Page 1

©Manitowoc Ice, Inc.

P/N 80-1099-9 8/03

Page 2

Page 3

Safety Notices

!

Warning

!

Caution

Important

As you work on a Q Model Ice Machine, be sure to pay

close attention to the safety notices in this handbook.

Disregarding the notices may lead to serious injury

and/or damage to the ice machine.

Throughout this handbook, you will see the following

types of safety notices:

Text in a Warning box alerts you to a potential

personal injury situation. Be sure to read the

Warning statement before proceeding, and work

carefully.

Text in a Caution box alerts you to a potential

personal injury situation. Be sure to read the Caution

statement before proceeding, and work carefully.

Procedural Notices

As you work on a Q Model Ice Machine, be sure to

read the procedural notices in this handbook. These

notices supply helpful information that may assist you

as you work.

Throughout this handbook, you will see the following

types of procedural notices:

Text in an Important box provides you with

information that may help you perform a procedure

more efficiently. Disregarding this information will not

cause damage or injury, but may slow you down as

you work.

NOTE: T ext set off as a Note provides you with simple,

but useful extra information about the procedure you

are performing.

Page 4

Read These Before Proceeding:

!

Caution

Important

!

Warning

!

Warning

Proper installation, care and maintenance are

essential for maximum ice production and trouble

free operation of your Manitowoc Ice Machine. If you

encounter problems not covered by this manual, do

not proceed; contact Manitowoc Ice, Inc. We will be

happy to provide assistance.

Routine adjustments and maintenance procedures

outlined in this manual are not covered by the

warranty.

We reserve the right to make product improvements at

any time. Specifications and design are subject to

change without notice.

PERSONAL INJURY POTENTIAL

Do not operate equipment that has b een misused,

abused, neglected, damaged, or altered/modified

from that of original manufactured specifications.

PERSONAL INJURY POTENTIAL

The ice machine head section contains refrigerant

charge. Installation and brazing of the line sets must

be performed by a properly trained refrigeration

technician aware of the dangers of dealing with

refrigerant charged equipment. The technician

must also be U.S. Government Environmental

Protection Agency (EPA) certified in proper

refrigerant handling and servicing procedures.

Page 5

Table of Contents

General Information

How to Read a Model Number..............................1

Ice Cube Sizes................ ... ... ................................1

Model/Serial Number Location.............................. 2

Ice Machine Warranty Information ........................2

Owner Warranty Registration Card .................. 2

Warranty Coverage.......................................... 3

Installation

Location of Ice Machine........................................ 5

Ice Machine Head Section Clearance

Requirements........................................................ 5

Stacking Two Ice Machines on a

Single Storage Bin ................................................6

Calculating Remote Condenser

Installation Distances........................................ 7

Removal from Service/Winterization

General ...............................................................11

Self-Contained Air-Cooled Ice Machines ............ 11

Water-Cooled Ice Machines................................11

Remote Ice Machines.......................................... 12

AuCS® Accessory...............................................12

Ice Making Sequence of Operation

Self-Contained Air- and Water-Cooled................ 13

Initial Start-Up or Start-Up After

Automatic Shut-Off......................................... 13

Freeze Sequence...........................................14

Harvest Sequence..........................................15

Automatic Shut-Off......................................... 16

Energized Parts Chart.................................... 17

Remote................................................................ 19

Initial Start-Up or Start-Up After

Automatic Shut-Off......................................... 19

Freeze Sequence...........................................20

Harvest Sequence..........................................21

Automatic Shut-Off......................................... 21

Remote Energized Parts Chart.......................22

Electrical System

Wiring Diagrams..................................................25

Wiring Diagram Legend..................................25

Page 6

Q200/Q280/Q320 - Self Contained -

1 Phase With Terminal Board.........................26

Q280/Q370 - Self Contained -

1 Phase Without Terminal Board....................27

Q320 - Self Contained -

1 Phase Without Terminal Board....................28

Q420/Q450/Q600/Q800/Q1000 - Self

Contained-

1 Phase With Terminal Board.........................29

Q420/Q450/Q600/Q800/Q1000 - Self

Contained-

1 Phase Without Terminal Board....................30

Q800/Q1000 - Self Contained -

3 Phase With Terminal Board.........................31

Q800/Q1000 - Self Contained -

3 Phase Without Terminal Board....................32

Q1300/Q1800 - Self Contained -

1 Phase With Terminal Board.........................33

Q1300/Q1600/Q1800 - Self Contained -

1 Phase Without Terminal Board....................34

Q1300/Q1800 - Self Contained -

3 Phase With Terminal Board.........................35

Q1300/Q1600/Q1800 - Self Contained -

3 Phase Without Terminal Board....................36

Q450/Q600/Q800/Q1000 - Remote -

1 Phase With Terminal Board.........................37

Q450/Q600/Q800/Q1000 - Remote -

1 Phase Without Terminal Board....................38

Q800/Q1000 -Remote -

3 Phase With Terminal Board.........................39

Q800/Q1000 - Remote -

3 Phase Without Terminal Board....................40

Q1300/Q1800 - Remote -

1 Phase With Terminal Board.........................41

Q1300/Q1600/Q1800 - Remote -

1 Phase Without Terminal Board....................42

Q1300/Q1800 - Remote -

3 Phase With Terminal Board.........................43

Q1300/Q1600/Q1800 - Remote -

3 Phase Without Terminal Board....................44

Component Specifications and

Diagnostics..........................................................45

General...........................................................45

Safety Limits...................................................45

Inputs..............................................................45

Page 7

Main Fuse.......................................................46

Bin Switch.......................................................47

Water Curtain Removal Notes........................ 49

ICE/OFF/CLEAN Toggle Switch..................... 50

Ice Thickness Probe (Harvest Initiation)......... 51

Ice Thickness Probe Diagnostics................... 53

Diagnosing Ice Thickness Control Circuitry.... 54

Water Level Control Circuitry..........................56

Diagnosing an Ice Machine Head Section

that Will Not Run............................................. 63

Compressor Electrical Diagnostics................. 64

Diagnosing Capacitors ...................................66

Refrigeration System

Refrigeration System Diagnostics....................... 71

Before Beginning Service............................... 71

Ice Production Check .....................................72

Installation/Visual Inspection Checklist........... 73

Water System Checklist.................................74

Ice Formation Pattern.....................................75

Safety Limits................................................... 77

Analyzing Discharge Pressure.......................85

Analyzing Suction Pressure............................88

Single Expansion Valve Ice Machines -

Comparing Evaporator Inlet and

Outlet Temperatures....................................... 92

Discharge Line Temperature Analysis............ 96

How to Use the Refrigeration System

Operational Analysis Tables........................... 98

Refrigeration System Operational Analysis

Tables........................................................... 101

Pressure Control Specifications

and Diagnostics.................................................108

Harvest Pressure Regulating (HPR) System

Remotes Only...............................................108

Headmaster Control Valve ...........................112

Fan Cycle Control

(Self-Contained Air-Cooled Models Only) .... 115

High Pressure Cutout (HPCO) Control......... 116

Refrigeration Tubing Schematics......................117

Self-Contained Air- or

Water -Cooled Models.................................. 117

Remote Models ............................................118

Page 8

Cycle Times/24-Hour Ice Production/

Refrigerant Pressure Charts..............................119

Q200 Series

Self-Contained Air-Cooled......................... 120

Self-Contained Water-Cooled....................121

Q280 Series

Self-Contained Air-Cooled......................... 122

Self-Contained Water-Cooled....................123

Q320 Series

Self-Contained Air-Cooled......................... 124

Self-Contained Water-Cooled....................125

Q370 Series

Self-Contained Air-Cooled......................... 126

Self-Contained Water-Cooled....................127

Q420/450 Series

Self-Contained Air-Cooled......................... 128

Self-Contained Water-Cooled....................129

Remote......................................................130

Q600 Series

Self-Contained Air-Cooled......................... 131

Self-Contained Water-Cooled....................132

Remote......................................................133

Q800 Series

Self-Contained Air-Cooled......................... 134

Self-Contained Water-Cooled....................135

Remote......................................................136

Q1000 Series

Self-Contained Air-Cooled......................... 137

Self-Contained Water-Cooled....................138

Remote......................................................139

Q1300 Series

Self-Contained Air-Cooled......................... 140

Self-Contained Water-Cooled....................141

Remote......................................................142

Q1600 Series

Self-Contained Water-Cooled....................143

Remote.....................................................144

Q1800 Series

Self-Contained Air-Cooled......................... 145

Self-Contained Water-Cooled....................146

Remote......................................................147

Page 9

Refrigerant Recovery/Evacuation......................148

Normal Self-Contained Model Procedures... 148

Normal Remote Model Procedures.............. 152

System Contamination Clean-Up...................... 157

General.........................................................157

Determining Severity Of Contamination....... 157

Cleanup Procedure ........................... .. ... ...... 159

Replacing Pressure Controls Without Removing

Refrigerant Charge.......................................162

Filter-Driers...................................................164

Total System Refrigerant Charge................. 165

Additional Refrigerant Charges.........................166

For Line Sets Between 50’ - 100’.................166

Page 10

THIS PAGE INTENTIONALLY LEFT BLANK

Page 11

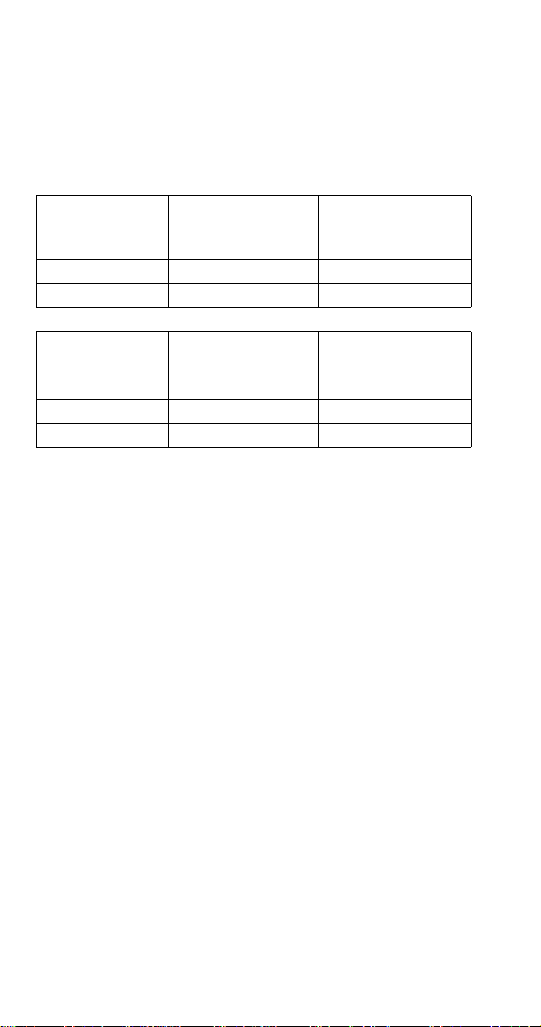

General Information

Q R 0450 A

ICE MACHINE

MODEL

ICE CUBE SIZE

R REGULAR

D DICE

Y HALF DICE

# C U BE S I Z E

0 REGULAR

1 REGULAR

2 DICE

3 DICE

4 HALF-DICE

5 HALF-DICE

CONDENSER TYPE

AIR-COOLED

WATER-COOLED

AIR-COOLED

WATER-COOLED

AIR-COOLED

WATER-COOLED

A SELF-CONTAINED AIR-COOLED

W SELF-CONTAINED WATER-COOLED

N REMOTE AIR-COOLED

9 REMOTE AIR-COOLED

CONDENSER TYPE

ICE MACHINE

SERI ES

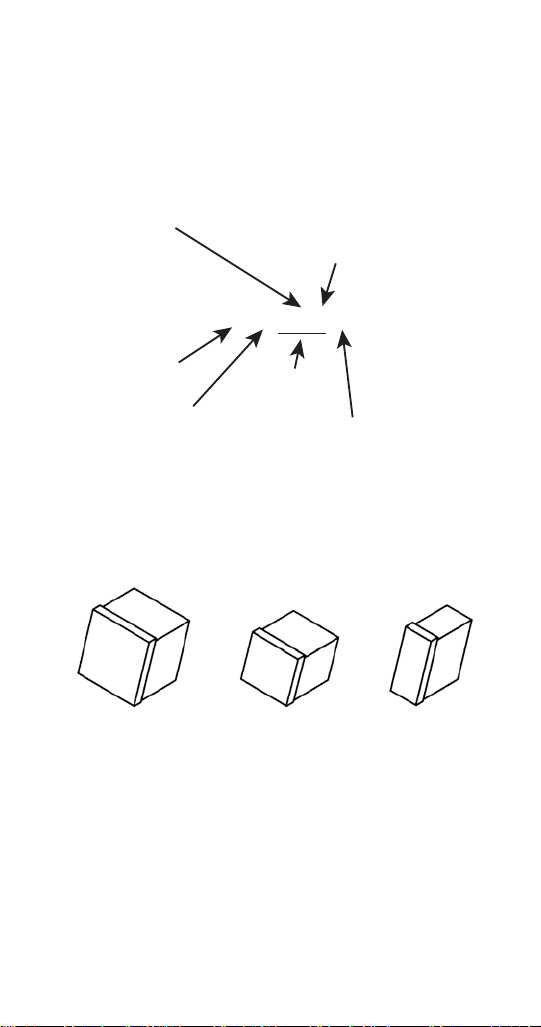

HOW TO READ A MODEL NUMBER

ICE CUBE SIZES

Regular

1-1/8" x 1-1/8" x 7/8"

2.86 x 2.86 x

2.22 cm

Dice

7/8" x 7/8" x 7/8"

2.22 x 2.22 x

2.22 cm

–1–

Half Dice

3/8" x 1-1/8" x 7/8"

0.95 x 2.86 x

2.22 cm

Page 12

MODEL/SERIAL NUMBER LOCATION

Important

These numbers are required when requesting

information from your local Manitowoc Distributor,

service representative, or Manitowoc Ice, Inc. The

model and serial number are listed on the OWNER

WARRANTY REGISTRATION CARD. They are also

listed on the MODEL/SERIAL NUMBER DECAL

affixed to the ice machine.

ICE MACHINE WARRANTY INFORMATION

Owner Warranty Registration Card

Warranty coverage begins the day the ice machine is

installed.

Complete and mail the OWNER WARRANTY

REGISTRATION CARD as soon as possible to

validate the installation date.

If the OWNER WARRANTY REGISTRA TION CARD is

not returned, Manitowoc will use the date of sale to the

Manitowoc Distributor as the first day of warranty

coverage for your new ice machine.

–2–

Page 13

Warranty Coverage

Important

GENERAL

The following Warranty outline is provided for your

convenience. For a detailed explanation, read the

warranty bond shipped with each product.

Contact your local Manitowoc representative or

Manitowoc Ice, Inc. if you need further warranty

information.

This product is intended exclusively for commercial

application. No warranty is extended for personal,

family, or household purposes.

PARTS

1. Manitowoc warrants the ice machine against

defects in materials and workmanship, under

normal use and service for three (3) years from the

date of original installation.

2. The evaporator and compressor are covered by an

additional two (2) year (five years total) warranty

beginning on the date of the original installation.

LABOR

1. Labor required to repair or replace defective

components is covered for three (3) years from the

date of original installation.

2. The evaporator is covered by an additional

two (2) year (five years total) labor warranty

beginning on the date of the original installation.

EXCLUSIONS

The following items are not included in the ice

machine’s warranty coverage:

1. Normal maintenance, adjustments and cleaning as

outlined in this manual.

2. Repairs due to unauthorized modifications to the

ice machine or use of non-standard parts without

prior written approval from Manitowoc Ice, Inc.

–3–

Page 14

3. Damage caused by improper installation of the ice

machine, electrical supply, water supply or

drainage, or damage caused by floods, storms, or

other acts of God.

4. Premium labor rates due to holidays, overtime, etc.;

travel time; flat rate service call charges; mileage

and miscellaneous tools and material charges not

listed on the payment schedule. Additional labor

charges resulting from the inaccessibility of

equipment are also excluded.

5. Parts or assemblies subjected to misuse, abuse,

neglect or accidents.

6. Damage or problems caused by installation,

cleaning and/or maintenance procedures

inconsistent with the technical instructions provided

in this manual.

This product is intended exclusively for commercial

application. No warranty is extended for personal,

family, or household purposes.

AUTHORIZED WARRANTY SERVICE

To comply with the provisions of the warranty, a

refrigeration service company qualified and authorized

by your Manitowoc Distributor, or a Contracted Service

Representative must perform the warranty repair.

NOTE: If the dealer you purchased the ice machine

from is not authorized to perform warranty service,

contact your Manitowoc Distributor or Manitowoc Ice,

Inc. for the name of the nearest authorized service

representative.

SERVICE CALLS

Normal maintenance, adjustments and cleaning as

outlined in this manual are not covered by the

warranty. If you have followed the procedures listed in

this manual, and the ice machine still does not perform

properly, call your Local Distributor or the Service

Department at Manitowoc Ice, Inc.

–4–

Page 15

Installation

LOCATION OF ICE MACHINE

The location selected for the ice machine head section

must meet the following criteria. If any of these criteria

are not met, select another location.

The location must be free of airborne and other

contaminants.

The air temperature must be at least 35°F (1.6°C),

but must not exceed 110°F (43.4°C).

The location must not be near heat-generating

equipment or in direct sunlight.

The location must not obstruct air flow through or

around the ice machine. Refer to chart below for

clearance requirements.

The ice machine must be protected if it will be

subjected to temperatures below 32°F (0°C). Failure

caused by exposure to freezing temperatures is not

covered by the warranty. See “Removal from

Service/Winterization”

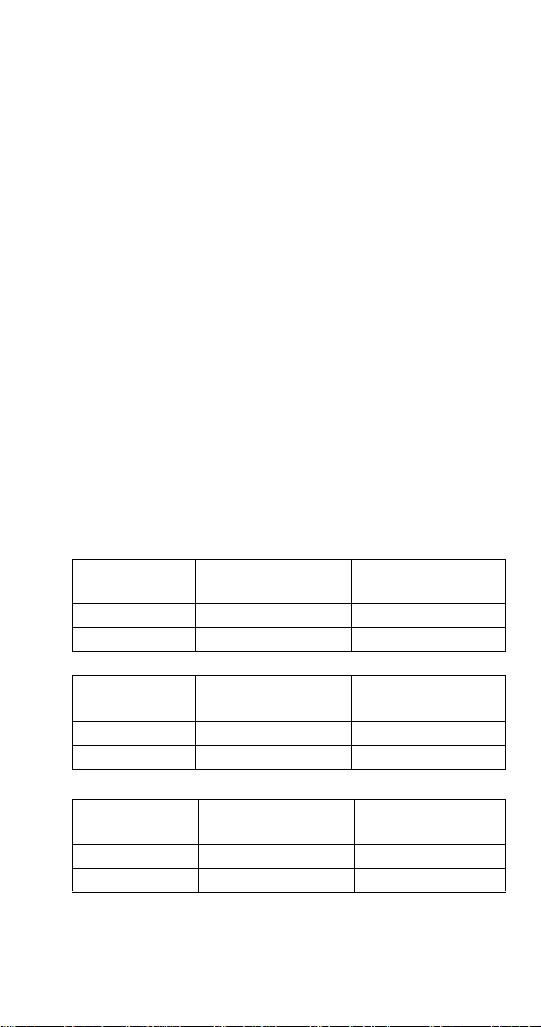

ICE MACHINE HEAD SECTION CLEARANCE

REQUIREMENTS

Q370

Top/Sides 12" (30.5 cm) 5" (12.7 cm)

Back 5" (12.7 cm) 5" (12.7 cm)

Self-Contained

Air-Cooled

Water-Cooled

Q1300 Q1600

Q1800

Top/Sides 24" (61 cm) 8" (20.3 cm)

Back 12" (30.5 cm) 5" (12.7 cm)

All other

Q models

Top/Sides 8" (20.3 cm) 5" (12.7 cm)

Back 5" (12.7 cm) 5" (12.7 cm)

Q1600 is not available as an air-cooled model.

Self-Contained

Air-Cooled

Self-Contained

Air-Cooled

–5–

Water-Cooled

and Remote

Water-Cooled

and Remote

Page 16

STACKING TWO ICE MACHINES ON A

SINGLE STORAGE BIN

A stacking kit is required for stacking two ice

machines. Installation instructions are supplied with

the stacking kit.

Q450/Q600/

Q800/Q1000

Top/Sides 16" (40.64 cm) 5" (12.70 cm)

Back 5" (12.70 cm) 5" (12.70 cm)

Q1300

Q1600

Q1800

Top/Sides 48" (121.92 cm) 24" (60.96 cm)

Back 12" (30.48 cm) 12" (30.48 cm)

Q1600 is not available as an air-cooled model.

Stacked

Self-Contained

Air-Cooled

Stacked

Self-Contained

Air-Cooled

Stacked

Water-Cooled and

Remote

Stacked

Water-Cooled and

Remote

–6–

Page 17

Calculating Remote Condenser

!

Caution

Installation Distances

LINE SET LENGTH

The maximum length is 100' (30.5 m).

The ice machine compressor must have the proper oil

return. The receiver is designed to hold a charge

sufficient to operate the ice machine in ambient

temperatures between -20°F (-28.9°C) and 120°F

(49°C), with line set lengths of up to 100' (30.5 m).

LINE SET RISE/DROP

The maximum rise is 35' (10.7 m).

The maximum drop is 15' (4.5 m).

If a line set has a rise followed by a drop, another

rise cannot be made. Likewise, if a line set has a

drop followed by a rise, another drop cannot be

made.

–7–

Page 18

CALCULATED LINE SET DISTANCE

The maximum calculated distance is 150' (45.7 m).

Line set rises, drops, horizontal runs (or combinations

of these) in excess of the stated maximums will

exceed compressor start-up and design limits. This will

cause poor oil return to the compressor.

Make the following calculations to make sure the line

set layout is within specifications.

1. Insert the measured rise into the formula below.

Multiply by 1.7 to get the calculated rise.

(Example: A condenser located 10 feet above the

ice machine has a calculated rise of 17 feet.)

2. Insert the measured drop into the formula below.

Multiply by 6.6 to get the calculated drop.

(Example. A condenser located 10 feet below the

ice machine has a calculated drop of 66 feet.)

3. Insert the measured horizontal distance into the

formula below. No calculation is necessary.

4. Add together the calculated rise, calculated drop,

and horizontal distance to get the total

calculated distance. If this total exceeds 150'

(45.7 m), move the condenser to a new location

and perform the calculations again.

MAXIMUM LINE SET DISTANCE FORMULA

Step 1.

Measured Rise ____ X 1.7 = ______Calculated Rise

(35 ft. Max)

Step 2.

Measured Drop ____ X 6.6 = ______Calculated Drop

(15 ft. Max.)

Step 3.

Measured Horizontal Distance = _________Horizontal

(100 ft. Max.) Distance

Step 4.

Total Calculated Distance = ________Total Calculated

(150 ft. Max.) Distance

–8–

Page 19

THIS PAGE INTENTIONALLY LEFT BLANK

–9–

Page 20

THIS PAGE INTENTIONALLY LEFT BLANK

–10–

Page 21

Removal from Service/Winterization

!

Caution

GENERAL

Special precautions must be taken if the ice machine is

to be removed from service for an extended period of

time or exposed to ambient temperatures of 32°F

(0°C) or below.

If water is allowed to remain in the ice machine in

freezing temperatures, severe damage to some

components could result. Damage of this nature is

not covered by the warranty.

Follow the applicable procedure below.

SELF-CONTAINED AIR-COOLED ICE MACHINES

1. Disconnect the electric power at the circuit breaker

or the electric service switch.

2. Turn off the water supply.

3. Remove the water from the water trough.

4. Disconnect and drain the incoming ice-making

water line at the rear of the ice machine.

5. Blow compressed air in both the incoming water

and the drain openings in the rear of the ice

machine until no more water comes out of the inlet

water lines or the drain.

6. Make sure water is not trapped in any of the water

lines, drain lines, distribution tubes, etc.

WATER-COOLED ICE MACHINES

1. Perform steps 1-6 under “Self-Contained AirCooled Ice Machines.”

2. Disconnect the incoming water and drain lines from

the water-cooled condenser.

–11–

Page 22

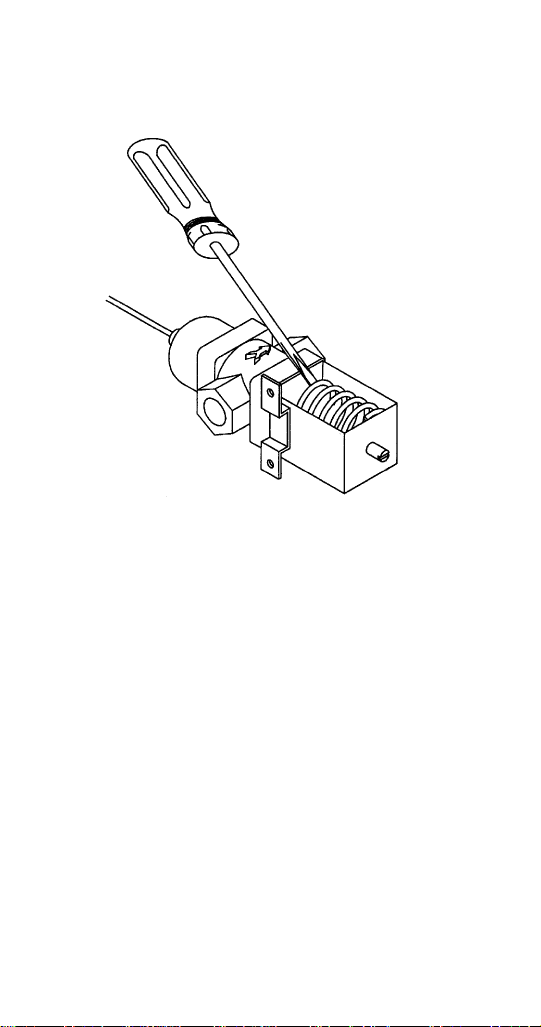

3. Insert a large screwdriver between the bottom

SV1624

spring coils of the water regulating valve. Pry

upward to open the valve.

4. Hold the valve open and blow compressed air

through the condenser until no water remains.

REMOTE ICE MACHINES

1. Move the ICE/OFF/CLEAN switch to OFF.

2. “Frontseat” (shut off) the receiver service valves.

Hang a tag on the switch as a reminder to open the

valves before restarting.

3. Perform steps 1-6 under “Self-Contained AirCooled Ice Machines.”

AUCS® ACCESSORY

Refer to the AuCS Accessory manual for

winterization of the AuCS

Accessory.

–12–

Page 23

Ice Making Sequence of Operation

SELF-CONTAINED AIR- AND WATER-COOLED

Initial Start-Up or Start-Up After

Automatic Shut-Off

1. Water Purge

Before the compressor starts, the water pump and

water dump solenoid are energized for 45 seconds to

purge the ice machine of old water. This ensures that

the ice-making cycle starts with fresh water.

The harvest valve(s) is also energized during the

water purge, although it stays on for an additional 5

seconds (50-second total on time) during the initial

refrigeration system start-up.

2. Refrigeration System Start-Up

The compressor starts after the 45 second water

purge, and it remains on throughout the entire Freeze

and Harvest Sequences. The water fill valve is

energized at the same time as the compressor. It

remains on until the water level sensor closes for 3

continuous seconds, or until a six-minute time period

has expired. The harvest valve(s) remains on for 5

seconds during initial compressor start-up and then

shuts off.

At the same time the compressor starts, the

condenser fan motor (air-cooled models) is supplied

with power throughout the entire Freeze and Harvest

Sequences. The fan motor is wired through a fan cycle

pressure control, therefore it may cycle on and off.

(The compressor and condenser fan motor are wired

through the contactor. As a result, anytime the

contactor coil is energized, the compressor and fan

motor are supplied with power.)

–13–

Page 24

Freeze Sequence

3. Prechill

The compressor is on for 30 seconds prior to water

flow to prechill the evaporator.

4. Freeze

The water pump restarts after the 30-second prechill.

An even flow of water is directed across the

evaporator and into each cube cell, where it freezes.

The water fill valve will cycle on, then off one more

time to refill the water trough.

When sufficient ice has fo rmed, the wate r flow (not the

ice) contacts the ice thickness probe. After

approximately 7 seconds of continual water contact,

the Harvest sequence is initiated. The ice machine

cannot initiate a Harvest sequence until a 6-minute

freeze lock has been surpassed.

–14–

Page 25

Harvest Sequence

5. Water Purge

The water pump continues to run, and the water dump

valve energizes for 45 seconds to purge the water in

the sump trough. The water fill valve energizes (turns

on) and de-energizes (turns off) strictly by time. The

water fill valve energizes for the last 15 seconds of the

45-second water purge. The water purge

must be at

the factory setting of 45 seconds for the fill valve to

energize during the last 15 seconds of the Water

Purge. If set at less than 45 seconds the water fill

valve does not energize during the water purge.

After the 45 second water purge, the water fill valve,

water pump and dump valve de-energize. (Refer to

“Water Purge Adjustment” for details.) The harvest

valve also opens at the beginning of the water purge to

divert hot refrigerant gas into the evaporator.

6. Harvest

The harvest valve(s) remains open and the refrigerant

gas warms the evaporator causing the cubes to slide,

as a sheet, off the evaporator and into the storage bin.

The sliding sheet of cubes swings the water curtain

out, opening the bin switch. The momentary opening

and re-closing of the bin switch terminates the harvest

sequence and returns the ice machine to the freeze

sequence (Step 3 - 4.)

–15–

Page 26

Automatic Shut-Off

7. Automatic Shut-Off

When the storage bin is full at the end of a harvest

sequence, the sheet of cubes fails to clear the water

curtain and will hold it open. After the water curtain is

held open for 7 seconds, the ice machine shuts off.

The ice machine remains off for 3 minutes before it

can automatically restart.

The ice machine remains off until enough ice has been

removed from the storage bin to allow the ice to fall

clear of the water curtain. As the water curtain swings

back to the operating position, the bin switch re-closes

and the ice machine restarts (steps 1 - 2), provided the

3 minute delay period is complete.

–16–

Page 27

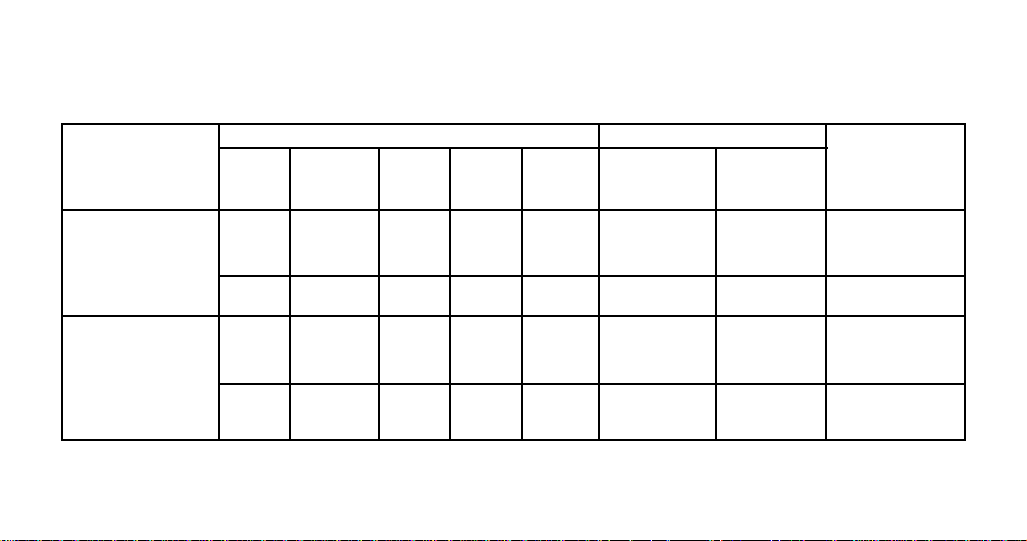

Ice Making

Sequence of

Operation

Initial Start-Up

1. Water Purge

–17–

2. Refrigeration

System Start-up

Freeze Sequence

3. Prechill

4. Freeze On

Energized Parts Chart

Control Board Relays Contactor

1

Water

Pump

On Off On On Off Off Off

Off On On Off On On

Off

2

Water Fill

Valve

May Cycle

On/Off

during first

45 sec.

Cycles

On then Off

one more

time

3

Harvest

Valve

4

Water

Dump

Valve

5

Contactor

Coil

Compressor

Off Off On On

Off Off On On

5A

Condenser

Fan Motor

May Cycle

On/Off

May Cycle

On/Off

May Cycle

On/Off

5B

Length

of Time

45 Seconds

5 Seconds

30 Seconds

Unit 7 Sec.

Water Contact

w/Ice Thickness Probe

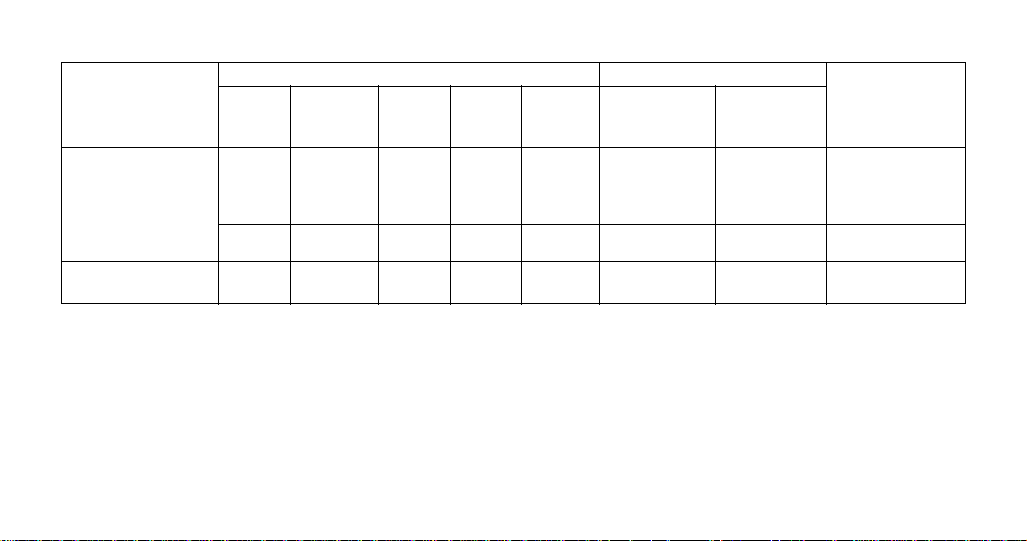

Page 28

Energized Parts Chart (Continued)

Ice Making

Sequence of

Operation

1

Water

Pump

Harvest Sequence

5. Water Purge

–18–

6. Harvest Off Off On Off On On

7. Automatic

Shut-Off

On

Off Off Off Off Off Off Off

Control Board Relays Contactor

2

Water Fill

Valve

30 sec.

Off

15 sec.

On

3

Harvest

Valve

4

Water

Dump

Valve

5

Contactor

Coil

On On On On

5A

Compressor

5B

Condenser

Fan Motor

May Cycle

On/Off

May Cycle

On/Off

Length

of Time

Factory

Set at

45 Seconds

Bin Switch

Activation

Until Bin Switch

Re-closes

Page 29

REMOTE

Initial Start-Up or Start-Up After

Automatic Shut-Off

1. Water Purge

Before the compressor starts, the water pump and

water dump solenoid are energized for 45 seconds, to

completely purge the ice machine of old water. This

feature ensures that the ice making cycle starts with

fresh water.

The harvest valve and harvest pressure regulating

(HPR) solenoid valves also energize during water

purge, although they stay on for an additional 5

seconds (50 seconds total on time) during the initial

refrigeration system start-up.

2. Refrigeration System Start-Up

The compressor and liquid line solenoid valve

energize after the 45 second water purge and remain

on throughout the entire Freeze and Harvest

Sequences. The water fill valve is energized at the

same time as the compressor. It remains on until the

water level sensor closes for 3 continuous seconds, or

until a six-minute time period has expired. The harvest

valve and HPR solenoid valves remain on for 5

seconds during initial compressor start-up and then

shut off.

The remote condenser fan motor starts at the same

time the compressor starts and remains on throughout

the entire Freeze and Harvest Sequences.

–19–

Page 30

Freeze Sequence

3. Prechill

The compressor is on for 30 seconds prior to water

flow, to prechill the evaporator.

4. Freeze

The water pump restarts after the 30 second prechill.

An even flow of water is directed across the

evaporator and into each cube cell, where it freezes.

The water fill valve will cycle on and then off one more

time to refill the water trough.

When sufficient ice has fo rmed, the wate r flow (not the

ice) contacts the ice thickness probe. After

approximately 7 seconds of continual water contact,

the harvest sequence is initiated. The ice machine

cannot initiate a harvest sequence until a 6 minute

freeze lock has been surpassed.

–20–

Page 31

Harvest Sequence

5. Water Purge

The water pump continues to run, and the water dump

valve energizes for 45 seconds to purge the water in

the sump trough. The water fill valve energizes (turns

on) and de-energizes (turns off) strictly by time. The

water fill valve energizes for the last 15 seconds of the

45-second water purge. The water purge

must be at

the factory setting of 45 seconds for the fill valve to

energize during the last 15 seconds of the Water

Purge. If set at less than 45 seconds the water fill

valve does not energize during the water purge.

After the 45 second water purge, the water fill valve,

water pump and dump valve de-energize. (Refer to

“Water Purge Adjustment”) The harvest valve(s) and

HPR solenoid valve also open at the beginning of the

water purge.

6. Harvest

The HPR valve and the harvest valve(s) remain open

and the refrigerant gas warms the evaporator causing

the cubes to slide, as a sheet, off the evaporator and

into the storage bin. The sliding sheet of cubes swings

the water curtain out, opening the bin switch. The

momentary opening and re-closing of the bin switch

terminates the harvest sequence and returns the ice

machine to the freeze sequence (Step 3 - 4.)

Automatic Shut-Off

7. Automatic Shut-Off

When the storage bin is full at the end of a harvest

sequence, the sheet of cubes fails to clear the water

curtain and will hold it open. After the water curtain is

held open for 7 seconds, the ice machine shuts off.

The ice machine remains off for 3 minutes before it

can automatically restart.

The ice machine remains off until enough ice has been

removed from the storage bin to allow the ice to drop

clear of the water curtain. As the water curtain swings

back to the operating position, the bin switch re-closes

and the ice machine restarts (steps 1 - 2) provided the

3 minute delay period is complete.

–21–

Page 32

Ice Making

Sequence of

Operation

Initial Start-Up

–22–

1. Water Purge

2. Refrigeration

System Start-up

Freeze Sequence

3. Prechill

4. Freeze On

Remote Energized Parts Chart

Control Board Relays Contactor

1

Water

Pump

On Off On On Off Off Off

Off On On Off On On On

Off

2

Water Fill

Valve

May Cycle

On/Off

during first

45 sec.

Cycles

On then Off

one more

time

3

a. Harvest

Valve(s)

b. HPR

Solenoid

4

Water

Dump

Valve

5

a. Contactor

Coil

b. Liquid Line

Solenoid

5A

Compressor5BCondenser

Off Off On On On

Off Off On On On

Fan Motor

Length

of Time

45 Seconds

5 Seconds

30 Seconds

Unit 7 Sec.

Water Contact

w/Ice Thickness

Probe

Page 33

Remote Energized Parts Chart (Continued)

Ice Making

Sequence of

Operation

1

Water

Pump

Harvest Sequence

5. Water Purge

–23–

On

6. Harvest Off Off On Off On On On

7. Automatic

Shut-Off

Off Off Off Off Off Off Off

Control Board Relays Contactor

2

Water Fill

Valve

30 sec.

Off

15 sec.

On

3

a. Harvest

Valve(s)

b. HPR

Solenoid

4

Water

Dump

Valve

5

a. Contactor

Coil

b. Liquid Line

Solenoid

5A

Compressor5BCondenser

On On On On On

Fan Motor

Length

of Time

Factory

Set at

45 Seconds

Bin Switch

Activation

Until Bin

Switch

Recloses

Page 34

THIS PAGE INTENTIONALLY LEFT BLANK

–24–

Page 35

Electrical System

!

Warning

WIRING DIAGRAMS

The following pages contain electrical wiring diagrams.

Be sure you are referring to the correct diagram for the

ice machine which you are servicing.

Always disconnect power before working on

electrical circuitry.

Wiring Diagram Legend

The following symbols are used on all of the wiring

diagrams:

* Internal Compressor Overload

(Some models have external

compressor overloads)

** Fan Motor Run Capacitor

(Some models do not incorporate fan

motor run capacitor)

TB Terminal Board Connection

(Terminal board numbers are printed

on the actual terminal board)

( ) Wire Number Designation

(The number is marked at each end of

the wire)

—>>— Multi-Pin Connection

(Electrical Box Side) —>>—

(Compressor Compartment Side)

–25–

Page 36

Q200/Q280/Q320 - Self Contained -

(20)

C

S

R

TB31

TB37

TB32

TB35

L1

TB34

(53)

TB33

(52)

(51)

(48)

(50)

(49)

(47)

(55)

(61)

(77)

(76)

(60)

(98)

(57)

(74)

(58)

(59)

(73)

(99)

(85) (86)

1F

3

1

2

4

FUSE (7A)

TRANS.

(56)

ICE THICKNESS PROBE

(75)

HARVEST

SOLENOID

DUMP

SOLENOID

(81)

(80)

WATER

PUMP

TB30

TB30

TB30

TB30

CONTACTOR

COIL

HIGH PRES

CUTOUT

BIN SWITCH LIGHT

HARVEST LIGHT/

SAFETY LIMIT CODE LIGHT

TB35

TB30

CONTACTOR

CONTACTS

L1

(42)

COMPRESSOR

FAN CYCLE CONTROL

FAN MOTOR

(AIR COOLED ONLY)

RUN CAPACITOR**

L2 (N)

SEE SERIAL PLATE FOR VOLTAGE

CAUTION: DISCONNECT POWER BEFORE WORKING

ON ELECTRICAL CIRCUITRY.

DIAGRAM SHOWN DURING FREEZE CYCLE

TERMINATES AT

PIN CONNECTION

PTCR

TB30

TB30

LOW D.C.

VOLTAGE

PLUG

(64)

(63)

BIN SWITCH

(62)

(66)

(65)

(69)

(67)

(68)

TOGGLE SWITCH

68

67

69

66

62

ICE

OFF

CLEAN

(66)

(62)

VIEW FOR WIRING

INTERNAL WORKING

VIEW

*OVERLOAD

CLEAN LIGHT

1C

WATER LEVEL LIGHT

WATER LEVEL PROBE

5

(21) (22)

WATER

VALVE

1G

NOT USED

SV1654

1 Phase With Terminal Board

–26–

Page 37

Q280/Q370 - Self Contained -

5

2

1

4

START

CAPACITOR

POTENTIAL

RELAY

C

S

R

COMPRESSOR

TERMINAL LAYOUT

VIEWED FROM END

OF COMPRESSOR

CAUTION: DISCONNECT POWER BEFORE WORKING

ON ELECTRICAL CIRCUITRY.

DIAGRAM SHOWN DURING FREEZE CYCLE

SAFETY LIMIT CODE LIGHT

HARVEST LIGHT/

WATER LEVEL

CLEAN LIGHT

BIN SWITCH LIGHT

CLEAN

OFF

ICE

(68)

(69)

(62)

(49)

(47)

COMPRESSOR

OVERLOAD INTERNAL

{230V 50/60 HZ}

R

C

S

(86)(85)

(51)

(48)

CONTACTOR

CONTACTS

(42)

L1

FAN CYCLE CONTROL

RUN CAPACITOR**

FAN MOTOR

(AIR COOLED ONLY)

(50)

62

66

VIEW FOR

WIRING

67

68

69

SEE SERIAL PLATE FOR VOLTAGE

L2 (N)

(74)

TERMINATES AT

PIN CONNECTION

(59)

(58)

(56)

(98)

DUMP

SOLENOID

(57)

(81)

(99)

(75)

(80)

(76)

HARVEST

SOLENOID

(77)

WATER

VALVE

(21)

(22)

(60)

(61)

(55)

HIGH PRES

CUTOUT

WATER LEVEL PROBE

NOT USED

ICE THICKNESS PROBE

LOW D.C.

VOLTAGE

PLUG

1G

1F

1C

BIN SWITCH

(64)

(66)

(66)

(67)

(63)

(62)

CONTACTOR

COIL

WATER

PUMP

FUSE (7A)

TRANS.

5

3

1

4

2

(65)

(89)

(88)

(20)

(46)

(44)

(45)

SV3018

1 Phase Without Terminal Board

–27–

Page 38

Q320 - Self Contained -

SV2070

1 Phase Without Terminal Board

CAUTION: DISCONNECT POWER BEFORE WORKING

ON ELECTRICAL CIRCUITRY.

L1

(89)

HIGH PRES

CUTOUT

(88)

(42)

CONTACTOR

CONTACTS

L1

DIAGRAM SHOWN DURING FREEZE CYCLE

(55)

ICE THICKNESS PROBE

WATER LEVEL PROBE

NOT USED

BIN SWITCH

(64)

*OVERLOAD

(48)

(85)

(51)

FAN CYCLE CONTROL

(20)

(61)

2

4

3

1

5

TRANS.

FUSE (7A)

1C

1F

1G

LOW D.C.

PLUG

(62)

(63)

(65)

(67)

(66)

COMPRESSOR

S

R

C

(86)

TOGGLE SWITCH

ICE

(68)

(69)

OFF

CLEAN

(62)

(49)

OVERLOAD

(48)

(60)

CLEAN LIGHT

WATER LEVEL

BIN SWITCH LIGHT

HARVEST LIGHT/

SAFETY LIMIT CODE LIGHT

(47)

FAN MOTOR

(AIR COOLED ONLY)

RUN CAPACITOR**

COMPRESSOR

SEE SERIAL PLATE FOR VOLTAGE

(21)

WATER

VALVE

(77)

HARVEST

SOLENOID

(76)

DUMP

SOLENOID

(57)

(98)

TERMINATES AT

(59)

PIN CONNECTION

(58)

(56)

VIEW FOR WIRING

68

66

67

62

69

PTCR

(49)

(47)

(22)

(80)

(81)

(99)

WATER

PUMP

CONTACTOR

COIL

(74)

(50)

RUN CAPACITOR

(46)

PTCR

L2 (N)

(75)

R

R

(50)

(45)

–28–

Page 39

Q420/Q450/Q600/Q800/Q1000 - Self Contained-

R

R

C

S

R

TB31

TB37

TB32

L1

TB34

*OVERLOAD

(53)

TB33

(52)

(51)

(48)

(45)

(46)

(50)

(49)

(47)

(55)

(61)

(21)

(76)

(60)

(98)

(57)

(74)

(58)

(59)

(73)

(99)

(85) (86)

1F

1C

4

1

3

5

FUSE (7A)

TRANS.

(56)

ICE THICKNESS PROBE

(75)

HARVEST

SOLENOID

DUMP

SOLENOID

(81)

(22)

WATER

PUMP

TB30

TB30

TB30

TB30

CONTACTOR

COIL

HIGH PRES

CUTOUT

BIN SWITCH LIGHT

HARVEST LIGHT/

SAFETY LIMIT CODE LIGHT

LOW D.C.

VOLTAGE

PLUG

TB30

CONTACTOR

CONTACTS

L1

(42)

COMPRESSOR

RUN CAPACITOR

FAN CYCLE CONTROL

FAN MOTOR

(AIR COOLED ONLY)

RUN CAPACITOR**

L2 (N)

SEE SERIAL PLATE FOR VOLTAGE

CAUTION: DISCONNECT POWER BEFORE WORKING

ON ELECTRICAL CIRCUITRY.

DIAGRAM SHOWN DURING FREEZE CYCLE

TERMINATES AT

PIN CONNECTION

PTCR

TB30

(64)

(63)

BIN SWITCH

(62)

(65)

(69)

(67)

(68)

TOGGLE SWITCH

68

67

69

66

62

ICE

OFF

CLEAN

(66)

(62)

VIEW FOR WIRING

INTERNAL WORKING

VIEW

CLEAN LIGHT

WATER LEVEL LIGHT

WATER LEVEL PROBE

(77)

(80)

WATER

VALVE

2

1G

NOT USED

(20)

SV1646

1 Phase With Terminal Board

–29–

Page 40

Q420/Q450/Q600/Q800/Q1000 - Self Contained-

C

S

R

L1

*OVERLOAD

(51)

(48)

(45)

(46)

(49)

(50)

(50)

(47)

(55)

(61)

(20) (21)

(76)

(60)

(98)

(57)

(74)

(58)

(59)

(99)

(85)

(86)

1F

1C

4

2

1

5

FUSE (7A)

TRANS.

(56)

ICE THICKNESS PROBE

(75)

HARVEST

SOLENOID

DUMP

SOLENOID

(81)

(22)

WATER

PUMP

CONTACTOR

COIL

HIGH PRES

CUTOUT

BIN SWITCH LIGHT

HARVEST LIGHT/

SAFETY LIMIT CODE LIGHT

LOW D.C.

VOLTAGE

PLUG

CONTACTOR

CONTACTS

L1

(42)

COMPRESSOR

FAN CYCLE CONTROL

FAN MOTOR

(AIR COOLED ONLY)

RUN CAPACITOR**

L2 (N)

SEE SERIAL PLATE FOR VOLTAGE

CAUTION: DISCONNECT POWER BEFORE WORKING

ON ELECTRICAL CIRCUITRY.

DIAGRAM SHOWN DURING FREEZE CYCLE

TERMINATES AT

PIN CONNECTION

PTCR

(64)

(63)

BIN SWITCH

(62)

(66)

(65)

(69)

(67)

(68)

TOGGLE SWITCH

68

67

69

66

62

ICE

OFF

CLEAN

(62)

VIEW FOR WIRING

CLEAN LIGHT

WATER LEVEL

WATER LEVEL PROBE

(77)

(80)

WATER

VALVE

3

1G

NOT USED

(89)

(88)

SV2071

1 Phase Without Terminal Board

–30–

Page 41

Q800/Q1000 - Self Contained -

TB31

TB37

(77)

(76)

(98)

(74)

(59)

(73)

(99)

(85)

(86)

(75)

HARVEST

SOLENOID

DUMP

SOLENOID

(81)

(80)

WATER

PUMP

TB30

TB30

TB30

CONTACTOR

COIL

TB30

FAN CYCLE CONTROL

FAN MOTOR

(AIR COOLED ONLY)

RUN CAPACITOR**

SEE SERIAL PLATE FOR VOLTAGE

CAUTION: DISCONNECT POWER BEFORE WORKING

ON ELECTRICAL CIRCUITRY.

DIAGRAM SHOWN DURING FREEZE CYCLE

TERMINATES AT

PIN CONNECTION

(61)

(60)

(57)

(58)

1F

1C

4

1

3

5

FUSE (7A)

TRANS.

(56)

ICE THICKNESS PROBE

TB30

BIN SWITCH LIGHT

HARVEST LIGHT/

SAFETY LIMIT CODE LIGHT

LOW D.C.

VOLTAGE

PLUG

TB32

TB35

TB34

(53)

TB33

(52)

HIGH PRES

CUTOUT

L1

(96)

(42)

COMPRESSOR

L3

L2

L1

L2

TB35

T2

T3

T1

(55)

TB30

(64)

(63)

BIN SWITCH

(62)

(66)

(65)

(69)

(67)

(68)

TOGGLE SWITCH

68

67

69

66

62

ICE

OFF

CLEAN

(66)

(62)

VIEW FOR WIRING

INTERNAL WORKING

VIEW

CLEAN LIGHT

WATER LEVEL LIGHT

(21)

(22)

WATER

VALVE

WATER LEVEL PROBE

2

1G

NOT USED

(20)

SV1647a

3 Phase With Terminal Board

–31–

Page 42

Q800/Q1000 - Self Contained -

L1L2L3

(51)

(55)

(61)

(20) (21)

(76)

(60)

(98)

(57)

(74)

(58)

(59)

(99)

(85)

(86)

1F

1C

4

2

1

5

FUSE (7A)

TRANS.

(56)

ICE THICKNESS PROBE

(75)

HARVEST

SOLENOID

DUMP

SOLENOID

(81)

(22)

WATER

PUMP

CONTACTOR

COIL

HIGH PRES

CUTOUT

BIN SWITCH LIGHT

HARVEST LIGHT/

SAFETY LIMIT CODE LIGHT

LOW D.C.

VOLTAGE

PLUG

CONTACTOR

CONTACTS

L1

L2

L3

T2

T1T3

FAN CYCLE CONTROL

FAN MOTOR

(AIR COOLED ONLY)

RUN CAPACITOR**

SEE SERIAL PLATE FOR VOLTAGE

CAUTION: DISCONNECT POWER BEFORE WORKING

ON ELECTRICAL CIRCUITRY.

DIAGRAM SHOWN DURING FREEZE CYCLE

TERMINATES AT

PIN CONNECTION

(64)

(63)

BIN SWITCH

(62)

(66)

(65)

(69)

(67)

(68)

TOGGLE SWITCH

68

67

69

66

62

ICE

OFF

CLEAN

(62)

VIEW FOR WIRING

CLEAN LIGHT

WATER LEVEL

WATER LEVEL PROBE

(77)

(80)

WATER

VALVE

3

1G

NOT USED

(89)

(88)

(42)

SV2072

3 Phase Without Terminal Board

–32–

Page 43

Q1300/Q1800 - Self Contained -

1 Phase With Terminal Board

L1

TB35

HIGH PRES

CUTOUT

ICE THICKNESS PROBE

WATER LEVEL PROBE

TB35

TB35

(42)

CONTACTOR

CONTACTS

L1

CAUTION: DISCONNECT POWER BEFORE WORKING

ON ELECTRICAL CIRCUITRY.

DIAGRAM SHOWN DURING FREEZE CYCLE

(55)

TB32

2

4

1

3

5

TRANS.

FUSE (7A)

1C

1F

LOW D.C.

1G

AUCS DISPENSE TIME

(64)

BIN SWITCH

(66)

(95)

*OVERLOAD

(48)

(51)

(52)

TB33

VOLTAGE

PLUG

(62)

(63)

(65)

(67)

(66)

CRANKCASE HEATER

COMPRESSOR

R

S

C

(85) (86)

FAN CYCLE CONTROL

(20)

(61)

(60)

CLEAN LIGHT

WATER LEVEL LIGHT

BIN SWITCH LIGHT

HARVEST LIGHT/

SAFETY LIMIT CODE LIGHT

TOGGLE SWITCH

(68)

ICE

(69)

OFF

CLEAN

(62)

(49)

(47)

(53)

TB34

RUN CAPACITOR**

SEE SERIAL PLATE FOR VOLTAGE

(21)

RH HARVEST

SOLENOID

(88)

(77)

LH HARVEST

SOLENOID

(76)

DUMP

SOLENOID

(57)

(98)

TB31

(58)

TB37

(59)

TERMINATES AT

PIN CONNECTION

(73)

(56)

INTERNAL WORKING

VIEW

RUN CAPACITOR

R

R

(46) (50)

(45)

PTCR

(44)

FAN MOTOR

(AIR COOLED ONLY)

WATER

VALVE

(22)

(87)

(80)

(81)

(99)

WATER

PUMP

CONTACTOR

COIL

VIEW FOR WIRING

66

62

(94)

CONTACTOR

CONTACTS

L2(N)

(75)

TB30

TB30

(74)

TB30

TB30

68

67

69

TB30

(96)

TB30

L2

–33–

SV1652

Page 44

Q1300/Q1600/Q1800 - Self Contained -

C

S

R

L1

*OVERLOAD

(51)

(48)

(95)

(45)

(46)

(49)

(47)

(50)

(94)

(96)

(55)

(61)

(20) (21)

(76)

(60)

(98)

(57)

(74)

(58)

(59)

(99)

(85)

(86)

1F

1C

4

2

1

5

FUSE (7A)

TRANS.

(56)

ICE THICKNESS PROBE

(75)

HARVEST

SOLENOID

DUMP

SOLENOID

(81)

(22)

WATER

PUMP

CONTACTOR

COIL

HIGH PRES

CUTOUT

BIN SWITCH LIGHT

HARVEST LIGHT/

SAFETY LIMIT CODE LIGHT

LOW D.C.

VOLTAGE

PLUG

CONTACTOR

CONTACTS

CONTACTOR

CONTACTS

L1 L2

COMPRESSOR

CRANKCASE HEATER

RUN CAPACITOR

FAN CYCLE CONTROL

FAN MOTOR

(AIR COOLED ONLY)

RUN CAPACITOR**

L2 (N)

SEE SERIAL PLATE FOR VOLTAGE

CAUTION: DISCONNECT POWER BEFORE WORKING

ON ELECTRICAL CIRCUITRY.

DIAGRAM SHOWN DURING FREEZE CYCLE

TERMINATES AT

PIN CONNECTION

PTCR

(64)

(63)

BIN SWITCH

(62)

(66)

(65)

(69)

(67)

(68)

TOGGLE SWITCH

68

67

69

66

62

ICE

OFF

CLEAN

(62)

VIEW FOR WIRING

CLEAN LIGHT

WATER LEVEL LIGHT

WATER LEVEL PROBE

AUCS DISPENSE TIME

(77)

(80)

WATER

VALVE

3

1G

(89)

(88)

(42)

SV2075

1 Phase Without Terminal Board

–34–

Page 45

Q1300/Q1800 - Self Contained -

(20)

TB31

TB37

(77)

(76)

(98)

(74)

(59)

(73)

(99)

(85)

(86)

(75)

LH HARVEST

SOLENOID

DUMP

SOLENOID

(81)

(80)

WATER

PUMP

TB30

TB30

TB30

CONTACTOR

COIL

TB30

TB30

FAN CYCLE CONTROL

FAN MOTOR

(AIR COOLED ONLY)

RUN CAPACITOR**

SEE SERIAL PLATE FOR VOLTAGE

CAUTION: DISCONNECT POWER BEFORE WORKING

ON ELECTRICAL CIRCUITRY.

DIAGRAM SHOWN DURING FREEZE CYCLE

TERMINATES AT

PIN CONNECTION

(61)

(60)

(57)

(58)

1F

1C

4

1

3

5

FUSE (7A)

TRANS.

(56)

ICE THICKNESS PROBE

TB30

BIN SWITCH LIGHT

HARVEST LIGHT/

SAFETY LIMIT CODE LIGHT

TB32

TB35

TB34

(53)

TB33

(52)

HIGH PRES

CUTOUT

TB35

CRANKCASE HEATER

(94)

(95)

L1

(96)

(42)

COMPRESSOR

L3 L2 L1

L2L3

TB35

T2

T3

T1

(55)

LOW D.C.

VOLTAGE

PLUG

(64)

(63)

BIN SWITCH

(62)

(66)

(65)

(69)

(67)

(68)

TOGGLE SWITCH

68

67

69

66

62

ICE

OFF

CLEAN

(66)

(62)

VIEW FOR WIRING

INTERNAL WORKING

VIEW

N - 50HZ

ONLY

TB30

NOTE: WIRE (96) IS NOT USED ON 50HZ

TB30

CLEAN LIGHT

WATER LEVEL LIGHT

2

WATER

VALVE

(21)

(22)

(87)

(88)

RH HARVEST

SOLENOID

1G

AUCS DISPENSE TIME

WATER LEVEL PROBE

SV1653

3 Phase With Terminal Board

–35–

Page 46

Q1300/Q1600/Q1800 - Self Contained -

(77)

(76)

(98) (99)

(85)

(86)

(75)

LH HARVEST

SOLENOID

DUMP

SOLENOID

(81)

(80)

WATER

PUMP

CONTACTOR

COIL

FAN CYCLE CONTROL

FAN MOTOR

(AIR COOLED ONLY)

RUN CAPACITOR**

SEE SERIAL PLATE FOR VOLTAGE

CAUTION: DISCONNECT POWER BEFORE WORKING

ON ELECTRICAL CIRCUITRY.

DIAGRAM SHOWN DURING FREEZE CYCLE

TERMINATES AT

PIN CONNECTION

(61)

(60)

(57)

(59)

(58)

1F

1C

4

2

1

5

FUSE (7A)

TRANS.

(56)

ICE THICKNESS PROBE

BIN SWITCH LIGHT

HARVEST LIGHT/

SAFETY LIMIT CODE LIGHT

(51)

HIGH PRES

CUTOUT

CRANKCASE HEATER

(94)

(95)

CONTACTOR

CONTACTS

L1

(96)

COMPRESSOR

L3 L2 L1

L2

L3

T2

T3

T1

LOW D.C.

VOLTAGE

PLUG

(64)

(88)

(89) (55)

(42)

(63)

BIN SWITCH

(62)

(65)

(69)

(67)

(68)

TOGGLE SWITCH

68

67

69

66

62

ICE

OFF

CLEAN

(66)

(62)

VIEW FOR WIRING

N - 50HZ

ONLY

NOTE: WIRE (96) IS NOT USED ON 50HZ

CLEAN LIGHT

WATER LEVEL LIGHT

3

WATER

VALVE

(21)

(20)

(22)

(87)

RH HARVEST

SOLENOID

1G

AUCS DISPENSE TIME

WATER LEVEL PROBE

(88)

SV3008

3 Phase Without Terminal Board

–36–

Page 47

Q450/Q600/Q800/Q1000 - Remote -

TB31

TB37

TB32

TB35

L1

(55)

(77)

(76)

(98)

(59)

(99)

(75)

HPR

SOLENOID

(79)(78)

HARVEST

SOLENOID

DUMP

SOLENOID

(81)

(80)

WATER

PUMP

LIQUID LINE

SOLENOID

TB30

TB30

(82)

(83)

HIGH PRES

CUTOUT

REMOTE

FAN MOTOR

RUN CAPACITOR

L2 (N)

SEE SERIAL PLATE FOR VOLTAGE

CAUTION: DISCONNECT POWER BEFORE WORKING

ON ELECTRICAL CIRCUITRY.

DIAGRAM SHOWN DURING FREEZE CYCLE

REMOTE CONDENSER

TERMINATES AT

PIN CONNECTION

(F1)

(F2)

(61)

(60)

(57)

(58)

1F

1C

4

1

3

FUSE (7A)

TRANS.

(56)

ICE THICKNESS PROBE

TB30

BIN SWITCH LIGHT

HARVEST LIGHT/

SAFETY LIMIT CODE LIGHT

(74)

(73)

TB30

CONTACTOR

COIL

R

R

C

S

R

TB34

*OVERLOAD

(53)

TB33

(52)

(51)

(48) (45)

(46)

(50)

(49)

(47)

TB35

CONTACTOR

CONTACTS

L1

(42)

COMPRESSOR

RUN CAPACITOR

PTCR

TB30

TB30

LOW D.C.

VOLTAGE

PLUG

(64)

(63)

BIN SWITCH

(62)

(66)

(65)

(69)

(67)

(68)

TOGGLE SWITCH

68

67

69

66

62

ICE

OFF

CLEAN

(66)

(62)

VIEW FOR WIRING

INTERNAL WORKING

VIEW

CLEAN LIGHT

WATER LEVEL LIGHT

WATER LEVEL PROBE

(22)(21)

WATER

VALVE

2

5

1G

NOT USED

(20)

SV1648

1 Phase With Terminal Board

–37–

Page 48

Q450/Q600/Q800/Q1000 - Remote -

SV2073

1 Phase Without Terminal Board

L1

HIGH PRES

CUTOUT

(88)

(42)

ICE THICKNESS PROBE

(89)

(55)

WATER LEVEL PROBE

AUCS DISPENSE TIME

BIN SWITCH

(64)

CONTACTOR

CONTACTS

(48)

L1

(51)

CAUTION: DISCONNECT POWER BEFORE WORKING

ON ELECTRICAL CIRCUITRY.

DIAGRAM SHOWN DURING FREEZE CYCLE

2

4

1

3

5

TRANS.

FUSE (7A)

1C

1F

1G

(62)

(63)

(65)

(67)

(66)

COMPRESSOR

SR

*OVERLOAD

C

F1 F2

LOW D.C.

VOLTAGE

PLUG

TOGGLE SWITCH

(68)

ICE

(69)

OFF

CLEAN

(62)

(20) (21)

(61)

(60)

(57)

CLEAN LIGHT

WATER LEVEL LIGHT

BIN SWITCH LIGHT

HARVEST LIGHT/

SAFETY LIMIT CODE LIGHT

VIEW FOR WIRING

66

62

(49)

RUN CAPACITOR

(47)

(46)

PTCR

REMOTE

FAN MOTOR

RUN CAPACITOR**

SEE SERIAL PLATE FOR VOLTAGE

(22)

WATER

VALVE

HPR

SOLENOID

(78) (79)

(88) (80)

HARVEST

SOLENOID

(77)

(81)

DUMP

SOLENOID

(99)

(98)

WATER

PUMP

(59) (83) (82)

LIQUID LINE

SOLENOID

(58)

CONTACTOR

COIL

(56)

(74)

68

67

69

RR

(94)

(50)

(45)

REMOTE CONDENSER

L2 (N)

(75)

–38–

Page 49

Q800/Q1000 -Remote -

TB31

TB37

TB32

TB35

TB34

(53)

TB33

(52)

(55)

(77)

(76)

(98)

(59)

(99)

(75)

HPR

SOLENOID

(79)

(78)

HARVEST

SOLENOID

DUMP

SOLENOID

(81)

(80)

WATER

PUMP

LIQUID LINE

SOLENOID

TB30

TB30

(82)

(83)

HIGH PRES

CUTOUT

TB30

TB30

CONTACTOR

CONTACTS

L1

(96)

(42)

COMPRESSOR

REMOTE

FAN MOTOR

RUN CAPACITOR

CAUTION: DISCONNECT POWER BEFORE WORKING

ON ELECTRICAL CIRCUITRY.

DIAGRAM SHOWN DURING FREEZE CYCLE

REMOTE CONDENSER

L3 L2 L1

L2

L3

TB35

T2

T3

T1

TERMINATES AT

PIN CONNECTION

(F1)

(F2)

(61)

(60)

(57)

(58)

1F

1C

4

1

3

5

FUSE (7A)

TRANS.

(56)

ICE THICKNESS PROBE

TB30

BIN SWITCH LIGHT

HARVEST LIGHT/

SAFETY LIMIT CODE LIGHT

LOW D.C.

VOLTAGE

PLUG

(74)

(73)

TB30

CONTACTOR

COIL

(64)

(63)

BIN SWITCH

(62)

(66)

(65)

(69)

(67)

(68)

TOGGLE SWITCH

68

67

69

66

62

ICE

OFF

CLEAN

(62)

VIEW FOR WIRING

INTERNAL WORKING

VIEW

CLEAN LIGHT

WATER LEVEL LIGHT

WATER LEVEL PROBE

2

(22)

(21)

WATER

VALVE

1G

AUCS DISPENSE TIME

(20)

SV1649

3 Phase With Terminal Board

–39–

Page 50

Q800/Q1000 - Remote -

SV2074

3 Phase Without Terminal Board

SEE SERIAL PLATE FOR VOLTAGE

L3 L2 L1

(55)

(89)

HIGH PRES

CUTOUT

(88)

(42)

ICE THICKNESS PROBE

WATER LEVEL PROBE

NOT USED

BIN SWITCH

(64)

L1

L2

L3

CONTACTOR

CONTACTS

(51)

T2

T3

T1

COMPRESSOR

CAUTION: DISCONNECT POWER BEFORE WORKING

ON ELECTRICAL CIRCUITRY.

DIAGRAM SHOWN DURING FREEZE CYCLE

(60)

2

4

3

1

5

TRANS.

FUSE (7A)

1C

1F

LOW D.C.

1G

VOLTAGE

PLUG

(62)

(63)

(65)

(85)

TOGGLE SWITCH

(68)

(67)

(69)

OFF

(66)

CLEAN

(62)

(F2)

CLEAN LIGHT

WATER LEVEL LIGHT

BIN SWITCH LIGHT

HARVEST LIGHT/

SAFETY LIMIT CODE LIGHT

ICE

(21)

(20)

HPR

(61)

SOLENOID

(78)

(77)

HARVEST

SOLENOID

(76)

DUMP

SOLENOID

(98)

(57)

WATER

PUMP

(59)

(83)

(58)

(56)

INTERNAL WORKING

VIEW

REMOTE

FAN MOTOR

REMOTE CONDENSER

RUN CAPACITOR

(22)

WATER

VALVE

(79)

(80)

(81)

(75)

(99)

(82)

LIQUID LINE

SOLENOID

CONTACTOR

COIL

(74)

VIEW FOR WIRING

68

66

67

62

69

(F1)

–40–

Page 51

Q1300/Q1800 - Remote -

SV1650

1 Phase With Terminal Board

L1

TB35

HIGH PRES

CUTOUT

ICE THICKNESS PROBE

WATER LEVEL PROBE

TB35

(42)

TB35

CAUTION: DISCONNECT POWER BEFORE WORKING

ON ELECTRICAL CIRCUITRY.

DIAGRAM SHOWN DURING FREEZE CYCLE

(55)

TB32

AUCS DISPENSE TIME

CONTACTOR

CONTACTS

L1

TB33

(51)

(64)

(66)

BIN SWITCH

*OVERLOAD

(48)

(52)

(F1)

(62)

(63)

(65)

R

TERMINATES AT

PIN CONNECTION

(20)

2

4

1

3

5

TRANS.

FUSE (7A)

1C

1F

1G

LOW D.C.

VOLTAGE

PLUG

TOGGLE SWITCH

(68)

(67)

(69)

(66)

(62)

CRANKCASE HEATER

COMPRESSOR

S

C

(53)

TB34

(21)

RH HARVEST

SOLENOID

(61)

(60)

(57)

(58)

TB37

CLEAN LIGHT

WATER LEVEL LIGHT

BIN SWITCH LIGHT

HARVEST LIGHT/

SAFETY LIMIT CODE LIGHT

ICE

INTERNAL WORKING

OFF

VIEW

CLEAN

(49)

RUN CAPACITOR

(47)

(46)

PTCR

(44)

REMOTE

FAN MOTOR

RUN CAPACITOR

SEE SERIAL PLATE FOR VOLTAGE

WATER

VALVE

(22)

HPR

SOLENOID

(79)(78)

(87)(88)

(77)

LH HARVEST

(80)

SOLENOID

(76)

(81)

DUMP

SOLENOID

TB31

(98)

(99)

WATER

PUMP

(83)

(59)

LIQUID LINE

SOLENOID

(73)

CONTACTOR

COIL

(56)

VIEW FOR WIRING

68

66

67

62

(94)(95)

R

R

(50)

CONTACTOR

CONTACTS

(45)

(F2)

REMOTE CONDENSER

L2 (N)

(75)

TB30

TB30

(82)

(74)

TB30

TB30

69

TB30

(96)

TB30

L2

–41–

Page 52

Q1300/Q1600/Q1800 - Remote -

SV2076

1 Phase Without Terminal Board

CAUTION: DISCONNECT POWER BEFORE WORKING

ON ELECTRICAL CIRCUITRY.

DIAGRAM SHOWN DURING FREEZE CYCLE

L1

(55)(89)

HIGH PRES

CUTOUT

(88)

ICE THICKNESS PROBE

WATER LEVEL PROBE

AUCS DISPENSE TIME

BIN SWITCH

(64)

(95)

(42)

*OVERLOAD

CONTACTOR

CONTACTS

(48)

L1

(51)

SEE SERIAL PLATE FOR VOLTAGE

(21)

HPR

(20)

2

4

1

3

5

TRANS.

FUSE (7A)

1C

1F

1G

LOW D.C.

VOLTAGE

PLUG

(62)

(63)

(65)

TOGGLE SWITCH

(68)

ICE

(67)

(69)

OFF

(66)

CLEAN

(62)

CRANKCASE HEATER

COMPRESSOR

RS

C

(F1) (F2)

SOLENOID

RH HARVEST

SOLENOID

(61)

(77)

LH HARVEST

(60)

SOLENOID

DUMP

SOLENOID

(57)

TB37

(59)

(58)

(56)

CLEAN LIGHT

WATER LEVEL LIGHT

BIN SWITCH LIGHT

HARVEST LIGHT/

SAFETY LIMIT CODE LIGHT

INTERNAL WORKING

VIEW

(49)

RUN CAPACITOR

(47)

RR

(46) (50)

(45)

PTCR

(44)

REMOTE

FAN MOTOR

RUN CAPACITOR

(78)

(88)

(76)

(98)

(83)

CONTACTOR

COIL

(94)

REMOTE CONDENSER

(22)

WATER

VALVE

(79)

(87)

(80)

(75)

(81)

(99)

WATER

PUMP

(82)

LIQUID LINE

SOLENOID

VIEW FOR WIRING

68

67

66

62

69

(F2)

CONTACTOR

CONTACTS

L2

L2 (N)

(74)

(96)

–42–

Page 53

Q1300/Q1800 - Remote -

Z

SV1651

3 Phase With Terminal Board

L3 L2 L1

L3

L1

L2

T2

T1

T3

CAUTION: DISCONNECT POWER BEFORE WORKING

ON ELECTRICAL CIRCUITRY.

DIAGRAM SHOWN DURING FREEZE CYCLE

SEE SERIAL PLATE FOR VOLTAGE

GROUND

TB35

TB35

(42)

CONTACTOR

CONTACTS

COMPRESSOR

TB32

HIGH PRES

CUTOUT

ICE THICKNESS PROBE

WATER LEVEL PROBE

AUCS DISPENSE TIME

BIN SWITCH

(64)

(95)

TB35

TB33 (52)(51)

(55)

(62)

(63)

(65)

(66)

(62)

(F1)

TERMINATES AT

PIN CONNECTION

(20)

RH HARVEST

SOLENOID

(61)

(60)

2

4

1

3

5

TRANS.

FUSE (7A)

1C

1F

1G

LOW D.C.

VOLTAGE

PLUG

(68)

TOGGLE SWITCH

(67)

(69)

CLEAN

CRANKCASE HEATER

(96)

NOTE: WIRE (96) IS NOT USED ON 50HZ

(53)

TB34

(77)

LH HARVEST

SOLENOID

(57)

TB31

(58)

TB37

(59)

(56)

CLEAN LIGHT

WATER LEVEL LIGHT

BIN SWITCH LIGHT

HARVEST LIGHT/

SAFETY LIMIT CODE LIGHT

ICE

INTERNAL WORKING

OFF

VIEW

REMOTE

FAN MOTOR

RUN CAPACITOR

REMOTE CONDENSER

WATER

VALVE

(21)

HPR

SOLENOID

(78)

(88)

(76)

DUMP

SOLENOID

(98)

(83)

(73)

CONTACTOR

COIL

VIEW FOR WIRING

66

62

(79)

(87)

(81)

(99)

WATER

PUMP

LIQUID LINE

SOLENOID

(94)

(22)

N - 50H

(82)

ONLY

(80)

TB30

(75)

TB30

TB30

(74)

TB30

TB30

68

67

69

TB30

TB30

(F2)

–43–

Page 54

Q1300/Q1600/Q1800 - Remote -

Z

Y

SV2077

3 Phase Without Terminal Board

CAUTION: DISCONNECT POWER BEFORE WORKING

ON ELECTRICAL CIRCUITRY.

SEE SERIAL PLATE FOR VOLTAGE

L3 L2 L1

L1

L2

L3

T2

T3

T1

COMPRESSOR

DIAGRAM SHOWN DURING FREEZE CYCLE

(55)(89)

HIGH PRES

CUTOUT

(88)

(42)

ICE THICKNESS PROBE

WATER LEVEL PROBE

NOT USED

BIN SWITCH

(64)

CONTACTOR

CONTACTS

(51)

2

4

3

1

5

TRANS.

FUSE (7A)

1C

1F

LOW D.C.

1G

VOLTAGE

CLEAN LIGHT

PLUG

WATER LEVEL LIGHT

(62)

(63)

(65)

(95) (94)

NOTE: WIRE (96) IS NOT USED ON 50HZ

(F1)

BIN SWITCH LIGHT

HARVEST LIGHT/

SAFETY LIMIT CODE LIGHT

TOGGLE SWITCH

(68)

(67)

(69)

(66)

(62)

REMOTE CONDENSER

(20)

LH HARVEST

SOLENOID

(61)

(60)

RH HARVEST

SOLENOID

(57)

(58)

(56)

ICE

INTERNAL WORKING

OFF

VIEW

CLEAN

REMOTE

FAN MOTOR

RUN CAPACITOR

(21)

HPR

SOLENOID

(78)

(88)

(77)

(76)

DUMP

SOLENOID

(98)

WATER

PUMP

(59)

(96) (96)

(22)

WATER

VALVE

(79)

(87)

(80)

(75)

(81)

(99)

(82)(83)

LIQUID LINE

SOLENOID

CONTACTOR

COIL

(74)

VIEW FOR WIRING

68

66

67

62

(F2)

N - 50 H

69

ONL

–44–

Page 55

COMPONENT SPECIFICATIONS AND

DIAGNOSTICS

General

Q-Model control boards use a dual voltage

transformer. This means only one control board is

needed for both 115V and 208-230V use.

Safety Limits

In addition to standard safety controls, such as the

high pressure cut-out, the control board has built-in

safety limits.

These safety limits protect the ice machine from major

component failures. For more information, see “Safety

Limits”

Inputs

The control board, along with inputs, controls all

electrical components, including the ice machine

sequence of operation. Prior to diagnosing, you must

understand how the inputs affect the control board

operation.

Refer to specific component specifications (inputs),

wiring diagrams and ice machine sequence of

operation sections for details.

As an example, refer to “Ice Thickness Probe” for

information relating to how the probe and control

board function together.

This section will include items such as:

How a harvest cycle is initiated

How the harvest light functions with the probe

Freeze time lock-in feature

Maximum freeze time

Diagnosing ice thickness control circuitry

–45–

Page 56

Main Fuse

!

Warning

!

Warning

FUNCTION

The control board fuse stops ice machine operation if

electrical components fail, causing high amp draw.

SPECIFICATIONS

The main fuse is 250 Volt, 7 amp.

High (line) voltage is applied to the control board

(terminals #55 and #56) at all times. Removing the

control board fuse or moving the toggle switch to

OFF will not remove the power supplied to the

control board.

CHECK PROCEDURE

1. If the bin switch light is on with the water curtain

closed, the fuse is good.

Disconnect electrical power to the entire ice

machine before proceeding.

2. Remove the fuse. Check for continuity across the

fuse with an ohmmeter.

Reading Result

Open (OL) Replace fuse

Closed (O) Fuse is good

–46–

Page 57

Bin Switch

!

Caution

FUNCTION

Movement of the water curtain controls bin switch

operation. The bin switch has two main functions:

1. Terminating the Harvest cycle and returning the ice

machine to the Freeze cycle. This occurs when the

bin switch is opened and closed again within

7

seconds during the Harvest cycle.

2. Automatic ice machine shut-off.

If the storage bin is full at the end of a Harvest

cycle, the sheet of cubes fails to clear the water

curtain and holds it open. After the water curtain is

held open for 7 seconds, the ice machine shuts off.

The ice machine remains off until enough ice is

removed from the storage bin to allow the sheet of

cubes to drop clear of the water curtain. As the

water curtain swings back to the operating position,

the bin switch closes and the ice machine restarts,

provide the 3-minute delay has expired.

The water curtain must be ON (bin switch(s) closed)

to start ice making.

SPECIFICATIONS

The bin switch is a magnetically operated reed switch.

The magnet is attached to the lower right corner of the

water curtain. The switch is attached to the

evaporator-mounting bracket.

The bin switch is connected to a varying D.C. voltage

circuit. (Voltage does not remain constant.)

NOTE: Because of a wide variation in D.C. voltage, it

is not recommended that a voltmeter be used to check

bin switch operation.

–47–

Page 58

CHECK PROCEDURE

1. Set the toggle switch to OFF.

2. Watch the bin switch light on the control board.

3. Move the water curtain toward the evaporator. The

bin switch must close. The bin switch light “on”

indicates the bin switch has closed properly.

4. Move the water curtain away from the evaporator.

The bin switch must open. The bin switch light “off”

indicates the bin switch has opened properly.

OHM TEST

1. Disconnect the bin switch wires to isolate the bin

switch from the control board.

2. Connect an ohmmeter to the disconnected bin

switch wires.

3. Cycle the bin switch by opening and closing the

water curtain.

NOTE: To prevent misdiagnosis:

Always use the water curtain magnet to cycle the

switch. Larger or smaller magnets will affect switch

operation.

Watch for consistent readings when the bin switch is

open and closed. Bin switch failure could be erratic.

–48–

Page 59

Water Curtain Removal Notes

The water curtain must be on (bin switch closed) to

start ice making. While a Freeze cycle is in progress,

the water curtain can be removed and installed at any

time without interfering with the electrical control

sequence.

If the ice machine goes into Harvest sequence while

the water curtain is removed, one of the following will

happen:

Water curtain remains off:

When the Harvest cycle time reaches 3.5 minutes

and the bin switch is not closed, the ice machine

stops as though the bin were full.

Water curtain is put back on:

If the bin switch closes prior to reaching the

3.5-minute point, the ice machine immediately

returns to another Freeze sequence prechill.

–49–

Page 60

ICE/OFF/CLEAN Toggle Switch

FUNCTION

The switch is used to place the ice machine in ICE,

OFF or CLEAN mode of operation.

SPECIFICATIONS

Double-pole, double-throw switch. The switch is

connected into a varying low D.C. voltage circuit.

CHECK PROCEDURE

NOTE: Because of a wide variation in D.C. voltage, it

is not recommended that a voltmeter be used to check