Page 1

Ice/Beverage Series 1090C Remote Ice Cube Machine

with Patented CVD Technology®

Model

IB-1094YC

Ice/Beverage Series 1090C Remote Ice Cube Machine

with Patented CVD Technology®

An Ice Machine Designed

Specifically for Beverage

Dispensers

Ice/Beverage Series 1090C ice machine - 115V

Servend SV-250 beverage dispenser

An “NSF Listed” Ice/Beverage Dispenser Combination

CVD Condensing Unit - 208-230V

QuietQube ice machine with CVD condensing unit is designed

as a Manitowoc system and cannot be used with any other ice

machine or remote condenser brand.

Standard Features

IB Series QuietQube® Remote System consists of a remote condensing

unit, interconnecting refrigerant lines, ice machine head section along

with a countertop dispenser, or ice storage bin. All ordered separately.

• Space-Saving Design - up to 1070 lbs. (485 kgs.) daily ice production

in narrow 22" footprint eases sanitation procedures for the ice

storage area and beverage valves.

• Also allows for convenient manual loading of ice in dispenser to

satisfy peak ice usage.

• Can be installed or retrofitted to virtually any commercial

beverage dispenser.

• Only 14" (35.56 cm) deep, 22" (55.88 cm) wide, and

30.5" (77.50 cm) high.

• Quiet Operation - eliminates most noise from the refrigeration

system. Promotes a relaxing atmosphere.

• Intelligent Diagnostics – provide 24 hour preventative maintenance

and diagnostic feedback for trouble free operation.

• Acoustical Ice Sensing Probe – for reliable operation in challenging

water conditions.

• EasyRead Display – communicates operating status, cleaning

reminders, and asset information through a blue illuminated display.

• Programmable Ice Production – by On/Off Time, Ice Volume or

Bin Level (with accessory bin level control) further improves energy

efficiency and savings.

• Easy to Clean Foodzone – Lift-off front door for easy access.

Removable water-trough, distribution tube, curtain, and sensing

probes for fast and efficient cleaning. Select components made with

AlphaSan® antimicrobial.

• DuraTech™ Exterior – provides superior corrosion resistance.

Stainless finish with innovative clear-coat resists fingerprints and dirt.

• AvailableLuminIce™ Growth Inhibitor controls the growth of

bacteria, yeast and other micro-organisms within the foodzone.

ICE MAKER EVAPORATOR

COMPRESSOR

Ice Shape

Half Dice

3

⁄8" x 11⁄8" x 7⁄8"

(.95 x 2.86 x 2.22 cm)

2110 South 26th Street

PO Box 1720

Manitowoc, WI 54221-1720 USA

Tel: 1.920.682.0161

Fax: 1.920.683.7589

YEAR YEAR

PARTS AND LABOR

www.manitowocice.com

YEAR PARTS

3 YEAR LABOR

Page 2

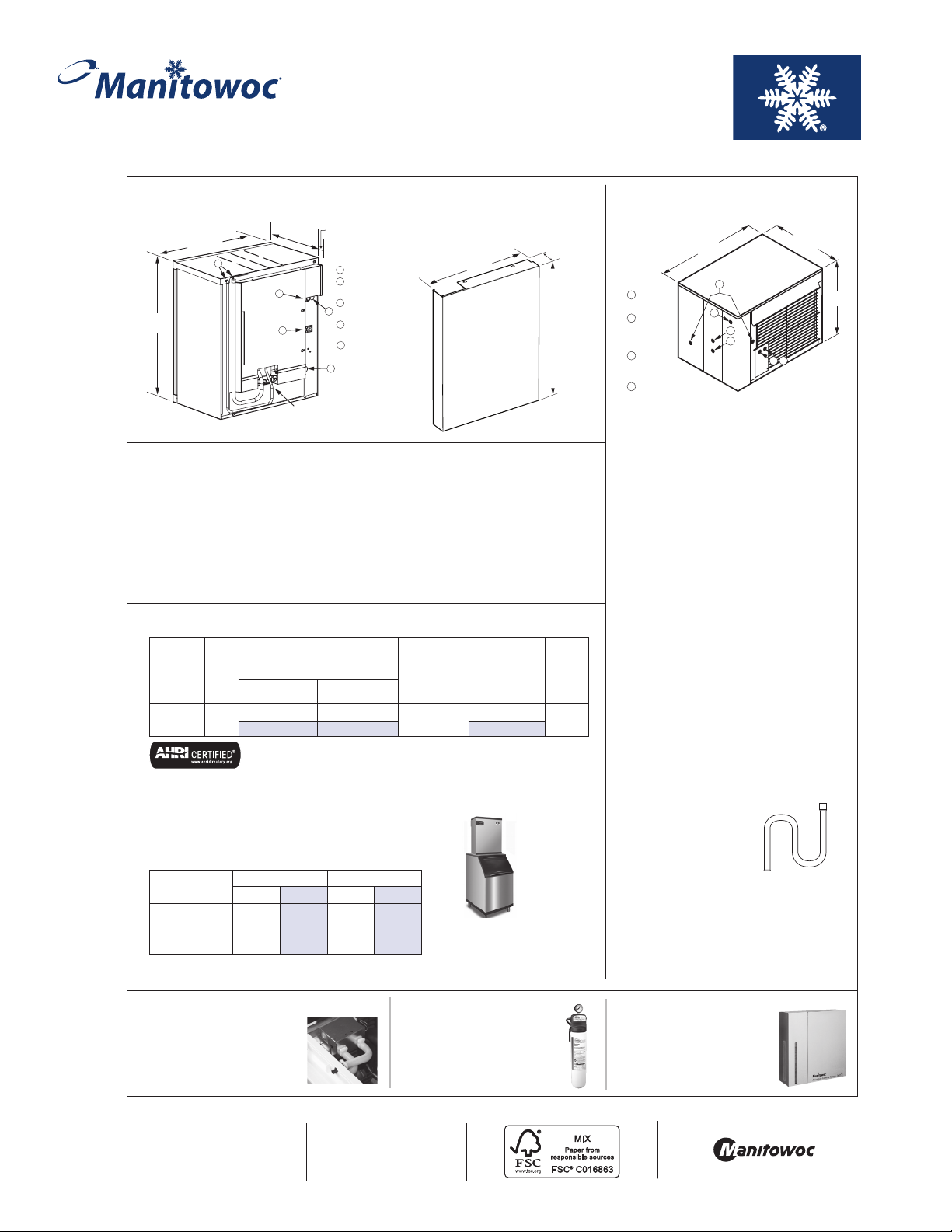

)

Ice/Beverage Series 1090C Remote Ice Cube Machine

with Patented CVD Technology®

(77.47 cm)

Ice/Beverage

iB-1090C Ice Machine

22.00"

(55.88 cm)

C

30.50"

14.00"

(35.56 cm)

A

D

Refrigeration line set

service loop provided.

1.26"

(3.20 cm)

Electrical Entrance

A

Communication

B

Wire Entrance

Suction & Liquid

C

Line Connections

B

D

3/8" (0.95 cm) F.P. T.

Ice Making Water Inlet

E

1/2 " (1.27 cm) F.P. T.

Ice Making Water

Drain

E

Accessory Rear Cover

K-00436

(for use with iB-1090C only)

22.00"

(55.88 cm)

(8.69 cm)

29.42"

(74.73 cm)

Shipping Weight: 148 lbs. / 67 kgs.

Ice Machine

Electric

115/60/1 standard.

Total Amps: 1.1

Max. fuse size: 15 amps

HACR-type circuit breakers

can be used in place of fuses.

Specifications

Operating Limits:

• Ambient Temperature Range:

35˚ to 110˚F (1.6˚ to 43.4˚C)

• Water Temperature Range:

35˚ to 90˚F (1.67˚ to 32.2˚C)

• Water Pressure Ice Maker Water In:

Min. 20 psi (137.9 kPA) / Max. 80 psi (551.1 kPA)

Refrigerant: R-404A

Remote Air-cooled Ice Machine

Ice production

Model

Ice

Shape

70°Air/50°F Water 90°Air/70°F Water*

IB-1094YC

Ice machine for use with ice dispenser, CVD condensing unit and dispenser adapter. All ordered separately.

kWh per 100 lbs. is total power of ice machine and condensing unit. Ice machine is 1 ph only. Condensing unit is 1

ph or 3 ph.

halfdice

*Ratings Certified in Accordance with AHRI Standard 810.

24 hours

1070 lbs. 910 lbs.

485 kgs. 413 kgs. 76 L.

Power kWh/

100 lbs

@ 90°Air/70°F*

4.85

Interconnecting Tubing with

Required Communication Wire*

Communication wire comes with each of the following line sets

Line Length Weight

Model

RC-26 20 6 12 5

RC-36 30 9 17 9

RC-56 50 15 27 13

*When using a non-Manitowoc line-set, a 186A 5-conductor communication

cable must be installed between the head and condenser sections.

ft. m. lbs. kgs.

Potable

Water Usage/

100 lbs.

ENERGY

45.4 kgs. of Ice*

20.1 gal.

Note: IB models

are designed

for use with an

Ice/Beverage

dispenser.

Adapter

required. Ordered separately.

For attachment to ice

storage bin, contact factory.

3.42"

STAR®

H

iCVD-1195 Condensing Unit

34.00"

(86.4 cm)

A

Electrical

Entrance

(2) Options

B

Optional

Suction

& Liquid

Line

Connections

Suction

C

& Liquid

Line

Connections

Communicator

D

Cable Entrance

A

D

B

B

208-230/60/1standard. 208-230/60/3

HACR-type circuit breakers can be used

in place of fuses.

Note: QuietQube ice machine power

supply is wired independent of CVD

condensing unit.

Min. circuit ampacity:

14.5 1ph 9.3 3ph

Max. fuse size:

25 amps 1ph 15 amps 3ph

HACR-type circuit breakers can be

used in place of fuses.

BTU Per Hour:

16,250 (average) 18,600 (peak)

Compressor:

Nominal rating: 1.75 HP

Operating Limits:

• Ambient Temperature Range:

-20˚ to 120˚F (-29˚ to 48.9˚C)

Installation Information

and Dimensions:

Maximum Line Length

—100' (30.5 m).*

Maximum Vertical Rise*

—35' (10.7 m) above ice machine.

Maximum Vertical Drop

—15' (4.5 m) below ice machine.

* A rise over 20' (6 m) requires S-Trap Kit

K-00172 - ordered separately.

24.13"

(61.3 cm)

(65.4 cm

C

C

Shipping Weight:

208 lbs. / 94 kgs.

25.75"

Accessories

LuminIce™

Growth Inhibitor

reduces yeast and bacteria

growth for a cleaner ice machine.

2110 South 26th Street

PO Box 1720

Manitowoc, WI 54221-1720 USA

Arctic Pure® Water Filters

Reduces sediment and chlorine

odors for better tasting ice.

Tel: 1.920.682.0161

Fax: 1.920.683.7589

www.manitowocice.com

AuCS®

schedules and performs

routine ice machine cleaning

automatically.

4779C ©2011 Manitowoc 11 /11 Continuing product improvement may necessitate change of specifications without notice.

Loading...

Loading...