Page 1

Q MODEL

DISPENSER

Q160/290/300

Installation,

Use, and Care

Thank you for selecting a Manitowoc Dispenser, the dependability leader in ice making equipment and related

products. With proper care and maintenance, your new Manitowoc Dispenser will provide you with many years

of reliable and economical performance.

Part Number

80-1388-3

Page 2

Safety Notices

Procedural Notices

Installation and start-up of this equipment should be

done by a qualified service technician.

When using or servicing a Q Model Dispenser, be sure

to pay close attention to the safety notices in this

manual. Disregarding the notices may lead to serious

injury and/or damage to the dispenser.

Throughout this manual, you will see the following

types of safety notices:

WARNING

Text in a Warning box alerts you to a potential

personal injury situation. Be sure to read the Warning

statement, and then proceed carefully.

CAUTION

Text in a Caution box alerts you to a situation in

which you could damage the dispenser. Be sure to

read the Caution statement, and then proceed

carefully.

When using or servicing a Q Model Dispenser, be sure

to read the procedural notices in this manual. These

notices supply helpful and important information.

Throughout this manual, you will see the following

types of procedural notices:

NOTE: Text set off as a Note provides you with

simple, but useful, extra information.

Important

Important boxes serve two functions.

They call the operator’s attention to important

information.

They also provide the service technician with

information that may help perform a procedure

more efficiently. Disregarding this information may

slow down the work.

CAUTION

Proper care and maintenance are essential for troublefree operation of your Manitowoc Dispenser.

Read and understand this manual. It contains valuable

care and maintenance information. If you encounter

problems not covered by this manual, feel free to

contact Manitowoc Ice, Inc. We will be happy to

provide assistance.

WARNING

Personal Injury Potential

Do not operate equipment that has been misused,

abused, neglected, damaged, or altered/modified from

that of original manufactured specifications.

2

Page 3

Page 4

We reserve the right to make product

improvements at any time.

Specifications and design are subject to

change wi thout notice.

MANITOWOC ICE, INC.

2110 South 26th Street P.O. Box 1720

Manitowoc, WI 54221-1720

Phone: (920) 682-0161

Service Fax: (920) 683-7585

Web Site - www.manitowocice.com

2002 Manitowoc Ice, Inc.

Litho in USA

Page 5

Table of Contents

Table of Contents

Section 1 - General Information

Foreword..................................................................................................................................................................1-1

Model/Serial Number Location..............................................................................................................................1-1

Warranty Information............................................................................................................................................1-2

Equipment Overview...............................................................................................................................................1-3

Section 2 – Equipment Specifications

Q Series Measurements...........................................................................................................................................2-1

Q Series Metric Measurements..............................................................................................................................2-2

Section 3 – Installation Procedures

Installation Check List............................................................................................................................................3-1

Installation Procedures...........................................................................................................................................3-3

Post-Installation Check List...................................................................................................................................3-4

Section 4 - Maintenance

Disassembling the Dispenser Parts

For Cleaning (Door Removal)................................................................................................................................4-1

Cleaning the Drain Pan...........................................................................................................................................4-2

Disassembling the Rocking Chute/Door................................................................................................................4-3

Re-Installing the Paddle Wheel Guard .................................................................................................................4-6

Disassembling the Dispenser Parts for Bin Cleaning

(Agitator and Paddle Wheel Removal)..................................................................................................................4-7

Monthly Sanitizing Procedure................................................................................................................................4-9

Sanitizing Procedure for

Water Valve Assembly............................................................................................................................................4-10

i

Page 6

Table of Contents

Table of Contents (continued)

Section 5 – Component Parts-Removal and Replacement

Gearmotor Shaft Seal Replacement ......................................................................................................................5-1

Removal of Front Panel of Dispenser

(See pages 4-1 and 4-2)

Removal of Pin, Agitator and Paddle Wheel

(See pages 4-5and 4-6)

Section 6 – Checklist

Problem: Ice Does Not Dispense When Rocking Chute is Depressed................................................................6-1

ii

Page 7

Section 1 General Information

N

N

General Information

This manual is a reference guide for the

owner/operator, service agent and installer of this

equipment. Please read this manual before

installation or operation of the machine. If you

encounter a problem, first consult the Trouble

shooting Guide or Adjustments sections of this

manual. I

f you cannot correct the problem, call your

Manitowoc Service Agent, Distributor or the Factory.

Always have your model and serial number available

when you call.

Q1000 Ice Machines are not approved for use on a QModel Dispenser.

Earthquake kits are available to secure the ice machine

to the dispenser and the dispenser to the floor.

Adapter Kit

A 22’’ wide machine mounted to a 30’’ wide dispenser

requires an adapter kit

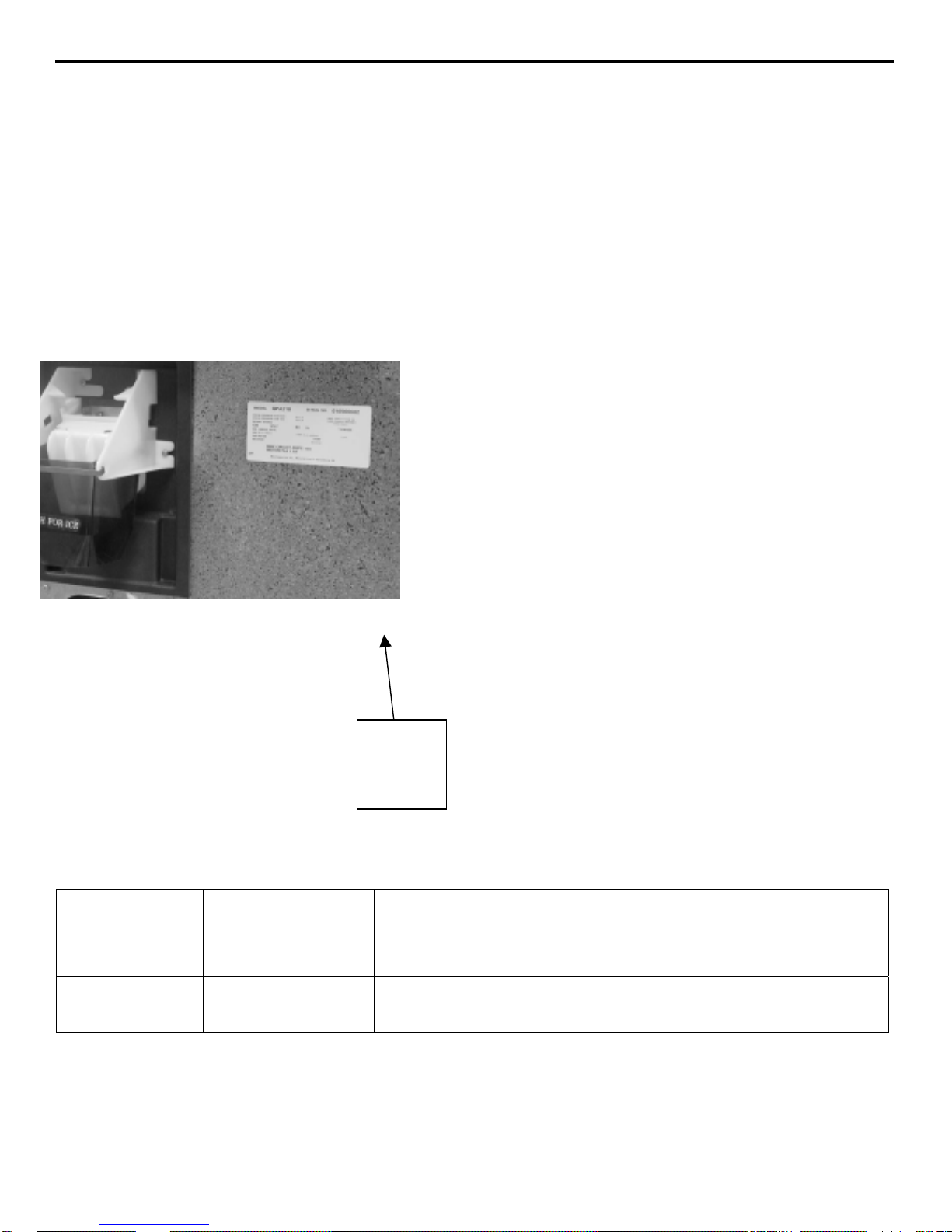

Front of Dispenser

Label with Model Number and

Serial Number is located behind

the front panel, to the right of

the rocking chute.

Locations of Model Number and Serial Number

Back of Dispenser

A second location for the Model

Number and Serial Number is on

Model

umber/

Serial

umber

the back of the dispenser, in the

upper right corner..

Dispensers Covered in This Manual

Series

Q160

Q300

Q290

Rocking Chute

Operated

QPA160 QRA164 QCA163 N/A

QPA310 QRA340 QCA330 N/A

N/A N/A N/A QFA291

NOTE: These dispensers are designed to dispense both dice and half dice ice.

These dispensers may be used in conjunction with a Manitowoc ice machine for automatic fill of dispenser.

Q160 dispensers are capable of storing 120 lbs. of ice.

Q290/Q300 dispensers are capable of storing 180 lbs. of ice.

Card Operated Coin Operated

Glass Fill

Dispenser

1-1

Page 8

General Information Section 1

WARRANTY INFORMATION

The packet containing this manual also includes

warranty information. Warranty coverage begins the

day your new dispenser is installed.

2. Repairs due to unauthorized modifications to the

dispenser or the use of non-standard parts without

prior written approval from Manitowoc Ice, Inc.

Important

Complete and mail the OWNER WARRANTY

REGISTRATION CARD as soon as possible to

validate the installation date.

3. Damage caused by improper installation of the

dispenser, electrical supply, water supply or

drainage, or damage caused by floods, storms, or

other acts of God.

If you do not return your OWNER WARRANTY

REGISTRATION CARD, Manitowoc will use the

date of sale to the Manitowoc Distributor as the first

day of warranty coverage for your new dispenser.

4. Premium labor rates due to holidays, overtime, etc.;

travel time; flat rate service call charges; mileage

and miscellaneous tools and material charges not

listed on the payment schedule. Additional labor

WARRANTY COVERAGE

The following Warranty outline is provided for your

convenience. For a detailed explanation, read the

warranty bond shipped with each product.

Contact your local Manitowoc representative or

Manitowoc Ice, Inc. if you need further warranty

information.

charges resulting from the inaccessibility of the

dispenser are also excluded.

5. Parts or assemblies subjected to misuse, abuse,

neglect or accidents.

6. Damage or problems caused by installation,

cleaning and/or maintenance procedures

inconsistent with the technical instructions provided

PARTS

in this manual.

Manitowoc warrants the dispenser against defects in

materials and workmanship, under normal use and

service, for three (3) years from the date of original

installation.

AUTHORIZED WARRANTY SERVICE

To comply with the provisions of the warranty, a

refrigeration service company, qualified and authorized

by a Manitowoc distributor, or a Contracted Service

LABOR

Labor required to repair or replace defective

components is covered for three (3) years from the date

of original installation.

Representative must perform the warranty repair.

NOTE: If the dealer the dispenser was purchased from

is not authorized to perform warranty service, contact

the Manitowoc distributor or Manitowoc Ice, Inc. for

the name of the nearest authorized service

EXCLUSIONS

representative.

The following items are not included in the dispenser’s

warranty coverage:

SERVICE CALLS

If you have followed the procedures listed the

1. Normal maintenance, adjustments and cleaning as

outlined in this manual.

Troubleshooting Guide of this manual, and the

dispenser still does not perform properly, call your

authorized service company.

1-2

Page 9

Section 1 General Information

A

r

A

r

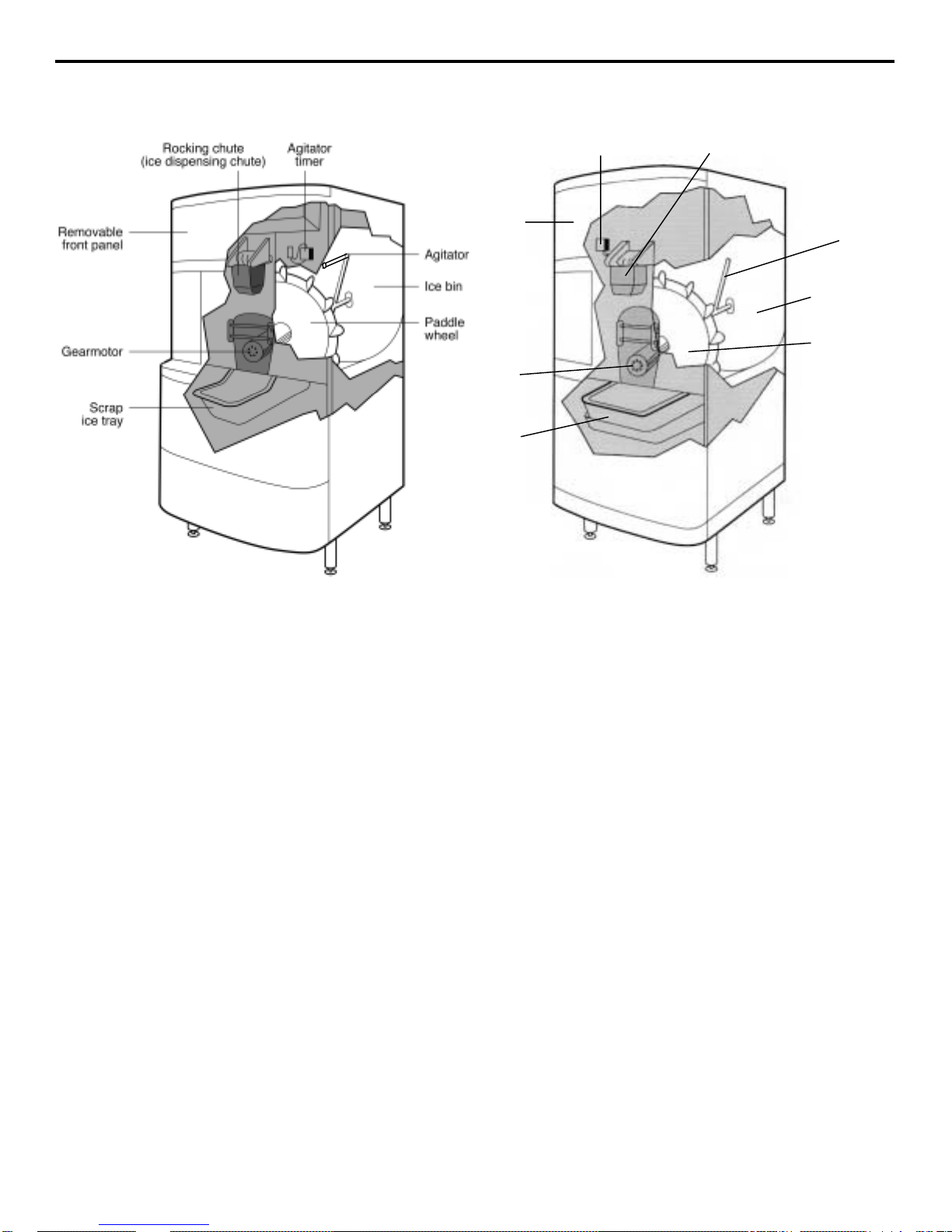

Equipment Overview

Q300 Dispensers

Removable

front panel

Gearmotor

Scrap ice

tray

gitator time

Q160 Dispensers

Rocking chute

gitato

Ice bin

Paddle

wheel

The operation of the Q Series ice dispenser can be

divided into three main operations. They are Dispenser

Activation, Ice Pick-Up and Ice Delivery.

Dispenser Activation

Dispenser activation can be accomplished with a

number of different mechanisms.

• Rocking Chute (Push for Ice) Activation –User

pushes the Rocking Chute, which energizes a

microswitch. The energized microswitch engages

the gearmotor.

• Room Key Card Activation – User places their

hotel room key card into a slot on the dispenser.

The room key card activates the microswitch. The

user then presses the Rocking Chute (Push for Ice)

for ice dispense. This action activates the

gearmotor.

• Coin Operated Activation – User places one

quarter into dispenser. The quarter activates the

coin mechanism. The user then presses the Rocking

Chute (Push for Ice) for ice dispense. This action

activates the gearmotor.

Ice Pick-Up

When the customer activates the dispenser, the

gearmotor inside the dispenser begins to turn.

The gearmotor shaft is attached to the paddle wheel

inside the bin of the dispenser. As the paddle wheel

turns it picks up ice from the dispenser bin. The paddle

wheel will bring the pocket containing the ice to the top

of the travel area.

Ice Delivery

When the paddle wheel pocket reaches the top of its

travel, the ice falls from the paddle wheel to the ice

chute opening of the dispenser bin. The bin chute then

directs the ice to the door assembly.

If the door closes before all the ice is dispensed, some

ice may be held back by the door assembly. If the door

is open, the ice will fall through the door and the ice

chute. The ice chute will direct the ice into the

customer’s container.

Model QFA-291 is equipped with an optional water

valve. When the water valve lever is pressed, water

flows through the system to the water valve nozzle.

1-3

Page 10

General Information Section 1

Room Key Card Activation

Coin Operated Activation

1. User places ice bucket under ice chute.

2. User places their hotel room key card into a slot

on the dispenser which is labeled “Insert Room

Key Card”. The room key activates the

microswitch.

3. The user then presses the Rocking Chute (Push

for Ice) for ice dispense. Pushing the ice chute

activates the gearmotor.

The room key card must stay in the slot for the

microswitch to remain activated.

1. User places ice bucket under ice chute.

2. User places one quarter (U.S. currency only) into

dispenser.

3. The user then presses the Rocking Chute (Push for

Ice) for ice dispense.

Pushing the ice chute activates the gearmotor. Ice

will dispense for up to one minute for each 25 cent

activation per factory setting.

Important

Coin Operated Activation will accept U.S. quarters

only. No other coin is accepted and no change is

returned to the user. To allow use of Canadian

coins, please contact your local dealer.

1-4

Page 11

Section 1 General Information

Adjusting the Coin Mechanism Timer

1. Remove the control box cover. On the inside of

the control box there is a white instruction label

which shows how to set intervals for coin

mechanism dispense times.

2. Inside the control box, the coin mechanism timer

is to the left. The ice agitation timer is to the

right.

3. With a small Phillips head screwdriver, adjust the

coin mechanism timer. For timer adjustment

reference information, see below or refer to the

white instruction label inside the control box

cover.

4. The timer is factory set at the midpoint (as shown

above) for 60 seconds of dispense time.

The adjustment pot can be set (counterclockwise)

for as low as 12 seconds of dispense time.

The adjustment pot can be set (clockwise) for as

high as 120 seconds of dispense time.

COIN MECHANISM

TIMER

1-5

Page 12

General Information Section 1

Adjusting the Coin Mechanism for Canadian Coins

Important

Canadian quarters are magnetic. Therefore the

magnet inside the coin mechanism must be

removed so Canadian quarters will drop through

the coin mechanism.

1. Remove the front panel of the dispenser. The

coin mechanism can be changed while in place in

the dispenser door, as shown above.

2. Pivot the coin magnet housing section away from

the rest of the coin mechanism.

3. Using a small screwdriver, loosen the set screw

which holds an aluminum plate in the coin

magnet housing.

4. Remove the aluminum plate.

5. Using a metal screwdriver tip, pull out the magnet

from the magnet housing. (The backside of the

magnet has the stronger magnetic attraction.)

6. The aluminum plate and magnet have now been

removed from the coin magnet housing. Pivot the

empty coin magnet housing section back into

place.

7. Reinstall the front door of the dispenser.

1-6

Page 13

Section 2

Installation

Pre-Installation Checks

For Q Series Dispensers

Front View

Back View

Side View

NOTE:

Dispensers must be

installed on a solid,

level floor or surface.

2-1

Page 14

Installation Section 2

Pre-Installation Checks

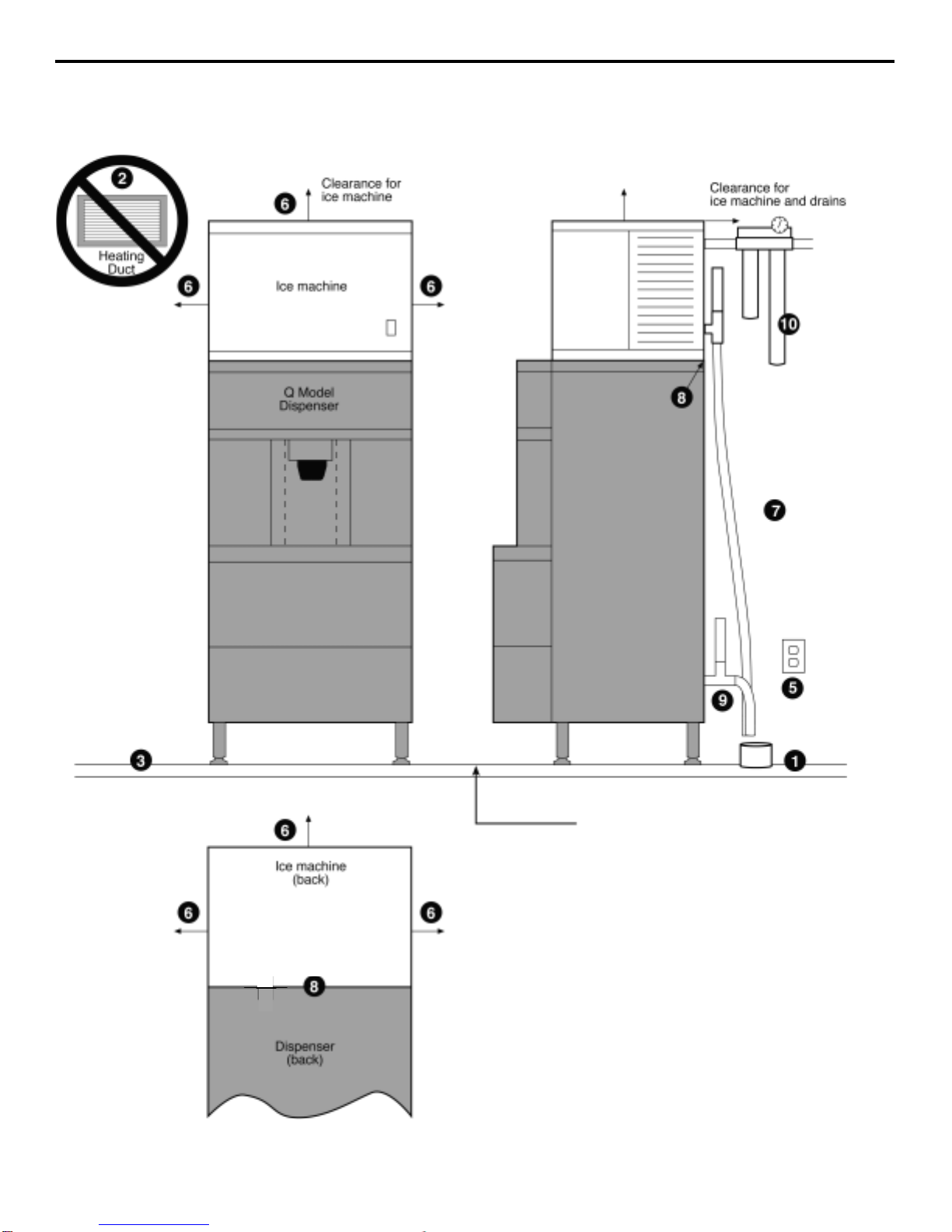

1. Location: Floor drain available - A floor drain

for the dispenser should be available. We

recommend that you vent the drain at the back of

the dispenser to reduce buildup of algae and

improve drainage. Drain tubing should be ½” I.D.

at minimum.

2. Location: Avoid heat sources – Avoid placing

the ice machine near heat sources such as

radiators, heating vents and direct sunlight. Avoid

placing air-cooled ice machines in kitchens, due to

grease, flour, or other particles, which can collect

on the condenser and fan blade, increasing ice

machine maintenance and reducing ice machine

efficiency.

3. Location: On a solid floor – The dispenser and

ice maker should be sitting on a good, solid, level

floor or surface.

4. Location: Do not obstruct traffic – The

dispenser should not extend from the wall in a

way that obstructs traffic through the area.

5. Electrical – Proper electrical voltage is available.

Receptacle is available and

within six feet.

The dispenser must be grounded in accordance with

all local and national electrical codes.

WARNING

Never use an extension cord. If an electrical outlet is

not within six feet, have proper amperage outlet

installed.

6. Clearances for top and both sides of ice

machine – Use clearances specified in the ice

machine’s Installation and Use & Care Guide.

7. Clearance behind ice machine for dispenser

and drains – The location must allow enough

clearance for the water and drain connection at the

rear of the dispenser.

8. Back of ice machine to be flush with back of

dispenser – This allows easy removal of dispenser

front panel.

9. Separate drains – a separate drain line is required

for the ice machine, in addition to a drain line for

the Q Series Dispenser. Vent all drain lines.

10. Water filtration – Water filtration is strongly

recommended in order to increase the performance

of the ice machine and reduce maintenance costs.

For full information about ice machine installation,

including plumbing lines, connections and electrical

requirements, see the ice machine installation manual.

WARNING

2-2

Page 15

Section 2

Installation Procedures

Installation

Do not attempt to move a dispenser without first

removing the ice machine. The combination can be

unstable and could tip, causing serious injury.

WARNING

1. Review the installation Check List then make sure

all utility and space requirements are present at the

installation site.

2. Remove the carton top from the dispenser.

3. Remove the legs and other accessories from inside

the dispenser bin.

4. Remove the carton from the sides of the dispenser.

5. Remove the dispenser from the shipping pallet.

6. Flatten the shipping carton.

7. Lay the dispenser on it back on the carton.

8. Thread the legs into the bottom of the dispenser.

9. Set the dispenser upright.

13. Connect the drain of the dispenser to the floor drain.

Vent the drain at the back of the dispenser to reduce

buildup of algae and improve drainage.

14. Follow local plumbing codes for drain installation.

15. If the dispenser has a water valve, connect your

water line to the water connection at the back of the

dispenser.

16. Test all drain and water lines for leaks.

17. Plug the dispenser into the proper electrical outlet.

18. Clean and sanitize all equipment. Follow cleaning

and sanitizing instructions in this manual.

19. Adjust the ice machine according to the

instructions provided with the ice machine.

20. Install ice baffle inside the ice maker

compartment. Follow installation instructions

supplied with ice baffle.

21. Install foam gasket on the bottom of the front

panel.

10. Place the dispenser in the desired location.

11. Make sure the dispenser bin top is level. A level bin

is important for proper operation of the ice machine.

12. Place the ice machine on top of the dispenser at this

time.

22. Fill the dispenser bin one quarter full of ice or start

the ice machine, allowing the ice machine to drop

at least three complete batches of ice.

23. Test the ice dispensing action of the dispenser

2-3

Page 16

Installation Section 2

Post-Installation Checks

1. Dispenser and ice machine are level?

2. Drains are vented?

3. Dispenser does not sit in direct sunlight?

4. Dispenser does not sit in direct airflow from a

heating duct?

5. Bin and ice machine drains are separate?

6. Ice dispenses properly?

7. Dispenser is accessible for servicing?

8. Ice Machine ice thickness control is properly set?

9. The warranty card was returned?

10. Owner was instructed on the operation of the

dispenser?

11. Owner knows how to clean and sanitize the

dispenser?

12. Owner knows how often to clean and sanitize the

dispenser?

13. Owner has your telephone number to call for followup service on the dispenser?

14. You have placed one of your service stickers on the

dispenser for follow-up service?

2-4

Page 17

Section 3

Installation

Installation Check List

For Q Series Dispensers

Front View

Back View

Side View

NOTE:

Dispensers must be

installed on a solid,

level floor or surface.

3-1

Page 18

Installation Section 3

With Top-Mounted Ice Machines

Installation Check List

For Q Series Dispensers

1. Location: Floor drain available - A floor drain

for the dispenser should be available. We

recommend that you vent the drain at the back of

the dispenser to reduce buildup of algae and

improve drainage. Drain tubing should be ½”

I.D. at minimum.

2. Location: Avoid heat sources – Avoid placing

the ice machine near heat sources such as

radiators, heating vents and direct sunlight.

Avoid placing air-cooled ice machines in

kitchens, due to grease, flour, or other particles,

which can collect on the condenser and fan blade,

increasing ice machine maintenance and reducing

ice machine efficiency.

3. Location: On a solid floor – The dispenser and

ice maker should be sitting on a good, solid,

level floor or surface.

4. Location: Do not obstruct traffic – The

dispenser should not extend from the wall in a

way that obstructs traffic through the area.

5. Electrical – Proper electrical voltage is available.

Receptacle is available and

within six feet.

The dispenser must be grounded in accordance with

all local and national electrical codes.

WARNING

WARNING

Never use an extension cord. If an electrical outlet is

not within six feet, have proper amperage outlet

installed.

6. Clearances for top and both sides of ice

machine – Use clearances specified in the ice

machine’s Installation and Use & Care Guide.

7. Clearance behind ice machine for dispenser

and drains – The location must allow enough

clearance for the water and drain connection at

the rear of the dispenser.

8. Back of ice machine to be flush with back of

dispenser – This allows easy removal of

dispenser front panel.

9. Separate drains – a separate drain line is

required for the ice machine, in addition to a

drain line for the Q Series Dispenser. Vent all

drain lines.

10. Water filtration – Water filtration is strongly

recommended in order to increase the

performance of the ice machine and reduce

maintenance costs.

For full information about ice machine installation,

including plumbing lines, connections and electrical

requirements, see the ice machine installation

manual

.

3-2

Page 19

Section 3

Installation

With Top-Mounted Ice Machines

Installation Procedures

Do not attempt to move a dispenser without first

removing the ice machine. The combination can be

unstable and could tip, causing serious injury.

1. Review the installation Check List on pages 3-1 and

3-2. Make sure all utility and space requirements

are present at the installation site.

2. Remove the carton top from the dispenser.

3. Remove the legs and other accessories from inside

the dispenser bin.

4. Remove the carton from the sides of the dispenser.

5. Remove the dispenser from the shipping pallet.

WARNING

11.Make sure the dispenser bin top is level. A level

bin is important for proper operation of the ice

machine.

12. Place the ice machine on top of the dispenser at this

time.

13.Connect the drain of the dispenser to the floor drain.

Vent the drain at the back of the dispenser to

reduce buildup of algae and improve drainage.

14. Follow local plumbing codes for drain installation.

15.If the dispenser has a water valve, connect your

water line to the water connection at the back of

the dispenser.

6. Flatten the shipping carton.

7. Lay the dispenser on it back on the carton.

8. Thread the legs into the bottom of the dispenser.

9. Set the dispenser upright.

10. Place the dispenser in the desired location.

16.Test all drain and water lines for leaks.

17.Plug the dispenser into the proper electrical outlet.

3-3

Page 20

Installation Section 3

Installation Procedures (continued)

18. Clean and sanitize all equipment. Follow

cleaning and sanitizing instructions in section 4.

19. QPA310/330/34 ONLY - If you have a topmounted ice machine, adjust the ice machine

according to the instructions provided with the

ice machine.

20. Install ice baffle inside the ice maker

compartment. Follow installation instructions

supplied with ice baffle.

21. Install foam gasket on the bottom of the front

panel.

22. Fill the dispenser bin one quarter full of ice or

start the ice machine, allowing the ice machine to

drop at least three complete batches of ice.

23. Test the ice dispensing action of the dispenser

__________________________________________________________________________________________

Post-Installation Check List

1. Dispenser and ice machine are level.

2. Drains are vented.

3. Dispenser does not sit in direct sunlight.

4. Dispenser does not sit in direct airflow from a

heating duct.

5. Bin and ice machine drains are separate.

6. Ice dispenses properly.

7. Installation is clean and neat.

8. Dispenser is accessible for servicing.

9. The warranty card was returned.

10. Owner was instructed on the operation of the

dispenser.

11. Owner knows how to clean and sanitize the

dispenser.

12. Owner knows how often to clean and sanitize the

dispenser.

13. Owner has your telephone number to call for

follow-up service on the dispenser.

14. You have placed one of your service stickers on

the dispenser for follow-up service.

3-4

Page 21

Section 4 Maintenance

Disassembling the Dispenser Parts

For Cleaning

WARNING

Electric Shock Hazard

Unplug unit before servicing or cleaning.

The agitator is operated by a timer and can agitate at

anytime.

1 Shut off water to ice machine.

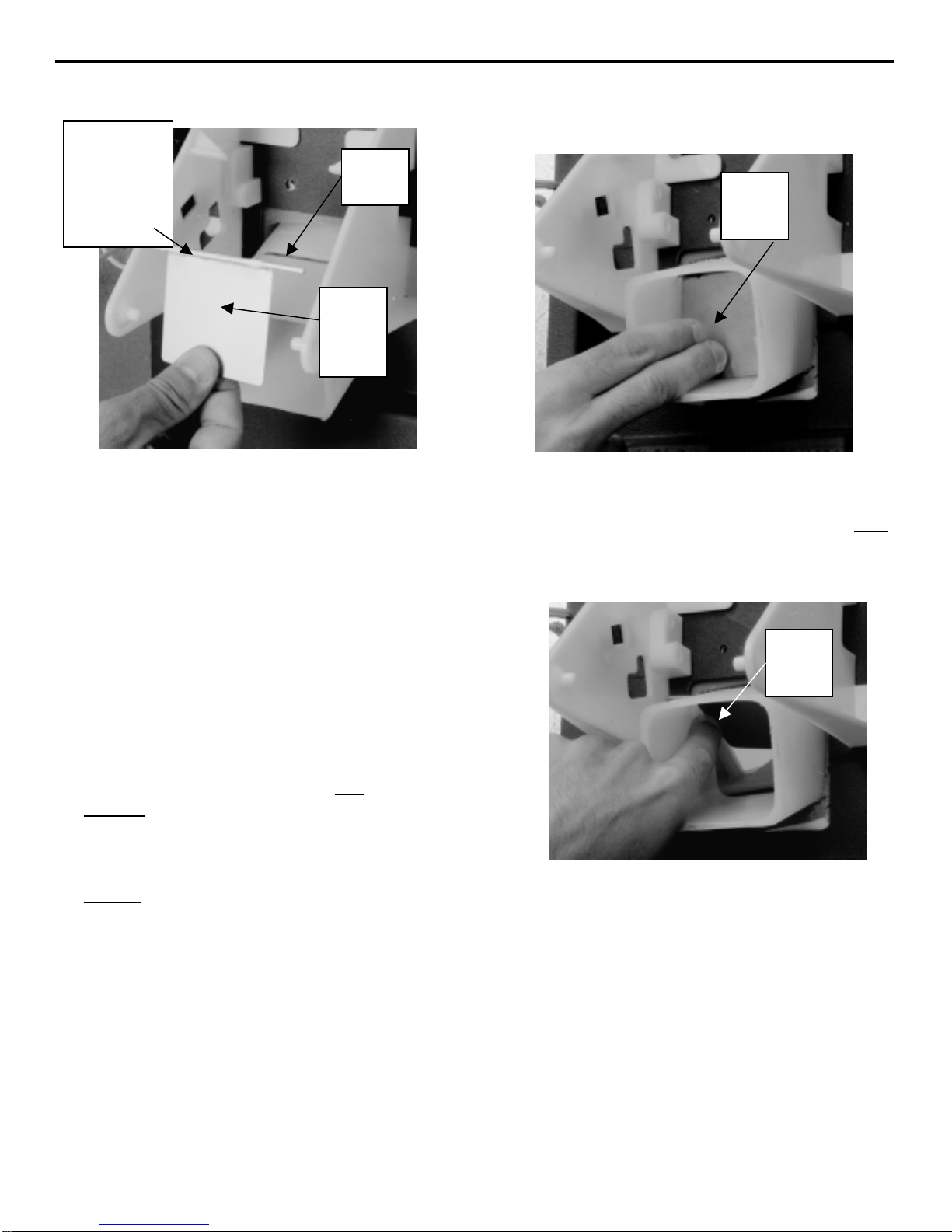

Black rubber

holes

Dispenser

Front

Panel

Catch

Hook

2 Locate a cylindrical object, such as a ballpoint

pen with a cap on the pen.

Insert the pen into the left and right black rubber

holes in the top of the front panel of the

dispenser.

This action releases the two clips which hold the

dispenser front panel in place.

While applying pressure on the pen, pull the front

panel forward slightly, so the clip in the panel

does not snap back into place.

3 Hold the front panel of the dispenser on both

sides and tilt the panel forward. The front panel

will be resting on the catch hooks at the bottom of

the panel.

4 QFA-291 ONLY - Disconnect water line at the

front panel “quick disconnect” fitting.

4-1

Page 22

Maintenance Section 4

Disassembling the Dispenser Parts

For Cleaning (continued)

Dispenser

Front

Panel

Removing the Drain Pan

Catch

Hook

7 Lift the front panel off the catch hooks and set the

panel aside.

1 The drain pan is visible when the front panel of

the dispenser is removed.

2 Slide the drain pan forward.

3 Remove scrap ice if any scrap ice has

accumulated.

4-2

Page 23

Section 4 Maintenance

Removing the Drain Pan

(continued)

Unplug unit before servicing or cleaning.

Drain Pan

Disassembling the

Rocking Chute/Door

WARNING

Electric Shock Hazard

1 Remove the front panel as described on pages

4-1 and 4-2.

4 Remove the inner drain pan. Clean the inner

drain pan with sanitizing solution. (See page

4-9.)

5 After cleaning, place inner drain pan back into

outer drain pan.

6 Slide drain pan back into place.

2 Remove outer bracket.

4-3

Page 24

Maintenance Section 4

Disassembling the Rocking Chute/Door (continued)

3 Remove door lock.

Metal

Support

Bracket

5 Remove metal support bracket.

Metal

Support

Bracket

4 Loosen the two thumbscrews of the metal support

bracket.

4-4

6 Remove door.

7 Remove ice chute.

Page 25

Section 4 Maintenance

Disassembling the Rocking Chute/Door (continued)

Paddle

wheel

guard

Retainer

8 Remove the two thumb screws from the plastic

paddle wheel guard retainer.

Paddle

wheel

guard

10 Pull the stainless steel paddle wheel guard

from the slot that is cut into the chute…

Paddle

wheel

guard

Retainer

9 Remove the paddle wheel guard retainer

Paddle

wheel

guard

11 …and remove the paddle wheel guard

retainer.

4-5

Page 26

Maintenance Section 4

Re-Installing the Paddle Wheel Guard

Cylinder

hinge

Welded to

Front of

Paddle wheel

Guard

Correct Installation

Slot in

Chute

Paddle

wheel

guard

(front)

Paddle

wheel

guard

1 When re-assembling the rocking chute/door, the

paddle wheel guard is placed in the slot in the ice

chute.

Notice that a cylinder hinge is welded to the top

front side of the paddle wheel guard, as shown in

the picture above.

When the paddle wheel guard is placed in the slot

in the ice chute, the cylinder hinge on the front of

the paddle wheel guard faces forward, as shown

in the picture above.

When the paddle wheel guard is correctly

installed, the paddle wheel guard will

outward toward the front of the chute, allowing

ice to flow out of the chute.

If incorrectly installed, the paddle wheel guard

will not

blocked.

swing

swing outward and ice delivery is

2 Correct Installation:

If you press your finger forward against the

paddle wheel guard, the paddle wheel guard does

not swing back open.

Incorrect Installation

Paddle

wheel

guard

3 Incorrect Installation:

If you press your finger forward against the

paddle wheel guard, the paddle wheel guard does

swing back open.

4-6

Page 27

Section 4 Maintenance

Disassembling the Dispenser Parts

For Bin Cleaning

WARNING

Unplug unit before servicing or cleaning.

Ice dispenser bin contains moving parts that can move

at any time and will cause injury if hands are in the

way.

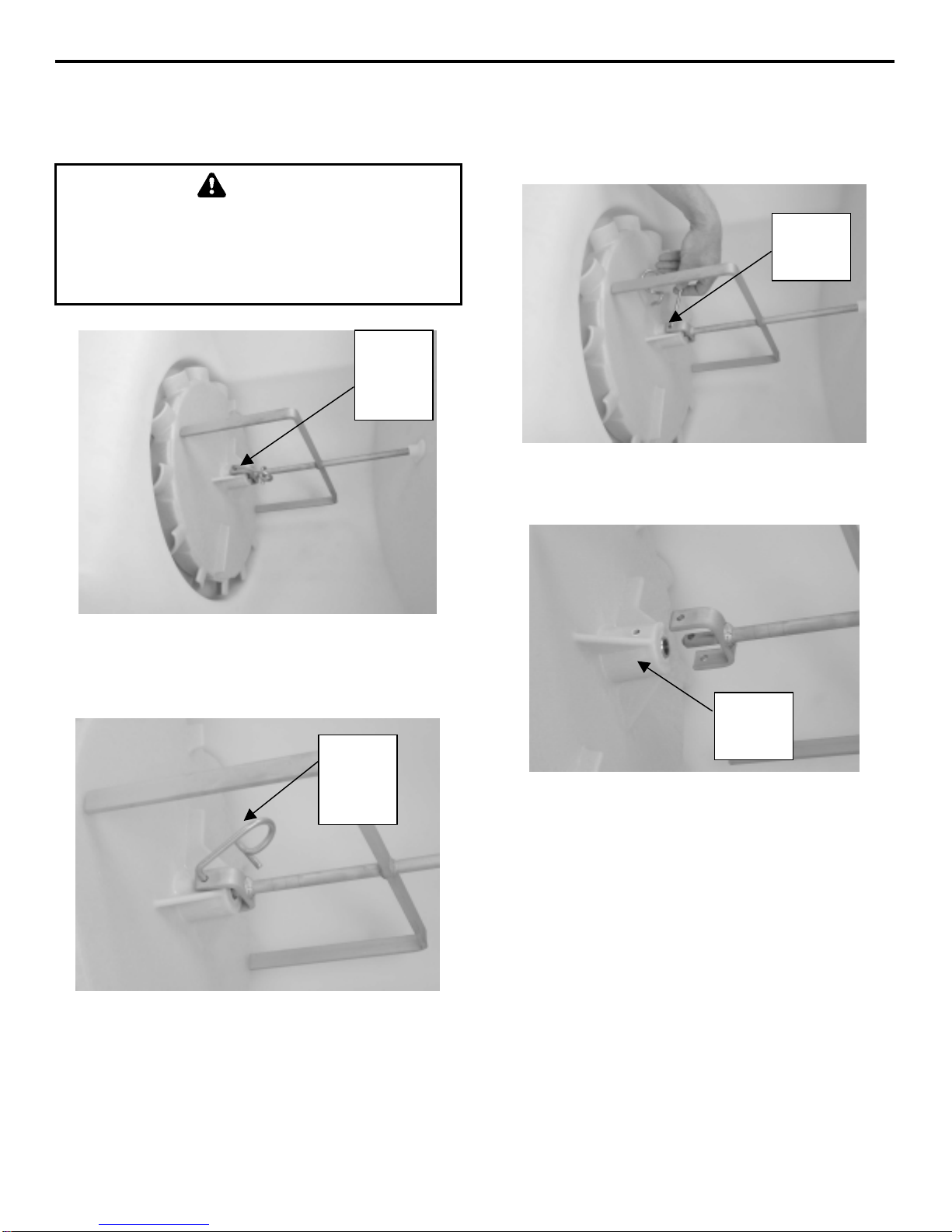

Paddle

wheel

pin

Paddle

wheel

pin

handle

3 …Then remove the paddle wheel pin by firmly

rotating the pin and pulling upward.

1 Inside the dispenser, rotate the agitator arm so the

paddle wheel pin handle is pointing up, toward

the ceiling.

Paddle

wheel

pin

handle

2 Un-clip the hand-removable paddle wheel pin

from the agitator…

Paddle

wheel

hub

4 Push the agitator bar toward the back of the bin

until agitator is free of the paddle wheel hub.

4-7

Page 28

Maintenance Section 4

Disassembling the Dispenser Parts

For Bin Cleaning (continued)

Bushing

5 Move the agitator to one side and slide the

agitator forward until the rear of the agitator

shaft is clear of the bushing.

6 Remove the agitator from the bin area.

7 Slide the paddle wheel from its shaft.

4-8

Page 29

Section 4 Maintenance

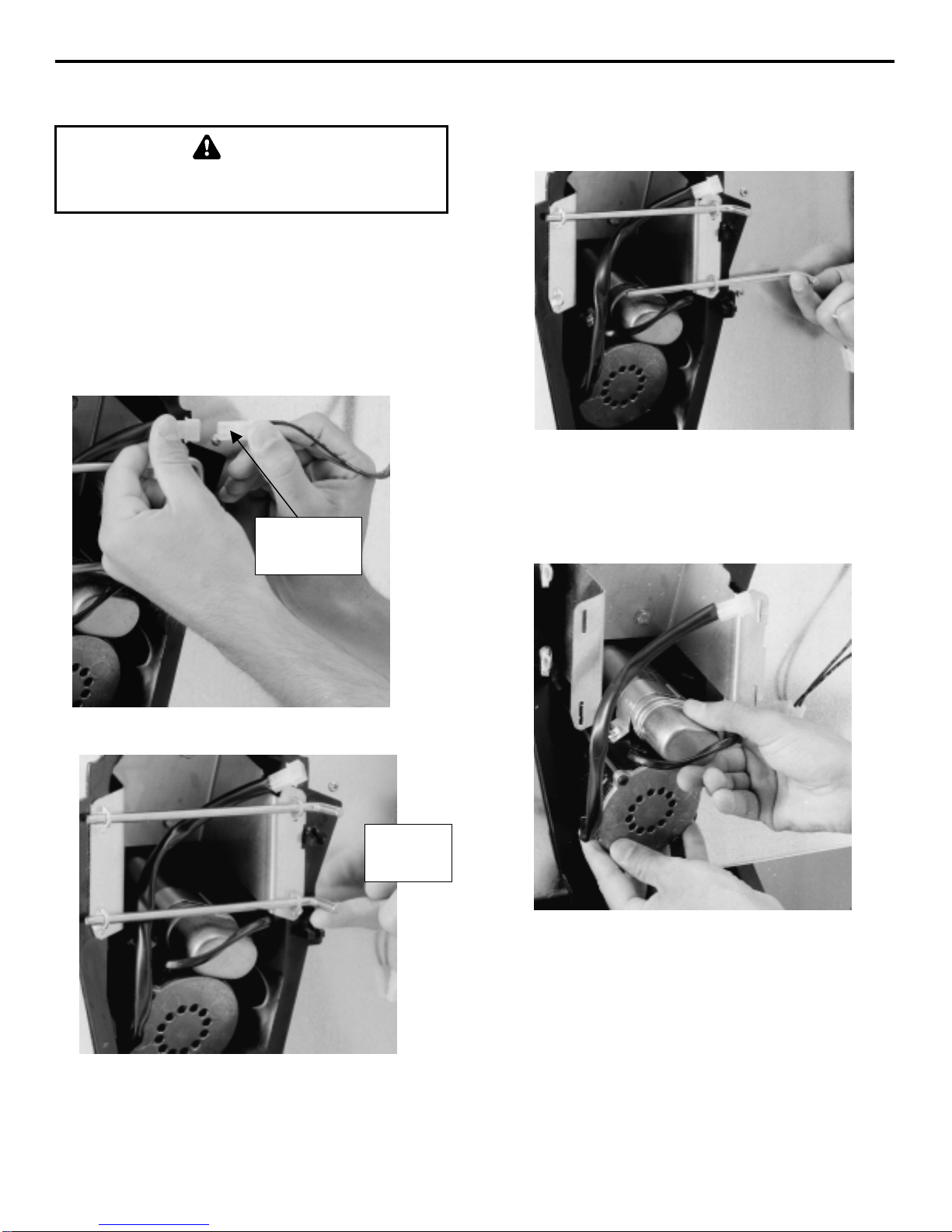

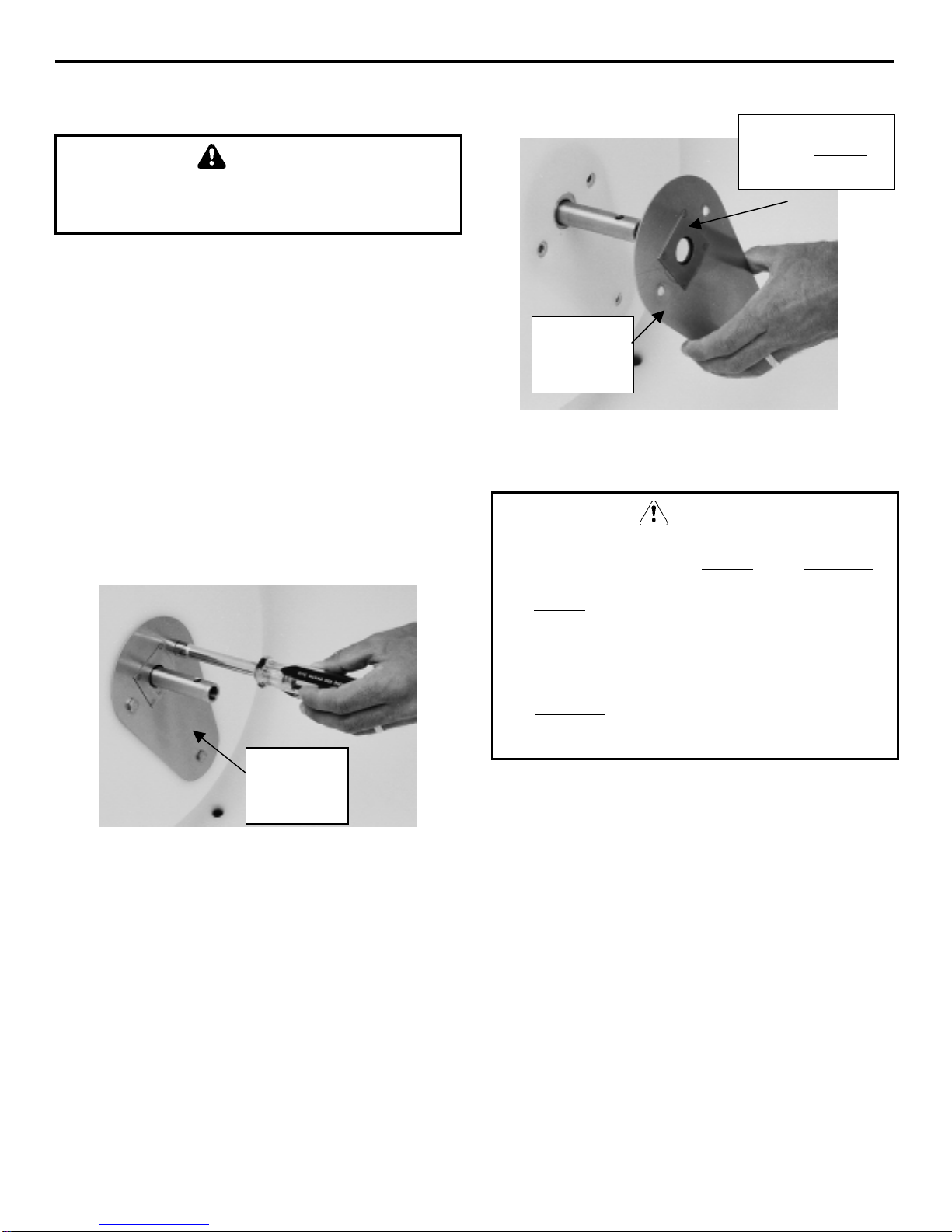

Removal of the Gearmotor

Unplug unit before servicing or cleaning.

Electric Shock Hazard.

WARNING

5 Pull removal pins out to the right.

1 Remove the front panel from dispenser. (See

pages 4-1 and 4-2.)

2 Remove paddle wheel pin, agitator, and paddle

wheel. (See pages 4-5 and 4-6.)

6 As soon as the second pin is removed, be sure to

hold onto the gearmotor as it slides forward.

Gearmotor

wire

Then place the gearmotor aside.

3 Unplug the gearmotor wire.

Removal

pins

4 Turn the two removal pins toward you as shown

in photo.

4-9

Page 30

Maintenance Section 4

Monthly Sanitizing Procedure

WARNING

Unplug unit before servicing or cleaning.

Electric Shock Hazard.

Remove the front panel, paddle wheel, ice chute

1.

and door assembly as shown on pages

4-1through 4-6.

2. Mix a solution of 3 ounces (100 ml) Manitowoc

cleaner per 1-gallon (4 liters) plain tap water.

3. Carefully clean all parts removed from inside the

bin with this cleaner. Clean the dispenser bin,

door assembly, and ice chute.

4. Rinse all cleaned parts with fresh, running tap

water.

5. Mix a solution of 1-ounce (30-ml) Manitowoc

sanitizer with 4 gallons (15 liters) plain tap water.

6. Sanitize each part washed in the previous step

with this sanitizer solution. Sanitize and reassemble in this order:

Paddle wheel

Agitator

Paddle wheel pin

Ice chute assembly

Scrap ice tray

Front panel

7. Do not rinse dispenser parts after they are

sanitized. Allow parts to air dry.

8. After all dispenser parts are replaced, restore

power to the dispenser.

9. Turn the ice machine on.

10. Allow the ice machine to begin filling the

dispenser.

11. After three batches are in the dispenser, test the

dispenser operation.

4-10

Page 31

Section 5 Component Parts – Removal & Replacement

Gearmotor Shaft Seal Replacement

Unplug unit before servicing or cleaning.

Electric Shock Hazard.

WARNING

1 If the dispenser is top mounted with an ice

machine, remove the ice machine front panel.

Most will allow access to the bin.

NOTE: The following photos show a bin that is not

top-mounted with an ice machine.

2 Remove the paddle wheel pin, agitator, and

paddle wheel. (See pages 4-5 and 4-6.)

Bin

insulator

plate

Bin

insulator

plate

Oil seal retainer

marks the topside

bin insulator plate

of

4 Remove the bin insulator plate.

It is important to know which side of the bin insulator

plate you are accessing, the topside

The topside

an approximately two-inch square of oil seal retainer

welded to the top of the bin insulator plate. (As

shown in Step 4 above.)

The underside

shaft seal is located. (As shown in Step 5 on page

5-2.)

of the bin insulator plate can be noted by

of the bin insulator plate is where the

CAUTION

or the underside.

3 The motor shaft seal can be replaced with the

gearmotor in or out.

With a 7/16” nut driver, remove the three bolts

on the bin insulator plate.

5-1

Page 32

Component Parts – Removal & Replacement Section 5

Gearmotor Shaft Seal Replacement (continued)

Shaft seal

Shaft seal marks the

underside

insulator plate

of bin

5 Locate the shaft seal on the underside of the bin

insulator plate.

Know which side of the shaft seal you are accessing,

the convex

Snap in the new seal with the concave (ridge) side

down. Otherwise the seal will not work and the

dispenser will leak.

side or the concave (ridge) side.

CAUTION

6 Using a screwdriver, pry out the shaft seal, then

throw the shaft seal away.

Convex side

(front of shaft seal)

Concave side

(ridge side…back

of shaft seal)

7 With the convex side of the shaft seal facing up

(and the concave, ridge side facing down), snap

the new shaft seal onto the bin insulator plate.

Preventive maintenance note:

Replace the motor shaft seal once a year.

CAUTION

5-2

Page 33

Section 5 Component Parts – Removal & Replacement

Gearmotor Shaft Seal Replacement (continued)

8 Press the bin insulator plate back into place.

9 Replace the three bolts. Using a 7/16” nut driver,

tighten a quarter turn past tight.

10 Replace the paddle wheel, agitator and paddle

wheel pin in the dispenser.

11 Refill the dispenser or restart the ice machine.

12 Restore power to the dispenser and ice

machine.

5-3

Page 34

Section 6 Before Calling Service

Checklist

Unplug unit before servicing or cleaning.

Ice dispenser bin contains parts that can move at any

time and will cause injury if hands are in

the way.

WARNING

WARNING

Unplug unit before servicing or cleaning.

Electric Shock Hazard.

Problem: Ice Does Not Dispense When Rocking Chute is Depressed.

Problem Possible Cause To Correct

There is no power to the

dispenser.

Is the dispenser plugged in?

Remove the paddle wheel pin. Is this

pin broken, damaged, or missing?

Is there any ice in the bin?

Is the paddle wheel guard installed

properly?

Plug the dispenser in.

If the paddle wheel pin is broken or

missing, replace the pin.

If the ice is not sufficient, add

additional to bin.

Refer to Section 4 “Maintenance”

6-1

Loading...

Loading...