Page 1

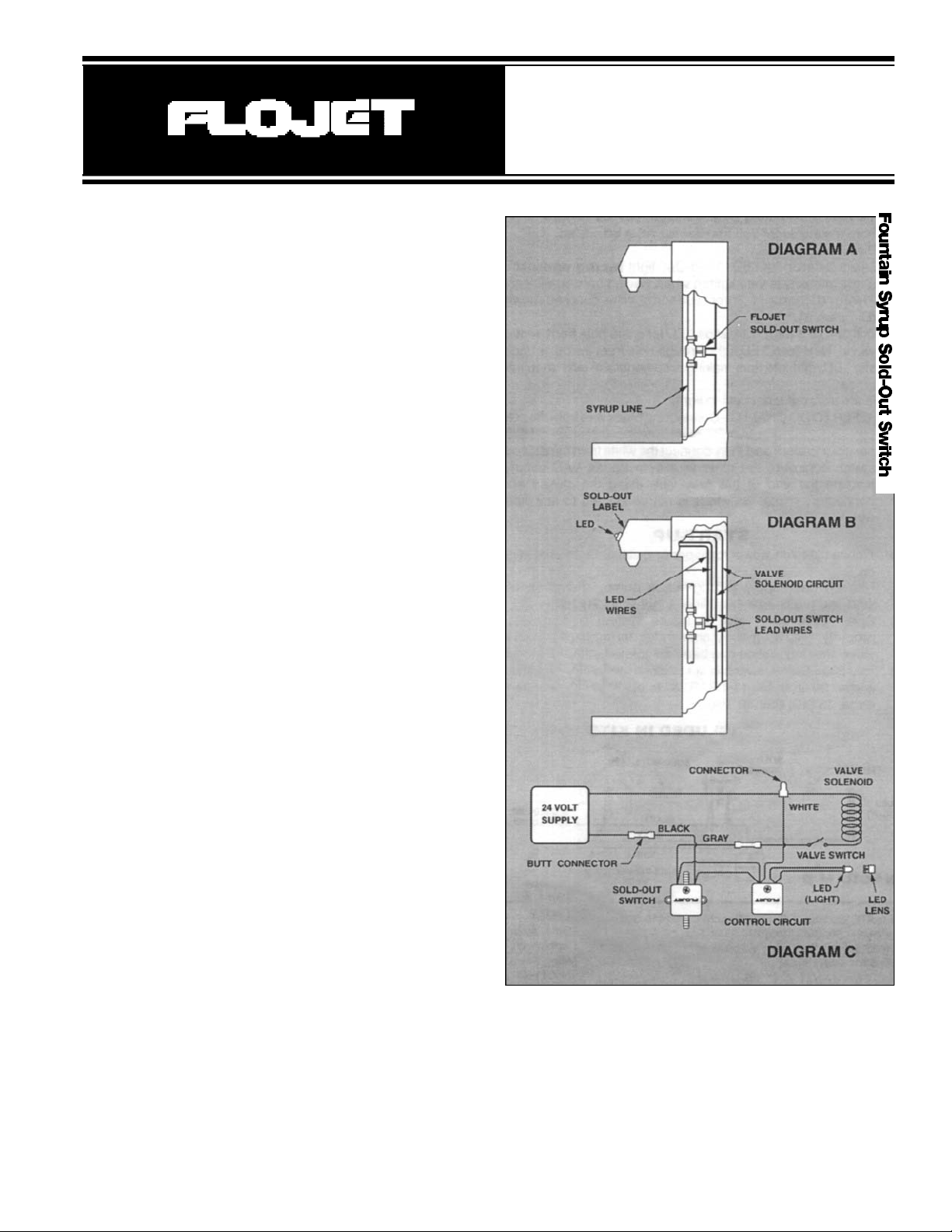

The 2095 Series syrup “Sold-Out” Switch automatically

FOR ELECTRICAL DISPENSING VALVES

shuts off an electric dispensing valve when syrup is sold

out and turns on “Sold-Out” light. This prevents the

operator from selling a drink of carbonated water only,

with no syrup. The switch automatically resets when the

empty Bag-In-Box is replaced and syrup line pressure is

restored.

Note: This switch is designed for use with Bag-In-Box

systems only, NOT transfer tanks.

PLUMBING

Refer to Diagram A

1) Shut off gas supply to syrup pump.

2) Open dispensing valve to relieve all syrup line

pressure.

3) Install barbed switch into syrup line near dispensing

valve and securely clamp both sides.

4) Switch may be mounted in any position in syrup line.

ELECTRICAL

Refer to Diagram B

1) Disconnect power.

2) Select location for LED “Sold-Out” light f a c i n g

operator. (Light intensity is very limited when viewed

from

side.) Preferred location is on front surface of valve

cover as shown. (Diagram B).

3) Drill 1/4” (6.3 mm) hole. slide LED lens into hole from

front of valve. Next feed LED light through hole from

inside or back, slip LED light into lens making sure

fingers of lens snap into place.

4) Place sold out label next to light.

5) REFER TO DIAGRAM C - Locate the 24 VAC leads

running up the tower to the dispensing valve switch

and solenoid. Cut one wire (the black wire if they are

colored white and black). On the end going up the

tower connect the gray wire from the “Sold Out”

switch. Then on the end going down connect the

black wire from switch. Connect these using the 2

butt connectors. Cut and strip the other wire (white if

they are color coded) and connect the white wire from

the switch to both ends of this wire using the closed

end connector.

START-UP

1) Reconnect power to dispensing valve. Light should

go on.

2) Turn on gas supply to Bag-In-Box pump. Pump

should start and pressurize syrup line. Light should go

off.

3) Open dispensing valve to insure system is dispensing

p ro p e r l y. NOTE: It is recommended to re - b r i x

dispensing valve after installation has been

completed.

Fountain Syrup Sold-Out Switch

Models 2095-501 (6.3mm) 1/4” ID Tu b e

2095-540 (9.6mm) 3/8” ID Tu b e

Page 2

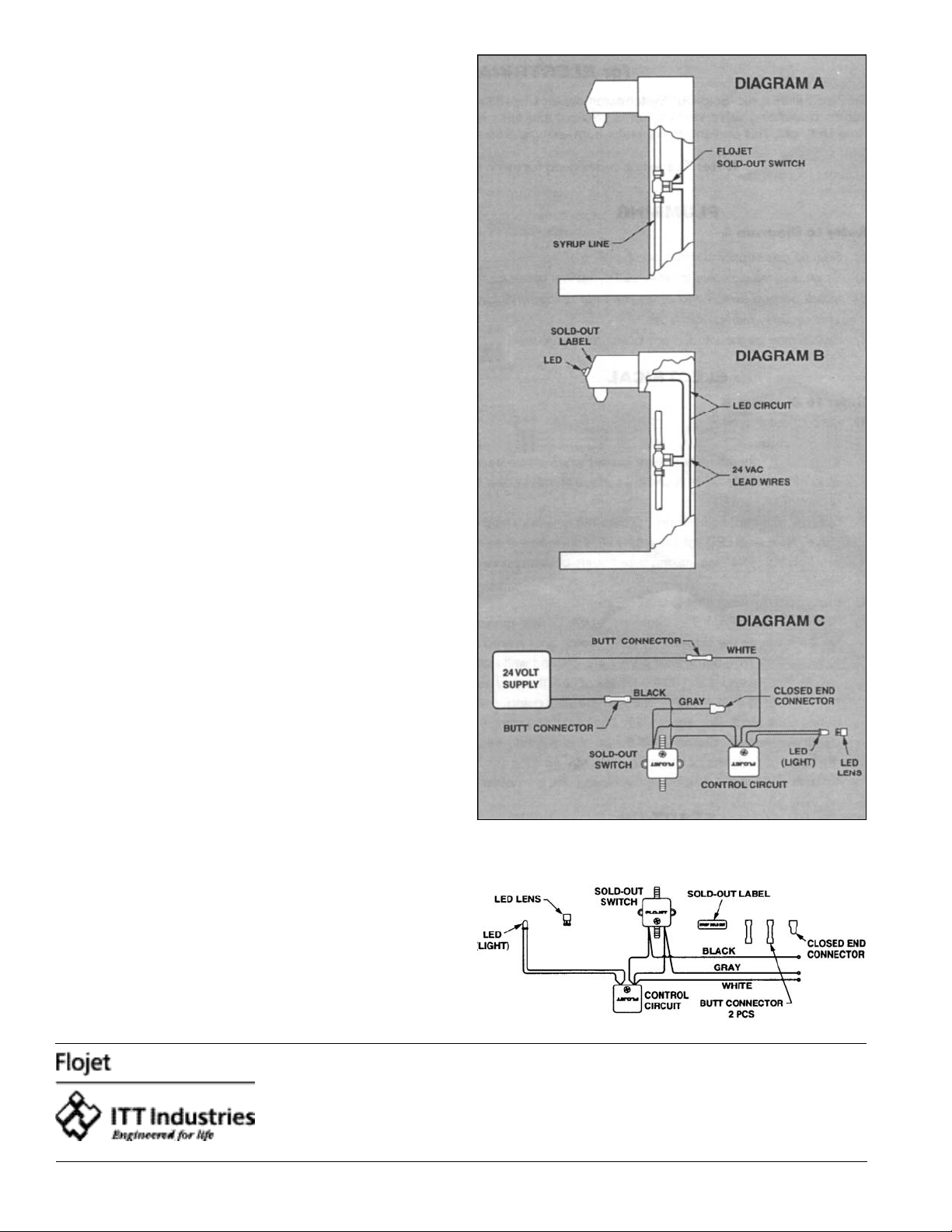

FOR MECHANICAL DISPENSING VALVES

The 2095 Series Syrup “Sold-Out” Switch automatically

turns on a automatically turns off the light when the

empty Bag-In-Box is “Sold-Out” light to alert operator

when the Bag-In-Box is empty or replaced and syrup

pressure is restored. if syrup pressure drops below

minimum required. The switch

Note: This switch is designed for use with Bag-In-Box

systems only, NOT transfer tanks.

PLUMBING

Refer to Diagram A

1 ) Shut off gas supply to syrup pump.

2) Open dispensing valve to relieve all syrup line

pressure.

3) Install barbed switch into syrup line near dispensing

valve and securely clamp both sides.

4) Switch may be mounted in any position in syrup line.

ELECTRICAL

Refer to Diagram B

The 2095 Series switch and LED light are designed to

operate on 24 Volt AC. An existing power source may be

used or if not available a suitable 24 Volt transformer

must be added.

1 ) Disconnect power.

2) Select location for LED “Sold-Out” light facing

operator. (Light intensity is very limited when viewed

from side). Preferred location is on front surface of

valve cover as shown. (Diagram B).

3) Drill 1/4” (6.3 mm) hole, slide LED lens into hole from

front of valve. Next feed LED light through hole from

inside or back, slip LED light into lens making sure

fingers of lens snap into place.

4) Place sold out label next to light.

5) REFER TO DIAGRAM C -Connect the black wire from

the sold out switch to one wire from 24 VAC supply

(black wire if they are color coded) and then connect

the white from the sold out switch control to the other

wire from the 24 VAC supply. Insulate the end of the

gray wire using the closed end connector. (Note:

Gray wire is not connected to any other wire.)

START-UP

1) Connect 24 Volt power to dispensing valve. Light

should go on.

2) Turn on gas supply to Bag-In-Box pump. Pump

should start and pressurize syrup line. Light should

go off.

3) Open dispensing valve to insure system is dispensing

p ro p e r l y. NOTE: It is recommended to re - b r i x

dispensing valve after installation has been

completed.

4) The 2095 Series switch is set to close when syrup

pressure is over 20 (±3) PSI (1.4 BAR) & to open when

pressure is under 13 (±3) PSI (.9 BAR)

PARTS INCLUDED IN KITS

DIAGRAM D

U.S.A.

Flojet

20 Icon

Foothill Ranch, CA 92610-3000

Tel: (949) 859-4945

Fax: (949) 859-1153

© Copyright 2001, ITT Industries Printed in U.S.A. All Rights Reserved Form: 81000-040 11/01

UNITED KINGDOM

Flojet, Unit 1, Avant Business Centre

Denbigh West Industrial Estate

Milton Keynes, Bucks, England MK1 1DL

Tel: 44 1908 370088

Fax: 44 1908 373731

Loading...

Loading...