Page 1

Indigo NXT Ice Machines

Installation, Operation and Maintenance Manual

Original Document

Read this instruction before operating this equipment.

Part Number: 000014141 Rev 03 2/18

Caution

,

Page 2

Page 3

Safety Notices

Definitions

Safety Notices

Read these precautions to prevent

personal injury:

• Read this manual thoroughly before

operating, installing or performing

maintenance on the equipment. Failure

to follow instructions in this manual

can cause property damage, injury or

death.

• Routine adjustments and maintenance

procedures outlined in this manual are

not covered by the warranty.

• Proper installation, care and

maintenance are essential for

maximum performance and troublefree operation of your equipment. Visit

our website www.manitowocice.com

for manual updates, translations, or

contact information for service agents

in your area.

DANGER

Indicates a hazardous situation that, if not

avoided, will result in death or serious

injury. This applies to the most extreme

situations.

Warning

n

Indicates a hazardous situation that, if not

avoided, could result in death or serious

injury.

Caution

,

Indicates a hazardous situation that, if not

avoided, could result in minor or moderate

injury.

Notice

Indicates information considered

important, but not hazard-related (e.g.

messages relating to property damage).

• This equipment contains high

voltage electricity and refrigerant

charge. Installation and repairs are

to be performed by properly trained

technicians aware of the dangers of

dealing with high voltage electricity

and refrigerant under pressure. The

technician must also be certified

in proper refrigerant handling and

servicing procedures. All lockout and

tag out procedures must be followed

when working on this equipment.

• This equipment is intended for indoor

use only. Do not install or operate this

equipment in outdoor areas.

NOTE: Indicates useful, extra information

about the procedure you are performing.

Page 4

Warning

n

Follow these precautions to prevent personal injury during installation of this

equipment:

• Installation must comply with all

applicable equipment fire and health

codes with the authority having

jurisdiction.

• To avoid instability the installation area

must be capable of supporting the

combined weight of the equipment and

product. Additionally the equipment

must be level side to side and front to

back.

• Ice machines require a deflector when

installed on an ice storage bin. Prior to

using a non-OEM ice storage system

with this ice machine, contact the

bin manufacturer to assure their ice

deflector is compatible.

• Prior to installing a non-OEM ice storage

system with this ice machine, follow the

manufacturers installation procedures

and verify the location and installation

meets the local/national mechanical

codes and stability requirements.

• Remove all removable panels before

lifting and installing and use appropriate

safety equipment during installation

and servicing. Two or more people are

required to lift or move this appliance to

prevent tipping and/or injury.

• Legs or casters must be installed and

the legs/casters must be screwed in

completely. When casters are installed

the mass of this unit will allow it to move

uncontrolled on an inclined surface.

These units must be tethered/secured

to comply with all applicable codes.

Swivel casters must be mounted on the

front and rigid casters must be mounted

on the rear. Lock the front casters after

installation is complete.

• Connect to a potable water supply only.

• Do not damage the refrigeration circuit

when installing, maintaining or servicing

the unit.

• This equipment contains refrigerant

charge. Installation of the line sets must

be performed by a properly trained and

EPA certified refrigeration technician

aware of the dangers of dealing with

refrigerant charged equipment.

• Some 50 Hz models may contain

up to 150 grams of R290 (propane)

refrigerant. R290 (propane) is flammable

in concentrations of air between

approximately 2.1% and 9.5% by volume

(LEL lower explosion limit and UEL upper

explosion limit). An ignition source

at a temperature higher than 470°C

is needed for a combustion to occur.

Refer to nameplate to identify the type

of refrigerant in your equipment. Only

trained and qualified personnel aware of

the dangers are allowed to work on the

equipment.

Page 5

Warning

n

Follow these electrical requirements

during installation of this equipment.

• All field wiring must conform to all

applicable codes of the authority

having jurisdiction. It is the

responsibility of the end user to

provide the disconnect means to satisfy

local codes. Refer to rating plate for

proper voltage.

Warning

n

Follow these precautions to prevent

personal injury while operating or

maintaining this equipment:

• Read this manual thoroughly before

operating, installing or performing

maintenance on the equipment. Failure

to follow instructions in this manual

can cause property damage, injury or

death.

• This appliance must be grounded.

• This equipment must be positioned so

that the plug is accessible unless other

means for disconnection from the

power supply (e.g., circuit breaker or

disconnect switch) is provided.

• Check all wiring connections, including

factory terminals, before operation.

Connections can become loose during

shipment and installation.

DANGER

Do not operate equipment that has

been misused, abused, neglected,

damaged, or altered/modified from that

of original manufactured specifications.

This appliance is not intended for use by

persons (including children) with reduced

physical, sensory or mental capabilities,

or lack of experience and knowledge,

unless they have been given supervision

concerning use of the appliance by a

person responsible for their safety. Do

not allow children to play with, clean or

maintain this appliance without proper

supervision.

• Crush/Pinch Hazard. Keep hands clear

of moving components. Components

can move without warning unless

power is disconnected and all potential

energy is removed.

• Moisture collecting on the floor will

create a slippery surface. Clean up

any water on the floor immediately to

prevent a slip hazard.

• Objects placed or dropped in the bin

can affect human health and safety.

Locate and remove any objects

immediately.

• Never use sharp objects or tools

to remove ice or frost. Do not use

mechanical devices or other means to

accelerate the defrosting process.

• When using cleaning fluids or

chemicals, rubber gloves and eye

protection (and/or face shield) must be

worn.

Page 6

DANGER

Follow these precautions to prevent personal injury during use and maintenance of this

equipment:

• It is the responsibility of the equipment

owner to perform a Personal Protective

Equipment Hazard Assessment to ensure

adequate protection during maintenance

procedures.

• Do Not Store Or Use Gasoline Or Other

Flammable Vapors Or Liquids In The

Vicinity Of This Or Any Other Appliance.

Never use flammable oil soaked cloths

or combustible cleaning solutions for

cleaning.

• All covers and access panels must be

in place and properly secured when

operating this equipment.

• Risk of fire/shock. All minimum

clearances must be maintained. Do not

obstruct vents or openings.

• Failure to disconnect power at the main

power supply disconnect could result

in serious injury or death. The power

switch DOES NOT disconnect all incoming

power.

• All utility connections and fixtures must

be maintained in accordance with the

authority having jurisdiction.

• Turn off and lockout all utilities (gas,

electric, water) according to approved

practices during maintenance or

servicing.

• Units with two power cords must be

plugged into individual branch circuits.

During movement, cleaning or repair it is

necessary to unplug both power cords.

• Never use a high-pressure water jet for

cleaning on the interior or exterior of

this unit. Do not use power cleaning

equipment, steel wool, scrapers or wire

brushes on stainless steel or painted

surfaces.

• Two or more people are required to

move this equipment to prevent tipping.

• Locking the front casters after

moving is the owner’s and operator’s

responsibility. When casters are installed,

the mass of this unit will allow it to move

uncontrolled on an inclined surface.

These units must be tethered/secured to

comply with all applicable codes.

• The on-site supervisor is responsible for

ensuring that operators are made aware

of the inherent dangers of operating this

equipment.

• Do not operate any appliance with a

damaged cord or plug. All repairs must

be performed by a qualified service

company.

Page 7

Safety Notices

Safety Notices ...........................................................................3

Section 1

General Information

Model Numbers ........................................................................9

Accessories ................................................................................ 9

How To Read A Model Number ................................................ 10

Section 2

Installation

Installation ..............................................................................11

Location Requirements ............................................................ 11

Installation Requirements ........................................................11

Ice Machine Heat of Rejection .................................................12

Air Baffle .................................................................................14

Bin Installation Requirements ..................................................14

Bin Installation ........................................................................15

Dispenser Installation .............................................................. 15

Electrical Requirements ...........................................................16

Maximum Breaker Size & Minimum Circuit Amperage Chart .... 17

Water Supply and Drain Line Sizing/Connections ..................... 20

Cooling Tower Applications

(Water-Cooled Models) ...........................................................21

Drain Connections ...................................................................21

Remote Condenser and Condensing Unit Refrigeration System

Installation ..............................................................................22

Starting the Ice Machine .......................................................... 29

Remote Ice Machine Usage with Non-Manitowoc Multi-Circuit

Condensers ..............................................................................29

Table of Contents

Calculating Installation Distances ......................................... 23

Remote Condenser Models .................................................. 24

QuietQube Models ............................................................... 25

Remove Ice Thickness Probe Shipping Brackets. .................. 29

Minimum/Maximum Slab Weight ........................................ 29

Part Number: 000014141 Rev 03 2/18 7

Page 8

Section 3

Operation

Section 4

Maintenance

Table of Contents (continued)

Touch Screen Features ............................................................. 31

Home Screen Icon Descriptions ............................................ 32

Setup Wizard ........................................................................... 33

Menu Screen Navigation .......................................................... 34

Ice Making Sequence of Operation ..........................................35

Control Board Timers ............................................................... 35

Minimum/Maximum Slab Weight ............................................ 37

Ice Thickness Check .................................................................37

Cleaning and Sanitizing ............................................................ 39

Cleaning/Sanitizing Procedure ................................................. 40

Cleaning Procedure ............................................................... 40

Sanitizing Procedure ............................................................. 42

Parts Removal for Cleaning/Sanitizing ..................................... 43

Preventative Maintenance Cleaning Procedure ........................ 44

Cleaning the Air Filter and Condenser ...................................... 45

Removal from Service/Winterization ....................................... 45

Section 5

Troubleshooting

Before Calling for Service Checklist .......................................... 47

Service Faults ..........................................................................49

8 Part Number: 000014141 Rev 03 2/18

Page 9

Section 1

General Information

Model Numbers

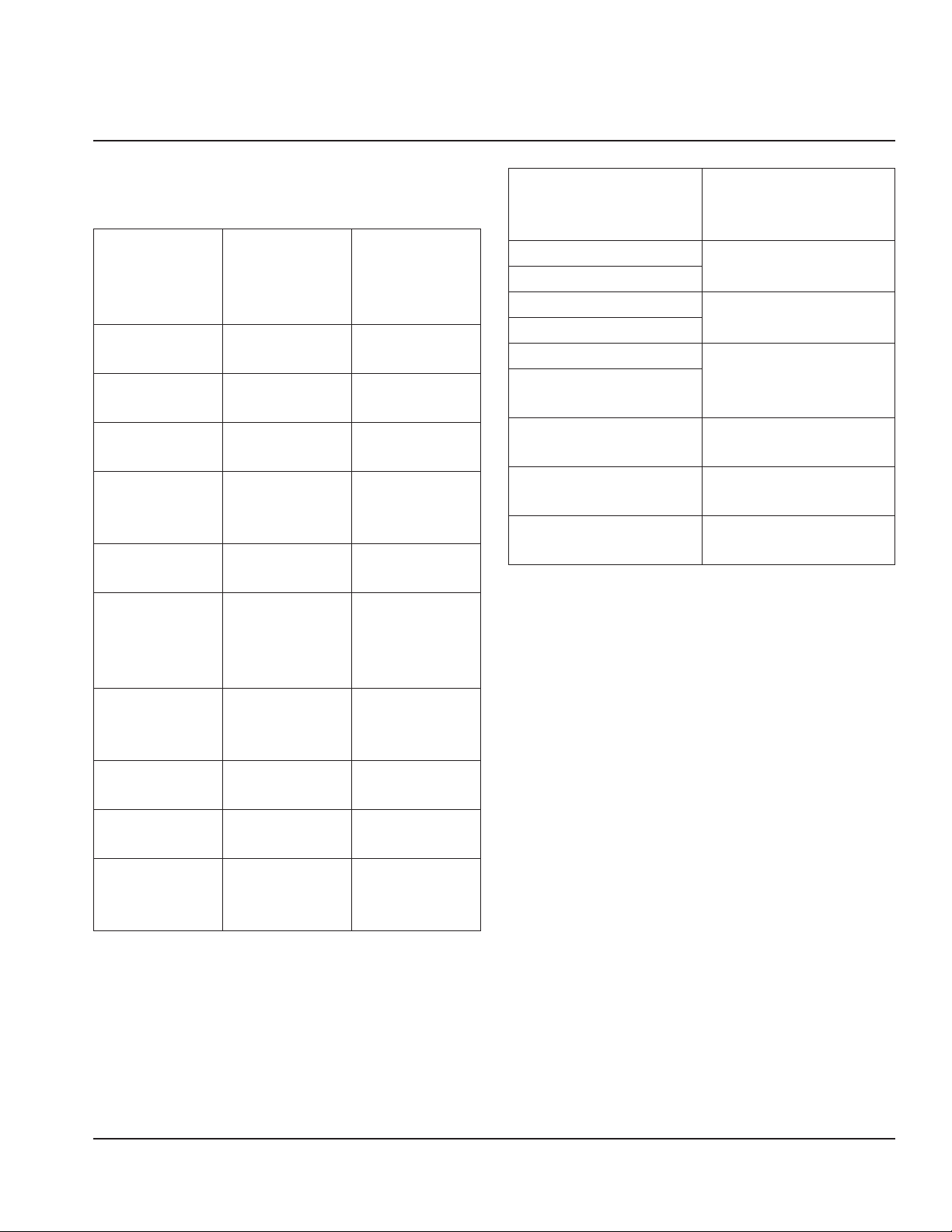

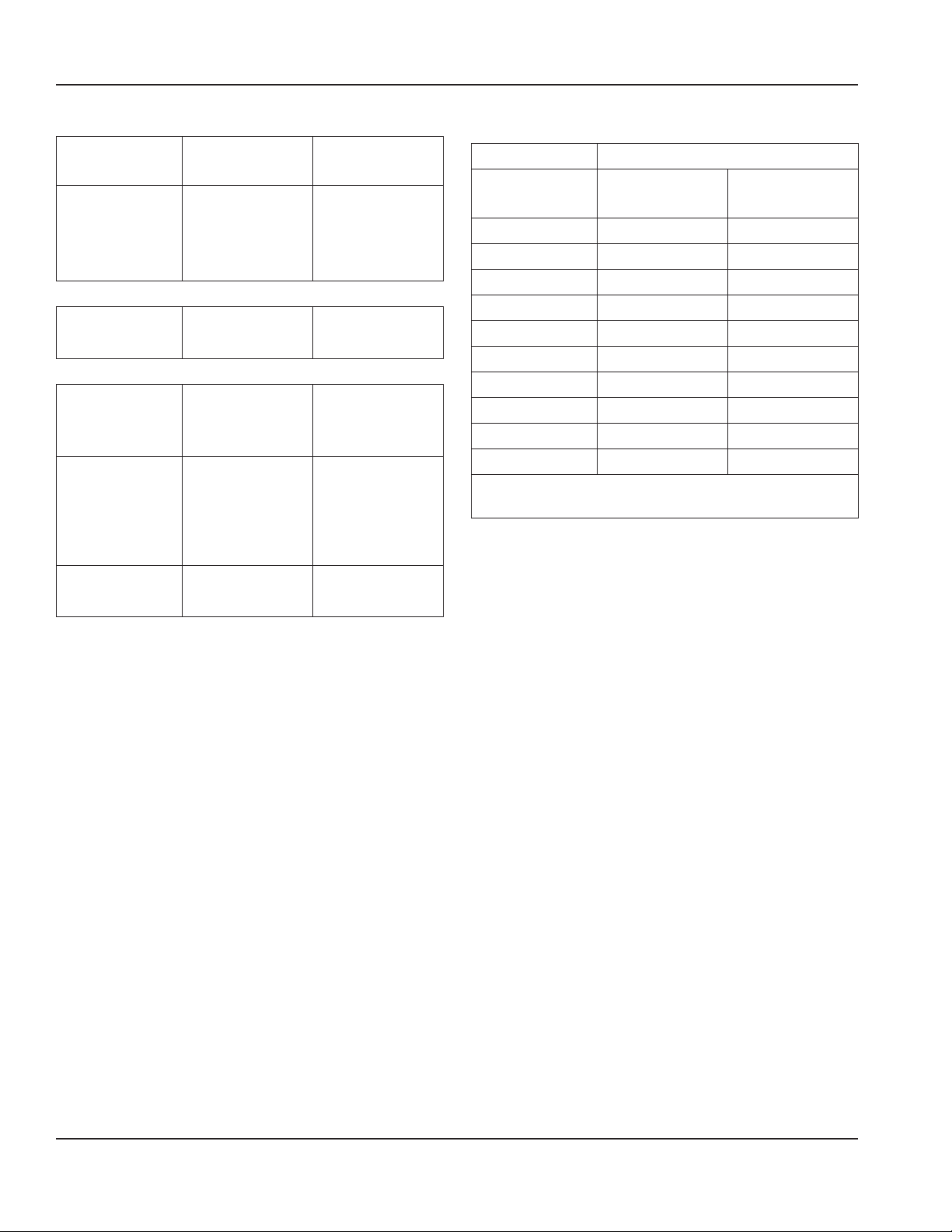

This manual covers the following models:

Self-

Contained

Air-Cooled

IDF0300A

IYF0300A

IDT0420A

IYT0420A

IDT0450A

IYT0450A

IDT0500A

IYT0500A

IRT0500A

IDF0600A

IYF0600A

IDT0620A

IYT0620A

IRT0620A

IDP0620A

IDF0900A

IYF0900A

IRF0900A

IDT1200A

IYT1200A

IDT1500A

IYT1500A

IDT1900A

IYT1900A

IRT1900A

Self-

Contained

WaterCooled

IDF0300W

IYF0300W

IDT0420W

IYT0420W

IDT0450W

IYT0450W

IDT0500W

IYT0500W

IRT0500W

IDF0600W

IYF0600W

IDT0620W

IYT0620W

----

----

IDF0900W

IYF0900W

----

IDT1200W

IYT1200W

IDT1500W

IYT1500W

IDT1900W

IYT1900W

----

Remote Air-

Cooled

----

----

----

----

----

----

IDT0500N

IYT0500N

----

IDF0600N

IYF0600N

----

----

----

----

IDF0900N

IYF0900N

----

IDT1200N

IYT1200N

IDT1500N

IYT1500N

IDT1900N

IYT1900N

IRT1900N

QuietQube

Indoor Head Section

IYF0600C

IBF0620C

IBF0820C

IYF0900C

IBT1020C

IDT1200C

IYT1200C

IDF1400C

IYF1400C

IDF1800C

IYF1800C

IDF2100C

IYF2100C

QuietQube

Air-Cooled

Condensing Unit

CVDF0600

CVDF0900

CVDT1200

CVDF1400

CVDF1800

CVDF2100

Accessories

Ice Deflector

An ice deflector is required when the

ice machine is installed on a bin. An ice

deflector is not required when the ice

machine is installed on a dispenser.

Bin Ice Level Accessory Kit

The bin level accessory connects to

the circuit board and allows bin level

adjustment of Indigo ice machines on B

model bins. Installation instructions are

included with the accessory. A bin level

sensor is required to set a lower level of ice

in the bin.

Part Number: 000014141 Rev 03 2/18 9

Page 10

General Information Section 1

Top Air Discharge Kit

The top air discharge kit can be used on

select ice machine models. This kit directs

warm exhaust air upward rather than out

the side panels.

AuCS® Automatic Cleaning System

This accessory reduces equipment cleaning

expense. The AuCS® accessory monitors

ice making cycles and initiates cleaning

procedures automatically.

How To Read A Model Number

I Y T 1500 N — 261 X

Ice Machine Model

I - Indigo Model

IB - Ice Beverage

Ice Cube Size

R - Regular

D - Dice

Y - Half-Dice

Not Used On IB Models

Refrigerant

P - R290

F - R404A

T - R410

LuminIce® II

The LuminIce® growth inhibitor recirculates

the air in the ice machine foodzone over

a UV bulb. This process will inhibit the

growth of common micro-organisms on all

exposed foodzone surfaces.

X - Luminice

HP - High Pressure Water

Regulating Valve

P - Correctional Model

M - Marine Model

V - Space Saver

Q - Coated Condenser

Blank - General Usage

Voltage

161 - 115/60/1

261 - 208-230/60/1

251 - 230/50/1

263 - 208-230/60/3

463 - 460/60/3

Nominal Production

Condenser Type

A - Self-Contained Air-Cooled

W - Self-Contained Water-Cooled

N - Remote Air-Cooled

C - CVD Air-Cooled

NOTE: These products are hermetically sealed and contain fluorinated greenhouse gas

R404A or R410A.

10 Part Number: 000014141 Rev 03 2/18

Page 11

Section 2

Installation

Installation

Location Requirements

The location selected for the ice machine

head section must meet the following

criteria. If any of these criteria are not met,

select another location.

• The location must be indoors and

must be free of airborne and other

contaminants.

• The location must not be near heatgenerating equipment or in direct

sunlight.

• The location must allow enough

clearance for water, drain, and electrical

connections in the rear of the ice

machine.

• The location must not obstruct airflow

through or around the ice machine.

Installation Requirements

• The ice machine and bin must be level.

• Vent the ice machine and bin drains

separately.

• Bin drain termination must have an air

gap.

• The ice machine and bin must be

sanitized after installation.

• The drain line must contain a union or

other suitable means of disconnection at

the ice machine.

QuietQube Models Only

• The ice machine top panel can be

trimmed with an aviator snips to allow

the line set, water line and electrical

connections to exit the top. Only cut out

what is needed, the back panel must

support the top panel.

• The water inlet and electrical connection

must contain a service loop to allow

future access.

Part Number: 000014141 Rev 03 2/18 11

Page 12

Installation Section 2

Minimum/Maximum Temperatures

Model

Minimum Air

Temperature

Maximum Air

Temperature

All Ice

Machine

Head

35°F

2°C

110°F

43°C

Sections

All Remote

Condensers

-20°F

-29°C

120°F

49°C

QuietQube

Condensing

Units

CVDF0600

CVDF0900

CVDT1200

-20°F

-29°C

120°F

49°C

CVDF2100

CVDF1400

CVDF1800

-20°F

-29°C

130°F

54°C

Ice Machine Heat of Rejection

Ice Machine Heat of Rejection

Series

IF0300 4600 5450

IT0420 *3800 *6000

IT0450 *5400 *6300

IT0500 *6100 *6900

IF0600 9000 13900

IT0620 *9000 *13900

IF0900 13000 16000

IT1200 *20700 *24500

IT1500 23000 27000

IT1900 26100 30500

* Data marked with an asterisk is preliminary

and subject to change.

Use this information when:

• Sizing air conditioning equipment where

self-contained air-cooled ice machines

are installed.

Air

Conditioning

Peak

• Determining the load on a cooling tower.

Use the peak figure for sizing the load.

12 Part Number: 000014141 Rev 03 2/18

Page 13

Section 2 Installation

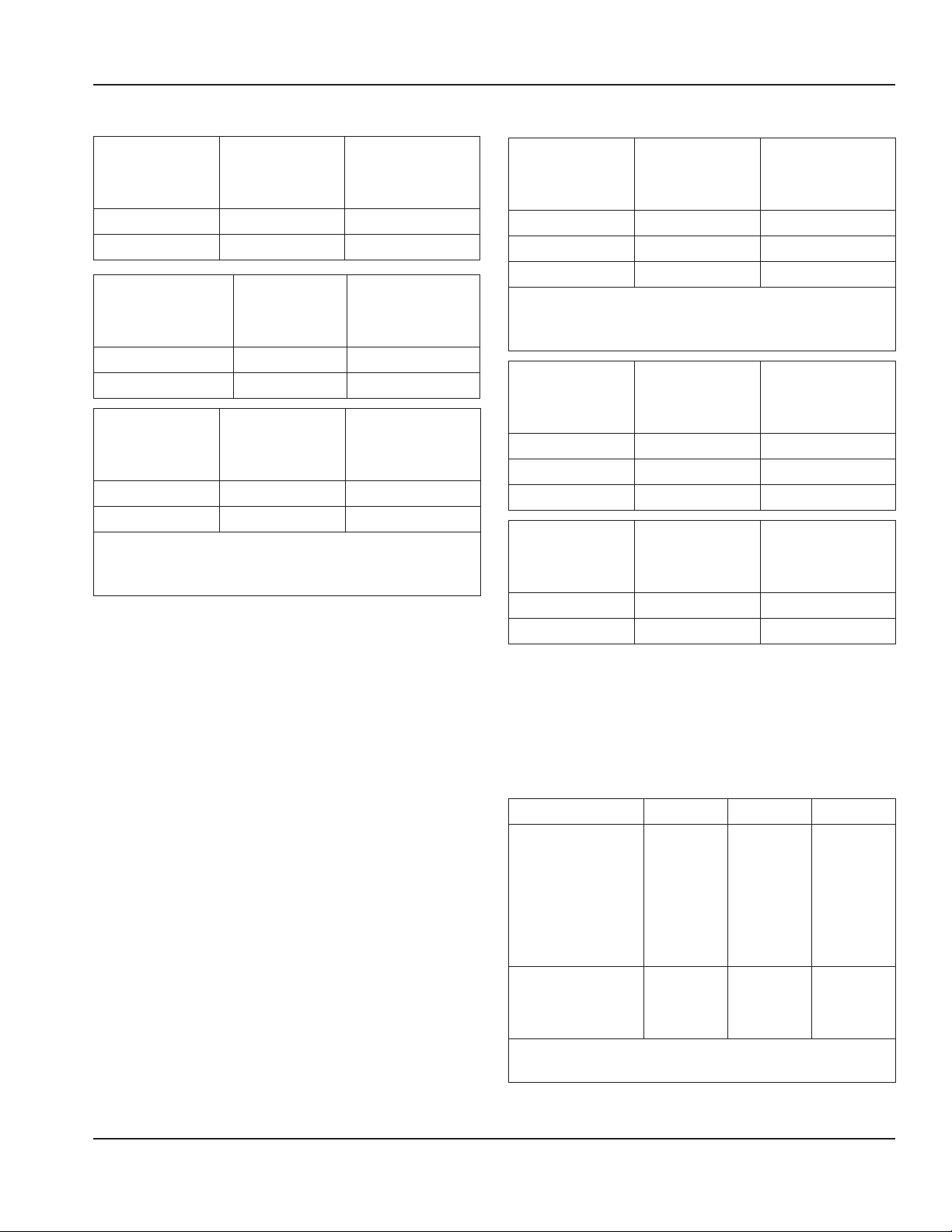

Clearance Requirements

I0300

Self-

Contained

Air-Cooled

Self-

Contained

Water-Cooled

Top/Sides *16" (40 cm) *8" (20 cm)

Back *5" (13 cm) *5" (13 cm)

IT0420 IT0450

IT0500 IT0620

Self-

Contained

Air-Cooled

Water-Cooled

or Remote

Condenser

Top/Sides 12" (31 cm) 8" (20 cm)

Back 5" (13 cm) 5" (13 cm)

IF0900

Self-

Contained

Air-Cooled

Self-

Contained

Water-Cooled

Top/Sides *8" (20 cm) *8" (20 cm)

Back *5" (13 cm) *5" (13 cm)

* Data marked with an asterisk is preliminary

and subject to change - Model/serial plate

information overrides all data listed in this chart.

IT1200

Self-

Contained

Air-Cooled

Water-Cooled

or Remote

Condenser

Top *8" (20 cm) *8" (20 cm)

Sides *12" (31 cm) *8" (20 cm)

Back *5" (13 cm) *5" (13 cm)

* Data marked with an asterisk is preliminary

and subject to change - Model/serial plate

information overrides all data listed in this chart.

IT1500

Self-

Contained

Air-Cooled

Water-Cooled

or Remote

Condenser

Top 12" (31 cm) 8" (20 cm)

Sides 8" (20 cm) 8" (20 cm)

Back 12" (31 cm) 5" (13 cm)

IT1900

Self-

Contained

Air-Cooled

Water-Cooled

or Remote

Condenser

Top/Sides 24" (61 cm) 8" (20 cm)

Back 12" (31 cm) 5" (13 cm)

NOTE: Top air discharge kits require the

same clearance requirements as the

comparable self-contained air-cooled

model.

QuietQube Model Clearance Requirements

Model Top Back Sides

IF0600C

IF0900C

IT1200C

IF1400C

5"

(13 cm)

5"

(13 cm)

5"

(13 cm)

IF1800C

IF2100C

IBF0620C

IBF0820C

IBF1020C

** 61 cm (24") is recommended on top/sides for

servicing

2"**

(5 cm)

5"

(13 cm)

8" **

(20 cm)

Part Number: 000014141 Rev 03 2/18 13

Page 14

Installation Section 2

Condensing Unit Clearance Requirements

Model

CVDF0600

CVDF0900

CVDT1200

CVDF1400

CVDF1800

CVDF2100

* 61 cm (24") is recommended on top/sides for

servicing

Top/

Sides

0"

(0 cm*)

Back Front

48"

(122 cm)

(122 cm)

48"

Notice

The ice machine must be protected if it

will be subjected to temperatures below

32°F (0°C). Failure caused by exposure to

freezing temperatures is not covered by

the warranty.

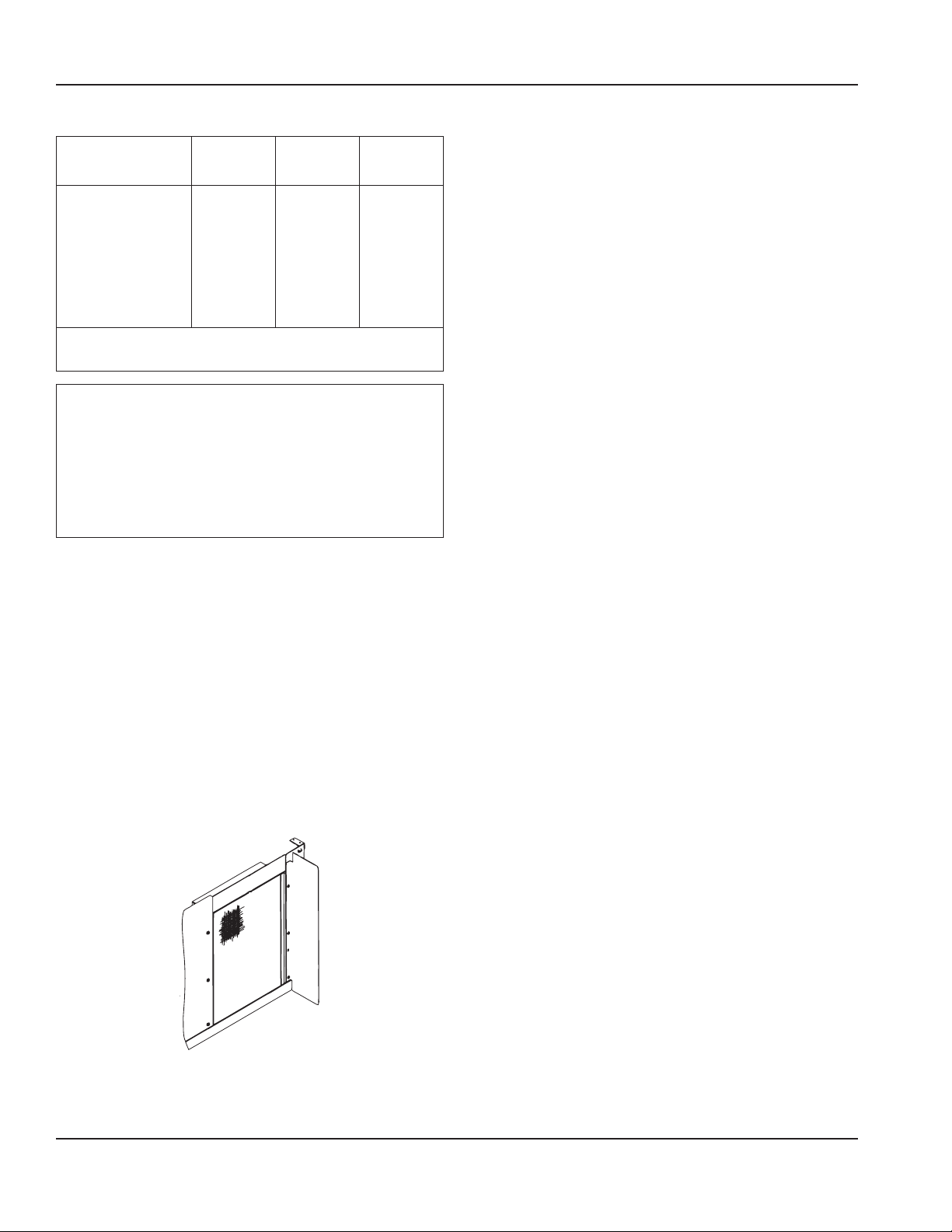

Air Baffle

Bin Installation Requirements

• The installation area must be capable of

supporting the combined weight of the

equipment and product.

• All ice machines installed on a bin

require an ice deflector.

• Manitowoc bins have a deflector

installed and require no modifications

when used with a forward-facing

evaporator.

• Ice machines with multiple evaporators

require a deflector kit.

• Align sides and back of ice machine with

sides and back of bin when placing ice

machine on bin.

• Optional sales kits are available to adapt

various sized or multiple ice machines on

large bins.

Self-Contained Air-cooled Only

The air-cooled baffle prevents condenser

air from recirculating. To install:

1. Loosen the back panel screws next to

the condenser.

2. Align the keyhole slots in the air baffle

with the screw holes and slide the

baffle down to lock in place.

14 Part Number: 000014141 Rev 03 2/18

Page 15

Section 2 Installation

Bin Installation

NOTE: When using casters, the units must

be tethered or secured to comply with all

applicable codes. Swivel casters must be

mounted on the front and rigid casters

must be mounted on the rear. Lock the

front casters after installation is complete.

1. Remove threaded plug from drain

fitting.

2. Screw the leveling legs onto the

bottom of the bin.

3. Screw the foot of each leg in as far as

possible.

4. Move the bin into its final position.

5. Level the bin to assure that the bin

door closes and seals properly. Use a

level on top of the bin. Turn the base

of each foot as necessary to level the

bin.

Dispenser Installation

Observe following recommendations unless

required by the dispenser manufacturer.

• An adapter is not required for ice

machines that match the dispenser size.

• A deflector is not required.

• Ice level management is recommended

to prevent water leakage or movement

of ice machine during agitation.

• Align sides and back of ice machine with

sides and back of dispenser when placing

ice machine.

• Follow ice machine installation

procedures in this manual and any

additional installation requirements

specified by the dispenser manufacturer.

6. Inspect bin gasket prior to ice machine

installation. (Manitowoc bins come

with a closed cell foam gasket installed

along the top surface of the bin.)

7. Remove all panels from ice machine

before lifting and installing on bin.

Remove both front panels, top cover,

left and right side panels.

Part Number: 000014141 Rev 03 2/18 15

Page 16

Installation Section 2

Electrical Requirements

All electrical work, including wire routing

and grounding, must conform to local, state

and national electrical codes. The following

precautions must be observed:

• The ice machine must be grounded.

• A separate fuse/circuit breaker

(dedicated circuit) must be provided

for each ice machine head section,

condenser or condensing unit.

• A qualified electrician must determine

proper wire size dependent upon

location, materials used and length of

run (minimum circuit ampacity can be

used to help select the wire size).

Warning

n

All wiring must conform to local, state and

national codes.

Minimum Circuit Ampacity

The minimum circuit ampacity is used to

help select the wire size of the electrical

supply. (Minimum circuit ampacity is not

the ice machine’s running amp load.)

The wire size (or gauge) also depends on

location, materials used, length of run, etc.,

so it must be determined by a qualified

electrician.

Ground Fault Circuit Interrupter

We do not recommend the use of a GFCI/

GFI circuit protection with our equipment.

If a GFCI/GFI is required by code, use a

GFCI/GFI breaker rather than an outlet,

which is more prone to intermittent

nuisance trips than panel circuit breakers.

Voltage

The maximum allowable voltage variation

is +10% / -5% of the rated voltage at ice

machine start-up (when the electrical load

is highest).

Warning

n

The ice machine must be grounded

in accordance with national and local

electrical codes.

Fuse/Circuit Breaker

A separate electrical disconnect, which

disconnects all poles and has 3 mm (1/8")

contact separation, must be provided

for fixed wiring. Circuit breakers must be

H.A.C.R. rated in USA.

16 Part Number: 000014141 Rev 03 2/18

Page 17

Section 2 Installation

Maximum Breaker Size & Minimum Circuit Amperage Chart

NOTE: Due to continuous product improvements, this information is for reference only.

Please refer to the ice machine data plate to verify electrical data. Data plate information

overrides information listed on this page.

Air-Cooled Water-Cooled Remote Condenser

Ice

Machine

IF0300

IT0420

IT0450

IT0500

IF0600

Voltage/

Phase/Cycle

115/1/60 15 *10.8 15 *10.0 - - - - - 230/1/50 15 *6.1 15 *5.6 - - - - - 230/1/60 15 *6.1 15 *5.7 - - - - - 115/1/60 15 11.3 15 10.6 - - - - - 208-230/

1/60

230/1/50 15 5.7 - - - - - - - - - - - 115/1/60 20 11.9 20 11.2 - - - - - 208-230/

1/60

230/1/50 15 5.6 15 5.3 - - - - - 115/1/60 15 11.5 15 10.8 20 13.7

208-230/

1/60

230/1/50 15 5.6 - - - - - - - - - - - 208-230/

1/60

230/1/50 15 *6.7 15 *6.1 15 *7.1

115/1/60

Maximum

Fuse/

Circuit

Breaker

15 5.5 15 5.2 - - - - - -

15 5.6 15 5.3 - - - - - -

15 5.1 15 4.8 - - - - - -

15 *11.1 15 *10.7 15 *11.7

20 12.2 20 11.6 - - - - - -

Minimum

Circuit

Amps

Maximum

Fuse/

Circuit

Breaker

Minimum

Circuit

Amps

Maximum

Fuse/

Circuit

Breaker

Minimum

Circuit

Amps

IT0620

IF0900

Part Number: 000014141 Rev 03 2/18 17

208-230/

1/60

230/1/50 15 5.6 15 5.4 - - - - - 208-230/

1/60

208-230/

3/60

230/1/50 20 *12.2 20 *11.2 15 *12.2

15 5.9 15 5.6 - - - - - -

20 *12.2 20 *11.2 20 *12.2

15 *9.7 15 *8.7 15 *9.7

Page 18

Installation Section 2

Air-Cooled Water-Cooled Remote Condenser

Ice

Machine

IT1200

Voltage/

Phase/Cycle

208-230/

1/60

208-230/

3/60

Maximum

Fuse/

Circuit

Breaker

Minimum

Circuit

Amps

20 14.2 20 13.4 15 11.0

15 8.6 15 7.9 15 9.2

Maximum

Fuse/

Circuit

Breaker

Minimum

Circuit

Amps

Maximum

Fuse/

Circuit

Breaker

Minimum

Circuit

Amps

230/1/50 20 14.0 20 13.3 15 11.1

IT1500

208-230/

1/60

208-230/

3/60

25 15.4 25 14.0 25 14.0

20 12.8 20 11.3 20 11.3

230/1/50 25 14.9 25 14.2 25 15.2

IT1900

380-460/

3/50-60

208-230/

1/60

208-230/

3/60

- - - - - - 15 *6.4 - - - - - -

30 17.9 25 16.5 25 17.0

20 14.2 20 12.8 20 13.0

230/1/50 25 15.8 25 15.0 25 15.3

380-460/

3/50-60

* Data marked with an asterisk is preliminary and subject to change - Model/serial plate information

overrides all data listed in this chart.

- - - - - - 15 *6.5 - - - - - -

18 Part Number: 000014141 Rev 03 2/18

Page 19

Section 2 Installation

QuietQube Head Sections

Ice Machine

Ice Beverage

Models

All Non IB

Voltage/Phase/

Cycle

115/1/60 15 amp - - - 1.2

230/1/50 15 amp - - - 1.2

115/1/60 15 amp 1.2 - - -

Maximum Fuse/

Circuit Breaker

Minimum Circuit

Amps

Total Amps

QuietQube

Models

230/1/50 15 amp 1.2 - - -

CVD Condensing Units

Condensing

Unit

Voltage/Phase/

Cycle

Maximum

Fuse/Circuit

Breaker

Minimum

Circuit Amps

Minimum Wire Size Required

by Manitowoc

208-230/1/60 15 amp *11.6 #12 Solid Copper Conductor

CVDF0600

208-230/3/60 15 amp *10.2 #12 Solid Copper Conductor

230/1/50 15 amp *10.2 #12 Solid Copper Conductor

208-230/1/60 20 amp *12.5 #10 Solid Copper Conductor

CVDF0900

208-230/3/60 15 amp *9.5 #12 Solid Copper Conductor

230/1/50 20 amp *12.5 #10 Solid Copper Conductor

208-230/1/60 25 amp 14.8 #10 Solid Copper Conductor

CVDT1200

208-230/3/60 15 amp 9.3 #12 Solid Copper Conductor

208-230/1/60 20 amp *11.7 #10 Solid Copper Conductor

CVDF1400

208-230/3/60 15 amp *8.9 #12 Solid Copper Conductor

208-230/1/60 40 amp *25.0 #8 Solid Copper Conductor

CVDF1800

208-230/3/60 25 amp *20.0 #10 Solid Copper Conductor

230/1/50 40 amp *25.0 #8 Solid Copper Conductor

208-230/1/60 50 amp *40.0 #6 Solid Copper Conductor

CVDF2100

208-230/3/60 30 amp *30.0 #10 Solid Copper Conductor

* Data marked with an asterisk is preliminary and subject to change - Model/serial plate information

overrides all data listed in this chart.

Part Number: 000014141 Rev 03 2/18 19

Page 20

Installation Section 2

Water Supply and Drain Line Sizing/Connections

Caution

,

Do not apply heat to water inlet valve or water drain fittings. Heating will damage the

nonmetallic connector. Do not over tighten fittings. Two turns after hand tight is the

maximum.

• Local water conditions may require treatment of the water to inhibit scale formation,

filter sediment, and remove chlorine odor and taste.

• Connect ice making water inlet to potable water only.

• Do not connect to hot water supply.

• Install a water shut-off valve.

• Insulate water and drain lines to prevent condensation.

Location

Ice Making

Water Inlet

Ice Making

Water Drain

Condenser Water

Inlet

Condenser Water

Drain

Bin Drain — —

Large Capacity

Bin Drain

Water

Temperature

40°F (4.4°C) Min.

90°F (32°C) Max.

— —

40°F (4.4°C) Min.

90°F (32°C) Max.

— —

Water Pressure

20 psi (140 kPa)

Min.

80 psi (550 kPa)

Max.

20 psi (140 kPa)

Min.

150 psi

(1030 kPa) Max.

Ice Machine

Fitting

3/8" Female Pipe

Thread

1/2" Female Pipe

Thread

I0300 - I1000 = 3/8"

Female Pipe Thread

I1200 - I1800 = 1/2"

Female Pipe Thread

1/2" Female Pipe

Thread

3/4" Female Pipe

Thread

1" Female Pipe

Thread

Tubing Size up

to Ice Machine

Fitting

3/8" (10 mm)

minimum inside

diameter

1/2" (13 mm)

minimum inside

diameter

1/2" (13 mm)

minimum inside

diameter

3/4" (19 mm)

minimum inside

diameter

1" (25 mm)

minimum inside

diameter

Min. = Minimum, Max. = Maximum

20 Part Number: 000014141 Rev 03 2/18

Page 21

Section 2 Installation

Air Gap

A greater than 1-inch air gap is built into

the ice machine for back-flow prevention.

This air gap exceeds NSF 12 requirements

for back-flow prevention.

This air gap is greater than 1"

Cooling Tower Applications

(Water-Cooled Models)

A water cooling tower installation does not

require modification of the ice machine.

• Water pressure at the condenser cannot

exceed 150 psig (1034 kPa). A special

order unit is available that allows water

pressure up to 350 psig (2413 kPa).

Drain Connections

Follow these guidelines when installing

drain lines to prevent drain water from

flowing back into the ice machine and

storage bin:

• Drain lines must have a of run 1.5 inch

drop per 5 feet (2.5 cm per meter) and

must not create traps.

• The floor drain must be large enough to

accommodate drainage from all drains.

• Run separate bin and ice machine

drain lines. Insulate them to prevent

condensation.

• Vent the ice machine drain to the

atmosphere.

• Drain termination must have an air gap

that meets local code.

Auxiliary Base Drain Installation

An auxiliary drain is located in the ice

machine base to remove moisture in high

humidity areas.

• Water entering the condenser must not

exceed 90°F (32°C).

• Water flow through the condenser

must not exceed 5 gallons (19 liters) per

minute.

• Allow for a pressure drop of 7 psi

(50 kPa) between the condenser water

inlet and the outlet of the ice machine.

• Water exiting the condenser must not

exceed 110°F (43°C).

1. View the back of the ice machine base

on the compressor side and locate and

remove the cap plug.

2. Route tubing to an open site drain:

• Use 1/2 inch CPVC tubing.

• Apply a bead of silicone around the

exterior of the ice machine tubing

and insert into ice machine base. The

silicone will secure the tubing and

provide a watertight seal.

• Provide support for tubing.

Part Number: 000014141 Rev 03 2/18 21

Page 22

Installation Section 2

Remote Condenser and Condensing Unit Refrigeration System Installation

Each ice machine head section ships from the factory with a refrigerant charge

appropriate for the entire system operation. The serial tag on the ice machine indicates

the refrigerant charge.

QuietQube® Ice

Machine

IF0600C

IBF0620C

IBF0820C

IF0900C

IBT1020C CVDT1200 2 lbs - 907 g

IT1200C CVDT1200 2 lbs - 907 g

IF1400C CVDF1400 RC-20

IF1800C CVDF1800 2 lbs - 907 g

IF2100C CVDF2100

Remote Condenser Line Set*

CVDF0600

RC-21

CVDF0900 2 lbs - 907 g

RC-31

RC-51

RC-30

RC-50

RC-23

RC-33

RC-53

Additional Refrigerant

Charge for 50' to 100'

(15 to 30 Meter) Line Sets

1.5 lbs - 680 g

2 lbs - 907 g

4 lbs - 1814 g

*Line Set Suction Line Liquid Line Minimum Insulation Thickness

RC 21/31/51

RC 20/30/50

RC 23/33/53

Warning

n

Installation of a QuietQube® Condensing

Unit may require the use of special

equipment for placement. Trained and

qualified personnel are required for proper

rigging and lifting. Holes are provided on

the corners of the condensing unit to allow

the use of lifting shackles.

5/8 inch

16 mm

3/4 inch

19 mm

3/4 inch

19 mm

3/8 inch

10 mm

1/2 inch

13 mm

5/8 inch

16 mm

1/2" (13 mm) Suction Line

1/4" (7 mm) Liquid Line

1/2" (13 mm) Suction Line

1/4" (7 mm) Liquid Line

1/2" (13 mm) Suction Line

1/4" (7 mm) Liquid Line

Important

Manitowoc remote systems are only

approved and warranted as a complete

new package. Warranty on the refrigeration

system will be void if a new ice machine

head section is connected to pre-existing

(used) tubing or condensing units or vice

versa.

22 Part Number: 000014141 Rev 03 2/18

Page 23

Section 2 Installation

Remote Condenser Models

Additional Amount

of Refrigerant

Ice

Machine

IT0500N JCT0500 1.5 lbs - 680 g

IF0600N JCT0900 1.5 lbs - 680 g

IF0900N JCT0900 2 lbs - 907 g

IT1200N JCT1200 2 lbs - 907 g

IT1500N JCT1500 2 lbs - 907 g

IT1900N JCT1500 2 lbs - 907 g

Line Set

RT

20/35/50

R404A

RT

20/35/50

R410A

RL

20/35/50

R410A

NOTE: R404A line sets have white

protective caps and R410A line sets have

pink protective caps.

Potential Personal Injury Situation

The ice machine head section contains

the refrigerant charge. Installation and

brazing of the line sets must be performed

by a properly trained and EPA certified

refrigeration technician aware of the

dangers of dealing with refrigerant charged

equipment.

Remote

Condenser

Discharge

Line

1/2 inch

13 mm

1/2 inch

13 mm

1/2 inch

13 mm

Warning

n

to Be Added to

Nameplate Charge

for 50' to 100'

(15 to 30 Meter)

Line Sets

Liquid

Line

5/16 inch

7.9 mm

5/16 inch

7.9 mm

3/8 inch

9.5 mm

Model

iF0600N

iF0900N

iT0500N

iT1200N

iT1500N

iT1900N

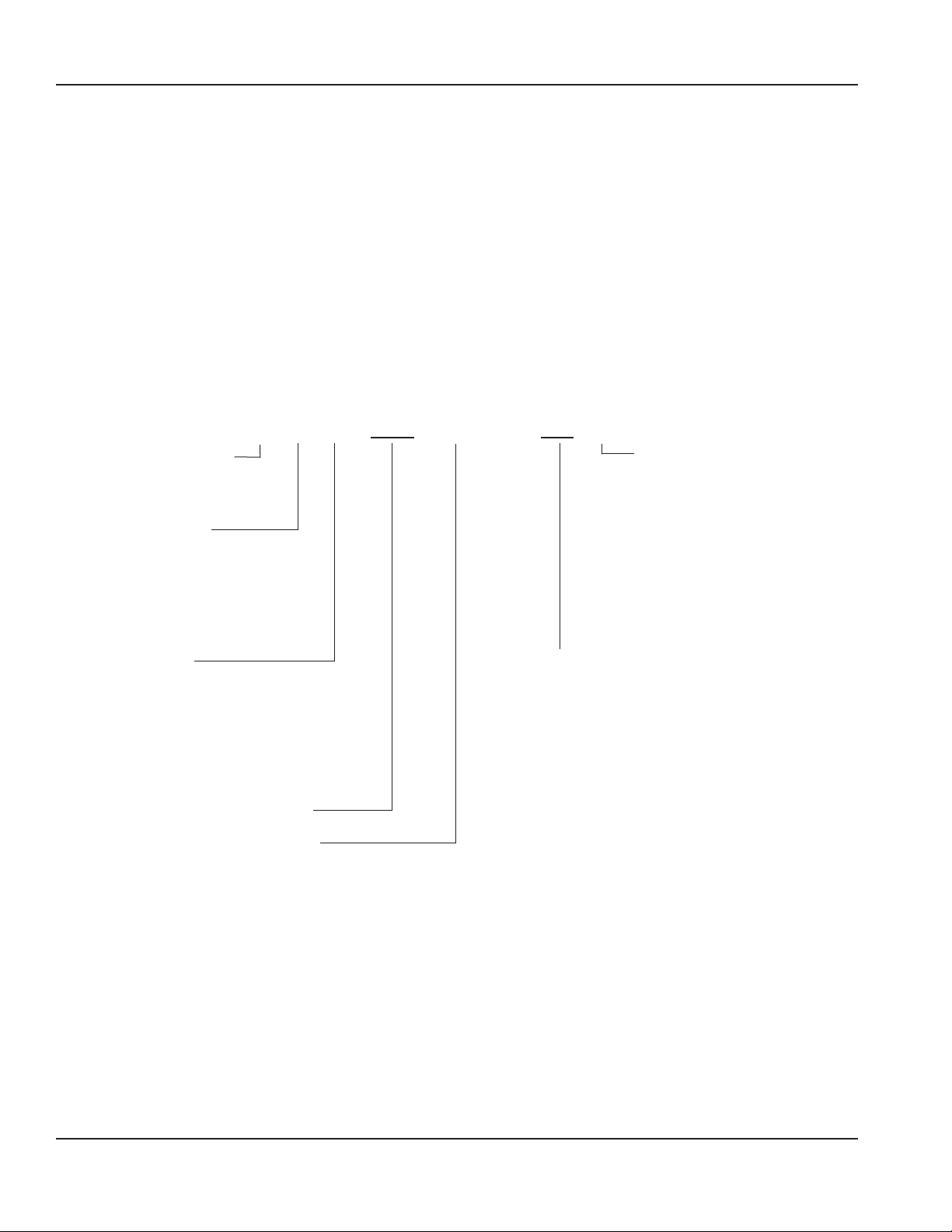

CALCULATING INSTALLATION DISTANCES

Line Set Length

The maximum tubing length is 100 feet (30

meters).

Line Set Rise/Drop

The maximum rise is 35 feet (10.7 meters).

The maximum drop is 15 feet (4.5 meters).

Notice

If a line set has a rise followed by a drop,

another rise cannot be made. Likewise,

if a line set has a drop followed by a rise,

another drop cannot be made.

Calculated Line Set Distance

The maximum calculated distance is 150

feet (45 meters).

Line set rises, drops, horizontal runs (or

combinations of these) in excess of the

stated maximums will exceed compressor

start-up and design limits. This will cause

poor oil return to the compressor. Make the

following calculations to make sure the line

set layout is within specifications.

1. Insert the measured rise into the

formula below. Multiply by 1.7 to get

the calculated rise.

2. Insert the measured drop into the

formula below. Multiply by 6.6 to get

the calculated drop.

3. Insert the measured horizontal

distance into the formula below. No

calculation is necessary.

Part Number: 000014141 Rev 03 2/18 23

Page 24

Installation Section 2

4. Add together the calculated rise,

calculated drop, and horizontal

distance to get the total calculated

distance. If this total exceeds 150 feet

(45 meters), move the condenser/

condensing unit to a new location and

perform the calculations again.

Maximum Line Set Distance Formula

Step 1.

Measured Rise (R) 35 feet (10.7 meters)

Maximum _____ x 1.7 =

_____ Calculated Rise

Step 2.

Measured Drop (D) 15 feet (4.5 meters)

Maximum _____ x 6.6 =

_____ Calculated Drop

Step 3.

Measured Horizontal Distance (H) 100 feet

(30 meters) Maximum

_____ Horizontal Distance

Step 4.

Total Calculated Distance 150 feet (45

meters) Maximum

_____ Total Calculated

Distance

Notice

The refrigeration system warranty will

not apply if the Manitowoc Ice Machine

and Manitowoc CVD Condensing Unit are

not installed according to specifications.

This warranty also will not apply if the

refrigeration system is modified with a

condenser, heat reclaim device, or other

parts or assemblies not approved by

Manitowoc.

REMOTE CONDENSER MODELS

Step 1 Secure the Condenser.

Through-holes are provided to secure

the condenser to a curb, rack or wooden

timber.

Warning

n

The ice machine head section contains

refrigerant charge. The ice machine head

section contains refrigeration valves

that must remain closed until proper

installation of the line sets is completed.

Warning

n

Electrical power to the ice machine head

section, condensing unit or condenser

must be disconnected before proceeding.

Step 2 Route the Refrigeration Tubing.

Route the refrigeration tubing between

the ice machine head section and the

condenser.

• Maximum line set exposed on rooftop is

25% of total line set length.

• A qualified person must perform all roof

penetrations.

Step 3 Connect the Line Set.

In most cases, by routing the line set

properly, shortening will not be necessary.

When shortening or lengthening is

required, do so before connecting the

line set to the ice machine or the remote

condenser. This prevents the loss of

refrigerant in the ice machine or condenser.

The quick connect fittings on the line sets

are equipped with access valves. Use these

valves to recover any vapor charge from the

line set.

24 Part Number: 000014141 Rev 03 2/18

Page 25

Section 2 Installation

When lengthening or shortening lines,

follow good refrigeration practices, purge

with nitrogen and insulate all tubing. Do

not change the tube sizes. Evacuate the

lines and place about 5 oz (145 grams) of

vapor refrigerant charge in each line.

1. Remove the dust caps from the line

set, condenser and ice machine.

2. Apply refrigeration oil to the threads

on the quick-disconnect couplers

before connecting them to the

condenser.

3. Carefully thread the female fitting to

the condenser or ice machine by hand,

then tighten the couplings with a

wrench until they bottom out.

4. Turn an additional quarter turn to

ensure proper brass-to-brass seating.

Torque to the following specifications:

Liquid Line Discharge Line

10 - 12 ft lbs

13.5-16.2 N•m

5. Check all fittings and valve caps for

leaks and reinstall and tighten caps.

35 - 45 ft lbs

47.5-61.0 N•m

QUIETQUBE MODELS

Step 1 Secure the Condensing Unit.

Through-holes are provided to secure the

condensing unit to a curb, rack or wooden

timber.

Step 2 Route the Refrigeration Tubing.

Route the refrigeration tubing between

the ice machine head section and the

condenser or CVD condensing unit.

• A suction line oil trap is required when

rise is more than 20 feet (6 meters).

• Only one trap is allowed in the line set.

• Shorten the line set as required, do not

coil line set.

Manitowoc S-Trap Kit

Model

IBF0620C IBF0820C

IBT1020C

IF0600C IF0900C

IT1200C

IF1400C IF1800C

IF2100C

S-Trap Kit

Number

K00172

K00166

Tubing

Size

5/8 inch

(16 mm)

3/4 inch

(19 mm)

6. The receiver service valve is closed

during shipment and must be opened

before starting the ice machine.

A. Remove the receiver service valve

cap.

B. Backseat (open) the valve.

C. Reinstall the cap and panels.

Installation is finished for remote

condenser models. Proceed to page 29

for start-up procedure.

Part Number: 000014141 Rev 03 2/18 25

• Maximum amount of time the

refrigeration system can be exposed to

the atmosphere is 15 minutes.

• Purge line set with dry nitrogen while

brazing.

• Shutoff valves for the line set on the ice

machine must remain closed and be

protected from heat during brazing.

• The condensing unit ships with a 50/50

mixture of nitrogen/helium.

Page 26

Installation Section 2

VALVES MUST

REMAIN CLOSED AND

BE PROTECTED FROM

HEAT WHEN BRAZING

(WRAP WITH WET

RAG)

Step 3 Pressure Test and Evacuate Line Set

and CVD Condensing Unit.

• Shutoff valves for the line set must

remain closed until pressure testing and

evacuation are complete.

• Valve core removal tools that allow for

removal and installation of the valve

cores without removing hoses for the

manifold gauge set are recommended to

decrease the evacuation time.

• Pressure test at 150 psi (1000 kPa) for a

minimum of 15 minutes.

• Minimum evacuation level is 500

microns.

CHECK

VALVE

CONDENSER

ALTERNATE CONNECTIONS

AT CONDENSING UNIT

SCHRADER VALVES

CONNECT MANIFOLD GAUGE

SET OR HOSE WITH CORE

DEPRESSORS ON BOTH ENDS

LINE SET CONNECTION

LOCATION

Pressure test the line sets and CVD

Condensing Unit with 150 psi (1000 kPa) of

dry nitrogen. Add nitrogen at the shutoff

valves for the line set located at the back

of the ice machine head section or from

the access valves located in the CVD

Condensing Unit. Complete the pressure

test, verify no leaks are present and remove

the nitrogen from the system before

connecting the vacuum pump. Connect

CONNECT VACUUM

PUMP TO SHUTOFF

VALVES FOR THE LINE SET

vacuum pump and evacuate system to 500

microns.

26 Part Number: 000014141 Rev 03 2/18

Page 27

Section 2 Installation

Step 4 Open Valves for the Line Set and

Receiver.

You will not hear refrigerant flow when the

valves are opened. Refrigerant will not flow

until the ice machine is started and the

solenoid valve opens.

• All valve caps must be reinstalled,

tightened and leak-checked to assure no

refrigerant leakage exists.

USE ALLEN WRENCH

TO OPEN (TURN

COUNTERCLOCKWISE)

SHUTOFF VALVES

FOR THE LIQUID AND

SUCTION LINES

• Counterclockwise opens all valves:

A. Open the shutoff valves for the

suction and liquid lines.

B. Open the receiver service valve

until back seated (when used).

USE ALLEN WRENCH TO OPEN

(TURN COUNTERCLOCKWISE)

SHUTOFF VALVES FOR THE LIQUID

AND SUCTION LINES

QuietQube Models

Ice Beverage Models

USE ALLEN WRENCH TO OPEN

(TURN COUNTERCLOCKWISE)

SHUTOFF VALVES FOR THE

LIQUID AND SUCTION LINES

IF1400C/IF1800C/IF2100C

Notice

After opening suction, discharge and

receiver service valves, refrigerant

pressure will not be detected until the

ice machine starts a freeze cycle and the

solenoid valves energize.

Part Number: 000014141 Rev 03 2/18 27

Page 28

Installation Section 2

Step 5 Leak-Check the Refrigeration

System.

A. Connect power to the ice machine

head section - Do not connect

power to the CVD condensing unit.

B. Press the power switch and

energize the ice machine for 60

seconds to equalize pressures.

C. Disconnect power to the ice

machine head section.

D. Leak-check line set connections, S

trap and all factory joints in head

section and condensing unit.

E. Connect power to the CVD

condensing unit and allow system

to pump down.

Step 6 Insulation Requirements

• To prevent condensation, the entire

suction line, including the shutoff valve,

must be insulated.

• All insulation must be airtight and sealed

at both ends.

The following insulation requirements

prevent condensation at 90° F (32°C)

ambient temperature and 90% relative

humidity. If higher humidity is expected,

increase insulation thickness:

Suction

Line

3/4 inch

19 mm

5/8 inch

16 mm

3/4 inch

19 mm

Step 7 Insulation for the Suction Shutoff

Valve

The insulation for the suction shutoff valve

is located in the plastic bag taped to the

water curtain.

Step 8 Ice Beverage Models Only

The thermostat probe must be moved from

the shipping position to the ice-making

position.

Liquid

Line

1/2 inch

13 mm

3/8 inch

10 mm

5/8 inch

16 mm

Min. Insulation

Thickness

Suction Line -

1/2" (13 mm)

Liquid Line -

1/4" (7 mm)

Suction Line -

3/4" (19 mm)

Liquid Line -

1/4" (7 mm)

• The bin thermostat probe must be

rotated down to enable ice contact and

proper operation.

• Verify probe wire does not interfere with

the water curtain.

• The control is preset and does not

require programming.

1. Loosen thumbscrew securing probe.

2. Rotate the probe from horizontal to

vertical position.

3. Tighten thumbscrew to secure probe.

28 Part Number: 000014141 Rev 03 2/18

Page 29

Section 2 Installation

Starting the Ice Machine

Starting the ice machine and completing

the Operational Checks are the

responsibilities of the owner/operator.

Adjustments and maintenance procedures

outlined in this manual are not covered by

the warranty.

REMOVE ICE THICKNESS PROBE

SHIPPING BRACKETS.

Remove and discard shipping brackets

before starting the ice machine.

Step 1 Ice machine must be programmed

refer to “Touch Screen Features” on page

31 for details.

Step 2 Refer to “Cleaning/Sanitizing

Procedure” on page 40 and sanitize

the ice machine and bin before placing in

operation.

Step 3 Refer to “Ice Making Sequence of

Operation” on page 35 for operational

details.

Remote Ice Machine Usage with NonManitowoc Multi-Circuit Condensers

Warranty

The sixty (60) month compressor warranty,

including thirty six (36) month labor

replacement warranty, shall not apply when

the remote ice machine is not installed

within the remote specifications. The

foregoing warranty shall not apply to any

ice machine installed and/or maintained

inconsistent with the technical instructions

provided by Manitowoc Ice. Performance

may vary from Sales specifications. ARI

certified standard ratings only apply when

used with a Manitowoc remote condenser.

If the design of the condenser meets the

specifications, Manitowoc’s only approval

is for full warranty coverage to be extended

to the Manitowoc manufactured part of

the system. Since Manitowoc does not

test the condenser in conjunction with the

ice machine, Manitowoc will not endorse,

recommend, or approve the condenser, and

will not be responsible for its performance

or reliability.

Important

Manitowoc warrants only complete

new and unused remote packages.

Guaranteeing the integrity of a new ice

machine under the terms of our warranty

prohibits the use of pre-existing (used)

tubing or condensers.

MINIMUM/MAXIMUM SLAB WEIGHT

Adjust ice thickness to maintain the correct

bridge thickness and “Minimum/Maximum

Slab Weight” on page 37.

Part Number: 000014141 Rev 03 2/18 29

Page 30

Installation Section 2

Design & Burst Pressure

Design Pressure 600 psig - 4137 kPa

Burst Pressure 2500 psig - 17237 kPa

Head Pressure Control Valve

Do not use a fan cycling control to try to

maintain discharge pressure. Compressor

failure will result. Any remote condenser

connected to a Manitowoc Ice Machine

must have the OEM head pressure control

valve installed. Manitowoc will not accept

substitute “off the shelf” head pressure

control valves.

Fan Motor

The condenser fan must be on during the

complete ice machine freeze cycle (do

not cycle on fan cycle control). The ice

maker has a condenser fan motor circuit

for use with a Manitowoc condenser. It is

recommended that this circuit be used to

control the condenser fan(s) on the multicircuit condenser to assure it is on at the

proper time. Do not exceed the rated amps

for the fan motor circuit listed on the ice

machine’s serial tag.

Internal Condenser Volume

The multi-circuit condenser internal

volume must not be less than or exceed

that used by Manitowoc. Do not exceed

internal volume and try to add charge to

compensate, as compressor failure will

result.

Model Minimum Maximum

IT0500N 0.020 0.030

IF0600N/IF0900N

0.045 0.060

IT1200N

IT1500N/IT1900N 0.085 0.105

Heat of Rejection

Model Peak Average

IT0500N 6100 6900

IF0600N 9000 13900

IF0900N 13000 1600

IT1200N 20700 24500

IT1500N 23000 27000

IT1900N 26100 30500

Refrigerant Charge

The ice machine model/serial tag lists the

refrigerant amount. Remote condensers

and line sets contain a vapor charge only.

Model Amount Type

IT0500N 6.0 lbs - 2.72 kg R410A

IF0600N *6.5 lbs - 2.95 kg R404A

IF0900N *7 lbs - 3.18 kg R404A

IT1200N 7.5 lbs - 3.40 kg R410A

IT1500N 8.0 lbs - 3.63 kg R410A

IT1900N 8.0 lbs - 3.63 kg R410A

*Data marked with an asterisk is preliminary and subject to change - Model/serial

plate information overrides all data listed in this chart.

Quick Connect Fittings

The ice machine and line sets come with

quick connect fittings. It is recommended

that matching quick connects (available

through Manitowoc Distributors K00129)

be installed in the multi-circuit condenser,

and that a vapor “holding” charge, 5 oz.

(150 ml), of proper refrigerant be added to

the condenser prior to connection of the

ice machine or line set to the condenser.

30 Part Number: 000014141 Rev 03 2/18

Page 31

Section 3

Operation

Lock/Unlock Screen

Power Button

4/17/2018 11:12 AM

Alert Icon

Notification Icon

Menu Icon

3

3

MAKING ICE

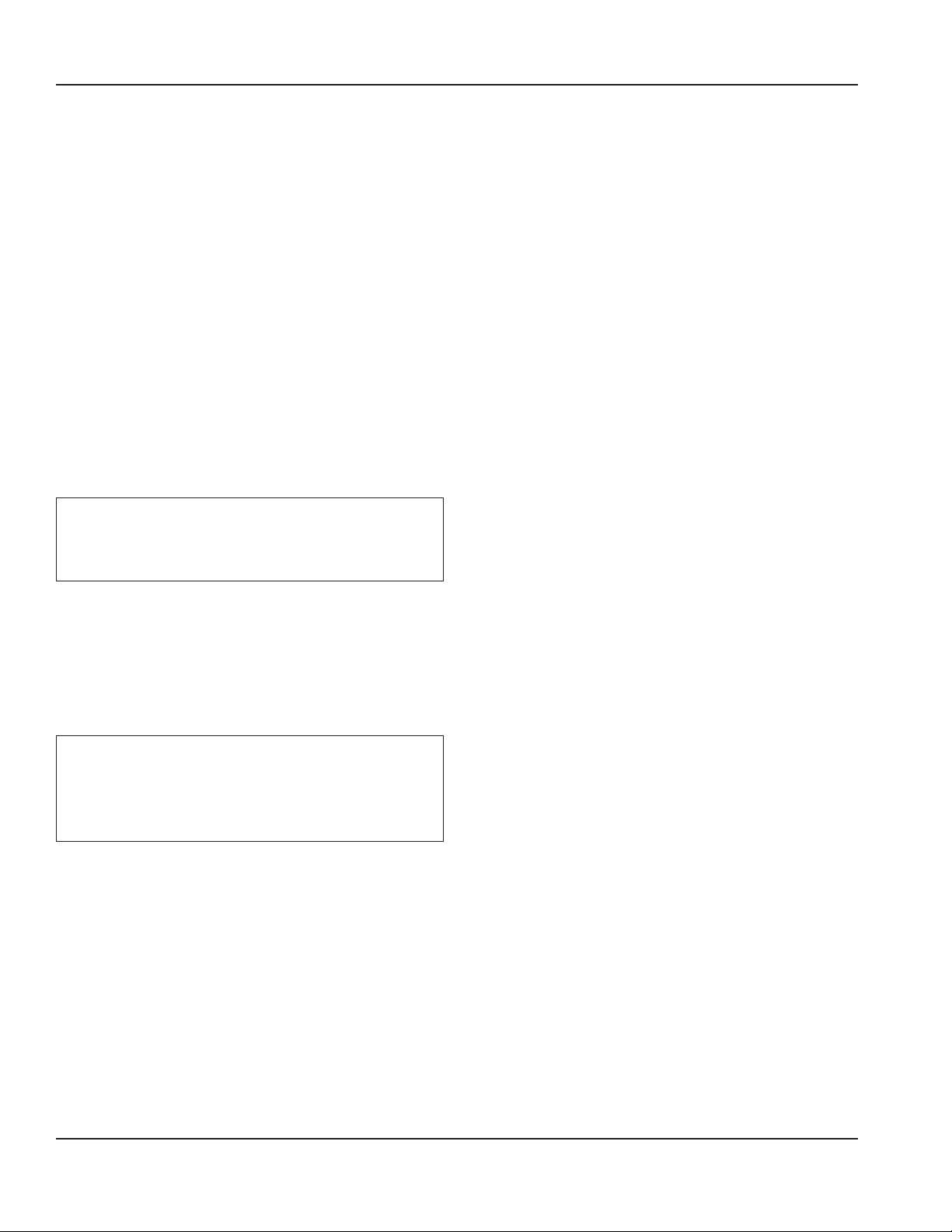

Touch Screen Features

The Indigo® control panel offers a series

of pressure-sensitive buttons and an

interactive touchscreen.

Buttons

Power Button: Provides On/Off functions

for the ice machine.

Cleaning Button

Screen Locked or

Unlocked

S

i

LuminIce

Service Locater

Information

Touchscreen

Home screen allows viewing of ice machine

status, alerts and messages. Navigation

with the touchscreen provides access to

menu items, machine information, settings

and event logs. Setup and Energy Saver

settings can be adjusted along with access

to service and troubleshooting information.

Lock/Unlock Button: Allows or prevents

touchscreen navigation.

Cleaning Button: Initiates a cleaning cycle.

Refer to Section 4 for details.

NOTE: Touchscreen is to be activated with

finger tips only.

Icons: Provide status indication and allow

navigation by pressing the icon.

Part Number: 000014141 Rev 03 2/18 31

Page 32

Operation Section 3

3

i

HOME SCREEN ICON DESCRIPTIONS

Icon Description

Home

Screen

Alert

3

Center portion of the screen displays the current condition of the ice

machine - Making ice, bin full, program mode or machine off

Alert icon with number of messages. Pressing this icon will display the alert

log which will allow viewing and resetting of alerts

Message

Menu

Information

Service

Locator

Lock/Unlock

Notification icon with quantity of messages. Pressing this icon will display

the routine maintenance reminder screen which will allow viewing and

resetting of the reminder

Menu icon will take you to the main menu

Information icon provides model and serial number, installation date and

other information specific to the ice machine

Provides contact information for your local service support - Default is the

Manitowoc Ice website service locator

Indicates if screen is locked or unlocked

LuminIce

S

32 Part Number: 000014141 Rev 03 2/18

Only visible when a LuminIce II accessory is connected.

Blue S - Normal operation

Red S - Replace bulb

Red/Blue alternating - Incorrect bulb installed

Page 33

Section 3 Operation

Setup Wizard

Screens will automatically advance after a

selection is made or press the right arrow

to advance one screen, press left arrow

to go back one screen. All settings can be

accessed and changed without the wizard

by using menu screen navigation.

Setup Description

Press ON/

OFF Button

Enter Model

Number

Select

Language

Start Wizard

Accessory

Detection

USB Setup

Configure

Date and

Time

Formats

Set Time Use arrows to set local time.

Set Date

Units Select standard or metric.

Brightness

On/Off button is used to

start/stop ice making.

Only visible if model number

can not be automatically

identified. The ice machine

will not start without model

identification.

Default is English. Scroll to

select a different language.

Setup wizard will guide ice

machine programming.

Detects if Ice Level Sensor,

LuminIce II or AuCS are

connected.

Checkmark = yes - X = no

Only used when setup

features have been

transferred to a USB drive.

Skip screen by selecting right

arrow.

Select Month/Day/Year or

Day/Month/Year.

Select 12 hour or 24 hour

time format.

Use arrows to set date for

your location.

Configure screen brightness

during normal operation.

Setup Description

Program ice machine run

Ice Program

Cleaning

Reminder

IAuCS

Only when

detected

Air Filter

Air-cooled

models only

Water Usage

Water Filter Select Yes or No.

LuminIce II

Only when

detected

Ice Level

Sensor

Only when

detected

Wizard

Complete

times or press right arrow to

skip this setup.

Set clean or sanitize

reminder or press right

arrow to skip.

Set frequency of operation

when this accessory is

installed.

Set to ON for self-contained

air cooled models.

Factory default

or

Use less water for reverse

osmosis systems

or

Use more water to improve

clarity for unfiltered water

12 month reminder is

automatically set.

Reminder to rotate the

sensor from shipping to

operational position.

Press right arrow or home

icon to return to home

screen.

Part Number: 000014141 Rev 03 2/18 33

Page 34

Operation Section 3

Menu Screen Navigation

Select SETTINGS Icon from the Home Screen to access Main Menu screen.

Energy Service Settings Reset Defaults

Ice Program Data Language

Water Usage Alert Log Reminders

Statistics Manual Harvest Time & Date

Control Board

Replacement

Diagnostics Brightness

Contact Information USB

Units

Require Setup

Wizard

Backup Current

Settings

Reset To Factory

Defaults

USB *AuCS

*AuCS

*Prime AuCS Pump

* Only visible when this optional accessory is installed

34 Part Number: 000014141 Rev 03 2/18

Page 35

Section 3 Operation

Ice Making Sequence of Operation

The power button must be depressed and

the water curtain/ice dampers must be

in place on the evaporator before the ice

machine will start.

Water Purge Cycle

The ice machine purges any remaining

water from the water trough down the

drain.

Prechill Cycle

The refrigeration system cools the

evaporator before the water pump is

energized.

Freeze Cycle

Water flows across the evaporator and the

refrigeration system chills the evaporator.

Ice builds on the evaporator and the freeze

cycle continues until the ice thickness

probe senses a sheet of ice has formed.

The ice thickness probe signals the control

board to start a harvest.

Harvest Cycle

Any remaining water is purged down

the drain as refrigerant gas warms the

evaporator. When the evaporator warms,

the sheet of cubes slides off the evaporator

and into the storage bin. If all cubes fall

clear of the water curtain (or ice damper)

the ice machine starts another freeze cycle.

Off Cycle

If the water curtain or ice damper are held

open by ice cubes the ice machine shuts

off. When the water curtain or ice damper

closes, the ice machine starts a new cycle at

the water purge.

Control Board Timers

The control board has the following nonadjustable timers:

• The ice machine control board will set

its own install date after 100 freeze and

harvest cycles.

• The ice machine is locked into the freeze

cycle for 6 minutes before a harvest cycle

can be initiated.

• The maximum freeze time is 35

minutes at which time the control

board automatically initiates a harvest

sequence.

• The maximum harvest time is 7 minutes,

the control board will perform a water

thaw cycle and then return the ice

machine to the freeze cycle.

Service Faults

Service Faults are stored and indicated by

the control board after three cycles. The

number of cycles required to stop the ice

machine varies for each Service Fault.

• Long Freeze Cycle - If the freeze time

reaches 35 minutes, the control board

automatically initiates a harvest cycle.

If 6 consecutive 35 minute freeze cycles

occur, the ice machine stops.

• Long Harvest Cycle - If the harvest time

reaches 7 minutes, the control board

automatically returns the ice machine to

the freeze cycle. After 3 consecutive long

harvest cycles the ice machine stops.

Refer to Section 5 if you receive an alert for

Service Fault E01 or E02.

Part Number: 000014141 Rev 03 2/18 35

Page 36

Operation Section 3

Safe Operation Mode

Allows the ice machine to operate up to

72 hours if the ice thickness probe and/or

water level probe sensors fail.

• When the control board starts the safe

mode, an alert is flashed on the display

to notify the end-user they have a

production problem.

• The control board automatically initiates

and monitors the safe mode. The control

will automatically exit the safe mode if a

normal signal is received from the input.

• After 72 hours, the control board will

enter a standby mode and turn off.

NOTE: The control board needs a five cycle

history to operate safe mode. If five cycles

have never been successfully completed

the ice machine will shut-off.

Water Assist Harvest

Water Thaw Cycle

When the damper/curtain does not open

during the 7 minute harvest cycle the

following water thaw cycle occurs:

• 7 minutes - The compressor, harvest

solenoid valve and dump valve deenergize.

1. The water pump remains energized

and the water inlet valve energizes

until water touches the high water

level probe.

2. Water is circulated over the

evaporator.

3. Water is circulated, dumped and

refilled to the high water level probe

for approximately 1 hour.

• At the end of the thaw cycle the ice

machine will start another freeze cycle

(approximately 1 - 1.75 hour).

When the damper/curtain does not open

within 3.5 minutes in the harvest cycle the

following occurs:

• 3.5 minutes - The water inlet valve

energizes until water touches the high

water level probe.

• 4 minutes - The water pump energizes.

• 6.5 to 7 minutes - The water dump valve

energizes.

36 Part Number: 000014141 Rev 03 2/18

Page 37

Section 3 Operation

Minimum/Maximum Slab Weight

Adjust ice thickness to meet chart

specifications.

Model

IF0300

IT0420 IT0450

IT0520 IT0620

IT0500

IF0600

IBF0820

IF0900

IT1200

IBF1020

IF1400 IT1500

IT1900

IF2100

Minimum

Ice Weight

Per Cycle

lbs

Grams

2.40 lbs

1089 grams

3.40 lbs

1542 grams

4.60 lbs

2087 grams

4.12 lbs

1869 grams

5.75 lbs

2608 grams

6.20 lbs

2812 grams

7.50 lbs

3402 grams

10.25 lbs

4649 grams

13.20 lbs

5987 grams

15.50 lbs

7031 grams

Maximum

Ice Weight

Per Cycle

lbs

Grams

2.80 lbs

1270 grams

3.90 lbs

1769 grams

5.20 lbs

2359 grams

4.75 lbs

2155 grams

6.50 lbs

2948 grams

7.20 lbs

3266 grams

8.20 lbs

3719 grams

11.50 lbs

5216 grams

14.80 lbs

6713 grams

16.75 lbs

7598 grams

Ice Thickness Check

After a harvest cycle, inspect the ice cubes

in the ice storage bin. The ice thickness

probe is factory-set to maintain the ice

bridge thickness at 1/8" (3 mm).

NOTE: Make sure the water curtain is

in place when performing this check. It

prevents water from splashing out of the

water trough.

1. Inspect the bridge connecting the

cubes. It must be approximately

1/8" (3 mm) thick.

2. If adjustment is necessary, turn the

ice thickness probe adjustment screw

clockwise to increase bridge thickness,

counterclockwise to decrease bridge

thickness. Set a 7 mm (9/32") gap

between ice thickness probe and

evaporator as starting point, then

adjust to achieve a 1/8" (3 mm) bridge

thickness.

NOTE: Turning the adjustment one-third of

a turn will change the ice thickness about

1/16" (1.5 mm).

ADJUSTING SCREW

1/8" (3 mm)

ICE BRIDGE THICKNESS

Important

Routine adjustments and maintenance

procedures are not covered by the

warranty.

PLACE 9/32"

(7 mm) DRILL BIT

BETWEEN PROBE AND

EVAPORATOR TO SET

INITIAL GAP

Verify the ice thickness probe wire doesn’t

restrict probe movement.

Part Number: 000014141 Rev 03 2/18 37

Page 38

Operation Section 3

THIS PAGE INTENTIONALLY LEFT BLANK

38 Part Number: 000014141 Rev 03 2/18

Page 39

Section 4

Maintenance

Cleaning and Sanitizing

General

You are responsible for maintaining

the ice machine in accordance with the

instructions in this manual. Maintenance

procedures are not covered by the

warranty.

Clean and sanitize the ice machine every

six months for efficient operation. If the ice

machine requires more frequent cleaning

and sanitizing, consult a qualified service

company to test the water quality and

recommend appropriate water treatment.

An extremely dirty ice machine must be

taken apart for cleaning and sanitizing.

Manitowoc Ice Machine Cleaner and

Sanitizer are the only products approved

for use in Manitowoc ice machines.

Caution

,

Use only Manitowoc approved Ice

Machine Cleaner and Sanitizer for this

application (Manitowoc Cleaner part

number 9405463 and Manitowoc Sanitizer

part number 9405653). It is a violation of

Federal law to use these solutions in a

manner inconsistent with their labeling.

Read and understand all labels printed on

bottles before use.

Warning

n

Wear rubber gloves and safety goggles

(and/or face shield) when handling Ice

Machine Cleaner or Sanitizer.

Cleaning/Sanitizing Procedure

This procedure must be performed a

minimum of once every six months.

• The ice machine and bin must be

disassembled cleaned and sanitized.

• All ice produced during the cleaning and

sanitizing procedures must be discarded.

• Removes mineral deposits from areas or

surfaces that are in direct contact with

water.

Preventative Maintenance Cleaning

Procedure

• This procedure cleans all components in

the water flow path, and is used to clean

the ice machine between the bi-yearly

cleaning/sanitizing procedure.

Caution

,

Do not mix Cleaner and Sanitizer solutions

together. It is a violation of Federal

law to use these solutions in a manner

inconsistent with their labeling.

Part Number: 000014141 Rev 03 2/18 39

Page 40

Maintenance Section 4

Exterior Cleaning

Clean the area around the ice machine as

often as necessary to maintain cleanliness

and efficient operation.

Wipe surfaces with a damp cloth rinsed

in water to remove dust and dirt from the

outside of the ice machine. If a greasy

residue persists, use a damp cloth rinsed in

a mild dish soap and water solution. Wipe

dry with a clean, soft cloth.

The exterior panels have a clear coating

that is stain resistant and easy to clean.

Products containing abrasives will damage

the coating and scratch the panels.

• Never use steel wool or abrasive pads for

cleaning.

• Never use chlorinated, citrus based or

abrasive cleaners on exterior panels and

plastic trim pieces.

Cleaning/Sanitizing Procedure

Caution

,

Use only Manitowoc approved Ice

Machine Cleaner and Sanitizer for this

application (Manitowoc Cleaner part

number 9405463 and Manitowoc Sanitizer

part number 9405653). It is a violation of

Federal law to use these solutions in a

manner inconsistent with their labeling.

Read and understand all labels printed on

bottles before use.

CLEANING PROCEDURE

Caution

,

Do not mix Cleaner and Sanitizer solutions

together. It is a violation of Federal

law to use these solutions in a manner

inconsistent with their labeling.

Warning

n

Wear rubber gloves and safety goggles

(and/or face shield) when handling Ice

Machine Cleaner or Sanitizer.

Ice machine cleaner is used to remove lime

scale and mineral deposits. Ice machine

sanitizer disinfects and removes algae and

slime.

NOTE: Although not required and

dependent on your installation, removing

the ice machine top cover may allow easier

access.

Step 1 Open the front door to access the

evaporator compartment. Ice must not be

on the evaporator during the clean/sanitize

cycle. Follow one of the methods below:

• Press the power switch at the end of

a harvest cycle after ice falls from the

evaporator(s).

• Press the power switch and allow the ice

to melt.

Notice

Never use anything to force ice from the

evaporator. Damage may result.

40 Part Number: 000014141 Rev 03 2/18

Page 41

Section 4 Maintenance

Step 2 Remove all ice from the bin/

dispenser.

Step 3 Press the Clean button and select

“Turn off when complete”. Water will flow

through the water dump valve and down

the drain. Wait approximately 1 minute

until the water trough refills and the display

indicates Add Chemical. Add the proper

amount of ice machine cleaner to the water

trough by pouring between the water

curtain and evaporator, then confirm the

chemical was added.

Model

IF0300/IT0420/IT0620

IT0450/IT0500/IF0600

IF0900/IT1200

IBF0620C/IBF0820C

IBT1020C

IF1400C/IT1500/IF1800C

IT1900/IF2100C

Step 4 Wait until the clean cycle is

complete (approximately *24 minutes).

Then disconnect power to the ice machine

(and dispenser when used).

Amount of

Cleaner

3 oz

(90 ml)

5 oz

(150 ml)

5 oz

(150 ml)

9 oz

(265 ml)

Step 5 Remove parts for cleaning.

Refer to parts removal page 43. Continue

with Step 6 when the parts have been

removed.

Step 6 Mix a solution of cleaner and

lukewarm water. Depending upon the

amount of mineral buildup, a larger

quantity of solution may be required. Use

the ratio in the table below to mix enough

solution to thoroughly clean all parts.

Solution

Type

Cleaner 1 gal (4 L)

Step 7 Use half of the cleaner/water

mixture to clean all components. The

cleaner solution will foam when it contacts

lime scale and mineral deposits; once the

foaming stops, use a soft-bristle nylon

brush, sponge or cloth (NOT a wire brush)

to carefully clean the parts. Soak parts for 5

minutes (15 - 20 minutes for heavily scaled

parts). Rinse all components with clean

water.

Water Mixed With

16 oz

(475 ml)

cleaner

Warning

n

Disconnect the electric power to the ice

machine at the electric service switch box.

Part Number: 000014141 Rev 03 2/18 41

Page 42

Maintenance Section 4

Step 8 While components are soaking,