Page 1

Model 2125

Electric Beverage Pump

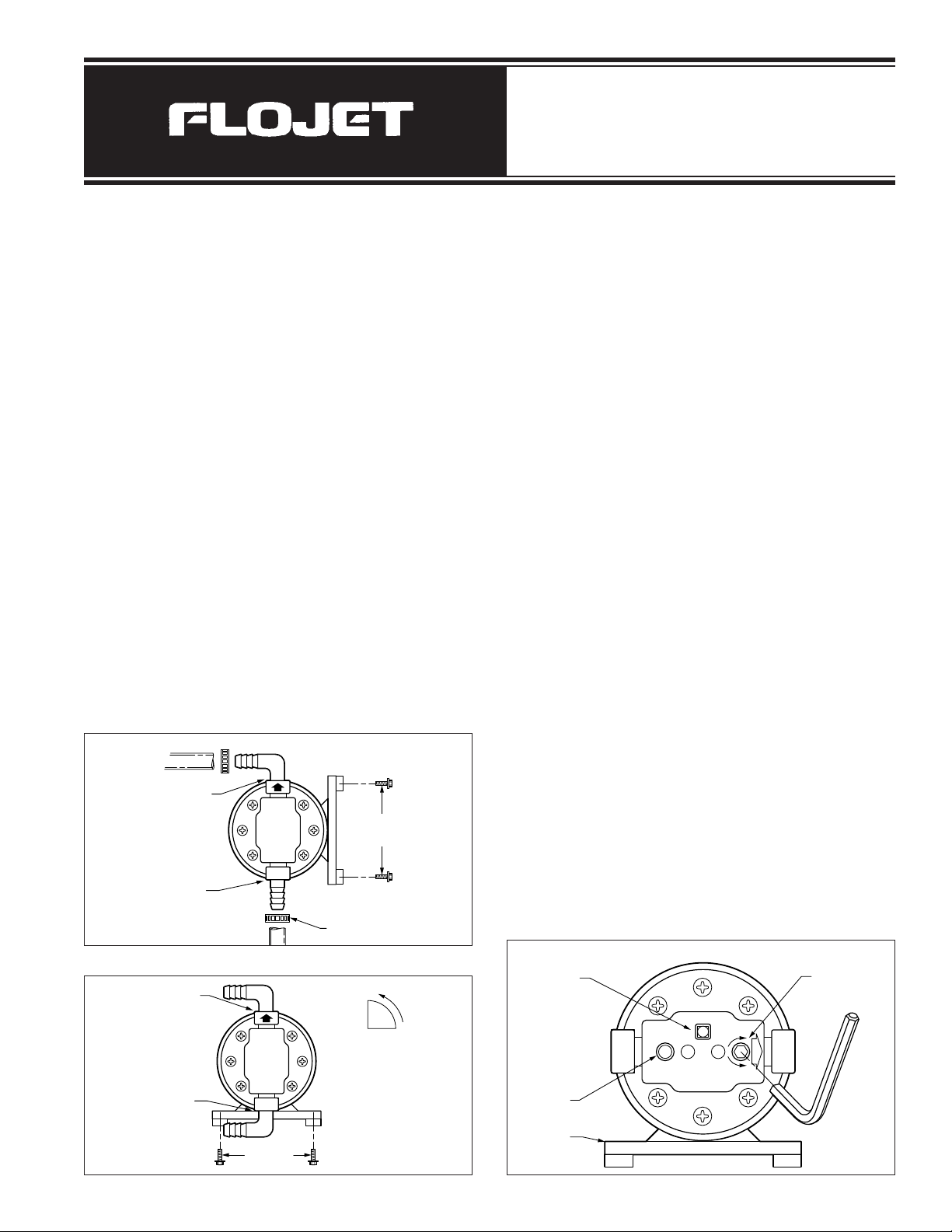

MOUNTING

• Ensure the area you have selected for installation is

dry, well ventilated, and has access to power.

• The suction side of the pump should be positioned so

that it is facing down. (See illustration below) This will

optimize the priming, and avoid cavitation from air in

the bag-in-box product.

• ideally the pump should be at the same level or just

below product.

• Position pump to desired area, secure mounting

screws through the rubber grommet in the baseplate

of pump. (See, illustration below)

HOSE CONNECTIONS

• Food grade Vinyl tygon tubing or equivalent with 3/8”

I.D. (8.9 mm) is recommended for both suction and

discharge.

• Total length of tubing run should not exceed 50’ (15.2 m)

to ensure sufficient pressure to brix the dispensing valve.

• The vertical lift of the, tubing run should not exceed

10” (3.0 m) within the 50’ (15.2 m) hose run.

• Use a #17.0 oetiker clamp or a worm gear clamp with

360° uniform clamping band.

• Avoid sharp, bends that could restrict flow especially

on suction side.

• After tubing installation is complete begin priming

sequence.

Model 2125 Electric Beverage Pump

2125 PUMP INSTALLATION

ELECTRICAL

24 Volt AC Power - Wire pump as follows: Black wire

and white wire to 24 Volt power supply. Green wire to

safety ground.

115 Volt AC Power - Plug pump into standard 115 Volt

grounded electrical source or GFI.

230 Volt AC Power - Wire appropriate connector for

system. Green wire to safety ground.

OPERATION

The Model 2125 is a demand pump. The pump will

come on when dispensing valve is open and shut off

when valve is closed.

To start operation, open dispensing valve to purge air

from the system. Pump will now operate automatically

by starting and stopping on demand, as beverage is

served and maintain constant pressure, at dispensing

valve. The pump will shut off when beverage bag has

been depleted and sold out light will go on. The pump

will automatically reset and the light will go out when a

full bag is connected. The pump is equipped with an

automatic timer designed to shut the pump off after 3

minutes of continuous running. The timer is set at the

factory and needs no adjustment. To restart, push white

reset button on face of pump. To purge any air trapped

in the pump open Dispensing Valve and run pump until

all air is purged from pump and inlet lines.

System pressure and flow can be adjusted as follows:

Pressure control - The hexhead screw on face of pump

adjusts the pressure (See Fig. #3). The pump is set at 50

PSI (3.4 BAR) max. at the factory. To reduce pressure

turn screw counter clockwise with Alien wrench. To

increase, turn screw clockwise. Pressure can be

adjusted between a high of 50 PSI (3.4 BAR) to a low of

30 PSI (2.1 BAR).

The 2125 has an automatic sold out switch which stops

the pump when bag is empty and high vacuum builds

up in the inlet line. The sold out switch is set at 14 ± 2

in Hg. The sold out switch will automatically restart the

pump when a new bag is connected and vacuum in the

inlet line has returned to normal.

FIGURE 3

FIGURE 1

FIGURE 1

Front View

Discharge

Side

Mounting

Screws

Suction

Side

Oetiker

Clamp

Discharge

Side

Suction

Side

Mounting

Screws

90°

0°

The Pump Head

Can Be Rotated

In 90° Increments

Sold Out

LIght

Reset

Plastic

Base Plate

RESET

SOLD OUT

Increase

Decrease

F

L

O

W

Pressure

Adjustment

Page 2

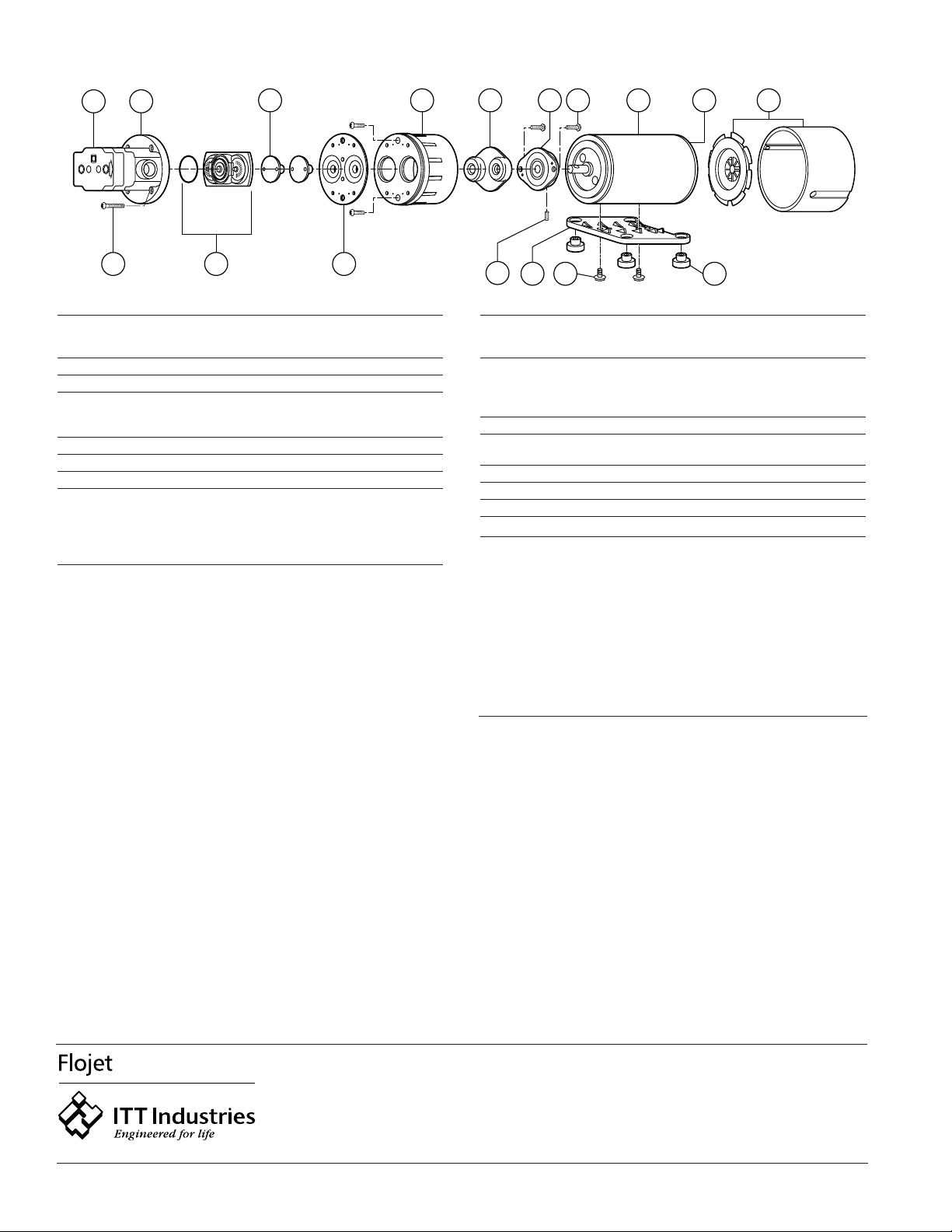

PARTS LIST MODEL 2125 SERIES

4 56

1216

8

2 37 111 91011

1415

13

KEY PART NO. DESCRIPTION PUMP DASH NO.

1 02029-034A 115 VAC Motor 030, 501, 504, 505

02039-033A 230 VAC Motor 502, 503

02059-001A 24 VAC Motor 330

4 11028-102 Base Assy (3, 4 & 5) All 2125 S

13 20028-057 Valve Chmbr Kit STO All 2125 S

2 20115-122 Endbell/Brush Assy 030, 501, 504, 505

20115-123 Endbell/Brush Assy 330

20115-124 Endbell/Brush Assy 230, 502, 503

16 20131-001 P/H & Bearing Cvr Screws All 2125 S

6 20131-002 Baseplate Screws All 2125 S

5 20132-000 Grommets All 2125 S

3 20145-100 TIM 24 VAC Kit 330

20145-101 TIM 115 VAC Kit 030

20145-102 TIM 230 VAC Kit 230, 503

20177-100 TIM 115 VAC Kit 501, 504, 505

20177-101 TIM 230 VAC Kit 502

KEY PART NO. DESCRIPTION PUMP DASH NO.

15 20244-104 SW Cover 24 VAC Kit 330

20244-105 SW Cover 115 VAC Kit 030, 501, 504, 505

20244-106 SW Cover 230 VAC Kit 230, 502, 503

14 20316-016A U/Housing (50 PSI) 030, 230, 330

20316-033A U/Housing (45 PSI) 501, 502, 504

20316-034A U/Housing (50 PSI) 503

20316-047A U/Housing (45 PSI) 505

10 20428-100 Bearing Cover All 2125 S

9 21033-000 0 Cam/Bearing All 2125 S

21033-001 1 Cam/Bearing All 2125 S

11 21041-001 Inner/Outer Pistons All 2125 S

7 21131-000 Cam/Bearing Screws All 2125 S

12 21195-003 Dia/Pist Kit STO All 2125 S

8 91008-000 Cam/Bearing Set Screw All 2125 S

TROUBLE SHOOTING

1.Pulsating flow - pump cycling on and off:

• Restricted pump delivery. Check discharge lines, fittings, valves.

• Check motor speed and pressure adjustments.

2. Failure to prime - Motor operates, but no pump discharge:

• Empty product bag.

• Bag connector not fully engaged.

• 0obstruction in product discharge line or dispensing valve.

• Air leak in intake line.

• Punctured pump diaphragm.

• Defective pump check valve.

• Faulty pump.

• Leak or break in product inlet or discharge line.

3. Pump contInues to operate when product is “Sold Out”:

• Leak in suction line or faulty automatic shutoff.

• Punctured pump diaphragm.

• Discharge line leak.

• Insufficient voltage to pump.

• Defective pump check valve.

4. Low pressure at dispensing valve:

• Excessive line restriction due to undersize tubing or fittings.

• Check pressure adjustment.

• Check motor speed adjustment.

• Air leak at pump intake.

• Accumulation of debris inside pump and plumbing.

• Worn pump bearing (excessive noise).

• Punctured pump diaphragm.

• Defective motor. Defective pump check valve.

© Copyright 2001, ITT Industries Printed in U.S.A. All Rights Reserved Form: 81000-128 10/00

UNITED KINGDOM

Flojet, Unit 1, Avant Business Centre

Denbigh West Industrial Estate

Milton Keynes, Bucks, England MK1 1DL

Tel: 44 1908 370088

Fax: 44 1908 373731

U.S.A.

Flojet

20 Icon

Foothill Ranch, CA 92610-3000

Tel: (949) 859-4945

Fax: (949) 859-1153

LIMITED WARRANTY

FLOJET warrants this product to be free of defects in material and/or workmanship

for a period of one year after purchase by the customer from FLOJET. During this

one year period, FLOJET will at its option, at no charge to the customer, repair or

replace this product with a new or reconditioned product, but not remove or install,

in the event that it is found to be defective in material and/or workmanship.

This Limited Warranty does not include service to diagnose a claimed malfunction

in this product at any location other than at Flojet’s corporate head-quarters, nor to

repair damage due to improper installation, incompatibility with accessories not

manufactured by FLOJET, external electrical fault, accident, or misuse.

All other express and implied warranties for this product including the warranties of

merchantability and fitness for a particular purpose, are hereby disclaimed. The

product covered by this warranty is marketed and sold by FLOJET as a business

rather than consumer product. (Some jurisdictions do not allow the exclusion of

implied warranties nor limitations on how long an implied warranty lasts, so the

above limitations may not apply to you.)

If this product is not free of defect as warranted above, your sole and exclusive

remedy shall be repair or replacement as provided herein. In no event will FLOJET

be liable to customer or to any third party for any damages in excess of the

purchase price of the product. This limitation applies to damages of any kind

including any direct or indirect damages, lost profits, lost investment capital or

savings, or other special, incidental, tort or otherwise, or whether arising out of the

use or inability to use such product even if FLOJET has been advised of the

possibility of such damages or of any claim by any other party. (Some jurisdictions

do not allow the exclusion or limitation of incidental or consequential damages for

some products, so the above limitations or exclusions may not apply to you.)

This warranty gives you specific legal rights. You may also have other rights which

may vary from jurisdiction to jurisdiction

.

5. Pump fails to restart automatically after bag replacement:

• Bag connector not fully engaged.

6. Pump fails to stop when dispensing valve is closed.

• Leak in discharge line. • Defective pump check valve.

• Empty product bag and • Insufficient voltage to pump.

• Faulty auto shutoff. • Speed control set to low.

• Faulty pump.

Loading...

Loading...