cloth or sponge to liberally apply the

solution. When sanitizing, pay particular attention to

the following areas:

• Evaporator plastic parts - including top, bottom and

sides

• Bin bottom, sides and top

Do not rinse the sanitized areas.

Step 20 Replace all removed components.

Step 21 Reapply power and water to the ice machine

and place the toggle switch in the ICE position.

Part Number 80-01111-9 7/10 59

Page 60

QM20/QM30

!

Caution

!

Caution

! Warning

CLEANING AND SANITIZING PROCEDURE

Use only Ma nitowoc app roved Ice Machine

Cleaner (p art number 94-0 546-3) and

Sanitizer (p art n umber 94 -0565-3). It is a

violation of F ederal law to use th ese

solutions in a manner inconsistent with their

labeling. Read and unde rstand all lab els

printed on bottles before use.

Do n ot mix Ice Machi ne Cleaner an d

Sanitizer solutions toge ther. It is a violation

of Federal law to use th ese solu tions in a

manner inconsistent with their labeling.

Wear rubb er glove s a nd safety goggles

(and/or face shie ld) w hen handling Ice

Machine Cleaner or Sanitizer.

Ice machine cleaner is used to remove lime scale and

mineral deposits. Ice machine sanitizer disinfects and

removes algae and slime.

60 Part Number 80-01111-9 7/10

Page 61

Step 1 Set the toggle switch to the OFF position after

!

Caution

!

Warning

ice falls from the evaporator at the end of a Harvest

cycle. Or, set the switch to the OFF position and allow

the ice to melt off the evaporator.

Never use anything to force ice from th e

evaporator. Damage may result.

Step 2 Remove all ice from the bin.

Step 3 To start a cleaning cycle, move the toggle

switch to the WASH position.

Step 4 Wait until water flows over the evaporator

(about three minutes) then add the proper amount of

Manitowoc Ice Machine Cleaner to the water trough.

Model Amount of Cleaner

QM20/QM30 45 ml

Step 5 Wait until the clean cycle is complete

(approximately 45 minutes) then place the toggle

switch in the OFF position, disconnect power and

water supplies to the ice machine.

Disconnect electric power to the ice machine

at the electric switch box before proceeding.

Part Number 80-01111-9 7/10 61

Page 62

Step 6 Remove parts for cleaning.

DRAIN

HOLE

OVERFLOW

TUBE

A. Remove the Overflow Tube

• To remove the tube, lift it up while using a slight

back and forth motion to loosen it from the drain

hole.

When installing the tube, be sure it is completely

inserted into the drain hole to prevent water leakage

during normal operation.

Removing the Overflow Tube

B. Remove the Vinyl Hose

• Disconnect the water pump discharge hose from

the distribution tube and water pump.

62 Part Number 80-01111-9 7/10

Page 63

C. Remove the Water Pump

WATER

PUMP

SCREWS

SV3019

REMOVE SCREWS

• Disconnect the water pump power cord.

• Loosen the screws that hold the water pump in

place.

• Lift the water pump and bracket assembly up and

off the screws.

Removing the Water Pump

D. Remove the Water Trough

• Remove the screws holding the water trough to the

walls of the cabinet.

Part Number 80-01111-9 7/10 63

Page 64

Step 7 Mix a solution of cleaner and warm water.

Depending on the amount of mineral buildup, a larger

quantity of solution may be required. Use the ratio in

the table below to mix enough solution to thoroughly

clean all parts.

Solution Type Water Mixed with

Cleaner 4L. (1 gal)

500 ml (16 oz)

cleaner

Step 8 Use half of the cleaner/water solution to clean

all components. The cleaner solution will foam when it

contacts lime scale and mineral deposits; once the

foaming stops use a soft bristle brush, sponge or cloth

(not a wire brush) to carefully clean the parts. Soak the

parts for 5 minutes (15 – 20 minutes for heavily scaled

parts). Rinse all components with clean water.

Step 9 While components are soaking, use half of the

cleaner/water solution to clean all foodzone surfaces

of the ice machine and bin. Use a nylon brush or cloth

to thoroughly clean the following ice machine areas:

• Evaporator plastic parts – including top, bottom

and sides

• Bin bottom, sides and top

Rinse all areas thoroughly with clean water.

Step 10 Mix a solution of sanitizer and warm water.

Solution

Type

Sanitizer 23 L. (6 gal )

Water Mixed With

120 ml

(4 ounces) sanitizer

Step 11 Use half of the sanitizer/water solution to

sanitize all removed components. Use a cloth or

sponge to liberally apply the solution to all surfaces of

the removed parts or soak the removed parts in the

sanitizer/water solution. Do not rinse parts after

sanitizing.

64 Part Number 80-01111-9 7/10

Page 65

Step 12 Use half of the sanitizer/water solution to

! Warning

sanitize all foodzone surfaces of the ice machine and

bin. Use a cloth or sponge to liberally apply the

solution. When sanitizing, pay particular attention to

the following areas:

• Evaporator plastic parts - including top, bottom and

sides

• Bin bottom, sides and top

Do not rinse the sanitized areas.

Step 13 Replace all removed components.

Step 14 Reapply power and water to the ice machine

and place the toggle switch in the WASH position.

Step 15 Add the proper amount of Manitowoc Ice

Machine Sanitizer to the water trough.

Model Amount of Sanitizer

QM20/QM30 45 ml

Step 16 Wait until the sanitize cycle is complete

(approximately 45 minutes) then place the toggle

switch in the OFF position, disconnect power and

water supplies to the ice machine.

Disconnect electric power to the ice machine

at the electric switch box before proceeding.

Step 17 Repeat step 6 to remove parts for hand

sanitizing.

Step 18 Mix a solution of sanitizer and warm water.

Solution Type Water Mixed With

Sanitizer 23L. (6 gal )

120 ml (4 oz)

sanitizer

Step 19 Use half of the sanitizer/water solution to

sanitize all removed components. Use a cloth or

sponge to liberally apply the solution to all surfaces of

the removed parts or soak the removed parts in the

sanitizer/water solution. Do not rinse parts after

sanitizing.

Part Number 80-01111-9 7/10 65

Page 66

Step 20 Use half of the sanitizer/water solution to

sanitize all foodzone surfaces of the ice machine and

bin. Use a cloth or sponge to liberally apply the

solution. When sanitizing, pay particular attention to

the following areas:

• Evaporator plastic parts - including top, bottom and

sides

• Bin bottom, sides and top

Do not rinse the sanitized areas.

Step 21 Replace all removed components.

Step 22 Reapply power and water to the ice machine

and place the toggle switch in the ICE position.

66 Part Number 80-01111-9 7/10

Page 67

SM50

!

Caution

!

Caution

CLEANING PROCEDURE

SM50 uses a tin plated evaporator. Do not use

standard cleaner, use only 000000084 cleaner for this

ice machine.

Use onl y Manitowoc app roved Ice Ma chine

Cleaner (part number 94-0546-3 original green ice

machine cl eaner or 000000084 cl ear met al safe

ice mach ine cleaner) and Sanitizer (part nu mber

94-0565-3). It is a viola tion of Fed eral law to use

these solutions in a manner inconsistent with their

labeling. Re ad and u nderstand a ll labels printed

on bottles before use.

Ice machine cleaner is used to remove lime scale or

other mineral deposits. It is not used to remove algae

or slime. Refer to “Sanitizing Procedure” on page 68

for removal of algae and slime.

1. To start a cleaning cycle, press the CLEAN

switch. The ice machine will initiate a 2 minute

harvest to remove any ice from the evaporator.

Or, set the switch to the OFF position and allow

the ice to melt off the evaporator.

Never use a nything to force i ce from the

evaporator. Damage may result.

2. Remove all ice from the bin.

3. The clean light will energize to indicate the clean

cycle has started.

Part Number 80-01111-9 7/10 67

Page 68

4. Wait until the Clean light flashes (3 minutes) then

add 3 oz of Manitowoc cleaner by lifting the water

shutter and pouring directly into the spray area.

The ice machine will automatically time out a ten

minute cleaning cycle, followed by eight rinse

cycles, and stop. The Clean light will turn off to

indicate the Clean cycle is complete. This entire

cycle lasts approximately 30 minutes.

5. When the cleaning process stops, remove all

parts as described in Removal of Parts for

Cleaning and Sanitizing.

6. Mix 16 oz (480 ml) cleaner with 1 gal (4 L) of

warm water in a non metallic container.-

7. Take all components to sink for cleaning. Use 1/2

of the Cleaner/Water mixture and clean all

components with a soft nylon brush or cloth.

Disassemble spray bar, remove nozzles and

inserts and soak for 5 minutes. For heavily scaled

parts, soak in solution for 15 – 20 minutes. Rinse

all components with clean water.

8. While components are soaking, use nylon brush

or cloth to clean inside of ice bin. Clean inside of

door, door gasket, bin, top of evaporator and

evaporator bucket. Rinse all areas thoroughly with

clean water.

SANITIZING PROCEDURE

Use sanitizer to remove algae or slime. Do not use it to

remove lime scale or other mineral deposits.

NOTE: Always perform a cleaning procedure before

sanitizing the ice machine.

1. Mix 4 oz (120 ml) sanitizer with 6 gal (13 L) of

warm water in a non metallic container.

2. Take all components to sink for sanitizing. Use the

Sanitizer/Water mixture and sanitize all

components that were removed for the Cleaning

Procedure with a soft nylon brush or cloth. Soak

for 5 minutes. Do not rinse sanitized components.

68 Part Number 80-01111-9 7/10

Page 69

3. While components are soaking, use nylon brush

! Warning

or cloth to sanitize the inside of ice bin. Sanitize

inside of door, door gasket, bin, top of evaporator

and evaporator bucket. Do not rinse sanitized

components.

4. Replace all components removed.

5. To start a sanitizing cycle, press the CLEAN

switch. The Clean light will energize to indicate

the sanitizing cycle has started.

6. Wait until the Clean light flashes (3 minutes) then

add 0.5 oz (15 ml) of Manitowoc sanitizer by lifting

the water shutter and pouring directly into the

spray area. The ice machine will automatically

time out a ten minute cleaning cycle, followed by

eight rinse cycles, and stop. The Clean light will

turn off to indicate the Cleaning cycle is

completed. This entire cycle lasts approximately

30 minutes.

NOTE: The ice machine will automatically continue from the

previous point before the clean cycle was initiated.

• If the ice machine was in the ice making cycle, the

control board will initiate a 2 minute harvest cycle,

perform the clean cycle and start ice making again

automatically.

• If the ice machine was in the off cycle, the control board

will perform a clean cycle and turn off automatically.

• If the ice machine was in a delay mode, the control board

will perform a clean cycle and resume the delay period

automatically.

REMOVAL OF PARTS FOR CLEANING AND SANITIZING

1. Disconnect power to the ice machine at the

electric switch box.

2. Turn off the water supply to the ice machine at the

water service valve.

Disconnect el ectric po wer to the ice machine at

the electric switch box before proceeding.

3. Remove the parts or components you want to

clean or sanitize:

Part Number 80-01111-9 7/10 69

Page 70

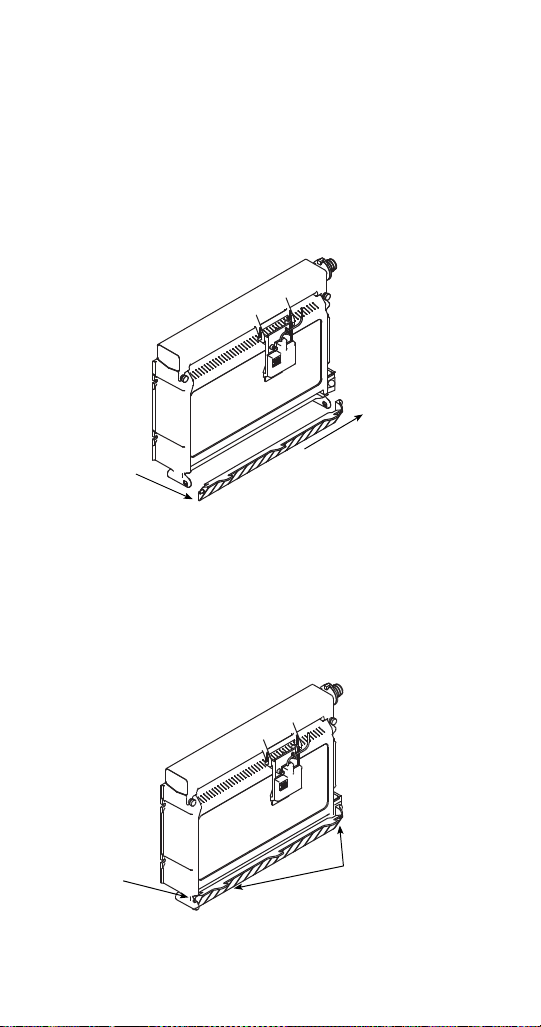

WATER SHUTTERS

!

Warning

GRASP

WATE R

SHUTTERS

HERE

WATER

SHUTTERS

SHUTTER

ASSEMBLY

The water shutter is designed to keep the spraying

water from escaping the evaporator compartment.

To remove just the water shutters:

1. Grasp one end of the water shutter and lift up.

2. Pivot water shutter and disengage remaining end.

3. To re-install into ice machine, grasp one end of

the water shutters, install one end, pivot the

opposite end and pull down into position. Make

sure tabs are secure in grooves.

To remove water shutter assembly:

1. Slide evaporator bucket forward 1/2" (13 mm).

2. Lift shutter assembly straight up.

Removing the water shu tters whil e the water

pump is runn ing will allow water to spray from ice

machine. D isconnect the e lectrical p ower to the

ice machine at the electric service switch box and

turn off the water supply.

70 Part Number 80-01111-9 7/10

Page 71

ICE CHUTE

The ice chute is positioned over the spray nozzles and

allows the ice to easily fall into the bin. It must be firmly

positioned over the spray bar, with the front edge

inside the water trough. Spray nozzles must align with

the spray holes or spray water will fall into the bin.

1. Grab protruding spray hole on one end and lift up

and remove.

2. To re-install ice chute, grasp protruding spray hole

and position over Water Distribution Assembly.

Make sure rear supports are over spray bar, and

front edge is inside of water trough.

Part Number 80-01111-9 7/10 71

Page 72

SUMP DRAIN OVERFLOW TUBE

REMOVE CLAMP

AND

PULL DOWN

1. Remove clamp.

2. Pull down to remove overflow tube and tubing as

an assembly. The sump trough water will drain

into the bin.

3. Remove overflow tube from vinyl tubing by

pulling.

72 Part Number 80-01111-9 7/10

Page 73

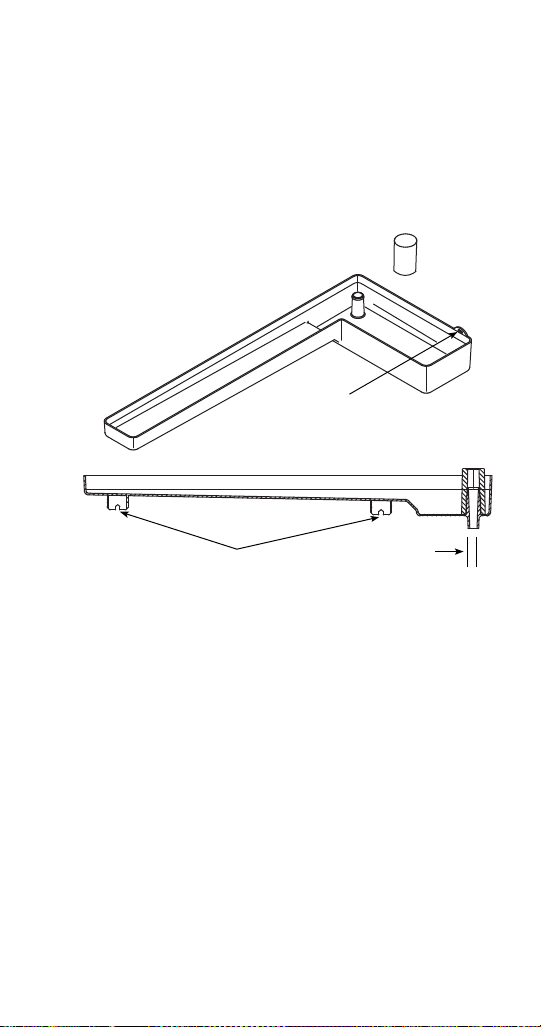

WATER TROUGH

1. Depress tabs on right and left side of the water

trough.

2. Allow front of water trough to drop as you pull

forward to disengage the rear pins.

Part Number 80-01111-9 7/10 73

Page 74

SPRAY BAR, WATER PUMP AND HOSE

! Warning

DO NOT

IMMERSE

MOTOR IN

SOLUTION

REMOVE

CLAMP

REMOVE

CLAMP

MAXIMUM

SOLUTION

HEIGHT WHEN

SOAKING

Disconnect the e lectric power to the ice machine

at the electric service switch b ox and turn off the

water supply before proceeding.

Remove spray bar clamp and spray bar.

1. Grasp pump and pull straight down until water

pump disengages and electrical connector is

visible.

2. Disconnect the electrical connector.

3. Remove the water pump from ice machine.

4. Remove clamp from hose to remove from pump.

5. Do not submerse the water pump motor in cleaner

or sanitizer. If soaking is required, immerse pump

to normal water level during the freeze.

74 Part Number 80-01111-9 7/10

Page 75

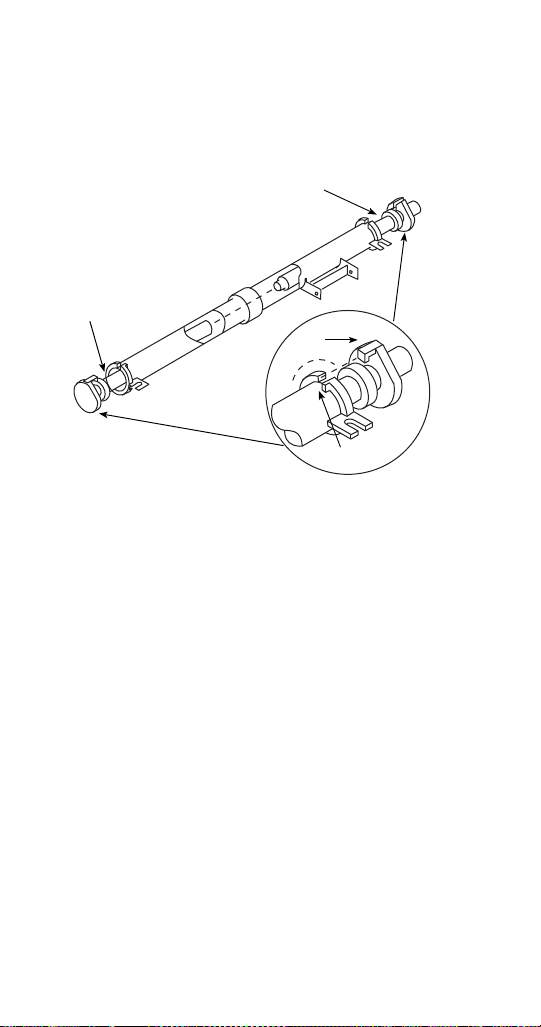

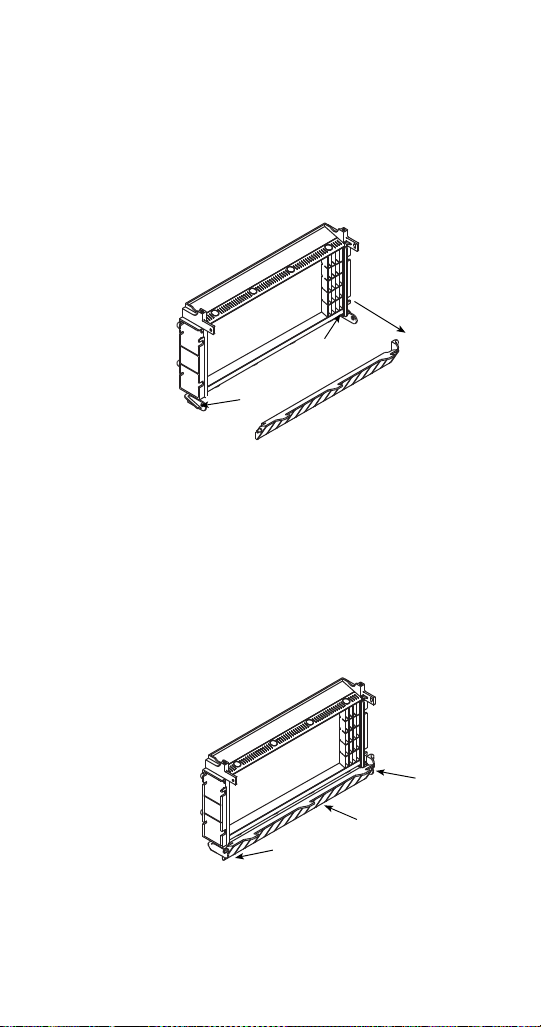

SPRAY BAR DISASSEMBLY

REMOVE

CLAMP

The spray bar supplies water to the individual ice

making cups. Water from the water pump sprays

through the nozzles, located on the upper portion of

the tubes.

1. Grasp one end of the spray bar, lift up and remove

from seat formed in evaporator bucket.

2. Remove clamp on water inlet tubing by grasping

both ears on clip and separating.

3. Apply food grade lubricant to ease re-assembly of

spray bar components when necessary.

4. To re-install spray bar, position water inlet tubing

on inlet ports, and squeeze clips until tight.

5. Reposition assembly on water trough seat.

Nozzles and inserts can be removed for cleaning

by unscrewing nozzles. Inserts are located inside

the spray bar ports. The spray bar also

disassembles for easy cleaning.

Part Number 80-01111-9 7/10 75

Page 76

!

Warning

Wear ru bber gloves an d sa fety g oggles (and/or

! Warning

!

Caution

face shie ld) when handling Ice Ma chine Clea ner

or Sanitizer.

6. Soak the removed part(s) in a properly mixed

solution.

Solution

Type

Cleaner 1 gal (4 l)

Sanitizer 6 gal (23 l)

7. Use a soft-bristle brush or sponge (NOT a wire

brush) to carefully clean the parts.

Do not mi x Cleaner and Sanitizer solu tions

together. It is a viola tion of Fe deral law to use

these solutions in a manner inconsistent with their

labeling.

Do not immerse the water pum p motor in the

cleaning or sanitizing solution.

8. Use the solution and a brush to clean the top,

sides, and bottom evaporator extrusions; the

inside of the ice machine panels; and the entire

inside of the bin.

NOTE: Do not rinse sanitized components.

9. Install the removed parts.

10. Turn on the water and electrical supply.

Water Mixed With

16 oz (500 ml)

cleaner

4 oz (120 ml)

sanitizer

76 Part Number 80-01111-9 7/10

Page 77

Removal from Service/Winterization

!

Caution

GENERAL

Special precautions must be taken if the ice machine is

to be removed from service for an extended period of

time or exposed to ambient temperatures of 32°F

(0°C) or below.

If water is a llowed to remain in the ice machine in

freezing temperatures, severe damag e to some

components could result. Damage of this nature is