Page 1

Manitowoc

BG0260

Spray Cube

Technician’s

Handbook

This manual is updated as new information and models are released.

Visit our website for the latest manual. www.manitowocfsg.com

America’s #1 Selling Ice Machine

Part Number STH48 6/15

Page 2

Page 3

General Information

Model Numbers ...................................5

BG0260A .............................................5

Model/Serial Number ...........................5

Manitowoc Cleaner and Sanitizer ........ 5

Installation

Location of Ice Machine ......................7

Installation Requirements ....................7

Potable Water Requirements .............. 8

Drain Connections ...............................8

Ice Machine Clearance Requirements 8

Electrical Service .................................9

Operation

Ice Making Sequence of Operation .........11

Thermostat settings .............................13

Maintenance

Cleaning & Sanitizing Procedure ......... 16

Cleaning the Condenser .....................20

Removal from Service/Winterization ...21

Page 4

Troubleshooting

Electrical Flowcharts ................................23

Electrical Flowchart Ice Machine Will Not

Run ...................................................... 24

Will Not cycle Into Harvest ...................28

Prematurely Cycles Into Harvest .........31

Refrigeration Troubleshooting ................34

Ice Production/Quality Check ..............35

Component Specifications

Thermostat Settings ............................41

Fan Cycle Control Settings ..................41

Total System Refrigerant Charge ........41

Filter-Driers .......................................... 42

Suction Cleanup Filter-Drier ................42

Charts

Cycle Times/24-Hour Ice Production/

Refrigerant Pressure Charts ....................43

BG0260A .............................................44

Diagrams

Wiring Diagram .........................................45

BG0260 ...............................................46

Refrigeration Tubing Schematics ...........47

Page 5

General Information

MODEL NUMBERS

BG0260A

MODEL/SERIAL NUMBER

These numbers are required when requesting

information from your local Manitowoc Distributor, or

Manitowoc Ice. The model and serial number are

listed on the MODEL/SERIAL NUMBER DECAL

affixed to the ice machine.

MANITOWOC CLEANER AND SANITIZER

Manitowoc Ice Machine Cleaner and Sanitizer are

available in 16 oz. (473 ml) bottles. These are the only

cleaners and sanitizer approved for use with

Manitowoc products.

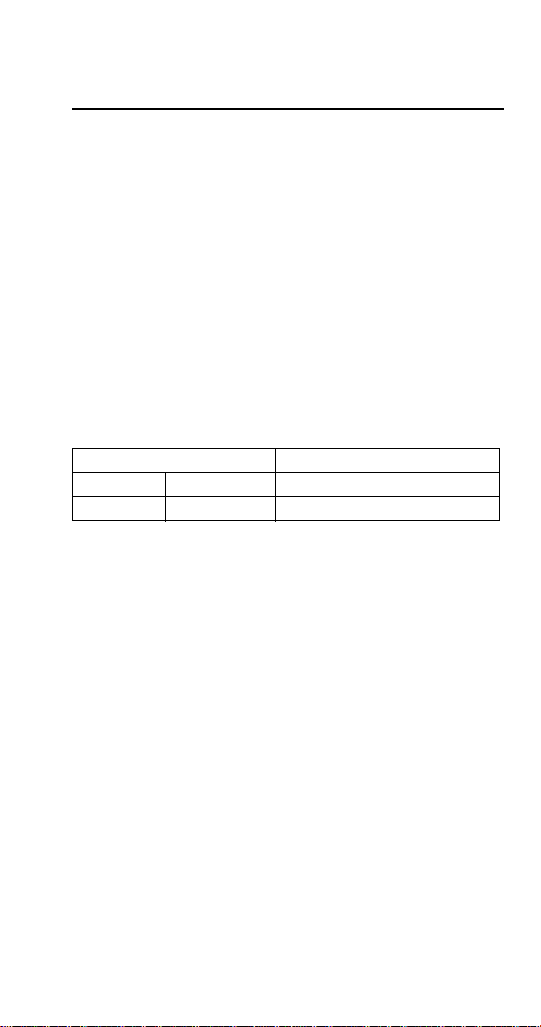

Cleaner Part Number Sanitizer Part Number

16 oz. 000000084 16 oz. 9405653

1 gal N/A 1 gal. 9405813

Part Number STH48 6/15 5

Page 6

6 Part Number STH48 6/15

This Page Intentionally Left Blan k

Page 7

Installation

LOCATION OF ICE MACHINE

The location selected for the ice machine must meet

the following criteria. If any of these criteria are not

met, select another location.

• The location must be free of airborne and other

contaminants.

• The location must not be near heat-generating

equipment or in direct sunlight.

• The location must be capable of supporting the

weight of the ice machine and a full bin of ice.

• The location must allow enough clearance for

water, drain and electrical connections in the rear

of the ice machine.

• The location must not obstruct airflow through or

around the ice machine.

INSTALLATION REQUIREMENTS

• The air temperature must be at least 50°F (10°C),

but must not exceed 110°F (43°C).

• The water temperature must be at least 50°F

(10°C), but must not exceed 100°F (38°C).

• The ice machine and bin must be level

• Vent the ice machine and bin drains separately

• Bin drain termination must have an air gap

• A back flow preventer is required on water inlet

lines

• Routine adjustments and maintenance procedures

outlined in this manual are not covered by the

warranty.

Part Number STH48 6/15 7

Page 8

POTABLE WATER REQUIREMENTS

• Plumbing must conform to local codes

• Do not connect the ice machine to a hot water

supply. Be sure all hot water restrictors installed for

other equipment are working. (Check valves on

sink faucets, dishwashers, etc.)

• If water pressure exceeds maximum pressure (6

bar) obtain a water pressure regulator from your

Manitowoc distributor.

• A union for both the ice making and condenser

water lines is required

• Water inlet lines require insulation to prevent

condensation.

DRAIN CONNECTIONS

• Drain lines must have a 1.5 inch drop per 5 feet of

run (2.5 cm per meter), and must not create traps

• The floor drain must be large enough to

accommodate drainage from all drains.

• Separate insulated bin and water-cooled

condenser drain lines are required

• The bin and ice machine drains require a vent.

ICE MACHINE CLEARANCE REQUIREMENTS

Air-Cooled Water-Cooled

Top/Sides 5" (13 cm) 5" (13 cm)

Back 8" (20 cm) 8" (20 cm)

8 Part Number STH48 6/15

Page 9

ELECTRICAL SERVICE

!

Warning

!

Warning

All wiring must conform to local and national codes.

Voltage

The maximum allowable voltage variation is ± 10% of

the rated voltage on the ice machine model/serial

number plate at compressor start-up.

Fuse/Circuit Breaker

A separate fuse/circuit breaker must be provided for

each ice machine.

The ice machine must be grounded in accordance

with national and local electrical codes.

Ground Fault Interrupter Circuit (GFIC)

A GFCI/GFI circuit protection is not recommended

with our equipment. If a GFCI/GFI is required by code

a GFCI/GFI breaker rather than outlet must be used to

avoid intermittent nuisance trips.

Part Number STH48 6/15 9

Page 10

10 Part Number STH48 6/15

This Page Intentionally Left Blan k

Page 11

Operation

Ice Making Sequence of Operation

Priming the Water system

The water inlet valve on this machine energizes in the

harvest sequence, therefore priming the system with

water will allow the system to start up with a full

reservoir of water. To prime system add 2 liters of

water into the water trough.

1. Freeze Cycle

Turn the toggle switch to ON. The compressor, and

water pump will energize, starting the freeze cycle.

The pump sprays water into the inverted cups. The

water freezes layer by layer, until an ice cube forms in

each cup.

The freeze cycle continues and the evaporator

thermostat reaches the adjusted se t po i nt .

The thermostat energizes the timer motor and the cam

starts to turn. When the cam cycles through the preset

freeze time the relays change position and the harvest

cycle starts.

Part Number STH48 6/15 11

Page 12

2. Harvest Cycle

The compressor continues to operate and the water

pump is de-energized. The harvest valve energizes,

allowing hot gas to enter and warm the evaporator.

The water valve is also energized, aiding with harvest,

as well as filling up the sump with fresh water for a

new freeze cycle.

The ice falls from the cups and drops into the bin. The

harvest cycle continues until the preset harvest time

expires.

The harvest valve and water valve de-energize. If ice

cubes are not contacting the bin thermostat, a new

freeze cycle is initiated and the water pump energizes

and sprays water into the cups.

3. Automatic Shut-Off

When the storage bin is full, ice will contact the bin

thermostat inside the bin. If the bin thermostat opens

during a freeze cycle the ice machine will finish the

freeze cycle and stop when it enters the harvest cycle.

The ice machine remains off until enough ice has been

removed from the storage bin to allow the ice to fall

clear of the bin thermostat probe. As the ice clears the

probe, the bin thermostat warms up and the machine

starts another freeze cycle.

12 Part Number STH48 6/15

Page 13

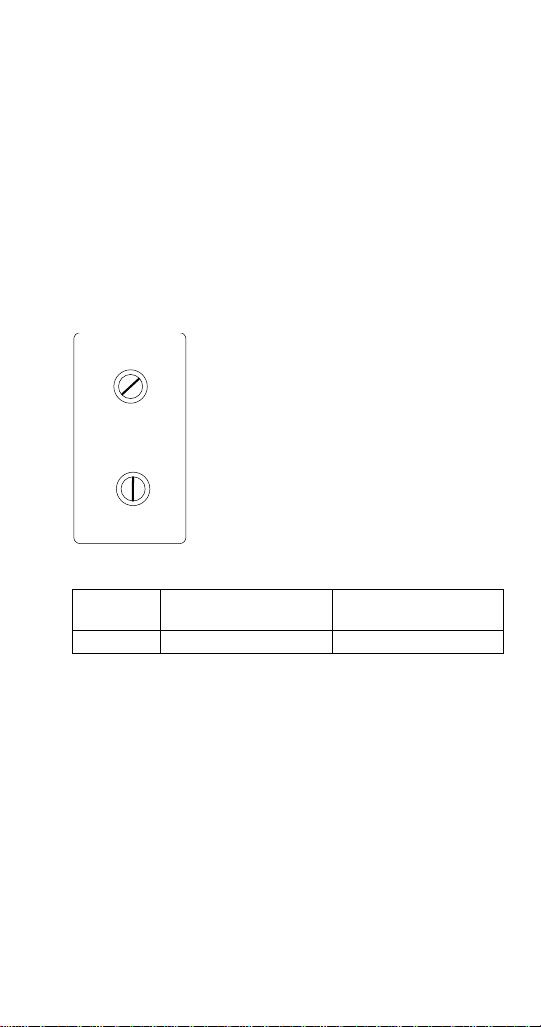

THERMOSTAT SETTINGS

1

2

3

4

5

6

7

1

2

3

4

5

6

7

Bin Thermostat

Small Numbers = Less ice in bin

Large Numbers = More ice in bin

Start at Chart Setting, then adjust as

required

Evaporator Thermostat

Small Numbers = Large dimple & lighter

cubes

Large Numbers = Small Dimple & heavier

cubes

Refer to chart for initial setting

Bin Thermostat:

The bin thermostat sensing bulb is located in holder on

the right side of the bin on self storage models. The

bin thermostat turns the ice machine on and off as the

level of ice in the bin changes. Use the initial setting

from the chart and adjust as required.

Evaporator Thermostat:

The evaporator thermostat energizes the timer motor.

After the preset time on the timer expires the harvest

cycle begins. Refer to chart for correct setting.

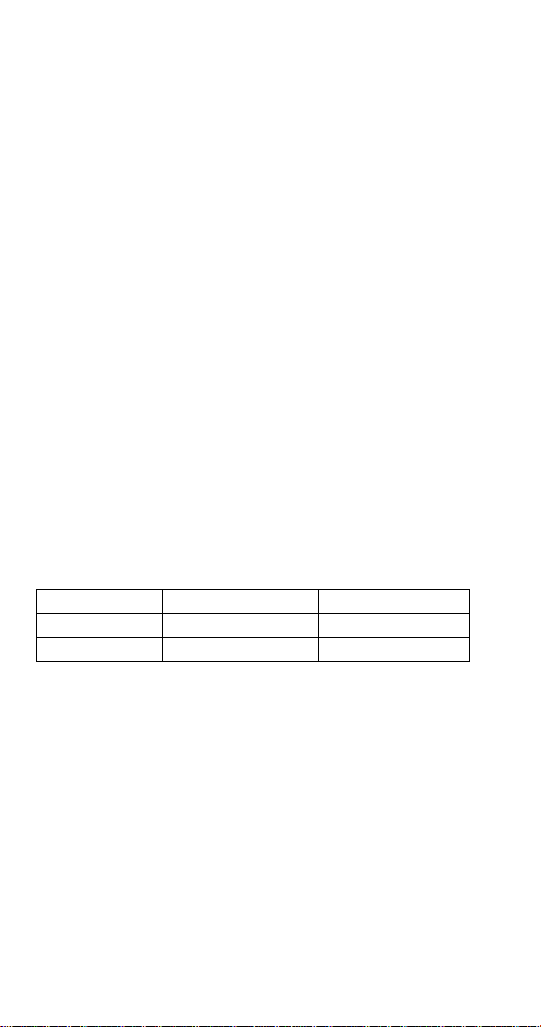

Thermostat Setting Chart

Model

Bin Thermostat

Setting

Evaporator

Thermostat Setting

BG0260 5 4

Part Number STH48 6/15 13

Page 14

14 Part Number STH48 6/15

This Page Intentionally Left Blan k

Page 15

Maintenance

!

Caution

!

Warning

Clean and sanitize the ice machine every six months

for efficient operation. If the ice machine requires more

frequent cleaning and sanitizing, consult a qualified

service company to test the water quality and

recommend appropriate water treatment.

An extremely dirty ice machine must be taken apart for

cleaning and sanitizing.

Use only approved Ice Machine Cleaner and

Sanitizer. Read and understand all labels printed on

bottles before use. Do not mix Ice Machine Cleaner

and Sanitizer solutions together.

Wear rubber gloves and safety goggles (and/or face

shield) when handling Ice Machine Cleaner or

Sanitizer

Part Number STH48 6/15 15

Page 16

CLEANING & SANITIZING PROCEDURE

!

Caution

Ice machine cleaner is used to remove lime scale or

other mineral deposits. Sanitizer is used to remove

algae or slime.

Mix 4 liters of water with 500 ml of cleaner in a plastic

or stainless container.

Cleaner Water

16 oz (500 ml) 1 gal (4L)

Step 1 Open the front door to access the evaporator

compartment. Ice must not be on the evaporator

during cleaning and sanitizing. Follow one of the

methods below:

• Press the power switch at the end of a

harvest cycle after ice falls from the

evaporator(s).

• Press the power switch and allow the ice to

melt.

Never use anything to force ice from the

evaporator. Damage may result.

Step 2 Remove all ice from the bin and remove top

cover of ice machine

Step 3 Remove overflow tube and drain water sump.

Step 4 Remove all parts for cleaning.

A. Remove two thumbscrews and shutter

assembly

B. Remove ice cube slide

C. Remove spray bar and vinyl tubing

D. Evaporator shield on top of evaporator

NOTE: The tubing, spray bar ends and nozzles can be

removed when required for easier cleaning.

.

Mix a solution of cleaner and lukewarm water.

16 Part Number STH48 6/15

Page 17

Step 5 Depending upon the amount of mineral

buildup, a larger quantity of solution may be required.

Use the ratio in the table below to mix enough solution

to thoroughly clean all parts.

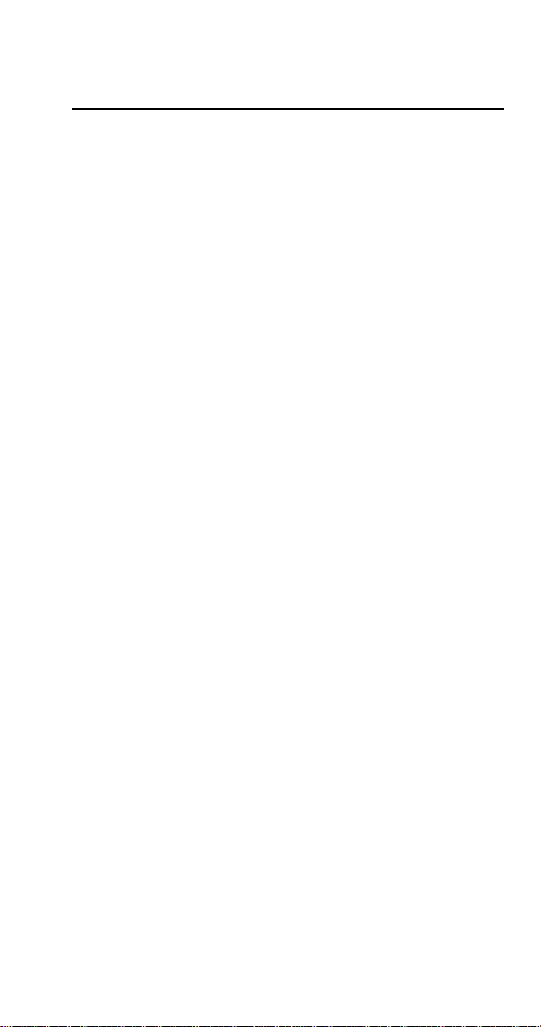

Solution Type Water Mixed With

Cleaner 1 gal (4L) 16 oz (500 ml)

cleaner

Step 6

all components. The cleaner solution will foam when it

contacts lime scale and mineral deposits; once the

foaming stops use a soft-bristle nylon brush, sponge

or cloth (NOT a wire brush) to carefully clean the parts.

All parts except the ice thickness probe can be soaked

when heavily scaled. Rinse all components with clean

water.

Part Number STH48 6/15 17

Use 1/2 of the cleaner/water mixture to clean

Page 18

Step 7 While components are soaking, use 1/2 of the

cleaner/water solution to clean all foodzone surfaces

of the ice machine and bin. Use a nylon brush or cloth

to thoroughly clean the following ice machine areas:

• Evaporator top panel

• Side walls

• W ater trough interior / exterior

• Evaporator and plastic parts - including top,

bottom, and sides bin

Step 8 Rinse all areas thoroughly with clean water.

Step 9 Mix a solution of sanitizer and lukewarm

water.

Solution Type Water Mixed With

Sanitizer 1 gal (4 L) 2 oz (60 Ml)

Sanitizer

Step 10 Use 1/2 of the sanitizer / water solution to

sanitize all removed components. Use a spray bottle

to liberally apply the solution to all surfaces of the

removed parts or soak the removed parts in the

sanitizer/water solution. Do not rinse parts after

sanitizing.

Step 11

machine

the solution. When sanitizing, pay particular attention

to the following areas:

Sanitize all foodzone surfaces of the ice

and bin. Use a spray bottle to liberally apply

• Evaporator top panel

• Side walls

• W ater trough interior / exterior

• Evaporator and plastic parts - including top,

bottom, and sides

•Bin

Do not rinse the sanitized areas.

18 Part Number STH48 6/15

Page 19

Step 12 Replace all removed components.

NOTE: Spray bar and nozzles.

• If the nozzles were removed from the spray

bar, take care to prevent cross threading

when reassembling.

• Verify the spray bar is correctly positioned

and the nozzles are aligned to the evaporator

cups.

Step 13 Reapply power to the ice machine and move

the toggle switch to the on position.

Step 14 Discard first batch of ice to remove any flavor

transmission from the cleaning process.

Part Number STH48 6/15 19

Page 20

CLEANING THE CONDENSER

!

Warning

!

Warning

Disconnect electric power to the ice machine at the

electric service switch before cleaning the

condenser. The condenser fins are sharp. Use care

when cleaning them.

Air-Cooled Condenser

Clean the condenser at least every six months. Follow

the steps below.

1. Shine a flashlight through the condenser to check

for dirt between the fins. Blow compressed air

through the condenser fins from the inside or use

a commercial condenser coil cleaner. Follow the

directions and cautions supplied with the cleaner.

2. Straighten any bent condenser fins with a fin

comb.

3. Carefully wipe of f the fan blades and motor with a

soft cloth. Do not bend the fan blades. If the fan

blades are excessively dirty, wash with warm,

soapy water and rinse thoroughly.

If you are cleaning the condenser fan blades with

water, cover the fan motor to prevent water damage.

20 Part Number STH48 6/15

Page 21

REMOVAL FROM SERVICE/WINTERIZATION

!

Caution

If water is allowed to remain in the ice machine in

freezing temperatures, severe damage to some

components could result. Damage of this nature is

not covered by the warranty.

Follow the procedure below.

1. Disconnect the electric power at the circuit

breaker or the electric service switch.

2. Turn off the water supply.

3. Disconnect and drain the incoming ice-making

water line at the rear of the ice machine.

4. Disconnect drain tubing and drain water into

container and discard.

5. Make sure water is not trapped in any of the water

or drain lines.

Part Number STH48 6/15 21

Page 22

22 Part Number STH48 6/15

This Page Intentionally Left Blan k

Page 23

Troubleshooting

Electrical Flowcharts

Diagnostic troubleshooting for the ice machine

involves following flowcharts that are dependant on

symptoms of the failed machine.

Follow the flowcharts for the failure symptom and

model you are working on.

NOTE: Refer to the sequence of operation to

determine where in the sequence the ice machine has

failed. An example would be an ice machine that

energizes the gear motor, but the compressor does

not energize. Following the electrical flowchart will

quickly and easily eliminate non issues.

Part Number STH48 6/15 23

Page 24

24 Part Number STH48 6/15

ELECTRICAL FLOWCHART ICE MACHINE WILL NOT RUN

Start

Power Supplied to

Ice Machine?

YES

Toggle Switch in

ON Posion?

YES

Plug in Ice Machine, Reset BreakerNO

Move Switch to ON PosionNO

Page 25

Part Number STH48 6/15 25

YES

Switch

Illuminated?

YES

Bin Thermostat

Closed?

YES

NO

Remove Ice – Allow

to warm and retest

Replace SwitchNO

Ice Contacng

Thermostat?

YES

NO

Verify New Seng

Cycles Machine On/

Adjusng Closes

Thermostat?

YES

Off

Replace Thermostat

NO

Page 26

26 Part Number STH48 6/15

YES

Line Voltage to

Compressor

Contactor?

Repair WiringNO

Contacts Closed? YES Replace ContactorNO

YES

Page 27

Part Number STH48 6/15 27

Line Voltage to

Compressor?

Repair WiringNO

Verify:

Compressor Overload is Closed, Start Components Funcon

YES

YES

Page 28

Part Number STH48 6/15 28

Start

Is the Evaporator

Temperature below

-7°F (-22°C)

Refer to Refrigeraon Diagnosis

(Long Freeze Cycle)

NO

Is the Evaporator

Thermostat Contacts

closed between #3 &

#2?

YES

Replace Evaporator

Thermostat

NO

Is there Voltage at

the Timer Motor

YES

Repair WiringNO

YES

WILL NOT CYCLE INTO HARVEST

Page 29

29 Part Number STH48 6/15

YES

Is the mer

motor turning

the cams?

YES

Aer 25 Minutes of the

Timer turning Cams

YES

Do the Cam Switches

Switch and send voltage to

Water Inlet valve and Hot

Gas Solenoid Valve?

YES

Replace the TimerNO

NO

Page 30

Part Number STH48 6/15 30

YES

Is the Water inlet

Valve and Hot Gas

Solenoid Valve

Energized?

NO

Repair Wiring

YES

Refer to: Ice

Machine will

not Harvest.

Page 31

31 Part Number STH48 6/15

Start

Is the Evaporator

Temperature below

-7°F (-22°C)

Refer to Refrigeraon Diagnosis

(Long Freeze Cycle)

NO

Is the Evaporator

Thermostat Contacts

closed between #3 &

#2?

YES

Replace Evaporator

Thermostat

NO

Is there Voltage at

the Timer Motor

YES

Repair WiringNO

YES

PREMATURELY CYCLES INTO HARVEST

Page 32

Part Number STH48 6/15 32

YES

Is the mer

motor turning

the cams?

YES

Aer 25 Minutes of the

Timer turning Cams

YES

Do the Cam Switches

Switch and send voltage to

Water Inlet valve and Hot

Gas Solenoid Valve?

YES

Replace the TimerNO

NO

Page 33

33 Part Number STH48 6/15

Is the Water inlet

Valve and Hot Gas

Solenoid Valve

Energized?

Repair Wiring

NO

YES

Refer to: Ice

Machine will

not Harvest.

YES

Page 34

34 Part Number STH48 6/15

Refrigeration Troubleshooting

If the compressor is not energized refer to Electrical Troubleshooting

Refer to Operational Pressure Charts for normal pressures and temperatures

Discharge Pressure Low High High Low

Suction Pressure Low High High Low

Evaporator Inlet Temperature Normal Low High Low

Evaporator Outlet Temperature High Normal High Low

Compressor Discharge Line Temperature

Normal Range =

> 158°F (70°C) @ 70°F (21°C)

>210°F (99°C) @ 110°F (43°C)

Low on

Refrigerant

High

Increases with

run time

Overcharge of

Refrigerant

Normal High

Non Condensible in

Increases with

System

run time

Restricted Capillary

Tube

High

Increases with

run time

Page 35

ICE PRODUCTION/QUALITY CHECK

The amount of ice a machine produces directly relates

to the operating water and air temperatures. This

means an ice machine with a 68°F

(20°C) outdoor

ambient temperature and 50°F (10.0°C) water

produces more ice than the same model ice machine

with a 90°F (32°C) outdoor ambient and 70°F (21°C)

water.

1. Determine the ice machine operating conditions:

Air temp entering condenser: ____°

Air temp around ice machine: ____°

Water temp entering sump trough: ____°

2. Refer to the appropriate 24-Hour Ice Production

Chart.

3. Use the operating conditions determined in Step 1

to find published 24 hr. ice production: ____

Times are in minutes.

Example: 1 min., 15 sec. converts to 1.25 min.

(15 seconds ÷ 60 seconds = .25 minutes)

Weights are in grams.

4. Perform an ice production check using the formula

below.

1. _________

Freeze Time

2. 1440

_________

Minutes in

24 Hrs.

3. _________

Weight of One

Harvest

+ _________

Harvest Time

_________

Total Cycle

Time

× _________

Cycles per Day

= _________

Total Cycle

Time

_________

Cycles per Day

= _________

Actual 24-Hour

Production

Weighing the ice is the only 100% accurate check.

Compare the results of Step 3 with Step 2. Ice

production is normal when these numbers match

closely. If they match closely, determine if:

Another ice machine is required.

Relocating the existing equipment to lower the load

conditions is required.

Part Number STH48 6/15 35

Page 36

WATER SYSTEM CHECKLIST

A water-related problem often causes the same

symptoms as a refrigeration system component

malfunction.

Water system problems must be identified and

eliminated prior to replacing refrigeration components.

Water area (evaporator) is dirty

Clean as needed

Water inlet pressure not between 1.4 and 5.5 bar

Install a water regulator valve or increase the water

pressure

Incoming water temperature is not between

1.7°C and 32.2°C

If too hot, check the hot water line check valves in

other store equipment

Water filtration is plugged (if used)

Install a new water filter

Hoses, fittings, etc., are leaking water

Repair/replace as needed

Water inlet valve is stuck open or closed

Clean/replace as needed

Water is spraying out of the sump trough area

Stop the water spray

Uneven water flow across the evaporator

Clean the ice machine

36 Part Number STH48 6/15

Page 37

DISCHARGE PRESSURE HIGH CHECKLIST

Improper Installation

Refer to Installation section of this manual

Restricted Condenser Air Flow

High inlet air temperature

Condenser discharge air re-circulation

Dirty condenser fins

Defective fan motor

Improper Refrigerant Charge

Overcharged

Non-condensable in system

Wrong type of refrigerant

Other

High side refrigerant lines/component restricted

(before mid-condenser)

Part Number STH48 6/15 37

Page 38

FREEZE CYCLE DISCHARGE PRESSURE LOW

CHECKLIST

Improper Installation

Refer to Installation section of this manual

Improper Refrigerant Charge

Undercharged

Wrong type of refrigerant

Other

High side refrigerant lines/component restricted

(before mid-condenser)

38 Part Number STH48 6/15

Page 39

SUCTION PRESSURE HIGH CHECKLIST

Improper Installation

Refer to Installation section of this manual

Discharge Pressure

Discharge pressure is too high, and is affecting

suction pressure

Improper Refrigerant Charge

Overcharged

Wrong type of refrigerant

Non Condensible in system

Other

Harvest valve leaking

Defective compressor

Part Number STH48 6/15 39

Page 40

SUCTION PRESSURE LOW CHECKLIST

Discharge Pressure

Discharge pressure (ambient temperature) is too

low, and is affecting suction pressure - Refer to

Installation section of this manual

Improper Refrigerant Charge

Undercharged

Wrong type of refrigerant

Other

Restricted capillary tube

Collapsed/restricted suction tubing

Harvest valve not opening in harvest cycle

40 Part Number STH48 6/15

Page 41

Component Specifications

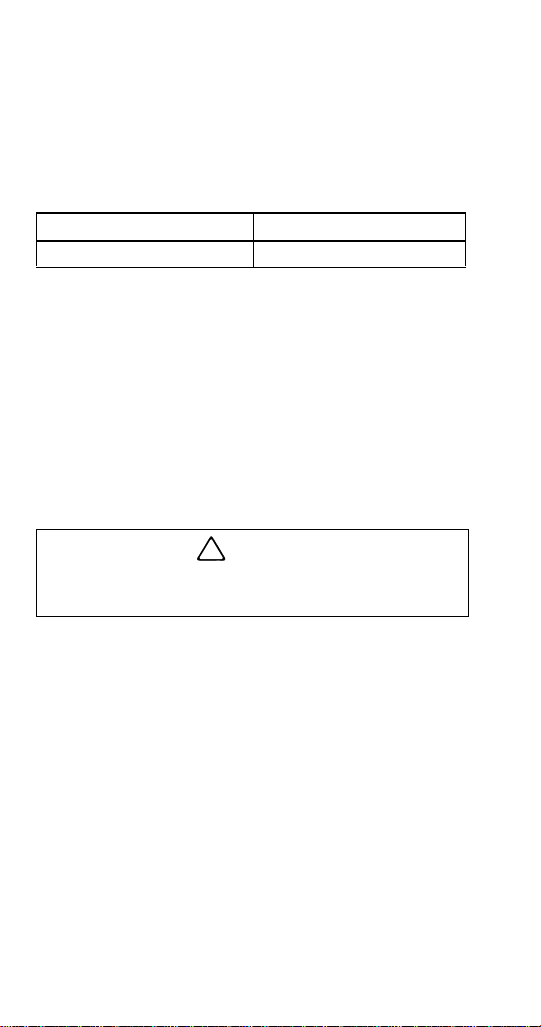

Important

THERMOSTAT SETTINGS

Model

BG0260A 5 4

Bin

Thermostat

Setting

Evaporator Thermostat

Setting

FAN CYCLE CONTROL SETTINGS

Model Cut-In (Close) Cut-Out (Open)

BG0260A

215 psi

1482 kPa

230 psi

1586 kPa

T OTAL SYSTEM REFRIGERANT CHARGE

This information is for reference only. Refer to the

ice machine serial number tag to verify the system

charge. Serial plate information overrides

information listed on this page.

Model R404A Refrigerant Charge

BG0260A 22 oz (620 g)

Part Number STH48 6/15 41

Page 42

FILTER-DRIERS

Important

The size of the filter-drier is important. The refrigerant

charge is critical. Using an improperly sized filter-drier

will cause the ice machine to be improperly charged

with refrigerant.

Driers are covered as a warranty part. The drier

must be replaced any time the system is opened for

repairs.

SUCTION CLEANUP FILTER-DRIER

Contaminated systems must have a suction line filterdrier installed to remove contamination. An access

valve must be installed on the inlet side of the suction

filter to allow pressure drop readings to be obtained.

42 Part Number STH48 6/15

Page 43

Charts

Cycle Times/24-Hour Ice Production/ Refrigerant Pressure Charts

These charts are used as guidelines to verify correct

ice machine operation.

Accurate collection of data is essential to obtain the

correct diagnosis.

• Ice production checks that are within 10% of the

chart are considered normal.This is due to three

factors:

1. The data listed is an average obtained from

testing a group of ice machines.

2. Freeze/harvest times have been rounded to the

nearest whole number

3. Air and water temperatures will seldom match the

charts exactly.

• Zero out manifold gauge set before obtaining

pressure readings to avoid misdiagnosis.

• Discharge and suction pressure are highest at the

beginning of the cycle and drop throughout the

freeze cycle.

• Water temperature will affect suction and

discharge pressure 50°F (10°C) water temperature

will result in pressures on the lower end of the

ranges specified. 90°F (32°C) water temperatures

will result in pressures on the upper end of the

range specified.

Part Number STH48 6/15 43

Page 44

BG0260A

SELF STORAGE AIR-COOLED

Averages are used for calculations, characteristics will vary

depending on your operating conditions.

CYCLE TIMES

Freeze Time + Harvest Time = Total Cycle Time

Air Temp.

Entering

Condenser

70°F/21°C 30-32 31-38 34-45

90°F/32°C 33-42 40-50 37-60

100°F/38°C 38-44 40-56 42-70

110°F/43°C 40-46 49-60 65-75

1 Times in minutes

NOTE: In addition to air/water temperatures, freeze cycle times will

increase/decrease significantly depending on cube weight

24 HOUR ICE PRODUCTION

Air Temp. Entering

Condenser F

1 Based on average ice weight of one Freeze/Harvest cycle 7.5 lbs

(3600 grams) 60 cubes @ 2 oz (60 grams)

70°F

21°C

90°F

32°C

100°F

38°C

110°F

43°C

°/°C

OPERATING PRESSURES

Air

Temperature

Entering

Condenser

50°F

10°C

70°F

21°C

90°F

32°C

100°F

38°C

110°F

43°C

Suction

Pressure

psig/kPa

18-48

124-331

20-50

138-345

25-60

172-414

25-65

172-448

30-65

207-448

Freeze Time

Water Temperature F°/°C

50/10 70/21 90/32

Water Temperature F°/°C

50/10 70/21 90/32

315 lbs

143 kgs

260 lbs

118 kgs

250 lbs

113 kgs

240 lbs

109 kgs

Freeze Cycle Harvest Cycle

Discharge

Pressure

psig/kPa

215-265

1482-1827

215-295

1482-2034

255-355

1758-2448

290-400

1999-2758

330-440

2275-3034

290 lbs

132 kgs

255 lbs

116 kgs

230 lbs

104 kgs

200 lbs

91 kgs

Suction

Pressure

psig/kPa

75-145

517-1000

75-145

517-1000

80-160

552-1103

85-175

586-1207

170-185

1172-1276

Harvest

270 lbs

122 kgs

230 lbs

104 kgs

200 lbs

91 kgs

150 lbs

68 kgs

Discharge

Pressure

psig/kPa

125-150

862-1034

125-150

1862-1034

140-240

965-1655

150-260

1034-1793

170-280

1172-1931

Time

2:45

to

4:00

1

1

44 Part Number STH48 6/15

Page 45

Diagrams

!

Warning

Wiring Diagram

The following pages contain electrical wiring diagrams.

Be sure you are referring to the correct diagram for the

ice machine you are servicing.

Always disconnect power before working on

electrical circuitry.

Part Number STH48 6/15 45

Page 46

BG0260

Refer to Nameplate for Voltage Rating

46 Part Number STH48 6/15

Page 47

Refrigeration Tubing Schematics

1

7

6

5

4

3

2

1 Compressor

2 Condenser (air or water cooled)

3 Liquid Line Drier

4 Capillary tube

5 Accumulator

6 Heat Exchanger

7Evaporator

Part Number STH48 6/15 47

Page 48

48 Part Number STH48 6/15

This Page Intentionally Left Blan k

Page 49

Page 50

Page 51

Page 52

2110 South 26th Street, P.O. Box 1720

Ph: 920-682-0161 Fax: 920-683-7589

Visit us online at: www.manitowocfsg.com

© 2015 Manitowoc Part Number STH48 6/15

Manitowoc Ice

Manitowoc, WI 54221-1720 , USA

Loading...

Loading...