Page 1

Service Manual

Garland GT Series

US Range UT Series

Heavy Duty Gas

Counter Equipment

TM

FOR YOUR SAFETY

DO NOT store or use gasoline or other flammable vapors or liquids in the vicinity of this or any other

appliance

WARNING

Improper installation, adjustment, alteration, service or maintenance can cause property damage,

injury, or death. Read the installation, operating and maintenance instructions thoroughly before

installing or servicing this equipment.

IMPORTANT

Please read all sections of this manual and retain for future reference.

This product has been certified as commercial cooking equipment and must be installed by

professional personnel as specified.

Users are cautioned that maintenance and repairs must be performed by a Garland/US Range

Authorized Service Agent using genuine Garland replacement parts. Garland/US Range will have no

obligation with respect to any product that has been improperly installed, adjusted, operated or not

maintained in accordance with national and local codes or installation instructions provided with

the product, or any product that has its serial number defaced, obliterated or removed, or which has

been modified or repaired using unauthorized parts or by unauthorized service agents. For a list of

authorized service agents, please refer to the Garland web site at www.garland-group.com

Garland Commercial Ranges, Ltd.

1177 Kamato Road

Mississauga, Ontario L4W 1X4 Canada

General Inquiries P: 905 624 0260 F: 905 624 5669

www.Garland-Group.com

Parts & Service

1 800 427 6668 (Phone, US & Canada)

1 800 361 7745 (Fax, US & Canada)

A_GC_SM_HDGASCOUNTERSERV_GT-UT-SERIES (Rev 1)

Page 2

Safety Requirements

WARNING

This product contains chemicals known to the state of California to cause cancer and/or birth defects or

other reproductive harm. Installation and servicing of this product could expose you to airborne particles of

glass wool/ceramic fibers. Inhalation of airborne particles of glass wool/ceramic fibers is known to the State

of California to cause cancer. Operatin of this product could expose you to carbon monoxide if not adjusted

properly. Inhalation of carbon monoxide is known to the State of California to cause birth defects or other

reporductive harm.

WARNING

Before working on any appliance, Shut Off the gas supply at the main shut-off valve and electrical supply at the

main power switch. On completion of any service work, test for gas leaks before returning the equipment into

service.

IMPORTANT

Please read and follow all the instructions carefully as the manufacturer cannot be held responsible for any

damage to property, persons caused by incorrect installation or operation of the equipment.

Your equipment must be installed and adjusted by a competent person in accordance with the law. Failure to

install appliances correctly could lead to prosecution. It is in your own interest and that of safety to ensure that

the law is complied with. Refer to Garland/US Range Installation And Operation Manual for further details.

Your Garland/US Range Authorized Service Agent (ASA) is well qualified to provide this service.

Periodic inspections by your Garland/US Range ASA or qualified service company are recommended to check

temperatures, burner adjustments and to ensure that moving parts are operative. Whenever possible avoid

overheating idle equipment as this is the primary cause for increased service cost.

NOTE

This manual is written for the model(s) specified on the front cover. Unless specified, this manual should not be

used for any other make or model of appliance.

Garland reserves the right to change product specifications without notices and accepts no liability for any

inaccuracies, errors or ommissions contained herein.

Keep your working area free and clear.

Remember Safety First.

A_GC_SM_HDGASCOUNTERSERV_GT-UT-SERIES (Rev 1)Page 2

Page 3

Contents

Safety Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Rating Plate, Serial Number Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Model Code Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

General Pilot Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Lighting Standing Pilots - All Models 15

Open Top Burner Models 15

Broilers Models 15

Griddles with Valve Controls 15

Griddles with SIT Thermostats 16

Griddles with GS Thermostats 16

Shutdown Procedure 16

Shutdown Procedure on Griddles with SIT Thermostats 16

Gas Pressure Regulator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Rear Gas Pressure Regulator Connection Options 17

Purpose of gas pressure regulator 17

Open Top Burners Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Pilot Adjustment Valves 18

Burner Gas / Air Shutter Adjustment 18

Troubleshooting — Open Top Burners. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Griddle Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Griddle Spark Igniter 20

High Tension Lead (HTL) & Insulation 21

Thermostatic Griddle Adjustments (SIT Control) 22

Thermostatic Griddle Adjustments (GS Control) 26

Griddles with Hi/Low Valves 28

Troubleshooting — Griddles. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Broiler Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Pilot Adjustment Valves 30

Gas Burner Control Valves 30

Burner Gas / Air Shutter Adjustment 31

Troubleshooting — Broilers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Wiring Diagram (GTGG/UTGG__M Models Electric Spark) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Wiring Diagram (GTGG/UTGG Electric Spark) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Gas Conversion Kits (from Natural to Propane). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Gas Conversion Kits (from Propane to Natural). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Bulletins & Revision History. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

A_GC_SM_HDGASCOUNTERSERV_GT-UT-SERIES (Rev 1) Page 3

Page 4

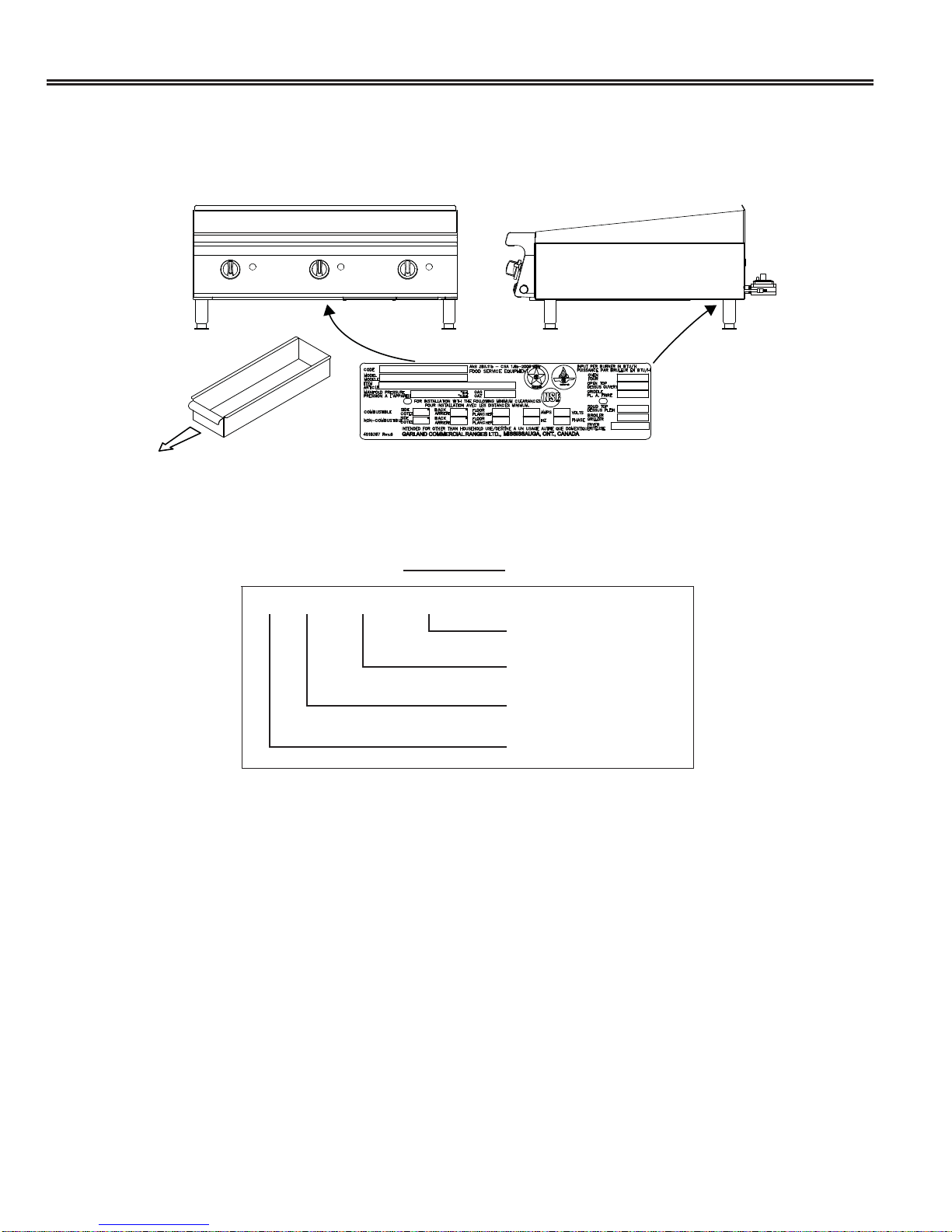

Rating Plate, Serial Number Information

Rating Plate

The rating plate is affixed to a bracket mounted at the rear of the unit, and visible from the front. The grease drawer

may need to be removed to view the rating plate.

Serial Number (Year/Month Information)

From June 2004 to Present, the Serial Number is 13 Digits Long.

10 05 1001 00668

Sequential Number

Factory Code

Month

Year

A_GC_SM_HDGASCOUNTERSERV_GT-UT-SERIES (Rev 1)Page 4

Page 5

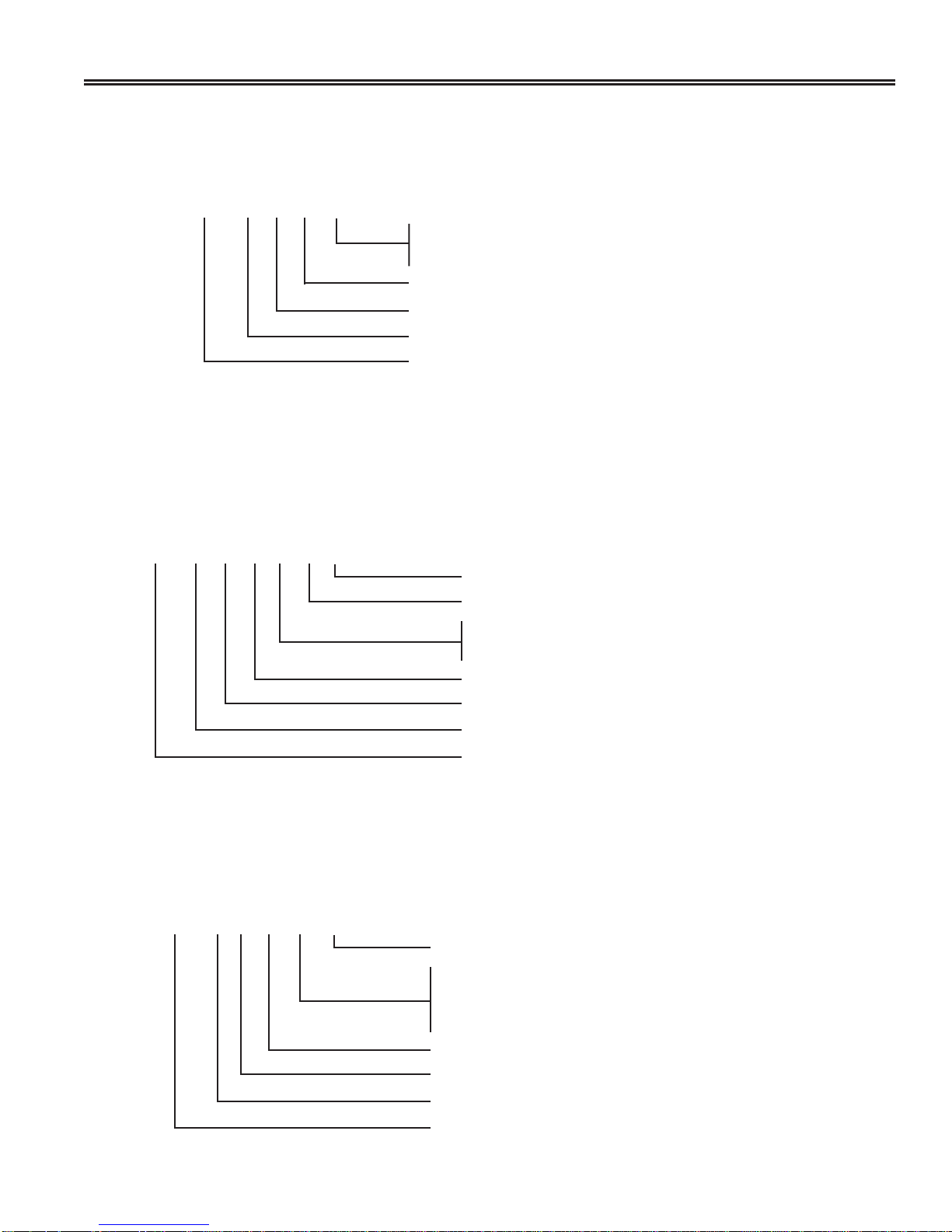

Model Code Information

Open Top Models:

• GTOG__-_ / UTOG__-_ Open Top Model

• GTOG__-SU_ / UTOG__-SU_ Open Top Step-Up Model

GT/UT O G 36 - 6

Number of Burners, or

SU (Step-Up) + Number of Burners

Nominal Width of Equipment

Fuel Type: Gas (Propane or Natural), Electric

Open Burner

Garland/US Range Heavy Duty Counter Top Model

Griddle Models:

• GTGG__-G__ / UTGG__-G__ Valve-Controlled Griddle Model (out-of-production)

• GTGG__-G__M / UTGG__-G__M Valve-Controlled Griddle Model with Suffix M

• GTGG__-GT__ / UTGG__-GT__ Thermostat-Controlled Griddle Model (out-of-production)

• GTGG__-GT__M / UTGG__-GT__M Thermostat-Controlled Griddle Model with Suffix M

GT/UT G G 48 - G 48 M

Models with Suffix M

Model Size

Griddle with Hi-Low Valve Control, or

GT - Thermostatic Griddle

Nominal Width of Equipment

Fuel Type: Gas (Propane or Natural), Electric

Griddle

Garland/US Range Heavy Duty Counter Top Model

Broiler Models:

• GTBG__-NR__ / UTBG__-NR__ Non-Adjustable (Fixed) Radiant Broiler Model

• GTBG__-AR__ / UTBG__-AR__ Adjustable Radiant Broiler Model

• GTBG__-AB__ / UTBG__-AB__ Adjustable Charcoal Broiler Model

GT/UT B G 48 - AR 48

Model Size

NR - Non-Adjustable (Fixed) Radiant

AR - Adjustable Radiant

AB - Adjustable Charcoal Broiler

Nominal Width of Equipment

Fuel Type: Gas (Propane or Natural), Electric

Broiler

Garland/US Range Heavy Duty Counter Top Model

A_GC_SM_HDGASCOUNTERSERV_GT-UT-SERIES (Rev 1) Page 5

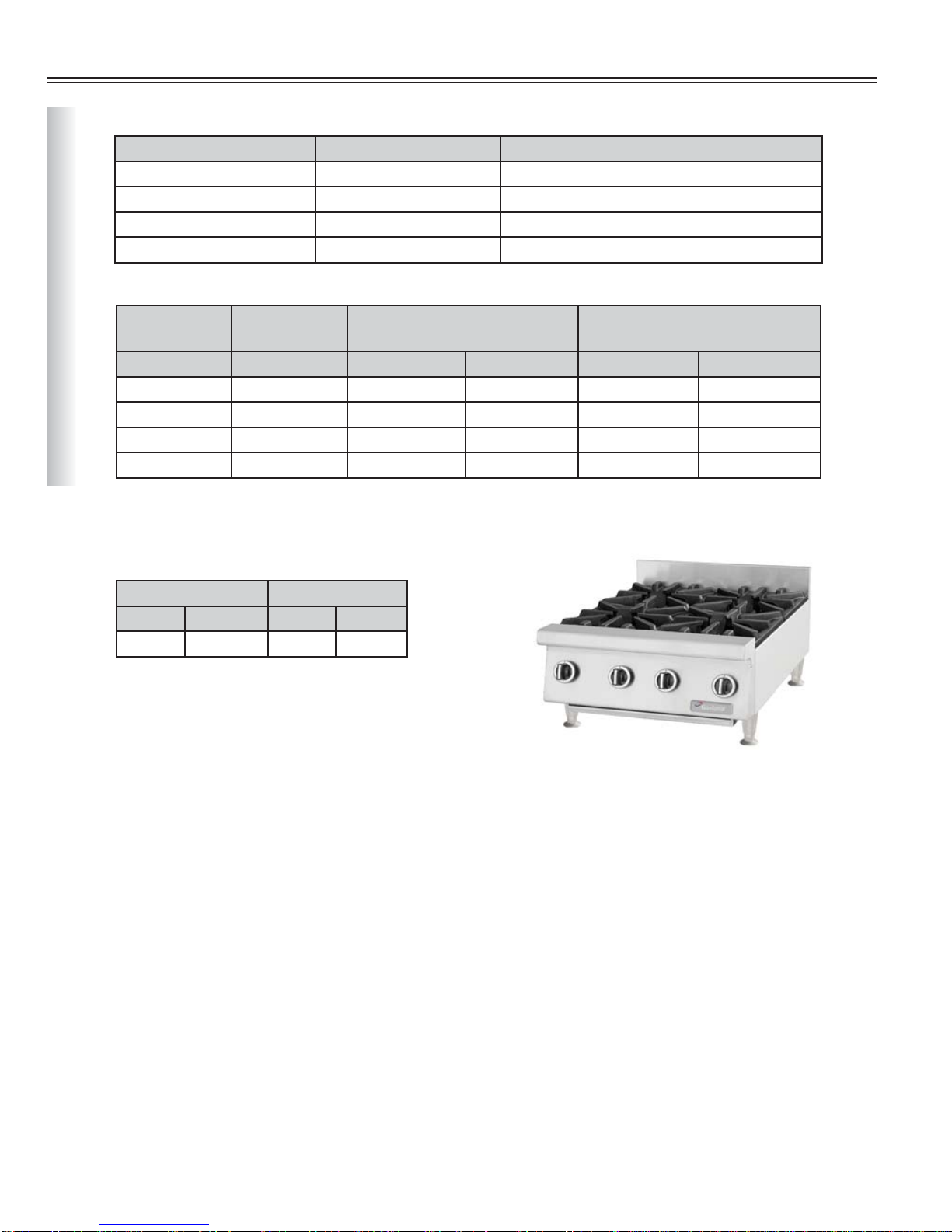

Page 6

Technical Data

Model Information

Garland Models US Range Models Model Information

GTOG12-2 UTOG12-2 Gas, Two Open Burners, 12” Wide

GTOG24-4 UTOG24-4 Gas, Four Open Burners, 24” Wide

GTOG36-6 UTOG36-6 Gas, Six Open Burners, 36” Wide

GTOG48-8 UTOG48-8 Gas, Eight Open Burners, 48” Wide

Line Ratings

Garland US Range Natural Gas @ 4.5”WC

Manifold Pressure

Models Models BTU/h Injectors BTU/h Injectors

GTOG12-2 UTOG12-2 60,000 #36 52,000 #53

GTOG24-4 UTOG24-4 120,000 #36 104,000 #53

Open Top Burner Models

For use with Natural or Propane gas only.

Gas input ratings shown for installation up to 2000 ft (610m) above sea level.

Supply Operating Pressure

GTOG36-6 UTOG36-6 180,000 #36 156,000 #53

GTOG48-8 UTOG48-8 240,000 #36 208,000 #53

Natural Gas Propane Gas

“WC MBar “WC MBar

7 17.5 11 27.5

L. Propane Gas @ 10”WC

Manifold Pressure

A_GC_SM_HDGASCOUNTERSERV_GT-UT-SERIES (Rev 1)Page 6

GTOG24-4 Shown

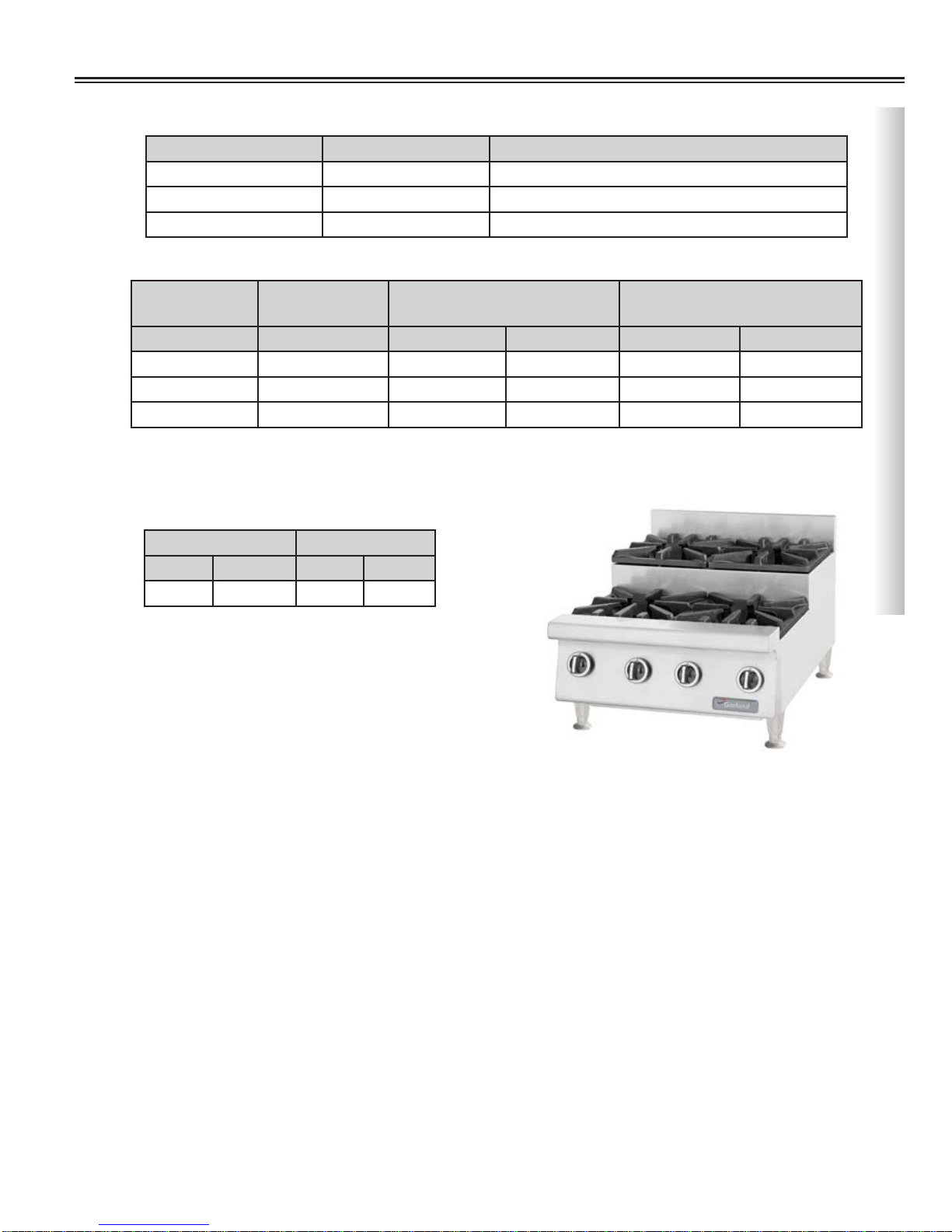

Page 7

Technical Data

Model Information

Garland Models US Range Models Model Information

GTOG24-SU4 UTOG24-SU4 Gas, Four Open Burners Step Up, 24” Wide

GTOG36-SU6 UTOG36-SU6 Gas, Six Open Burners Step Up, 36” Wide

GTOG48-SU8 UTOG48-SU8 Gas, Eight Open Burners Step Up, 48” Wide

Line Ratings

Open Top Burner Step-Up Models

Garland US Range Natural Gas @ 4.5”WC

Manifold Pressure

Models Models BTU/h Injectors BTU/h Injectors

GTOG24-SU4 UTOG24-SU4 120,000 #36 108,000 #1.6mm

GTOG36-SU6 UTOG36-SU6 180,000 #36 162,000 #1.6mm

GTOG48-SU8 UTOG48-SU8 240,000 #36 216,000 #1.6mm

For use with Natural or Propane gas only.

Gas input ratings shown for installation up to 2000 ft (610m) above sea level.

Supply Operating Pressure

Natural Gas Propane Gas

“WC MBar “WC MBar

7 17.5 11 27.5

L. Propane Gas @ 10”WC

Manifold Pressure

GTOG24-SU4 Shown

A_GC_SM_HDGASCOUNTERSERV_GT-UT-SERIES (Rev 1) Page 7

Page 8

Technical Data

Model Information

Garland Models US Range Models Model Information

GTGG24-G24 UTGG24-G24 Gas, Valve Controlled Griddle, 24” Wide

GTGG36-G36 UTGG36-G36 Gas, Valve Controlled Griddle, 36” Wide

GTGG48-G48 UTGG48-G48 Gas, Valve Controlled Griddle, 48” Wide

GTGG60-G60 UTGG60-G60 Gas, Valve Controlled Griddle, 60” Wide

GTGG72-G72 UTGG72-G72 Gas, Valve Controlled Griddle, 72” Wide

Line Ratings

Garland US Range Natural Gas @ 4.5”WC

Manifold Pressure

Models Models BTU/h Injectors BTU/h Injectors

GTGG24-G24 UTGG24-G24 52,000 #37 52,000 #53

GTGG36-G36 UTGG36-G36 78,000 #37 78,000 #53

GTGG48-G48 UTGG48-G48 104,000 #37 104,000 #53

GTGG60-G60 UTGG60-G60 130,000 #37 130,000 #53

GTGG72-G72 UTGG72-G72 156,000 #37 156,000 #53

Valve Controlled Griddle Models

For use with Natural or Propane gas only.

Gas input ratings shown for installation up to 2000 ft (610m) above sea level.

Supply Operating Pressure

Natural Gas Propane Gas

“WC MBar “WC MBar

7 17.5 11 27.5

L. Propane Gas @ 10”WC

Manifold Pressure

A_GC_SM_HDGASCOUNTERSERV_GT-UT-SERIES (Rev 1)Page 8

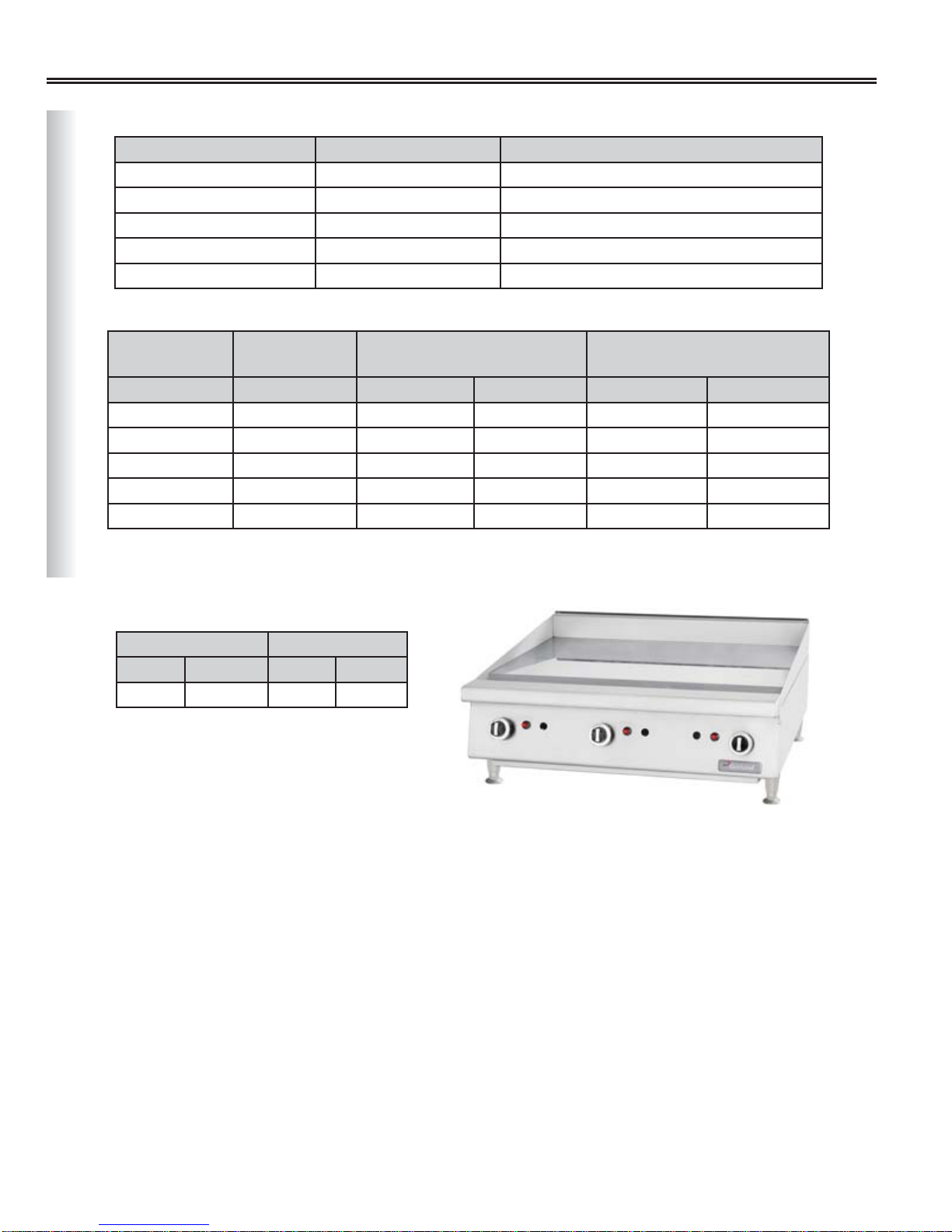

GTGG36-G36 Shown

Page 9

Technical Data

Model Information

Garland Models US Range Models Model Information

GTGG24-G24M UTGG24-G24M Gas, Valve Controlled Griddle, 24” Wide

GTGG36-G36M UTGG36-G36M Gas, Valve Controlled Griddle, 36” Wide

GTGG48-G48M UTGG48-G48M Gas, Valve Controlled Griddle, 48” Wide

GTGG60-G60M UTGG60-G60M Gas, Valve Controlled Griddle, 60” Wide

GTGG72-G72M UTGG72-G72M Gas, Valve Controlled Griddle, 72” Wide

Line Ratings

Garland US Range Natural Gas @ 4.5”WC

Manifold Pressure

Models Models BTU/h Injectors BTU/h Injectors

GTGG24-G24M UTGG24-G24M 54,000 #35 54,000 #52

GTGG36-G36M UTGG36-G36M 81,000 #35 81,000 #52

GTGG48-G48M UTGG48-G48M 108,000 #35 108,000 #52

GTGG60-G60M UTGG60-G60M 135,000 #35 135,000 #52

GTGG72-G72M UTGG72-G72M 162,000 #35 162,000 #52

For use with Natural or Propane gas only.

Gas input ratings shown for installation up to 2000 ft (610m) above sea level.

L. Propane Gas @ 10”WC

Manifold Pressure

Valve Controlled Griddle Models (with Suffix M)

Supply Operating Pressure

Natural Gas Propane Gas

“WC MBar “WC MBar

7 17.5 11 27.5

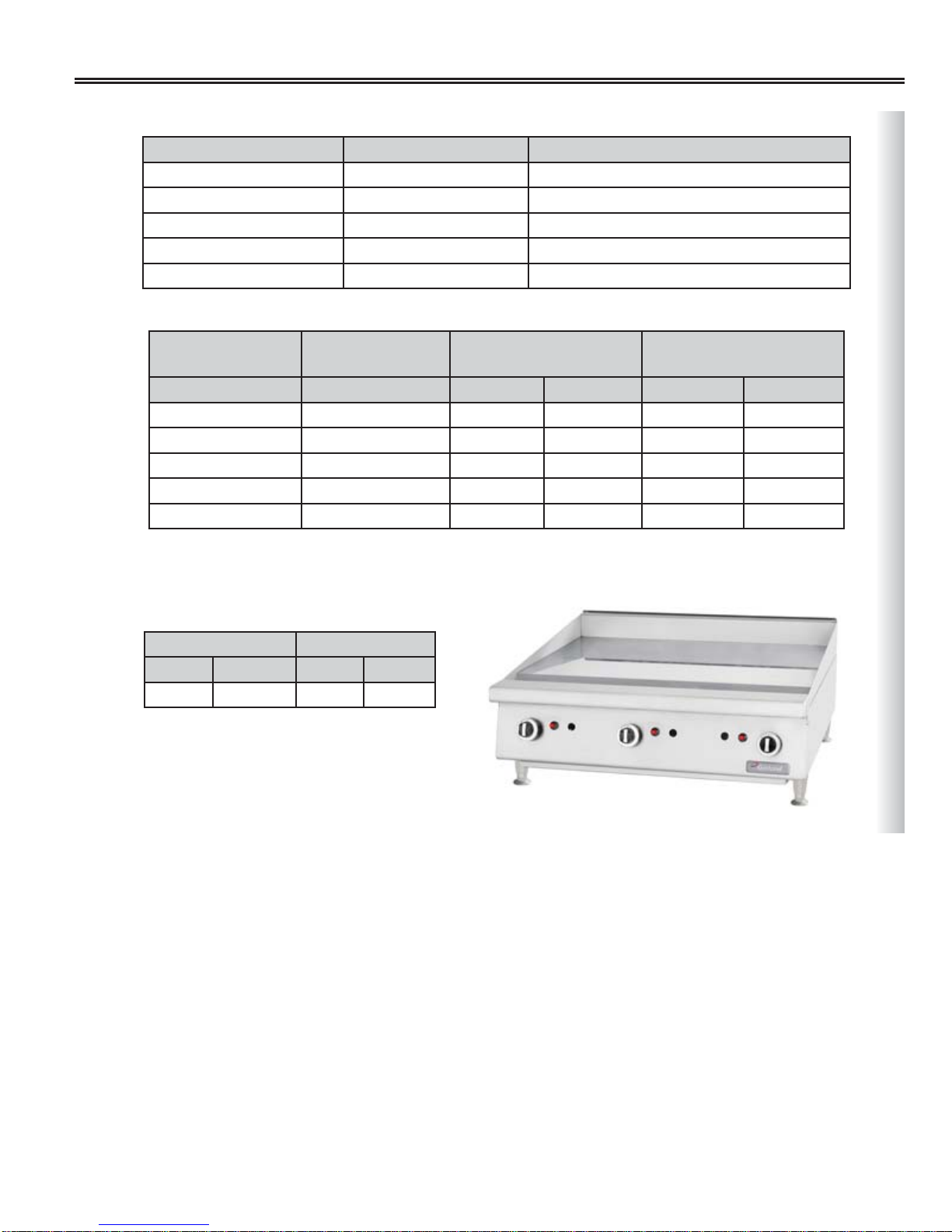

GTGG36-G36M Shown

A_GC_SM_HDGASCOUNTERSERV_GT-UT-SERIES (Rev 1) Page 9

Page 10

Technical Data

Model Information

Garland Models US Range Models Model Information

GTGG24-GT24 UTGG24-GT24 Gas, Thermostatically Controlled Griddle, 24” Wide

GTGG36-GT36 UTGG36-GT36 Gas, Thermostatically Controlled Griddle, 36” Wide

GTGG48-GT48 UTGG48-GT48 Gas, Thermostatically Controlled Griddle, 48” Wide

GTGG60-GT60 UTGG60-GT60 Gas, Thermostatically Controlled Griddle, 60” Wide

GTGG72-GT72 UTGG72-GT72 Gas, Thermostatically Controlled Griddle, 72” Wide

Line Ratings

Garland US Range Natural Gas @ 4.5”WC

Manifold Pressure

Models Models BTU/h Injectors# BTU/h Injectors#

GTGG24-GT24 UTGG24-GT24 64,000 #36 64,000 #51

GTGG36-GT36 UTGG36-GT36 96,000 #36 96,000 #51

GTGG48-GT48 UTGG48-GT48 128,000 #36 128,000 #51

GTGG60-GT60 UTGG60-GT60 160,000 #36 160,000 #51

GTGG72-GT72 UTGG72-GT72 192,000 #36 192,000 #51

For use with Natural or Propane gas only.

Gas input ratings shown for installation up to 2000 ft (610m) above sea level.

Supply Operating Pressure

Thermostat Controlled Griddle Models

Natural Gas Propane Gas

“WC MBar “WC MBar

7 17.5 11 27.5

L. Propane Gas @ 10”WC

Manifold Pressure

A_GC_SM_HDGASCOUNTERSERV_GT-UT-SERIES (Rev 1)Page 10

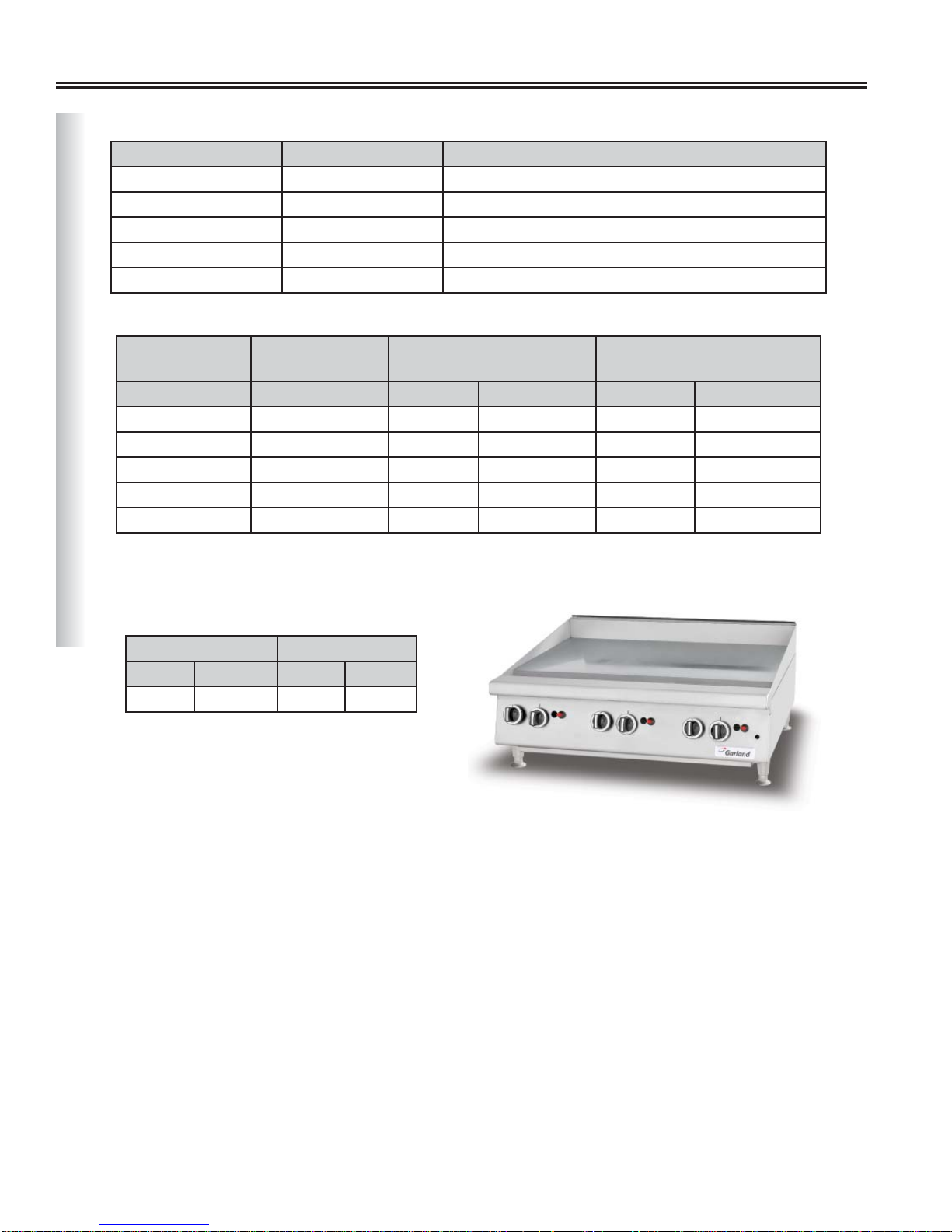

GTGG36-GT36 Shown

Page 11

Technical Data

Model Information

Garland Models US Range Models Model Information

GTGG24-GT24M UTGG24-GT24M Gas, Thermostatically Controlled Griddle, 24” Wide

GTGG36-GT36M UTGG36-GT36M Gas, Thermostatically Controlled Griddle, 36” Wide

GTGG48-GT48M UTGG48-GT48M Gas, Thermostatically Controlled Griddle, 48” Wide

GTGG60-GT60M UTGG60-GT60M Gas, Thermostatically Controlled Griddle, 60” Wide

GTGG72-GT72M UTGG72-GT72M Gas, Thermostatically Controlled Griddle, 72” Wide

Line Ratings

Garland US Range Natural Gas @ 4.5”WC

Manifold Pressure

Models Models BTU/h Injectors# BTU/h Injectors#

GTGG24-GT24M UTGG24-GT24M 56,000 #33 56,000 #52

GTGG36-GT36M UTGG36-GT36M 84,000 #33 84,000 #52

GTGG48-GT48M UTGG48-GT48M 112,000 #33 112,000 #52

GTGG60-GT60M UTGG60-GT60M 140,000 #33 140,000 #52

GTGG72-GT72M UTGG72-GT72M 168,000 #33 168,000 #52

For use with Natural or Propane gas only.

Gas input ratings shown for installation up to 2000 ft (610m) above sea level.

L. Propane Gas @

10”WC Manifold

Thermostat Controlled Griddle Models (with Suffix M)

Pressure

Supply Operating Pressure

Natural Gas Propane Gas

“WC MBar “WC MBar

7 17.5 11 27.5

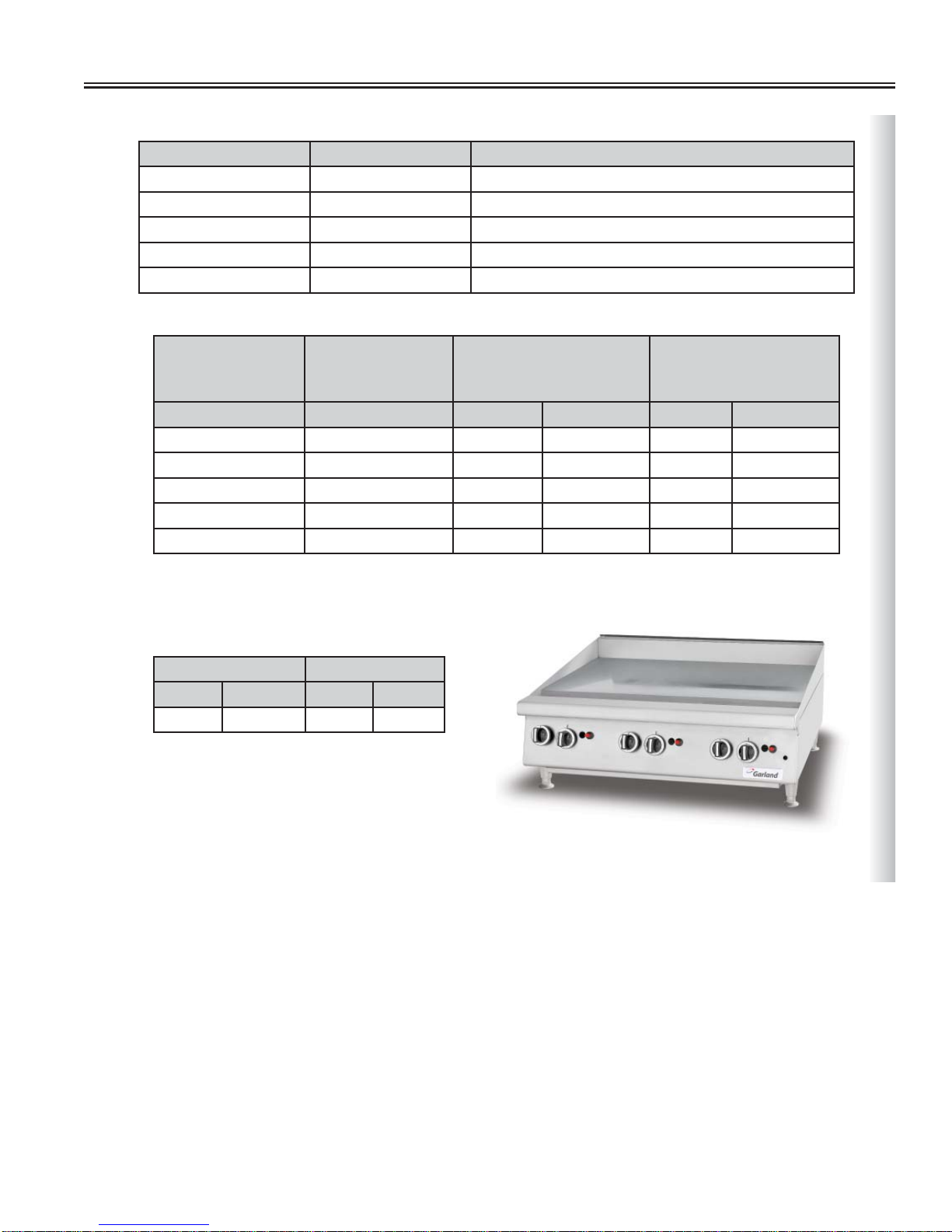

GTGG36-GT36M Shown

A_GC_SM_HDGASCOUNTERSERV_GT-UT-SERIES (Rev 1) Page 11

Page 12

Technical Data

Model Information

Garland Models US Range Models Model Information

GTBG24-NR24 UTBG24-NR24

GTBG36-NR36 UTBG36-NR36

GTBG48-NR48 UTBG48-NR48

GTBG60-NR60 UTBG60-NR60

Line Ratings

Gas Broiler, Non-Adjustable Grates and Cast Iron

Radiant

Gas Broiler, Non-Adjustable Grates and Cast Iron

Radiant

Gas Broiler, Non-Adjustable Grates and Cast Iron

Radiant

Gas Broiler, Non-Adjustable Grates and Cast Iron

Radiant

Garland US Range Natural Gas @ 4.5”WC

Manifold Pressure

Models Models BTU/h Injectors# BTU/h Injectors#

GTBG24-NR24 UTBG24-NR24 72,000 #45 72,000 #1.3mm

GTBG36-NR36 UTBG36-NR36 108,000 #45 108,000 #1.3mm

GTBG48-NR48 UTBG48-NR48 144,000 #45 144,000 #1.3mm

GTBG60-NR60 UTBG60-NR60 180,000 #45 180,000 #1.3mm

For use with Natural or Propane gas only.

Gas input ratings shown for installation up to 2000 ft (610m) above sea level.

Broiler Non-adjustable Grates Models

Supply Operating Pressure

Natural Gas Propane Gas

“WC MBar “WC MBar

7 17.5 11 27.5

L. Propane Gas @ 10”WC

Manifold Pressure

A_GC_SM_HDGASCOUNTERSERV_GT-UT-SERIES (Rev 1)Page 12

GTBG24-NR24 Shown

Page 13

Technical Data

Model Information

Garland Models US Range Models Model Information

GTBG24-AR24 UTBG24-AR24

GTBG36-AR36 UTBG36-AR36

GTBG48-AR48 UTBG48-AR48

GTBG60-AR60 UTBG60-AR60

Line Ratings

Garland US Range Natural Gas @ 4.5”WC

Models Models BTU/h Injectors# BTU/h Injectors#

GTBG24-AR24 UTBG24-AR24 72,000 #45 72,000 #1.3mm

GTBG36-AR36 UTBG36-AR36 108,000 #45 108,000 #1.3mm

GTBG48-AR48 UTBG48-AR48 144,000 #45 144,000 #1.3mm

GTBG60-AR60 UTBG60-AR60 180,000 #45 180,000 #1.3mm

For use with Natural or Propane gas only.

Gas input ratings shown for installation up to 2000 ft (610m) above sea level.

Gas, Broiler W/Adjustable Grates and Cast Iron

Radiant

Gas, Broiler W/Adjustable Grates and Cast Iron

Radiant

Gas, Broiler W/Adjustable Grates and Cast Iron

Radiant

Gas, Broiler W/Adjustable Grates and Cast Iron

Radiant

L. Propane Gas @ 10”WC

Manifold Pressure

Manifold Pressure

Broiler Adjustable Grates Models

Supply Operating Pressure

Natural Gas Propane Gas

“WC MBar “WC MBar

7 17.5 11 27.5

GTBG24-AR24 Shown

A_GC_SM_HDGASCOUNTERSERV_GT-UT-SERIES (Rev 1) Page 13

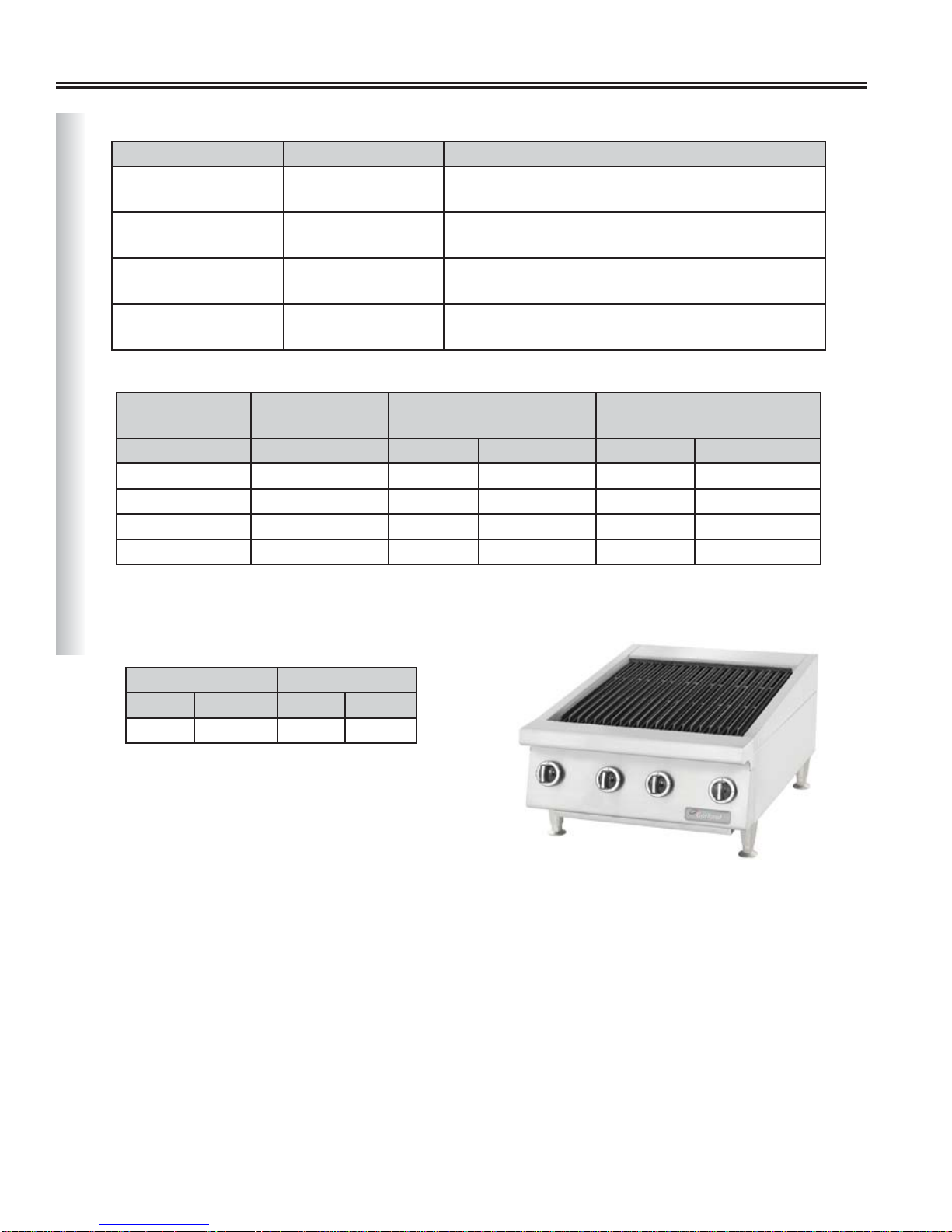

Page 14

Technical Data

Model Information

Garland Models US Range Models Model Information

GTBG24-AB24 UTBG24-AB24

GTBG36-AB36 UTBG36-AB36

GTBG48-AB48 UTBG48-AB48

GTBG60-AB60 UTBG60-AB60

Line Ratings

Gas,Broiler W/Adjustable Grates and Ceramic

Coals, 24”Wide

Gas,Broiler W/Adjustable Grates and Ceramic

Coals, 36”Wide

Gas,Broiler W/Adjustable Grates and Ceramic

Coals, 48”Wide

Gas,Broiler W/Adjustable Grates and Ceramic

Coals, 60”Wide

Garland US Range Natural Gas @ 4.5”WC

Manifold Pressure

Models Models BTU/h Injectors# BTU/h Injectors#

GTBG24-AB24 UTBG24-AB24 60,000 #36 60,000 #51

GTBG36-AB36 UTBG36-AB36 90,000 #36 90,000 #51

GTBG48-AB48 UTBG48-AB48 120,000 #36 120,000 #51

GTBG60-AB60 UTBG60-AB60 150,000 #36 150,000 #51

For use with Natural or Propane gas only.

Gas input ratings shown for installation up to 2000 ft (610m) above sea level.

Supply Operating Pressure

Natural Gas Propane Gas

“WC MBar “WC MBar

7 17.5 11 27.5

L. Propane Gas @ 10”WC

Manifold Pressure

Broiler Adjustable Grates & Ceramic Coals Models

A_GC_SM_HDGASCOUNTERSERV_GT-UT-SERIES (Rev 1)Page 14

GTBG24-AB24 Shown

Page 15

General Pilot Procedures

Lighting Standing Pilots - All Models

After the appliance has been installed by a licensed

gas trades-person and all connections, pilot lights and

controls have been inspected for proper operation.

All gas appliances that use standing pilot systems are

generally assumed to be operating with the pilot on

continuously. The appliances should not be restarted

except in the event of a gas service interruption to the

facility.

If a pilot flame does go out, here are the basic steps to

check before you re-light the pilot:

1. Check that all gas lines are in place and secured

and there is no accumulation of gas inside the

unit.

2. Ensure the main shut off valve is in the off

position.

3. Turn off all individual burner valves.

4. Turn on or open the main shut off valve to the

appliance.

5. Follow the pilot lighting procedure applicable to

your model. The pilot should ignite within a few

attempts. You will be able to see the pilot flame on

a hotplate under the protective pilot shield cast

into the burner top grate. Pilot flames on griddles

and broilers can be viewed through observation

holes in the stainless steel front panels.

6. If you do not have a pilot flame established fairly

quickly and begin to smell gas, shut off the main

valve and wait five minutes to let the gas build-up

escape.

7. Only once the pilot flame has been established

should you turn on the burner control. When

the burner control is on it allows gas flow to the

burner. if there is no pilot flame it will allow gas

to build up and cause possible delayed ignition,

which could result in an explosion.

Open Top Burner Models

Pilots are easily accessible. Make sure the individual burner valve is

in the off position, then use an open flame device, match, or BBQ

lighter to ignite.

Broilers Models

Pilots are easily accessible. Make sure the individual burner valve is

in the off position, then use an open flame device, match, or BBQ

lighter to ignite.

Griddles with Valve Controls

• Make sure the individual valve control is in the off position.

• Use the piezo spark button(s), or electric spark if your model

has this option, to ignite the pilot.

• Once the pilots are lit you may now turn your valve control to

the high or low flame setting.

• To shut down the main burner turn the valve to off position.

A_GC_SM_HDGASCOUNTERSERV_GT-UT-SERIES (Rev 1) Page 15

Page 16

General Pilot Procedures (continued)

Griddles with SIT Thermostats

1. Turn thermostat control knob to the “ ” (Figure 1) position. Then push in to engage the

flow of gas through the safety device to the pilot.

2. While holding the knob in, light pilot by pressing the red piezo lighter button or the black

igniter button if your model has the electric ignition option.

3. Continue to hold the knob in for 15 seconds after ignition, then release. Pilot should remain

lit.

4. If the pilot burner fails to light or does not stay lit, wait 5 minutes and repeat steps 1 to 3.

5. Turn the thermostat knob to the desired cooking temperature.

Figure 1

6. To shut down the main burner, turn the control knob to the “

” position.

Griddles with GS Thermostats

1. Ensure the individual on-off valve is in the off position.

2. Use the piezo, or electric spark if your model has this option, button(s) to ignite the pilot.

3. Once the pilot is lit, turn the thermostat knob to the desired cooking temperature.

4. To shut down, turn individual on-off valves to the off position.

Shutdown Procedure

To shutdown, turn all main burner valves to OFF position. If the appliance is to be shut down for a extended period

of time, close the pilot valves, (gum valve) by turning their set screws fully clockwise.

Shutdown Procedure on Griddles with SIT Thermostats

The Garland/US Range SIT thermostat control knob is configured to leave the pilot flame on continuously. The

knob is designed with a tab which will not permit complete pilot shutdown. In order to shutdown the griddle pilot

flame completely, you must perform Steps 1 to 3 below. Note There are no pilot valves (gum valve).

A

B

C

1. Turn griddle thermostat control knob to symbol “ ” position and then

loosen the knob set screw (C). Gently pull knob off.

2. With the knob removed, push-down and turn the hub until the symbol (

lines up with symbol (A). With the hub in the position shown, the gas should

be off at the pilots and burners. There are no pilot valves (gum valve).

Hub

Pilot Flame On

3. Finally, turn the manual valve on the main gas supply to the OFF position.

A_GC_SM_HDGASCOUNTERSERV_GT-UT-SERIES (Rev 1)Page 16

•) (B)

Complete Shutdown

Page 17

Gas Pressure Regulator

Rear Gas Pressure Regulator Connection Options

• Pipe size: 3/4” (19.05mm) NPT for all models.

Ther are two options to connent a Gas Pressure Regulator, as shown in Figure 2 and Figure 3 below. Refer to

Installation and Operation Manual for further details

Figure 2:

Gas pressure regulator connection is designed to

flush-mount.

Note: when installing as a flush mount gas pressure

regulator connection, (to allow for equipment

installation against a noncombustible wall), a

certified flexible gas hose and quick disconnect

assembly is required to allow the unit to be moved in

the event an adjustment of the gas pressure regulator

is required.

Figure 2

Figure 3:

Gas pressure regulator connection is designed

straight through.

Garland recommends the use of certified flexible gas

hose and quick disconnect assembly to allow the unit

to be moved in the event an adjustment of the gas

pressure regulator is required.

Purpose of gas pressure regulator

Basics Of A Gas Pressure Regulator

Removable Seal Cap

Atmospheric

Vent

Inlet

Adjustment (Screw)

Loading Element

(Spring)

Measuring Element

(Diaphragm)

Restricting Element

(Valve Disk and Seat)

Outlet

Figure 3

Gas pressure regulators have two main purposes, to

reduce supply main pressure to safe operating pressures

of connected appliances and to maintain constant

downstream pressure, regardless of changes in the gas

flow or upstream pressure variations.

Note: Gas service suppliers usually supply gas pressure

higher than the safe operating pressures of connected

appliances.

If an appliance receives too much fuel, it will over-fire. If

it receives too little fuel, it will under-fire. It will produce

too much or too little heat. Combustion characteristics

could change resulting in carbon monoxide generation.

The appliance may not work properly or efficiently.

Note: Always refer to the rating plate of appliance for actual manifold pressure required.

A_GC_SM_HDGASCOUNTERSERV_GT-UT-SERIES (Rev 1) Page 17

Page 18

Open Top Burners Adjustments

Pilot Adjustment Valves

• Also known as gum valves (Figure 16).

• Available in single or double.

• Adjustable with a set-screw using a straight blade pocket

screwdriver.

• Turn set-screw counter-clockwise to increase flow; turn

set-screw clockwise to decrease flow.

• Precisely adjust the pilot flame to a slight yellow tip to

provide maximum performance.

Pilot Adjustment Valves Location

• All pilots adjustment valves are located on the manifold,

behind the front panel (Figure 17).

• To remove the front panel, first remove the knobs with set

screws. Then release the four (4) screws holding the panel

and remove panel.

Burner Gas / Air Shutter Adjustment

Adjustable

Set-Screw

Pilot Tip Figure 16

Front

Panel

Gas

Manifold

Gum

Val ve

Figure 17

Variations in field conditions, and/or rough handling of the

equipment in transit may result in the need for adjustment of

the primary air to the burners. The following steps will show

you how to provide a sharp blue flame at the full rate (open

valve fully for the maximum gas flow).

1. On the burner locate the aeration shutter (Figure 6).

2. Loosen the fixing screw so that the aeration shutter turns

freely.

3. Turn on the gas flow and ignite the burner.

4. Rotate the air shutter to obtain the 1/2” stable, sharp inner

blue cones (Figure 7).

US Range and Garland Burner Heads:

Fixing Screw

Air Flow

Injector LŽĐĂƟŽŶ

AeraƟon

^ŚƵƩĞƌ

Figure 6

1/2” stable sharp inner blue cone

Open Burner

Figure 7

US Range

Burner Head

Garland

Star Burner Head

A_GC_SM_HDGASCOUNTERSERV_GT-UT-SERIES (Rev 1)Page 18

Page 19

Troubleshooting — Open Top Burners

WARNING

Inspection, testing and repair of equipment should be performed only by qualified service personnel. Certain

procedures in this section require gas tests or measurements while gas is applied to the unit. Use extreme caution

at all times. If test points are not easily accessible, disconnect main gas line, attach test equipment and reapply gas

supply to continue the test.

Always confirm manifold gas pressure at all times.

PROBLEM POSSIBLE CAUSE SOLUTION

Burner Flame soft –lazy tip yellow Not enough air mixing with gas Open air shutter

Flames lift off burners

Too much air mixing with gas Reduce air shutter openingFlashes back in burner

“Pop’s” excessively when turned off

Unit over-gassed fired Adjust manifold pressure

Delayed ignition

Pilot burner will not ignite

Flame lifts off pilot Pilot over-gassed fired Adjust pilot valve

Incorrect injector Check injector size

Burner ports plugged Clean burner ports

Pilot flame too small Adjust pilot valve

Draft in Kitchen Determine cause

A_GC_SM_HDGASCOUNTERSERV_GT-UT-SERIES (Rev 1) Page 19

Page 20

Griddle Adjustments

Griddle Spark Igniter

Garland has two different igniter systems on the griddle units:

1. Push-button piezo igniter system

2. Electronic Spark igniter system

1. Push-button Piezo igniter system (Figure 8) consists

of a small, spring-loaded hammer, which creates

voltage when a button is pressed. 120V electric

connection is NOT required; wires are needed to move

the electricity to an electrode close to the pilot. Proper

alignment is critical for better performance. Only one

spark is generated per press of the button. When

equipment installed above 8000 feet sea-level, lighters

with piezo-electric ignition are no longer reliable.

2. Electronic Spark Igniter System consists of an

Electronic Spark Generator (ESG) box (Figure 10),

a momentary switch (Figure 9), and electrical

components, plus wires to discharge a spark across a

gap between electrodes (spark gap). See below, section

2.3 ESG Technical Specification.

Figure 8

Momentary

Switch Side Panel

Front

Rail

When electrical voltage connection is required, refer to

section Wiring Diagram.

2.1 Remove, Test, and Replace a Momentary Switch

(MS)

a. Ensure power cord is unplugged.

b. Remove decorative dress nut off the

momentary switch

c. Remove knobs with set screws.

d. Remove the four (4) screws from front panel

and remove panel.

e. Griddle with SIT Thermostat: On the LEFT

hand side of the unit remove screw and the

momentary switch side panel (Figure 9).

Griddle with GS Thermostat: On the

RIGHT hand side of the unit remove screw

and the momentary switch side panel

(not shown).

f. Remove momentary switch nut and unplug

rear terminal wires.

Momentary

Electronic Spark

Generator (ESG)

Switch

Figure 9. SIT Tstat and Momentary Switch

REAR VIEW

ZĂƟŶŐ^ĞƌŝĂů

Plate

Figure 10

Knob

g. Connect multi-tester probes on the

momentary switch terminals. Continuity

must be indicated when button is pressed,

if not, replace switch.

A_GC_SM_HDGASCOUNTERSERV_GT-UT-SERIES (Rev 1)Page 20

Page 21

Griddle Adjustments (continued)

2.2 Removal and Replacement of Electronic Spark

Generator (ESG);

a. Verify the rating plate voltage to ESG specification.

See section 2.3 below.

b. Ensure power cord is unplugged.

c. Before removing ESG, check wires for continuity

in case a wire is damaged. Refer to section Wiring

diagrams.

d. Remove the ESG front box panel located at the back

of the unit (Figure 10).

e. Unscrew the two screws at each side of the ESG

unit, and unplug the terminal wires. Remove the

ESG unit.

f. Replace ESG unit in reverse order.

2.3 ESG Technical Specification

Input Voltage (1-2) 220-240 +10%,-15% (1-2) 110-120 ±10%

Spark Type Repetitive, 3Hz at 230v Repetitive, 3Hz at 120v

Outlets (a-d) 4 (a-d) 4

Main Frequency 50-60 Hz 50-60 Hz

Electronic Spark Generator (ESG)

Power Consumption 0.8VA MAX. 0.6VA MAX.

Spark Gap 4 X 4 mm (0.157”) MAX. 4 X 4 mm (0.157”) MAX.

REAR VIEW

Electronic Spark

Generator (ESG)

ZĂƟŶŐ^ĞƌŝĂů

Plate

Part # 4514749 Part # 4514750

Figure 10

High Tension Lead (HTL) & Insulation

The pilot HTL is exposed to high temperatures where they are located.

IMPORTANT

Keep the insulation in place.

Insulation should cover wire, connector, plus bottom of electrode as

shown in Figure 11.

Electrode

Wire Insulation

(black)

Wire (HTL)

(orange)

Figure 11.

A_GC_SM_HDGASCOUNTERSERV_GT-UT-SERIES (Rev 1) Page 21

Page 22

Griddle Adjustments — SIT Thermostat

Thermostatic Griddle Adjustments (SIT Control)

SIT Valve Control

Garland’s Heavy Duty Counterline contains a gas control system enclosed in one component — the SIT Control.

The griddle pilot safety system is an internal subcomponent of the control. This control (part#CK4528339) is

modified to snap action. There is no Bypass on this control.

This control, although very similar to the mechanical controls found on Garland’s current range and griddle

models, has several major economical efficiencies that offer reliability advantages to the customer.

NOTE

0

1. Griddle SIT control - Temperature control range 175

2740C).

2. It is a safety valve, and thermostat in one assembly. The safety valve

should not be removed from the body of the control for any reason.

3. Verify manifold pressure before replacing.

4. Familiar Open circuit, closed circuit, and drop out checks should be

made if the internal safety valve is suspected to be at fault.

F - 5250F (800C -

5. This control does not require any initial flame setting.

6. This control does not require internal calibration. (Some minor knob

adjustments could be appropriate, but it would be rare.

7. If a SIT control component is suspected to be internally at fault,

replace the control.

Installing a Thermocouple

A thermocouple nut should be started and turned all the way in by hand. An additional quarter turn with a small

wrench will be sufficient to seat the lock washer and maintain adequate contact. Connection that is too loose or

too tight of the thermocouple nut to the automatic pilot valve can prevent the thermocouple from activating the

valve. Inspect the thermocouple lead visually to ensure there are no cracks or ruptures.

Testing the Magnet Assembly and Thermocouple Operation

Heating at the thermocouple tip by a pilot flame produces an electric potential for energizing the magnet that, in

turn, holds open the main and pilot valves.

When the pilot is “out” or improperly adjusted, insufficient heat is applied to the thermocouple tip to produce

adequate electrical generation that results in the control shutting itself off. If, while following the proper lighting

procedures, the magnet cannot be made to “hold”, inspect the pilot flame for proper size and adjustment (see pilot

burner adjustment).

If the magnet will still not hold, perform the following tests: closed circuit test, open circuit test.

A_GC_SM_HDGASCOUNTERSERV_GT-UT-SERIES (Rev 1)Page 22

Page 23

Griddle Adjustments — SIT Thermostat (continued)

Closed Circuit Test (To test magnet & thermostat as a complete unit)

To perform the closed circuit test, remove the thermocouple lead from

Ter minal Boss

RED

Adapter

the magnet contact.

Place an adapter in the magnet contact and turn the thermocouple

into the adapter finger tight. Connect millivolt leads to the adapter

and thermocouple lead as shown.

Thermocouple Tube

In the Sit Control, insert a metric M9 adapter in the magnet

contact to complete the safety valve check as shown

BLACK

PN 4526299

1. Make sure the thermocouple is properly inserted into the pilot housing, and has no play. Also check gas

tubing connection at the pilot and tighten if loose.

2. Re-light the pilot, and read the meter after the pilot has been burning for three minutes. If the pilot will not

continue burning, depress and hold the temperature knob to manually open the SIT safety valve to check

the thermocouple output for this closed circuit check. If insufficient (normal output for closed circuit is 8-14

millivolts), and under 7 millivolts, replace the thermocouple. If the millivolt reading is above 7 mV, and the

safety magnet does not hold, replace the valve.

3. If the closed circuit mV reading is the same as the open circuit reading, the coil is electrically open, and the

valve must be replaced.

4. Check for drop out time which should occur within 60 seconds and at approximately 2 mV since the pilot was

out.

5. Re-light the pilot and turn on the main burner. As the griddle heats up, it is normal to see a slight decrease in

millivolts.

Open Circuit Test

1. Disconnect the thermocouple from the safety valve.

2. Attach the thermocouple to the millivolt test instrument.

3. Heat the sensor end of the thermocouple at the pilot flame or similar flame characteristics, monitoring the

millivolt meter

4. If the millivolt reading is below 18 millivolts, replace the thermocouple

Note: The SIT thermocouple open circuit voltage will be approximately 18-28 millivolts

SIT Thermocouple

Closed Circuit 8-14

mV

Open Circuit 18-28

Drop Out 2

A_GC_SM_HDGASCOUNTERSERV_GT-UT-SERIES (Rev 1) Page 23

Page 24

Griddle Adjustments — SIT Thermostat (continued)

Thermostatic Griddle Pilot Adjustment

1. Adjustment with a screw located on the SIT control (refer to photo).

2. Turn the screw clockwise to reduce the gas flow.

3. Precisely adjust the pilot flame to a slight yellow tip to provide maximum performance. Flame must engulf

only the tip of thermocouple.

No adjustment here

Pilot adjustment screw. The

pilot ame should be approximately

3/4” long

A_GC_SM_HDGASCOUNTERSERV_GT-UT-SERIES (Rev 1)Page 24

3/4" long

Engulf Tip of thermocouple

Page 25

Griddle Adjustments — SIT Thermostat (continued)

SIT Valve Calibration Instructions

These are mandatory steps for thermostat validation in the field. You MUST perform these steps before replacing.

They confirm if the SIT griddle control is working as per specification or is failing.

Note:

• Griddle plate must be clear (without product).

• Ensure your temperature meter is accurate (surface probe or magnetic T-couple only).

• Calibration temperature = average of the flame ON and flame OFF/ temperature, (on+off )/2.

1 Check Manifold Pressure 4.5”W.C. Natural Gas; 10” W.C. Propane Gas

Inspect pilots and place

2

thermocouple on plate (as

shown figure 13)

36"(914.4mm)

'ƌŝĚĚůĞ^ĞĐƟŽŶ

Moisten the thermocouple with oil.

12" (304.8mm)

6" (152.4mm)

Place

Probe

Here

FRONT

Figure 13. Griddle Top View - Data for Griddle with SIT thermostat. Figure 14.

3 Set Dial at 3500F on all burners

4 Start Up

6"(152.4mm)

Screws for Knob Dial

(Û)URP0LGSRLQW

Take dial to Max. and back down to 3500F position on the dial

insert.

Do not take temperature readings for the first 30 minutes if the

griddle was started from cold. Must be preheated and saturated.

5 Visual check Pilot flame and ignition, burner flame.

0

Note: Accepted Tolerance Temperatures swing at 350

Average temperatures at 350

F is ± 150F

0

F ± 100F

Read and record consecutively the lowest and highest

temperature values for each control (approx. 15 minutes).

0

6 Monitor Temperature

Temperature must be within 350

F ± 250F.

The average of high and low values must be 3500F ± 100F.

If not, go to step 7.

Additional Calibration if not

7

within accepted tolerance

(Figure 14).

0

Set Dial at 400

8

and confirm calibration on

F on all burners

Rotate the dial in small increments until within tolerance and

adjust dial following “Knob calibration instructions” . Knob

calibration can adjust set point by 30

setting).

Take dial to Max. and back down to 4000F position on the dial

insert. The average of high and low values must be 4000F ± 200F.

those corrected at step 7

Change the control if low and high values exceed swing of 50

9 Replacement

and/or average is not between 3800F and 4200F after Knob

Calibration Procedure.

Calibration

0

F (± 150F from midpoint

0

F

A_GC_SM_HDGASCOUNTERSERV_GT-UT-SERIES (Rev 1) Page 25

Page 26

Griddle Adjustments — GS Thermostat

Thermostatic Griddle Adjustments (GS Control)

GS Thermostat Calibration Instructions

1. Use a test instrument with a special disc type thermocouple or a reliable surface type pyrometer.

Note A drop of oil on the face of the disc will provide better contact with the griddle plate.

2. Set all griddle thermostats to 350 deg F. In order to stablize the griddle temperature, you must cycle the

thermostats twice before taking a test reading.

3. Check the griddle temperature when the thermostat just cycles OFF by placing the thermocouple firmly on

the griddle surface directly above the sensing bulb of the thermostat.

35-7/16"(900mm)

'ƌŝĚĚůĞ^ĞĐƟŽŶ

Place

Probe

Here

5-3/4" (146.1mm)

11-13/16" (300mm)

18-3/4"(476.3mm)

FRONT

4. Take the reading and it should be between 335 deg F and 365 deg F. If the reading is outside of these limits,

calibrate as follows:

a. Carefully remove the dial without disturbing the

shaft position.

b. Hold the shaft steady and with a small flat screw

driver, turn the calibration screw located inside

the shaft clockwise to descrease temperature or

anit-clockwise to increase temperature.

Note: Each 1/4 turn of the screw will create a

change of approximately 25 deg F.

c. Replace the thermostat dial and repeat steps 1

through 3 to verify that a correct adjustment has

been made.

A_GC_SM_HDGASCOUNTERSERV_GT-UT-SERIES (Rev 1)Page 26

Page 27

Griddle Adjustments — GS Thermostat (continued)

Replace a GS Thermostat

Note: It is not required to raise the griddle assembly for thermostat replacement.

1. Remove knobs from all valves and thermostats.

2. Un-install screws retaining the valve panel to unit and remove valve panel from unit.

3. Disconnect tubing connecting thermostat to on-off valve and to burner orifice fitting.

4. While grasping capillary line as close as possible to front edge of griddle plate, slide back the insulation

sleeve.

5. Carefully pull outward on capillary and slide thermostat bulb out of clamp assembly on bottom of plate.

6. Remove the insulation sleeve from capillary.

7. Unfasten screws mounting thermostat to manifold and remove thermostat from unit.

8. Mount replacement thermostat to manifold with screws removed in Step 7.

9. Slide insulation sleeve removed in Step 6 onto capillary of new thermostat.

10. Place thermostat bulb through cut-out in front support/shield and into the V-opening of clamp assembly

and push into clamp assembly until it comes to a stop.

11. Slide insulation sleeve along capillary line up to start of clamp assembly.

12. Re-install valve panel and knobs.

A_GC_SM_HDGASCOUNTERSERV_GT-UT-SERIES (Rev 1) Page 27

Page 28

Griddle Adjustments — Hi/Low Valve

Griddles with Hi/Low Valves

The Hi/Low Gas Valves are located behind the knobs, connected to the manifold. Use a straight blade pocket

screwdriver to adjust low setting higher or lower.

Reminder

. Adjustments on valves are for the low flames setting only. See section “Adjuct Hi-Lo Valve”

below.

Adjust a Hi-Lo Valve

Griddles equipped with Hi-Lo valves required a low flame setting. To

adjust:

1. Burner must be cold.

2. Ensure pilot flames are lit and adjusted.

3. Turn dial to “LO” position, then remove dial.

4. With a screwdriver, turn the small adjusting screw inside the valve

stem and adjust to obtain the low cooking temperature desired,

maintaining a stable flame covering the entire burner (minimum

3/16” (5mm) long flame).

5. Replace the dial and turn to “OFF” position.

Remove and replace a Hi/Low Valve

1. Remove knobs.

2. Remove the four (4) screws from front panel and remove panel.

Adjustable Valve

3. Disconnect gas line and then unscrew valve from manifold.

4. Install new valve in reverse order.

5. Reconnect gas line.

6. Check for gas leaks.

Burner Gas / Air Shutter Adjustment

Variations in field conditions, and/or rough handling

of the equipment in transit may result in the need

for adjustment of the primary air to the burners. The

following steps will show you how to provide a sharp

blue flame at the full rate (open valve fully for the

maximum gas flow).

1. On the burner locate the aeration shutter (figure 6).

2. Loosen the fixing screw so that the aeration shutter

turns freely.

3. Turn on the gas flow and ignite the burner.

4. Rotate the air shutter to obtain the 5/16” stable,

sharp inner blue cones (figure 15).

Fixing Screw

Air Flow

5/16” stable sharp inner blue cone

H Burner - Side View

Injector LŽĐĂƟŽŶ

AeraƟon

^ŚƵƩĞƌ

Figure 6

Figure 15

A_GC_SM_HDGASCOUNTERSERV_GT-UT-SERIES (Rev 1)Page 28

Page 29

Troubleshooting — Griddles

WARNING

Inspection, testing and repair of equipment should be performed only by qualified service personnel. Certain

procedures in this section require gas tests or measurements while gas is applied to the unit. Use extreme caution

at all times. If test points are not easily accessible, disconnect main gas line, attach test equipment and reapply gas

supply to continue the test.

Always confirm manifold gas pressure at all times.

PROBLEM POSSIBLE CAUSE SOLUTION

Burner Flame soft –lazy tip yellow Not enough air mixing with gas Open air shutter

Flames lift off burners

Too much air mixing with gas Reduce air shutter openingFlashes back in burner

“Pop’s” excessively when turned off

Thermostat out of Calibration

(Thermostat Griddle)

Griddle too hot or too cold

Hi/lo valve set wrong

(Hi/Lo Valve Griddle)

Unit over-gassed fired Adjust manifold pressure

Delayed ignition

Pilot burner will not ignite

Flame lifts off pilot Pilot over-gassed fired Adjust pilot valve

Pilot Outage (SIT Control Models) Bad thermocouple

Incorrect injector Check injector size

Burner ports plugged Clean burner ports

Pilot flame too small Adjust pilot valve on manifold

Draft in Kitchen Determine cause

Check Calibration temperature

with actual readings. See

calibration procedure.

Adjust hi/lo valve. Adjust on

low setting only, burner cold.

Lowest stable flame

Check actual mV open and

closed circuits. See table

below.

SIT Thermocouple

Closed Circuit 8-14

mV

Open Circuit 18-28

Drop Out 2

A_GC_SM_HDGASCOUNTERSERV_GT-UT-SERIES (Rev 1) Page 29

Page 30

Broiler Adjustments

Pilot Adjustment Valves

• Also known as gum valves (Figure 16).

• Available in single or double.

• Adjustable with a set-screw using a straight blade pocket

screwdriver.

• Turn set-screw counter-clockwise to increase flow; turn setscrew clockwise to decrease flow.

• Precisely adjust the pilot flame to a slight yellow tip to provide

maximum performance.

Pilot Adjustment Valves Location

• All pilots adjustment valves are located on the manifold,

behind the front panel (Figure 17).

• To remove the front panel, remove knobs with set screws.

Then release the four (4) screws holding the panel and remove

panel.

Gas Burner Control Valves

1. Non-adjustable Burner Control Valve (Charcoal models

only)

Adjustable

Set-Screw

Pilot Tip Figure 16

Front

Panel

Gas

Manifold

Gum

Val ve

Figure 17

• Regulates the flow of gas to the burner.

• Fixed and non-adjustable control.

• Valves located behind the knobs, connected to the

manifold.

2. Adjustable Hi/Low Burner Control Valve

• Regulates the flow of gas to the burner.

• Use a straight blade pocket screwdriver to adjust low

setting higher or lower.

• Valves are located behind the knobs, connected to the

manifold.

• Reminder: Adjustments on valves are for the low

flames setting only.

To remove and replace a control valve:

1. Remove the knobs.

2. Remove the four (4) screws holding the front panel, and remove panel.

Non-adjustable Valve

Adjustable Valve

3. Disconnect gas line. Then unscrew valve from the manifold.

4. Install a new valve in reverse order.

5. Reconnect gas line.

A_GC_SM_HDGASCOUNTERSERV_GT-UT-SERIES (Rev 1)Page 30

Page 31

Broiler Adjustments (continued)

Burner Gas / Air Shutter Adjustment

Variations in field conditions, and/or rough handling of the equipment in transit may result in the need for

adjustment of the primary air to the burners. Follow the steps below to provide a sharp blue flame at the full rate

(open valve fully for the maximum gas flow).

To adjust a burner air shutter:

1. Confirm manifold pressure matches rating

plate.

2. Locate the aeration shutter on the burner.

• For Charcoal Broiler Models,

see Figure 6.

• For Radiant Broiler Models,

see Figure 18.

3. Loosen the fixing screw to allow the

aeration shutter turn freely.

4. Turn on the gas flow and ignite the burner.

5. Rotate the air shutter until you obtain

flame with 5/16” stable, sharp inner blue

cones (Figure 15).

6. Tighten the fixing screw.

ĞƌĂƟŽŶ^ŚƵƩůĞƌ

Fixing Screw

Air Flow

Figure 6. Charcoal Broiler Air Shutter.

Fixing Screw

Air Flow

Broiler Straight Burner

Figure 18. Radiant Broiler Air Shutter.

5/16” stable sharp inner blue cone

Injector LŽĐĂƟŽŶ

AeraƟon

^ŚƵƩĞƌ

H Burner - Side View

Figure 15. H Burner shown as an example.

A_GC_SM_HDGASCOUNTERSERV_GT-UT-SERIES (Rev 1) Page 31

Page 32

Troubleshooting — Broilers

WARNING

Inspection, testing and repair of equipment should be performed only by qualified service personnel. Certain

procedures in this section require gas tests or measurements while gas is applied to the unit. Use extreme caution

at all times. If test points are not easily accessible, disconnect main gas line, attach test equipment and reapply gas

supply to continue the test.

Always confirm manifold gas pressure at all times.

PROBLEM POSSIBLE CAUSE SOLUTION

Burner Flame soft –lazy tip yellow Not enough air mixing with gas Open air shutter

Flames lift off burners

Flashes back in burner

“Pop’s” excessively when turned off

Delayed ignition

Pilot burner will not ignite

Flame lifts off pilot Pilot over-gassed fired Adjust pilot valve

Griddle too hot or too cold

Too much air mixing with gas Reduce air shutter opening

Unit over-gassed fired Adjust manifold pressure

Incorrect injector Check injector size

Burner ports plugged Clean burner ports

Pilot flame too small Adjust pilot valve

Draft in Kitchen Determine cause

Hi/Lo valve set wrong (Broiler, Hi/

Lo Valves Models)

Adjust hi/lo valve. Adjust on

low setting only, burner cold.

Lowest stable flame

A_GC_SM_HDGASCOUNTERSERV_GT-UT-SERIES (Rev 1)Page 32

Page 33

Notes

A_GC_SM_HDGASCOUNTERSERV_GT-UT-SERIES (Rev 1) Page 33

Page 34

Wiring Diagram (GTGG/UTGG__M Models Electric Spark)

A_GC_SM_HDGASCOUNTERSERV_GT-UT-SERIES (Rev 1)Page 34

Page 35

Wiring Diagram (GTGG/UTGG Electric Spark)

<9*;4.5.,=;8-.<

MODELS 60" & 72" WIDE REQUIRE (2) SPARK GENERATORS

MODELS 24", 36" & 48" WIDE REQUIRE (1) SPARK GENERATOR

0;8>7->7><.-

=.;627*5<

2072=287@2;.<

0;8>7->7><.-

=.;627*5<

<9*;4

0.7.;*=8;

<9*;4

0.7.;*=8;

0*=.@

5

5

7.

*

5

7.

+540;7;.-

/.6*5.<=;29!

!,

*

*

*

!,

5

07-

FLEX CONDUIT 38" (FOR 24" & 48" WIDTH MODELS)

FLEX CONDUIT 50" (FOR 36", 60" & 72" WIDTH MODELS)

<@2=,1+8A

75

<,1.6*=2,-2*0;*6

686.7=*;B<@2=,1

,866.;,2*5;*70.<5262=.-

62<<2<<*>0*87=*;28,*7*-*

.07- 7 5

+5*,45

@12=.7

?875B

0;..707-

0=0>=0.5.,=;2,<9*;4

"

57,-4

A_GC_SM_HDGASCOUNTERSERV_GT-UT-SERIES (Rev 1) Page 35

,?/

Page 36

Gas Conversion Kits (from Natural to Propane)

PART # KIT COMPONENTS BTU/HR PER BURNER QTY

Open Tops and Step-Up Open Tops (Kit part# 4528882)

M853 #53 Ori ce – Open Top Burners (Hotplate Only) – Pro

M81.6MM 1.6Mm Ori ce – Open Top Burners (Step Up Only) – Pro

4528897 Instructions Conversion Kit Hd Hotplate – Nat/Propane

4528891 Label – Conversion Ratings Hd Hotplates

4516405 Label - Conversion Declaration

2127500 3/4" Regulator Propane 10" W.C.

Hi/Low Griddle model GTGG__-G__ (Kit Part# 4528884)

M853 #53 Ori ce – Griddles (Hi-Lo Valve) – Pro 26,000 6

2200703 Pilot Ori ce #23 Propane 6

4528898 Instructions Conversion Kit Hd Counter Griddles – Nat/Propane 1

4528893 Label – Conversion Ratings Hd Counter Griddles 1

4516405 Label - Conversion Declaration 1

2127500 3/4" Regulator Propane 10" W.C. 1

Hi/Low Griddle model GTGG__-G__M (Kit Part# 4531366)

M853 #53 Ori ce – Griddles (Hi-Lo Valve) – Pro 27,000 6

2200703 Pilot Ori ce #23 Propane 6

4531371

4516405 Label - Conversion Declaration 1

4531369

2127500

Instructions Conversion Kit GTGGM Griddle, Nat/Propane 1

Label - Conversion Ratings, Propane 1

3/4” Regulator Propane 10” W.C. 1

26,000 8

27,000 8

1

1

1

1

Thermostatic Griddle model GTGG__-GT__ (Kit Part# 4528886)

M851 #51 Ori ce – Griddles (Tstat) – Pro 32,000 6

2200703 Pilot Ori ce #23 Propane

4528898 Instructions Conversion Kit Hd Counter Griddles – Nat/Propane 1

4528893 Label – Conversion Ratings Hd Counter Griddles 1

4516405 Label - Conversion Declaration 1

2127500 3/4" Regulator Propane 10" W.C. 1

Thermostatic Griddle model GTGG__-GT__M (Kit Part# 4531368)

M852 #52 Ori ce – Griddles (Tstat) – Pro 28,000 6

2200703 Pilot Ori ce #23 Propane

4531371 Instructions Conversion Kit GTGGM Griddle, Nat/Propane

4516405 Label - Conversion Declaration 1

4531369 Label - Conversion Ratings, Propane

2127500 3/4” Regulator Propane 10” W.C.

Fixed & Adjustable Radiant Broiler (Kit Part# 4528888)

M81.3MM 1.3Mm Ori ce – Radiant Broiler – Pro 18,000 10

4528899 Instructions Conversion Kit Hd Counter Broilers – Nat/Propane 1

4528895 Label – Conversion Ratings Hd Counter Broilers 1

4516405 Label - Conversion Declaration 1

2127500 3/4" Regulator Propane 10" W.C. 1

Adjustable Charcoal Broiler (Kit Part# 4528890)

M851 #51 Ori ce – Ceramic Briquette Broiler Pro 30,000 6

4528899 Instructions Conversion Kit Hd Counter Broilers – Nat/Propane 1

4528895 Label – Conversion Ratings Hd Counter Broilers 1

4516405 Label - Conversion Declaration 1

2127500 3/4" Regulator Propane 10" W.C. 1

6

6

1

1

1

A_GC_SM_HDGASCOUNTERSERV_GT-UT-SERIES (Rev 1)Page 36

Page 37

Gas Conversion Kits (from Propane to Natural)

PART # KIT COMPONENTS BTU/HR PER BURNER QTY

Open Tops and Step-Up Open Tops (Kit part# 4528881)

M836 #36 Ori ce - Open Top Burners (All Models) - Nat 30,000 8

4528897 Instructions Conversion Kit Hd Hotplate – Nat/Propane 1

4528892 Label – Conversion Ratings Hd Hotplates 1

4516405 Label - Conversion Declaration 1

2127502 3/4" Regulator Natural 4½" W.C. 1

Hi/Low Griddle model GTGG__-G__ (Kit Part# 4528883)

M837 #37 Ori ce – Griddles (Hi-Lo Valve) - Nat 26,000 6

2200702 Pilot Ori ce #32 Natural

4528898 Instructions Conversion Kit Hd Counter Griddles – Nat/Propane 1

4528894 Label – Conversion Ratings Hd Counter Griddles 1

4516405 Label - Conversion Declaration 1

2127502 3/4" Regulator Natural 4½" W.C. 1

Hi/Low Griddle model GTGG__-G__M (Kit Part# 4531365)

M837 #37 Ori ce – Griddles (Hi-Lo Valve) - Nat 27,000 6

2200702 Pilot Ori ce #32 Natural

4531371 Instructions Conversion Kit GTGGM Griddle, Nat/Propane 1

4516405 Label - Conversion Declaration 1

4531370 Label - Conversion Ratings, Natural 1

2127502 3/4” Regulator Natural 4½” W.C. 1

6

6

Thermostatic Griddle model GTGG__-GT__ (Kit Part# 4528885)

M836 #36 Ori ce – Griddles (Tstat) – Nat 32,000 6

2200702 Pilot Ori ce #32 Natural

4528898 Instructions Conversion Kit Hd Counter Griddles – Nat/Propane 1

4528894 Label – Conversion Ratings Hd Counter Griddles 1

4516405 Label - Conversion Declaration 1

2127502 3/4" Regulator Natural 4½" W.C. 1

Thermostatic Griddle model GTGG__-GT__M (Kit Part# 4531367)

M833 #33 Ori ce – Griddles (Tstat) – Nat 28,000 6

2200702 Pilot Ori ce #32 Natural

4531371 Instructions Conversion Kit GTGGM Griddle, Nat/Propane

4516405 Label - Conversion Declaration 1

4531370 Label - Conversion Ratings, Natural 1

2127502 3/4” Regulator Natural 4½” W.C. 1

Fixed & Adjustable Radiant Broiler (Kit Part# 4528887)

M845 #45 Ori ce – Radiant Broiler - Nat 18,000 10

4528899 Instructions Conversion Kit Hd Counter Broilers – Nat/Propane 1

4528896 Label – Conversion Ratings Hd Counter Broilers 1

4516405 Label - Conversion Declaration 1

2127502 3/4" Regulator Natural 4½" W.C. 1

Adjustable Charcoal Broiler (Kit Part# 4528889)

M836 #36 Ori ce – Ceramic Briquette Broiler Nat 30,000 6

4528899 Instructions Conversion Kit Hd Counter Broilers – Nat/Propane 1

4528896 Label – Conversion Ratings Hd Counter Broilers 1

4516405 Label - Conversion Declaration 1

2127502 3/4" Regulator Natural 4½" W.C. 1

6

6

1

A_GC_SM_HDGASCOUNTERSERV_GT-UT-SERIES (Rev 1) Page 37

Page 38

Bulletins & Revision History

Bulletins

BULLETIN # SUBJECT DATE

03B2010SP New Heavy Duty Gas Counter line 20JULY10

07B2010S Wire Link Rod Upgrade 26OCT10

GAR0111AIC Wire Link Rod & Lifting Bar Assembly Lock Upgrades 4FEB11

GAR0211AIC Correct Gas Connections for SIT Griddle Controls 25MAR11

GAR0511AIC Service Kit for Momentary Switch Part Numbers 4527834 & G03053-1 13SEP11

GAR0711AIC New SIT Griddle Control Thermostat Kit 30SEP11

Revision History

REV# DESCRIPTION DATE

0 New Service Manual released 20AUG10

1 Added new GT/UTGG__M models with GS Tstat. 18MAR13

A_GC_SM_HDGASCOUNTERSERV_GT-UT-SERIES (Rev 1)Page 38

Page 39

Page 40

GT/UT Series Heavy Duty Counter Equipment — Service Manual

Garland Commercial Ranges, Ltd.

1177 Kamato Road

Mississauga, Ontario L4W 1X4 Canada

General Inquiries P: 905 624 0260 F: 905 624 5669

www.Garland-Group.com

Parts & Service

1 800 427 6668 (Phone, US & Canada)

1 800 361 7745 (Fax, US & Canada)

Loading...

Loading...