Page 1

M series

Manitowoc

Ice Machines

Technician’s

Handbook

This manual is updated as new information and models are

released. Visit our website for the latest manual. www.welbilt.cn

Part Number 040005626 5/17

Page 2

Page 3

Safety Notices

!

Warning

!

Caution

As you work on Manitowoc equipment, be sure to pay

close attention to the safety notices in this handbook.

Disregarding the notices may lead to serious injury

and/or damage to the equipment.

Throughout this handbook, you will see the following

types of safety notices:

Text in a Warning box alerts you to a potential

personal injury situation. Be sure to read the

Warning statement before proceedi ng, and work

carefully.

Text in a Caution box alerts you to a situation in

which you could damage the equipment. Be sure

to read the Caution statement before proceeding,

and work carefully.

Page 4

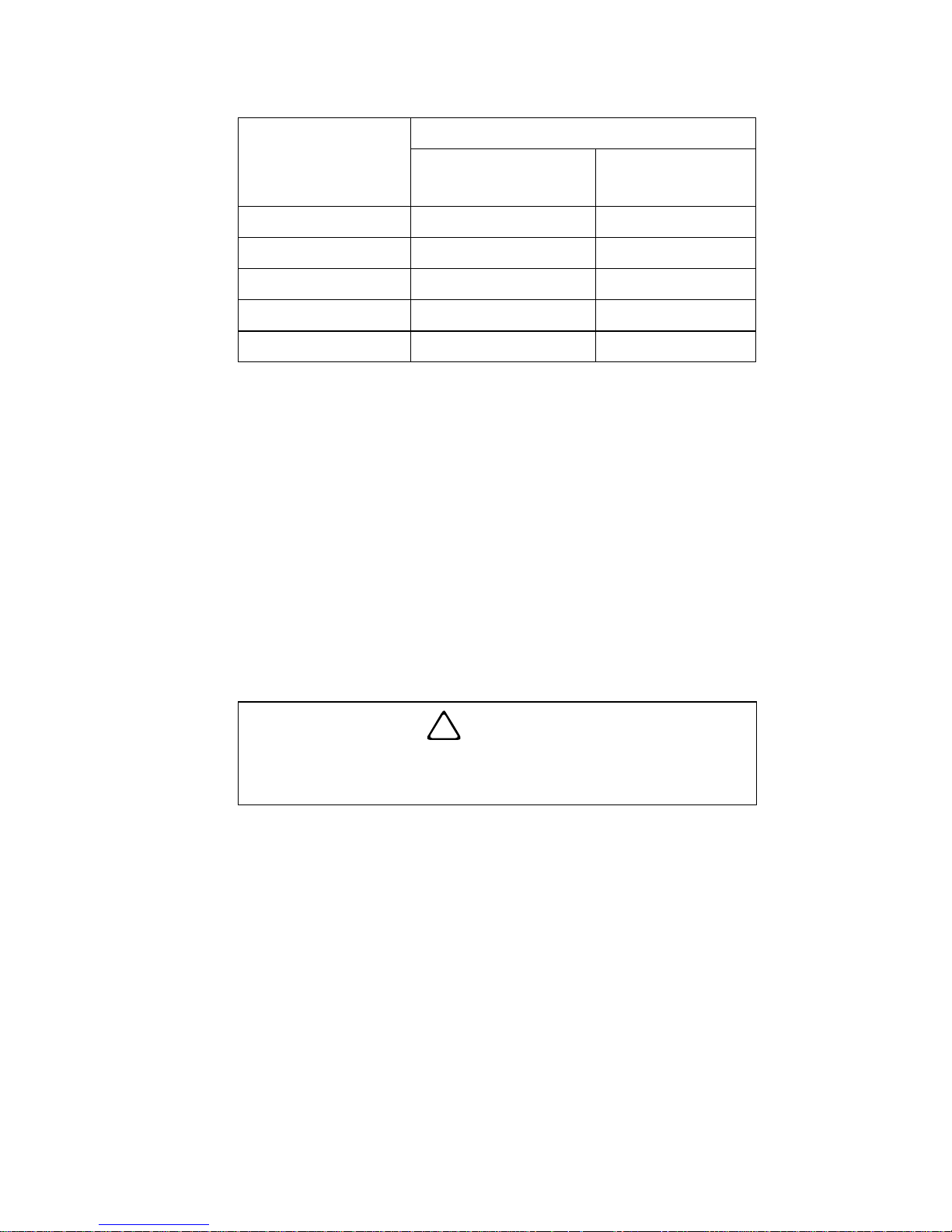

Procedural Notices

Important

As you work on M anitowoc e quipment, be s ure to read

the procedu ral notices in t his handbook . These noti ces

supply helpful information which may assist you as

you work.

Throughout this handbook, you will see the following

types of procedural notices:

Text in an Important box provides you with

information that may help you perform a

procedure more efficiently. Disregarding this

informat io n wi ll no t caus e dam age or in jury, but it

may slow you down as you work.

NOTE: Text set of f as a Note prov ides you with simple,

but useful, extra information about the procedure you

are performing.

Page 5

Read These Before Proceeding:

!

Caution

Important

!

Warning

!

Warning

!

Warning

Proper installation, care and maintenance are

essential for maximum performance and troublefree operation of your equipment. Visit our

website www.kool-aire.com for manual updates,

translations, or contact information for service

agents in you r area.

Routine adjustments and maintenance

procedures outlined in this handbook are not

covered by the warranty.

Read this manual thoroughly before operating,

installing or performing maintenance on the

equipment. Failure to follow instructions in this

manual can cause property damage, injury or

death.

Do not use electrical appliances or accessories

other than those supplied by Manitowoc for your ice

machine model.

Two or more people or a lifting device are

required to lift this appliance.

Page 6

!

Warning

This equipment contains high voltage electricity

!

Warning

!

Warning

!

Warning

and refrigerant charge. Inst allatio n and rep airs are

to be performed by properly trained technicians

aware of the dangers of dealing with high voltage

electricity and refrigerant under pressure.The

technician must also be certified in proper

refrigerant handling and servicing procedures. All

lockout and tag out procedures must be followed

when working on this equipment.

Do not damage the refrigeration circuit when

installing, maintaining or servicing the unit.

Do not operate equipment that has been misused,

abused, neglected, damaged, or altered/modified

from that of original manufactured specifications.

This appliance is not intended for use by persons

(including children) with reduced physical, sensory

or mental capabilities, or lack of experience and

knowledge, unless they have been given

supervision concerning use of the appliance by a

person responsible for their safety. Do not allow

children to play with this appliance.

All covers and access panels must be in place

and properly secured, before operating this

equipment.

Page 7

!

Warning

Do not obstruct machine vents or openings.

!

Warning

!

Warning

!

Warning

!

Warning

Do not store gasoline or other flammable vapors

or liquids in the vicinity of this or any other

appliance.

Do not clean with water jet.

It is the responsibility of the equipment owner to

perform a Personal Protective Equipment Hazard

Assessment to ensure adequate protection

during maintenance procedures.

Two or more people are required to move this

equipment to prevent tipping.

Page 8

!

Warning

When using electric appliances, basic

We reserve the right to make product

improvements at any time. Specifications and

design are subject to change without notice.

precautions must always be followed, including

the following:

a. Read all the instructions before using

the appliance.

b. To reduce the risk of injury, close

supervision is neces sa ry when an

appliance is used near children.

c. Do not contact moving parts.

d. Only use attachments recommended or

sold by the manufacturer.

e. Do not use outdoors.

f. For a cord-connected applia nc e, the

following must be included:

• Do not unplug by pulling on cord. To

unplug, grasp the plu g, not the co rd.

• Unplug from outlet when not in use

and before servicing or cleaning.

• Do not operate any appliance with a

damaged cord or plug, or after the

appliance m al fun cti ons o r is dro pp ed

or damaged in any manner. Contact

the nearest authorized service facility

for examination, rep a ir, or electrical

or mechanical adjustment.

g. Follow applicable lock out tag out

procedures before working on

equipment.

h. Connect to a properly grounded outlet

only.

Page 9

Table of Contents

GENERAL INFORMATION

Model Numbers . . . . . . . . . . . . . . . . . . . . .13

How to Read a Model Number . . . . . . . . .14

Ice Machine Warranty Information . . . . . 15

Commercial Warranty Coverage . . . . .15

Residential Warranty Coverage . . . . .18

INSTALLATION

Location of Ice Machine . . . . . . . . . . . . . .21

Ice Machine Clearance Requirements . .22

Clearance Requirements . . . . . . . . . . . . .22

Ice Machine Heat of Rejection . . . . . . . . .23

Leveling the Ice Machine . . . . . . . . . . . . .23

Electrical Requirements . . . . . . . . . . . . . . 24

Water Service/Drains . . . . . . . . . . . . . . . .25

Water Supply . . . . . . . . . . . . . . . . . . . . 25

Water Inlet Lines . . . . . . . . . . . . . . . . . 25

Drain Connections . . . . . . . . . . . . . . . .26

Cooling Tower Applications . . . . . . . . .26

MAINTENANCE

Interior Cleaning and Sanitizing . . . . . . .29

General . . . . . . . . . . . . . . . . . . . . . . . .29

Cleaning and Sanitizing Procedure . . .29

Toggle switch Operation . . . . . . . . . . .30

Remove Parts for Cleaning . . . . . . . . .34

Preventative Maintenance Cleaning . . . .36

Ice Machine Inspection . . . . . . . . . . . . . .37

Cleaning the Condenser . . . . . . . . . . . . .38

Removal from Service/Winterization . . .39

Air-cooled Models . . . . . . . . . . . . . . . .39

Water-cooled Models . . . . . . . . . . . . . 39

Part Number 040005626 5/17 9

Page 10

OPERATION

Ice Making Sequence of Operation . . . . 41

Control Board Timers . . . . . . . . . . . . 42

Safety Limits . . . . . . . . . . . . . . . . . . . . 43

Energized Parts Chart . . . . . . . . . . . . 45

Operational Ch ecks . . . . . . . . . . . . . . . . . 47

Ice Thickness Check . . . . . . . . . . . . . 47

TROUBLESHOOTING

Control Board Test Mode . . . . . . . . . . . . 49

Diagnosing an Ice Machine that Will Not Run

50

Ice Machine Does Not Cycle Into Harvest

when Water Loses Contact with the Harvest

Float Switch . . . . . . . . . . . . . . . . . . . . . . . 51

Ice Machine Cycles Into Harvest Before Water

loses Contact with the Harvest Float Switch

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Ice Production Check . . . . . . . . . . . . . . . 54

Installation/Vis ual Insp ecti on Che ckl ist 55

Water System Checklist . . . . . . . . . . . . . 56

Ice Formation Pattern . . . . . . . . . . . . . . . 57

Safety Limits . . . . . . . . . . . . . . . . . . . . 60

Analyzing Dischar ge Pressur e . . . . . . . . 67

Analyzing Suction Pressure . . . . . . . . . . 69

Harvest Valve . . . . . . . . . . . . . . . . . . . . . . 73

Comparing Evaporator Inlet/Outlet

Temperatures . . . . . . . . . . . . . . . . . . . . . . 77

Discharge Line Temperature Analysis . 78

Refrigeration Component Diagnostics . 80

Final Analysis . . . . . . . . . . . . . . . . . . . 82

Refrigeration Component Diagnostic Chart

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

10 Part Number 040005626 5/17

Page 11

COMPONENT CHECK PROCEDURES

Main Fuse . . . . . . . . . . . . . . . . . . . . . . . . .87

Bin Switch . . . . . . . . . . . . . . . . . . . . . . . . .88

Float Switch . . . . . . . . . . . . . . . . . . . . . . .90

Compressor Electrical Diagnostics . . . .92

Fan Cycle Control . . . . . . . . . . . . . . . . . . .94

High Pressure Cutout (HPCO) Control . . 95

Refrigeration Components . . . . . . . . . . .96

Head Pressure Control Valve . . . . . . .96

Harvest Cycle Operation . . . . . . . . . . .97

Harvest Pressure Regula ting (HPR) System

Remote Condenser Only . . . . . . . . . . .100

Water Regulating Valve . . . . . . . . . . .103

Refrigerant Recovery/Evacuation . . . . . .104

Definitions . . . . . . . . . . . . . . . . . . . . . .104

Refrigerant Re-use Policy . . . . . . . . . . 105

Recovery and Recharging Procedures 107

System Contamination Cleanup . . . . . . .110

Refrigerant Amount . . . . . . . . . . . . . . . . . 116

CHARTS

Cycle Times, 24 Hr. Ice Production and

Refrigerant Pressure Charts . . . . . . . . . . 117

Determining Severity of Contamination 110

Mild System Contamination Cleanup

Procedure . . . . . . . . . . . . . . . . . . . . . .112

Severe System Contamination Cleanup

Procedure . . . . . . . . . . . . . . . . . . . . . .113

Replacing Pressure Controls without

Removing Refrigerant Charge . . . . . . .114

M0420A Self-contained Air-cooled . . .118

M0500A Self-contained Air-cooled . . .119

M0500W Self-contained Water-cooled 120

M0700A Self-contained Air-cooled . . .121

M0700W Self-contained Water-cooled 122

M1000A Self-contained Air-cooled . . .123

M1000W Self-contained Water-cooled 124

M1400A Self-contained Air-cooled . . .125

Part Number 040005626 5/17 11

Page 12

DIAGRAMS

Wiring Diagrams . . . . . . . . . . . . . . . . . . . 127

Wiring Diagram Legend . . . . . . . . . . . 127

M0420,M0500, M0700, M1000 1 PH Self-

contained Air/Water-cooled . . . . . . . . 128

Electronic Control Board . . . . . . . . . . . 129

Refrigeration Tubing Schematics . . . . . 130

Self-contained Air or Water-cooled . . . 130

12 Part Number 040005626 5/17

Page 13

General Information

Model Numbers

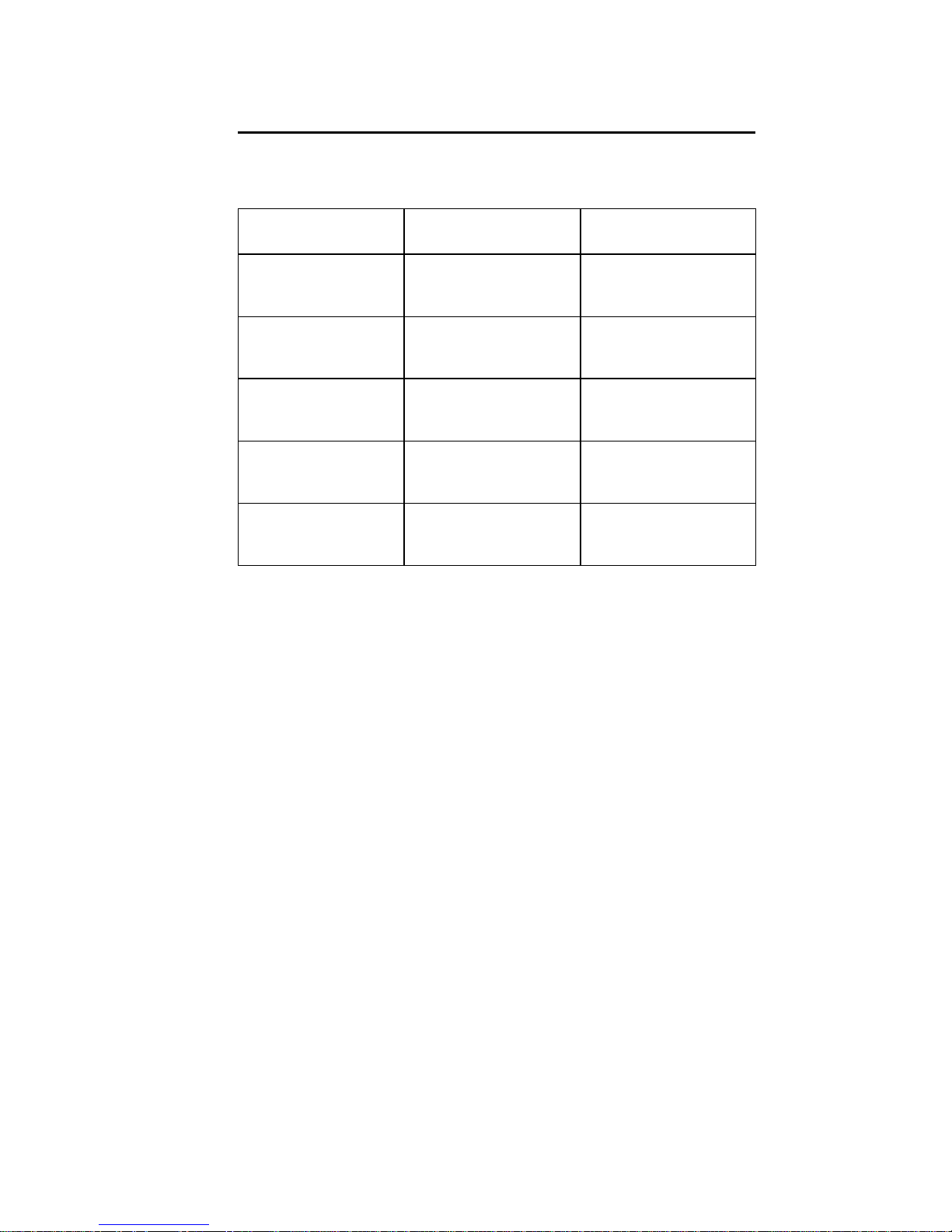

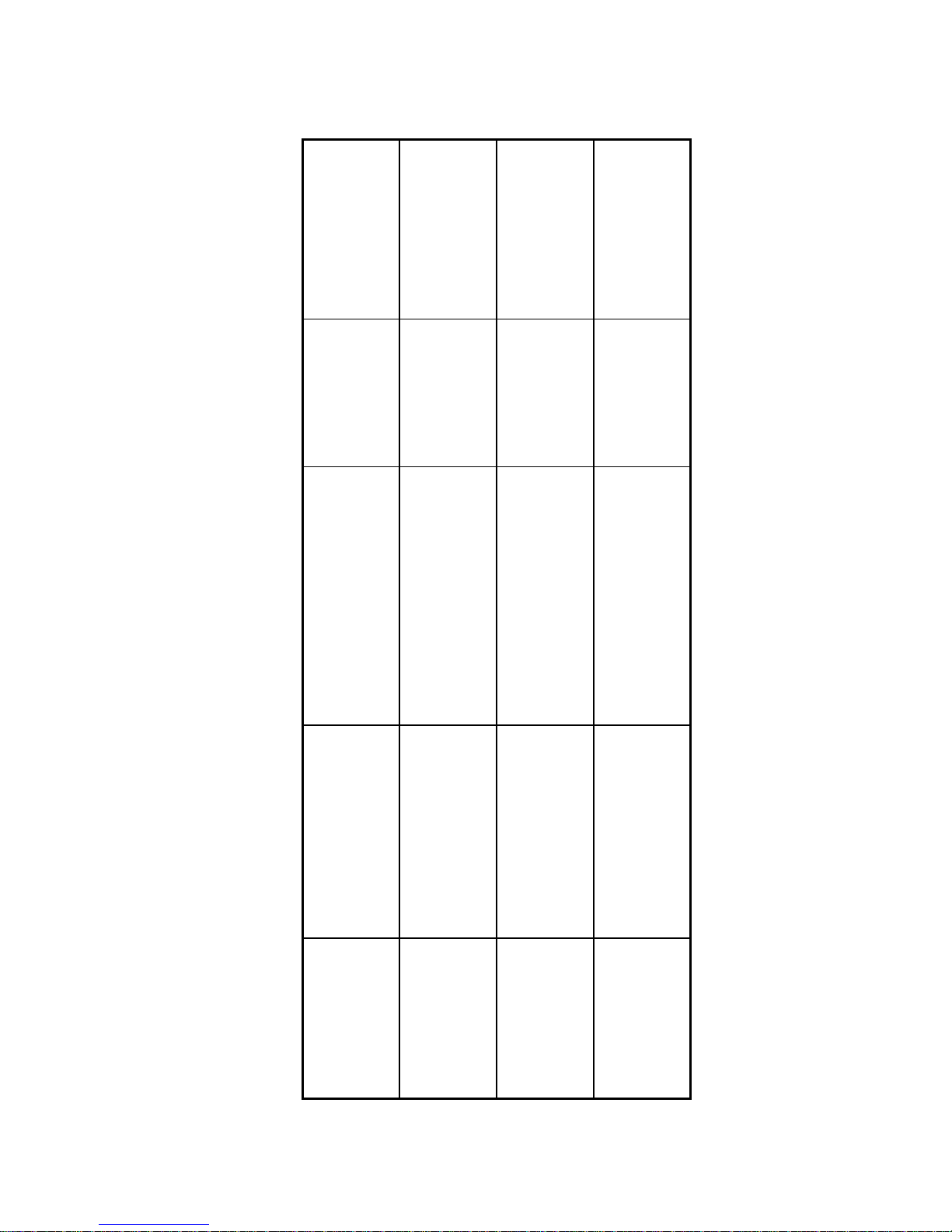

This manual covers the following models:

Self-Contained

Air-Cooled

Self-Contained

Water-Cooled

MD0420A

MY0420A

MD0500A

MD0500W

MY0500A

MD0700A

MD0600W

MY0700A

MD1000A

MY1000A

MD1000W

MY1000W

MD1400A ----

----

----

----

----

----

Remote

----

----

----

----

----

----

----

----

----

----

Part Number 040005626 5/17 13

Page 14

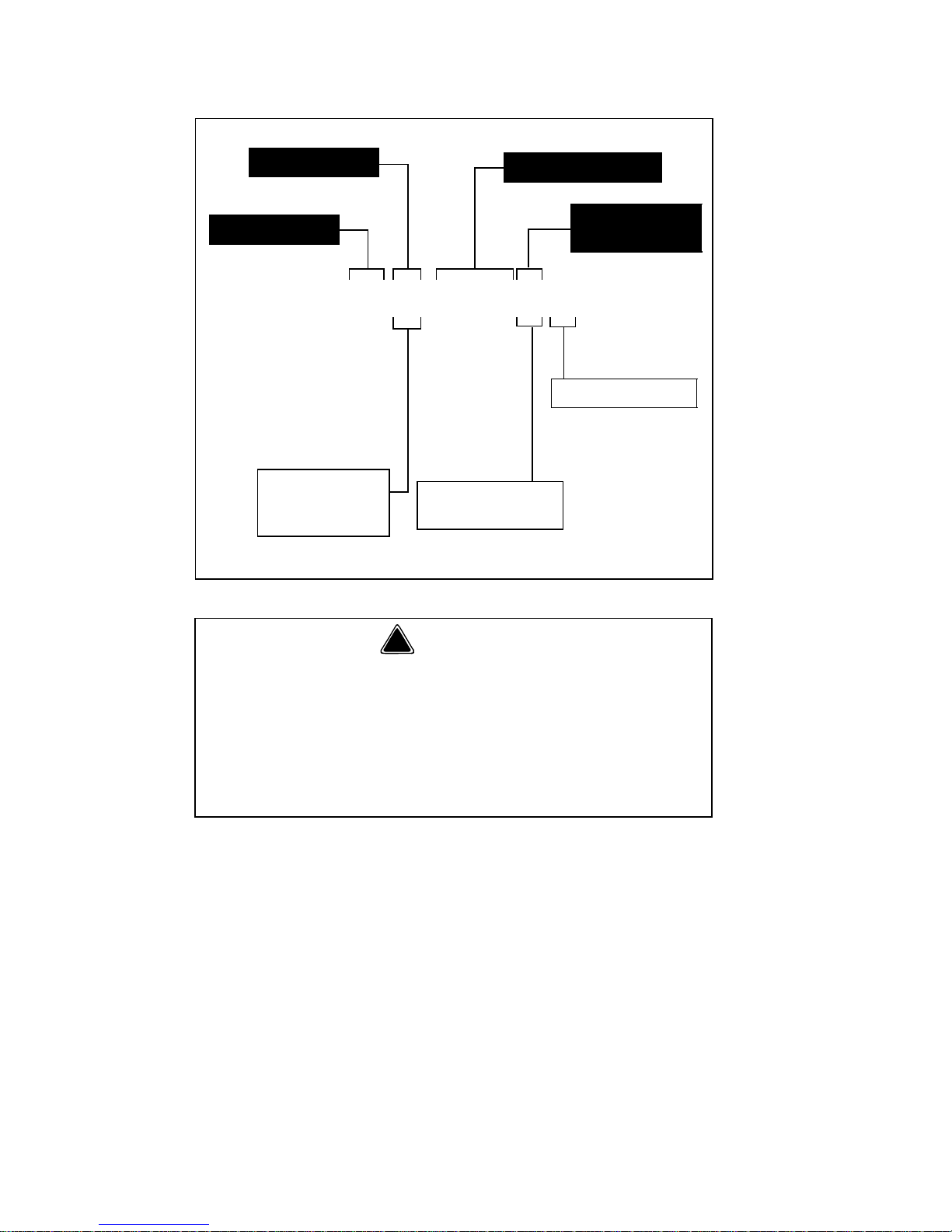

How to Read a Model Number

!

Warning

A - Air-cooled

W - Water-cooled

Series

Condenser

Type

Model

M D 0500 A E

R - Regular

D - Dice

Y - Half-dice

Cube Size

E - WRAS 50Hz

An ice machine contains high voltage electricity

and refrigerant charge. Repairs are to be

performed by properly trained refrigeration

technicians aware of the dangers of dealing with

high voltage electricity and refrigerant under

pressure.

14 Part Number 040005626 5/17

Page 15

Ice Machine Warranty Information

Important

Owner Warranty Registration Card

General

Warranty coverage begins the day the ice machine is

installed.

Complete and mail the OWNER WARRANTYREGISTRATION CARD as soon as possible to

validate the installation date.

If the OWNER WARRANTY REGISTRA TION CARD is

not returned, we will use the date of sale to the

Distributor as the first day of warranty coverage for

your new ice machine.

COMMERCIAL WARRANTY COVERAGE

Welbilt, (hereinafter referred to as the “COMPANY”)

warrants for a period of thirty-six months from the

installati on d ate (exc ep t as l im ited bel ow) tha t new ic e

machines manufactured by the COMPANY shall be

free of defects in material or workmanship under

normal and proper use and maintenance as specified

by the COMPANY and upon proper installation and

start-up in accord anc e wi th the instruc ti on man ual

supplied with the ice machine. The COMPANY’s

warranty hereunder with respect to the compressor

and evaporator shall apply for an additional twentyfour months, excluding all labor charges.

The obligat ion of the CO MPANY under this warranty is

limited to the repair or replacement of parts,

components, or assemblies that in the opinion of the

COMPANY are defective. This warranty is further

limited to the cost of parts, components or assemblies

and standard straight time labor charges at the

servicing location.

Part Number 040005626 5/17 15

Page 16

Time and hourly rate schedules, as published from

time to time by the COMPANY, apply to all service

procedures. Additional expenses including without

limita tion, travel time, overt ime premium , material cost,

accessing or removal of the ice machine, or shipping

are the responsibility of the owner, along with all

maintenance, adjustments, cleaning, and ice

purchases. La bor cover ed under this warranty must b e

performed by a COMPANY Contracted Service

Representative or a refrigeration service agency as

qualified and authorized by the COMPANY’s local

Distributor. The COMPANY’s liability under this

warranty shall in no event be greater than the actual

purchase price paid by customer for the ice machine.

The foregoing warranty shall not apply to (1) any part

or assembly that has been altered, modified, or

changed; (2) any part or assembly that has been

subjected to misuse, abuse, neglect, or accidents; (3)

any ice machine that has been installed and/or

maintained inconsistent with the technical instructions

provided by the COMPANY; or (4) any ice machine

initially installed more than five years from the serial

number produc tio n date . This warran ty shall not apply

if the Ice Machine’s refrigeration system is modified

with a condenser, heat reclaim device, or parts and

assemblies other than those manufactured by the

COMPANY, unless the COMPANY approves these

modifications for specific locations in writing.

THIS WARRANTY IS IN LIEU OF ALL OTHER

WARRANTIES OR GUARANTEES OF ANY

KIND, EXPRESSED OR IMPLIED, INCLUDING

ANY IMPLIED WARRANTY OF

MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE.

COMPANY be liable for any special, indirect,

incidental or consequential damages. Upon the

expiration of the warranty period, the COMPANY’s

liability under this warranty shall terminate. The

foregoing warranty shall constitute the sole liability of

the COMPANY and the exclusive remedy of the

customer or user.

16 Part Number 040005626 5/17

In no event shall the

Page 17

To secure prompt and continuing warranty

service, the warranty registration card must be

completed and sent to the COMPANY within five

(5) days from the installation date.

Warranty Service

To comply with the provisions of the warranty, a

refrigeration service comp any qual ified and authorize d

by your M series distributor, or a Factory Authorized

Servicer must perform the warranty repair.

Service Calls

Normal maintenance, adjustments and cleaning as

outlined in this manual are not covered by the

warranty.

Authorized

Part Number 040005626 5/17 17

Page 18

RESIDENTIAL WARRANTY COVERAGE

WHAT DOES THIS LIMITED WARRANTY COVER?

Subject to the exclus ions and limit ations b elow, Welbilt

warrants to the original consumer that any new ice

machine manu fac ture d by Welbilt (the “Product”) s ha ll

be free of defects in material or workmanship for the

warranty period outlined below under normal use and

maintenance, and upon proper installation and startup in accordance with the instruction manual supplied

with the Product.

HOW LONG DOES THIS LIMITED WARRANTY

LAST?

Product CoveredWarranty Period

Ice MachineTwelve (12) months from the sale date

WHO IS COVERED BY THIS LIMITED WARRANTY?

This limited warranty only applies to the original

consumer of the Product and is not transferable.

WHA T ARE WELBILT’S OBLIGA TIONS UNDER THIS

LIMITED WARRANTY?

If a defect arise s an d W e lbi lt rec ei ves a va li d w arran ty

claim prior to the expiration of the warranty period,

Welbilt shall, at its option: (1) repair the Product at

Welbilt’s cost, including standard straight time labor

charges, (2) replace the Product with one that is new

or at least as functionally equivalent as the original, or

(3) refund the purchase price for the Product.

Replacement parts are warranted for 90 days or the

balance of the original warranty period, whichever is

longer. The foregoing constitutes Welbilt’s sole

obligation and the consumer’s exclusive remedy for

any breach of this limited warranty. Welbilt’s liability

under this limited warranty is limited to the purchase

price of Product. Additional expenses including,

without limitation, service travel time, overtime or

premium labor charges, accessing or removing the

Product, or shipping are the responsibility of the

consumer.

18 Part Number 040005626 5/17

Page 19

HOW TO OBTA IN WARRANTY SERVICE

To obtain warranty service or inform at ion regardi ng

your M series product, please contact:

WELBIL T

2110 So. 26th St.

P.O. Box 1720,

Manitowoc, WI 5422 1-1 720

Telephone: 920-682-0161 Fax: 920-683-7585

WHAT IS NOT COVERED?

This limited warranty does not cover, and you are

solely responsible for the costs of: (1) periodic or

routine maintenance, (2) repair or replacement of the

Product or parts due to normal wear and tear, (3)

defects or damage to the Product or parts resulting

from misuse, abuse, neglect, or accidents, (4) defects

or damage to the Product or parts resulting from

improper or un authori zed altera tions , modif icatio ns, or

changes; and (5) defects or damage to any Product

that has not been installed and/or maintained in

accordance with the instruction manual or technical

instructions provided by Welbilt. To the extent that

warranty exclusions are not permitted under some

state laws, these exclusions may not apply to you.

Except As Stated In The Following Sentence, This

Limited Warranty Is The Sole And Exclusive Warranty

Of Welbilt With Regard To The Product. All Implied

Wa rranties Are Strictly Limited To The Duration Of The

Limited Warranty Applicable To The Products As

Stated Above, Including But Not Limited To, Any

Warranty Of Merchantability Or Of Fitness For A

Particular Purpose.

Some states do not allow limitations on how long an

implied wa rranty la st s, so the ab ove limit atio n may not

apply to you.

Continued on next page …

Part Number 040005626 5/17 19

Page 20

In No Event Shall Welbilt Or Any Of Its Affiliates Be

Liable To The Consumer Or Any Other Person For

Any Inciden tal, Co nsequential Or S pe cial Damag es Of

Any Kind (Including, Without Limitation, Loss Profits,

Revenue Or Business) Arising From Or In Any Manner

Connected With The Product, Any Breach Of This

Limited Warranty, Or Any Other Cause Whatsoever,

Whether Based On Contract, Tort Or Any Other

Theory Of Liability.

Some states do not allow the exclusion or limitation of

incidental or consequential damages, so the above

limitation or exclusion may not apply to you.

HOW STATE LAW APPLIES

This limited warranty gives you specific legal rights,

and you may also have rights that vary from state to

state or from one jurisdiction to another.

REGISTRATION CARD

To secure prompt and continuing warran ty service, this

warranty regist ration card must be completed and sent

to Welbilt within thirty (30) days from the sale date.

Complete the foll ow in g reg is trat ion card and se nd i t to

Welbilt.

20 Part Number 040005626 5/17

Page 21

Installation

Location of Ice Machine

The location selected for the ice machine must meet

the following criteria. If any of these criteria are not

met, select another location.

• The location must be indoors.

• The location must be free of airborne and other

contaminants.

• Air temperature: Must be at least 40°F (4°C) but

must not exceed 110°F (43.4°C).

• The location must not be near heat-generating

equipment or in direct sunlight.

• The location must be capable of supporting the

weight of the ice machine and a full bin of ice.

• The location must allow enough clearance for

water, drain, and electr ica l co nne cti on s in the rear

of the ice machine.

• The location must not obstruct airflow through or

around the ice mac hine co ndenser a ir flow is in the

back and out the sides. Refer to the chart for

clearance requirements.

• The ice machine must be protected if it will be

subjected to temperatures below 32°F (0°C).

Failure caused by exposure to freezing

temperatures is not covered by the warranty.

Part Number 040005626 5/17 21

Page 22

Ice Machine Clearance Requirements

!

Warning

!

Caution

Clearance Requirements

Do not obstruct ice machine vents or

openings

M0420

M0500 -M0

M1000 -

M1400

Top/Sides 8" (20.3 cm) 8" (20.3 cm)

Back 5" (12.7 cm) 5" (12.7 cm)

*There is no minimum clearance required for water-cooled

or remote ice machines. This value is recommended for

efficient operation and servicing only.

700

Self-Contained

Air-Cooled

Water-Cooled

Remote*

and

The ice machine must be protected if it will

be subjected to temperatures below 32°F

(0°C). Failure caused by exposure to

freezing temperatures is not covered by the

warranty.

22 Part Number 040005626 5/17

Page 23

Ice Machine Heat of Rejection

!

Caution

Heat of Rejection

1

Series

Ice Machine

Conditioning

Air

2

Peak

M0420 5400 6300

M0500 5300 6100

M0700 9000 13900

M1000 16250 18600

M1400 28300 34300

1 B.T.U./Hour

2 B ecause the heat of rejection varies during the ice making

cycle, the figure shown is an average.

Ice machines , like other re frigeration equip ment, reject

heat through the condenser. It is helpful to know the

amount of heat rejected by the ice machine when

sizing air cond itioning eq uipment whe re self-con tained

air-cooled ice machines are installed.

Leveling the Ice Machine

1. The leveling legs must be s crewed into the bottom

of the bin as far as possible.

The legs must be screwed in tightly to prevent

them from bending.

2. Move the bin into its final position.

3. Use a level on top of the bin. Adjust each foot as

necessary and leve l from front to back and side to

side.

Part Number 040005626 5/17 23

Page 24

Electrical Requiremen ts

!

Warning

!

Warning

Voltage

The maximum allowable voltage variation is ±10% of

the rated voltage on the ice machine model/serial

number plate at start-up (when the electrical load is

highest).

Fuse/Circuit Breake r

A separate fuse/circuit breaker must be provided for

each ice machine.

Total Circuit Ampacity

The total circuit ampacity is used to help select the

wire size of the electrical supply.

The wire size (or gauge) is also dependent upon

location, materials used, length of run, etc., so it must

be determined by a qualified electrician

Refer to ice machine data plate, for electrical

requirements. The ice machine data plate information

overrides all other published data.

All wiring must conform to local, state and national

codes.

The ice mach ine mu st be grou nded in accord ance

with national and local electrical code.

24 Part Number 040005626 5/17

Page 25

Water Service/Drains

Important

!

Warning

WATE R SUPPLY

Local water conditions may require treatment of the

water to inhibit scale formation, filter sediment, and

remove chlorine odor and taste.

If you are installing a water filter system, refer to

the Installation Instructions supplied with the filter

system for ice making water inlet connections.

For ice making, connect to a potable water supply

only.

WATER INLET LINES

Follow these guidelines to install water inlet lines:

• Do not connect the ice machine to a hot water

supply . Be sure all hot w ater restrictors installed for

other equipment are working. (Check valves on

sink faucets, dishwashers, etc.)

• If water pres sure exc eeds the maximum

recommend ed pre ssure, 80 psig (5.5 ba r) o bt a in a

water pressure regulator from your Manitowoc

distributor.

• Install a water shut-off valve for ice making potable

water.

• Insulate water inlet lines to prevent condensation.

Part Number 040005626 5/17 25

Page 26

DRAIN CONNECTIONS

!

Caution

Follow these guidelines when installing drain lines to

prevent drain water from flowing back into the ice

machine and storage bin:

• Drain lines m ust have a 1.5-inch drop p er 5 fe et of

run (2.5 cm per meter), and must not create traps.

• The floor drain must be large enough to

accommodate drainage from all drains.

• Install a tee to vent the ice machine drain to the

atmosphere.

• Insulate drain lines to prevent condensation.

COOLING TOWER APPLICATIONS

Water Cooled Models Only

A water-cooling tower installation does not require

modification of the ice mac hin e. The water regu lat or

valve for the condenser continues to control the

refrigeration discharge pressure.

It is necessary to know the amount of heat rejected,

and the pressure drop through the condenser and

water valves (inlet to outlet) when using a cooling

tower on an ice machine.

• Water entering the condenser must not exceed

90°F (32.2°C).

• Water flow through the condenser must not

exceed 5 gallons (19 liters) per minute.

• Allow for a pressure drop of 7 psig (.48 bar)

between the condenser water inlet and the outlet

of the ice machine.

• Water exiting the condenser must not exceed

110°F (43.3° C).

Plumbing must conform to state and local codes

26 Part Number 040005626 5/17

Page 27

WATER SUPPLY AND DRAIN LINE SIZING/

CONNECTIONS

Fitting

Ice Machine

T ubing Siz e Up to

Fitting

Ice Machine

3/8" (9.5 mm) min.

3/8" Female

inside diameter

Pipe Thread

3/8" (9.5 mm) min.

3/8" Female

inside diameter

Pipe Thread

3/8" (9.5 mm) min.

3/8" Female

inside diameter

Pipe Thread

—

Water

Pressure

80 psi (5.5 bar) max.

20 psi (1.38 bar) min.

20 psi (1.38 bar) min.

150 psi (10.3 bar) max.

—

Water

Temperature

33°F (0.6°C) min.

90°F (32.2°C) max.

33°F (0.6°C) min.

90°F (32.2°C) max.

Part Number 040005626 5/17 27

Location

Water Inlet

Ice Making

Water Inlet

Condenser

Condenser

Water Dra in

Page 28

28 Part Number 040005626 5/17

This Page Intentionally Left Blank

Page 29

Maintenance

!

Caution

Interior Cleaning and Sanitizing

GENERAL

Clean and sanitize the ice machine every six months

for effici ent operation. If the ic e machine requires more

frequent cleaning and sanitizing, consult a qualified

service company to test the water quality and

recommend appropriate water treatment.

The ice mach ine mus t be t a ke n ap art for cleaning and

sanitizing.

Use only Manitowoc approved Ice Machine

Cleaner (part number 94-0546-3) and

Sanitizer (part number 94-0565-3). It is a

violation of Federal law to use these solutions

in a manner inconsistent with their labeling.

Read and understand all labels printed on

bottles before use.

CLEANING AND SANITIZING PROCEDURE

Ice machine cleaner is used to remove lime scale and

mineral deposits. Ice machine sanitizer disinfects and

removes algae and slime.

Part Number 040005626 5/17 29

Page 30

TOGGLE SWITCH OPERATION

!

Caution

!

Warning

Moving the toggle switch to clean will start a Clean

cycle.

• Setting the ice machine to stop after the clean

cycle: Place the toggle switch in the clean

position. The ice machine will stop after the clean

cycle.

• Pausing the cleaning cycle: Move the toggle

switch to Of f. Movi ng the toggle switch to clean will

restart the clean cycle.

• Setting the ice machine to start ice making

after the clean cycle: Place the toggle switch in

the Ice positi on more than 2 minut es int o the c lean

cycle.

Step 1 Place the toggle switch in the clean position

after ice falls from the evaporator at the end of a

Harvest cycle. Or, place the toggle switch in the off

position and allow the ice to melt off the evaporator.

Never use anything to force ice from the

evaporator. Damage may result.

Step 2 Remove all ice from the bin.

.

Wear rubber gloves and safety goggles

(and/or face shield) when handling Ice

Machine Cleaner or Sanitizer.

30 Part Number 040005626 5/17

Page 31

!

Caution

Do not mix Ice Machine Cleaner and Sanitizer

solutions together. It is a violation of Federal

law to use these solutions in a manner

inconsistent with their labeling.

Step 3 To start a cleaning cycle, move the toggle

switch to Clean. Water will flow through the water

dump valve and down the drain. Wait until the water

trough refills, then add the proper amount of ice

machine cleaner to the water trough.

Model Amount of Cleaner

M0420 3 ounces (90 ml)

M0500 M0700 M1000 5 ounces (150 ml)

M1400 9 ounces (265 ml)

Step 4 Wait until the clean cycle is complete

(approximately 24 minutes) then place the toggle

switch in the off position and disconnect power and

water supplies to the ice machine.

Step 5 Remove parts for cleaning.

Refer to the proper parts removal for your machine.

Continue with step 6 when the parts have been

removed.

Part Number 040005626 5/17 31

Page 32

Step 6 Mix a solution o f clea ner and l ukewarm water.

Depending on the amount of mineral buildup, a larger

quantity of solution may be required. Use the ratio in

the table below to mix enough solution to thoroughly

clean all parts.

Solution Type Water Mixed with

Cleaner 1 gal. (4 l) 16 oz (500 ml) cleaner

Step 7 Use half of the clea ner/wate r solut ion to c lean

all compo ne nt s . Th e c le aner solution will f oam whe n i t

contacts lime scale and mineral deposits; once the

foaming s tops use a sof t b r ist le bru sh , s pon ge or cl oth

(not a wire bru sh) to ca refully c lean the p art s. Soak th e

parts for 5 minu tes (15 – 20 minute s for heav ily scal ed

parts). Rinse all components with clean water.

Step 8 Whil e component s are soaking , use half of the

cleaner/water solution to clean all foodzone surfaces

of the ice machin e and bin. Use a nylon brush or cl oth

to thoroughly clean the following ice machine areas:

• Evaporator pl astic parts – including top, bottom

and sides

• Bin bottom, sides and top

• Rinse all areas thoroughly with clean water.

32 Part Number 040005626 5/17

Page 33

Step 9 Mix a solution of sanitizer and warm water.

Solution Type Water Mixed With

Sanitizer 3 gal. (12 l) 2 oz (60 ml) sanitizer

Step 10 Use half of the sanitizer/water solution to

sanitize all remov ed co mpo n e nt s . Use a spray bot tle

to liberally apply the solution to all surfaces of the

removed parts or soak the removed parts in the

sanitizer/water solution. Do not rinse parts after

sanitizing.

Step 11 Use half of the sanitizer/water solution to

sanitize all foodzone surfaces of the ice machine and

bin. Use a spray bottle to liberally apply the solution.

When sanitizing, pay particular attention to the

following areas:

• Evaporator p lastic p arts - in cluding top , bottom and

sides

• Bin bottom, sides and top

Do not rinse the sanitized areas.

Step 12 Replace all removed components.

Step 13 Wait 25 minutes.

Step 14 Reapply power a nd w ater to the i ce ma chine

and place the toggle switch in the ice position.

Step 15 W a ter will flow throu gh the wate r dump valve

and down the drain. Wait until the water trough refills,

then add th e proper a mount of ice mac hine sa nitizer to

the water trough.

Model Amount of Sanitizer

M0420 M0500 M0700

M1000

M1350 6 ounces (180 ml)

3 ounces (90 ml)

Wa it until the sani tize cycle is complete (app roximately

24 minutes) then place the toggle switch in the ice

position to start ice making.

Part Number 040005626 5/17 33

Page 34

REMOVE PARTS FOR CLEANING

!

Warning

Disconnect electric power to the ice machine

at the electric switch box before proceeding.

1. Remove the water curt ai n

• Gently flex the curtain in the center and

remove it from the right side.

• Slide the left pin out.

2. Remove the water trough

• Depress t abs on ri ght and left side of the water

trough.

• Allow front of water trough to drop as you pull

forward to disengage the rear pins.

3. Remove the ice thickness and harvest float

switches

• Pull the float switch straight down to

disengage.

• Lower the float switch until the wiring

connector is visible.

• Disconnect the wire lead from the float switch.

• Remove the float switch from the ice machine.

4. Remove the water distri buti on tube

NOTE: Distribution tube thumbscrews are retaine d to

prevent loss. Loosen thumbscrews but do not pull

thumbscrews out of distribution tube.

• Loosen the two outer screws (do not remove

screws completely they are retained to prevent

loss) and pull forward on the distri buti on tub e

to release from slip joint.

• Disassemble distribution tube by loosening the

two (2) middle thumbscrews and dividing the

distribution tube into two pieces.

• Proceed to page 32 Step 6.

34 Part Number 040005626 5/17

Page 35

5. Remove the Water Trough

• Depress tabs on right and left side of the water

trough.

• Allow front of water trough to drop as you pull

forward to disengage the rear pins.

• Remove the water trough from the bin area.

Part Number 040005626 5/17 35

Page 36

Preventative Maintenance Cleaning

!

Caution

!

Warning

This cleaning procedure can be performed

between the bi-annual cleaning and sanitizing

cycles. This procedure does not require

removing the ice from the bin.

Step 1 Place the to ggle s witch in the of f pos ition afte r

ice falls from the evaporator at the end of a Harvest

cycle. Or, place the toggle switch in the off position

and allow the ice to melt off the evaporator.

Never use anything to force ice from the

evaporator. Damage may result.

.

Wear rubber gloves and safety goggles

(and/or face shield) when handling Ice

Machine Cleaner or Sanitizer.

Step 2 To start a cleaning cycle, place the toggle

switch in th e clean po sition. W a ter will flow through th e

water dump valve and down the drain. Wait until the

water trough refills, then add the proper amount of ice

machine cleaner to the water trough.

Model Amount of Cleaner

M0420 3 ounces (90 ml)

M0500 M0700 M1000 5 ounces (150 ml)

M1400 9 ounces (265 ml)

Step 3 Wait until the clean cycle is complete

(approximately 24 minutes) then place the toggle

switch in the off position.

36 Part Number 040005626 5/17

Page 37

Ice Machine Inspection

Check all water fittings and lines for leak s. Al so, mak e

sure the refrigeration tubing is not rubbing or vibrating

against other tubing, panels, etc.

There must be adequate airflow through and around

the ice machine to maximize ice production and

ensure long component life.

Exterior Cleaning

Clean the area around the ice machine as often as

necessary to maintain cleanliness and efficient

operation.

Sponge any dust and dirt off the outside of the ice

machine with mild soap and water. Wipe dry with a

clean, sof t clot h.

Cleanup any fallen ice or water spills as they occur.

Part Number 040005626 5/17 37

Page 38

Cleaning the Condenser

!

Warning

!

Warning

General

Disconnect electric power to the ice machine

head section and the remote condensing unit

at the electric service switches before cleaning

the condenser.

A dirty condenser restricts airflow, resulting in

excessively high operating temperatures. This

reduces ice production and shortens component life.

• Clean the condenser at least every six months.

The condenser fins are sharp. Use care when

cleaning them.

• Shine a flashlight through the condenser to check

for dirt between the fins.

• Blow compressed air or rinse with water from the

inside out (opposite direction of airflow).

• If dirt still remains call a service agent to clean the

condenser.

38 Part Number 040005626 5/17

Page 39

Removal from Service/Winterization

AIR-COOLED MODELS

1. Clean and sanitize the ice machine.

2. Place the toggle switch in the off position to turn

off the ice machine.

3. Turn off the water supply, disconnect and drain

the incoming ice-making water line at the rear of

the ice machine and dra in the water trough.

4. Energize the i ce m achin e, wait one minute for the

water inlet valv e to open and blow co mpressed air

in both the incomin g water and the dra in openings

in the rear of the ice machine to remove all water.

5. Place the toggle switch in the off position and

disconnect the electric power at the circuit

breaker or the electric service switch.

6. Fill spray bottle with sanitiz er and spray all interior

food zone surfaces. Do not rinse and allow to air

dry .

7. Replace all panels.

WATER-COOLED MODELS

1. Perform steps 1-6 under “ Air-Cooled Models.”

2. Disconnect the incoming w ater and drai n line from

the water-cooled condenser.

3. Energize the ice ma ch ine in the freeze cycle. The

increasing ref rigerant pre ssure will ope n the water

regulating valve .

4. Blow compressed air through the condenser until

no water remains.

Part Number 040005626 5/17 39

Page 40

40 Part Number 040005626 5/17

This Page Intentionally Left Blank

Page 41

Operation

Ice Making Sequence of Operation

NOTE: The toggle switch must be in the ON position

and the water curtain must be closed before the ice

machine will start.

Water Purge Cycle

The ice m ac hin e purg es an y rem ain ing w at er f rom the

water trough down the drain.

Freeze Cycle

Prechill - The ref rigeration system chills the evaporat or

before water flow over the evaporator starts. The

water inlet valve energizes during the pre-chill and

remains on until the ice thickness float switch is

satisfied.

Freeze - Water flowing across the evaporator freezes

and builds ice on the evaporator. After a sheet of ice

has formed , the Harvest fl oat switch si gnals the co ntrol

board to start a harvest cy cle.

Harvest Cycle

Any remaining water is purged down the drain as

refrigerant gas warms the evaporator. When the

evaporator warms, the sheet of cubes slides off the

evaporator and into the storage bin. If all cubes fall

clear of the water curtain, the ice machine starts

another freeze cycle.

Full Bin Cycle

If the water curtain is held open by ice cubes the ice

machine shuts off. When the water curtain closes the

ice machine starts a new cycle at the water purge.

Part Number 040005626 5/17 41

Page 42

CONTROL BOARD TIMERS

• The ice machine is locked into the freeze cycle for

6 minutes before a harvest cycle can be initiated.

The freeze time lock in feature is bypassed on the

initial cycle (manual start or after a full bin/safety

limit conditio n).

If the Harvest float Switch is in the down position

for 10 continuous seconds during the start of a

freeze cycle, a harvest sequence is initiated.

• The maximum freeze time is 60 minutes at which

time the control board automatically initiates a

harvest sequence.

• The maximum harvest time is 3.5 minutes. The

control board automatically initiates a freeze

sequence when these times are exceeded.

• The ice machine will continue to fill with with water

for up to six minutes, or until the high water float

opens for 5 continuous seconds. Th e control boa rd

will energize the water inlet valve one more time 3

minutes into the freeze cycle.

42 Part Number 040005626 5/17

Page 43

SAFETY LIMITS

Safety limits are stored and indicated by the control

board. The number of cycles required to stop the ice

machine varies for each safety limit.

Safety limits can be reset by cycling the toggle switch

Off/On and starting a new ice making cycle.

A safety limit is indicated by a flashing light on the

control board.

Safety Limit 1

If the freeze time reaches 60 minutes, the control

board automatically initiates a harvest cycle.

• After 3 consecutive 60 minute cycles control board

light SL#1 light will flash on/off at 1 second

intervals.

• If 6 consecuti ve 60-mi nute freeze cycles occur, the

ice machine stops and the SL#1 light on the

control board will be on continuously.

Safety Limit 2

If the harvest time reaches 3.5 minutes, the control

board automatically returns the ice machine to the

freeze cycle.

• If three consecutive 3.5 minute harvest cycles

occur the SL#2 light on the control board will flash

on/off at 1 second intervals. After 75 consecutive

3.5 minutes harvest cycles the SL#2 light will be

energized con tin uou sl y.

• If 100 consecutive 3.5 minute harvest cycles

occur, the ice machine stops and the SL#2 light on

the control board will be on continuously.

Part Number 040005626 5/17 43

Page 44

Safety Limit 3

If the harvest float switch hasn’t opened for 10

continuous seconds w ithin 4 mi nutes of the water inlet

valve energizing the ice machine stops.

• Safety Limit 3 is bypassed on the initial cycle

(manual start or after a full bin/safety limit

condition). For all subsequent cycles the ice

machine sto p s for 30 minutes when the wat er i nle t

valve is energized for 4 minutes and the harvest

float valve didn’t open. Control board lights SL#1

and SL#2 will flash on/off at 1 second intervals.

• The ice machi ne auto matically res tarts at th e end

of the 30 minute delay period and stops flashing

the control board lights.

• If 100 consecutive failures occur the ice machine

stops and the SL#1 & SL#2 lights flash on/off at 1

second intervals.

• SL#1 & SL#2 will flash 3 times on startup and

automa tically erase after 100 normal cycles.

44 Part Number 040005626 5/17

Page 45

Time

Length of

Float Switch

Ice Thickness

5 seconds

45 seconds

5 seconds

5 seconds

120

Seconds

initial cycle

Thereafter

60 seconds

Harvest

Float Switch

&

Motor*

Compressor

Condenser Fa n

Valve

Dump

Valve

Water Inlet

Valve

Harvest

Water Pump

ON ON OFF ON OFF CLOSED CLOSED

OFF OFF OFF OFF OFF CLOSED CLOSED

OFF ON OFF OFF OFF CLOSED CLOSED

OFF ON OFF OFF ON CLOSED CLOSED

OFF OFF ON OFF ON OPEN CLOSED

ENERGIZED PARTS CHART

Self-Contained Ice Machines

Part Number 040005626 5/17 45

ICE MAKING

Start-up

Pressure

OPERATION

SEQUENCE OF

Initial Start-up

1a. Water p urge

1b. Delay period

2a. Equalize

2. Refrigeration

System Start-up

2b. Compressor

3. Pre chill

Freeze Sequence

Page 46

Until

Harvest

Float Swi tch

THEN

CLOSED

closes for

OPEN

10 continual

seconds

activation

Bin switch

45 seconds

Until bin

switch

re-closes

THEN

CLOSED

ON OFF ON OFF ON OPEN

4. Freeze

46 Part Number 040005626 5/17

ON ON OFF ON ON CLOSED CLOSED

Harvest

Sequence

5. Water Purge

OFF ON OFF OFF ON CLOSED CLOSED

6. Harvest

7. Automatic

OFF OFF OFF OFF OFF CLOSED CLOSED

Shut-off

* Condenser Fan Motor: The fan motor is wired through a fan cycle pressure control; therefore, it may cycle on and off.

Page 47

Operational Checks

Ice Thickness Float

Switch Adjustment

ICE THICKNESS CHECK

After a harvest cycle, inspect the ice cubes in the ice

storage bin. Th e ice bridge connec ts the ice cu bes and

must be set to maintain an ice bridge thickness of 1/8"

(3.2 mm). To adjust the thic kness of the bridg e refer to

ice thickness adjustment.

The ice thicknes s fl oat s witch is f act ory-se t to maint ain

the ice bridge thickness at 1/8" (3 mm).

NOTE: Make sure the water curtain is in place

when performing this check. It prevents water

from splashing out of the water trough.

1. Inspect the bridge connecting the cubes. It

should be about 1/8" (3 mm) thick.

2. If adjustment is necessary, turn the ice

thickness float switch clockwise to increase

bridge thickness, counterclockwise to

decrease bridge thickness. Adjust to achieve

a 1/8" (3 mm) bridge thickness.

NOTE: The float can be adjusted with a 3/4"

wrench while the water trough is in-place.Test

run two cycles to verify ice bridge thickness.

Part Number 040005626 5/17 47

Page 48

48 Part Number 040005626 5/17

This Page Intentionally Left Blank

Page 49

Troubleshooting

Control Board Test Mode

NOTE: The water curtain/bin switch can be open or

closed and does not effect the operation of the test

mode.

To enter the test mode move the toggle switch to off,

then press and hold the test button on the control

board for 3 seconds. The control board test mode

performs the following functions for a 2 minute time

period:

• Energizes all control board relay s

• Energizes all control board lights

After 2 minutes the control board will automatically

initiate and complete one ice making cycle, then stop.

Canceling a test cycle:

To cancel a test cycle press the test button a second

time.

Restarting a test cycle:

The test cycle will restart each time the test button is

pressed for a 3 second time period.

Part Number 040005626 5/17 49

Page 50

Diagnosing an Ice Machine

!

Warning

that

NOTE: If any control board lights are on, the fuse is

okay.

Will Not Run

High (line) voltage is applied to the control board

at all times. Removing the control board fuse or

cycling the toggle switch Off/On will not remove

the power supplied to the control board.

1. Verify primary voltage is supplied to ice machine

and the fuse/circuit breaker is closed.

2. Verify control board fuse is okay.

3. Verify the bin switch functions properly. A

defective bin switch can falsely indicate a full bin

of ice.

4. V erify togg le switch f unctions pr operly . A defective

toggle switch may keep the ice machine in the

OFF mode. Refer to toggle switch diagnostics

when steps 1-3 tes t good.

5. Be sure Steps 1 – 4 were followed thoroughly.

Intermittent problems are not usually related to

the control board. Replace control board if toggle

switch operation is correct.

50 Part Number 040005626 5/17

Page 51

Ice Machine Does Not Cycle Into Harvest

HARVEST FLOAT SWITCH

ICE THICKNESS FLOAT

SWITCH

when Water Loses Contact with the

Harvest Float Switch

NOTE: The ice machine will make a thick or double

slab when a new freeze cycle is started with ice

already present on the evaporator.

Two of the most common scenarios are:

• Power is cycled off/on with ice on the evaporator.

• The water curtain/bin switch is opened/closed in

the harvest cycle before the ice releases.

Remove all ice from the evaporator before starting

diagnostic procedures.

Freeze Time Lock-In Feature

The ice machine control system incorporates a freeze

time lock-in feature. This prevents the ice machine

from short cycling in and out of harvest. The control

board locks the ice machine in the freeze cycle for six

minutes. After six minutes a harvest cycle can be

initiated. To allow the service technician to initiate a

harvest cy cl e wi thou t delay, this feature is not use d o n

the first cycle after moving the toggle switch to OFF

and back to ON.

Part Number 040005626 5/17 51

Page 52

Step 1 Disconnec t pow er to the ice mac hine, remov e

the electrical panel to allow viewing of the control

board lights. Disconnect the harvest float switch wire

from the control board and place a jumper on the

control board harvest switch terminals.

Step 2 Bypass the freeze time lock-in feature by

moving the toggle switch Off/On to cycle the ice

machine on. W ait until wate r flows ov er the evapo rator ,

then refer to chart.

Result Correction

10 seconds into the freeze

cycle the ice machine cycles

from freeze to harvest and

the control board harvest

light energizes.

The harvest light comes on,

but the ice machine remains

in the freeze cycle.

The harvest light stays off

and the ice machine remains

in freeze.

The ice thickness float

switch, connectors or wiring

are causing the

malfunction.

The ice machine is in a 6

minute freeze lock - Cycle

on/off and retest.

Replace the control board.

52 Part Number 040005626 5/17

Page 53

Ice Machine Cycles Into Harvest Before

HARVEST FLOAT SWITCH

ICE THICKNESS FLOAT

SWITCH

Water loses Contact with the Harvest

Float Switch

Step 1 Disconnec t pow er to the ice mac hine, remov e

the electrical panel to allow viewing of the control

board lights and disconnect the harvest float switch

from the control board.

Step 2 Reapp ly power an d mo ve the tog gle switc h to

ice to bypass the freeze time lock-in feature. Wait until

water flows over the evaporator, then refer to chart.

Result Correction

The harvest light does not

come on and the ice

machine stays in freeze.

10 seconds into the freeze

cycle the ice machine cycles

from freeze to harvest and

the control board harvest

light energizes.

The ice thickness float

switch, connectors or wiring

are causing the malfunction.

Refer to fl o a t sw itch

diagnostics.

Replace the control board.

Part Number 040005626 5/17 53

Page 54

Ice Production Check

The amount of ice a machine produces directly relates to the

operating water and air temperatures. This means an ice

machine with a 70°F (21°C) ambient temperature and 50°F

(10°C) water produces more ice than the same ice machine

with 90°F (32°C) ambient and 70°F (21°C) water.

1. Determine the ice machine operating conditions:

Air temp entering condenser: ____°

Air temp around ice machine: ____°

Water temp entering sump trough: ____°

2. Refer to the appropriate 24-Hour Ice Production Chart.

Use the operating conditions determined in Step 1 to

find published 24 hr. ice production:____

Times are in minutes.

Example: 1 min., 15 sec. converts to 1.25 min.

(15 seconds ÷ 60 seconds = .25 minutes)

Weights are in pounds.

Example: 2 lb., 6 oz. converts to 2.375 lb.

(6 oz. ÷16 oz. = .375 lb.)

3. Perform an ice production check using the formula

below.

1. _______ + _______ = _______

Freeze Time Harvest Time Total Cycle Time

2. 1440 ÷ _______ = _______

Mins in 24 hrs Total Cycle Time Cycles Per Day

3. _______ x _______ = _______

Weight of One Cycles Per Day Actual 24 Hr

Harvest Production

Weighing the ice is the only 100% accurate check.

4. Compare the results of step 3 with step 2. Ice production

is normal when these numbers match closely. If they

match closely, determine if:

Another larger ice machine is required.

Relocating the existing equipment to lower the load

conditions is required.

Contact the local distributor for information on available

options and accessories.

54 Part Number 040005626 5/17

Page 55

Installation/Visual Inspection Checklist

Ice machine is not level

• Level the ice machine

Condenser is dirty

• Clean the condenser

Water filtration is plugged (if used)

• Install a new water filter

Water drains are not run separately and/or are not

vented

• Run and vent drains according to the Installation

Manual

Part Number 040005626 5/17 55

Page 56

Water System Checklist

A water-related problem often causes the same

symptoms as a refrigeration system component

malfunction.

Example: A water dump valve leaking during the

freeze cycle, a system low on charge, and a starving

TXV have similar symptoms.

Water system problems must be identified and

eliminated prior to replacing refrigeration components.

Water area (evaporator) is dirty

• Clean as needed

Water inlet pressure not between 20 and 80 psig

(1–5 bar, 138–552 kPa)

• Install a water regulator valve or increase the

water pressure

Incoming water temperature is not between 35°F

(1.7°C) and 90°F (32.2°C)

• If too hot, check the hot water line check valves in

other store equipment

Water filtration is plugged (if used)

• Install a new water filter

Vent tube is not installed on water outlet drain

• See Installation Instructions

Hoses, fittings, etc., are leaking water

• Repair/replace as needed

Water valve is stuck open, closed or is leaking

• Clean/replace as needed

Water is spraying out of the sump trough area

• Stop the water spray

Uneven water flow across the evaporator

• Clean the ice machine

Water is freezing behind the evaporator

• Correct the water flow

Plastic extrusions and gaskets are not secured to

the evaporator

• Remount/replace as needed

56 Part Number 040005626 5/17

Page 57

Ice Formation Pattern

INLET

OUTLET

Evaporator ice formation pattern analysis is helpful in

ice machine diagnostics.

Analyzing the ice formation pattern alone cannot

diagnose an ice machine malfunction. However, when

this analysis is used along with the Refrigeration

System Operational Analysis Table, it can help

diagnose an ice machin e malfun ction.

Example of Ev aporato r Tubing Rout ing

Normal Ice Formation

Ice forms across the entire evaporator surface.

At the beginning of the Freeze cycle, it may appear

that more ice is forming on the inlet of the evaporator

than at the outlet. At the end of the Freeze cycle, ice

formation at the outlet will be close to, or just a bit

thinner than, ice formation at the inlet. The dimples in

the cubes at the outlet of the evaporator may be more

pronounced than those at the inlet. This is normal.

If ice forms uniformly across the evaporator surface,

but does n ot do so in the pro per am ount o f time , this is

still considered a normal ice fill pattern.

Part Number 040005626 5/17 57

Page 58

Extremely Thi n at Evaporator Outlet

There is no ice, or a consi der able lack of ic e format ion

on the outlet of the evaporator.

Examples: No ice at all at the outlet of the evaporator,

but ice forms at the inle t hal f of th e evaporator. Or, the

ice at the outlet of the evaporator reaches the correct

thickness, but the outlet of the evaporator already has

1/2" to 1" of ice formation.

Possible cause: Water loss, low on refrigerant,

starving TXV, faulty water inlet valve, etc.

Extremely Thin at Evaporator Inlet

There is no ice, or a consi der able lack of ic e format ion

at the inlet of the eva porator. Examples: The ice at the

outlet of the eva por ator reaches the correct th ic kn ess ,

but there is no ice formation at all at the inlet of the

evaporator.

Possible cause: Insufficient water flow, flooding TXV,

etc.

No Ice Formation

The ice machine operates for an extended period, but

there is no ice formation at all on the evaporator.

Possible cause: water inlet valve, water pump,

starving expansion valve, low refrigerant charge,

compressor, etc.

58 Part Number 040005626 5/17

Page 59

Evaporator Tubing Routing

Outlet

Inlet

Thin at Outlet

Thin at Inlet

ICE

ICE

Routing of the tubing on the back of the evaporator

determines the ice fill pattern failure mode.

One Evaporator, One TXV Models

The evaporator outl et tubing does not exit directly at

the top of the evaporator, but exits several inches

below the top of the evaporator. Extremely Thin at the

Evaporator Outlet will first be visible several inches

below the top of the evaporator. Extremely Thin at

Evaporator Inle t will first be visible at the bottom of the

evaporator.

Part Number 040005626 5/17 59

Page 60

SAFETY LIMITS

Safety limits are stored and indicated by the control

board. The number of cycles required to stop the ice

machine varies for each safety limit.

Safety limits can be reset by cycling the toggle switch

Off/On and starting a new ice making cycle.

A safety limit is indicated by a flashing light on the

control board.

Safety Limit 1

If the freeze time reaches 60 minutes, the control

board automatically initiates a harvest cycle.

• After 3 consecutive 60 minute cycles control board

light SL#1 light will flash on/off at 1 second

intervals.

• If 6 consecuti ve 60-mi nute freeze cycles occur, the

ice machine stops and the SL#1 light on the

control board w i ll be on continuously.

Safety Limit 2

If the harvest time reaches 3.5 minutes, the control

board automatically returns the ice machine to the

freeze cycle.

• If three consecutive 3.5 minute harvest cycles

occur the SL#2 light on the control board will flash

on/off at 1 second intervals. After 75 consecutive

3.5 minutes harvest cycles the SL#2 light will be

energized con tin uou sl y.

• If 100 consecutive 3.5 minute harvest cycles

occur, the ice machine stops and the SL#2 light on

the control board will be on continuously.

60 Part Number 040005626 5/17

Page 61

Safety Limit 3

If the harvest float switch hasn’t opened for 10

continuous seconds w ithin 4 mi nutes of the water inlet

valve energizing the ice machine stops.

• Safety Limit 3 is bypassed on the initial cycle

(manual start or after a full bin/safety limit

condition). For all subsequent cycles the ice

machine sto p s for 30 minutes when the wat er i nle t

valve is energized for 4 minutes and the harvest

float valve didn’t open. Control board lights SL#1

and SL#2 will flash on/off at 1 second intervals.

• The ice machi ne auto matically res tarts at th e end

of the 30 minute delay period and stops flashing

the control board lights.

• If 100 consecutive failures occur the ice machine

stops and the SL#1 & SL#2 lights flash on/off at 1

second intervals.

• SL#1 & SL#2 will flash 3 times on startup and

automa tically erase after 100 normal cycles.

Part Number 040005626 5/17 61

Page 62

Determining Which Safety Limit Stopped

Ice Machine:

the

1. Cycle the toggle switch Off.

2. Cycle the toggle switch On to start ice making.

3. Watch the safety limit lights.

• One will fla sh c orre sp ond ing to safety limi t s 1 or 2.

4. Safety limit 3 is indicated by both SL#1 & SL#2

flashing.

After safety li mit ind ication, th e ice m achin e will res tart

and run until a safety limit is exceeded again.

Safety Limit Notes

• A continuous run of 100 harvests automatically

erases the safety limit code.

• The co ntrol board will store and indicate only one

safety limit – the last one exceeded.

• If the toggle switch is cycled OFF and then ON

prior to reaching the 100-harvest point, the last

safety limit exceeded will be indicated.

62 Part Number 040005626 5/17

Page 63

Safety Limit Checklist

The following checklists are designed to assist the

service technician in analysis. However, because

there are many possible external problems, do not

limit your diagnosis to only the items listed.

Safety Limit #1

Freeze time exceeds 60 minutes for 3 consecutive

freeze cycles.

Possible Cause Checklist

Improper installation

• Refer to “Installation/Visual Inspection Checklist”

on page 55

Water System

• Float switch or water escaping water trough

• Low water pressure (20 psig min.)

• High water pressure (80 psig max.)

• High water temperature (90°F/32.2°C max.)

• Clogged water distrib uti on tube

• Dirty/defective water inlet valve

• Defective water pump

Electrical System

• Harvest cycle not initiated electrically

• Contactor not energizing

• Compressor ele ctri ca lly non-o pera tio nal

• Restricted condenser air flow

• High inlet air temperature (110°F/43.3°C max.)

• Condenser discha rge air re-c irc ula tio n

• Dirty condenser fins

• Defective fan cycling control

• Defective fan motor

• Dirty condenser

Part Number 040005626 5/17 63

Page 64

Refrigeration System

• Non- OEM components

• Improper refrigerant charge

• Defect ive compressor

• TXV starving or flooding (check bulb mounting)

• Non-condensible in refrigeration system

• Plugged or restricted high side refrigerant lines or

component

• Defective harvest valve

64 Part Number 040005626 5/17

Page 65

Safety Limit #2

Harvest time exceeds 3.5 minutes for 100

Consecutive harvest cycles.

Possible Cause Checklist

Improper installation

• Refer to “Installation/Visual Inspection Checklist”

on page 55.

Water System

• Water area (evaporator) dirty

• Dirty/defective water dump valve

• Vent tube not installed on water outlet drain

• Water freezing behind evaporator

• Plastic extrusions and gaskets not securely

mounted to the evaporator

Electrical system

• Bin switch defective

• Premature harvest

Refrigeration system

• Non-OEM components

• Improper refrigerant charge

• Defective harvest valve

• TXV flooding (check bulb mounting)

• Defective fan cycling control

Part Number 040005626 5/17 65

Page 66

Safety Limit 3

The harvest float switch hasn’t opened for 10

continuous seconds within 4 minutes of the water

inlet valve energizing.

Possible Cause Checklist

Improper installation

• Refer to “Installation/Visual Inspection Checklist”

on page 55.

Water System

• Water dump va lve

• Harvest float valve dirty or defective

• Low water pressure (20 psig min.)

• Dirty defective water filter (when used)

• Loss of water from sump area

• Dirty/defective water inlet valve

Electrical system

• Water inlet valve coil defective

• Harvest float valve defective

66 Part Number 040005626 5/17

Page 67

Analyzing Discharge Pressure

1. Determine the ice machi ne ope rati ng con di tion s:

Air temp. entering condenser ______

Air temp. around ice machine ______

Water temp. entering sump trough ______

2. Refer to “Cycle Times, 24 Hr. Ice Production and

Refrigerant Pressure Charts” on page 117 for ice

machine being checked.

Use the operating conditions determined in step 1 to

find the published normal discharge pressures.

Freeze Cycle ______

Harvest Cycle ______

3. Perform an actual discharge pressure check.

Beginning of

Cycle

Middle of

Cycle

End of

Cycle

Freeze

Cycle PSIG

__________ __________

__________ __________

__________ __________

Harvest

Cycle PSIG

4. Compare the actual discharge pressure (step 3)

with the published discharge pressure (step 2).

The discharge pressure is normal when the act ual

pressure falls within the published pressure range for

the ice mach in e’s operating conditions. It is normal for

the dischar ge pressure to be high er at the beginnin g of

the freeze cycle (when load is greatest), then drop

through out the freeze cy cl e.

Part Number 040005626 5/17 67

Page 68

Discharge Pressure High Checklist

Improper Installation

• Refer to “Installation/Visual Inspection Checklist”

on page 55.

Condenser Air Flow

• High inlet air temperature

• Condenser discha rge air re-c irc ula tio n

• Dirty conden se r fins

• Defective fan cycling control

• Defective fan motor

Improper Refrigerant Charge

• Overcharged

• Non-condensible in system

• Wrong type of refrigerant

Other

• Non-OEM components in system

• High side refrigerant lines/component restricted

(before mid-condenser)

Freeze Cycle Discharge Pressure Low Checklist

Improper Installation

• Refer to “Installation/Visual Inspection Checklist”

on page 55.

Improper Refrigerant Charge

• Undercharged

• Wrong type of refrigerant

Other

• Non-OEM components in system

• High side refrigerant lines/component restricted

(before mid-condenser)

• Defective fan cycle con trol

NOTE: Do not limit your diagnosis to only the items

listed in the checkli st s .

68 Part Number 040005626 5/17

Page 69

Analyzing Suction Pressure

The suction pressure gradually drops throughout the

freeze cycle. The actual suction pressure (and drop

rate) changes as the air and water temperature

entering the ice machine changes. These variables

also determine the freeze cycle times.

To analyze and identify the proper suction pressure

drop throughout the freeze cycle, compare the

published suction pressure to the published freeze

cycle time.

NOTE: Analyze discharge pressure before analyzing

suction press ure . H igh or lo w dis c harg e pre ss ure ma y

be causing high or low suction pressure.

Part Number 040005626 5/17 69

Page 70

Procedure

Step

1. Determine the ice machine operating conditions.

Example:

Air temp. entering condenser: 90°F/32.2°C

Air temp. around ice machine: 80°F/26.7°C

Water temp. entering water fill valve: 70°F/21.1°C

2A. Refer to “Cycle Time” and “Operating Pressure” charts

for ice machine model being checked. Using operating

conditions from Step 1, determine published freeze cycle

time and published freeze cycle suction pressure.

Example:

Published freeze cycle time: 14.8 - 15.9 minutes

Published freeze cycle suction pressure: 65 - 26 psig

2B. Compare the published freeze cycle time and

published freeze cycle suction pressure. Develop a chart.

Example:

Published Freeze Cycle Time (minutes)

1247101214

|||||||

65 55 47 39 34 30 26

Published Freeze Cycle Suction Pressure (psig)

In the example, the proper suction pressure should be

approximately 39

minutes; etc.

psig at 7 minutes; 30 psig at 12

3. Perform an actual suction pressure check at the

beginning, middle and end of the freeze cycle. Note the

times at which the readings are taken.

Example:

Manifold gauges were connected to the example ice

machine and suction pressure readings taken as

follows: ________ PSIG

Beginning of Freeze cycle: 79 (at 1 min.)

Middle of freeze cycle: 48 (at 7 min.)

End of freeze cycle: 40 (at 14 min.)

4. Compare the actual freeze cycle suction pressure (Step

3) to the published freeze cycle time and pressure

comparison (Step 2B). Determine if the suction pressure is

high, low or acceptable.

Example:

In this example, the suction pressure is considered high

throughout the freeze cycle. It should have been:

Approximately 65 psig (at 1 minute) – not 79

Approximately 39 psig (at 7 minutes) – not 48

Approximately 26 psig (at 14 minutes) – not 40

70 Part Number 040005626 5/17

Page 71

Suction Pressure High Checklist

Improper Installation

• Refer to “Installation/Visual Inspection Checklist”

on page 55.

Discharge Pressure

• Discharge pressure is too high, and is affecting

suction pressure, refer to

“Discharge Pressure

High Checklist” on page 68.

Improper Refrigerant Charge

• Overcharged

• Wrong type of refrigerant

• Non-condensible in system

Other

• Non-OEM components in system

• Harvest valve leaking

• TXV flooding (check bulb mounting)

• Defect ive compressor

Part Number 040005626 5/17 71

Page 72

Suction Pressure Low Checklist

Improper Installation

• Refer to “Installation/Visual Inspection Checklist”

on page 55.

Discharge Pressure

• Discharge pressure is too low, and is affecting

suction press ure, refer to “Fre eze Cycle Disc harge

Pressure Low Checklist”

Improper Refrigerant Charge

• Undercharged

• Wrong type of refrigerant

Other

• Non-OEM components in system

• Improper water supply over evaporator refer to

“Water System Checklist” on page 56.

• Loss of heat transfer from tubing on back side of

evaporator

• Restricted/plugged liquid line drier

• Restricted/plugged tubing in suction side of

refrigeration system

• TXV starving

NOTE: Do not limit your diagnosis to only the items

listed in the checkli st s .

72 Part Number 040005626 5/17

Page 73

Harvest Valve

General

The harvest v alve is an elec trically operate d val ve tha t

opens when energized, and closes when

de-energized.

Normal Operation

The valve is de-energized (closed) during the freeze

cycle and energized (open) during the harvest cycle.

The valve is positioned between the compressor

discharge line and the evaporator and performs two

functions:

1. Prevents refrigerant from entering the evaporator

during the freeze cycle.

The harvest valve is not used during the freeze

cycle. The harvest valve is de-energized (closed)

preventing refrigerant flow from the receiver into

the evaporator.

2. Allows refriger ant va por to en ter the e vapora tor in

the harvest cycle.

During the harvest cycle, the harvest valve is

energized ( open) allowing refrigerant gas from the

discharge line of the compressor to flow into the

evaporator. The heat is absorbed by the

evaporator and allows release of the ice slab.

Exact pressures vary according to ambient

temperature and ice machine model. Harvest

pressures c an be f ound in the Cycle Time/24 Hour Ice

Production/ Refrigerant Pressure Charts in this book.

Part Number 040005626 5/17 73

Page 74

Harvest Valve Analysis

The valve can fail in two positions:

• Valve will not open in the harvest cycle.

• Valve remai ns open d uring the freeze cycle.

VALVE WILL NOT OPEN IN THE HARVEST CYCLE

Although the ci rcuit board has initi ated a harvest cy cle,

the evaporator temperature remains unchanged from

the freeze cycle.

VALVE REMAINS OPEN IN THE FREEZE CYCLE:

Symptoms of a harvest valve remaining partially open

during the freeze cycle can be similar to symptoms of

an expansion valve or compressor problem.

Symptoms are de pendent on th e amount of l eakage in

the freeze cycle.

A small amount of leakage w ill cause increased freeze

times and an ice fill pattern that is “Thin at the Outlet”,

but fills in at the end of the cycle.

As the amount of leakage increases the length of the

freeze cycle increases and the amount of ice at the

outlet of the evaporator decreases.

Refer to the Parts Manua l for prope r valve applicati on.

If replacement is necessary, use only “original”

replacement parts.

74 Part Number 040005626 5/17

Page 75

Use the following procedure and table to help

Important

!

Warning

determine i f a harvest va lve is re maining partial ly open

during the freeze cycle.

1. Wait five minutes into the freeze cycle.

2. Feel the inlet of the harvest valve(s).

Feeling the harvest valve outlet or across the

harvest valve itself will not work for this