Manitowoc KY0350A, KD0250A, KY0250A, KD0350A, KD0350W Installation, Operation And Maintenance Manual

...Page 1

Ice Machines

K Series

Installation, Operation and Maintenance Manual

Part Number 000012545 Rev 02 11/16

Page 2

Page 3

Safety Notices

Safety Notices

Read these precautions to prevent personal injury:

• Read this manual thoroughly before operating,

installing or performing maintenance on the

equipment. Failure to follow instructions in this

manual can cause property damage, injury or death.

• Routine adjustments and maintenance procedures

outlined in this manual are not covered by the

warranty.

• Proper installation, care and maintenance are essential

for maximum performance and trouble-free operation

of your equipment.

Visit our website www.kool-aire.com for manual

updates, translations, or contact information for

service agents in your area.

• This equipment contains high voltage electricity and

refrigerant charge. Installation and repairs are to be

performed by properly trained technicians aware of

the dangers of dealing with high voltage electricity

and refrigerant under pressure. The technician must

also be certified in proper refrigerant handling

and servicing procedures. All lockout and tag out

procedures must be followed when working on this

equipment.

• This equipment is intended for indoor use only. Do

not install or operate this equipment in outdoor areas.

Warning

n

Follow these electrical requirements during

installation of this equipment.

• All field wiring must conform to all applicable

codes of the authority having jurisdiction. It is

the responsibility of the end user to provide the

disconnect means to satisfy local codes. Refer to rating

plate for proper voltage.

• This appliance must be grounded.

• This equipment must be positioned so that the plug is

accessible unless other means for disconnection from

the power supply (e.g., circuit breaker or disconnect

switch) is provided.

• Check all wiring connections, including factory

terminals, before operation. Connections can become

loose during shipment and installation.

Warning

n

Follow these precautions to prevent personal injury

during installation of this equipment:

• Installation must comply with all applicable

equipment fire and health codes with the authority

having jurisdiction.

• To avoid instability the installation area must be

capable of supporting the combined weight of the

equipment and product. Additionally the equipment

must be level side to side and front to back.

• Ice machines require a deflector when installed on

an ice storage bin. Prior to using a non-OEM ice

storage system with this ice machine, contact the

bin manufacturer to assure their ice deflector is

compatible.

• Remove all removable panels before lifting and

installing and use appropriate safety equipment

during installation and servicing. Two or more people

are required to lift or move this appliance to prevent

tipping and/or injury.

• Do not damage the refrigeration circuit when

installing, maintaining or servicing the unit.

• Connect to a potable water supply only.

• This equipment contains refrigerant charge.

Installation of the line sets must be performed by

a properly trained and EPA certified refrigeration

technician aware of the dangers of dealing with

refrigerant charged equipment.

• Legs or casters must be installed and the legs/casters

must be screwed in completely. When casters are

installed the mass of this unit will allow it to move

uncontrolled on an inclined surface. These units must

be tethered/secured to comply with all applicable

codes. Swivel casters must be mounted on the front

and rigid casters must be mounted on the rear. Lock

the front casters after installation is complete.

• Some 50 Hz models may contain up to 150 grams

of R290 (propane) refrigerant. R290 (propane)

is flammable in concentrations of air between

approximately 2.1% and 9.5% by volume (LEL lower

explosion limit and UEL upper explosion limit). An

ignition source at a temperature higher than 470°C is

needed for a combustion to occur. Refer to nameplate

to identify the type of refrigerant in your equipment.

Only trained and qualified personnel aware of the

dangers are allowed to work on the equipment.

Page 4

Warning

n

Follow these precautions to prevent personal injury

while operating or maintaining this equipment:

• Read this manual thoroughly before operating,

installing or performing maintenance on the

equipment. Failure to follow instructions in this

manual can cause property damage, injury or death.

• Crush/Pinch Hazard. Keep hands clear of moving

components. Components can move without warning

unless power is disconnected and all potential energy

is removed.

• Moisture collecting on the floor will create a slippery

surface. Clean up any water on the floor immediately

to prevent a slip hazard.

• Objects placed or dropped in the bin can affect

human health and safety. Locate and remove any

objects immediately.

• Never use sharp objects or tools to remove ice or frost.

Do not use mechanical devices or other means to

accelerate the defrosting process.

• When using cleaning fluids or chemicals, rubber

gloves and eye protection (and/or face shield) must

be worn.

DANGER

Do not operate equipment that has been misused,

abused, neglected, damaged, or altered/modified

from that of original manufactured specifications. This

appliance is not intended for use by persons (including

children) with reduced physical, sensory or mental

capabilities, or lack of experience and knowledge, unless

they have been given supervision concerning use of the

appliance by a person responsible for their safety. Do

not allow children to play with, clean or maintain this

appliance without proper supervision.

Warning

n

This product is hermetically sealed and contains

fluorinated greenhouse gas R410A.

DANGER

Follow these precautions to prevent personal injury

during use and maintenance of this equipment:

• It is the responsibility of the equipment owner to

perform a Personal Protective Equipment Hazard

Assessment to ensure adequate protection during

maintenance procedures.

• Do Not Store Or Use Gasoline Or Other Flammable

Vapors Or Liquids In The Vicinity Of This Or Any Other

Appliance. Never use flammable oil soaked cloths or

combustible cleaning solutions for cleaning.

• All covers and access panels must be in place and

properly secured when operating this equipment.

• Risk of fire/shock. All minimum clearances must be

maintained. Do not obstruct vents or openings.

• Failure to disconnect power at the main power supply

disconnect could result in serious injury or death.

The power switch DOES NOT disconnect all incoming

power.

• All utility connections and fixtures must be

maintained in accordance with the authority having

jurisdiction.

• Turn off and lockout all utilities (gas, electric, water)

according to approved practices during maintenance

or servicing.

• Units with two power cords must be plugged into

individual branch circuits. During movement, cleaning

or repair it is necessary to unplug both power cords.

• Never use a high-pressure water jet for cleaning on

the interior or exterior of this unit. Do not use power

cleaning equipment, steel wool, scrapers or wire

brushes on stainless steel or painted surfaces.

• Two or more people are required to move this

equipment to prevent tipping.

• Locking the front casters after moving is the owner’s

and operator’s responsibility. When casters are

installed, the mass of this unit will allow it to move

uncontrolled on an inclined surface. These units must

be tethered/secured to comply with all applicable

codes.

• The on-site supervisor is responsible for ensuring that

operators are made aware of the inherent dangers of

operating this equipment.

• Do not operate any appliance with a damaged cord

or plug. All repairs must be performed by a qualified

service company.

Page 5

Safety Notices

Section 1

General Information

Section 2

Installation

Table of Contents

Safety Notices ..................................................................................................................... 3

Model Numbers .................................................................................................................. 7

Ice Deflector ........................................................................................................................7

Bin Installation .........................................................................................................................................7

Air Baffle .............................................................................................................................7

Warranty Information ........................................................................................................ 7

Model Nomenclature ............................................................................................................................8

Location of Ice Machine ..................................................................................................... 9

Clearance Requirements ....................................................................................................9

Ice Machine Heat of Rejection .........................................................................................10

Removing Drain Plug and Leveling the Ice Storage Bin ................................................10

Air Baffle ...........................................................................................................................10

Electrical Service ..............................................................................................................11

Minimum Circuit Ampacity .............................................................................................................. 11

Electrical Requirements .................................................................................................................... 11

Ground Fault Circuit Interrupter .................................................................................................... 11

Minimum Power Cord Specifications ........................................................................................... 11

For United Kingdom Only ................................................................................................................ 11

Maximum Breaker Size & Minimum Circuit Amperage Chart .......................................12

Water Supply and Drain Requirements .......................................................................... 13

Water Supply ......................................................................................................................................... 13

Water Inlet Lines .................................................................................................................................. 13

Drain Connections .............................................................................................................................. 13

Water Supply and Drain Line Sizing/Connections ......................................................... 14

Water-Cooled Condenser Water Pressure ..................................................................................14

Cooling Tower Applications (Water-Cooled Models) ............................................................. 14

Remote Condenser/Line Set Installation ........................................................................15

Remote Ice Machine Refrigerant Charge ....................................................................................15

General ....................................................................................................................................................16

Wiring ...................................................................................................................................................... 16

Guidelines for Routing Line Sets ....................................................................................................16

Calculating Remote Condenser Installation Distances ..........................................................17

Route the Line Set ............................................................................................................................... 18

Connect the Line Set .......................................................................................................................... 18

Pressure Test and Evacuate Line Set and Condenser ............................................................. 18

Open Line Set Valves .......................................................................................................................... 18

Installation Check List ......................................................................................................19

Additional Checks for Remote Models ...........................................................................19

Before Starting the Ice Machine ......................................................................................19

Part Number 000012545 Rev 02 11/16 5

Page 6

Section 3

Operation

Section 4

Maintenance

Section 5

Troubleshooting

Table of Contents (continued)

Ice Making Sequence of Operation .................................................................................21

Control Board Timers ......................................................................................................................... 21

Safety Limits .......................................................................................................................................... 21

Operational Checks ..........................................................................................................22

General ....................................................................................................................................................22

Minimum/Maximum Slab Weights ............................................................................................... 22

Ice Thickness Check ............................................................................................................................ 22

Cleaning and Sanitizing ................................................................................................... 23

General ....................................................................................................................................................23

Cleaning/Sanitizing Procedure.......................................................................................................23

Preventative Maintenance Cleaning Procedure .......................................................................23

Exterior Cleaning ................................................................................................................................. 23

Cleaning/Sanitizing Procedure .......................................................................................24

Sanitizing Procedure .......................................................................................................................... 25

Parts Removal for Cleaning/Sanitizing ..........................................................................26

Preventative Maintenance Cleaning Procedure ............................................................27

Door Removal ...................................................................................................................27

Cleaning the Condenser Filter .........................................................................................27

Cleaning the Condenser ..................................................................................................27

Removal from Service/Winterization .............................................................................28

Water-Cooled Ice Machines ............................................................................................................. 28

Checklist ............................................................................................................................ 29

Safety Limit Feature .........................................................................................................30

6 Part Number 000012545 Rev 02 11/16

Page 7

Section 1

General Information

Model Numbers

This manual covers the following models:

Self-Contained

Air-Cooled

KD0250A

KY0250A

KD0350A

KY0350A

KD0420A

KY0420A

KD0500A

KY0500A

KD0600A

KY0600A

KD1000A

KY1000A

KD1350A

KY1350A

KD1800A

KY1800A

Self-Contained

Water-Cooled

----

---KD0350W

KY0350W

KD0420W

KY0420W

KD0500W

KY0500W

KD0600W

KY0600W

KD1000W

KY1000W

KD1350W

KY1350W

Remote

----

----

----

----

----

----

----

----

----

---KY1000N

KD1000N

KY1350N

KD1350N

KY1800N

KD1800N

Ice Deflector

An ice deflector is required when the ice machine is

installed on a bin. An ice deflector is not required when the

ice machine is installed on a dispenser.

BIN INSTALLATION

• All ice machines installed on a bin require an ice

deflector.

• Koolaire bins have a deflector installed and require

no modifications when used with a forward facing

evaporator.

• Align sides and back of ice machine with sides and back

of bin, when placing ice machine on bin.

Air Baffle

Self-Contained Air-Cooled Only

The air-cooled baffle prevents condenser air from

recirculating.

Warranty Information

Visit www.kool-aire.com for:

• Warranty Verification

• Warranty Registration

• View and download a copy of your warranty

Part Number 000012545 Rev 02 11/16 7

Page 8

General Information Section 1

MODEL NOMENCLATURE

CONDENSER TYPE

A -Self-Contained Air-Cooled

W -Self-Contained Water-Cooled

N -Remote Air-Cooled

3 -Three Phase

NO INDICATOR -1 Phase

ICE CUBE SIZE

D -Dice

Y -Half-Dice

ICE MACHINE MODEL

Ice Machine Series

# HERTZ

5 -50HZ

6 -60HZ

KD 1350 A3 – 263

VOLTAGE

161 -115/60/1

261 -208-230 /60/1

251 -230/50/1

263 -208-230 /60/3

8 Part Number 000012545 Rev 02 11/16

Page 9

Section 2

Installation

Location of Ice Machine

The location selected for the ice machine must meet the

following criteria. If any of these criteria are not met, select

another location.

• The location must be free of airborne and other

contaminants.

• The air temperature must be at least 35°F (1.6°C), but

must not exceed 110°F (43.4°C).

NOTE: K1350 Minimum air temperature is 40°F (4.4°C).

• Remote air-cooled - The air temperature must be at least

-20°F (-29°C), but must not exceed 120°F (49°C).

• The location must not be near heat-generating (ovens,

dishwashers, etc.) equipment or in direct sunlight and

must be protected from weather.

• The location must not obstruct airflow through

or around the ice machine. Refer to the clearance

requirements chart.

These ice machines are intended for use in applications

such as:

• Staff kitchen areas in shops, offices and other work

environments

• Clients in hotels, motels, farmhouses, bed and breakfast

and other residential type environments

• Catering and similar non-retail applications

Clearance Requirements

Warning

n

Do not obstruct ice machine vents or openings.

K0250 Self-Contained

Air-Cooled

Top/Sides 12" (30.5 cm) N/A

Back 5" (12.7 cm) N/A

K0350/K0420

K0500/K0600/

K1000/K1350/

K1800

Top/Sides 8" (20.3 cm) 8" (20.3 cm)

Back 5" (12.7 cm) 5" (12.7 cm)

K0420

Tropical Rating

50 Hz Only

Top 24" (61.0 cm) 8" (20.3 cm)

Sides 12" (30.5 cm) 8" (20.3 cm)

Back 5" (12.7 cm) 5" (12.7 cm)

K1000

Tropical Rating

50 Hz Only

Top 12" (30.5 cm) 8" (20.3 cm)

Sides 8" (20.3 cm) 8" (20.3 cm)

Back 5" (12.7 cm) 5" (12.7 cm)

Self-Contained

Air-Cooled

Self-Contained

Air-Cooled

Self-Contained

Air-Cooled

Self-Contained

Water-Cooled

Water-Cooled

and Remote*

Water-Cooled

Water-Cooled

and Remote

Warning

n

Two or more people or a lifting device are required to lift

this appliance.

The ice machine must be protected if it will be subjected

to temperatures below 32°F (0°C). Failure caused by

Caution

,

exposure to freezing temperatures is not covered by the

warranty.

Part Number 000012545 Rev 02 11/16 9

Page 10

Installation Section 2

Ice Machine Heat of Rejection

Series

Ice Machine

K0250 4600 5450

K0350 3800 6000

K0420 5400 6300

K0500 5300 6100

K0600 9000 13900

K1000 17000 20700

K1350 23900 29000

K1800 29800 34700

1 B.T.U./Hour

2 Because the heat of rejection varies during the ice making cycle, the

figure shown is an average.

Air Conditioning

Heat of Rejection

2

Ice machines, like other refrigeration equipment, reject

heat through the condenser. It is helpful to know the

amount of heat rejected by the ice machine when sizing air

conditioning equipment where self-contained air-cooled

ice machines are installed.

This information is also necessary when evaluating the

benefits of using water-cooled or remote condensers to

reduce air conditioning loads. The amount of heat added to

an air conditioned environment by an ice machine using a

water-cooled or remote condenser is negligible.

Knowing the amount of heat rejected is also important

when sizing a cooling tower for a water-cooled condenser.

Use the peak figure for sizing the cooling tower.

1

Peak

Removing Drain Plug and Leveling the Ice

Storage Bin

Warning

n

To avoid instability, the bin/dispenser must be installed

in an area capable of supporting the weight of the bin/

dispenser, ice machine and a full bin of ice (48" models

1000 lbs [454 kg], 30" models 750 lbs [340 kg]). The bin/

dispenser must be level side-to-side and front-to-back

before installing the ice machine.

1. Remove threaded plug from drain fitting.

2. Screw the leveling legs onto the bottom of the bin.

3. Screw the foot of each leg in as far as possible.

Caution

,

The legs must be screwed in tightly to prevent them

from bending.

4. Move the bin into its final position.

5. Level the bin to assure that the bin door closes and

seals and the ice machine operates properly. Use a

level on top of the bin. Turn the base of each foot as

necessary to level the bin.

6. Inspect bin gasket prior to ice machine installation.

(Our bins come with a closed cell foam gasket installed

along the top surface of the bin.)

7. Remove all panels from ice machine before lifting and

installing on bin. Remove front panel, top cover, left

and right side panels.

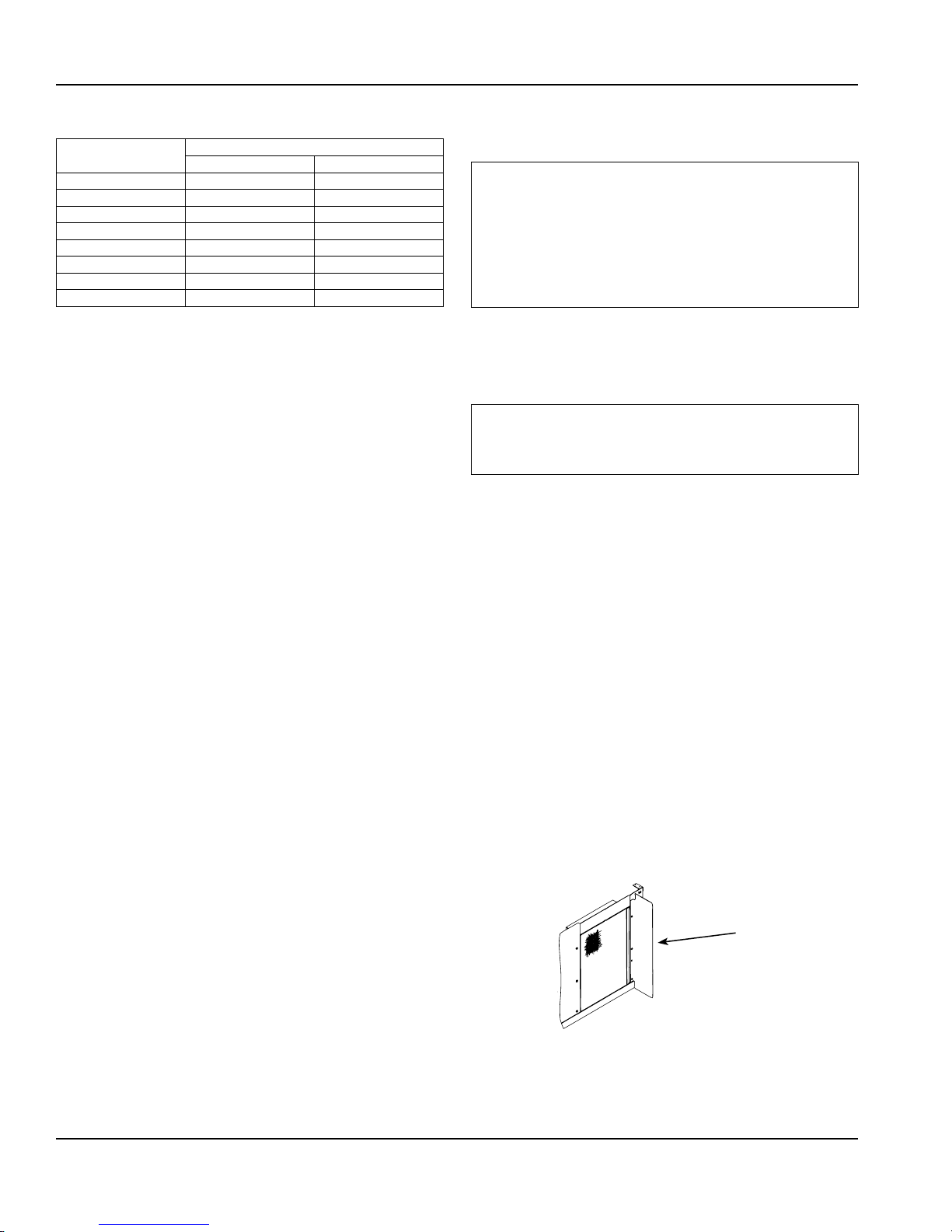

Air Baffle

Self-Contained Air-Cooled Only

To install:

1. Loosen the back panel screws next to the condenser.

2. Align the keyhole slots in the air baffle with the screw

holes and slide the baffle down to lock in place.

Air Baffle

10 Part Number 000012545 Rev 02 11/16

Page 11

Section 2 Installation

Electrical Service

Warning

n

All electrical work, including wire routing and grounding

must conform to all applicable national and local

electrical codes.

MINIMUM CIRCUIT AMPACITY

The minimum circuit ampacity is used to help select the

wire size of the electrical supply. (Minimum circuit ampacity

is not the ice machine’s running amp load.)

ELECTRICAL REQUIREMENTS

Refer to Ice Machine Model/Serial Plate for voltage/

amperage specifications.

• A separate fuse/circuit breaker must be provided for

each ice machine.

• The wire size (or gauge) is dependent upon location,

materials used, length of run, etc., so it must be

determined by a qualified electrician.

• The ice machine must be grounded. Check all green

ground screws in the control box and verify they are

tight before starting the ice machine.

• The maximum allowable voltage variation is ±10% of

the rated voltage at ice machine start-up (when the

electrical load is highest).

Caution

,

Observe correct polarity of incoming line voltage.

Incorrect polarity can lead to erratic ice machine

operation. Operate equipment only on the type of

electricity indicated on the specification plate.

GROUND FAULT CIRCUIT INTERRUPTER

Ground Fault Circuit Interrupter (GFCI/GFI) protection is a

system that shuts down the electric circuit (opens it) when

it senses an unexpected loss of power, presumably to

ground. GFCI/GFI circuit protection is not recommended

with our equipment. If code requires the use of a GFCI/GFI,

then you must follow the local code. The circuit must be

dedicated, sized properly and there must be a panel GFCI/

GFI breaker. We do not recommend GFCI/GFI outlets as they

are known for more intermittent nuisance trips than panel

breakers.

MINIMUM POWER CORD SPECIFICATIONS

Maximum Breaker

Size

15 amp 14 gauge 6 feet (1.83 m)

20 amp 12 gauge 6 feet (1.83 m)

30 amp 10 gauge 6 feet (1.83 m)

40 amp 8 gauge 6 feet (1.83 m)

Minimum Wire

Size

Maximum Length

of Power Cord

If a power cord is used, the wire size to the receptacle is

dependent upon location, materials used, length of run,

etc., so it must be determined by a qualified electrician.

Local, state or national requirements will supersede our

minimum requirements.

FOR UNITED KINGDOM ONLY

As the colors of the wires in the mains lead of the

appliance may not correspond with the colored markings

identifying the terminals in your plug, proceed as follows:

• The wire which is colored green and yellow must be

connected to the terminal in the plug which is marked

with the letter E or by the earth ground symbol or

colored green or green and yellow.

• The wire colored blue must be connected to the

terminal which is marked with the letter N or colored

black.

• The wire colored brown must be connected to the

terminal which is marked with the letter L or colored

red.

Part Number 000012545 Rev 02 11/16 11

Page 12

Installation Section 2

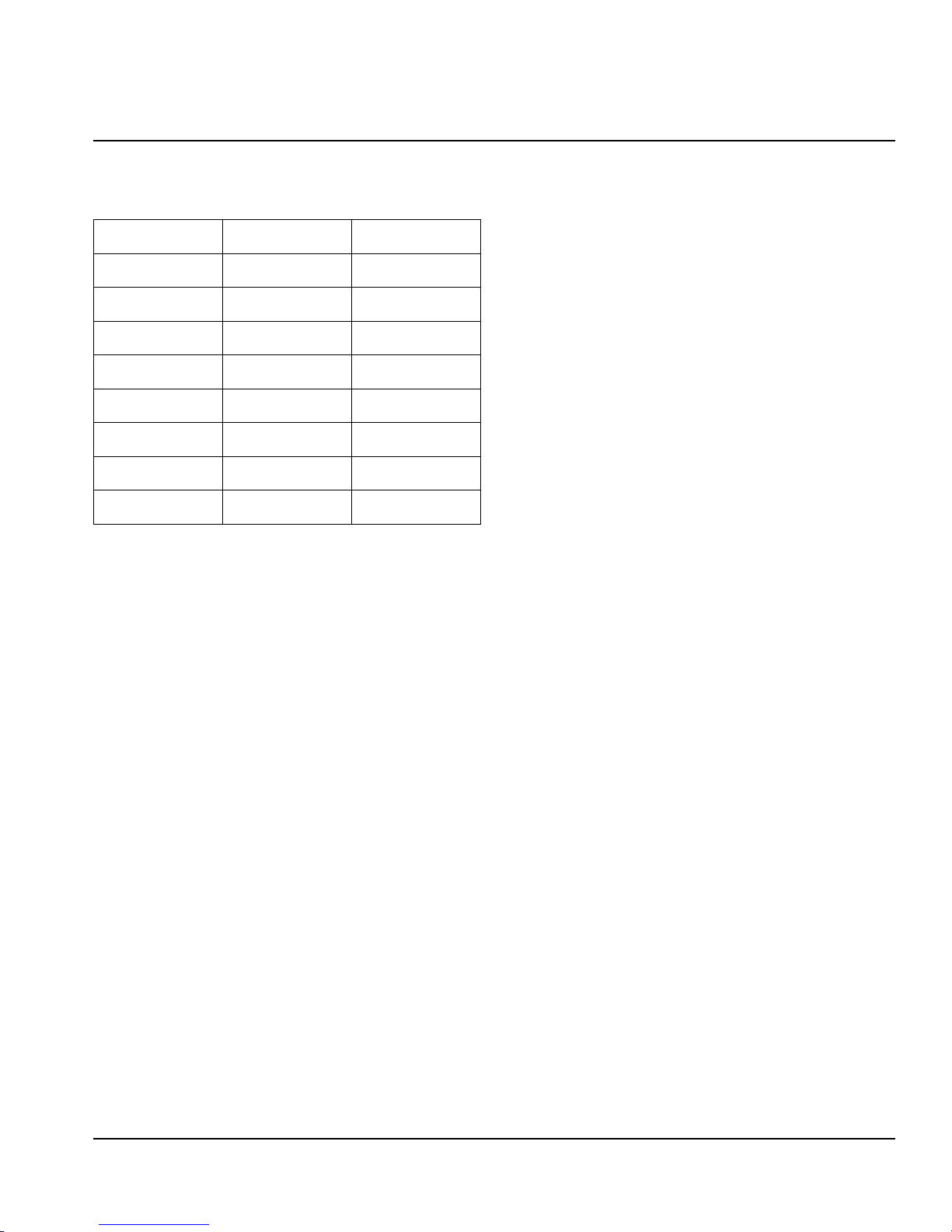

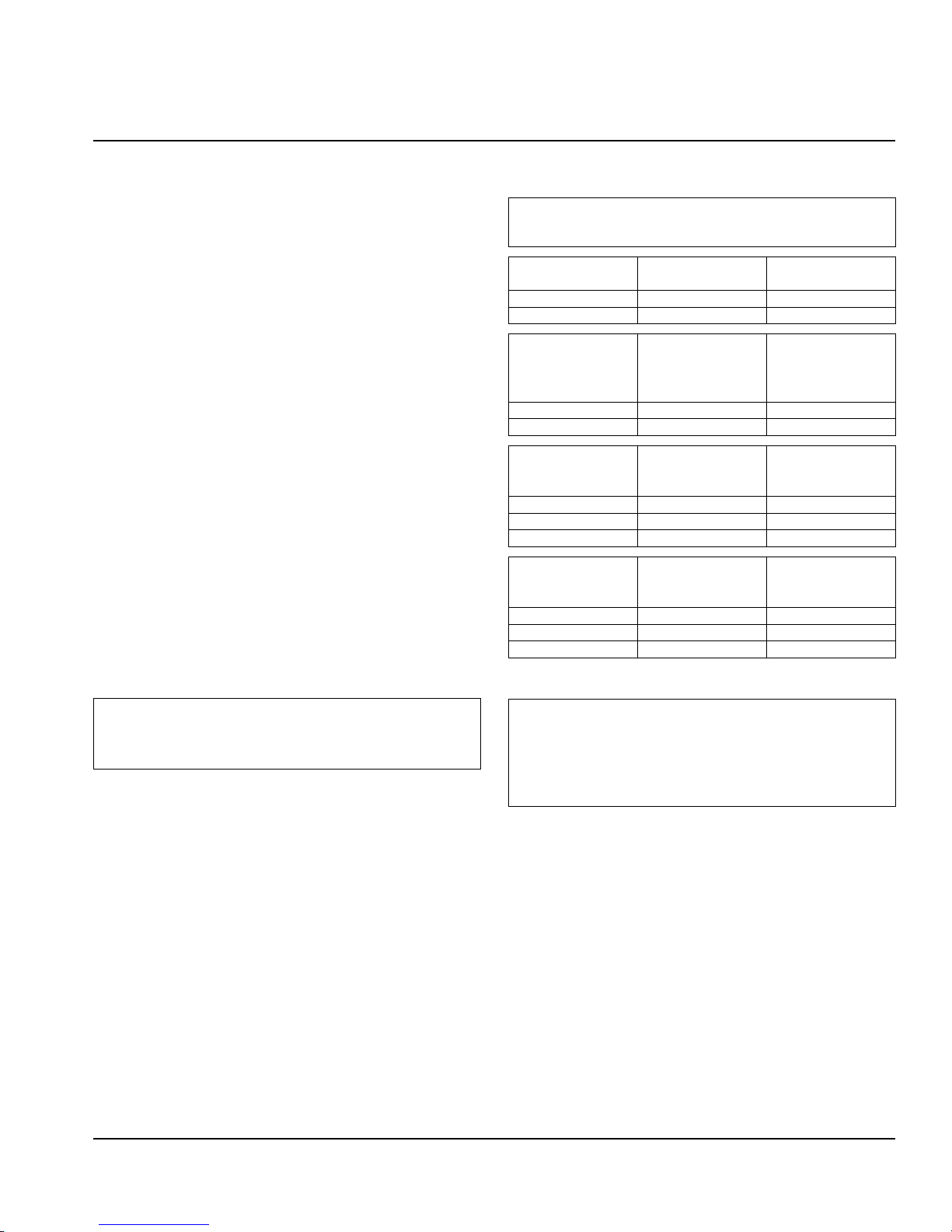

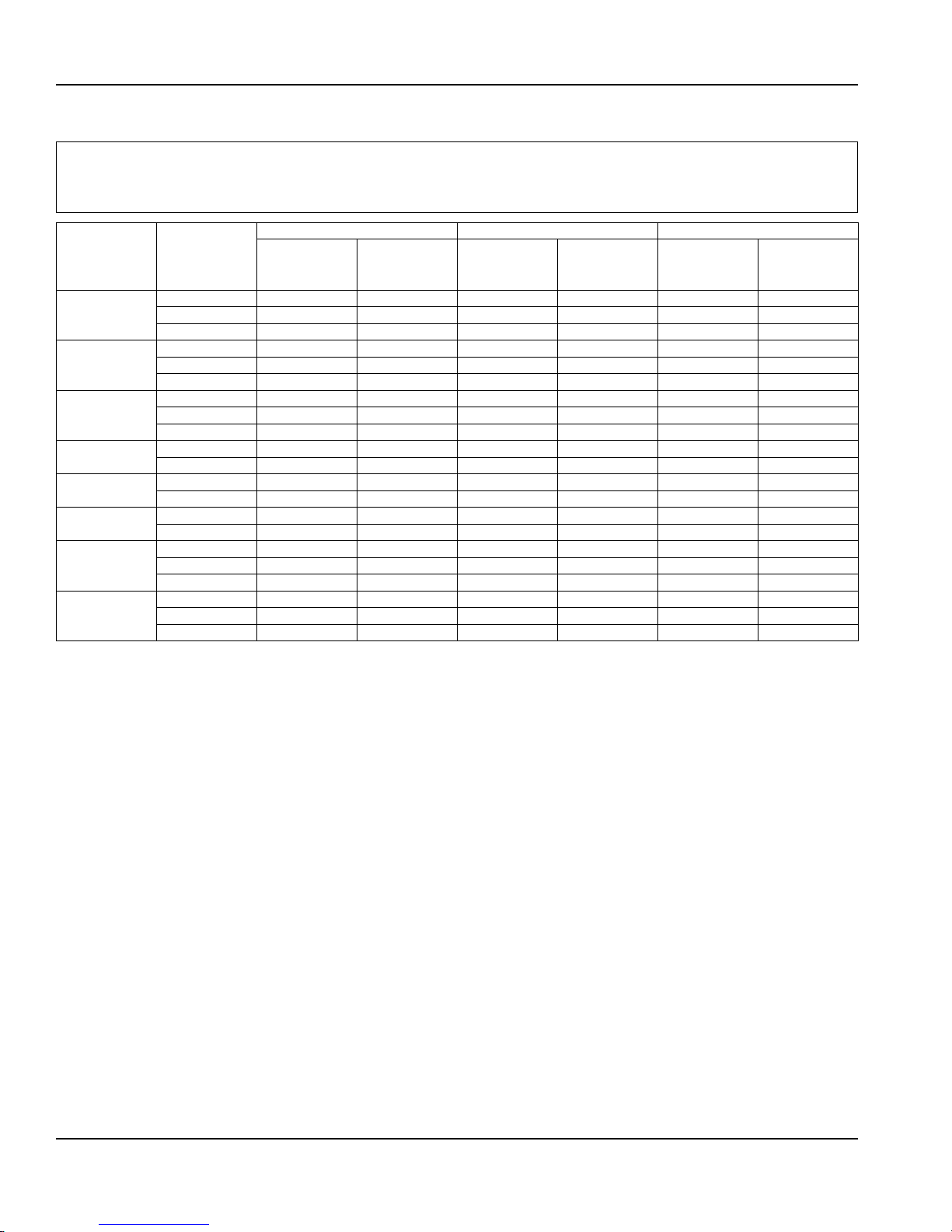

Maximum Breaker Size & Minimum Circuit Amperage Chart

Important

Due to continuous improvements, this information is for reference only. Please refer to the ice machine serial number tag

to verify electrical data. Serial tag information overrides information listed on this page.

Air-Cooled Water-Cooled Remote

Ice Machine

K0250

K0350

K0420

K0500

K0600

K1000

K1350

K1800

Voltage/

Phase/Cycle

115/1/60 15 9.44 N/A N/A N/A N/A

230/1/50 15 4.5 N/A N/A N/A N/A

230/1/60 15 4.7 N/A N/A N/A N/A

115/1/60 15 12.1 15 11.4 N/A N/A

230/1/50 15 6.3 15 5.9 N/A N/A

230/1/60 15 6.2 15 5.8 N/A N/A

115/1/60 15 11.3 15 10.6 N/A N/A

230/1/50 15 6.2 15 5.8 N/A N/A

230/1/60 15 6.2 15 5.8 N/A N/A

115/1/60 20 12.7 20 12.0 N/A N/A

230/1/50 15 6.3 15 5.9 N/A N/A

208-230/1/60 20 9.2 20 8.8 N/A N/A

230/1/50 20 8.6 20 8.2 N/A N/A

208-230/1/60 20 13.9 20 13.2 20 12.8

230/1/50 20 13.8 20 13.1 20 14.1

208-230/1/60 30 18.2 30 16.8 30 17.8

208-230/3/60 20 13.6 20 12.2 20 13.2

230/1/50 30 18.2 30 16.8 30 17.8

208-230/1/60 30 19.6 N/A N/A 30 19.6

208-230/3/60 20 13.3 N/A N/A 20 12.9

230/1/50 30 19.6 N/A N/A 30 19.6

Maximum

Fuse/Circuit

Breaker

Minimum

Circuit Amps

Maximum

Fuse/Circuit

Breaker

Minimum

Circuit Amps

Maximum

Fuse/Circuit

Breaker

Minimum

Circuit Amps

12 Part Number 000012545 Rev 02 11/16

Page 13

Section 2 Installation

Water Supply and Drain Requirements

WATER SUPPLY

Local water conditions may require treatment of the water

to inhibit scale formation, filter sediment, and remove

chlorine odor and taste.

Warning

n

Connect to a potable water supply only. Plumbing must

conform to state, local and national codes.

WATER INLET LINES

Follow these guidelines to install water inlet lines:

• If you are installing a water filter system, refer to the

installation instructions supplied with the filter system

for ice making water inlet connections.

• Do not connect the ice machine to a hot water supply.

Be sure all hot water restrictors installed for other

equipment are working. (Check valves on sink faucets,

dishwashers, etc.)

• If water pressure exceeds the maximum recommended

pressure of 80 psi (552 kPa), obtain a water pressure

regulator from your local distributor.

• Install a water shut-off valve for both the ice making and

condenser water lines.

• Insulate water inlet lines to prevent condensation.

DRAIN CONNECTIONS

Follow these guidelines when installing drain lines to

prevent drain water from flowing back into the ice machine

and storage bin:

• Drain lines must have a 1.5 inch drop per 5 feet of run

(2.5 cm per meter), and must not create traps.

• The floor drain must be large enough to accommodate

drainage from all drains.

• Run separate bin and ice machine drain lines. Insulate

them to prevent condensation.

• Vent the bin and ice machine drain to the atmosphere.

Do not vent the condenser drain on water-cooled

models.

• A separate auxiliary drain is located in the ice machine

base to remove moisture in high humidity areas. The

drain fitting is a female socket for 1/2" CPVC pipe. The

drain is sealed and the seal must be removed before

attaching the drain fitting/tubing. Tap the seal out with

a wooden dowel or similar tool. Seal the CPVC pipe to

the ice machine socket with silicone sealant to allow

future removal.

Caution

,

Do not apply heat to water valve inlet fitting. This will

damage plastic water inlet connection.

Part Number 000012545 Rev 02 11/16 13

Page 14

Installation Section 2

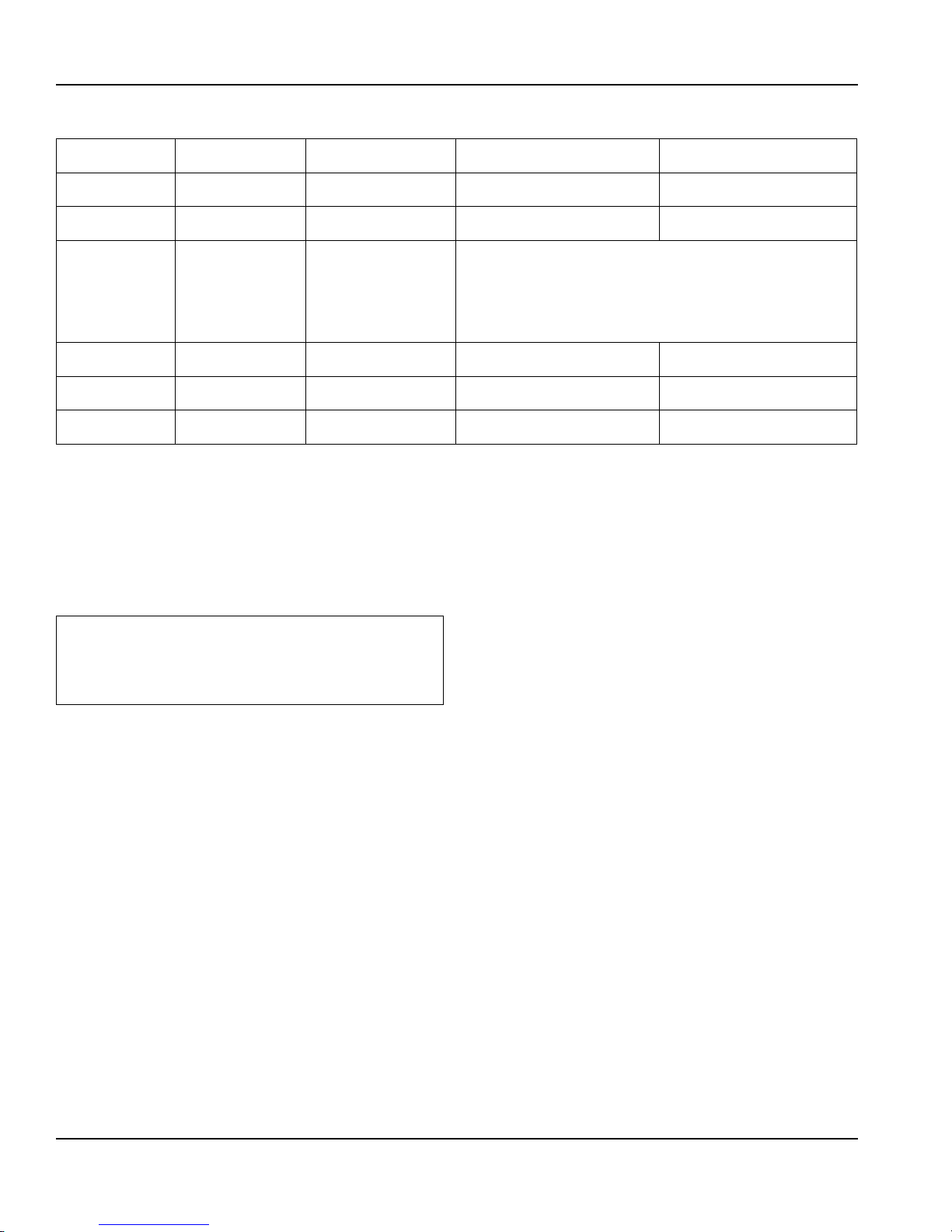

Water Supply and Drain Line Sizing/Connections

Location Water Temperature Water Pressure Ice Machine Fitting

Ice Making Water

Inlet

Ice Making Water

Drain

Condenser Water

Inlet

Condenser Water

Drain

Bin Drain

Large Capacity

Bin Drain

WATERCOOLED CONDENSER WATER PRESSURE

Water pressure at the condenser cannot exceed 150 psig

(1034 kPa) with the standard water-regulating valve.

Contact your distributor if your water pressure is greater

than 150 psig (1034 kPa). A special order condenser/waterregulating valve is available that allows water pressure up

to 350 psig (2413 kPa).

The Commonwealth of Massachusetts requires that

all water-cooled models must be connected only to a

closed loop, cooling tower system.

35°F (2°C) Min.

90°F (32°C) Max.

– – 1/2" (1.27 cm) Female Pipe Thread 1/2" (1.27 cm) min. inside

90°F (32°C) Max. Standard

– – 1/2" (1.27 cm) Female Pipe Thread 1/2" (1.27 cm) min. inside

– – 3/4" (1.91 cm) Female Pipe Thread 3/4" (1.91 cm) min. inside

– – 1" (2.54 cm) Male Pipe Thread 1" (2.54 cm) min. inside diameter

20 psi (140 kPa) Min.

80 psi (552 kPa) Max.

20 psi (140 kPa) Min.

150 psi (1034 kPa) Max.

High Pressure Option

20 psi (140 kPa) Min.

350 psi (2410 kPa) Max.

3/8" (.95 cm) Female Pipe Thread 3/8" (.95 cm) min. inside

COOLING TOWER APPLICATIONS WATERCOOLED

MODELS

A water cooling tower installation does not require

modification of the ice machine. The water regulator valve

for the condenser continues to control the refrigeration

discharge pressure.

It is necessary to know the amount of heat rejection and

Important

the pressure drop through the condenser and water valves

(inlet and outlet) when using a cooling tower on an ice

machine.

• Water entering the condenser must not exceed 90°F

(32°C).

• Water flow through the condenser must not exceed 5

gallons (19 liters) per minute.

• Allow for a pressure drop of 7 psi (50 kPa) between the

condenser water inlet and the outlet of the ice machine.

• Water exiting the condenser must not exceed 110°F

(43°C).

Tubing Size Up to Ice Machine

Fitting

diameter

diameter

3/8" Female Pipe Thread

diameter

diameter

14 Part Number 000012545 Rev 02 11/16

Page 15

Section 2 Installation

Remote Condenser/Line Set Installation

Ice Machine

K1000 KC1000

K1350 KC1350

K1800 KC1350

*Line Set Discharge Line Liquid Line

RTK 1/2" (1.27 cm) 5/16" (.79 cm)

RLK 1/2" (1.27 cm) 3/8" (.95 cm)

Air Temperature Around the Condenser

Minimum Maximum

-20°F (-29°C) 120°F (49°C)

Remote systems are only approved and warranted as a

complete new package. Warranty on the refrigeration

system will be void if a new ice machine head section

is connected to pre-existing (used) tubing or remote

condensers.

Remote Single

Circuit Condenser

Important

Line Set*

RTK-20-R410A

RTK-35-R410A

RTK-50-R410A

RLK-20-R410A

RLK-35-R410A

RLK-50-R410A

RLK-20-R410A

RLK-35-R410A

RLK-50-R410A

REMOTE ICE MACHINE REFRIGERANT CHARGE

Each remote ice machine ships from the factory with a

refrigerant charge appropriate for installation with line

sets of up to 50' (15 m). The serial tag on the ice machine

indicates the refrigerant charge.

Additional refrigerant may be required for installations

using line sets between 50' and 100' (15-30 m) long. If

additional refrigerant is required, refer to the chart below

for the correct amount to be added.

Ice Machine

K1000 2 lbs (907g)

K1350 2 lbs (907g)

K1800 2 lbs (907g)

Refrigerant to be added for

50'-100' Line Sets

Important

EPA CERTIFIED TECHNICIANS

If remote line set length is between 50' and 100'

(15 and 30 m), add additional refrigerant to the

nameplate charge. Refer to the table below for the

model being worked on.

Tubing length: _________________________________

Refrigerant added to nameplate: __________________

New total refrigerant charge: _____________________

Warning

n

Potential Personal Injury Situation

The ice machine contains refrigerant charge. Installation

of the line sets must be performed by a properly trained

and EPA certified refrigeration technician aware of

the dangers of dealing with refrigerant charged

equipment.

Part Number 000012545 Rev 02 11/16 15

Page 16

Installation Section 2

GENERAL

Condensers must be mounted horizontally with the fan

motor on top with nothing obstructing it. There must be at

least a 16" (41 cm) clearance from the bottom for air intake.

The front coupling panel and one other panel (back or side)

must also be unobstructed.

Remote condenser installations consist of vertical and

horizontal line sets between the ice machine and the

condenser. When combined, they must fit within approved

specifications. The following guidelines, drawings and

calculation methods must be followed to verify a proper

remote condenser installation.

Caution

,

The compressor warranty (including the labor

replacement warranty) will not apply if the remote ice

machine is not installed according to specifications.

The warranty also will not apply if the refrigeration

system is modified with a condenser, heat reclaim

device, or other parts or assemblies not manufactured

by us unless we specifically approved the component in

writing.

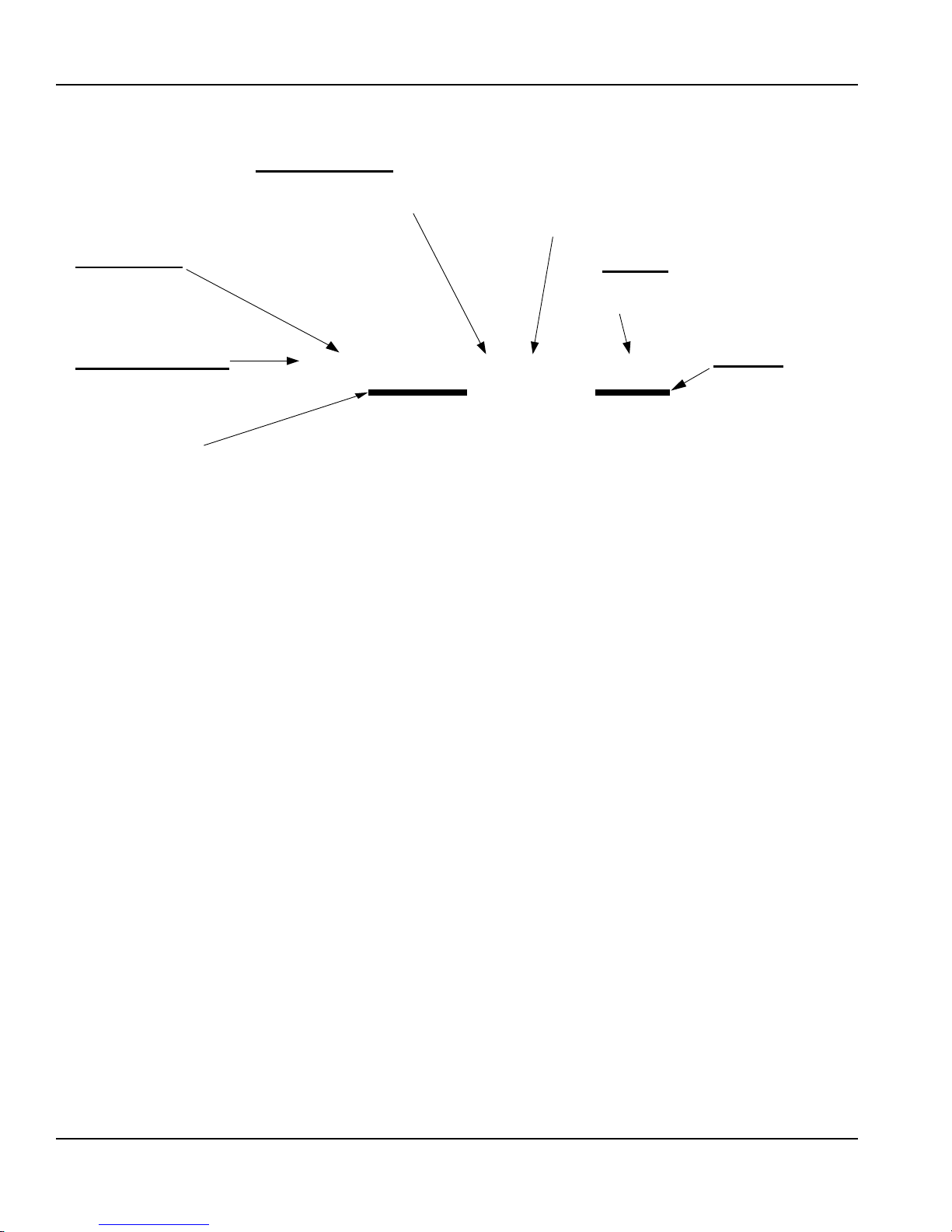

3

2

1

DOWNWARD

DOWNWARD

HORIZONTAL

HORIZONTAL

SPIRAL

SPIRAL

1

2

3

WIRING

Interconnecting line voltage wiring is used to energize and

de-energize the condenser fan motor.

• The remote condenser voltage matches the ice machine

head section voltage.

Interconnecting Wire Connections

Ice Machine Head Section Remote Condenser

F1 L1

F2 L2

GUIDELINES FOR ROUTING LINE SETS

First, cut a 2.5" (6.35 cm) circular hole in the wall or roof

for tubing routing. The line set end with the 90° bend will

connect to the ice machine. The straight end will connect to

the remote condenser.

Follow these guidelines when routing the refrigerant lines.

This will help ensure proper performance and service

accessibility.

1. Optional - Make the service loop in the line sets (as

shown in Routing Line Sets graphic). This permits easy

access to the ice machine for cleaning and service. Do

not use hard rigid copper at this location.

2. Required - Do not form traps in the refrigeration lines

(except the service loop). Refrigerant oil must be free to

drain toward the ice machine or the condenser. Route

excess tubing in a supported downward horizontal

spiral (as shown below). Do not coil tubing vertically.

3. Required - Keep outdoor refrigerant line runs as short

as possible.

Routing Line Sets

16 Part Number 000012545 Rev 02 11/16

Page 17

Section 2 Installation

H

H

H

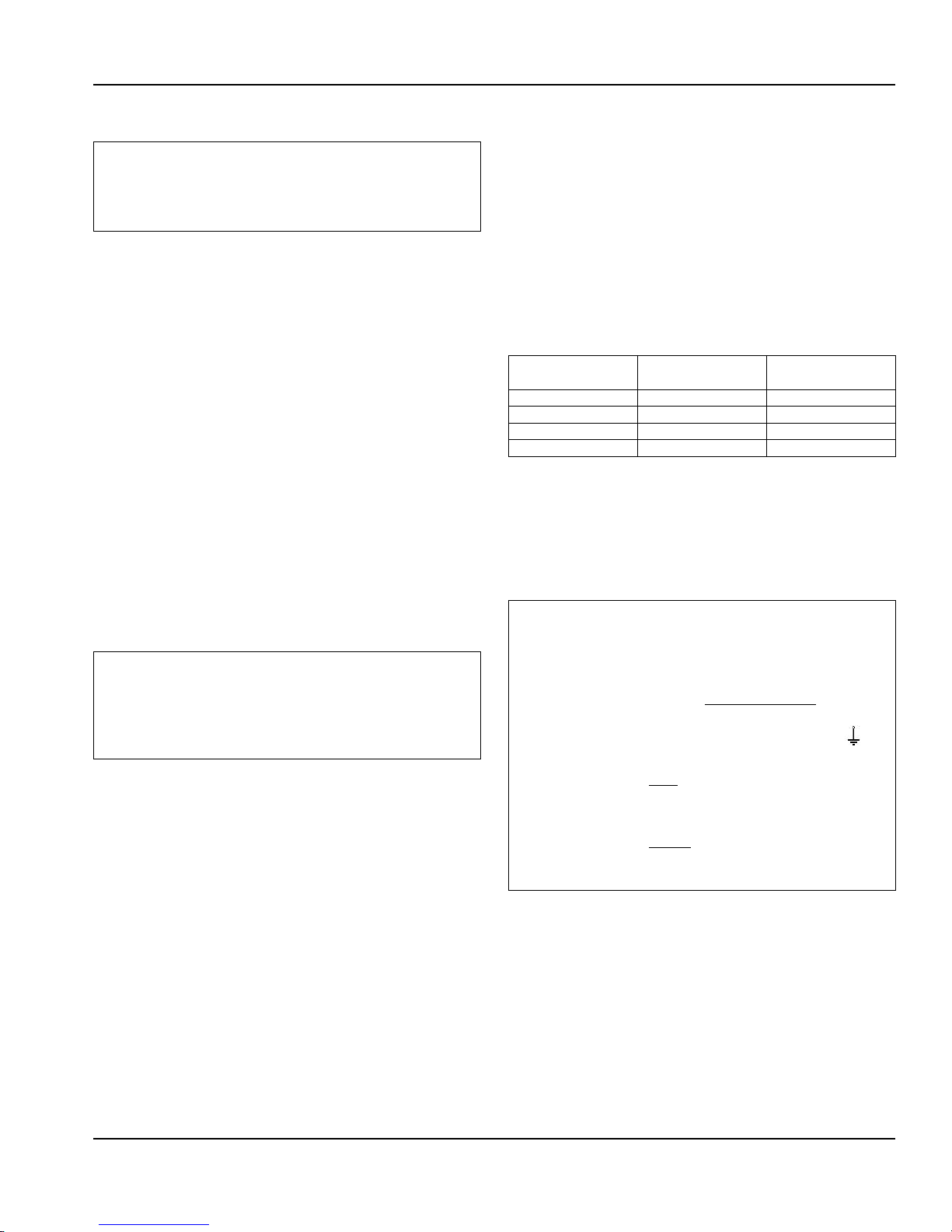

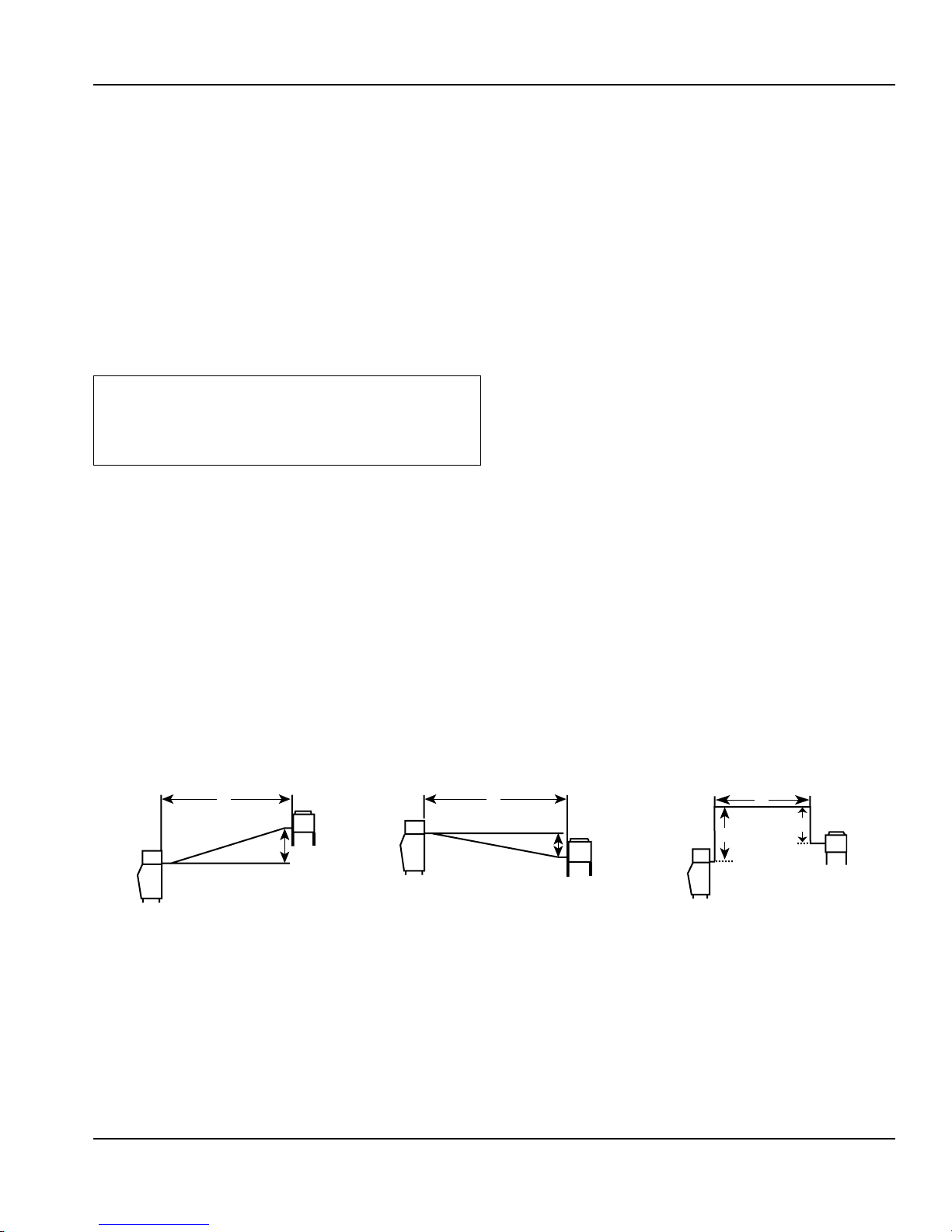

CALCULATING REMOTE CONDENSER INSTALLATION

DISTANCES

Line Set Length

The maximum length is 100' (30 m).

The ice machine compressor must have the proper oil

return. The receiver is designed to hold a charge sufficient

to operate the ice machine in ambient temperatures

between -20°F (-29°C) and 120°F (49°C), with line set

lengths of up to 100' (30 m).

Line Set Rise/Drop

The maximum rise is 35' (10.7 m).

The maximum drop is 15' (4.5 m).

Caution

,

If a line set has a rise followed by a drop, another

rise cannot be made. Likewise, if a line set has a drop

followed by a rise, another drop cannot be made.

Calculated Line Set Distance

The maximum calculated distance is 150' (45 m).

Line set rises, drops, horizontal runs (or combinations

of these) in excess of the stated maximums will exceed

compressor start-up and design limits. This will cause poor

oil return to the compressor.

Make the following calculations to make sure the line set

layout is within specifications.

1. Insert the measured rise into the formula below.

Multiply by 1.7 to get the calculated rise.

(Example: A condenser located 10 feet above the ice

machine has a calculated rise of 17 feet.)

2. Insert the measured drop into the formula below.

Multiply by 6.6 to get the calculated drop.

(Example. A condenser located 10 feet below the ice

machine has a calculated drop of 66 feet.)

3. Insert the measured horizontal distance into the

formula below. No calculation is necessary.

4. Add together the calculated rise, calculated drop,

and horizontal distance to get the total calculated

distance. If this total exceeds 150' (45 m), move

the condenser to a new location and perform the

calculations again.

Maximum Line Set Distance Formula

Step 1. Measured Rise (35' [10.7 m] Maximum) ______ x 1.7 = _______ Calculated Rise

Step 2. Measured Drop (15' [4.5 m] Maximum) ______ x 6.6 = _______ Calculated Drop

Step 3. Measured Horizontal Distance (100' [30 m] Maximum) _______ Horizontal Distance

Step 4. Total Calculated Distance 150' (45 m) _______ Total Calculated Distance

D

R

SV1196 SV1195 SV1194

Combination of a Rise and a

HorizontalRun

D

Combination of a Drop and a

HorizontalRun

R

Combination of a Rise, a Drop and a

Horizontal Run

Part Number 000012545 Rev 02 11/16 17

Page 18

Installation Section 2

ROUTE THE LINE SET

• Route the line set to avoid traps and kinks.

• Minimize the amount of line set exposed on the roof.

CONNECT THE LINE SET

• Cut the line set to the correct length.

• Purge line set with dry nitrogen while brazing.

• Line set shutoff valves on the ice machine must remain

closed and be protected from heat during brazing.

PRESSURE TEST AND EVACUATE LINE SET AND

CONDENSER

• Lineset shutoff valves must remain closed until pressure

testing and evacuation are complete.

• Pressure test @ 150 psi (1000 kPa) for a minimum of 15

minutes.

• Minimum evacuation level is 500 microns.

• Pressure test the line set and condenser with 150 psig of

dry nitrogen. Add nitrogen at the line set shutoff valves

located at the back of the ice machine head section.

Complete the pressure test, verify no leaks are present

and remove the nitrogen from the system before

connecting the vacuum pump.

OPEN LINE SET VALVES

You will not hear refrigerant flow when the valves are

opened. Refrigerant will not flow until the ice machine is

started and the solenoid valve opens.

• All valve caps must be reinstalled, tightened and leakchecked to assure no refrigerant leakage exists.

• Counterclockwise opens all valves.

18 Part Number 000012545 Rev 02 11/16

Page 19

Section 2 Installation

Installation Check List

Is the Ice Machine level?

Have all of the electrical and water connections

beenmade?

Has the supply voltage been tested and checked

against the rating on the nameplate?

Is there proper clearance around the ice machine forair

circulation?

Is the ice machine grounded and polarity correct?

Has the ice machine been installed where ambient

temperatures will remain in the range of 35° - 110°F

(1.6° - 43.3°C)?

Has the ice machine been installed where the incoming

water temperature will remain in the rangeof 35° - 90°F

(1.6° - 32.2°C)?

Is there a separate drain for the potable water,

binandwater-cooled condenser?

Additional Checks for Remote Models

Does the remote condenser fan operate properly

afterstart-up?

Has the remote condenser been located where

ambient temperatures will remain in the range of -20°120°F (-29 - 49°C).

Is the line set routed properly?

Are both refrigeration lines to remote condenser run so

they do not lay in water and are properly insulated?

Before Starting the Ice Machine

All ice machines are factory-operated and adjusted before

shipment. Normally, new installations do not require any

adjustment.

To ensure proper operation, follow the Operational Checks

in Section 3 of this manual. Starting the ice machine and

completing the Operational Checks are the responsibilities

of the owner/operator.

Adjustments and maintenance procedures outlined in this

manual are not covered by the warranty.

Are the ice machine and bin drains vented?

Are all refrigerant lines free from contact with

othercomponents?

Are all electrical leads free from contact with

refrigeration lines and moving equipment?

Has the owner/operator been instructed

regardingmaintenance and the use of our Cleanerand

Sanitizer?

Has the owner/operator completed the

warrantyregistration card?

Has the ice machine and bin been sanitized?

Is the ice thickness set correctly? (Refer to

OperationalChecks to check/set the correct ice

bridgethickness).

Warning

n

Potential Personal Injury Situation

Do not operate equipment that has been misused,

abused, neglected, damaged, or altered/modified from

that of original manufactured specifications.

Part Number 000012545 Rev 02 11/16 19

Page 20

Installation Section 2

THIS PAGE INTENTIONALLY LEFT BLANK

20 Part Number 000012545 Rev 02 11/16

Page 21

Section 3

Operation

Ice Making Sequence of Operation

NOTE: The toggle switch must be in the ICE position and the

water curtain must be closed before the ice machine will

start.

Water Purge Cycle

The ice machine purges any remaining water from the

water trough down the drain and the refrigeration

compressor starts.

Freeze Cycle

Prechill - The refrigeration system chills the evaporator

before water flow over the evaporator starts. The water inlet

valve energizes during the pre-chill and remains on until

the Ice Thickness Float Switch is satisfied.

Freeze - Water flowing across the evaporator freezes and

builds ice on the evaporator. After a sheet of ice has formed,

the Harvest Float Switch signals the control board to start a

harvest cycle.

Harvest Cycle

Any remaining water is purged down the drain as

refrigerant gas warms the evaporator. When the evaporator

warms, the sheet of cubes slides off the evaporator and into

the storage bin. If all cubes fall clear of the water curtain,

the ice machine starts another freeze cycle.

Full Bin Cycle

If the water curtain is held open by ice cubes, the ice

machine shuts off and starts a 3-minute delay period. When

the water curtain closes, the ice machine starts a new cycle

at the water purge, provided the 3-minute delay period has

expired.

CONTROL BOARD TIMERS

The control board has the following non-adjustable timers:

• The ice machine is locked into the freeze cycle for 6

minutes before a harvest cycle can be initiated.

• The maximum freeze time is 60 minutes, at which time

the control board automatically initiates a harvest

sequence.

• The maximum harvest time is 3.5 minutes. The control

board automatically initiates a freeze sequence when

these times are exceeded.

SAFETY LIMITS

Safety limits are stored and indicated by the control board.

The number of cycles required to stop the ice machine

varies for each safety limit.

Safety limits can be reset by pressing the On/Off button and

starting a new ice making cycle.

A safety limit is indicated by a flashing Service Light on the

control board.

• Safety Limit 1 - If the freeze time reaches 60 minutes,

the control board automatically initiates a harvest cycle.

If 6 consecutive 60-minute freeze cycles occur, the ice

machine stops.

• Safety Limit 2 - If the harvest time reaches 3.5 minutes,

the control board automatically returns the ice machine

to the freeze cycle. If 500 consecutive 3.5 minute harvest

cycles occur, the ice machine stops.

• Safety Limit 3 - If the freeze time reaches 4 minutes

and water is not sensed, the ice machine stops and

initiates a 30 minute delay period. The ice machine will

automatically restart at the end of the 30 minute delay

period. If 100 consecutive failures occur, the ice machine

stops.

Part Number 000012545 Rev 02 11/16 21

Page 22

Operation Section 3

Operational Checks

GENERAL

All ice machines are factory-operated and adjusted before

shipment. Normally, new installations do not require any

adjustment.

To ensure proper operation, always follow the Operational

Checks:

• when starting the ice machine for the first time

• after a prolonged out-of-service period

• after cleaning and sanitizing

NOTE: Routine adjustments and maintenance procedures

are not covered by the warranty.

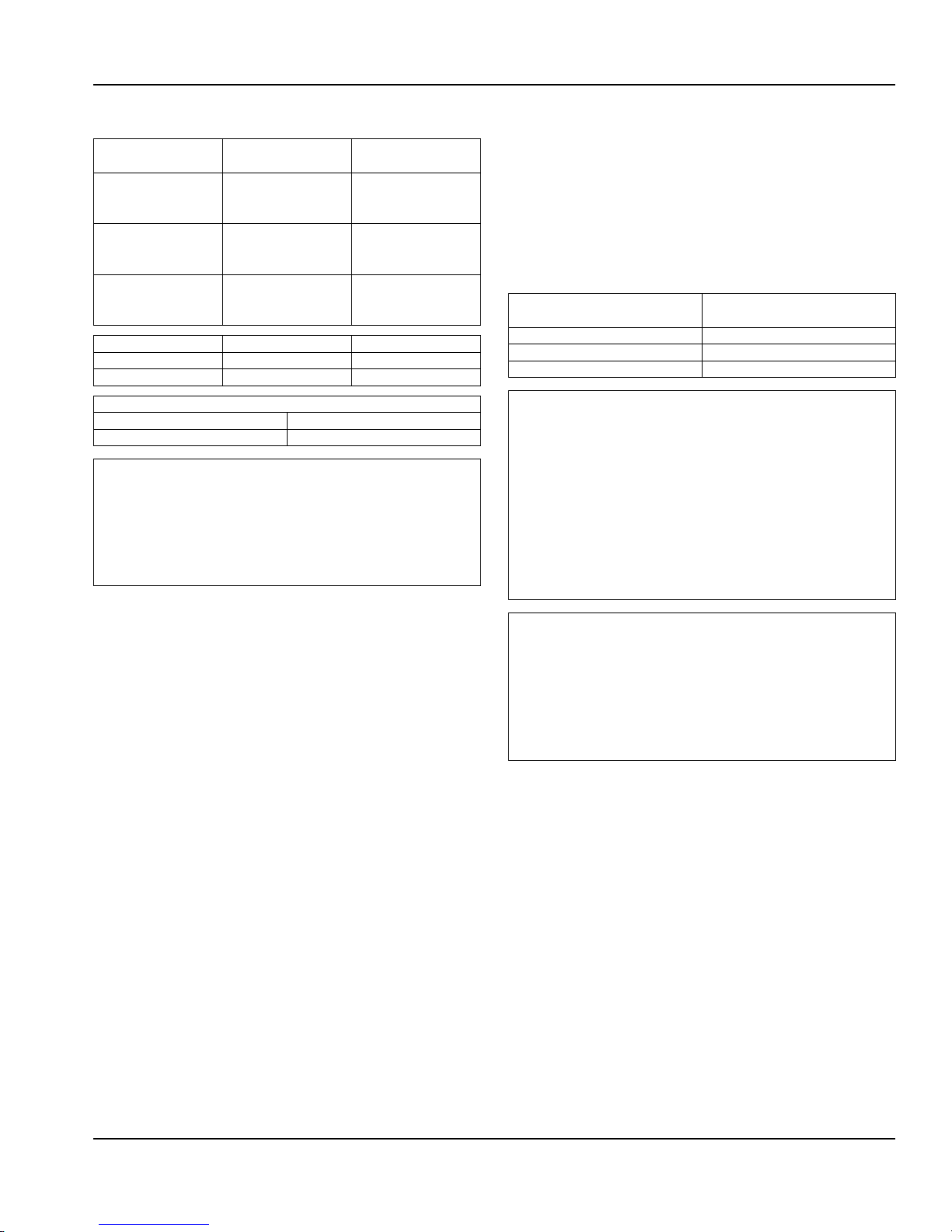

MINIMUM/MAXIMUM SLAB WEIGHTS

Adjust ice thickness to meet chart specifications.

Model Minimum Ice Weight

Per Cycle

K0250 3.4 lbs

1542 g

K0350 3.4 lbs

1542 g

K420 3.4 lbs

1542 g

K0500 4.125 lbs

1871 g

K0600 4.125 lbs

1871 g

K1000 7.25 lbs

3288 g

K1350 12.8 lbs

5805 g

K1800 12.8 lbs

5805 g

Maximum Ice Weight

Per Cycle

3.9 lbs

1769 g

3.9 lbs

1769 g

3.9 lbs

1769 g

4.75 lbs

2154 g

4.75 lbs

2154 g

7.75 lbs

3515 g

14.4 lbs

6532 g

14.4 lbs

6532 g

ICE THICKNESS CHECK

After a harvest cycle, inspect the ice cubes in the ice storage

bin. The ice thickness float switch is factory-set to maintain

the ice bridge thickness at 1/8" (3 mm).

NOTE: Make sure the water curtain is in place when

performing this check. It prevents water from splashing out

of the water trough.

1. Inspect the bridge connecting the cubes. It should be

about 1/8" (3 mm) thick.

2. If adjustment is necessary, turn the ice thickness

float switch clockwise to increase bridge thickness,

counterclockwise to decrease bridge thickness. Adjust

to achieve a 1/8" (3 mm) bridge thickness.

NOTE: The float can be adjusted with a 3/4" wrench while

the water trough is in place. Test run two cycles to verify

water level.

Ice Thickness Float

Switch Adjustment

22 Part Number 000012545 Rev 02 11/16

Page 23

Section 4

Maintenance

Cleaning and Sanitizing

GENERAL

You are responsible for maintaining the ice machine

in accordance with the instructions in this manual.

Maintenance procedures are not covered by the warranty.

Clean and sanitize the ice machine every six months

for efficient operation. If the ice machine requires more

frequent cleaning and sanitizing, consult a qualified

service company to test the water quality and recommend

appropriate water treatment. An extremely dirty ice

machine must be taken apart for cleaning and sanitizing.

Manitowoc Ice Machine Cleaner and Sanitizer are the only

products approved for use in this ice machine.

Caution

,

Use only approved Ice Machine Cleaner and Sanitizer

for this application (Manitowoc Cleaner part number

9405463 and Manitowoc Sanitizer part number

9405653). It is a violation of Federal law to use these

solutions in a manner inconsistent with their labeling.

Read and understand all labels printed on bottles before

use.

Caution

,

Do not mix Cleaner and Sanitizer solutions together. It

is a violation of Federal law to use these solutions in a

manner inconsistent with their labeling.

Warning

n

Wear rubber gloves and safety goggles (and/or face

shield) when handling Ice Machine Cleaner or Sanitizer.

CLEANING/SANITIZING PROCEDURE

This procedure must be performed a minimum of once

every six months.

• The ice machine and bin must be disassembled, cleaned

and sanitized.

• All ice produced during the cleaning and sanitizing

procedures must be discarded.

• Removes mineral deposits from areas or surfaces that

are in direct contact with water.

PREVENTATIVE MAINTENANCE CLEANING PROCEDURE

• This procedure cleans all components in the water flow

path, and is used to clean the ice machine between

the bi-yearly cleaning/sanitizing procedure without

removing the ice from the bin/dispenser.

• This technology will also allow initiation and completion

of a clean or sanitize cycle, after which the ice machine

automatically starts ice making again.

EXTERIOR CLEANING

Clean the area around the ice machine as often as necessary

to maintain cleanliness and efficient operation.

Wipe surfaces with a damp cloth rinsed in water to remove

dust and dirt from the outside of the ice machine. If a greasy

residue persists, use a damp cloth rinsed in a mild dish soap

and water solution. Wipe dry with a clean, soft cloth.

The exterior panels have a clear coating that is stain

resistant and easy to clean. Products containing abrasives

will damage the coating and scratch the panels.

• Never use steel wool or abrasive pads for cleaning.

• Never use chlorinated, citrus-based or abrasive cleaners

on exterior panels and plastic trim pieces.

Part Number 000012545 Rev 02 11/16 23

Page 24

Maintenance Section 4

Cleaning/Sanitizing Procedure

Caution

,

Use only approved Ice Machine Cleaner and Sanitizer for

this application (Manitowoc Cleaner part number 940546-3 and Manitowoc Sanitizer part number 94-0565-

3). It is a violation of Federal law to use these solutions

in a manner inconsistent with their labeling. Read and

understand all labels printed on bottles before use.

Caution

,

Do not mix Cleaner and Sanitizer solutions together. It

is a violation of Federal law to use these solutions in a

manner inconsistent with their labeling.

Warning

n

Wear rubber gloves and safety goggles (and/or face

shield) when handling Ice Machine Cleaner or Sanitizer.

Ice machine cleaner is used to remove lime scale and

mineral deposits. Ice machine sanitizer disinfects and

removes algae and slime.

Step 1 Remove the front door to access the evaporator

compartment. Ice must not be on the evaporator during

the clean/sanitize cycle. Set the toggle switch to the OFF

position after ice falls from the evaporator at the end of a

harvest cycle. Or, set the switch to OFF and allow the ice to

melt off the evaporator(s).

Caution

,

Never use anything to force ice from the evaporator.

Damage may result.

Step 2 Remove all ice from the bin/dispenser.

Step 3 Place the toggle switch in the CLEAN position.

Water will flow through the water dump valve and down

the drain. Wait until the water trough refills, then add the

proper amount of ice machine cleaner.

Model Amount of Cleaner

K0250 K0350 K0420 3 ounces (90 ml)

K0500 K0600 K1000 5 ounces (150 ml)

K1350 K1800 9 ounces (265 ml)

Step 4 Wait until the clean cycle is complete

(approximately 24 minutes). Then disconnect power to the

ice machine (and dispenser when used).

Warning

n

Disconnect the electric power to the ice machine at the

electric service switch box.

Step 5 Remove parts for cleaning.

Please refer to the proper parts removal for your ice

machine. Continue with step 6 when the parts have

been removed.

Single Evaporator Ice Machines - page 26

24 Part Number 000012545 Rev 02 11/16

Page 25

Section 4 Maintenance

Step 6 Mix a solution of cleaner and lukewarm water.

Depending upon the amount of mineral buildup, a larger

quantity of solution may be required. Use the ratio in the

table below to mix enough solution to thoroughly clean all

parts.

Solution Type Water Mixed with

Cleaner 1 gal. (4 L) 16 oz (500 ml) cleaner

Step 7 Use 1/2 of the cleaner/water mixture to clean

all components. The cleaner solution will foam when it

contacts lime scale and mineral deposits; once the foaming

stops use a soft-bristle nylon brush, sponge or cloth (NOT

a wire brush) to carefully clean the parts. Soak parts for

5 minutes (15-20 minutes when heavily scaled). Rinse all

components with clean water.

Step 8 While components are soaking, use 1/2 of the

cleaner/water solution to clean all foodzone surfaces of the

ice machine and bin (or dispenser). Use a nylon brush or

cloth to thoroughly clean the following ice machine areas:

• Evaporator plastic parts – including top, bottom and

sides

• Bin bottom, sides and top

Rinse all areas thoroughly with clean water.

SANITIZING PROCEDURE

Step 9 Mix a solution of sanitizer and lukewarm water.

Solution Type Water Mixed with

Sanitizer 3 gal. (12 L) 2 oz (60 ml) sanitizer

Step 10 Use 1/2 of the sanitizer/water solution to sanitize

all removed components. Use a spray bottle to liberally

apply the solution to all surfaces of the removed parts or

soak the removed parts in the sanitizer/water solution. Do

not rinse parts after sanitizing.

Step 11 Use 1/2 of the sanitizer/water solution to sanitize

all foodzone surfaces of the ice machine and bin (or

dispenser). Use a spray bottle to liberally apply the solution.

When sanitizing, pay particular attention to the following

areas:

• Evaporator plastic parts - including top, bottom and

sides

• Ice machine base (top of bin) and area above the water

trough

• Bin sides and bottom

Do not rinse the sanitized areas.

Step 12 Replace all removed components.

Step 13 Wait 25 minutes.

Step 14 Reapply power to the ice machine and place the

toggle switch in the CLEAN position.

Step 15 Wait until the water trough refills, then add the

proper amount of Manitowoc Ice Machine Sanitizer to the

water trough.

Model Amount of Sanitizer

K0250 K0350 K0420

K0500 K0600 K1000

K1350 K1800 6 ounces (180 ml)

3 ounces (90 ml)

Step 16 After the sanitize cycle is complete (approximately

24 minutes) move the toggle switch to the ICE position to

start ice making.

Part Number 000012545 Rev 02 11/16 25

Page 26

Maintenance Section 4

Parts Removal for Cleaning/Sanitizing

Single Evaporator Ice Machines

A. Remove the water curtain

• Gently flex the curtain in the center and remove it from

the right side.

• Slide the left pin out.

B. Remove the water trough

• Depress tabs on right and left side of the water trough.

• Allow front of water trough to drop as you pull forward

to disengage the rear pins.

C. Remove the ice thickness and harvest float switches

• Pull the float switch straight down to disengage.

• Lower the float switch until the wiring connector is

visible.

• Disconnect the wire lead from the float switch.

• Remove the float switch from the ice machine.

D. Remove the water distribution tube

NOTE: Distribution tube thumbscrews are retained

to prevent loss. Loosen thumbscrews but do not pull

thumbscrews out of distribution tube.

• Loosen the two outer screws (do not remove screws

completely they are retained to prevent loss) and pull

forward on the distribution tube to release from slip

joint.

• Disassemble distribution tube by loosening the two (2)

middle thumbscrews and dividing the distribution tube

into two pieces.

• Proceed to page 25 Step 6.

D

C

A

B

26 Part Number 000012545 Rev 02 11/16

Page 27

Section 4 Maintenance

Preventative Maintenance Cleaning Procedure

This procedure cleans all components in the water flow

path, and is used to clean the ice machine between the biyearly cleaning/sanitizing procedure.

Ice machine cleaner is used to remove lime scale and

mineral deposits. Ice machine sanitizer disinfects and

removes algae and slime.

NOTE: Although not required and dependent on your

installation, removing the ice machine top cover may allow

easier access.

Step 1 Ice must not be on the evaporator during the

clean/sanitize cycle. Follow one of the methods below:

• Move the toggle switch to the OFF position at the end

of a harvest cycle after ice falls from the evaporator(s).

• Move the toggle switch to the OFF position and allow

the ice to melt.

Caution

,

Never use anything to force ice from the evaporator.

Damage may result.

Step 2 Open the front door and move the toggle switch

to the CLEAN position. Wait until the water trough refills

(approximately 1 minute) and then add the proper amount

of Ice Machine Cleaner to the water trough.

Model Amount of Cleaner

K0250 K0350 K0420 3 ounces (90 ml)

K0500 K0600 K1000 5 ounces (150 ml)

K1350 K1800 9 ounces (265 ml)

Step 3 After 1 minute place the toggle switch in the

ICE position and close and secure the front door. The ice

machine will automatically start ice making after the Clean

cycle is complete (approximately 24 minutes).

Door Removal

1. Use a Phillips screwdriver to loosen the two screws

securing the door. Do not remove, they are retained to

prevent loss.

2. Tilt door forward and lift up to remove.

Cleaning the Condenser Filter

The washable filter on self-contained ice machines is

designed to catch dust, dirt, lint and grease. Clean the filter

with a mild soap and water.

Cleaning the Condenser

Warning

n

Disconnect electric power to the ice machine head

section and the remote condensing unit at the electric

service switches before cleaning the condenser.

A dirty condenser restricts airflow, resulting in excessively

high operating temperatures. This reduces ice production

and shortens component life.

• Clean the condenser at least every six months.

Warning

n

The condenser fins are sharp. Use care when cleaning

them.

• Shine a flashlight through the condenser to check for

dirt between the fins.

• Blow compressed air or rinse with water from the inside

out (opposite direction of airflow).

• If dirt still remains call a service agent to clean the

condenser.

Part Number 000012545 Rev 02 11/16 27

Page 28

Maintenance Section 4

Removal from Service/Winterization

1. Clean and sanitize the ice machine.

2. Move the toggle switch to the OFF position and turn off

the ice machine.

3. Turn off the water supply, disconnect and drain the

incoming ice-making water line at the rear of the ice

machine and drain the water trough.

4. Energize the ice machine, wait one minute for the

water inlet valve to open and blow compressed air in

both the incoming water and the drain openings in the

rear of the ice machine to remove all water.

5. Move the toggle switch to the OFF position and turn off

the ice machine. Disconnect the electric power at the

circuit breaker or the electric service switch.

6. Fill spray bottle with sanitizer/water solution and spray

all interior food zone surfaces. Do not rinse and allow to

air dry.

7. Replace all panels.

WATERCOOLED ICE MACHINES

1. Perform steps 1-6 under “Removal from Service/

Winterization”.

2. Disconnect the incoming water and drain line from the

water-cooled condenser.

3. Energize the ice machine in the freeze cycle. The

increasing refrigerant pressure will open the water

regulating valve.

4. Blow compressed air through the condenser until no

water remains.

5. Replace all panels.

28 Part Number 000012545 Rev 02 11/16

Page 29

Section 5

Troubleshooting

Checklist

If a problem arises during operation of your ice machine, follow the checklist below before calling service. Routine

adjustments and maintenance procedures are not covered by the warranty.

Problem Possible Cause To Correct

Ice machine does not operate. No electrical power to the ice machine. Replace the fuse/reset the breaker/turn on the

main switch/plug power cord into receptacle.

Ice machine needs to be turned on. Place the toggle switch in the ICE position to

start ice making.

Curtain in open position (down). Curtain must be in the closed position and

capable of swinging freely.

Ice machine stops, and can be restarted

by turning the ice machine OFF and then

ON.

Ice sheet is thick Water trough level is too high. Adjust ice thickness float.

Ice machine does not release ice or is slow

to harvest.

Ice machine does not cycle into harvest

mode.

Ice quality is poor

(soft or not clear).

Ice machine produces shallow or

incomplete cubes, or the ice fill pattern on

the evaporator is incomplete.

Safety limit feature stopping the ice machine. Refer to “Safety Limit Feature” on the next

page.

Power button was turned off/on during freeze

cycle and ice remained on evaporator.

Ice damper was opened then closed in the

harvest cycle before the ice released.

Ice machine is dirty. Clean and sanitize the ice machine.

Ice machine is not level. Level the ice machine.

Low air temperature around ice machine (aircooled models).

Water regulating valve leaks in harvest mode

(water-cooled models).

The six-minute freeze time lock-in has not

expired yet.

Ice thickness float switch is dirty. Clean and sanitize the ice machine.

Ice thickness float switch wire is disconnected. Connect the wire.

Ice thickness float switch is out of adjustment. Adjust the ice thickness float switch.

Uneven ice fill (thin at top of evaporator). See “Shallow or Incomplete Cubes” on the

Poor incoming water quality. Contact a qualified service company to test

Water filtration is poor. Replace the filter.

Ice machine is dirty. Clean and sanitize the ice machine.

Water softener is working improperly (if

applicable).

Ice thickness float switch is out of adjustment. Adjust the ice thickness float switch.

Water trough level is too high or too low. Check the water level and adjust if required.

Water filtration is poor. Replace the filter.

Hot incoming water. Connect the ice machine to a cold water

Incorrect incoming water pressure. Water pressure must be 20-80 psi (137.9 -

Ice machine is not level. Level the ice machine.

Allow ice to thaw and release from evaporator,

then restart.

Allow ice to thaw and release from evaporator,

then restart.

Air temperature must be at least 40°F (4°C).

Replace water regulating valve.

Wait for freeze lock-in to expire.

next page.

the quality of the incoming water and make

appropriate filter recommendations.

Repair the water softener.

supply.

551.5 kPa).

Continued on next page...

Part Number 000012545 Rev 02 11/16 29

Page 30

Troubleshooting Section 5

Problem Possible Cause To Correct

Low ice capacity. The condenser is dirty. Clean the condenser.

High air temperature around ice machine (aircooled models).

Inadequate clearance around the ice machine. Provide adequate clearance.

Objects stacked around ice machine, blocking

airflow to condenser (air-cooled models).

Hot incoming water. Connect the ice machine to a cold water

Incorrect incoming water pressure. Water

pressure is too low or water filter is restricted.

Air temperature must not exceed 110°F (43°C).

Remove items blocking airflow.

supply.

Water pressure must be 20-80 psi (137.9 -

551.5 kPa). Refer to Section 2 for plumbing

requirements. Replace water filter.

Safety Limit Feature

In addition to the standard safety controls, such as the high

pressure cutout, your ice machine features built-in safety

limits which will stop the ice machine if conditions arise

which could cause a major component failure.

Refer to Safety Limits Section 3 for more information on

safety limits.

Before calling for service, re-start the ice machine using the

following procedure:

1. Move the toggle switch to OFF, then the ICE position,

A. If the safety limit feature has stopped the ice

machine, it will restart after a short delay. Proceed

to step 2.

B. If the ice machine does not restart, see “Ice

machine does not operate” on the previous page.

2. Allow the ice machine to run to determine if the

condition repeats.

A. If the ice machine stops again, the condition has

repeated. Call for service.

B. If the ice machine continues to run, the condition

has corrected itself. Allow the ice machine to

continue running.

30 Part Number 000012545 Rev 02 11/16

Page 31

Page 32

Page 33

Avis de sécurité

Avis de sécurité

Lire ces précautions pour éviter des blessures

corporelles:

• Lire attentivement ce manuel avant de faire

fonctionner, d’installer ou de faire un entretien sur

l’équipement. Ne pas suivre les instructions dans

ce manuel peut entraîner des dégâts matériels, des

blessures corporelles, voire même la mort.

• Les réglages de routine et les procédures d’entretien

indiqués dans ce manuel ne sont pas couverts par la

garantie.

• L’installation, le soin et l’entretien sont essentiels pour

un rendement maximal et un fonctionnement sans

problème de votre appareil.

Visitez notre site Web www.manitowocice.com pour

des mises à jour manuelles, des traductions, ou bien

les coordonnées des agents techniques de votre

région.

• Cet appareil est soumis à des tensions électriques et

des charges de fluide frigorigène élevées. L’installation

et les réparations doivent être effectuées par des

techniciens adéquatement formés et conscients des

dangers propres aux tensions électriques élevées et

au liquide frigorigène sous pression. Le technicien

doit également être certifié dans le secteur de la

manipulation appropriée de fluide frigorigène et dans

les procédures d’entretien. Toutes les procédures de

verrouillage et d’étiquetage doivent être suivies lors

d’une intervention sur cet équipement.

• Cet équipement est destiné uniquement à un usage

intérieur. Ne pas installer ou faire fonctionner cet

équipement à l’extérieur.

Avertissement

n

Suivez ces exigences électriques pendant l’installation

de cet équipement.

• Tout le câblage sur site doit être conforme à tous les

codes applicables de l’autorité ayant juridiction. Il

est de la responsabilité de l’utilisateur de fournir les

moyens de déconnexion pour satisfaire les codes

locaux. Se reporter à la plaque signalétique pour la

tension appropriée.

• Cet appareil doit être mis à terre.

• Cet équipement doit être positionné de sorte que la

prise de courant soit accessible à moins qu’un autre

moyen de déconnexion de l’alimentation électrique

(par ex. disjoncteur ou interrupteur général) soit

fourni.

• Vérifier toutes les connexions de câblage, y compris

les bornes d’usine, avant de faire fonctionner. Les

connexions peuvent se desserrer durant l’expédition

et l’installation.

Page 34

Avertissement

n

Suivre ces précautions pour éviter des blessures

corporelles durant l’installation de cet équipement:

• L’installation doit être conforme aux codes d’incendie

et de santé applicables selon l’autorité ayant

juridiction.

• Afin d’éviter toute instabilité, la zone de l’installation

doit être capable de supporter le poids combiné de

l’équipement et du produit. De plus l’équipement

doit être mis à niveau d’un côté à l’autre et d’en avant

à en arrière.

• Les machines à glaçons requièrent un déflecteur

lorsqu’elles sont installées sur un bac de stockage

de glaçons. Avant toute utilisation d’un système de

stockage de glaçons autre que Manitowoc avec cette

machine à glaçons, contacter le fabricant du bac pour

s’assurer de la compatibilité de leur déflecteur de

glaçons.

• Retirer tous les panneaux amovibles avant de

soulever et d’installer; utiliser l’équipement de

sécurité approprié pendant l’installation et l’entretien.

Pour déplacer ou soulever cet appareil et l’empêcher

de basculer ou de causer des blessures, il est

nécessaire de faire appel à au moins deux personnes.

• Ne pas endommager le circuit de réfrigération lors

de l’installation, de l’entretien ou de la réparation de

l’appareil.

• Connecter à une alimentation en eau potable

uniquement.

• Cet équipement contient une charge de fluide

frigorigène. L’installation des conduites doit être

effectuée par un technicien adéquatement formé et

certifié dans le secteur de la réfrigération par l’EPA,

qui est conscient des dangers que comportent les

équipements chargés de fluide frigorigène.

• Les pieds ou les roulettes doivent être installés et les

pieds/roulettes doivent être vissés complètement.

Lorsque des roulettes sont installées, la masse de

cet appareil est suffisante pour que celui-ci puisse

se déplacer de façon incontrôlée sur une surface

inclinée. Ces appareils doivent être attachés/fixés

en conformité avec tous les codes applicables. Les

roulettes orientables doivent être montées à l’avant

et les roulettes fixes doivent être montées à l’arrière.

Verrouiller les roulettes avant une fois l’installation

terminée.

Avertissement

n

Suivre ces précautions pour éviter des blessures

corporelles durant l’installation ou l’entretien de cet

équipement:

• Lire attentivement ce manuel avant de faire

fonctionner, d’installer ou de faire un entretien sur

l’équipement. Ne pas suivre les instructions dans

ce manuel peut entraîner des dégâts matériels, des

blessures corporelles, voire même la mort.

• Risque d’écrasement ou de pincement. Garder les

mains éloignées des composants en mouvement.

Les composants peuvent bouger sans avertissement

à moins que le courant soit déconnecté et que tout

potentiel d’énergie soit éliminé.

• L’humidité qui s’accumule sur le plancher peut créer

une surface glissante. Nettoyer immédiatement toute

eau sur le plancher pour éviter un risque de glisser.

• Les objets placés ou échappés dans le bac peuvent

affecter la santé et la sécurité des personnes. Repérer

et enlever tout objet immédiatement.

• Ne jamais utiliser des objets ou outils tranchants

pour enlever la glace ou le givre. Ne pas utiliser

des dispositifs mécaniques ou autres moyens pour

accélérer le processus de dégivrage.

• Lors de l’utilisation de liquides de nettoyage ou

tout autre produit chimique, porter des gants en

caoutchouc et des lunettes de protection (et/ou écran

facial).

DANGER

Ne pas faire fonctionner un appareil ayant fait l’objet

d’une mauvaise utilisation, ayant été abusé, négligé,

endommagé ou altéré/modifié par rapport aux

caractéristiques d’origine de fabrication. Cet appareil

n’a pas été conçu pour être utilisé par des personnes

(y compris des enfants) aux capacités physiques,

sensorielles ou mentales réduites ou n’ayant pas une

expérience ou des connaissances suffisantes, sauf si

elles sont supervisées par une personne responsable

de leur sécurité. Ne pas laisser les enfants jouer avec,

nettoyer ou entretenir cet appareil sans une surveillance

adéquate.

Warning

n

Ça produire c'est hermétiquement sceller et renfermer