Page 1

PRODUCT DATA

Pump Design ..............................................Quad Diaphragm

Motor ................Permanent Magnet ............................TENV

Wetted Parts ....Diaphragm Material ..................Santoprene

Check Valve Material ........................EPDM

Housing Material ..................Polypropylene

Accumulator Tank

..Diaphragm Material ............................Butyl

Liner Material ........................Polypropylene

Ports ..............................3/4” HB Inlet & 1/2” HB/Qest Outlet

Net Weight ................................................8.8 Pounds (4 kgs)

PERFORMANCE SPECIFICATIONS

PUMP

Motor ................Max Amp Draw ....................1.5 @ 115 VAC

0.75 @ 230 VAC

Cycle ........................................50/60 Hertz

Liquid Temperature

..Min. ..............................................45°F (7°C)

Max. ........................................140°F (60°C)

Priming ..............Dry ............................................5 ft. (1.5 M)

Wet ..........................................15 ft. (4.6 M)

Flow Rate ..........Max ..............3.5/4.5 GPM @ 0 PSI (0.0 bar)

Pressure Switch

Off ......................................45 PSI (3.1 bar)

On ......................................30 PSI (2.1 bar)

TANK

Total Volume ....................................................1.1 gal. (4.1 It.

Operating Pressure ..............................................Gal (0.8 It.)

Air Pressure Setting........................................25 PSI (1.7 bar)

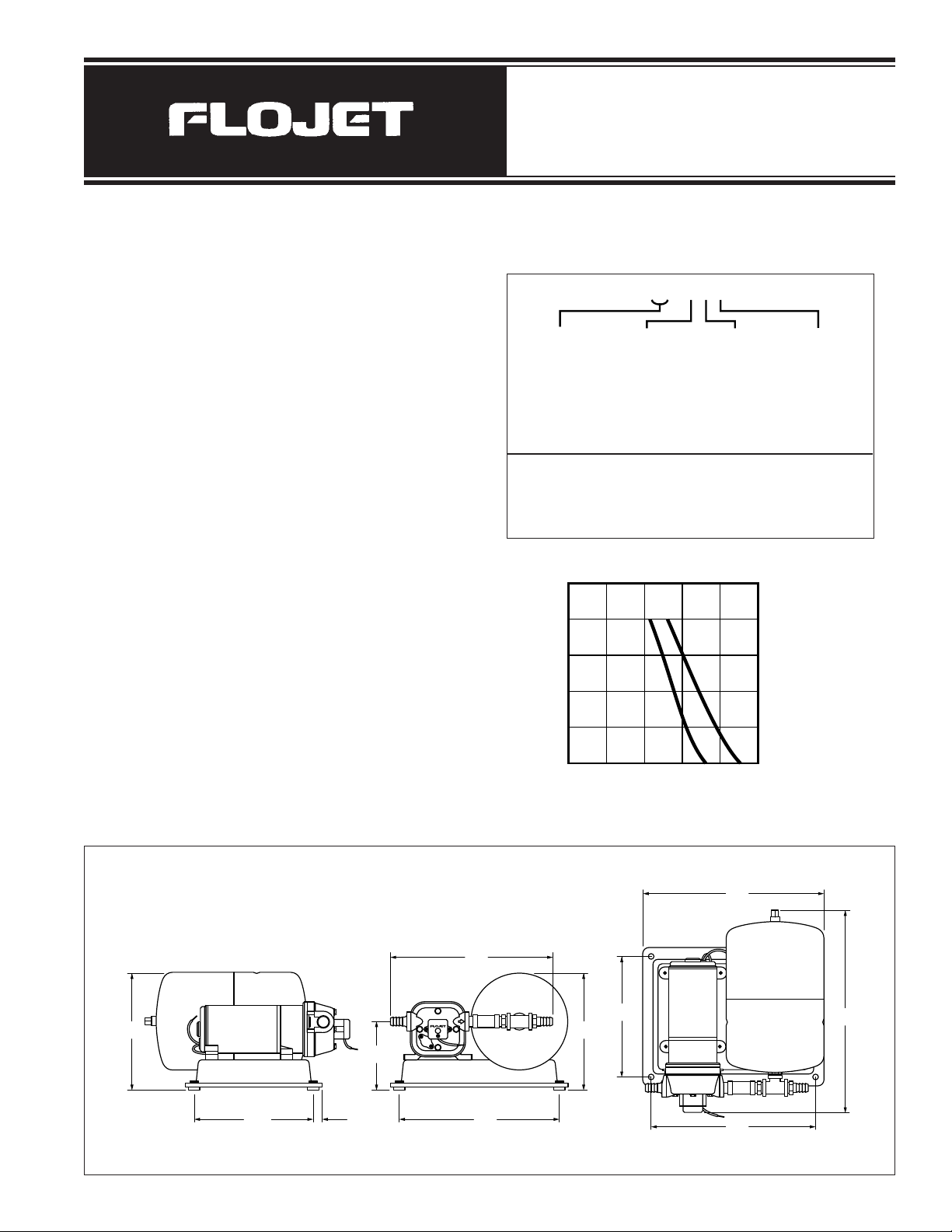

STANDARD MODEL NUMBERING SYSTEM

2840 Series

Booster Pump System

DIMENSIONAL DRAWING

Inches (millimeters)

The standard model numbering system is used for models up

to -500. Numbers -500 and over are used for variations from

standard assemblies such as special pump or tank

specifications. Consult the factory for special models to meet

specific requirements.

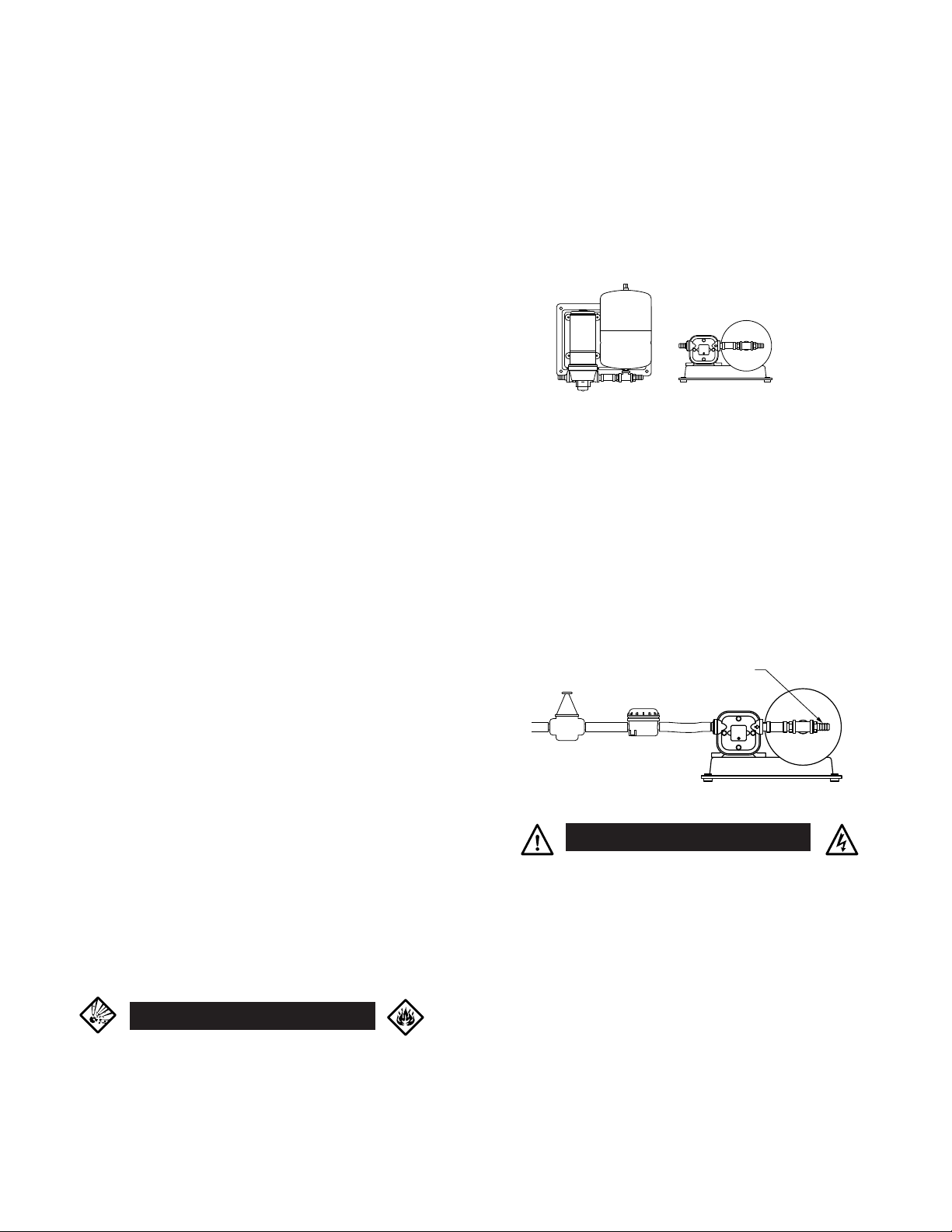

INSTALLATION & SERVICE INFORMATION FOR MODELS 2840-000 & 2840-010 115 VOLTS AC

AND MODEL 2840-210 230 VOLTS AC

a:

Model 2840-010

Model 2840-210

b:

Model 2840-000

2840 Series Booster Pump System

28 X X - X X X

Pump Service Voltage Switch Options

20 = Duplex 0 = 115V AC 0 = 40 PSI 0 = Std

(2130) 1 = 12V DC 1 = 45 PSI 1 = Timer

40 = Quad 2 = 230V AC 4 = 70 PSI 2 = Inlet Sw.

(4300) 3 = 24V DC 6 = 95 PSI

Pentaflex

50 =

50

(3.4)

40

(2.8)

30

(2.1)

20

(1.4)

10

(0.7)

Pressure in PSI (bar)

0

4 = 36V DC

b

a

3.0

4.0

1.0

2.0

(7.6)

(11.4)

(3.8)

Flow in GPM (l/min)

(15.1)

5.0

(18.9)

7 1/2

(191)

7 13/16

(198)

(13)

11 1/4

(286)

10 1/4

(260)

7 13/16

(198)

7 1/2

(191)

4 3/16

(106)

1/2

10 1/4

(260)

10 1/4

(260)

12 7/8

(327)

Page 2

GENERAL SAFETY INFORMATION

Protect yourself and others by observing all safety

information. Shut off power and drain pressure from

system prior to service.

DESCRIPTION

The FLOJET 2840 series Booster Pump Systems are

designed to provide a constant water pressure of 25 to

45 psi (1.7 - 3.1 bar) and maximum flow of 3.5 or 4.5

GPM at 10 psi (0. 7 bar). The pump is fully automatic

with a built-in switch and check valve to maintain

system pressure and will supply smooth water flow from

a trickle to full flow Typical uses are; Commercial Ice

Machines, Pure Water Dispensing, Water Purifiers,

Small Domestic and Commercial Appliances where the

water supply pressure is very low or fluctuates widely.

OPERATION

IMPORTANT - For correct operation, the tank must be

properly pressurized on the air side before the pump is

started. Follow instructions on the tank label and check

air pressure after filling and before starting the pump.

The air valve is a standard tire valve. Compressed air

hose or hand pump may be used to pressurize.

Pressure can be reduced by pressing the center pin in

the valve.

Make sure pump inlet connection is securely connected

to the water supply and no inlet valves are open. Open

all valves or taps on outlet side to purge air from the

system. Turn power on to the pump, pump will start up.

Allow system to pump for a minute or until all the air has

been purged from the system. Close all valves in the

system, the pump will pressurize the tank, shut off and

operate automatically to maintain pressure In the system.

To completely fill the pressure tank for maximum

volume, shut off power to pump and open faucet (or valve)

closest to tank. Trapped air will be expelled. Turn on

power to pump. and close faucet when water is free of air.

WINTERIZING TIP

When units are exposed to freezing conditions.

1. Open discharge valve (Faucet nearest to the

Booster System).

2. Open inlet side to pump (Remove inlet hose to the

Booster System).

3. Run Pump for approximately 2 minutes, (Dry) or

until system is out of fluid.

4. Leave discharge. value open and inlet hose

removed until next usage.

DO NOT USE PUMP IN A FLAMMABLE

ENVIRONMENT. DO NOT USE TO PUMP

FLAMMABLE OR EXPLOSIVE FLUIDS

SUCH AS GASOLINE, FUEL OIL,

KEROSENE, ETC.

MOUNTING

The FLOJET 2840 Series Water Pressure System should

be mounted in a dry and adequately ventilated area.

Select a location where the plumbing is as direct as

possible and the inlet strainer is visible and accessible

for cleaning.

The unit can be floor or wall mounted. If wall mounted,

the Pump head should be down or lower than the motor.

Fasten base securely with the four rubber mounting feet

assembled to base as shown below.

PLUMBING

Fasten strainer in a visible and accessible location for

future cleaning. Use 3/4” ID hose between pump inlet &

strainer. Connect strainer inlet to water supply line and

clamp all hose connections securely to avoid air leaks.

IMPORTANT - if water supply line has pressure

fluctuations that may exceed 30 psi (2.1 bar) - use a

pressure regulator to limit inlet pressure to 30 psi (2.1

bar) maximum.

Regulator may be installed at any convenient location

between water supply and inlet strainer.

ELECTRICAL

RISK OF AN ELECTRICAL SHOCK!

When wiring an electrically driven pump, follow all

electrical and safety codes, as well as the most recent

National Electrical Code (NEC) and the Occupational

Safety and Health Act (OSHA).

RISK OF PRODUCT DAMAGE!

Make certain the power source conforms to the pump

voltage. Be sure all power is disconnected before

installation or removal.

Use the maximum recommended fuse for pump

protection. Recommended fuse amp rating is located

on pump label. Failure to provide correct overload

device may result in motor failure.

For 115V AC plug AC cord into a conventional 115V AC outlet.

WARNING

WARNING

Vertical Horizontal

1/2” NPT

Pressure

Out

Water

Supply

Optional

Regulator

If Required

Inlet

Strainer

Page 3

DISASSEMBLE

Pressure Switch (9)

1. Disconnect power to pump and open a faucet or valve to

relieve system pressure.

2. Remove the two visible Pressure Switch Screws located on

each side of the Pressure Switch (9). DO NOT ADJUST

ALLEN HEAD SCREW IN CENTER OF SWITCH.

Upper Housing (1)

3. Loosen but DO NOT remove the four Pump Head Screws and

carefully remove Upper Housing Assembly (1).

4. Slide Port Clip (8) back and unplug from Tank Plumbing.

6. Remove Check Valve (2) and inspect for debris.

Check Valve Assembly (2) Follow Steps 1, 3 & 4

6. Inspect Check Valve (2) and O-Ring

Lower Housing (4) Follow Step 1

7. Remove pump from both Base and Tank Plumbing.

8. Remove Rubber Feet by pulling out and sliding to the rear

and follow step 3.

9. Rotate Lower Housing (4), so access Rubber Grommet foot

notch is aligned with Cam Bearing Set Screw (4-C), loosen

set screw with a 1/8” Allen Wrench and slide pump head off

motor

shaft.

Diaphragm (3-B)

10. Loosen four cam piston screws with Phillips head screw

driver and pull apart cam (4-B) from Inner Pistons (3-A). (Both

pistons (3-A & C) should be replaced when a new Diaphragm

(3-B) is installed.)

Motor (5) Follow Steps 1, 7, 8 & 9

REASSEMBLE

Diaphragm (3-B)

1. Insert Outer Pistons (3-C) into Lower Housing (4-A) by

bending pistons at center fold.

2.

Placing the Diaphragm (3-B) (flatter side of Diaphragm facing the

motor) on the Lower Housing (4-A). Press each Inner Piston (3-A)

through the Diaphragm and Lower Housing (4-A) into Outer

Piston (3-C). Hex stem of Inner Pistons (3-A) must be aligned into

hex holes in Outer Pistons (3-C). Tighten cam piston screws

partially, center piston in diaphragm, and tighten screws securely

(18 in. lbs. torque). Also, the Outer Pistons (3-C) must be aligned

with alignment slots on Cam Assembly (4-B) making sure screw

holes align in cam assembly, otherwise diaphragm will leak.

Cam Bearing (4-B)

3. Place Cam Bearing (4-B) over Inner Pistons (3-C) and tighten

down with four Phillips Head Screws. (18 in. lbs. torque)

Lower Housing (4) to Motor (6)

Coat motor shaft with grease prior to installing Cam Bearing

(4-B).

4. When installing the Lower Housing (4), rotate mounting foot

notch to align with Cam Bearing Set Screw (4-C).

6. Attach Cam Bearing (4-B) to motor shaft indentation with

Cam Bearing Set Screw (4-C). (35 in. lbs. torque)

6. Reinsert Rubber Feet.

Check Valve (2)

7. Place Ferrules (Rubber Cones) in the Upper Housing (1)

coned side first.

8. Properly seat O-Ring in Check Valve (2) and insert Check

Valve (2) into the Upper Housing (1).

Upper Housing (1)

9. Place Upper Housing (1) on top of the Lower Housing (4-A)

and tighten Hex Bolts (30 in. lbs. torque) through the Upper

Housing (1) to the Motor.

2

1

4

6

3

A

5

B

A

B

C

D

C

7 Includes items 1 thru 4

Key Part No. Description Qty

8 20408-000 Port Clips (Set of 2) 1

9 02096-540 Pressure Switch - 40 PSI Off 1

Sealed

** 04325-143A

Complete MPU

1

115 Volt -

3.5 GPM

** 04325-242A

Complete MPU

1

230 Volt -

3.5 GPM

** 04325-043C

Complete MPU

1

115 Volt -

4.5 GPM

** 01740-002 Strainer 1

** 20799-000A Accumulator Tank 1

** 20796-000A Base 1

**Not Shown in Diagram

Key Part No. Description Qty

1 20404-003 Upper Housing Assy Kit 1

2 20407-030 Check Valve Kit - EPDM 1

w/O-Ring & Ferrules

3 20403-040 Diaphragm Kit, Santo 1

w/Pistons & Screws

4 20419-00 Lower Housing 3.5 GPM 1

20419-002 Lower Housing 4.5 GPM 1

5 02029-091A Motor 115 Volt AC 1

02039-087A Motor 230 Volt AC 1

6 20381-022 Port Kit - (set of 2)

EDPM, 3/4” Barb, 90° 1

& EDPM, 5/8” Barb, Straight 1

7 20406-000A Pump Head Assy. 3.5 GPM 1

7 20406-002A Pump Head Assy. 4.5 GPM 1

WARNING: DISCONNECT POWER TO PUMP AND OPEN VALVE TO

RELIEVE WATER PRESSURE PRIOR TO SERVICING PUMP

!!

Page 4

UNITED KINGDOM

Jabsco/Flojet

Bingley Road, Hoddesdon

Hertfordshire EN11 OBU

Tel: +44 (0) 1992 450145

Fax: +44 (0) 1992 467132

CANADA

Fluid Products Canada

55 Royal Road

Guelph, Ontario N1H 1T1

Tel: (519) 821-1900

Fax: (519) 821-2569

JAPAN

NHK Jabsco Company Ltd.

3-21-10, Shin-Yokohama

Kohoku-Ku, Yokohama, 222

Tel: 045-475-8906

Fax: 045-475-8908

U.S.A.

Flojet

20 Icon

Foothill Ranch, CA 92610-3000

Tel: (949) 859-4945

Fax: (949) 859-1153

GERMANY

Jabsco GmbH

Oststrasse 28

22844 Norderstedt

Tel: +49-40-53 53 73-0

Fax: +49-40-53 53 73-11

© Copyright 2001, ITT Industries Printed in U.S.A. All Rights Reserved Form: 81000-298 12/00

WARRANTY

FLOJET warrants this product to be free of defects in material and/or

workmanship for a period of one year after purchase by the customer

from FLOJET. During this one year warranty period, FLOJET will at its

option, at no charge to the customer, repair or replace this product if

found defective, with a new or reconditioned product, but not to

include costs of removal or installation. No product will be accepted

for return without a return material authorization number. All return

goods must be shipped with transportation charges prepaid. This is

only a summary of our Limited Warranty. For a copy of our complete

warranty, please request Form No. 100-101.

RETURN PROCEDURE

Prior to returning any product to FLOJET, call customer service for an

authorization number. This number must be written on the outside

of the shipping package. Place a note inside the package with an

explanation regarding the reason for return as well as the

authorization number. Include your name, address and phone number.

CONVERSION TABLE

TO CONVERT TO MULTIPLY BY

Gallons, U.S. Liters 3.785

Liters Gallons, U.S. 0.264

Pounds/Sq. Inch Bar 0.069

Bar Pounds/Sq. Inch 14.5

Fahrenheit Celsius (°F-32) .556

Celsius Fahrenheit (°C X 1.8) + 32

TROUBLESHOOTING CHART

Symptom Possible Cause(s) Corrective Action

Pump will not prime or retain 1. Air leak in suction line 1. Repair or replace

prime after operating 2. Defective check valve 2. Replace

3. Upper housing leaking 3. Tighten bolts

4. Suction lift too high 4. Lower pump

5. Debris in check valve(s) 5. Clean check valve(s)

Pump runs but no fluid 1. Faulty suction piping 1. Repair or replace

2. Defective check valve 2. Replace

3. Suction lift too high 3. Lower pump

4., Clogged inlet 4. Clean or replace

5. Inlet line valve closed 5. Open valve

Motor runs too hot 1. Voltage incorrect 1. Check voltage

2. Insufficient ventilation for motor 2. Insure proper ventilation

Flow rate is low 1. Piping or hose is damaged 1. Clean or replace

2. Clogged check valve 2. Clear obstruction

3. Worn check valve 3. Replace

4. Voltage incorrect 4. Check voltage

Pump leaks 1. Upper housing loose 1. Tighten screws

2. Pistons loose 2. Tighten piston screws

3. Pump head loose on motor 3. Tighten pump head screws

4. Switch loose 4. Tighten switch

Pump will not run 1. No electricity 1. Check connections, fuse, breakers

2. Defective pressure switch 2. Replace switch

3. Motor has open circuit 3. Replace

4. Thermal protector has cut off 4. Allow motor to cool 15-30 min

Loading...

Loading...