Page 1

Undercounter, Prep Table

and Low Boy Refrigerators

and Freezers

Installation, Use & Care Manual

This manual is updated as new information and models are released.

Visit our website for the latest manual. www.manitowocfsg.com

America’s Quality Choice in Refrigeration

Part Number 14514 2/08

Page 2

Safety Notices

! Warning

!

Caution

Important

!

Caution

Important

! Warning

As you work on Manitowoc equipment, be sure to pay

close attention to the safety notices in this manual.

Disregarding the notices may lead to serious injury and/

or damage to the equipment.

Throughout this manual, you will see the following types

of safety notices:

Text in a Warning box alerts you to a potential

personal injury situation. Be sure to read the

Warning statement before proceeding, and work

carefully.

Text in a Caution box alerts you to a situation in

which you could damage the equipment. Be sure to

read the Caution statement before proc eeding, and

work carefully.

Procedural Notices

As you work on Manitowoc equipment, be sure to read

the procedural notices in this manual. These notices

supply helpful information which may assist you as you

work.

Throughout this manual, you will see the following types

of procedural notices:

Read These Before Proceeding:

Proper installation, care and maintenance are

essential for maximum performance and troublefree operation of your Manitow oc equipment. Read

and understand this manual. It contains valuable

care and maintenance information. If you encounter

problems not covered by this manual, do not

proceed, contact Manitowoc Foodservice Group.

We will be happy to provide assistance.

Routine adjustments and maintenance procedures

outlined in this manual are not covered by the

warranty.

PERSONAL INJURY POTENTIAL

Do not operate equipment that has been misused,

abused, neglected, damaged, or altered/modified

from that of original manufactured specifications.

NOTE: SAVE THESE INSTRUCTIONS.

Text in an Important box provides you with

information that may help you perform a procedure

more efficiently. Disregarding this information will

not cause damage or injury, but it may slow you

down as you work.

NOTE: Text set off as a Note provides you with simple,

but useful, extra information about th e pr oce dur e yo u

are performing.

We reserve the right to make product improvements at any time.

Specifications and design are subject to change without notice.

Page 3

Section 1

General Information

Table of Contents

Model Numbers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Sandwich/Salad Prep Tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Pizza Prep Tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Undercounter Refrigerators and Freezers . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Work Tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Low Boy Chef Stands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

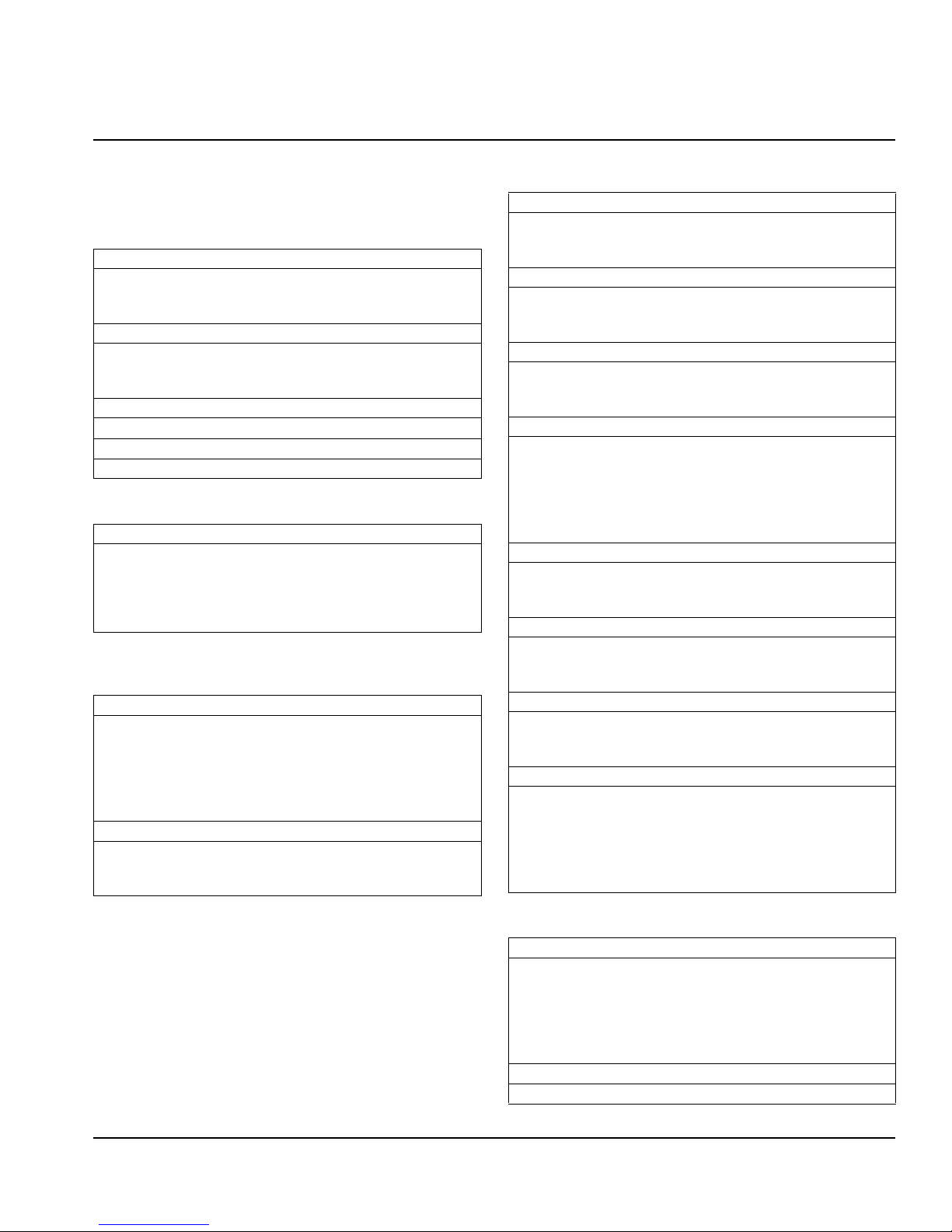

How to Read Model Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Undercounters / Sandwich / Salad Prep Table Example . . . . . . . . . . . . . . 1-2

Work Table / Chef Stand Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Pizza Prep Table Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Model/Serial Number Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Warranty Coverage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Parts Coverage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Labor Coverage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Exclusions from Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Warranty Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Section 2

Installation Instructions

Locating the Cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Pre-installation Checklist. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Uncrating. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Leveling the Cabinet. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Shelf/Tray Slide Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Condensate Water Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Defrost Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Shelves — Undercounter Units & Sandwich/Salad Units . . . . . . . . . . . . . . 2-3

Shelves — Pizza Prep Units & Refrigerated Work Tables . . . . . . . . . . . . . 2-3

Tray Slides (Optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Electrical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Defrost Timers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Defrost Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Setting Defrost Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Adjusting Defrost Duration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Temperature Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Part Number 14514 2/08 i

Page 4

Section 3

Operation

Section 4

Maintenance

Table of Contents (continued)

Sequence of Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Loading Shelves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Loading Pans . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Operating Checks and Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Door Hinge Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Removing Doors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Rehinging Doors — Single Door Models . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Cleaning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Exterior . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Interior . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Cleaning the Condenser Coil. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Condenser Cleaning Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Cleaning the Fan Blades and Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Cleaning the Evaporator Drain Pan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Section 5

Before Calling for Service

Troubleshooting Guide. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

ii Part Number 14514 2/08

Page 5

Section 1

General Information

Model Numbers

This manual covers the following models:

SANDWICH/SALAD PREP TABLES

Sandwich / Salad Prep Tables

P-6

P-10-8

P-10-12

Super Sandwich / Salad Prep Tables

ST-27-2

ST-45-3

ST-45-4

Super Prep Tables

ST-45-12 ST-59-16

Smoothie Table

FST-45-2EN

PIZZA PREP TABLES

Pizza Prep Tables

PTA-1

PTA-2

PTA-2D

PTA-3

PTA-3D

UNDERCOUNTER REFRIGERATORS AND

FREEZERS

Refrigerated Undercounters — Solid Door Glass Door

R-6E

RS-6E

RSC-6E

R-10E

RS-10E

RSC-10E

Freezer Undercounter Units

F-6E

FS-6E

FSC-6E

P-15-12

P-15-16

ST-59-3

ST-59-4

PTS-1

PTS-2

PTS-2D

PTS-3

PTS-3D

R-15E

RS-15E

RSC-15E

R-10EGD

RS-10EGD

RSC-10EGD

R-10E

FS-10E

FSC-10E

WORK TABLES

Refrigerated Work Tables (1 Door)

STA-10-RSE

STSA-10-RSE

LTA-10-RSE

Refrigerated Work Tables (2 Door)

STA-20-RSE

STSA-20-RSE

LTA-20-RSE

Refrigerated Work Tables (3 Door)

STA-30-RSE

STSA-30-RSE

LTA-30-RSE

Refrigerated Work Tables (Remote)

STSA-20-RRE

STSA-30-RRE

STA-20-RRE

STA-30-RRE

LTA-20-RRE

LTA-30-RRE

Freezer Work Tables (1 Door)

STA-10-FSE

STSA-10-FSE

LTA-10-FSE

Freezer Work Tables (2 Door)

STA-20-FSE

STSA-20-FSE

LTA-20-FSE

Freezer Work Tables (3 Door)

STA-30-FSE

STSA-30-FSE

LTA-30-FSE

Freezer Work Tables (Remote)

STSA-20-FRE

STSA-30-FRE

STA-20-FRE

STA-30-FRE

LTA-20-FRE

LTA-30-FRE

STS-10-RSE

STSS-20-RSE

LTS-10-RSE

STS-10-RSE

STSS-20-RSE

LTS-20-RSE

STS-30-RSE

STSS-30-RSE

LTS-30-RSE

STSS-20-RRE

STSS-30-RRE

STS-20-RRE

STS-30-RRE

LTS-20-RRE

LTS-30-RRE

STS-10-FSE

STSS-10-FSE

L TS-10-FSE

STS-20-FSE

STSS-20-FSE

L TS-20-FSE

STS-30-FSE

STSS-30-FSE

L TS-30-FSE

STSS-20-FRE

STSS-30-FRE

STS-20-FRE

STS-30-FRE

L TS-20-FRE

LTS-30-FRE

Part Number 14514 2/08 1-1

LOW BOY CHEF STANDS

Low Boy Chef Stands

LBS-2D-ST

LBS-4D-ST

LBS-6D-ST

LBS-2D-LT

LBS-4D-LT

LBS-6D-LT

Compact Low Boy Chef Stand

LBS-4DS-ST

LBR-2D-ST

LBR-4D-ST

LBR-6D-ST

LBR-2D-LT

LBR-4D-LT

LBR-6D-LT

Page 6

General Information Section 1

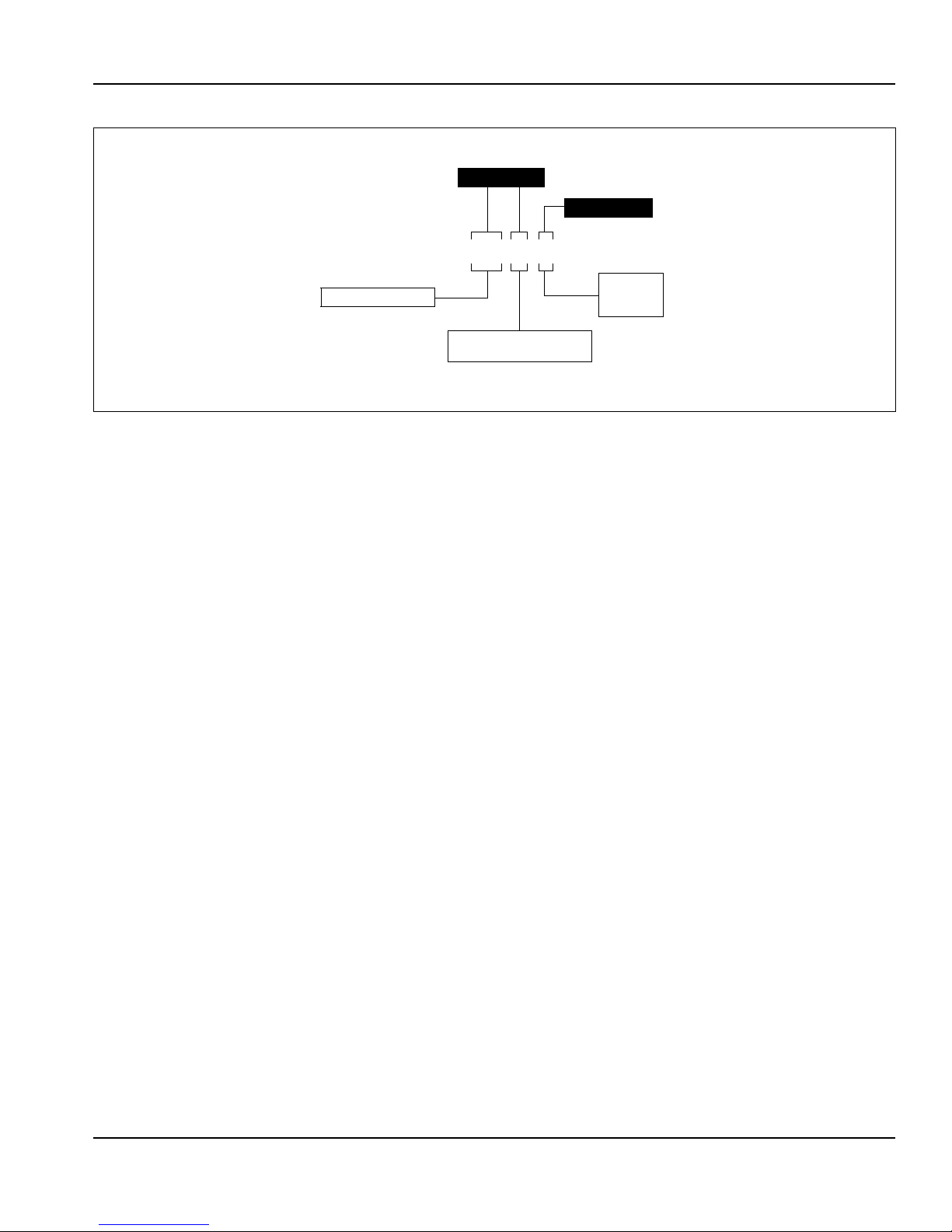

Undercounters

R - Refrigerator

F - Freezer

Sandwich / Salad Prep Table

P - Pan top (30" depth)

ST - Supertop (34" depth)

6 - 27" Wide

10 - 45" Wide

15 - 59" Wide

27 - Supertop 27"

45 - Supertop 45"

49 - Supertop 59"

Prefix

Suffix

Body Type

P–15–16

Undercounters

E - Series

Sandwich / Salad Prep Table

P Series

6 - 6 Pans

8 - 8 Pans

12 - 12 Pans

16 - 16 Pans

ST Series

2 - 2 Cutouts, 6 Pans each

3 - 3 Cutouts, 6 Pans each

4 - 4 Cutouts, 6 Pans each

Superprep

12 - 12 Pans

16 - 6 Pans

Work Tables

ST - Stainless steel flat top

LT - Sub top

STS - Stainless steel top

with backsplash

Chef Stands

LBS - Low boy chef stand

self-contained

LBR - Low boy chef stand

remote

Work Tables

R - Refrigerator

S - Self-contained

E - Series

Chef Stands

LT - Galvanized flat top

ST - Stainless steel “V” edge top

Work Tables

20 - 2 Door

30 - 3 Door

Chef Stands

2D - 2 Drawers

4D - 4 Drawers

6D - 6 Drawers

Prefix

Suffix

Body Type

STS A–30–R S E

Work Tables Only

A - Aluminum interior

S - Stainless steel interior

How to Read Model Numbers

UNDERCOUNTERS / SANDWICH / SALAD PREP TABLE EXAMPLE

WORK TABLE / CHEF STAND EXAMPLE

1-2

Part Number 14514 2/08

Page 7

Section 1 General Information

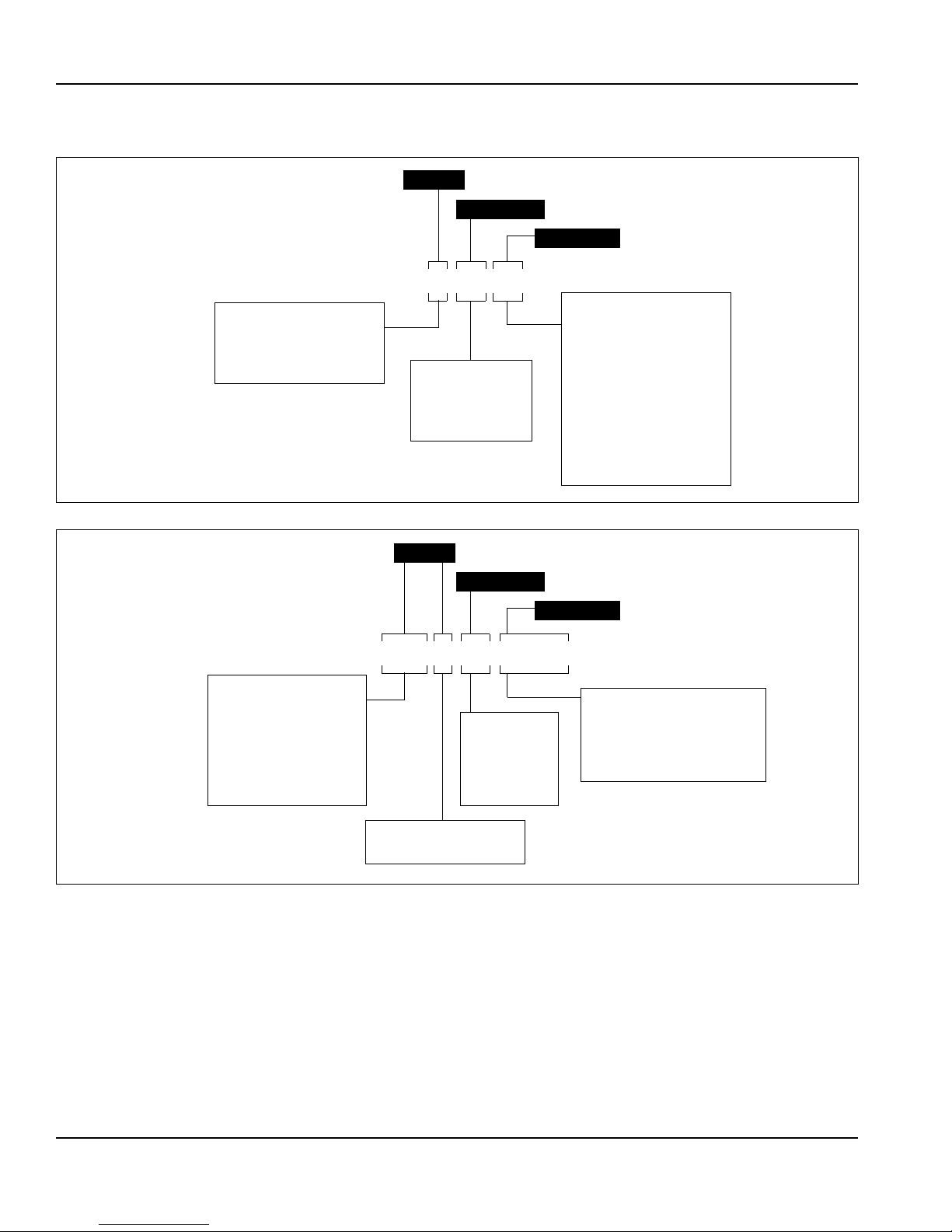

PT - Pizza Top Table

A - Aluminum Interior

A - Stainless Steel Interior

Model Prefix

Body Type

PT–A–2

1 - 1 Door

2 - 2 Door

3 - 3 Door

PIZZA PREP TABLE EXAMPLE

Part Number 14514 2/08 1-3

Page 8

General Information Section 1

Model/Serial Number Location

The McCall data plate which includes the model num ber

and serial number, as well as important electrical and

technical information, is located on the left interior wall of

the cabinet.

For convenience and quick reference, record the model

and serial numbers, voltage, and installation date in the

spaces below:

Model Number ________________________________

Serial Number ________________________________

Voltage ______________________________________

Installation Date _______________________________

Warranty Coverage

Warranty coverage on a McCall cabinet begins on the

date it is installed. Please read the warranty certificate

included with the cabinet for details.

PARTS COVERAGE

1. McCall warrants the cabinet, refrigeration, and

mechanical components against defects in mater ials

and workmanship for a period of one (1) year from

the date of original installation.

2. Refrigerator and freezer compressors are covered

for five (5) years from the date of original installation.

LABOR COVERAGE

Labor is covered for (1) year from the date of original

installation.

EXCLUSIONS FROM WARRANTY

1. Normal start-up, maintenance, adjustments, and

cleaning.

2. Damage caused by improper installation of the

McCall cabinet as outlined in this manual.

3. Labor charges resulting from the inaccessibility of

the McCall cabinet.

4. Damage to parts due to misuse, abuse, neglect, or

accidents.

5. Premium labor rates due to holidays, overtime,

travel time, mileage, etc., not specifically authorized

by McCall prior to service.

6. Miscellaneous tools or materials charges.

7. Repairs due to modifications to the McCall cabinet

or refrigeration system not authorized by McCall in

writing.

8. Claims for indirect or consequential damages,

including food spoilage or product loss.

9. Damage due to faulty or incorrect power supply,

floods, storms, or other acts or God.

WARRANTY SERVICE

To ensure warranty coverage, a qualified service

company, authorized by McCall, must perform the

warranty repair.

If the dealer the McCall cabinet was purchased from

does not perform warranty service, please contact the

McCall Service Department for assistance.

1-4

Part Number 14514 2/08

Page 9

Section 2

Important

!

Caution

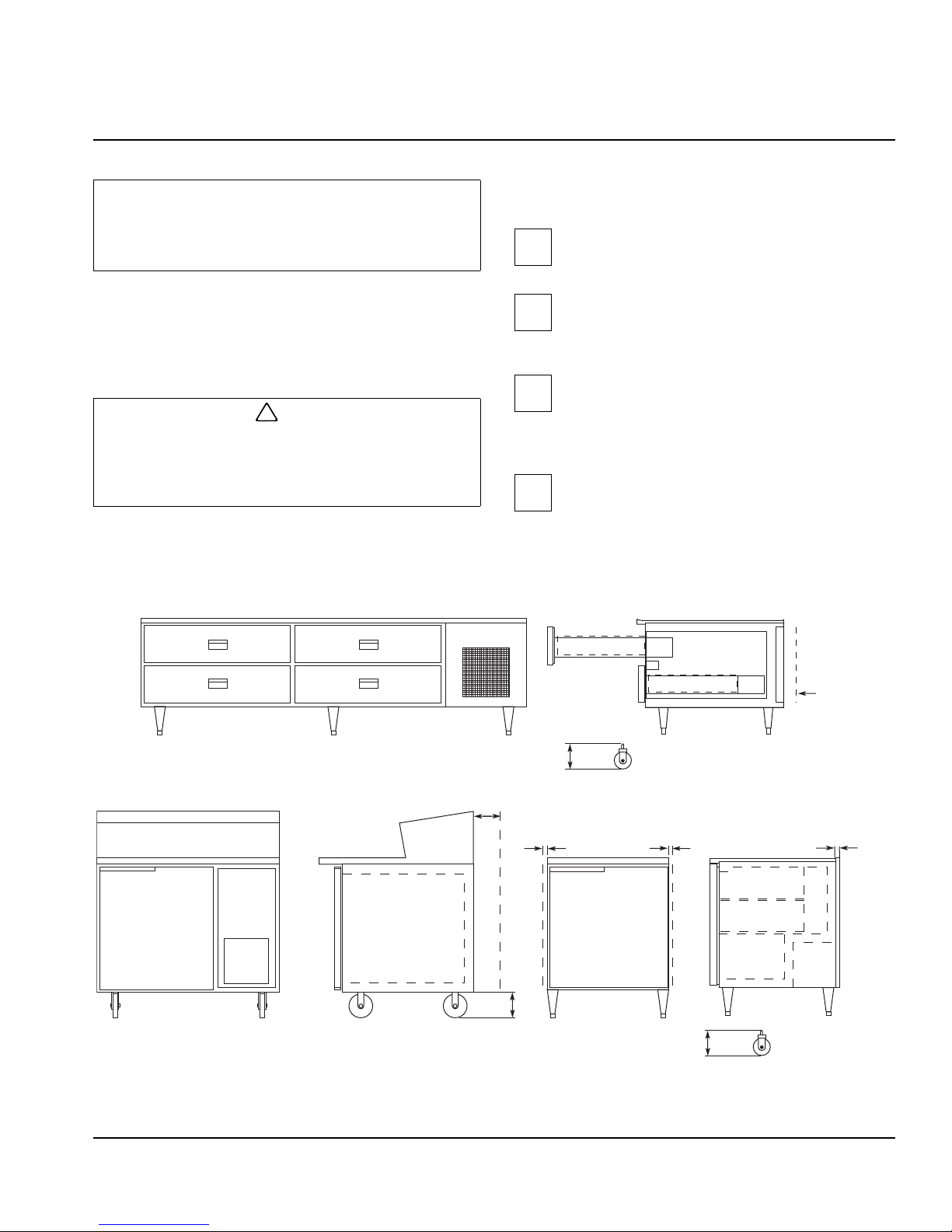

PIZZA TABLES AND

REFRIGERATED BASES

E-3045-B

CHEF STANDS

COMPACT UNDERCOUNTERS

REFRIGERATOR AND FREEZERS

Front View

Side View

6.00"

(15.2 cm)

(Load Height)

Front View Side View Front View Side View

6.00"

(15.2 cm)

(Load Height)

6.00"

(15.2 cm)

(Load Height)

1.00"

(2.5 cm)

Line

Cover

3.00"

(7.6 cm)

6.00"

(15.2 cm)

1.00"

(2.5 cm)

Note:

1" side clearance

is recommended

on 27" and 45"

freezers.

No side clearance

is needed on

refrigerators.

1.00"

(2.5 cm)

Installation Instructions

These instructions are of the utmost importance in

assuring that the McCall cabinet operates as

designed. Follow them closely.

Pre-installation Checklist

Install the cabinet in an indoor environment

only .

Please call your local McCall dealer or the McCall

Service Department if you have any questions regardin g

proper installation.

Locating the Cabinet

When selecting a permanent location for the unit,

observe the following guidelines. Failure to do so

may cause reduced performance and efficiency,

cause damage, and/or void your warranty.

The air temperature entering the refrigerator or

freezer condenser should be between 55°F

(13°C) and 100°F (38°C).

Allow space for air circulation in the refriger ation

condensing unit compartment on refrigerator s

and freezers. The minimum space requirements

are shown below.

The floor must be strong enough to support the

weight of the cabinet and product load.

NOTE: A fully loaded cabinet can weigh more than

2,000 pounds.

Cabinet Clearances (Typical Single Door Cabinet Shown)

Part Number 14514 2/08 2-1

Page 10

Installation Instructions Section 2

!

Warning

!

Caution

!

Caution

!

Caution

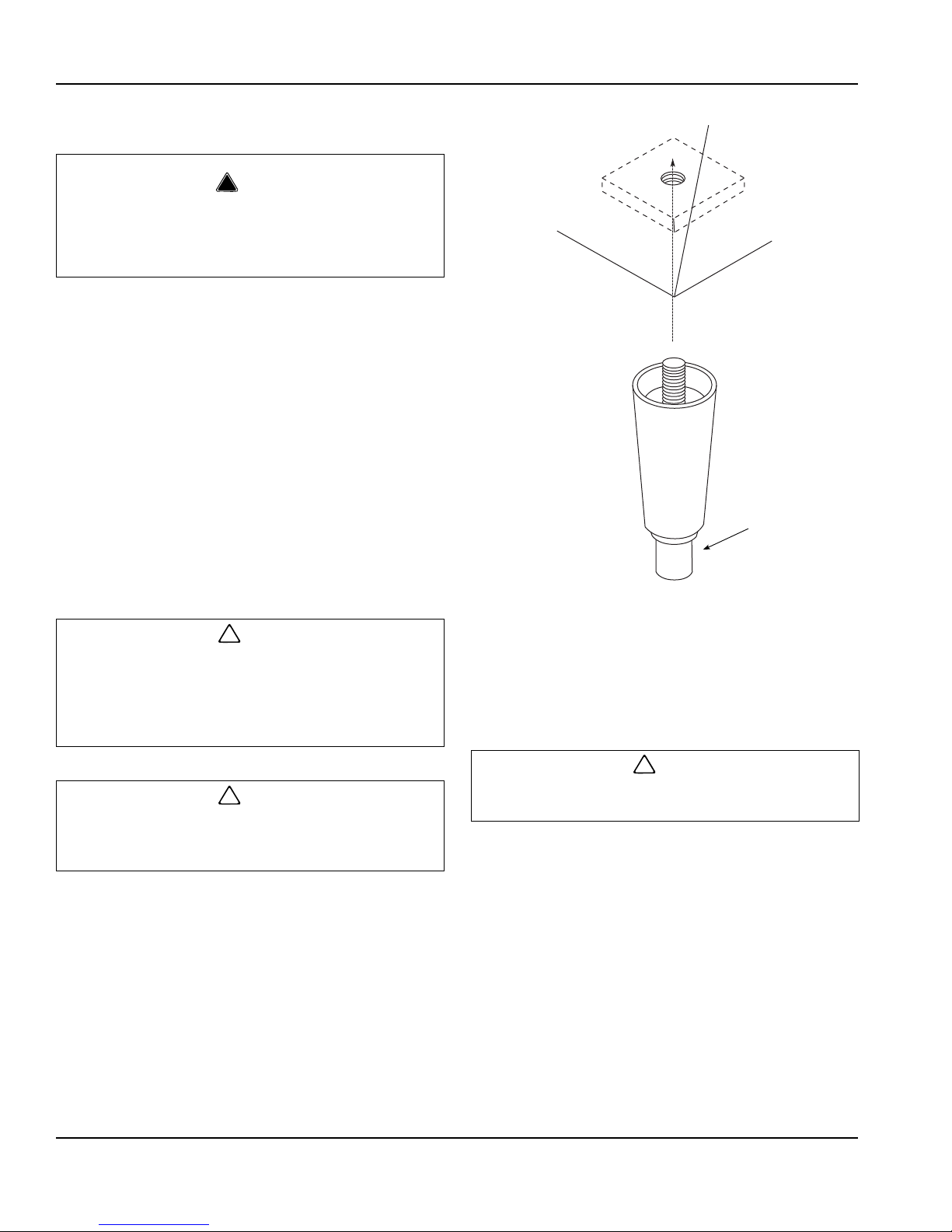

Thread Foot in

as Far as

Possible

Thread Leveling

Leg into Base of

Cabinet

SV1342

Uncrating

Never attempt to tilt the cabinet alone. Always use

two or more people when tilting the cabinet to

remove the shipping skid or to move it through

doorways.

1. Remove the bottom shipping skid using one of the

methods below:

- Lay the cabinet on its back, elevated and

supported by wooden blocks. Remove the skid

mounting bolts and separate the skid from the

cabinet.

- Tilt the cabinet from side to side and remove the

mounting bolts. Support the weight of the cabinet

apart from the skid.

2. Install the legs or casters and torque them to

360 inch-pounds (41 Nm). Refer to the drawing at

right.

3. Return the cabinet to the upright position.

4. Remove any remaining crating materials.

If the cabinet was placed on its back while moving it

or while removing the bottom shipping skid, wait at

least two hours after returning the cabinet to the

upright position before starting the refrigeration

system.

Never use sharp instruments to cut the plastic or

cardboard crating materials. Damage to the cabinet

exterior may result.

Installing Cabinet Legs

Leveling the Cabinet

The cabinet must be leveled after it is positioned in its

permanent location. This insures proper door alignment

on all cabinets, adequate condensate water drainage

and proper refrigeration system operation.

If casters are installed instead of legs, the floor must

be leveled before final positioning of the ca bin et .

1. Move the cabinet to its permanent location.

2. Place a level on top of the cabinet.

3. Turn the leveling foot of the lowest corner leg to

center the bubble in the level.

4. Adjust each of the other corners until the bubble is

centered and the cabinet is stable.

5. Re-check the cabinet from side to side and from

front to rear with the level.

2-2

Part Number 14514 2/08

Page 11

Section 2 Installation Instructions

Shelf

Support

Standard

SV1342

Extensions are required when using

18" wide (left to right) trays or pans

Tray

Slide

Note: Shelf support

standards are shown

outside for clarity.

Shelf/T ray Slide Installation

SHELVES — UNDERCOUNTER UNITS & SANDWICH/

SALAD UNITS

Shelf clips are factory-installed on undercounter

refrigerators and freezers, and on regular and super top

sandwich/salad prep units.

To install the shelves, simply unpackage the shelves

from the cardboard container and place one on each set

of clips.

SHELVES — PIZZA PREP UNITS & REFRIGERATED

WORK TABLES

Pizza prep units and work tables are factory-fitted with

shelf support standards. The shelf clips are packaged

separately and must be installed as shown in the

drawing below.

Four shelf clips are required for each shelf. Make sure

that the clips are level side-to-side and front-to-rear.

Place one shelf on each set of clips.

TRAY SLIDES (OPTIONAL)

Refrigerated pizza tables include a chrome plated steel

pan or tray rack (Model RA-11-T) behind one door

opening on 2- and 3-door models. All other tray slides for

pizza tables and refrigerated work tables are optional

accessories and are included only when ordered. To

install a tray slide:

1. Locate the appropriate square shelf standard holes

at the desired height.

2. Insert the tabs of each slide into the 3/8" holes in the

shelf support standards and pull it straight down to

lock it into place (refer to drawing below).

Shelf Installation

Tray Slide Installation

Part Number 14514 2/08 2-3

Page 12

Installation Instructions Section 2

SER.4

5-15P5-20P

!

Warning

Electrical

All cord-connected units must be plugged into a

grounded and properly sized electrical outlet with

appropriate overcurrent protection. Refer to the drawing

below for electrical plug configurations.

5-20P and 5-15P Electrical Plug Configurations

All permanently connected (hard wired) units are fitted

with a power junction box and 6" pigtail wires for power

connection.

Connect one end of the power line to the pi gt ail fro m the

cabinet junction box. Connect the other end to a properly

sized electrical source.

As a rule, the power lines must be enclosed inside a

conduit secured to the power junction boxes on both

ends.

NOTE: Power installation must be in compliance with the

National Electrical Code and all applicable local and

state codes.

Never use an extension cord.

Never alter the power cord or plug supplied with the

cabinet. Failure to follow this warning could result in

serious injury or death.

After the power source has been connected, turn on the

main power switch. The switch is located on the cabinet

top, behind the front louvered panel.

2-4

Part Number 14514 2/08

Page 13

Section 2 Installation Instructions

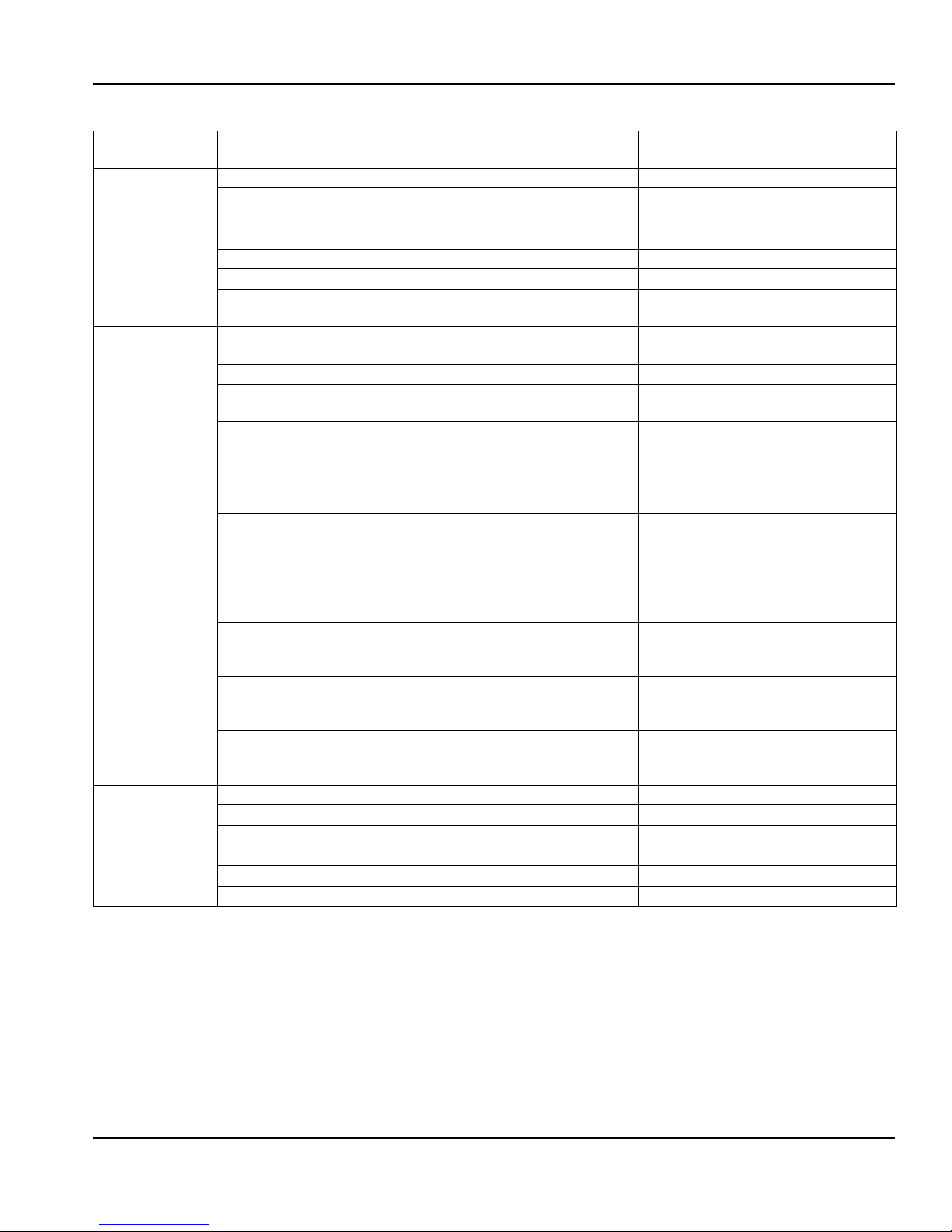

ELECTRICAL SPECIFICATIONS

Product

Type

Undercounter

Refrigerators

Undercounter

Freezers

Sandwich/Salad

Units

Refrigerated

Work

Tables

Low Boy

Chef

Stands

Pizza

Prep

Tables

Self-Contained

Base Models

R-6E, RS-6E, RSC-6E 115/60/1 6.0 15 amp NEMA 5-15

R-10E, RS-10E, RSC-10E 115/60/1 8.0 15 amp NEMA 5-15

R-15E, RS-15E, RSC-15E 115/60/1 6.0 15 amp NEMA 5-15

F-6E, FS-6E, FSC-6E 115/60/1 8.0 15 amp NEMA 5-15

F-10E, FS-10E, FSC-10E 115/60/1 8.5 15 amp NEMA 5-15

RP-6EN 115/60/1 6.0 15 amp NEMA 5-15

RP-10-6EN, RP-10-8EN,

RP-10-12EN

RP-15-8EN, RP-15-12EN,

RP-15-16EN

RST-27-2EN 115/60/1 6.0 15 amp NEMA 5-15

RST-45-2EN, RST-45-3EN,

RST-45-12EN

RST-59-3EN, RST-59-4EN,

RST-59-16EN

LTA-10-RSE, LTS-10-RSE,

STA-10-RSE, STS-10-RSE,

STSA-10-RSE, STSS-10-RSE

LTA-20-RSE, LTS-20-RSE,

STA-20-RSE, STS-20-RSE,

STSA-20-RSE, STSS-20-RSE

LTA-30-RSE, LTS-30-RSE,

STA-30-RSE, STS-30-RSE,

STSA-30-RSE, STSS-30-RSE

LTA-10-FSE, LTS-10-FSE,

STA-10-FSE, STS-10-FSE,

STSA-10-FSE, STSS-10-FSE

LTA-20-FSE, LTS-20-FSE,

STA-20-FSE, STS-20-FSE,

STSA-20-FSE, STSS-20-FSE

LTA-30-FSE, LTS-30-FSE,

STA-30-FSE, STS-30-FSE,

STSA-30-FSE, STSS-30-FSE

LBS-2D-ST, LBS-2D-LT 115/60/1 7.0 15 amp NEMA 5-15

LBS-4D-ST, LBS-4D-LT 115/60/1 10.0 15 amp NEMA 5-15

LBS-6D-ST, LBS-6D-LT 115/60/1 12.0 15 amp NEMA 5-15

PTA-10, PTS-10 115/60/1 10.0 15 amp NEMA 5-15

PTA-20, PTS-20 115/60/1 12.0 15 amp NEMA 5-15

PTA-30, PTS-30 115/60/1 16.0 20 amp NEMA 5-20

Vo ltage/Cycles/

Phase

115/60/1 8.0 15 amp NEMA 5-15

115/60/1 10.0 15 amp NEMA 5-15

115/60/1 8.0 15 amp NEMA 5-15

115/60/1 10.0 15 amp NEMA 5-15

115/60/1 7.0 15 amp NEMA 5-15

115/60/1 10.0 15 amp NEMA 5-15

115/60/1 12.0 15 amp NEMA 5-15

115/60/1 7.0 15 amp NEMA 5-15

115/60/1 12.0 15 amp NEMA 5-15

208-230/60/1 11.8 15 amp Hard Wired

Total

Amps

Maximum

Fuse Size

ANSI Electrical

Plug Configuration

Part Number 14514 2/08 2-5

Page 14

Installation Instructions Section 2

!

Caution

Important

Condensate Water Removal

McCall cabinets are equipped with condensate vaporizer

systems.

Remote units use an electrically operated system.

Most self-contained units use either an energy-free

automatic type or an electrically-operated type. No drain

connection is required.

Defrost Systems

GENERAL

Refrigerator coils are kept below the freezing point

(32°F). During compressor off time, the evaporator fan

continues to circulate 38°F refrigerator compartment air

through the evaporator coil. This air circulation raises the

coil temperature above the freezing point, melting any

accumulated frost. The run-off water is drained into the

vaporizer pan and is evaporated.

Freezer coils are defrosted electrically.

NOTE: A freezer’s evaporator fans do not run

immediately upon start-up or during and immedi at ely

following the defrost cycles. The fans start when the coil

reaches a cold temperature. This prevents th e fans from

blowing heated air on the stored products.

DEFROST TIMERS

Undercounter freezer models F-10E, FS-10E, and

FSC-10E use an adjustable defrost timer which may be

custom-set to initiate defrost periods. All other models

use non-adjustable freezer defrost timers, which

automatically initiate at pre-set intervals and for a

pre-determined duration.

DEFROST SETTINGS

The defrost timer is factory preset to defrost the

evaporator coil each day at 2:00 AM, 8:00 AM,

2:00 PM, and 8:00 PM.

If you wish to change the defrost times, remove the pins

from the outer dial and re-insert them into the desired

time slots. (Refer to drawing.)

Leave at least one hole between adjacent pins.

Defrost Timer

Set the defrost timer to defrost the cabinet during

the lowest usage periods.

SETTING DEFROST TIME

The defrost timer must be set to real time after the power

is turned on, or after a power failure.

To set the time:

1. Grasp the knob in the center of the inner dial.

2. Turn it counterclockwise to rotate the outer dial.

3. Line up the current time of day on the outer dial with

the pointer.

2-6

Part Number 14514 2/08

Page 15

Section 2 Installation Instructions

Important

Important

!

Caution

!

Caution

ADJUSTING DEFROST DURATION

The defrost cycle is terminated by a temperaturesensing switch located on the suction line, adjacent to

the evaporator coil.

The defrost duration is factory-set. Normally, no

adjustment is required. For a longer defrost time, press

down on the inner dial pointer and rotate the pointer until

the desired time lines up.

The coil defrosts only until the temperature-sensing

switch terminates the cycle, regardless of the

defrost duration that is set.

TEMPERATURE CONTROLS

The temperature controls are factory-set to maintain an

average temperature of 38°F in refrigerators, and an

average temperature of 0°F in freezers.

The temperature variance is 6-8 degrees. A freezer

should run between -2 to -3°F and +3 to +4°F. A

refrigerator should run between +35 to +36°F and +41 to

+42°F.

For a different cabinet temperature setting, turn the

temperature control knob or screw, located on the

evaporator coil/blower housing.

Setting the temperature control to the coldest setting

may cause the coil and/or air ducts to freeze and ice

up. This will eventually result in a warmer cabinet

temperature.

If ice accumulation occurs and the temperature is

lower than the guidelines, turn the control knob to a

warmer setting.

Allow the cabinet to reach proper operating

temperature before filling it with product. Do not

place hot or steaming foods in the cabinet.

Store products with high acid content (such as

lettuce, other fresh vegetables or fruits, salad

dressings, etc.) in closed containers. This will

prevent corrosion on the evaporator coil and other

metal parts in the air distribution system.

Part Number 14514 2/08 2-7

Page 16

Installation Instructions Section 2

THIS PAGE INTENTIONALLY LEFT BLANK

2-8

Part Number 14514 2/08

Page 17

Sequence of Operation

!

Caution

Important

Supply Air

0301

Evaporator Fan

Shelf

Evaporator Coil

Shelf Compressor

Return Air

Evaporator Coil

Supply Air

Return Air

COMPACT UNDERCOUNTER

REFRIGERATOR AND FREEZERS

CHEF STANDS

PIZZA TABLES AND

REFRIGERATOR BASES

Evaporator Coil

Shelves

Return Air

Supply Air

Section 3

Operation

LOADING SHELVES

For maximum operating efficiency, load the shelves with

space between the stored items. This allows air to

circulate properly. Refer to the drawings below.

Store products with high acid content (such as

lettuce, other fresh vegetables or fruits, salad

dressings, etc.) in closed containers. This will

prevent corrosion on the evaporator coil and other

metal parts in the air distribution system.

Uncovered food will dehydrate much more rapidly

than covered food. For best food quality, always

store in covered container.

LOADING PANS

Pan-top refrigerators are designed for operation with all

pans in place, even if some pans are to be left empty.

For maximum food freshness, fill the pans only with an

amount than can be used in a specific usage period

(breakfast, lunch, dinner, etc). During non-use or

slow-use periods, close the lid cover.

Loading the Shelves

Part Number 14514 2/08 3-1

Page 18

Operation Section 3

Hinge Pin

Screw

0302

Hinge Pin

Removable

Mechanism

Hinge Mechanism

Mounting Screws

Operating Checks and Adjustments

DOOR HINGE ADJUSTMENT

1. Loosen 2 Phillips head screws on the top and

bottom hinges where the hinges fasten to the

cabinet exterior front facing.

2. Firmly press the door tight to the cabinet front while

re-tightening the hinge screws.

NOTE: For some adjustments, it may be necessary to

add shims behind the hinges.

REMOVING DOORS

Remove 2 Phillips head screws from the top door hinge

and 2 Phillips head screws from the bottom hinge.

Carefully lift the door off the cabinet front.

REHINGING DOORS — SINGLE DOOR MODELS

McCall’s one door models are factory-shippe d hinged on

the right side (facing the unit front). If it becomes

necessary to change the hinging on a door:

1. Remove 2 Phillips head screws from the top and

bottom door hinges.

2. Carefully lift the door off of the cabinet.

3. Remove the (3) screws securing the door handle

and remove the handle.

4. Turn the door 180 degrees.

Hinge Removal

5. Attach handle at the position indicated by the prepunched mounting holes.

6. Remove the hinges from the door as shown in the

drawing.

7. Position and attach the new hinge

(Part #HAH-0702-001 for the top hinge,

Part #2HAH-0704-001 for the bottom hing e ).

8. Remove and reposition the hinge cartridge

mechanism.

9. Attach the door to the cabinet using the screws

removed earlier.

10. Perform the “Door Hinge Adjustment” procedure

above.

3-2

Part Number 14514 2/08

Page 19

Section 4

!

Caution

!

Caution

!

Caution

!

Warning

!

Caution

!

Warning

Maintenance

Cleaning

EXTERIOR

Clean cabinet exterior surfaces with a solution of mild

soap and water. To minimize streaking, follow with a

fresh water rinse.

If stainless steel becomes discolored, scrub only in the

direction of the finished grain.

For high shine, see your kitchen equipment dealer for a

high-quality stainless steel polish.

Do not use steel wool, caustic soap, or abrasive

cleaners, as these may damage the metal finish.

Alcohol-based cleaners may damage the nylon door

cams.

If the cabinet has a synthetic cutting board, r emove it by

simply lifting the board straight up. Make sure the board

and the metal cabinet surface are completely dry before

replacing the cutting board.

The condensate evaporator pan, located u nderneath the

cabinet, should be cleaned periodically with soapy water

to remove any mineral deposits.

INTERIOR

Clean cabinet interior surfaces with warm water and

baking soda, applied with a cloth or sponge.

Cleaning the Condenser Coil

Disconnect electric power before cleaning. Failure

to follow this warning could result in serious injury or

death.

For efficient operation, it is very important to clean the

condenser coil surface and keep it free of dust, dirt, and

lint. McCall recommends checking the condition of the

condenser coil once a month.

The condensing unit fan draws dust, lint and small

particles to the condenser coil, where it for ms a “blanket”

on the coil surface. This is normal and should be

periodically removed.

Failure to clean and maintain the condenser coil

properly will result in reduced air circulation through

the condenser fins. This will cause reduced

efficiency, high operating pressures, and can

shorten compressor life.

CONDENSER CLEANING PROCEDURES

One or more of the following methods may be used to

clean the condenser coil surface, depending upon the

extent of the build-up on the fins.

The air duct and shelf support standards can be

removed without special tools to facilitate cleaning.

Wash door gaskets weekly with a mild soap and water

solution, followed by a fresh water rinse.

While cleaning, check the door gaskets for proper

sealing. Adjust if needed.

Do not clean cabinet interior surfaces with any

cleaning product not specifically approved for use

where food may come into contact.

Do not use steel wool, caustic soap, or abrasive

cleaners, as these may damage the metal finish.

Part Number 14514 2/08 4-1

Condenser fins are sharp. Use care when working

around them.

Method 1

Remove light build-up with a soft brush or a vacuum with

a brush attachment. Brush the condenser fins from top

to bottom, not from side to side. Shine a light through the

fins to check for dirt inside the condenser.

Method 2

Clean moderately dirty fins with compressed air, blowing

from the inside out. Follow by brushing, if necessary.

Method 3

Clean with a commercial condenser coil cleaner,

available from a kitchen equipment dealer. Follow the

directions and precautions supplied with the cleaner.

Page 20

Maintenance Section 4

fin_comb

Fin Comb

Condenser

Comb

Down Only

After cleaning, straighten any bent condenser fins with a

fin comb.

Using a Fin Comb

CLEANING THE FAN BLADES AND MOTOR

If necessary, clean the fan blades and motor with a soft

cloth. If it is necessary to wash the fan blades, cover the

fan motor to prevent moisture damage.

CLEANING THE EVAPORATOR DRAIN PAN

The evaporator drain pan, located at the bottom of the

evaporator blower panel, should be cleaned periodically

to remove any food, debris, etc. that may have fallen or

been drawn into the pan.

To clean the pan drain outlet, gently insert a pliable wire,

such as a pipe cleaner, 3-4" (7-10 cm) into the mouth of

the outlet. Remove any obvious debris in the pan

bottom.

4-2

Part Number 14514 2/08

Page 21

Section 5

!

Warning

Before Calling for Service

T roubleshooting Guide

If a problem arises during operation of your refrigerator

or freezer, follow the checklist below before calling

service. Routine adjustments and maintenance

procedures are not covered by the warranty.

Problem Possible Cause To Correct

Cabinet not running Fuse blown or circuit breaker tripped. Replace fuse or reset circuit bre aker.

Power cord unplugged. Plug in power cord.

Thermostat set too high. Set thermostat to lower temperature.

Main power switch turned off. Turn main power switch on.

Cabinet in defrost cycle.

(Freezer models)

Condensing unit runs

for long periods or

continuously

Cabinet temperature

is too high

Cabinet is noisy Loose part(s). Locate and tighten loose part(s).

Refrigerator is freezing product

Compressor will not

start — hums and trips on overload

protector

Excessive amount of warm product

placed in cabinet.

Prolonged door openings or door(s) ajar. Make sure door(s) are closed when not in

Door gasket(s) not sealing properly. Check gasket condition. Adjust door or

Dirty condenser coil. Clean the condenser coil.

Evaporator coil iced over. Turn unit off and allow coil to defrost.

Thermostat set too high. Set thermostat to lower temperature.

Poor air circulation in cabinet. Re-arrange product to allow proper air

Exterior thermometer is out of calibration. Re-calibrate thermometer.

Excessive amount of warm product

placed in cabinet.

Prolonged door openings or door(s) ajar. Make sure door(s) are closed when not in

Dirty condenser coil. Clean the condenser coil.

Evaporator coil iced over. Turn unit off and allow coil to defrost.

Tubing vibration. Insure tubing is free from contact with

Thermostat is set too low. Set thermostat to higher temperature.

Dirty condenser coil. Clean the condenser coil.

Not enough cabinet clearance for proper

refrigeration system operation.

Low voltage to cabinet. Check and correct incoming voltage to

Disconnect electric power before performing any

service. Failure to follow this warning could result in

injury or death.

Wait for defrost cycle to finish.

Allow adequate time for product to cool

down.

use. Avoid prolonged door openings.

replace gasket if necessary.

Make sure thermostat is not set too cold.

Also, check gasket condition.

circulation.

Allow adequate time for product to cool

down.

use. Avoid prolonged door openings.

Make sure thermostat is not set too cold.

Also, check gasket condition.

other tubing or components.

Move cabinet or make other adjustments

to gain proper cabinet clearances.

cabinet.

Part Number 14514 2/08 5-1

Page 22

Before Calling for Service Section 5

THIS PAGE INTENTIONALLY LEFT BLANK

5-2

Part Number 14514 2/08

Page 23

Page 24

© 2008 Manitowoc

Continuing product improvements

may necessitate change of

specifications without notice.

Part Number 14514 2/08

McCall Refrigeration, Inc.

81 West Holly Street

Parsons, TN 38363, USA

Ph: 731-847-5365 Fax: 731-847-9012

Visit us online at: www.manitowocfsg.com

Loading...

Loading...