Page 1

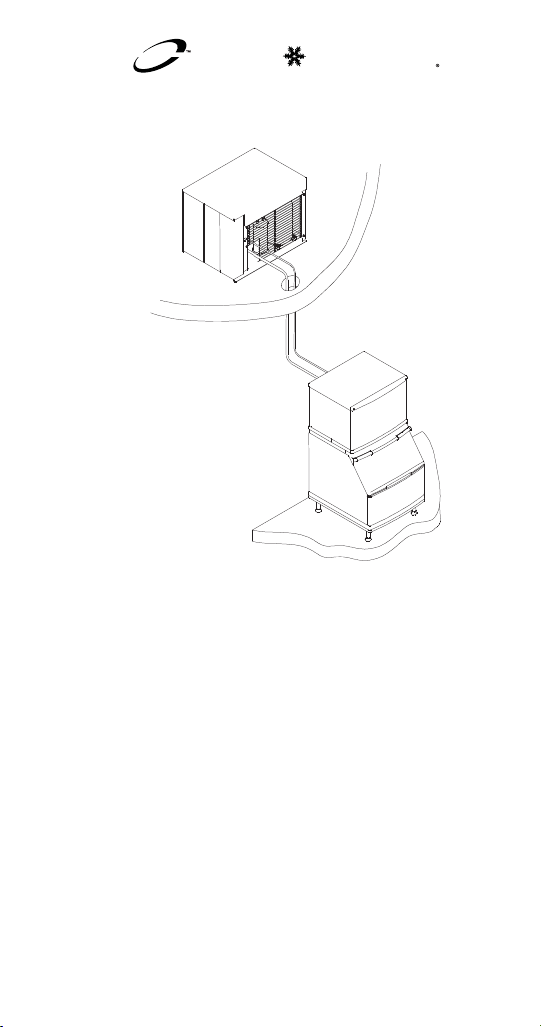

Manitowoc

S Model & Ice Beverage

QuietQube

Ice Machines

Technician’s

Handbook

This manual is updated as new information and models are

released. Visit our website for the latest manual.

America’s #1 Selling Ice Machine

Part Number 80-1505-3 6/10

www.manitowocice.com

®

Page 2

Page 3

Safety Notices

!

Warning

!

Caution

Important

As you work on Manitowoc equipment, be sure to pay

close attention to the safety notices in this handbook.

Disregarding the notices may lead to serious injury

and/or damage to the equipment.

Throughout this handbook, you will see the following

types of safety notices:

Text in a Warning b ox alerts yo u to a p otential

personal injury si tuation. Be su re to read the

Warning st atement before proceeding, and work

carefully.

Text in a Caution box alerts you to a si tuation in

which you could damage the equipment. Be sure

to read the Caution statement before proceeding,

and work carefully.

Procedural Notices

As you work on Manitowoc equipment, be sure to read

the procedural notices in this handbook. These notices

supply helpful information which may assist you as

you work.

Throughout this handbook, you will see the following

types of procedural notices:

Text in an Impo rtant b ox provid es you wi th

information t hat ma y h elp yo u perform a

procedure more ef ficiently. Di sregarding thi s

information will not cause damage or injury, but it

may slow you down as you work.

Page 4

NOTE: Text set off as a Note provides you with simple,

!

Caution

Important

! Warning

We reserve the right to make product

improvements at any time. Specifications and

design are subject to change without notice.

but useful, extra information about the procedure you

are performing.

Read These Before Proceeding:

Proper i nstallation, ca re and ma intenance are

essential for maximum performance and troublefree op eration of you r Manitowo c eq uipment. If

you en counter prob lems not covered by this

handbook, do no t procee d, contact Ma nitowoc

Foodservice Group. We will be happy to p rovide

assistance.

Routine ad justments and main tenance

procedures outlin ed in thi s handbook are not

covered by the warranty.

PERSONAL INJURY POTENTIAL

Do n ot ope rate eq uipment that has b een

misused, ab used, ne glected, d amaged, o r

altered/modified from that of origi nal

manufactured specifications.

Page 5

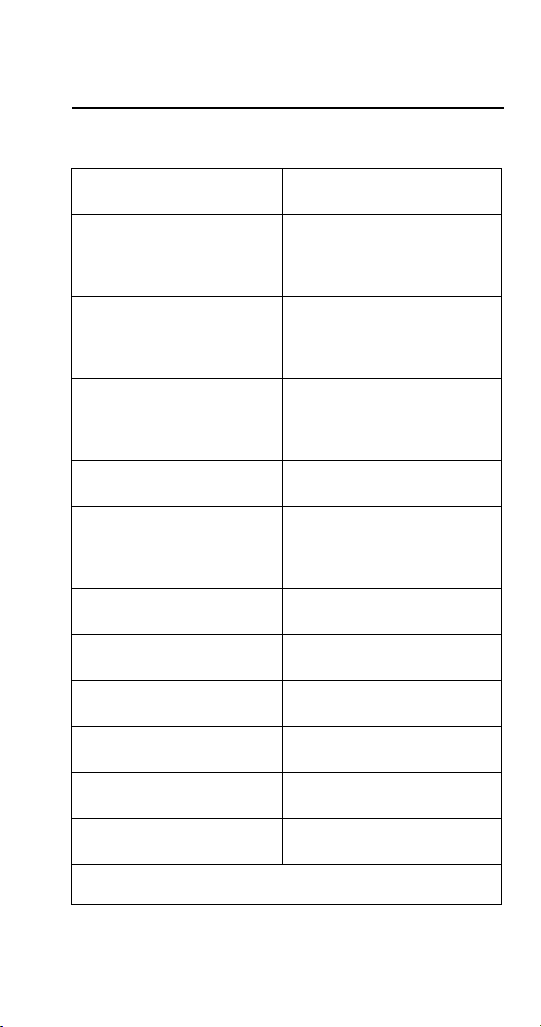

Table of Contents

General Information

Model Numbers . . . . . . . . . . . . . . . . . . 13

How to Read a Model Number . . . . . . 14

Ice Cube Sizes . . . . . . . . . . . . . . . . . . 15

Model/Serial Number Location . . . . . . 16

Energy Efficient Ice Machine

Serial Breaks . . . . . . . . . . . . . . . . . . . . 16

Ice Machine Warranty Information . . . 17

Installation

Location of Ice Machine . . . . . . . . . . . 23

Ice Machine Head Section

Clearance Requirements . . . . . . . . . . . 24

Stacking Two Ice Machines on a

Single Storage Bin . . . . . . . . . . . . . . . 25

Ice Deflector . . . . . . . . . . . . . . . . . . . . 25

Removing the Front Panels . . . . . . . . . 26

Location of CVD

Condensing Unit Clearance

Requirements . . . . . . . . . . . . . . . . . . . 28

Bin Installation . . . . . . . . . . . . . . . . . . . 29

S1470C/S1870C/S2070C/S2170C

Installation on a Manitowoc Bin . . . . . . 31

Ice Machine on a Dispenser Installation 33

Ice Machine Head Section Water

Supply and Drains . . . . . . . . . . . . . . . . 36

Water Cooled Condenser Water Supply

and Drains . . . . . . . . . . . . . . . . . . . . . .38

Electrical Requirements . . . . . . . . . . . 39

Refrigeration System Installation . . . . . 41

®

Condensing Unit . . . 27

Part Number 80-1505-3 6/10 5

Page 6

Operational Checks . . . . . . . . . . . . . . . . . 61

General . . . . . . . . . . . . . . . . . . . . . . . . 61

Water Level . . . . . . . . . . . . . . . . . . . . 61

Ice Thickness Check . . . . . . . . . . . . . 62

Harvest Sequence Water Purge . . . . . 63

Electronic Bin Thermostat Instructions

IB600C/IB680C/IB800C/IB1000C Only . . 64

Positioning . . . . . . . . . . . . . . . . . . . . . 64

Component Identification

Ice Machine Head Sections . . . . . . . . 67

®

Condensing Units . . . . . . . . . . . 71

CVD

Maintenance

General . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Cleaning / Sanitizing Procedure . . . . . . . 74

Cleaning Procedure . . . . . . . . . . . . . . 74

Parts Removal for Cleaning/Sanitizing 76

Sanitizing Procedure . . . . . . . . . . . . . 83

Procedure to Clean Heavily Scaled

Ice Machines . . . . . . . . . . . . . . . . . . . . . . 85

General . . . . . . . . . . . . . . . . . . . . . . . . 85

Cleaning Procedure . . . . . . . . . . . . . . 85

Parts Removal for Cleaning/Sanitizing 88

Sanitizing Procedure . . . . . . . . . . . . . 102

Additional Component Removal . . . . . 104

Removal from Service/Winterization . . . 109

General . . . . . . . . . . . . . . . . . . . . . . . . 109

CVD1486 Water Cooled Condensing Unit

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Sequence of Operation

Initial Start-Up or Start-Up After

Automatic Shut-Off . . . . . . . . . . . . . . . 111

Freeze Sequence . . . . . . . . . . . . . . . . 113

Harvest Sequence . . . . . . . . . . . . . . . 114

Automatic Shut-Off . . . . . . . . . . . . . . . 117

6 Part Number 80-1505-3 6/10

Page 7

Troubleshooting

Safety Limits . . . . . . . . . . . . . . . . . . . . . . . 123

Analyzing Why Safety Limits May Stop the

Ice Machine . . . . . . . . . . . . . . . . . . . . .125

Safety Limit#1 . . . . . . . . . . . . . . . . . . . 126

Safety Limit #2 . . . . . . . . . . . . . . . . . . 127

Safety Limit #3 . . . . . . . . . . . . . . . . . . 128

Control Board Testing . . . . . . . . . . . . . . . 129

Control Board Test Cycle . . . . . . . . . . 129

Troubleshooting By Symptom . . . . . . . . 130

Symptom #1 Ice Machine Will Not Run . 131

Diagnosing an Ice Machine Head Section

that Will Not Run . . . . . . . . . . . . . . . . . 133

Diagnosing a Condensing Unit

That Will Not Run . . . . . . . . . . . . . . . . 134

Compressor Electrical Diagnostics . . . 135

Symptom #2 Low Production, Long Freeze

Cycle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

Symptom #2 - Refrigeration System Opera-

tional Analysis Tables . . . . . . . . . . . . . 140

Symptom #2 - Freeze Cycle Refrigeration

System Operational Analysis Table Proce-

dures . . . . . . . . . . . . . . . . . . . . . . . . . . 149

Symptom #3 Ice Will Not Harvest . . . . . . 166

Ice Machine will Not Harvest Diagnostics

166

Harvest Problems . . . . . . . . . . . . . . . . 167

Symptom #3 Ice Will Not Harvest, Cubes Are

Not Melted Flowchart . . . . . . . . . . . . . . . . 168

Symptom #4 Ice Will not Harvest - Cubes Are

Melted Flowchart . . . . . . . . . . . . . . . . . . . 172

Part Number 80-1505-3 6/10 7

Page 8

Component Check Procedures

Electrical Components . . . . . . . . . . . . . . 175

Main Fuse . . . . . . . . . . . . . . . . . . . . . . 175

Bin Switch . . . . . . . . . . . . . . . . . . . . . . 176

Harvest Assist Air Pump . . . . . . . . . . . 179

ICE/OFF/CLEAN Toggle Switch . . . . . 180

Ice Thickness Probe (Harvest Initiation)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

Water Level Control Circuitry . . . . . . . 187

Electronic Bin Thermostat Control . . . 193

Compressor Electrical Diagnostics . . . 199

Diagnosing Start Components . . . . . . 201

Refrigeration Components . . . . . . . . . . . 204

Refrigerant Charge Verification . . . . . 204

Suction Accumulator Operation . . . . . 206

Headmaster Control Valve . . . . . . . . . 207

Headmaster Valve Water-Cooled Condens-

ing Unit - CVD1476 . . . . . . . . . . . . . . . 213

Water Regulating Valve CVD1476 . . . 215

Fan Cycle Control . . . . . . . . . . . . . . . . 216

High Pressure Cutout (HPCO) Control 217

Low Pressure Cutout (LPCO) Control 218

Refrigerant Recovery/Evacuation . . . . . 219

Connections . . . . . . . . . . . . . . . . . . . . 220

Recovery/Evacuation PROCEDURES 222

Charging Procedures . . . . . . . . . . . . . 223

System Contamination Cleanup . . . . . . . 224

Determining Severity of Contamination 224

Cleanup Procedure . . . . . . . . . . . . . . 226

Refrigerant Reuse Policy . . . . . . . . . . . . 231

8 Part Number 80-1505-3 6/10

Page 9

Component Specifications

Main Fuse . . . . . . . . . . . . . . . . . . . . . . 233

Bin Switch . . . . . . . . . . . . . . . . . . . . . . 233

Harvest Assist Air Pump . . . . . . . . . . .233

ICE/OFF/CLEAN Toggle Switch . . . . . 233

Electronic Bin Thermostat Control . . . . 233

Water Regulating Valve . . . . . . . . . . . 233

Fan Cycle Control . . . . . . . . . . . . . . . .234

High Pressure Cutout (HPCO) Control 234

Low Pressure Cutout (LPCO) Control . 234

Filter-Driers . . . . . . . . . . . . . . . . . . . . . 235

Total System Refrigerant Charge . . . . 237

Charts

Cycle Times/24-Hour Ice Production/Refriger-

ant Pressure . . . . . . . . . . . . . . . . . . . . . . . 239

S0600C/CVD0675 Series Remote Air

Cooled . . . . . . . . . . . . . . . . . . . . . . . . . 240

SD0682C/CVD0685 Series Remote Air

Cooled . . . . . . . . . . . . . . . . . . . . . . . . . 241

SY0684C/CVD0685 Series Remote Air

Cooled . . . . . . . . . . . . . . . . . . . . . . . . . 242

IB0600C/CVD675 Series Remote Air

Cooled . . . . . . . . . . . . . . . . . . . . . . . . . 243

IB0682DC/CVD685 Series Remote Air

Cooled . . . . . . . . . . . . . . . . . . . . . . . . . 244

IB0684YC/CVD685 Series Remote Air

Cooled . . . . . . . . . . . . . . . . . . . . . . . . . 245

SD0872C/SY0874C/CVD0885 Series

Remote Air Cooled

Machines Before Serial Number 110682385

246

SD0872C/CVD0885 Series Remote Air

Cooled

Machines After Serial Number 110682385

247

SY0874C/CVD0885 Series Remote Air

Cooled

Machines After Serial Number 110682385

248

IB0822DC/IB0824YC/CVD885 Series Re-

Part Number 80-1505-3 6/10 9

Page 10

mote Air Cooled Machines Before Serial

Number 110682385 . . . . . . . . . . . . . . 249

IB0822DC/CVD885 Series Remote Air

Cooled Machines After Serial Number

110682385 . . . . . . . . . . . . . . . . . . . . . 250

IB0824YC/CVD885 Series Remote Air

Cooled Machines After Serial Number

110682385 . . . . . . . . . . . . . . . . . . . . . 251

SD1072C/SY1074C/CVD1085 Series Remote Air Cooled Machines Before Serial

Number 110697654 . . . . . . . . . . . . . . 252

SD1072C/CVD1085 Series Remote Air

Cooled Machines After Serial Number

110697654 . . . . . . . . . . . . . . . . . . . . . 253

SY1074C/CVD1085 Series Remote Air

Cooled Machines After Serial Number

110697654 . . . . . . . . . . . . . . . . . . . . . 254

IB1022DC/IB1024YC/CVD1075/CVD1085/

CVD1285 Series Remote Air Cooled Machines Before Serial Number 110697294

255

IB1022DC/CVD1185 Series Remote Air

Cooled Machines After Serial Number

110697294 . . . . . . . . . . . . . . . . . . . . . 256

IB1024YC/CVD1185 Series Remote Air

Cooled Machines After Serial Number

110697294 . . . . . . . . . . . . . . . . . . . . . 257

SD1272C/SY1274C/CVD1285 Series Remote Air Cooled Machines Before Serial

Number 110706336 . . . . . . . . . . . . . . 258

SD1272C/CVD1285 Series Remote Air

Cooled Machines After Serial Number

110706336 . . . . . . . . . . . . . . . . . . . . . 259

SY1274C/CVD1285 Series Remote Air

Cooled Machines After Serial Number

110706336 . . . . . . . . . . . . . . . . . . . . . 260

S1470C/CVD1485 Series Remote Air

Cooled . . . . . . . . . . . . . . . . . . . . . . . . 261

S1470C/CVD1486 Remote Water Cooled

262

SD1872C/CVD1885 Series Remote Air

10 Part Number 80-1505-3 6/10

Page 11

Cooled . . . . . . . . . . . . . . . . . . . . . . . . . 263

SY1874C/CVD1885 Series Remote Air

Cooled . . . . . . . . . . . . . . . . . . . . . . . . . 264

SD2072C/CVD2075 Series Remote Air

Cooled . . . . . . . . . . . . . . . . . . . . . . . . . 265

SY2074C/CVD2075 Series Remote Air

Cooled . . . . . . . . . . . . . . . . . . . . . . . . . 266

SD2172C/CVD2085 Series Remote Air

Cooled . . . . . . . . . . . . . . . . . . . . . . . . . 267

SY2174C/CVD2085 Series Remote Air

Cooled . . . . . . . . . . . . . . . . . . . . . . . . . 268

SD3072C/CVD3085 Series Remote Air

Cooled . . . . . . . . . . . . . . . . . . . . . . . . . 269

SY3074C/CVD3085 Series Remote Air

Cooled . . . . . . . . . . . . . . . . . . . . . . . . . 270

Diagrams

Wiring Diagrams . . . . . . . . . . . . . . . . . . . . 271

Wiring Diagram Legend . . . . . . . . . . . . 271

S600C/S850C/1000C/S1200C . . . . . . 272

S600C/S680C/S850C/1000C/S1200C 273

S1470C/S1870C/S2070C/S2170C . . . 274

S3070C 115/60/1 . . . . . . . . . . . . . . . .275

S3070C 230V/50Hz/1Ph . . . . . . . . . . 276

IB0600C/IB0800C/IB1000C

with S Control Board and Electronic Bin

Thermostat . . . . . . . . . . . . . . . . . . . . . 277

IB0600C/IB0680C/IB0800C/IB1000C

with Air Assist/S Control Board/Electronic

Bin Thermostat . . . . . . . . . . . . . . . . . . 278

CVD675/CVD685/CVD885/CVD1075/

CVD1085/CVD1185/CVD1285/CVD1485/

CVD1486/CVD1885/CVD2075/CVD3085 -

1 Phase . . . . . . . . . . . . . . . . . . . . . . . . 279

Part Number 80-1505-3 6/10 11

Page 12

CVD2085 without PTCR-

1 Phase . . . . . . . . . . . . . . . . . . . . . . . 280

CVD2085 with PTCR-

1 Phase . . . . . . . . . . . . . . . . . . . . . . . 281

CVD675/CVD685/CVD885/CVD1075/

CVD1085/CVD1185/CVD1285/CVD1485/

CVD1486/CVD1885/CVD2075/CVD2085/

CVD3085 - 3 Phase . . . . . . . . . . . . . . 282

CVD3085 380V/50hz/3ph . . . . . . . . . . 283

Electronic Control Board . . . . . . . . . . . . 284

Single and Twin Evaporator Models . . 284

Quad Evaporator Models . . . . . . . . . . 286

Refrigeration Tubing Schematics . . . . . 287

S600C/S680C/S850C/S1000C/S1200C

287

S600C/S680C/S850C/S1000C/S1200C

288

Ice Beverage IB0600C/IB0680C/IB0800C/

IB1000C . . . . . . . . . . . . . . . . . . . . . . . 289

Ice Beverage IB0600C/IB0680C/IB0800C/

IB1000C . . . . . . . . . . . . . . . . . . . . . . . 290

S1470C/S1870C/S2070C/S2170C . . . 291

S1470C/S1870C/S2070C/S2170C . . . 292

S1476C Water-Cooled Condenser . . . 293

S3070C Without Check Valve . . . . . . 294

S3070C With Check Valve . . . . . . . . . 295

12 Part Number 80-1505-3 6/10

Page 13

General Information

MODEL NUMBERS

This manual covers the following models:

Ice Machine Head

Section

SD0672C

SY0674C

IB0624YC

IB0622DC

SD0682C

SY0684C

IB0684YC

IB0682DC

SD0872C

SY0874C

IB0824YC

IB0822DC

SD1072C

SY1074C

IB1024YC

IB1022DC

SD1272C

SY1274C

SD1472C

SY1474C

SD1872C

SY1874C

SD2072C

SY2074C

SD2172C

SY2174C

SD3072C

SY3074C

*For 3 phase electrical option: add the number “3”

to end of model number (CVD10853).

CVD Condensing Unit*

CVD0675

CVD0685

CVD0885

CVD1085

CVD1185

CVD1285

CVD1085

CVD1075

CVD1285

CVD1485

CVD1486

CVD1885

CVD2075

CVD2085

CVD3085

Part Number 80-1505-3 6/10 13

Page 14

HOW TO READ A MODEL NUMBER

S Y 1074 C 3

ICE MACHINE

MODEL

ICE CUBE SIZE

D DICE

Y HALF DICE

# CUBE SIZE

2 DICE

3 DICE

4 HALF-DICE

5 HALF-DICE

CONDENSER TYPE

AIR-COOLED

WATER-COOLED

AIR-COOLED

WATER-COOLED

AY Y SELF-CONTAINED AIR-COOLED

WY Y

SELF-CONTAINED WATER-COOLED

CY Y CVD REMOTE AIR or WATER-COOLED

DC CVD REMOTE AIR-COOLED - DICE

YC CVD REMOTE AIR-COOLED - HALF DICE

7 CVD REMOTE

AIR-COOLED

CONDENSER TYPE

ICE MACHINE

SERIES

ADDITIONAL SPECS

3 3 PHASE

SI INCLUDES

AuCS SI BUILT IN

CVD 1485 3

CONDENSING

UNIT MODEL

3 PHASE

CONDENSING

UNIT SERIES

5 AIR-COOLED

6 WATER-COOLED

Head Section

Condensing Unit

14 Part Number 80-1505-3 6/10

Page 15

ICE CUBE SIZES

! Warning

! Warning

Dice

7/8" x 7/8" x 7/8"

2.22 x 2.22 x2.22 cm

Half Dice

3/8" x 1-1/8" x 7/8"

0.95 x 2.86 x 2.22 cm

Do not op erate eq uipment that ha s b een

misused, abu sed, neglected, d amaged, or

altered/modified from that o f original

manufactured specifications.

This appliance is not intend ed for use by

persons (in cluding childr en) with re duced

physical, sensory or mental capabilities, or lack

of e xperience a nd knowledge, u nless they

have been given supervision concerning use of

the appliance by a person responsible for their

safety.

All Man itowoc ice ma chines re quire th e ice

storage system (bin, dispenser, etc.) to

incorporate an ice deflector.

Prior to using a non -Manitowoc ice sto rage

system with other Manitowoc ice machin es,

contact th e manufacturer to assu re th eir ice

deflector is comp atible wi th Mani towoc ice

machines.

Part Number 80-1505-3 6/10 15

Page 16

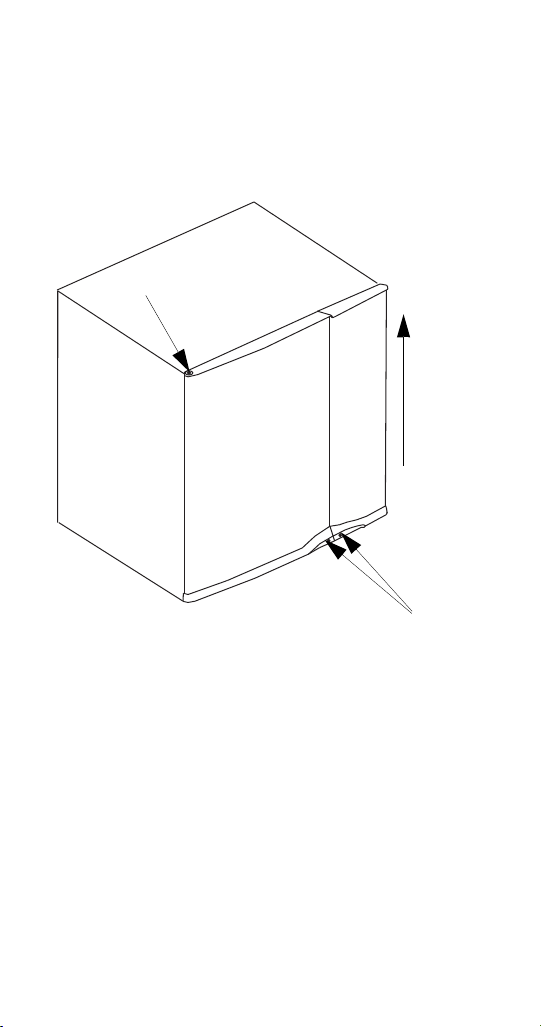

MODEL/SERIAL NUMBER LOCATION

These numbers are required when requesting

information from your local Manitowoc Distributor,

service representative, or Manitowoc Ice, Inc. The

model and serial number are listed on the OWNER

WARRANTY REGISTRATION CARD. They are also

listed on the MODEL/SERIAL NUMBER DECAL

affixed to the ice machine.

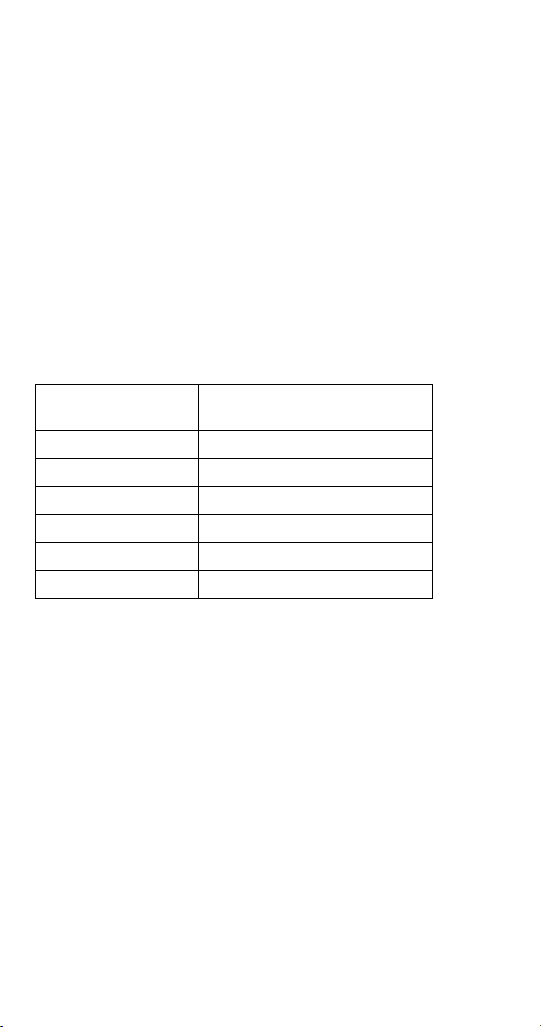

ENERGY EFFICIENT ICE MACHINE SERIAL BREAKS

Some specifications have changed since our release

of Energy Efficient machines. The following machines

have a serial break to indicate when they became

Energy Efficient.

Series Ice

Machine

S850C 110682385

S1000C 110697654

S1200C 110706336

IB800C 110682385

IB1000C 110697294

CVD885 110673885

Serial Break for Energy

Efficient Machines

16 Part Number 80-1505-3 6/10

Page 17

ICE MACHINE WARRANTY INFORMATION

Important

Owner Warranty Registration Card

Warranty coverage begins the day the ice machine is

installed.

Complete and mail the OW NER WARRANTY

REGISTRATION C ARD as soon as p ossible to

validate the installation date.

If the OWNER WARRANTY REGISTRATION CARD is

not returned, Manitowoc will use the date of sale to the

Manitowoc Distributor as the first day of warranty

coverage for your new ice machine.

Part Number 80-1505-3 6/10 17

Page 18

Commercial Warranty Coverage

GENERAL

The following Warranty outline is provided for your

convenience. For a detailed explanation, read the

warranty bond shipped with each product.

Contact your local Manitowoc representative or

Manitowoc Ice if you need further warranty

information.

PARTS

1. Manitowoc warrants the ice machine against

defects in materials and workmanship, under

normal use and service for three (3) years from

the date of original installation.

2. The evaporator and compressor are covered by

an additional two (2) year (five years total)

warranty beginning on the date of the original

installation.

LABOR

1. Labor required to repair or replace defective

components is covered for three (3) years from

the date of original installation.

2. The evaporator is covered by an additional

two (2) year (five years total) labor warranty

beginning on the date of the original installation.

18 Part Number 80-1505-3 6/10

Page 19

EXCLUSIONS

The following items are not included in the ice

machine’s warranty coverage:

1. Normal maintenance, adjustments and cleaning

as outlined in this manual.

2. Repairs due to unauthorized modifications to the

ice machine or use of non-standard parts without

prior written approval from Manitowoc Ice

3. Damage caused by improper installation of the ice

machine, electrical supply, water supply or

drainage, or damage caused by floods, storms, or

other acts of God.

4. Premium labor rates due to holidays, overtime,

etc.; travel time; flat rate service call charges;

mileage and miscellaneous tools and material

charges not listed on the payment schedule.

Additional labor charges resulting from the

inaccessibility of equipment are also excluded.

5. Parts or assemblies subjected to misuse, abuse,

neglect or accidents.

6. Damage or problems caused by installation,

cleaning and/or maintenance procedures

inconsistent with the technical instructions

provided in this manual.

AUTHORIZED WARRANTY SERVICE

To comply with the provisions of the warranty, a

refrigeration service company qualified and authorized

by your Manitowoc Distributor, or a Contracted Service

Representative must perform the warranty repair.

SERVICE CALLS

Normal maintenance, adjustments and cleaning as

outlined in this manual are not covered by the

warranty. If you have followed the procedures listed in

this manual, and the ice machine still does not perform

properly, call your Local Distributor or the Service

Department at Manitowoc Ice.

Part Number 80-1505-3 6/10 19

Page 20

RESIDENTIAL ICE MACHINE LIMITED WARRANTY

WHAT DOES THIS LIMITED WARRANTY COVER?

Subject to the exclusions and limitations below,

Manitowoc Ice (“Manitowoc”) warrants to the original

consumer that any new ice machine manufactured by

Manitowoc (the “Product”) shall be free of defects in

material or workmanship for the warranty period

outlined below under normal use and maintenance,

and upon proper installation and start-up in

accordance with the instruction manual supplied with

the Product.

HOW LONG DOES THIS LIMITED WARRANTY LAST?

Product Covered Warranty Period

Ice Machine

Twelve months from the

sale date

WHO IS COVERED BY THIS LIMITED WARRANTY?

This limited warranty only applies to the original

consumer of the Product and is not transferable.

WHAT ARE MANITOWOC ICE’S OBLIGATIONS UNDER THIS LIMITED WARRANTY?

If a defect arises and Manitowoc receives a valid

warranty claim prior to the expiration of the warranty

period, Manitowoc shall, at its option: (1) repair the

Product at Manitowoc’s cost, including standard

straight time labor charges, (2) replace the Product

with one that is new or at least as functionally

equivalent as the original, or (3) refund the purchase

price for the Product. Replacement parts are

warranted for 90 days or the balance of the original

warranty period, whichever is longer. The foregoing

constitutes Manitowoc’s sole obligation and the

consumer’s exclusive remedy for any breach of this

limited warranty. Manitowoc’s liability under this limited

warranty is limited to the purchase price of Product.

Additional expenses including, without limitation,

service travel time, overtime or premium labor

charges, accessing or removing the Product, or

shipping are the responsibility of the consumer.

20 Part Number 80-1505-3 6/10

Page 21

HOW TO OBTAIN WARRANTY SERVICE

To obtain warranty service or information regarding

your Product, please contact us at:

MANITOWOC ICE

2110 So. 26th St.

P.O. Box 1720,

Manitowoc, WI 54221-1720

Telephone: 920-682-0161 Fax: 920-683-7585

www.manitowocice.com

WHAT IS NOT COVERED?

This limited warranty does not cover, and you are

solely responsible for the costs of: (1) periodic or

routine maintenance, (2) repair or replacement of the

Product or parts due to normal wear and tear, (3)

defects or damage to the Product or parts resulting

from misuse, abuse, neglect, or accidents, (4) defects

or damage to the Product or parts resulting from

improper or unauthorized alterations, modifications, or

changes; and (5) defects or damage to any Product

that has not been installed and/or maintained in

accordance with the instruction manual or technical

instructions provided by Manitowoc. To the extent that

warranty exclusions are not permitted under some

state laws, these exclusions may not apply to you.

E

XCEPT AS STATED IN THE FOLLOWING SENTENCE, THIS

L

IMITED WARRANTY IS THE SOLE AND EXCLUSIVE

W

ARRANTY OF MANITOWOC WITH REGARD TO THE

RODUCT. ALL IMPLIED WARRANTIES ARE STRICTLY

P

L

IMITED TO THE DURATION OF THE LIMITED WARRANTY

A

PPLICABLE TO THE PRODUCTS AS STATED ABOVE,

NCLUDING BUT NOT LIMITED TO, ANY WARRANTY OF

I

M

ERCHANTABILITY OR OF FITNESS FOR A PARTICULAR

P

URPOSE.

Some states do not allow limitations on how long an

implied warranty lasts, so the above limitation may not

apply to you.

Part Number 80-1505-3 6/10 21

Page 22

IN NO EVENT SHALL MANITOWOC OR ANY OF ITS

A

FFILIATES BE LIABLE TO THE CONSUMER OR ANY

THER PERSON FOR ANY INCIDENTAL, CONSEQUENTIAL

O

O

R SPECIAL DAMAGES OF ANY KIND (INCLUDING,

W

ITHOUT LIMITATION, LOSS OF PROFITS, REVENUE OR

USINESS) ARISING FROM OR IN ANY MANNER

B

C

ONNECTED WITH THE PRODUCT, ANY BREACH OF THIS

L

IMITED WARRANTY, OR ANY OTHER CAUSE

HATSOEVER, WHETHER BASED ON CONTRACT, TORT

W

O

R ANY OTHER THEORY OF LIABILITY.

Some states do not allow the exclusion or limitation of

incidental or consequential damages, so the above

limitation or exclusion may not apply to you.

HOW STATE LAW APPLIES

This limited warranty gives you specific legal rights,

and you may also have rights that vary from state to

state or from one jurisdiction to another.

REGISTRATION CARD

To secure prompt and continuing warranty service, this

warranty registration card must be completed and sent

to Manitowoc within thirty (30) days from the sale date.

Complete the registration card and send it to

Manitowoc.

22 Part Number 80-1505-3 6/10

Page 23

Installation

LOCATION OF ICE MACHINE

S600C/S680C/S850C/S1000C/S1200C/S1470C/

S1870C/S2070C/S2170C/S3070C

The location selected for the ice machine head section

must meet the following criteria. If any of these criteria

are not met, select another location.

• The location must be free of airborne and other

contaminants.

• The air temperature must be at least 35°F (1.7°C),

but must not exceed 110°F (43.4°C).

• The location must not be near heat-generating

equipment, in direct sunlight and be protected from

weather.

• The location must not obstruct airflow through or

around the ice machine. Refer to ice machine

head section clearance requirements.

IB0600C/IB0680C/IB0800C/IB1000C

• Ice/Beverage Ice Machines require the installation

of a thermostat to maintain dispenser ice level.

The thermostat ships with the ice machine.

• The ice machine head is installed with the

electrical inlet, water supply inlet, refrigeration

tubing and water drain entering from the back of

the ice machine.

• The ice machine head section contains a service

loop that must remain installed between the ice

machine head section and line set. Sufficient

tubing length must be available to allow 180°

rotation of the ice machine.

• Maintain a 3” space between the back of the ice

machine and the back of the dispenser to allow

room for the refrigeration line set service loop.

• The water inlet and electrical connection must

contain a service loop to allow future service and

maintenance access.

• The drain line must contain a union or other

suitable means of disconnection at the ice

machine head section.

Part Number 80-1505-3 6/10 23

Page 24

• The location must be free of airborne and other

contaminants.

• The air temperature must be at least 35°F (1.6°C),

but must not exceed 110°F (43.4°C).

• The location must not be near heat-generating

equipment or in direct sunlight.

• The location must not obstruct airflow through or

around the ice machine. Refer to ice machine

head section clearance requirements.

ICE MACHINE HEAD SECTION CLEARANCE REQUIREMENTS

S600C/S680C/S850C/S1000C/S1200C/S1470C/ S1870C/S2070C/S2170C

Top 5” (12.7 cm) is recommended for efficient

operation and removal of top cover/servicing.

Sides 5” (12.7 cm) is recommended for efficient

operation and servicing. There is no minimum

clearance required.

Back 3” (7.6 cm) required when routing electrical inlet,

water inlet and refrigeration tubing out of the top of the

unit.

5” (12.7 cm) required when routing all connections out

the back.

IB0600CIB0680C/IB0680C/IB0800C/IB1000C

Top 2” (5.1 cm) required clearance for cleaning

procedures and servicing.

Back 5” (12.7 cm) required when routing all

connections out the back.

Sides 8” (20.3 cm) required for servicing.

S3070C

Top/Sides 8” (20.3 cm) recommended clearance for

efficient operation and removal of top cover/servicing.

There is no minimum clearance required.

Back 24” (61.0 cm) required when routing all

connections out the back.

NOTE: 24” (61.0 cm) on all sides is recommended

to allow access without moving the machine.

24 Part Number 80-1505-3 6/10

Page 25

!

Caution

The ice machine head section must be protected

!

Warning

!

Warning

if it will be subjected to temperatures below 32°F

(0°C). F ailure cau sed by e xposure to freezi ng

temperatures is not covered by the warranty. See

“Removal from Service/Winterization” page 109.

STACKING TWO ICE MACHINES ON A SINGLE STORAGE BIN

S QuietQube ice machines cannot be stacked.

However an adapter is available that allows two S

QuietQube ice machines to be placed side by side on

60” Manitowoc F & B style bins.

ICE DEFLECTOR

An ice deflector is required for all ice machines

installed on a bin.

S1470C/S1870C/S2170C ice machines are not

approved for use on Manitowoc B570 bins.

30” large capacity B model bins must be attached

to the wall with the bracket provided with the bin.

Part Number 80-1505-3 6/10 25

Page 26

REMOVING THE FRONT PANELS

3

2

5

1. Disconnect power to ice machine.

2. Loosen screws. Do not remove they are retained

by o-rings to prevent loss.

3. To remove right front door lift up and remove.

Door Removal

4. Open left front door to 45 degrees.

5. Support with left hand, depress top pin, tilt top of

door forward and lift out of bottom pin to remove.

26 Part Number 80-1505-3 6/10

Page 27

LOCATION OF CVD® CONDENSING UNIT

The location selected for the CVD Condensing Unit

must meet the following criteria. If any of these criteria

are not met, select another location.

• CVD885/CVD1075/CVD1085/CVD1485/

CVD1885/CVD2085 Only - The air temperature

must be at least -20°F (-28.9°C) but must not

exceed 130°F (54.4°C).

• CVD675/CVD685/CVD1185/CVD2075/CVD3085

Only - The air temperature must be at least

-20°F (-28.9°C) but must not exceed 120°F

(48.9°C).

• CVD1486 Only- The air temperature must be at

least 50°F (10°C) but must not exceed 110°F

(43°C).

• The location must not allow exhaust fan heat and/

or grease to enter the condenser.

• The location must not obstruct airflow through or

around the condensing unit. See below for

clearance requirements.

Part Number 80-1505-3 6/10 27

Page 28

CONDENSING UNIT CLEARANCE REQUIREMENTS

CVD675/CVD685/CVD885/CVD1075/CVD1085/ CVD1185/ CVD2075/CVD2085

Top/Sides - There is no minimum clearance required,

although 6” (15.2 cm) is recommended for efficient

operation and servicing only.

Front/Back - 48” (122 cm)

CVD1285/CVD1485/CVD1885

Top/Sides - There is no minimum clearance required,

although 6” (15.2 cm) is recommended for efficient

operation and servicing only.

Front - 24” (61 cm)

Back - 48” (122 cm)

CVD1486 ONLY

Top - 5” (12.7 cm) is required for efficient operation

and servicing.

Front/Back/Sides - 12” (30.5 cm)

CVD3085

Top/Sides - There is no minimum clearance required,

although 8” (20.3 cm) is recommended for efficient

operation and servicing only.

Front/Back - 24” (122 cm)

NOTE: 24” (61.0 cm) on all sides is recommended

to allow easy access.

28 Part Number 80-1505-3 6/10

Page 29

BIN INSTALLATION

!

Warning

All ice machines installed on a bin require an ice

deflector. Manitowoc bins have a built in deflector that

requires no modifications when used with a forward

facing evaporator. Ice machines with multiple

evaporators require a deflector kit.

Bin adapters or custom bin tops are available to allow

installation of a 30” ice machine on a 48” or 60” bin.

Refer to ice machine price list for options

(http://www.manitowocice.com/sales/price.asp).

Manitowoc Quie tQube ice machines re quire the

ice storage bin to incorporate an ice deflector.

Prior to using a no n-Manitowoc ice sto rage

system with other Manitowoc ice ma chines,

contact th e manu facturer to assure the ir ice

deflector i s comp atible wi th Manitowo c ice

machines.

Part Number 80-1505-3 6/10 29

Page 30

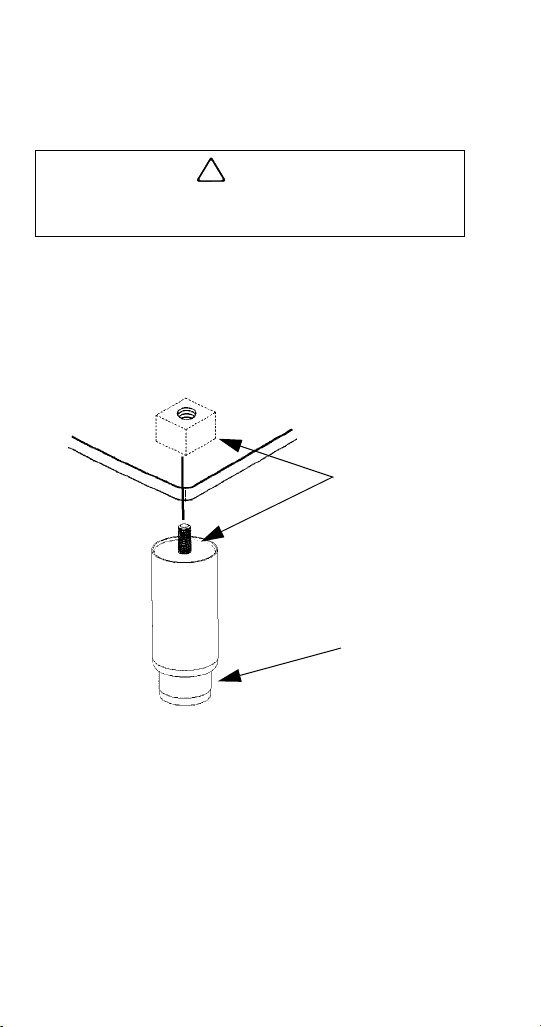

Leveling the Ice Storage Bin

!

Caution

THREAD

LEVELING LEG

INTO BASE AS

FAR AS

POSSIBLE

ADJUST

LEGS TO

LEVEL BIN

1. Screw the leveling legs onto the bottom of the bin.

2. Screw the foot of each leg in as far as possible.

The legs mu st be scre wed in tightly to prevent

them from bending.

3. Move the bin into its final position.

4. Level the bin to assure that the bin door closes

and seals properly. Use a level on top of the bin.

Turn each foot as necessary to level the bin.

Leveling Leg and Foot

30 Part Number 80-1505-3 6/10

Page 31

S1470C/S1870C/S2070C/S2170C

RE-INSTALL TOP

COVER

REMOVE 1

SCREW

ON EACH

SIDE

REMOVE

DEFLECTOR

REMOVE 2

SCREWS

ON EACH

SIDE

INSTALLATION ON A MANITOWOC BIN

An ice deflector kit is required for installation. Order

appropriate kit (30” or 48”) for your bin.

Step 1 Remove the stock ice deflector.

A. Remove the left and right side cover screws

B. Remove the cover to expose four screws,

which secure the plastic deflector.

C. Remove fours screws and plastic deflector

D. Install polymer spacer on each side and

secure with the four screws.

E. Reinstall cover and screws.

Part Number 80-1505-3 6/10 31

Page 32

Step 2 Install front support and filler panels.

1. SLIDE

FORWARD

2. LOCK IN PLACE WITH PIN

A. Remove foam tape from front support

location.

B. Set front support in place and install foam

tape.

C. Position filler panels (align with front support),

drill and secure.

D. Install foam tape on front and back. Seal all

foam tape edges.

Step 3 Install ice deflector.

A. Locate center of ice machine drop zone

(center is 11” from left edge of ice machine to

left edge of bracket).

B. Cut and remove foam tape on the front and

the back of the bin where the deflector will be

located.

C. Remove any residual adhesive; areas must

be clean and dry.

D. Remove protective covering from double

sided tape on bottom of deflector bracket.

E. Install deflector bracket; Distribute equally to

the front and back and locate pin to the rear.

F. Apply foam tape over bracket and seal joints

with silicone sealant.

G. Refer to illustration and install deflector in

mounting bracket.

32 Part Number 80-1505-3 6/10

Page 33

ICE MACHINE ON A DISPENSER INSTALLATION

Important

!

Warning

No deflector is needed for machines that match the

size of the dispenser (30” head section on a 30”

dispenser) unless required by the dispenser

manufacturer. Adapters are required when a smaller

ice machine is going on a larger dispenser (22”

machine on a 30” dispenser).

IB0600C/IB0680C/IB0800C/IB1000C

Securing the Ice Machine to the Dispenser

Manitowoc Ice/Beverage Ice Machines req uire

an ad apter fo r mounting. Adapters are no t

included with the i ce machin e, dispe nser or b in

and mu st b e orde red sep arately. Wh en a nonManitowoc adapter is used, verify the adapter is

compatible wi th Manitowoc Ice /Beverage Ice

Machines prior to installation.

The ice machine and adapter plate must be secured to

the dispenser to prevent tipping.

• Two holes are located in the front bottom rail of the

ice machine, to allow attachment to the adapter

plate.

• The adapter cover must be secured to the

dispenser to prevent ice from dislodging the cover

during agitation.

The ice machi ne an d ada pter pla te must be

secured to the dispenser to prevent tipping.

Part Number 80-1505-3 6/10 33

Page 34

Typical Ice Beverage on a Dispenser

BIN

COVER

ADAPTER

SCREWS

1. Install bin level thermostat bracket.

2. Set adapter on dispenser. Position the adapter so

that the front flange of the adapter will be up

against the front lip of the dispenser. Adapter may

have to be moved towards the back of the

dispenser.

3. Using the slotted holes in the adapter as a

template, drill four (4) 9/64” diameter holes at the

bottom of the slots. Note: Do not drill deeper than

1/4” past the sheet metal. Use a drill stop!

4. Fasten the adaptor to dispenser using the four (4)

#8 screws supplied with the adaptor kit.

5. Set the ice machine on top of the adapter. Align

holes in ice machine front angle with threaded

bosses on the adapter.

34 Part Number 80-1505-3 6/10

Page 35

6. Secure the ice machine to the adaptor with two

PLACE A LARGE FILLET OF

FOOD GRADE RTV INSIDE

EDGE ALONG BOTH SIDES

WHERE ADAPTER

TOUCHES BIN

DEFLECTOR MUST

STAY IN PLACE

(2) #8-32 screws supplied with the kit.

7. Set the bin cover on the adapter, move backwards

until the cover hits the stop, and lower the plastic

cover insuring that the latch locks.

8. To remove the bin cover, twist the knob, lift up,

and pull forward.

Part Number 80-1505-3 6/10 35

Page 36

ICE MACHINE HEAD SECTION WATER

Important

SUPPLY AND DRAINS

Potable Water Supply

Local water conditions may require treatment of the

water to inhibit scale formation, filter sediment, and

remove chlorine odor and taste.

If you are installing a Manitowoc water filter system,

refer to the Installation Instructions supplied with the

filter system for ice making water inlet connections.

Potable Water Inlet Lines

Follow these guidelines to install water inlet lines:

• Do not connect the ice machine to a hot water

supply. Be sure all hot water restrictors installed for

other equipment are working. (Check valves on

sink faucets, dishwashers, etc.)

• If water pressure exceeds the maximum

recommended pressure obtain a water pressure

regulator from your Manitowoc Distributor.

• Maximum water pressure - 80 psi (551.6 kPA)

• Install a water shut-off valve for ice making potable

water.

• Insulate water inlet lines to prevent condensation.

• A 3’ service loop or disconnect (union) must be

installed at the ice machine head section.

36 Part Number 80-1505-3 6/10

Page 37

Drain Connections

Important

Follow these guidelines when installing drain lines to

prevent drain water from flowing back into the ice

machine and storage bin:

• Drain lines must have a 1.5 in. drop per 5 ft. of run

(2.5 cm per meter), and must not create traps.

• The floor drain must be large enough to

accommodate drainage from all drains.

• Run separate bin and ice machine drain lines.

Insulate them to prevent condensation.

• Vent the bin and ice machine drain to the

atmosphere. The ice machine drain requires an

18” vent.

• Drains must have a union or other suitable means

to allow in place disconnection from the ice

machine when servicing is required.

• S3070C requires base drain connection (1” FPT).

Cooling Tower Application (Water-Cooled Models)

A water cooling tower installation does not require

modification of the ice machine. The water regulator

valve for the condenser continues to control the

refrigeration discharge pressure.

It is necessary to know the amount of heat rejection,

and the pressure drop through the condenser and

water valves (inlet and outlet) when using a cooling

tower on an ice machine.

• Water entering the condenser must not exceed

90°F (32.2°C).

• Water flow through the condenser must not

exceed 5 gallons (19 liters) per minute.

• Allow for a pressure drop of 7 psi (48 kPA)

between the condenser water inlet and the outlet

of the ice machine.

• Water exiting the condenser must not exceed

110°F (43.3°C).

The Commonwealth of Massachusetts requires that

all water-cool ed models must be conne cted only to

a closed loop, cooling tower system.

Part Number 80-1505-3 6/10 37

Page 38

WATER COOLED CONDENSER WATER SUPPLY AND DRAINS

Water Cooled Condenser Lines

Follow these guidelines to install water lines:

• Contact your distributor if your water pressure is

greater than 150 psig (1034 kPA). A special order

condensing unit is available that allows water

pressure up to 350 psig (2413 kPA).

• Install a shutoff valve (inlet and outlet on cooling

tower or closed loop circuits) to allow isolation of

the water system.

• Water entering the condenser must not exceed

90°F (32.2°C).

• Water flow through the condenser must not

exceed 5 gallons (19 liters) per minute.

• Allow for a pressure drop of 8 psig (55 kPA)

between the condenser water inlet and outlet.

• Water exiting the condenser must not exceed

110°F (43.3°C).

• Do not connect to the potable water filter system.

Condensing Unit Drain Connections

The condensing unit drain is provided to remove any

condensate produced by the suction accumulator.

Condensate amounts will vary depending on

temperature and humidity.

• The condensing unit must be level front to back

and side to side to allow the condensate to drain.

• Drain lines must have a 1.5-inch drop per 5 feet of

run (2.5 cm per meter), and must not create traps.

• Drain termination must meet applicable costs.

38 Part Number 80-1505-3 6/10

Page 39

ELECTRICAL REQUIREMENTS

Important

Local or state electrical code, length of wire run or materials

used, can increase the minimum wire or breaker size

requirement. A qualified electrician must determine the wire

and breaker size, although the minimum wire size must meet

or exceed the specifications in these charts.

Head Sections

Ice Machine Head Section

Voltage Phase

Cycle

S0600C

S0680C

S0850C

IB0620C

IB0680C

IB0820C

IB1020C

S1000C

S1200C

S1470C

S1870C

S2070C

S2170C

S3070C

*Not available on S2070C or S2170C models.

**All conductors must be solid copper wire.

115/1/60

208-230/1/60

230/1/50

115/1/60

230/1/50

115/1/60

230/1/50

115/1/60

230/1/50

115/1/60

208-230/1/60

230/1/50*

115/1/60

230/50/1

Max. Fuse/

Circuit

Breaker

15 amp

15 amp

15 amp

15 amp

15 amp

15 amp

15 amp

15 amp

15 amp

15 amp

15 amp

15 amp

15 amp

10 amp

Total Amps

1.1

0.6

0.6

1.1

1.5

1.4

0.8

2.5

1.5

1.1

0.6

0.6

2.0

2.0

The Q uietQube® Ice Mach ine Head Secti on a nd

CVD® Con densing Un it a re wired inde pendently

from each other.

Part Number 80-1505-3 6/10 39

Page 40

Condensing Units

CVD® Condensing Unit

Voltage

Phase

Cycle

208-230/1/60

CVD0675

208-230/3/60

230/1/50

CVD0685

208-230/1/60

208-230/3/60

208-230/1/60

CVD0885

208-230/3/60

230/1/50

208-230/1/60

CVD1075

208-230/3/60

230/1/50

208-230/1/60

CVD1085

208-230/3/60

230/1/50

208-230/1/60

CVD1185

208-230/3/60

230/1/50

208-230/1/60

CVD1285

208-230/3/60

230/1/50

208-230/1/60

CVD1485

208-230/3/60

230/1/50

208-230/1/60

CVD1486

208-230/3/60

230/1/50

208-230/1/60

CVD1885

208-230/3/60

230/1/50

CVD2085*

085*

CVD3

*CVD2085 & CVD3085 Only - Verify the direction of the rotation is

correct on the 3ph scroll compressor. The ice machine will have

high suction pressure, low discharge pressure and will be

noticeably loud. Reverse two incoming power leads to reverse

rotation.

208-230/1/60

208-230/3/60

230/3/60

208-

460/3/50

Max. Fuse/

Circuit

Breaker

15 amp

15 amp

15 amp

15 amp

15 amp

20 amp

15 amp

20 amp

25 amp

20 amp

25 amp

20 amp

15 amp

20 amp

25 amp

15 amp

20 amp

25 amp

20 amp

20 amp

20 amp

15 amp

30 amp

20 amp

15 amp

20 amp

40 amp

25 amp

30 amp

50 amp

40 amp

35 amp

15 amp

Min.

Circuit

Amps

9.6

7.3

9.0

11. 0

7.5

11. 8

9.1

10.0

15.6

10.6

13.8

12.5

9.4

10.9

15.7

10.8

11. 2

14.7

10.6

11. 7

20.0

15.0

20.0

20.0

15.0

20.0

25.0

20.0

20.0

40.0

30.0

30.0

15.0

40 Part Number 80-1505-3 6/10

Page 41

REFRIGERATION SYSTEM INSTALLATION

QuietQube®

Ice Machine

S0600C

IB0620C

S0680C

IB0680C

S0850C

IB0820C

S1000C

IB1020C

S1200C CVD1285

IB1020C

S1470C

S1870C CVD1885

S2070C CVD2075

S2170C CVD2085

S3070C CVD3085

Remote Single

Circuit

Condenser

CVD675

CVD685

CVD885

CVD1085

CVD1185

CVD1285

CVD1075

CVD1485

CVD1486

Line Set*

RC-21

RC-31

RC-51

RC-20

RC-30

RC-50

RC-23

RC-33

RC-53

RC-24

RC-34

RC-54

*Line Set

RC 21/31/51

RC 20/30/50**

RC 23/33/53

Suction

Line

5/8 in.

(15.9 mm)

3/4 in.

(19.1 mm)

3/4 in.

(19.1 mm)

Two Lines -

RC 24/34/54

3/4 in.

(19.1 mm)

**NOTE: The CVD2075 has a suction line fitting of 7/8” and a

liquid line fitting of 5/8”. Since the line set is sized differently,

please use the provided bushings to properly connect the line

set to the CVD condensing unit.

Liquid

Line

3/8 in.

(9.5 mm)

1/2 in.

(12.7 mm)

5/8 in.

(15.9 mm)

One Line -

5/8 in.

(15.9 mm)

Insulation

Thickness

Suction Line

1/2" (13mm)

Liquid Line

1/4" (7mm)

Part Number 80-1505-3 6/10 41

Page 42

Important

Manitowoc remote systems are onl y approved and

!

Caution

!

Caution

warranted as a complete new package. Warranty on

the refr igeration system w ill be void if a new ice

machine h ead section is co nnected to pre-existing

(used) tubing or condensing units or vice versa.

Usage With Non-Manitowoc Condensing Units

Manitowoc CVD® Condensing Units are specifically

designed for usage with a QuietQube® Ice Machine

Head Section. Standard condensing units and NonManitowoc condensing units will not operate a

QuietQube® Ice Machine Head Section.

Factory Equipment Refrigerant Amounts

ICE MACHINE HEAD SECTION

Each ice machine head section ships from the factory

with a R-404A refrigerant charge appropriate for the

entire system operation. The serial tag on the ice

machine indicates the refrigerant charge. The

refrigerant charge is sufficient to operate the ice

machine in ambient temperatures between -20°F to

130°F (-28.9°C to 54.4°C)*. With line set lengths of up

to 100 feet (30.5 m).

*CVD685/CVD1185/CVD2085/CVD3085 =

-20°F to 120°F (-29°C to 49°C)

CVD1486 = 50°F to 110°F (10°C to 43°C)

Never ad d more than n ameplate charge to the

refrigeration system for any application.

The 60-month comp ressor warranty (incl uding the

36-month labor replacement warranty) will not apply

if the Manitowoc Ice Machi ne and Manitowoc CVD

Condensing Uni t a re no t i nstalled accordi ng to

specifications. This warranty also will not apply if the

refrigeration system is mo dified wi th a co ndenser,

heat reclaim device, or other parts or assemblies not

manufactured by Manitowoc Ice.

42 Part Number 80-1505-3 6/10

®

Page 43

!

Warning

Potential Personal Injury Situation

!

Warning

The ice machine hea d se ction cont ains the

refrigerant charge. Installation and brazing of the line

sets must be pe rformed by a prop erly train ed a nd

EPA certified refrigera tion techn ician awa re of the

dangers of dealing with refrigerant ch arged

equipment.

CVD® CONDENSING UNIT

Each condensing unit ships from the factory

pressurized with 50/50 nitrogen helium mixture that

must be removed during the installation process

(approximately 20 psig).

REFRIGERATION LINE SETS/TRAP KIT

Refrigeration Rated Tubing and Trap Kits are shipped

capped with atmospheric pressure.

Installation of a Quie tQube® Condensing U nit may

require the use of sp ecial equipment for place ment.

Trained and qualified person nel are re quired for

proper rigging and lifting.

Part Number 80-1505-3 6/10 43

Page 44

Refrigeration Line Set Installation

!

Warning

!

Warning

Refrigeration line set installation consists of vertical

and horizontal line set distances between the ice

machine and the condensing unit. The following

guidelines, drawings and calculation methods must be

followed to assure proper oil return and CVD

Condensing Unit/ice Machine operation.

The refrigeration line set installer must be USA

Government-Environmental Protection Agency (EPA)

certified in proper refrigerant handling and servicing

procedures.

The ice machine head sectio n co ntains refrigerant

charge. T he ice ma chine hea d section co ntains

three (3) refrigerat ion valve s that must remain

closed un til prope r inst allation of the l ine se ts is

completed.

Disconnect electrical power to the ice machine head

section and CVD® condensing unit before

proceeding.

VERIFY ICE MACHINE AND CVD® CONDENSING

UNIT LOCATIONS ARE WITHIN GUIDELINES.

Prior to installation of the ice machine and CVD®

Condensing Unit be sure that the distance between

them is within the line set routing guidelines outlined in

this manual.

Roof/Wall Penetration

If required, cut a 3-inch (76.2 mm) circular hole in the

wall or roof for routing of refrigeration tubing. A

qualified person must perform all roof penetrations.

ROUTE REFRIGERATION TUBING

Properly route refrigeration tubing between the ice

machine head section and the CVD® condensing unit.

®

44 Part Number 80-1505-3 6/10

Page 45

A. LINE SET LENGTH

!

Caution

Important

QuietQube® Ice Machines will not function with li ne

sets greater than 100 ft. (30.5 m). Do not attempt to

go b eyond this di stance and add refrigerant charge

to compensate!

100 feet (30.5 m) Length: The maximum measured

length the line set can be.

The receiver is designed to hold a charge sufficient to

operate the ice machine in ambient temperatures

between -20°F (-28.9°C) and 130°F (54.4°C)*, with

line set lengths of up to 100 feet (30.5 m).

*CVD685/CVD1185/CVD2085/CVD3085 =

-20°F to 120°F (-29°C to 49°C)

CVD1486 = 50°F to 110°F (10°C to 43°C)The

maximum amount of lineset which can be exposed on

the rooftop is 25% of the total length of the lineset.

QuietQube® ice machines will not function with line

sets greater than 100 feet (30.5 m). Do not attempt

to g o b eyond thi s distance a nd add re frigerant

charge to compensate!

Part Number 80-1505-3 6/10 45

Page 46

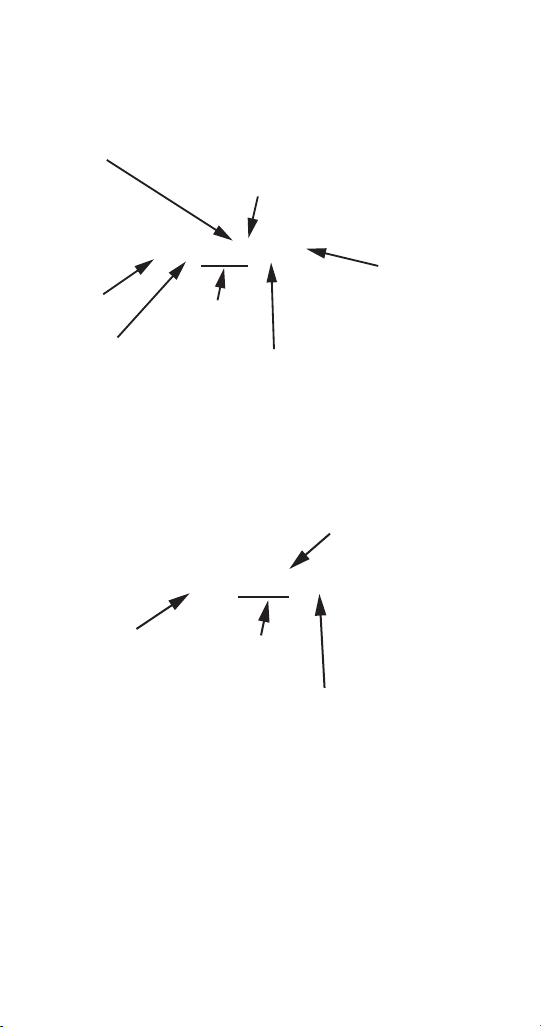

B. Line Set Rise or Drop

SV1751

35 FT. (10.7 M)

MAXIMUM

DISTANCE

SV1750

15 FT . (4.5 M)

MAXIMUM

DISTANCE

35 ft. (10.7 m) Rise: The maximum distance the CVD

Condensing Unit can be above the ice machine.

15 ft. (4.5 m) Drop: The maximum distance the CVD

Condensing Unit can be below the ice machine.

®

®

46 Part Number 80-1505-3 6/10

Page 47

C. Suction Line Oil Traps

!

Caution

21 FT. OR

MORE RISE

ADDITIONAL

TRAP KIT

REQUIRED.

Do no t fo rm un wanted tra ps in refrigeration lines.

Never coil excess refrigeration tubing.

0 to 20 ft. (0 to 6.1 m) Rise: The ice machine head

section has one oil trap built in which allows for a

maximum condenser rise of 20 ft. (6.1 m) without

additional traps in the suction line.

21 to 35 ft. (6.4 to 10.7 m) Rise: The suction line

requires an additional oil trap (“S” type) to be installed.

Install the trap as close as possible to midpoint

between the ice machine head section and CVD

®

Condensing Unit. S-Trap Kits are available from

Manitowoc (refer to chart).

MANITOWOC S-TRAP KIT

Model

S600C IB600C

S680C IB680C

S850C IB800C

S1000C

IB1000C S1200C

S1470C S1870C

S2070C S2170C

S3070C*

* Requires two S-Trap kits, one for each suction line.

Part Number 80-1505-3 6/10 47

S-Trap

Kit

Number

K00172

K00166

Tubing Size

5/8 inch

(15.9 mm)

3/4 inch

(19.1 mm)

Page 48

SERVICE LOOP

!

Caution

!

Caution

!

Warning

• The supplied service loop (on Ice Beverage ice

machines) is an installation requirement.

Excess tubing length must be sufficient to

allow 180° rotation of the ice machine.

• A service loop is not considered an oil trap.

• The service loop is not included when calculating

length, rise or drop of the tubing run.

• Do not use hard rigid copper for the service loop.

If a li ne se t h as a rise fo llowed by a drop , a nother

rise cann ot be mad e. Likew ise, if a li ne se t h as a

drop fo llowed by a rise, another drop cannot be

made.

Step 4 Lengthening or Reducing Line Set Lengths

When the line set requires shortening or lengthening,

do so before connecting the line set to the ice machine

head section or the CVD

Do no t fo rm un wanted tra ps in refrigeration lines.

Never coil excess refrigeration tubing.

Step 5 Connecting the line set.

To prevent oxidation of the copper, purge line set and

condensing unit with dry nitrogen while brazing.

®

Condensing Unit.

The ice machine head sectio n co ntains refrigerant

charge. T he ice ma chine hea d section co ntains

three (3) refrigerat ion valve s that must remain

closed un til prope r inst allation of the l ine se ts is

completed.

48 Part Number 80-1505-3 6/10

Page 49

CONNECT THE LINE SET TO THE ICE MACHINE

VALVES MUST REMAIN CLOSED AND BE

PROTECTED FROM HEAT WHEN BRAZING

(WRAP WITH WET RAG)

HEAD SECTION

The line set can be routed for entry through the top or

rear of the ice machine head section.

• Top routing requires the cover to be trimmed.

• Rear routing requires the use of the supplied 90°

elbows.

The line set shut-off valves at the back of the ice

machine must remain closed and be protected from

heat during the brazing process. Wrap the valves in a

wet rag or other type of heat sink prior to brazing. Cool

braze joint with water immediately after brazing to

prevent heat migration to the valve.

Part Number 80-1505-3 6/10 49

Page 50

CONNECT THE LINE SET TO THE CVD®

!

Warning

MINIMIZE THE TIME THE REFRIGERATION

SYSTEM IS EXPOSED TO THE ATMOSPHERE

(15 MINUTES MAXIMUM).

SUCTION

FILTER

SUCTION LINE

CONDENSING UNIT

The cond ensing u nit shi ps from the factory

pressurized with a 50/50 mixture of nitroge n/helium.

Bleed o ff pressure from bo th suction and liquid line

access ports prior to cutting into refrigeration lines.

The compressor oil rapidly absorbs moisture. Be

prepared to complete line set installation and start

your evacuation process in order to minimize the time

the compressor is exposed to the atmosphere.

(Maximum amount of time the system can be exposed

to the atmosphere is 15 minutes.)

The line set can be routed for entry through the front or

left side of the condensing unit.

• Remove knockout for side location.

• Insert supplied plastic bushings in knockout holes

to prevent tubing from contacting sheet metal.

• Use the supplied 90° elbows to route tubing.

• Cut the tubing ends of the suction and liquid lines

and braze line sets to the condensing unit.

• S3070C Only - use the provided tee to connect

the 2 suction lines from the head section to the

suction line on the condensing unit.

50 Part Number 80-1505-3 6/10

Page 51

LIQUID

LINE

SUCTION

LINE

SUCTION

LINE

FROM

HEAD

SECTION

SUCTION

LINE

FROM

HEAD

SECTION

SUCTION LINE ON

CONDENSING UNIT

S3070C TUBING

MUST BE

CONNECTED TO

TEE AS SHOWN

Part Number 80-1505-3 6/10 51

Page 52

PRESSURE TEST AND EVACUATE THE LINE SET AND CVD CONDENSING UNIT

Schrader valve core removal tools that allow for

removal and installation of the valve cores without

removing manifold gauge set hoses are recommended

to decrease the evacuation time.

Leave the line set shut-off valves closed (front seated).

All CVD condensing units manufactured after

December 2009 contain a check valve in the

compressor discharge line. The check valve

requires an additional connection on the condensing

unit during evacuation and recovery procedures.

Connections are required at five points:

Ice Machine Head Section

1. Receiver Service Valve

2. Low Side Access Valve

3. High Side Access Valve

CVD Condensing Unit

4. Compressor Discharge Access Valve

5. Suction Filter Access Valve

52 Part Number 80-1505-3 6/10

Page 53

Connection of a manifold gauge set (or a hose with

CHECK VAL VE

CONNECT MANIFOLD GAUGE SET OR

HOSE WITH CORE DEPRESSORS ON BOTH ENDS

C

O

N

D

E

N

S

E

R

LINESET

CONNECTION

LOCATION

core depressors on both ends) between the suction

filter access port and the compressor access valve

(located between the compressor and discharge line

check valve) is required.

Pressure test the line sets and CVD

with 150 psig of dry nitrogen. Add nitrogen at the line

set shut-off valves located at the back of the ice

machine head section or from the schrader valves

located in the CVD® Condensing Unit. Complete the

pressure test, verify no leaks are present and remove

the nitrogen from the system before connecting the

vacuum pump.

Part Number 80-1505-3 6/10 53

®

Condensing Unit

Page 54

Connect a vacuum pump to both of the line set shut-off

CONNECT VACUUM

PUMP TO LINE SET

SHUT-OFF VALVES.

ALTERNATE CONNECTIONS AT

CONDENSING UNIT SCHRADER VALVES

valves located at the back of the ice machine head

section or from the schrader valves located in the

®

CVD

Condensing Unit. Schrader valve core removal

tools (that allow for putting the cores back in without

removing vacuum pump hoses) will greatly decrease

evacuation time.

Evacuate to 500 microns (or less) at the CVD

condensing unit.

Isolate the vacuum pump from the line set shut-off

valves and/or condensing unit access ports prior to

proceeding.

54 Part Number 80-1505-3 6/10

Page 55

OPEN REFRIGERATION SERVICE VALVES

USE ALLEN WRENCH TO OPEN

(TURN COUNTERCLOCKWISE)

LIQUID AND SUCTION LINE

SHUT-OFF VALVES.

USE ALLEN WRENCH TO

OPEN (TURN

COUNTERCLOCKWISE)

LIQUID AND SUCTION LINE

SHUT OFF VALVES

IB Series

S600C/S680C/S850C/S1000C/S1200C

OPEN SUCTION AND LIQUID LINE SHUT OFF VALVES

The suction line, liquid line and receiver service valves

are closed during shipment and installation.

Open the valves prior to starting the ice machine.

A. Slowly backseat (open – turn

counterclockwise) the suction line shut-off

valve.

B. Slowly backseat (open – turn

counterclockwise) the liquid line shut-off

valve.

C. Slowly backseat (open-turn

counterclockwise) the receiver service valve.

NOTE: You will not hear refrigerant flow when the valves are

opened. Refrigerant will not flow until the toggle switch is

placed in the ice position and the solenoid valve opens.

Part Number 80-1505-3 6/10 55

Page 56

USE ALLEN WRENCH TO

OPEN (TURN

COUNTERCLOCKWISE)

LIQUID AND SUCTION LINE

SHUT OFF VALVES

OPEN SUCTION AND LIQUID LINE SHUT OFF VALVES

S1470C/S1870C/S2070C/S2170C

56 Part Number 80-1505-3 6/10

Page 57

S3070C

!

Caution

Important

USE ALLEN WRENCH

TO OPEN (TURN

LIQUID AND SUCTION

LINE SHUT OFF

VALVES

After op ening suctio n, discharge a nd receiver

service valve s, refrige rant pressure w ill n ot be

detected until the togg le swit ch is place d in the ice

position and the harvest valve energizes.

All refrige ration valve ca ps must be reinstalled to

prevent future refrigeration leaks.

Part Number 80-1505-3 6/10 57

Page 58

Verify O-rings in schrader valve caps are intact and

SV1756

TURN

COUNTERCLOCKWISE

TO OPEN.

RECEIVER SERVICE VALVE CAP

(TURN COUNTERCLOCKWISE

TO REMOVE.)

RECEIVER SERVICE VALVE

reinstall on shut-off valves to prevent refrigerant

leakage. Replace shut-off valve access caps and

torque to the following specifications.

Torque Values

Stem 18-20 ft. lbs.

Caps 12-15 ft. lbs.

Schrader Core 1.5-3 in. lbs.

Replace cap on receiver service valve and tighten.

There is a liquid line solenoid valve at the outlet of the

receiver; refrigerant will not flow to the condensing unit

until the ice machine head section is started. Connect

power to both the ice machine head section and the

®

CVD

Condensing Unit. Place the ice machine toggle

switch into the ICE position; this will allow refrigerant

to enter the line set and condensing unit.

LEAK CHECK THE REFRIGERATION SYSTEM

Leak check the new line set connections at the ice

machine head section, condensing unit and S-trap as

well as all factory joints throughout the entire system.

Disconnect power to the CVD

®

Condensing Unit.

Place the ICE/OFF/CLEAN toggle switch in the ICE

position. This allows the low side and high side

pressures to equalize. Place the ICE/OFF/CLEAN

toggle switch in the OFF position. Connect power to

the CVD

®

Condensing Unit and allow system to pump

down.

58 Part Number 80-1505-3 6/10

Page 59

INSULATION REQUIREMENTS

Important

To prevent condensation, the entire suction line

including the shut-off valve must be insulated. All

insulation must be airtight and sealed at both ends.

The following insulation requirements prevent

condensation at 90°F (32.2°C) ambient 90% Relative

Humidity. If higher humidity is expected, increase

insulation thickness.

The entire suction line set, including the suction service

valve located on the back of the ice machine, requires:

Suction Line Liquid Line

3/4 inch

(19.1 mm)

5/8 inch

(15.9 mm)

3/4 inch

(19.1 mm)

1/2 inch

(12.7 mm)

3/8 inch

(9.5 mm)

5/8 inch

(15.9 mm)

Min. Insulation

Thickness

1/2”(13mm)

Suction Line

1/4” (7mm)

Liquid Line

To preve nt condensation th e entire sucti on lin e

including th e sh ut off va lve mu st be insu lated. Al l

insulation must be airtight and sealed at both ends.

The min imum requirements are for condi tions at or

below 90% h umidity an d 90 °F (32 .2°C) ambient.

When higher humidity will be experienced, insulation

wall thickness will need to be increased.

Part Number 80-1505-3 6/10 59

Page 60

Suction Shut-off Valve In su lation

PREFORMED

INSULATION

TIGHTEN VALVE CAPS

TO SPECIFICATIONS.

PLACE TAB BETWEEN

VALVE BODY AND PANEL.

FOLD INSULATION OVER

RIGHT SIDE OF VALVE

AND SECURE WITH

ELECTRICAL TAPE.

The preformed suction shut-off valve insulation is

located in the plastic bag taped to the water curtain.

A. Verify valve and schrader caps are tightened

to specifications (see step 6).

B. Place insulation over schrader valve cap and

left side of valve. Position the tab between

the mounting bracket and rear panel.

C. Fold insulation and hold against right hand

side of valve while securing with electrical

tape. Seal the line set insulation to the shutoff valve insulation with electrical tape.

60 Part Number 80-1505-3 6/10

Page 61

Operational Checks

GENERAL

Your Manitowoc ice machine was factory-operated

and adjusted before shipment. Normally, a newly

installed ice machine does not require any adjustment.

To ensure proper operation, always perform these

Operational Checks when starting the ice machine:

• For the First Time

• After a Prolonged Out-of-Service Period

• After Cleaning and Sanitizing

Routine adjustments and maintenance procedures

outlined in this manual are not covered by the

warranty.

WATER LEVEL

The water level sensor is set to maintain the proper

water level above the water pump housing. The water

level is not adjustable.

If the water level is incorrect, check the water level

probe for damage (probe bent, etc.). Clean, repair or

replace the probe as necessary.

Part Number 80-1505-3 6/10 61

Page 62

ICE THICKNESS CHECK

SV3113

ADJUSTING

SCREW

ICE THICKNESS ADJUSTMENT

1/8” ICE BRIDGE THICKNESS

After a harvest cycle, inspect the ice cubes in the ice

storage bin. The ice thickness probe is factory-set to

maintain the ice bridge thickness at 1/8” (3.2 mm).

NOTE: Make sure the water curtain is in place when

performing this check. It prevents water from splashing

out of the water trough.

1. Inspect the bridge connecting the cubes. It should

be about 1/8" (3.2 mm) thick.

2. If adjustment is necessary, turn the ice thickness

probe adjustment screw clockwise to increase

bridge thickness, counterclockwise to decrease

bridge thickness. Set at 1/4” gap between ice

machine and evaporator as starting point, then

adjust to achieve a 1/8" bridge thickness.

NOTE: Turning the adjustment 1/3 of a turn will

change the ice thickness about 1/16" (1.5 mm).

3. Make sure the ice thickness probe wire and

bracket do not restrict movement of the probe.

62 Part Number 80-1505-3 6/10

Page 63

HARVEST SEQUENCE WATER PURGE

!

Warning

Important

45 second

setting

0 second

setting

The Harvest sequence water purge adjustment may

only be used when the ice machine is hooked up to

special water systems, such as a reverse osmosis or

de-ionized water treatment system.

Disconnect elect ric power to the ice machine at the

electrical disconnect before proceeding.

The Harvest sequence water purg e is factory-set at 45

seconds. A shorter purge se tting (w ith st andard water

supplies such as city water) is not recommended. This can

increase w ater system cleaning and sa nitizing

requirements.

• The Harvest sequence water purge may be set to

0 or 45 seconds. Repositioning the jumper will set

the harvest water purge to 0 seconds. This setting

does not affect the SeCs or AuCS (cleaning)

sequences.

• During the Harvest sequence water purge, the

water fill valve energizes and de-energizes by

time. The water purge must be at the factory

setting of 45 seconds for the water fill valve to

energize during the last 15 seconds of the water

purge. If it is set to 0 seconds, the water fill valve

will not energize during the water purge.

Part Number 80-1505-3 6/10 63

Page 64

Electronic Bin Thermostat Instructions

Final Position

A. Loosen

Rear

Screw

B. Remove

Front Screw &

Rotate Probe/

Bracket.

Re-install

Screw

Control

Location

IB600C/IB680C/IB800C/IB1000C Only

POSITIONING

1. Remove water trough.

2. Refer illustration below.

A. Loosen rear screw.

B. Remove front screw & rotate probe/bracket.

C. Re-install front screw & tighten.

D. Tighten rear screw.

3. Re-install water trough.

4. Remove slack from sensor probe wire and verify wire

does not contact or obstruct the water curtain or water

level probe.

5. The control is preset and does not require programming.

For control specifications refer to page page 193.

Bin Thermostat Location

Control Location

64 Part Number 80-1505-3 6/10

Page 65

Part Number 80-1505-3 6/10 65

This Page Intentionally Left Blan k

Page 66

66 Part Number 80-1505-3 6/10

This Page Intentionally Left Blan k

Page 67

Component Identification

WATER CURTAIN

CONTROL BOX

WATER

DISTRIBUTION

TUBE

TOGGLE

SWITCH

WATER

TROUGH

REFRIGERATION

ACCESS VALVES

ICE

THICKNESS

CONTROL

EVAPORATOR

WA TER LEVEL

PROBE

WATER PUMP

WATER INLET

LOCATION, THE

WA TER INLET V ALVE

IS LOCATED IN THE

REFRIGERATION

COMPARTMENT

ICE MACHINE HEAD SECTIONS

S600C/S680C/S850C/S1000C/S1200C

Part Number 80-1505-3 6/10 67

Page 68

S1470C/S1870C/S2070C/S2170C

AIR

PUMP

DISTRIBUTION

TUBE

ICE

THICKNESS

PROBE

EVAPORATOR

SPLASH

SHIELD

BIN

SWITCH

WATER

TROUGH

SHIELD

ICE

DAMPER

WATER

TROUGH

WATER

PUMP

DUMP

VALVE

RECEIVER

LIQUID LINE

SOLENOID

VALVE

DRIER

ICE/OFF/

CLEAN

SWITCH

WATER

LEVEL

PROBE

LEFT SIDE

HARVEST

VALVE

TXV SENSING

BULB

BOOT

AIR

PUMP

EXPANSION

VALVE

WATER

INLET

VALVE

68 Part Number 80-1505-3 6/10

Page 69

IB0600C/IB0680C/IB0800C/IB1000C

WATER

DISTRIBUTION

TUBE

WATER

CURTAIN

DUMP

VALVE

SHUT OFF

VALVES

ELECTRICAL

COMPARTMENT

ICE/OFF/CLEAN

TOGGLE

SWITCH

ICE

THICKNESS

PROBE

WATER

TROUGH

COOL

VAPOR

VALVE

LIQUID LINE

SOLENOID

VALVE

RECEIVERS

LIQUID

LINE

DRIER

WATER

INLET

VALVE

RECEIVER

SERVICE

VALVE

ELECTRICAL

COMPARTMENT

DISCHARGE

LINE

CHECK

VALVE

Part Number 80-1505-3 6/10 69

Page 70

S3070C

WATER

PUMPS

WA TER LEVEL

PROBE

EVAPORATORS

WATER

TROUGH

CONTROL

BOX

ICE DAMPERS

ICE

THICKNESS

PROBE

ICE

THICKNESS

PROBE

70 Part Number 80-1505-3 6/10

Page 71

CVD® CONDENSING UNITS

ACCESS

VALVE

CONDENSER

FAN MOTOR

HEAD PRESSURE

CONTROL VALVE

AIR

CONDENSER

COMPRESSOR

SUCTION

ACCUMULATOR

LIQUID LINE AND

SUCTION LINE

CONNECTION

POINTS

ELECTRICAL

COMPARTMENT

CHECK VALVE

ACCESS VALVE

LPCO

HEAD PRESSURE

CONTROL VALVE

ELECTRICAL

COMPARTMENT

COMPRESSOR

SUCTION

ACCUMULATOR

WATER

REGULATING

VALVE

LIQUID LINE

AND SUCTION LINE

CONNECTION

POINTS

WATER

COOLED

CONDENSER

CVD675/CVD685/CVD875/CVD885/CVD1075/CVD1085/ CVD1185/CVD1285/CVD1485

CVD1486

Part Number 80-1505-3 6/10 71

Page 72

CVD1885/CVD2075/CVD2085/CVD3085

SUCTION

ACCUMULATOR

COMPRESSOR

LIQUID LINE

AND

SUCTION LINE

CONNECTION

POINTS

AIR

CONDENSER

HEAD PRESSURE

CONTROL VALVE

CONDENSER

FAN MOTOR

(CVD3085 HAS 2 FANS)

ACCESS

VALVES

ELECTRICAL

COMP.