Page 1

QuietQube Series Ice Machines

®

Technician’s Handbook

Part Number: 000015431 Rev01 5/19

Page 2

Page 3

Safety Notices

Read these precautions to prevent personal injury:

• Read this manual thoroughly before operating,

installing or performing maintenance on the

equipment. Failure to follow instructions in this

manual can cause property damage, injury or death.

• Routine adjustments and maintenance procedures

outlined in this manual are not covered by the

warranty.

• Proper installation, care and maintenance are essential

for maximum performance and trouble-free operation

of your equipment.

• Visit our website www.manitowocice.com for manual

updates, translations, or contact information for

service agents in your area.

• This equipment uses high voltage electricity and

contains refrigerant charge. Installation and repairs are

to be performed by properly trained technicians aware

of the dangers of dealing with high voltage electricity

and refrigerant under pressure. The technician

must also be certified in proper refrigerant handling

and servicing procedures. All lockout and tag out

procedures must be followed when working on this

equipment.

• As you work on this equipment, be sure to pay close

attention to the safety notices in this handbook.

Disregarding the notices may lead to serious injury

and/or damage to the equipment.

Page 4

DEFINITIONS

DANGER

Indicates a hazardous situation that, if not avoided,

will result in death or serious injury. This applies to the

most extreme situations.

Warning

n

Indicates a hazardous situation that, if not avoided,

could result in death or serious injury.

Caution

,

Indicates a hazardous situation that, if not avoided,

could result in minor or moderate injury.

Notice

Indicates information considered important, but not

hazard-related (e.g. messages relating to property

damage).

NOTE: Indicates useful, extra information about the

procedure you are performing.

Page 5

Warning

n

Follow these electrical requirements during

installation of this equipment:

• All field wiring must conform to all applicable

codes of the authority having jurisdiction. It is

the responsibility of the end user to provide the

disconnect means to satisfy local codes. Refer to

rating plate for proper voltage.

• This appliance must be grounded.

• This equipment must be positioned so that the plug

is accessible unless other means for disconnection

from the power supply (e.g., circuit breaker or

disconnect switch) is provided.

• Check all wiring connections, including factory

terminals, before operation. Connections can

become loose during shipment and installation.

Page 6

Warning

n

Follow these precautions to prevent personal injury

during installation of this equipment:

• Installation must comply with all applicable

equipment fire and health codes with the authority

having jurisdiction.

• Connect to a potable water supply only.

• To avoid instability the installation area must be

capable of supporting the combined weight of the

equipment and product. Additionally the equipment

must be level side to side and front to back.

• Remove all removable panels before lifting and

installing and use appropriate safety equipment

during installation and servicing. Two or more

people are required to lift or move this appliance to

prevent tipping and/or injury.

• Do not damage the refrigeration circuit when

installing, maintaining or servicing the unit.

• This equipment contains refrigerant charge.

Installation of the line sets must be performed by

a properly trained and EPA certified refrigeration

technician aware of the dangers of dealing with

refrigerant charged equipment.

• Ice machines require a deflector when installed on

an ice storage bin. Prior to using a non-OEM ice

storage system with this ice machine, contact the

bin manufacturer to assure their ice deflector is

compatible.

• Prior to installing a non-OEM ice storage system

with this ice machine, follow the manufacturers

installation procedures and verify the location and

installation meets the local/national mechanical

codes and stability requirements.

Page 7

Warning

n

Follow these precautions to prevent personal injury

while operating or maintaining this equipment:

• Legs or casters must be installed and the legs/casters

must be screwed in completely. When casters

are installed the mass of this unit will allow it to

move uncontrolled on an inclined surface. These

units must be tethered/secured to comply with all

applicable codes. Swivel casters must be mounted

on the front and rigid casters must be mounted on

the rear. Lock the front casters after installation is

complete.

• Refer to nameplate to identify the type of refrigerant

in your equipment.

• Only trained and qualified personnel aware of the

dangers are allowed to work on the equipment.

• Read this manual thoroughly before operating,

installing or performing maintenance on the

equipment. Failure to follow instructions in this

manual can cause property damage, injury or death.

• Crush/Pinch Hazard. Keep hands clear of moving

components. Components can move without

warning unless power is disconnected and all

potential energy is removed.

• Moisture collecting on the floor will create a

slippery surface. Clean up any water on the floor

immediately to prevent a slip hazard.

Page 8

Warning

n

Follow these precautions to prevent personal injury

while operating or maintaining this equipment:

• Objects placed or dropped in the bin can affect

human health and safety. Locate and remove any

objects immediately.

• Never use sharp objects or tools to remove ice or

frost.

• Do not use mechanical devices or other means to

accelerate the defrosting process.

• When using cleaning fluids or chemicals, rubber

gloves and eye protection (and/or face shield) must

be worn.

DANGER

Do not operate equipment that has been misused,

abused, neglected, damaged, or altered/modified

from that of original manufactured specifications. This

appliance is not intended for use by persons (including

children) with reduced physical, sensory or mental

capabilities, or lack of experience and knowledge,

unless they have been given supervision concerning

use of the appliance by a person responsible for their

safety. Do not allow children to play with, clean or

maintain this appliance without proper supervision.

Page 9

DANGER

Follow these precautions to prevent personal injury

during use and maintenance of this equipment:

• It is the responsibility of the equipment owner to

perform a Personal Protective Equipment Hazard

Assessment to ensure adequate protection during

maintenance procedures.

• Do Not Store Or Use Gasoline Or Other Flammable

Vapors Or Liquids In The Vicinity Of This Or Any

Other Appliance. Never use flammable oil soaked

cloths or combustible cleaning solutions for

cleaning.

• All covers and access panels must be in place and

properly secured when operating this equipment.

• Risk of fire/shock. All minimum clearances must be

maintained. Do not obstruct vents or openings.

• Failure to disconnect power at the main power

supply disconnect could result in serious injury or

death. The power switch DOES NOT disconnect all

incoming power.

• All utility connections and fixtures must be

maintained in accordance with the authority having

jurisdiction.

• Turn off and lockout all utilities (gas, electric, water)

according to approved practices during maintenance

or servicing.

• Units with two power cords must be plugged

into individual branch circuits. During movement,

cleaning or repair it is necessary to unplug both

power cords.

Page 10

Warning

n

Follow these precautions to prevent personal injury

while operating or maintaining this equipment.

• Refer to nameplate to identify the type of refrigerant

in your equipment.

• Only trained and qualified personnel aware of the

dangers are allowed to work on the equipment.

• Read this manual thoroughly before operating,

installing or performing maintenance on the

equipment. Failure to follow instructions in this

manual can cause property damage, injury or death.

• Crush/Pinch Hazard. Keep hands clear of moving

components. Components can move without

warning unless power is disconnected and all

potential energy is removed.

• Moisture collecting on the floor will create a

slippery surface. Clean up any water on the floor

immediately to prevent a slip hazard.

• Never use sharp objects or tools to remove ice or

frost. Do not use mechanical devices or other means

to accelerate the defrosting process.

• When using cleaning fluids or chemicals, rubber

gloves and eye protection (and/or face shield) must

be worn.

Page 11

Warning

n

Follow these precautions to prevent personal injury

during use and maintenance of this equipment:

• Units with two power cords must be plugged

into individual branch circuits. During movement,

cleaning or repair it is necessary to unplug both

power cords.

• Never use a high-pressure water jet for cleaning on

the interior or exterior of this unit. Do not use power

cleaning equipment, steel wool, scrapers or wire

brushes on stainless steel or painted surfaces.

• Two or more people are required to move this

equipment to prevent tipping.

• Locking the front casters after moving is the

owner’s and operator’s responsibility. When casters

are installed, the mass of this unit will allow it to

move uncontrolled on an inclined surface. These

units must be tethered/secured to comply with all

applicable codes.

• The on-site supervisor is responsible for ensuring

that operators are made aware of the inherent

dangers of operating this equipment.

• Do not operate any appliance with a damaged cord

or plug. All repairs must be performed by a qualified

service company.

Page 12

THIS PAGE INTENTIONALLY LEFT BLANK

Page 13

Table of Contents

Safety Notices ...............................3

Definitions ..............................4

General Information

How to Read a Model Number ................19

Head Sections ..........................19

CVD Condensing Units ...................20

Ice Cube Sizes ..............................20

Model/Serial Number Location................21

Warranty ..................................22

Warranty Registration....................22

Model Numbers ............................23

QuietQube® Models .....................23

LuminIce® II ................................24

Installation

Stacking Two Ice Machines on a Single Storage

Bin....................................25

Ice Deflector ...........................25

Location of Ice Machine ......................26

Head Section ...........................26

Ice Beverage Models.....................27

Location of CVD Condensing Units .........28

Clearance Requirements .....................29

Dual Evaporator Model Installation on a Manitowoc

Bin........................................30

Ice Machine on a Dispenser Installation ........31

Water Supply and Drains .....................32

Lineset Applications .........................33

QuietQube® Remote Condensing Unit..........34

Additional Refrigerant Charge For 51' to 100' Line

Sets .......................................35

Part Number: 000015431 Rev01 5/19 13

Page 14

Maintenance

Cleaning and Sanitizing ......................37

General................................37

Cleaning/Sanitizing Procedure .............38

Preventative Maintenance Cleaning Procedure

......................................38

iAuCS® ................................38

Exterior Cleaning ........................38

Touchscreen Operation For The Clean Cycle .....39

Starting a clean cycle ....................39

Water curtain/damper operation during the

clean cycle .............................39

Pausing a clean cycle.....................39

Power interruption during clean cycle ......39

Aborting a clean cycle....................39

Cleaning/Sanitizing Procedure ................40

Cleaning Procedure......................40

Sanitizing Procedure .....................43

Parts Removal for Cleaning/Sanitizing.......45

Preventative Maintenance Cleaning Procedure ..54

Removal from Service/Winterization ...........56

Operation

Operational Checks..........................57

General................................57

Ice Thickness Check......................58

Sequence of Operation ......................60

QuietQube® Models .....................60

Initial Start-Up or Start-Up After

Automatic Shut-Off ......................60

Freeze Sequence . . . . . . . . . . . . . . . . . . . . . . . .61

Harvest Sequence .......................63

Automatic Shut-Off ......................64

Restart After Automatic Shut-off ...........64

14 Part Number: 000015431 Rev01 5/19

Page 15

Menu Navigation

Touch Screen Features .......................69

Home screen icon descriptions ............71

Setup Wizard ...............................73

Menu Navigation Overview...................74

Settings Menu Screen Navigation ..........74

USB Flash Drive Specifications and Formatting .

......................................79

Upgrading Firmware with a Flash Drive .....79

Exporting Data to a Flash Drive ............80

Troubleshooting

Troubleshooting ............................81

Event Log ..............................82

Event Log Detail.........................83

Thaw Cycle.............................88

Safe Operation Mode ....................89

E01 Long Freeze Cycle ..................90

E02 Long Harvest Cycle .................90

Analyzing Why A Service Fault (E01 & E02)

Stopped the Ice Machine .................90

E01 Long Freeze.........................91

E02 Long Harvest........................92

Part Number: 000015431 Rev01 5/19 15

Page 16

Troubleshooting By Symptom .................93

Symptom #1 Ice Machine Stops Running ...93

Symptom #2 Ice Machine has a Long Freeze

Cycle ..................................93

Symptom #3 Will not harvest, cubes normal .93

Symptom #4 Will not harvest cubes melted..93

Reset To Factory Defaults .................94

Symptom #1 Ice Machine Will Not Run......95

Diagnosing a Condensing Unit

That Will Not Run .......................98

Symptom #2 Low Production, Long Freeze Cycle

......................................99

Symptom #3 Harvest Problems ...........115

Failure Type and Symptoms: .............119

Symptom #3 QuietQube® Models With CVD

Condensing Units ......................121

Symptom #4 QuietQube® Models With CVD

Condensing Units ......................125

16 Part Number: 000015431 Rev01 5/19

Page 17

Component Check Procedures

Control Board, Display And Touchscreen ...127

Operating an ice machine without a

Touchscreen...........................129

Control Board Relay Test.................130

Programming A Replacement Control Board 131

USB Flash Drive Specifications and Formatting .

.....................................132

Exporting Data to a Flash Drive ...........133

Upgrading Firmware with a Flash Drive ....134

Main Fuse ............................135

Bin Switch ............................136

Water Level Control Circuitry .............139

Ice Thickness Probe (Initiates Harvest) .....142

Bin Level Probe ........................146

Thermistors ...........................148

High Pressure Cutout (HPCO) Control ......151

Low Pressure Cutout (LPCO) Control.......152

Compressor Time Delay .................153

Fan Cycle Control.......................154

Harvest Assist Air Pump .................155

Compressor Electrical Diagnostics.........156

Diagnosing Start Components ............158

Refrigeration Components...................159

Head Pressure Control Valve .............159

Suction Accumulator Operation...........165

Recovery/Evacuation/Charging Procedures

QuietQube® Models ........................166

Connections...........................167

Recovery/Evacuation Procedures .........168

Charging Procedures....................169

System Contamination Clean-Up .............170

Determining Severity of Contamination ....170

Contamination Cleanup Chart ............171

Cleanup Procedure .....................172

Liquid Line Filter-Driers..................175

Suction Filter ..........................175

Replacing Pressure Controls Without Removing

Refrigerant Charge .....................176

Total System Refrigerant Charge

QuietQube® CVD Models....................177

Part Number: 000015431 Rev01 5/19 17

Page 18

Charts

Cycle Times/24-Hour Ice Production/Refrigerant

Pressure Charts ............................179

IF0600C/CVDF0600 .....................180

IBF0620C/CVDF0600....................181

IBF0820C/CVDF0900....................182

IF0900C/CVDF0900 ....................183

IBT1020C/CVDT1200....................184

IT1200C/CVDT1200.....................185

IF1400C/CVDF1400 .....................186

IF1800C/CVDF1800 .....................187

IF2100C/CVDF2100 .....................188

Diagrams

Wiring Diagrams ...........................189

Wiring Diagram Legend .................189

IF0600C/IBF0620C/IBF0820C/IF0900C 1ph .190

IT1200C/IBT1020C 1ph ..................192

IF1400C/IF1800C/IF2100C 1ph ...........194

CVD 1ph Condensing Unit ...............196

CVD 3ph Condensing Unit ...............198

Electronic Control Board ....................200

Refrigeration Tubing Schematics..............202

IF0600C/CVDF0600 IB0620C/CVDF0600

IBF0820/CVDF0900 IF0900C/CVDF0900 ....202

IBT1020C/CVDT1200 IT1200C/CVDT1200 ..204

Dual Evaporators...........................206

IF1400C/IF1800C.......................206

IF2100C ..............................208

18 Part Number: 000015431 Rev01 5/19

Page 19

General Information

How to Read a Model Number

HEAD SECTIONS

A alternate compressor

Qcoated condenser

(AUS)

SPECIAL USE

Blankgeneral use

I oblique V blades

Zcord without plug

B NEMA plug (USA)

F schuko plug (EU)

POWER CORD OPTION

G 13A blade (GBR)

Blank juncon box

H high pressure

Mmarine

Pcorreconal

Ttop air discharge

XLuminice/Sanitaon

L lever

V space maker

MARKET IDENTIFIER

Blank not market specific

SSaudi Arabia (GCC)

K Korea (KC)

C China (CCC)

D Germany (GS)

N Brazil (InMetro)

(tradional)

ELECTRICAL

CONFIGURATION

161 = 115/60/1

261 = 208-230/60/1

251 = 220-240/50/1 (S=230)

263 = 208-230/60/3

271 = 200/50-60/1

273 = 200/50-60/3

453 = 380-415/50/3

463 = 460/60/3

C CVD (remote)

Aair cooled

Wwater cooled

N remote

CONDENSER TYPE

2= 22" wide cabinet

#= all other #s mean

producon value

Soo is stated in kg/day

0300 produces ~300 #/day

0320 produces ~320 #/day

0350 produces ~350 #/day

etc. . .

REFRIGERANT TYPE

NOMINAL PRODUCTION @ 70/50

P R290 (propane)

F R404A (four)

T R410A (ten)

B R600A (butane)

E R134A (eight)

ICE MACHINE SERIES

I Indigo

U Undercounter

KKoolaire

RFlake/Nugget

B Big shot

SS-series

IB Ice Beverage

C Countertop

ICE TYPE

RRegular

DDice

Y Half-dice

F Flake

NNugget

G Gourmet

Blank for IB only

I Y T1 2 0 0 C –2 6 1 X

Part Number: 000015431 Rev01 5/19 19

Page 20

CVD CONDENSING UNITS

CVDT 1200 3

CONDENSING

UNIT MODEL

REFRIGERANT TYPE

F = R404A

T = R410

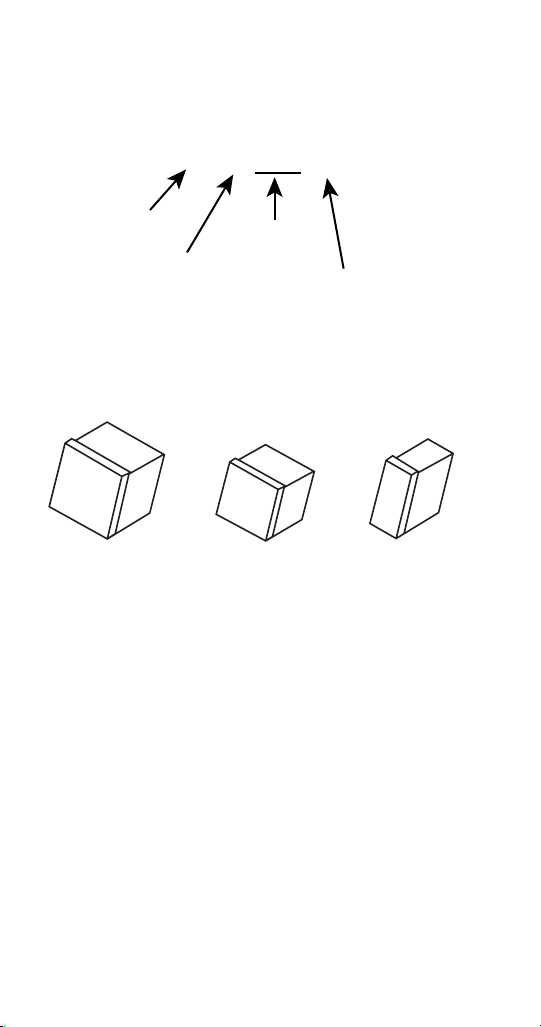

Ice Cube Sizes

Regular

1-1/8" x 1-1/8" x 7/8"

2.86 x 2.86 x 2.22 cm

CONDENSING

UNIT SERIES

Dice

7/8" x 7/8" x 7/8"

2.22 x 2.22 x 2.22 cm

3 PHASE

Half Dice

3/8" x 1-1/8" x 7/8"

0.95 x 2.86 x 2.22 cm

20 Part Number: 000015431 Rev01 5/19

Page 21

Notice

All Manitowoc ice machines require the ice storage

system (bin, dispenser, etc.) to incorporate an ice

deflector.

Prior to using a non-Manitowoc ice storage system

with other Manitowoc ice machines, contact the

manufacturer to assure their ice deflector is compatible

with Manitowoc ice machines.

Model/Serial Number Location

These numbers are required when requesting information

from your local Manitowoc Distributor, service

representative, or Manitowoc Ice, Inc.

• The model and serial number can be viewed by

pressing the information icon on the touchscreen.

• The owner warranty registration card.

• The model/serial number data plate located in the

evaporator compartment and on the back of the ice

machine.

The model and serial number displayed on the

touchscreen must match the data plate for proper

operation. For example a model number listed on the data

plate may show IDT1200C-161X but the display would only

show IDT1200C-161.

Part Number: 000015431 Rev01 5/19 21

Page 22

Warranty

For warranty information visit:

www.manitowocice.com/Service/Warranty

• Warranty Coverage Information

• Warranty Registration

• Warranty Verification

Warranty coverage begins the day the ice machine is

installed.

WARRANTY REGISTRATION

Completing the warranty registration process is a quick and

easy way to protect your investment.

Scan the QR code with your smart device or enter the link

in a web browser to complete your warranty registration.

WWW.MANITOWOCICE.COM/SERVICE/WARRANTY#WARRANTY-

REGISTRATION

Registering your product insures warranty coverage and

streamlines the process if any warranty work is required.

22 Part Number: 000015431 Rev01 5/19

Page 23

Model Numbers

QUIETQUBE® MODELS

Ice Machine Head Section CVD® Condensing Unit

IYF0600C

IBF0620C

IBF0820C

IYF0900C

IBT1020C

IDT1200C

IYT1200C

IDF1400C

IYF1400C

IDF1800C

IYF1800C

IDF2100C

IYF2100C

CVDF0600

CVDF0900

CVDT1200

CVDF1400

CVDF1800

CVDF2100

Part Number: 000015431 Rev01 5/19 23

Page 24

LuminIce® II

The LuminIce® growth inhibitor recirculates the air in the

ice machine foodzone over a UV bulb. This process will

inhibit the growth of common micro-organisms on all

exposed foodzone surfaces.

• LuminIce® bulbs require replacement on a yearly basis.

• The control board can be set to automatically display a

reminder after 12 months.

NOTE: LuminIce® and LuminIce® II bulbs are not

interchangeable; verify your model before ordering a

replacement bulb. LuminIce® bulbs have a white base and

LuminIce® II bulbs have a blue base.

Cleanup Procedure for Accidental Bulb Breakage

The cleanup procedure is identical to the procedure used

to clean up compact fluorescent (CFL) or fluorescent tube

lights. These lights contain a small amount of mercury

sealed within a glass tube. Breaking these types of lights

will release mercury and mercury vapor. The broken bulb

can continue to release mercury vapor until it is cleaned up

and removed.

The latest EPA procedures can be viewed on their website

at www.epa.gov/cfl/cflcleanup.html.

24 Part Number: 000015431 Rev01 5/19

Page 25

Installation

Warning

n

PERSONAL INJURY POTENTIAL

Remove all ice machine panels before lifting.

Notice

IF1400C/IF1800C/IF2100C ice machines are not

approved for use on Manitowoc D570 bins.

Notice

The ice machine head section must be protected if it

will be subjected to temperatures below 32°F (0°C).

Failure caused by exposure to freezing temperatures is

not covered by the warranty.

STACKING TWO ICE MACHINES ON A SINGLE STORAGE BIN

Indigo Model ice machines cannot be stacked. However

an adapter is available that allows two QuietQube® ice

machines to be placed side by side on 60" bins.

ICE DEFLECTOR

An ice deflector is required for all ice machines installed on

a bin and may be required by the dispenser manufacture

when installed on a dispenser.

Part Number: 000015431 Rev01 5/19 25

Page 26

Location of Ice Machine

HEAD SECTION

The location selected for the ice machine head section

must meet the following criteria. If any of these criteria are

not met, select another location.

• The location must be free of airborne and other

contaminants.

• The air temperature must be at least 35°F (1.6°C), but

must not exceed 110°F (43°C).

• Ice Making Water Inlet - Water Pressure must be

at least 20 psi (1.4 bar), but must not exceed 80 psi

(5.5 bar).

• The location must not be near heat-generating

equipment or in direct sunlight and protected from

weather.

• The ice machine must be protected if it will be

subjected to temperatures below 32°F (0°C). Failure

caused by exposure to freezing temperatures is not

covered by the warranty.

26 Part Number: 000015431 Rev01 5/19

Page 27

ICE BEVERAGE MODELS

• Ice/Beverage Ice Machines require that a proper ice

level be maintained when installed on a dispenser. Ice

Beverage machines ship with a ice level management

sensor pre-installed.

• The ice machine head is installed with the electrical

inlet, water supply inlet, refrigeration tubing and water

drain entering from the back of the ice machine.

• The ice machine head section contains a service loop

that must remain installed between the ice machine

head section and line set. Sufficient tubing length must

be available to allow 180° rotation of the ice machine.

• Maintain a 3" space between the back of the ice

machine and the back of the dispenser to allow room

for the refrigeration line set service loop.

• The water inlet and electrical connection must contain

a service loop to allow future service and maintenance

access.

• The drain line must contain a union or other suitable

means of disconnection at the ice machine head

section.

• The location must be free of airborne and other

contaminants.

• The air temperature must be at least 35°F (1.6°C), but

must not exceed 110°F (43°C).

• The location must not be near heat-generating

equipment or in direct sunlight.

Part Number: 000015431 Rev01 5/19 27

Page 28

LOCATION OF CVD CONDENSING UNITS

The location selected for the CVD Condensing Unit must

meet the following criteria. If any of these criteria are not

met, select another location.

• The air temperature must be at least -20°F (-28.9°C)

but must not exceed 120°F (48.9°C).

• The location must not allow exhaust fan heat and/or

grease to enter the condenser.

• The location must not obstruct airflow through or

around the condensing unit. See below for clearance

requirements.

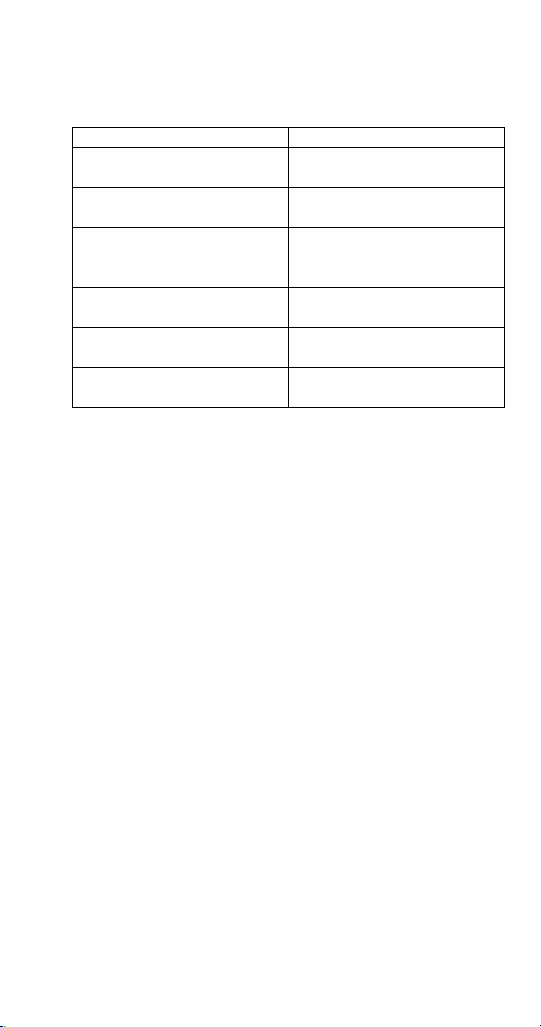

Minimum/Maximum Temperatures

Model

All Ice Machine

Head Sections

QuietQube

Condensing Units

CVDF0600

CVDF0900

CVDT1200

CVDF2100

CVDF1400

CVDF1800

Minimum Air

Temperature

35°F

2°C

-20°F

-29°C

-20°F

-29°C

Maximum Air

Temperature

110°F

43°C

120°F

49°C

130°F

54°C

28 Part Number: 000015431 Rev01 5/19

Page 29

Clearance Requirements

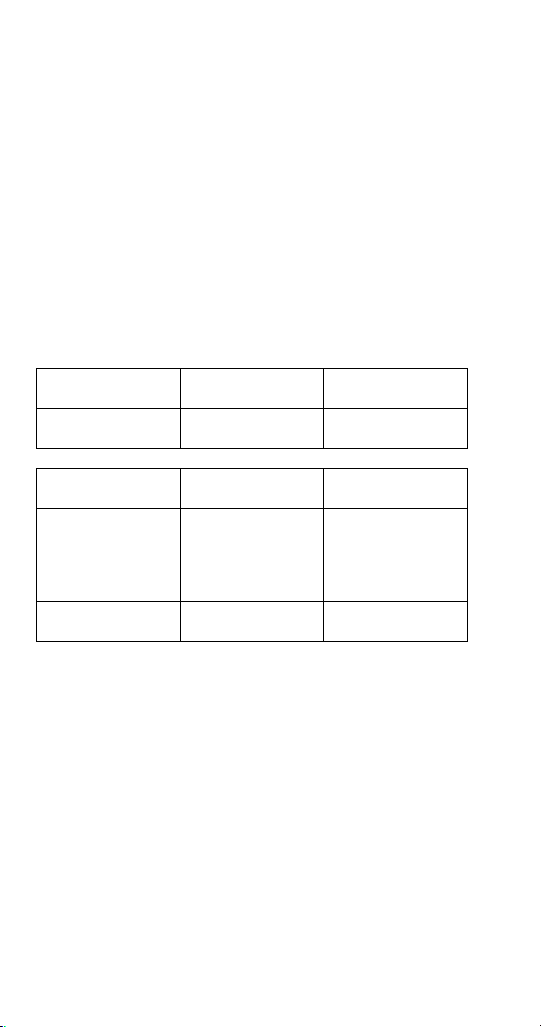

QuietQube Model Clearance Requirements

Model Top Back Sides

IF0600C

IF0900C

IT1200C

IF1400C

IF1800C

IF2100C

IBF0620C

IBF0820C

IBT1020C

** 24" (61 cm) is recommended on top/sides for servicing

Condensing Unit Clearance Requirements

Model Top/Sides Back Front

CVDF0600

CVDF0900

CVDT1200

CVDF1400

CVDF1800

CVDF2100

* 24" (61 cm) is recommended on top/sides for servicing

5"

(13 cm)

2"**

(5 cm)

0"

(0 cm*)

5"

(13 cm)

5"

(13 cm)

48"

(122 cm)

5"

(13 cm)

8" **

(20 cm)

48"

(122 cm)

Part Number: 000015431 Rev01 5/19 29

Page 30

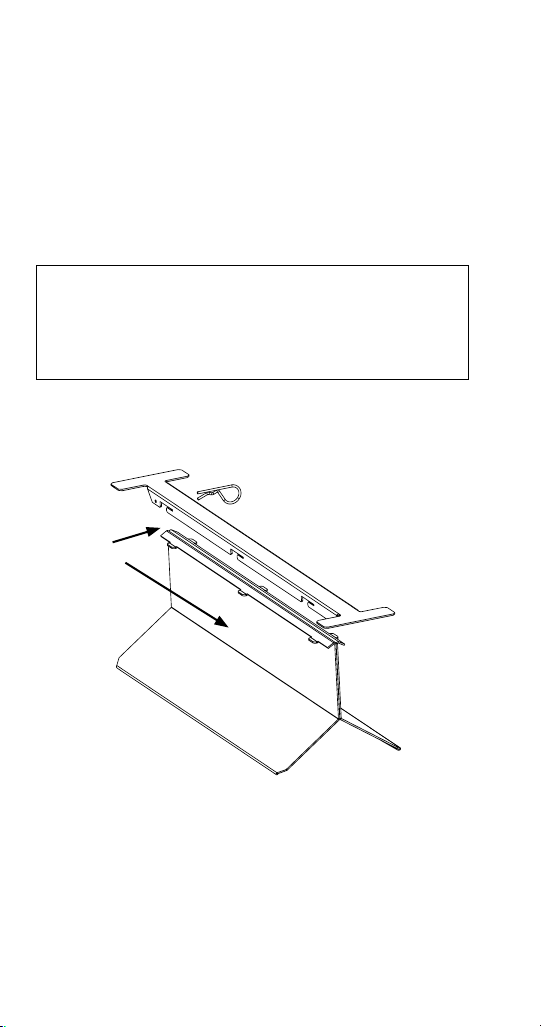

Dual Evaporator Model Installation on a Manitowoc Bin

Dual evaporator models will not function correctly with

the stock bin deflector. An ice deflector kit is required for

installation and is ordered separate. Order appropriate kit

(30" or 48") for your bin.

The stock bin deflector must be removed and replaced

with the correct deflector to prevent injury.

Warning

n

PERSONAL INJURY POTENTIAL

Do not operate any ice machine with the deflector

removed.

NOTE: A deflector must be installed on all dual evaporator

models used in bin applications.

2. LOCK IN PLACE WITH PIN

1. SLIDE

FORWARD

30 Part Number: 000015431 Rev01 5/19

Page 31

Ice Machine on a Dispenser Installation

No deflector is needed for machines that match the size of

the dispenser (30" head section on a 30" dispenser) unless

required by the dispenser manufacturer.

Adapters are required when a smaller ice machine is going

on a larger dispenser (22" machine on a 30" dispenser).

Ice level management is recommended to prevent water

leakage or movement of ice machine during agitation.

A dispenser baffle is required to prevent ice from

contacting the ice machine door and prevent possible

water leakage. K00348 is used on 22" ice machines and

K00346 is used on 30" ice machines.

Important

Manitowoc Ice/Beverage Ice Machines require an

adapter for mounting. Adapters are not included with

the ice machine, dispenser or bin and must be ordered

separately. When a non-Manitowoc adapter is used,

verify the adapter is compatible with Manitowoc Ice/

Beverage Ice Machines prior to installation.

Warning

n

Ice Beverage ice machines, adapter plates and adapter

covers must be secured to the dispenser to prevent

tipping or dislodging during agitation.

Part Number: 000015431 Rev01 5/19 31

Page 32

Water Supply and Drains

Potable Water

• Water temperature must be between

40°F (4.4°C) and 90°F (32°C).

• Water pressure must be between

20 psi (140 kPa) and 80 psi (550 kPa).

• Minimum internal diameter of tubing 3/8" (10 mm).

Drain Connections

• Drain lines must have a 1.5 inch drop per 5 feet (2.5 cm

per meter) of run and must not create traps.

• The floor drain must be large enough to accommodate

drainage from all drains.

• Run separate bin and ice machine drain lines.

• Insulate drain lines to prevent condensation.

• Vent the ice machine drain to the atmosphere.

• Drain termination must have an air gap that meets

local code.

Auxiliary Base Drain Installation

An auxiliary drain is located in the ice machine base to

remove moisture in high humidity areas.

1. View the back of the ice machine base on the

compressor side and locate and remove the cap plug.

2. Route tubing to an open site drain:

• Use 1/2 inch ID CPVC tubing.

• Apply a bead of silicone around the exterior of the ice

machine tubing and insert into ice machine base. The

silicone will secure the tubing and provide a watertight

seal.

• Provide support for tubing.

32 Part Number: 000015431 Rev01 5/19

Page 33

Lineset Applications

Notice

The 60-month compressor warranty (including the

36-month labor replacement warranty) will not

apply if the Manitowoc Ice Machine, Condenser or

QuietQube® Condensing Unit were not installed

according to specifications. This warranty also will

not apply if the refrigeration system is modified with

a condenser, heat reclaim device, or other parts or

assemblies not manufactured by Manitowoc Ice. Or

refrigeration system additives such as leak detection

dyes, inhibitors or non OEM approved chemicals.

Warning

n

Recovery locations vary by model. Verify you are

making the correct connections for your model to

prevent accidental release of high pressure refrigerant.

Important

Manitowoc remote systems are only approved and

warranted as a complete new package. Warranty on

the refrigeration system will be void if new equipment

is connected to pre-existing (used) tubing, remote

condenser, remote condensing unit or ice machine

head section.

Part Number: 000015431 Rev01 5/19 33

Page 34

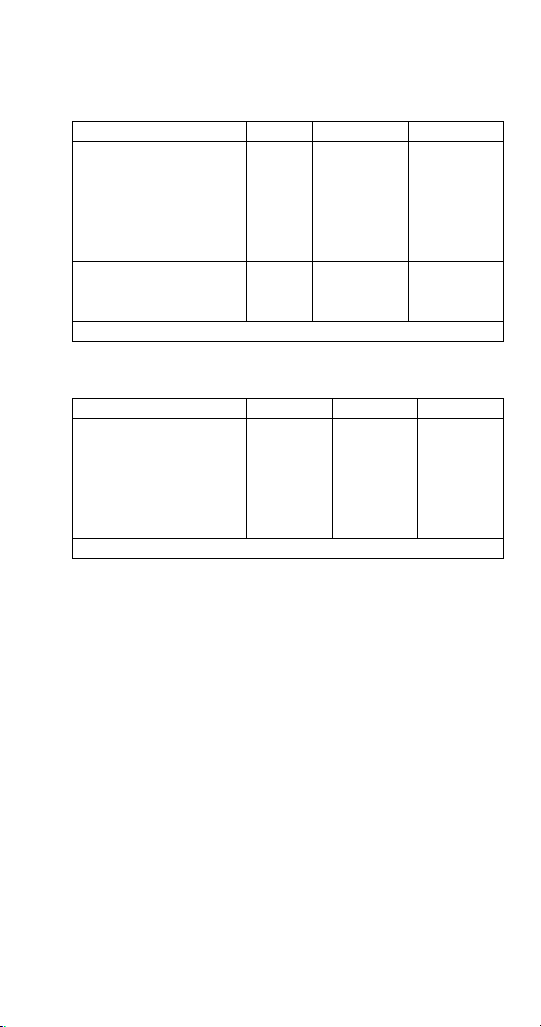

QuietQube® Remote Condensing Unit

QuietQube® Ice

Machine

IF0600C

IBF0620C

IBF0820C

IF0900C

IBT1020C CVDT1200

IT1200C CVDT1200

IF1400C CVDF1400 RC-20

IF1800C CVDF1800

IF2100C CVDF2100

*Line Set

RC 21/31/51

RC 20/30/50

RC 23/33/53

Remote Single

Circuit Condenser

CVDF0600

CVDF0900

Suction

Line

5/8 inch

(16 mm)

3/4 inch

(19 mm)

3/4 inch

(19 mm)

Line Set* S Trap

RC-21

RC-31

RC-51

RC-30

RC-50

RC-23

RC-33

RC-53

Liquid

Line

3/8 inch

(10 mm)

1/2 inch

(13 mm)

5/8 inch

(16 mm)

K00172

K00166

Minimum

Insulation

Thickness

1/2" (13 mm)

Suction Line

1/4" (7 mm)

Liquid Line

1/2"(13 mm)

Suction Line

1/4" (7 mm)

Liquid Line

1/2" (13 mm)

Suction Line

1/4" (7 mm)

Liquid Line

34 Part Number: 000015431 Rev01 5/19

Page 35

Additional Refrigerant Charge For 51' to 100' Line Sets

Ice

Machine

IF0600C

IBF0820C

IBT1020C

IT1200C

IF1400C CVDF1400

IF1800C CVDF1800

IF2100C CVDF2100

Condenser

CVDF0600

CVDF0900

CVDT1200

Additional Amount of

Refrigerant To Be Added

To Nameplate Charge

1.5 lbs

680 gIBF0620C

4 lbs

1814 gIF0900C

2 lbs

907 g

2 lbs

907 g

2 lbs

907 g

2 lbs

907 g

4 lbs

1814 g

Part Number: 000015431 Rev01 5/19 35

Page 36

Calculating Allowable Lineset Distance

Line Set Length

The maximum length is 100' (30.5 m).

Line Set Rise/Drop

The maximum rise is 35' (10.7 m).

The maximum drop is 15' (4.5 m).

S TRAP

REQUIRED IF

RISE IS HIGHER

THAN 20'

35 FT. (10.7 M)

MAXIMUM

DISTANCE

35 ft. (10.7 m) Rise: The maximum distance the Condenser

or Condensing Unit can be above the ice machine.

15 FT. (4.5 M)

MAXIMUM

DISTANCE

15 ft. (4.5 m) Drop: The maximum distance the Condenser

or Condensing Unit can be below the ice machine.

If a line set has a rise followed by a drop, another rise

cannot be made. Likewise, if a line set has a drop followed

by a rise, another drop cannot be made.

36 Part Number: 000015431 Rev01 5/19

Page 37

Maintenance

Cleaning and Sanitizing

GENERAL

You are responsible for maintaining the ice machine

in accordance with the instructions in this manual.

Maintenance procedures are not covered by the warranty.

Clean and sanitize the ice machine every six months for

efficient operation. If the ice machine requires more

frequent cleaning and sanitizing, consult a qualified

service company to test the water quality and recommend

appropriate water treatment. An extremely dirty ice

machine must be taken apart for cleaning and sanitizing.

Manitowoc Ice Machine Cleaner and Sanitizer are the only

products approved for use in Manitowoc ice machines.

Caution

,

Use only Manitowoc approved Ice Machine Cleaner

and Sanitizer for this application (Manitowoc Cleaner

part number 9405463 and Manitowoc Sanitizer part

number 9405653). It is a violation of Federal law to

use these solutions in a manner inconsistent with their

labeling. Read and understand all labels printed on

bottles before use.

Caution

,

Do not mix Cleaner and Sanitizer solutions together. It

is a violation of Federal law to use these solutions in a

manner inconsistent with their labeling.

Warning

n

Wear rubber gloves and safety goggles (and/or face

shield) when handling Ice Machine Cleaner or Sanitizer.

Part Number: 000015431 Rev01 5/19 37

Page 38

CLEANING/SANITIZING PROCEDURE

This procedure must be performed a minimum of once

every six months.

• The ice machine and bin must be disassembled

cleaned and sanitized.

• All ice produced during the cleaning and sanitizing

procedures must be discarded.

• Removes mineral deposits from areas or surfaces that

are in direct contact with water.

PREVENTATIVE MAINTENANCE CLEANING PROCEDURE

• This procedure cleans all components in the water

flow path, and is used to clean the ice machine

between the bi-yearly cleaning/sanitizing procedure.

IAUCS®

iAuCS® does not operate when the Clean button is used to

start a clean cycle. To prime the hose activation is required

through the Service Menu/iAuCS® icon.

EXTERIOR CLEANING

Clean the area around the ice machine as often as

necessary to maintain cleanliness and efficient operation.

Wipe surfaces with a damp cloth rinsed in water to remove

dust and dirt from the outside of the ice machine. If a

greasy residue persists, use a damp cloth rinsed in a mild

dish soap and water solution. Wipe dry with a clean, soft

cloth.

The exterior panels have a clear coating that is stain

resistant and easy to clean. Products containing abrasives

will damage the coating and scratch the panels.

• Never use steel wool or abrasive pads for cleaning.

• Never use chlorinated, citrus based or abrasive

cleaners on exterior panels and plastic trim pieces.

38 Part Number: 000015431 Rev01 5/19

Page 39

Touchscreen Operation For The Clean Cycle

STARTING A CLEAN CYCLE

Pressing the clean button will display a Continue/Abort

screen, and a warning that pressing Continue will result in

a clean cycle that can last up to 35 minutes.

WATER CURTAIN/DAMPER OPERATION DURING THE CLEAN CYCLE

The water curtain/damper must remain closed during the

clean sequence. When the curtain/damper is open for

more than 3 seconds the clean cycle stops and a message

is displayed on the touchscreen with a choice to continue

or stop the clean cycle. Stopping the clean cycle will result

in a series of rinse and dump cycles to verify cleaner or

sanitizer has been removed before ice making.

PAUSING A CLEAN CYCLE

The clean cycle can be paused and resumed at any time

by pressing the on/off button. The clean cycle will resume

from the beginning of either the wash or rinse cycle

depending on the point of interruption.

POWER INTERRUPTION DURING CLEAN CYCLE

If the power supply is interrupted during the clean cycle

the state is retained in the circuit board. When power is

reapplied the clean cycle will resume from the beginning

of either the wash or rinse cycle depending on the point of

interruption.

ABORTING A CLEAN CYCLE

Verify cleaner/sanitizer is not present in the water system

before aborting a clean cycle.

1. Press and hold the Clean button, then press and

release the On/Off button.

2. Release the Clean button and select abort from the

touchscreen.

Part Number: 000015431 Rev01 5/19 39

Page 40

Cleaning/Sanitizing Procedure

CLEANING PROCEDURE

Caution

,

Do not mix Cleaner and Sanitizer solutions together. It

is a violation of Federal law to use these solutions in a

manner inconsistent with their labeling.

Warning

n

Wear rubber gloves and safety goggles (and/or face

shield) when handling Ice Machine Cleaner or Sanitizer.

Ice machine cleaner is used to remove lime scale and

mineral deposits. Ice machine sanitizer disinfects and

removes algae and slime.

NOTE: Although not required and dependent on your

installation, removing the ice machine top cover may allow

easier access.

40 Part Number: 000015431 Rev01 5/19

Page 41

Step 1 Open the front door to access the evaporator

compartment. Ice must not be on the evaporator during

the clean/sanitize cycle. Follow one of the methods below:

• Press the power switch at the end of a harvest cycle

after ice falls from the evaporator(s).

• Press the power switch and allow the ice to melt.

• Use the touchscreen to initiate a manual harvest cycle.

Notice

Never use anything to force ice from the evaporator.

Damage may result.

Step 2 Remove all ice from the bin/dispenser.

Step 3 Press the Clean button and select “Turn off

when complete”. Water will flow through the water dump

valve and down the drain. Wait approximately 1 minute

until the water trough refills and the display indicates Add

Chemical. Add the proper amount of ice machine cleaner

to the water trough by pouring between the water curtain

and evaporator, then confirm the chemical was added.

NOTE: There is a 10 minute time limit to confirm chemical

was added.

• Confirmation is pushed within 10 minutes - The ice

machine will start a 10 minute wash cycle, followed by

6 rinse and flush cycles.

• Confirmation is not pushed within 10 minutes - The ice

machine will skip the 10 minute wash cycle and start 6

rinse and flush cycles.

Step 4

Model Amount of Cleaner

IF0600C/IBF0620C/IBF0820C

IF0900C/IBT1020C/IT1200C

IF1400C/IF1800C/IF2100C 9 ounces (265 ml)

5 ounces (150 ml)

Part Number: 000015431 Rev01 5/19 41

Page 42

Step 5 Wait until the clean cycle is complete, then

disconnect power to the ice machine (and dispenser when

used).

Warning

n

Disconnect the electric power to the ice machine at

the electric service switch box.

Step 6 Remove parts for cleaning.

Please refer to the proper parts removal for your ice

machine. Continue with next step when the parts have

been removed.

“Single Evaporator Ice Machines” on page 45

“Ice Beverage Ice Machines” on page 47

“Dual Evaporator Ice Machines” on page 49

Step 7 Mix a solution of cleaner and lukewarm water.

Depending upon the amount of mineral buildup, a larger

quantity of solution may be required. Use the ratio in the

table below to mix enough solution to thoroughly clean all

parts.

Solution Type Water Mixed With

Cleaner 1 gal. (4 L)

16 oz (500 ml)

cleaner

42 Part Number: 000015431 Rev01 5/19

Page 43

Step 8 Use 1/2 of the cleaner/water mixture to clean

all components. The cleaner solution will foam when it

contacts lime scale and mineral deposits; once the foaming

stops use a soft-bristle nylon brush, sponge or cloth (NOT

a wire brush) to carefully clean the parts. Soak parts for 5

minutes (15 - 20 minutes for heavily scaled parts). Rinse all

components with clean water.

Step 9 While components are soaking, use 1/2 of the

cleaner/water solution to clean all food zone surfaces of

the ice machine and bin (or dispenser). Use a nylon brush

or cloth to thoroughly clean the following ice machine

areas:

• Side walls

• Base (area above water trough)

• Evaporator plastic parts - including top, bottom, and

sides

• Bin or dispenser

Rinse all areas thoroughly with clean water.

SANITIZING PROCEDURE

Step 10 Mix a solution of sanitizer and lukewarm water.

Solution

Type

Sanitizer 3 gal. (12 L) 2 oz (60 ml) sanitizer

Water Mixed With

Step 11 Use 1/2 of the sanitizer/water solution to

sanitize all removed components. Use a spray bottle to

liberally apply the solution to all surfaces of the removed

parts or soak the removed parts in the sanitizer/water

solution. Do not rinse parts after sanitizing.

Part Number: 000015431 Rev01 5/19 43

Page 44

Step 12 Replace all removed components.

Step 13 Wait 20 minutes.

Step 14 Reapply power to the ice machine and press the

Clean button.

Step 15 Press the Clean button and select “Make ice

when complete”. Water will flow through the water dump

valve and down the drain. Wait approximately 1 minute

until the water trough refills and the display indicates Add

Chemical. Add the proper amount of ice machine sanitizer

to the water trough by pouring between the water curtain

and evaporator, then confirm the chemical was added.

Model Amount of Sanitizer

IF0600C/IBF0620C/ IBF0820C

IF0900C/IBT1020C/IT1200C

IF1400C/IF1800C/IF2100C 12 ounces (355 ml)

3 ounces (90 ml)

Step 16 The ice machine will automatically start ice

making after the sanitize cycle is complete.

44 Part Number: 000015431 Rev01 5/19

Page 45

PARTS REMOVAL FOR CLEANING/SANITIZING

Single Evaporator Ice Machines

D

E

A

C

B

A. Remove the water curtain

• Gently flex the curtain in the center and remove it

from the right side.

• Slide the left pin out.

B. Remove the water trough

• Depress tabs on right and left side of the water trough.

• Allow front of water trough to drop as you pull forward

to disengage the rear pins.

C. Remove the water level probe

• Pull the water level probe straight down to disengage.

• Lower the water level probe until the wiring connector

is visible.

• Disconnect the wire lead from the water level probe.

• Remove the water level probe from the ice machine.

Part Number: 000015431 Rev01 5/19 45

Page 46

D. Remove the ice thickness probe

• Compress the hinge pin on the top of the ice thickness

probe.

• Pivot the ice thickness probe to disengage one pin

then the other. The ice thickness probe can be cleaned

at this point without complete removal. If complete

removal is desired, disconnect the ice thickness control

wiring from the control board.

E. Remove the water distribution tube

NOTE: Distribution tube thumbscrews are retained

to prevent loss. Loosen thumbscrews but do not pull

thumbscrews out of distribution tube.

• Loosen the two outer screws (do not remove screws

completely they are retained to prevent loss) and pull

forward on the distribution tube to release from slip

joint.

• Disassemble distribution tube by loosening the two (2)

middle thumbscrews and dividing the distribution tube

into two pieces.

NOTE: Proceed to step 7 on page 42.

46 Part Number: 000015431 Rev01 5/19

Page 47

Ice Beverage Ice Machines

C

B

E

D

A

A. Remove splash shield

• Grasp the top center of splash shields.

• Lift up and then out.

B. Remove ice thickness probe

• Compress the hinge pin on the top of the ice thickness

probe.

• Pivot the ice thickness probe to disengage one pin

then the other. The ice thickness probe can be cleaned

at this point without complete removal. If complete

removal is desired, disconnect the ice thickness control

wiring from the control board.

Part Number: 000015431 Rev01 5/19 47

Page 48

C. Remove the water trough

• Depress tabs on right and left side of the water trough.

• Allow front of water trough to drop as you pull forward

to disengage the rear pins.

D. Remove the water level probe

• Pull the water level probe straight down to disengage.

• Lower the water level probe until the wiring connector

is visible.

• Disconnect the wire lead from the water level probe.

• Remove the water level probe from the ice machine.

E. Remove the water distribution tube

NOTE: Distribution tube thumbscrews are retained

to prevent loss. Loosen thumbscrews but do not pull

thumbscrews out of distribution tube.

• Loosen the two outer screws (do not remove screws

completely they are retained to prevent loss) and pull

forward on the distribution tube to release from slip

joint.

• Disassemble distribution tube by loosening the two (2)

middle thumbscrews and dividing the distribution tube

into two pieces

NOTE: Proceed to step 7 on page 42.

48 Part Number: 000015431 Rev01 5/19

Page 49

Dual Evaporator Ice Machines

A

B

C

D

E

F

A. Remove front splash shield

• Grasp the top of the splash shield.

• Lift up and then out.

B. Remove evaporator splash shields

• Grasp the top center of splash shields.

• Lift up and then out.

C. Remove the water trough shield

• Grasp the water trough shield in the center and the

left end.

• Flex the water trough shield in the center and pull the

left end forward until clear of the side wall. Repeat for

the right end.

• Pull water trough shield forward to remove.

Part Number: 000015431 Rev01 5/19 49

Page 50

D. Remove ice thickness probe

• Compress the hinge pin on the top of the ice thickness

probe.

• Pivot the ice thickness probe to disengage one pin

then the other. The ice thickness probe can be cleaned

at this point without complete removal. If complete

removal is desired, disconnect the ice thickness control

wiring from the control board.

E. Remove ice dampers

• Grasp ice damper and apply pressure toward the back

mounting bracket.

• Apply pressure to the front mounting bracket with

thumb.

• Pull ice damper download when the front ice damper

pin disengages.

F. Remove the water pump assembly

• Disconnect the vinyl distribution tube from the water

pump.

• Disconnect the water pump and water level probe

electrical connections.

• After the wires are disconnected, remove the two

thumbscrews and lift the water pump assembly out of

the ice machine.

• Depress tabs, lift and remove water pump. Do not

immerse the water pump motor in cleaner or sanitizer

solutions.

• Remove the water level probe from the assembly

housing.

50 Part Number: 000015431 Rev01 5/19

Page 51

G. Remove distribution tubes

• Distribution tubes thumbscrews are retained to

prevent loss. Loosen thumbscrews but do not pull

thumbscrews out of distribution tube.

• Loosen the two outer screws and pull forward on the

distribution tube to release from slip joint.

• Disassemble distribution tube by loosening the two (2)

middle thumbscrews and dividing the distribution tube

into two pieces.

H. Remove the water trough

• Depress the two tabs on the top of the water trough.

• Turn left and right ice dampers down to clear water

trough.

• Pull forward on the water trough to remove.

NOTE: Proceed to page 42 Step 7.

Part Number: 000015431 Rev01 5/19 51

Page 52

Ice Thickness Probe & Water Level Probe

Clean the probes using the following procedure.

NOTE: Do not soak electrical connectors in cleaner or

sanitizer solution.

1. Mix a solution of Manitowoc ice machine cleaner and

water (2 ounces of cleaner to 16 ounces of water) in

a container.

2. Soak probes in container of cleaner/water solution

while disassembling and cleaning water circuit

components (soak probes for 10 minutes or longer).

3. Clean all probe surfaces including all plastic parts

(do not use abrasives). Verify all surfaces are clean.

Thoroughly rinse probes with clean water.

4. Reinstall probe, then sanitize the ice machine and bin/

dispenser interior surfaces.

52 Part Number: 000015431 Rev01 5/19

Page 53

Water Inlet Valve

The water inlet valve normally does not require removal

for cleaning. Refer to ”Water System Checklist” on page

103, if you are troubleshooting water related problems.

1. When the ice machine is off, the water inlet valve

must completely stop water flow into the machine.

Watch for water flow.

When the ice machine is on, the water inlet valve must

allow the proper water flow through it. Press the Power

button to energize the ice machine. Watch for water

flow into the ice machine. If the water flow is slow or

only trickles into the ice machine, refer to water system

checklist.

Water Dump Valve

The water dump valve normally does not require removal

for cleaning. To determine if removal is necessary:

1. Locate the water dump valve.

2. While the ice machine is in the freeze mode, check

the rain to determine if the dump valve is leaking. If

there is no or little water in the water trough (during

the freeze cycle) the dump valve is leaking.

A. If the dump valve is leaking and debris is not

visible and easily removed, the dump valve must

be replaced.

B. If the dump valve is not leaking, do not remove

it. Instead, follow the “Ice Machine Cleaning

Procedure”.

Part Number: 000015431 Rev01 5/19 53

Page 54

Preventative Maintenance Cleaning Procedure

This procedure will descale the components in the water

flow path, and is used to descale the ice machine between

the bi-yearly cleaning/sanitizing procedures.

Ice machine cleaner/descaler is used to remove lime scale

and mineral deposits. Ice machine sanitizer disinfects and

removes algae and slime.

NOTE: Although not required and dependent on your

installation, removing the ice machine top cover may allow

easier access.

1. Ice must not be on the evaporator during the clean/

sanitize cycle. Follow one of the methods below:

A. Press the power button at the end of a harvest

cycle after ice falls from the evaporator(s).

B. Press the power button and allow the ice to

melt.

Caution

,

Never use anything to force ice from the evaporator.

Damage may result

2. Open the front door to access the evaporator.

3. Press the Clean button and select “Make ice when

complete”. Water will flow through the water dump

valve and down the drain. Wait approximately 1

minute until the water trough refills and the display

indicates Add Chemical. Add the proper amount of

ice machine descaler to the water trough by pouring

between the water curtain and evaporator, then

confirm the chemical was added.

54 Part Number: 000015431 Rev01 5/19

Page 55

Model Amount of Cleaner

IF0600C/IBF0620C/IBF0820C

IF0900C/IBT1020C/IT1200C

IF1400C/IF1800C/IF2100C 9 ounces (265 ml)

5 ounces (150 ml)

4. Close and secure the front door. The ice machine will

automatically start ice making after the descale cycle

is complete (approximately 24 minutes).

NOTE: Once the cycle has started it must complete before

the ice machine can make ice again. Returning it to ice

making mode will not cancel a clean cycle

Part Number: 000015431 Rev01 5/19 55

Page 56

Removal from Service/Winterization

General

Special precautions must be taken if the ice machine is to

be removed from service for an extended period of time or

exposed to ambient temperatures of 32°F (0°C) or below.

Notice

If water is allowed to remain in the ice machine

in freezing temperatures, severe damage to some

components could result. Damage of this nature is not

covered by the warranty.

1. Turn off the ice machine by pressing the On/Off

Button.

2. Turn off the water supply.

3. Remove the water from the water trough.

4. Disconnect and drain the incoming ice-making water

line at the rear of the ice machine.

5. Start the Ice making cycle by pressing the On/Off

Button and wait one minute for the water inlet valve

to open - or - Energize all relays in the touchscreen

service menu.

6. Blow compressed air in both the incoming water and

the drain openings in the rear of the ice machine until

no more water comes out of the water inlet lines or

the drain.

7. Disconnect the electric power at the circuit breaker or

the electric service switch.

8. Make sure water is not trapped in any of the water

lines, drain lines, distribution tubes, etc.

NOTE: www.manitowocice.com has an informational video

on this and other topics.

56 Part Number: 000015431 Rev01 5/19

Page 57

Operation

Operational Checks

GENERAL

Manitowoc ice machines are factory-operated and

adjusted before shipment. Normally, new installations do

not require any adjustment.

To ensure proper operation, always follow the Operational

Checks:

• when starting the ice machine for the first time

• after a prolonged out of service period

• after cleaning and sanitizing

NOTE: Routine adjustments and maintenance procedures

are not covered by the warranty.

Important

Refrigeration compressors must be operated for a

minimum break in period of 24 hours before full ice

production will be reached.

Part Number: 000015431 Rev01 5/19 57

Page 58

ICE THICKNESS CHECK

The ice thickness probe is factory-set to maintain the ice

bridge thickness at 1/8 in. (3 mm).

NOTE: Make sure the water curtain/splash shields are in

place when performing this check. It prevents water from

splashing out of the water trough. Remove the curtain to

make an adjustment, then replace immediately after the

adjustment is made.

1. Inspect the bridge connecting the cubes. It should be

about 1/8 in. (3 mm) thick.

2. If adjustment is necessary, turn the ice thickness

probe adjustment screw clockwise to increase bridge

thickness or counterclockwise to decrease bridge

thickness. Set a 9/32" gap between the ice thickness

probe and evaporator as a starting point. Then adjust

to achieve 1/8" ice thickness.

3. Make sure the ice thickness probe wire and the

bracket do not restrict movement of the probe.

1/8" (3 mm)

ICE BRIDGE THICKNESS

PLACE 9/32" (7MM) DRILL BIT

HERE TO SET INITIAL GAP

Ice Thickness Check

NOTE: Turning the adjustment 1/3 of a turn will change the

ice thickness about 1/16" (1.5 mm). Make adjustment only

when the ice machine is off to prevent initiating a harvest.

58 Part Number: 000015431 Rev01 5/19

Page 59

Control Board Timers

The control board has the following non-adjustable timers:

• The ice machine is locked into the freeze cycle for 6

minutes before a harvest cycle can be initiated. This

can be overridden by initiating a manual harvest. Refer

to “Manual Harvest” on page 75.

• The maximum freeze time is 35 minutes at which time

the control board automatically initiates a harvest

sequence.

• The maximum harvest time is 7 minutes, the control

board will perform a remove thaw cycle and then

return the ice machine to the freeze cycle.

• Maximum water fill time in the freeze cycle:

• Single evaporator 6 minutes.

• Dual evaporator 8 minutes.

Part Number: 000015431 Rev01 5/19 59

Page 60

Sequence of Operation

QUIETQUBE® MODELS

NOTE: The power button must be depressed and the water

curtain/ice dampers must be in place on the evaporator

before the ice machine will start.

INITIAL START-UP OR START-UP AFTER AUTOMATIC SHUT-OFF

1. Water Purge

Before the compressor starts, the water pump and water

dump solenoid are energized to purge the ice machine of

old water. This feature ensures that the ice making cycle

starts with fresh water.

2. Refrigeration System Start-Up

Ice Machine Head Section:

The harvest valve(s), air pump(s) and liquid line solenoid

valve energize to equalize high and low side refrigeration

pressure. After 10 seconds the harvest valve(s) and air

pump(s) de-energize.

CVD Condensing Unit:

The low pressure switch closes and sends voltage to

the time delay relay. The time delay relay when closed

sends voltage to the contactor coil, which energizes the

compressor.

60 Part Number: 000015431 Rev01 5/19

Page 61

FREEZE SEQUENCE

3. Prechill

The compressor lowers the temperature of the

evaporator(s) before the water pump is energized. The

water fill valve will energize and remain on until water

completes the water level probe circuit.

4. Freeze

The water pump energizes and water flows over the

evaporator. After water contacts the water level probe

the water fill valve de-energizes. The control board will

automatically cycle the water fill valve. The valve energizes

once in the pre-chill and up to twice in the freeze cycle.

The freeze cycle continues until the six minute freeze lock

expires and enough ice has formed to send a signal from

the ice thickness probe to the control board.

Water Pump

The water pump(s) energizes and water flows over the

evaporator. The water pump is energized throughout the

freeze cycle.

Part Number: 000015431 Rev01 5/19 61

Page 62

Water Inlet Valve

The water inlet valve energized in prechill. After water

contacts the low and high water probes the water fill valve

de-energizes. Ice builds on the evaporator and the water

level drops. When water loses contact with the high water

probe, the water fill valve energizes until water contacts

the high water probe again.

Maximum Fill Time = Prechill fill time + first fill + second fill.

SINGLE EVAPORATOR MAXIMUM FILL TIME

Initial startup or startup after automatic shutoff

Prechill (2 minutes) + first fill time (6 minutes) + second fill

time (6 minutes) = 14.0 minutes.

Consecutive cycles

Prechill (30 sec.) + first fill time (6 minutes) + second fill

time (6 minutes) = 12.5 minutes.

DUAL EVAPORATOR MAXIMUM FILL TIMES

Initial startup or startup after automatic shutoff

Prechill (2 minutes) + first fill time (8 minutes) + second fill

time (8 minutes) = 18.0 minutes.

Consecutive cycles

Prechill (30 sec.) + first fill time (8 minutes) + second fill

time (8 minutes) = 16.5 minutes.

62 Part Number: 000015431 Rev01 5/19

Page 63

HARVEST SEQUENCE

5. Water Purge

The air pump(s) and the harvest valve(s) open at the

beginning of the water purge to divert refrigerant gas into

the evaporator.

The water pump continues to run, and the water dump

valve energizes to purge the water in the water trough.

CVD Condensing Unit:

When the refrigerant pressure is low enough to open

the fan cycling pressure control the condenser fan motor

stops.

6. Harvest

The air pump(s) remain energized and the harvest valve(s)

remains open. The refrigerant gas warms the evaporator

causing the cubes to begin melting and slide, as a sheet,

off the evaporator and into the storage bin.

If the damper/curtain does not open within 3.5 minutes in

the harvest cycle the following occurs:

• 3.5 minutes - The water inlet valve energizes until

water touches the high water level probe.

• 4 minutes - The water pump energizes.

• 6.5 to 7 minutes - The water dump valve energizes.

• If bin switch does not open before 7 minutes the ice

machine will start a Thaw Cycle xx

Single evaporator models - The sliding sheet of cubes

opens the water curtain/ice damper and bin switch.

The momentary opening and re-closing of the bin switch

will terminate the harvest sequence and return to the

freeze sequence (Step 3 - 4).

Dual evaporator models - The sliding sheet of cubes opens

the ice damper and bin switch. The momentary opening

and re-closing of the bin switch de-energizes the harvest

valve for that evaporator. When the bin switches have

opened and closed for both evaporators the ice machine

will terminate the harvest sequence and return to the

freeze sequence (Step 3 - 4).

Part Number: 000015431 Rev01 5/19 63

Page 64

AUTOMATIC SHUT-OFF

7. Automatic Shut-Off

Ice Machine Section: Shuts off when:

• The storage bin is full at the end of a harvest sequence.

• The sheet of cubes fails to clear the water curtain and

holds it open.

• One or both ice dampers are held down.

• Bin level probe thermistor senses setpoint (when

used).

After the water curtain or ice damper are held open for

30 seconds, the ice machine shuts off. The ice machine

control board starts a 10 minute delay which must time

out before the ice machine can automatically restart.

CVD Condensing Unit: The liquid line solenoid valve closes

and the condensing unit pumps down. The LPCO opens,

starts a five minute delay period and de-energizes the

contactor coil, which de-energizes the compressor and

condenser fan motor.

RESTART AFTER AUTOMATIC SHUT-OFF

The ice machine remains off until enough ice has been

removed to allow the ice to fall clear of the water curtain

or ice damper. As the water curtain or ice damper swings

back to the operating position, the bin switch re-closes

and the ice machine restarts (steps 1 - 2), provided the

10 minute control board delay period and 5 minute

condensing unit delay periods have completed.

64 Part Number: 000015431 Rev01 5/19

Page 65

Time

Length of

Contactor

Refrigeration

Compressor &

Solenoid

Liquid Line

Dump

Water

Valve

Water Inlet

Energized Parts Chart

Air

Harvest

Pumps

Valve(s)

Single & Twin Evaporator QuietQube® Models

Pump

Water

Motor*

Condenser Fan

Valve

Valve

On Off Off Off On Off Off 45 Seconds

Operation

Ice Making

Sequence of

Start-up

1. Water Purge

Shut Off

2. Refrigeration System

Start-Up - Initial or After Auto

Pressure Equalization Off On On Off Off Off Off 5 Seconds

Compressor Start Off On On Off Off On On 5 Seconds

Part Number: 000015431 Rev01 5/19 65

Page 66

Time

Length of

120 Seconds

Initial Start-Up is

30 Seconds thereafter

ice thickness probe

Until Ice contact with

45 Seconds

Factory-set at

Contactor

Refrigeration

Compressor &

Solenoid

Liquid Line

Dump

Water

Valve

Water Inlet

Energized Parts Chart

Air

Harvest

Pumps

Valve(s)

Single & Twin Evaporator QuietQube® Models

Pump

Water

Condenser Fan

Valve

Valve

Motor*

May cycle

Off On On

Off Off Off

Off On On

On/Off

Cycles Off

times

two more

then On/Off,

On Off Off

On On On Off On On On

Operation

Ice Making

Sequence of

3. Pre chill

Freeze Sequence

4. Freeze

5. Water Purge

Harvest Sequence

66 Part Number: 000015431 Rev01 5/19

Page 67

Time

Length of

activation

Until curtain switch

activation

expires & all bin

Until 10 min. delay

switches re-close

Bin switch

Contactor

Refrigeration

Compressor &

Solenoid

Liquid Line

Dump

Water

Valve

Water Inlet

Energized Parts Chart

Air

Harvest

Pumps

Valve(s)

Single & Twin Evaporator QuietQube® Models

Pump

Water

Condenser Fan

Valve

Valve

Motor*

Off ** On On On Off** On On

Off Off Off Off Off Off Off

Operation

Ice Making

Sequence of

Shut-Off

Water Assist

Starts 3.5 minutes in

6. Harvest Off On On Off Off On On

harvest cycle

7. Automatic

* The condenser fan motor is controlled by a fan cycle control and may cycle on/off.

* The contactor is controlled by a low pressure control and may cycle on/off whenever power is supplied to the condensing unit.

Part Number: 000015431 Rev01 5/19 67

** Water Pump On after 4 minutes - Dump Valve On after 6.5 minutes.

Page 68

THIS PAGE INTENTIONALLY LEFT BLANK

68 Part Number: 000015431 Rev01 5/19

Page 69

Menu Navigation

Power Button Touchscreen Lock Clean Button

11/18/2018 10:42 AM

3

MAKING

ICE

3

i

Touch Screen Features

The Indigo® control panel offers a series of pressuresensitive buttons and an interactive touchscreen.

Buttons

Power Button: Provides On/Off functions for the ice

machine.

Lock/Unlock Button: Allows or prevents touchscreen

navigation.

Cleaning Button: Initiates a cleaning cycle. Refer to

“Cleaning and Sanitizing” on page 37 for details on

starting and bypassing a clean cycle.

S

“Part Number: 000015431 Rev01 5/19” 69

Page 70

Touchscreen

11/18/2018 10:42 AM

11/18/2018 10:42 AM

3

MAKING

ICE

3

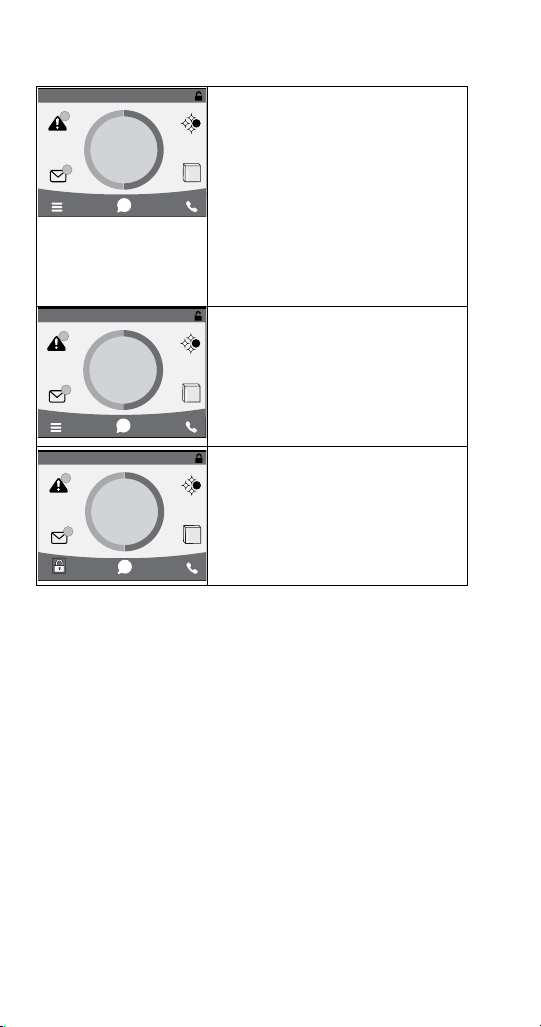

Home screen allows viewing of ice

machine status, alerts and messages.

S

Navigation with the touchscreen

provides access to menu items,machine

information, settings and event logs.

i

Setup and Energy Saver settings can be

adjusted along with access to service

and troubleshooting information. The

icons provide status indication and

allow navigation by pressing the icon.

11/18/2018 10:42 AM

3

Program

Mode On

3

i

3

MAKING

ICE

3

i

The touchscreen will display Program

Mode On, whenever the ice machine

S

is off due to a bin level probe, weight

program or time program.

The touchscreen will display a lock

in place of the menu icon when the

S

touchscreen has been locked.

70 “Part Number: 000015431 Rev01 5/19”

Page 71

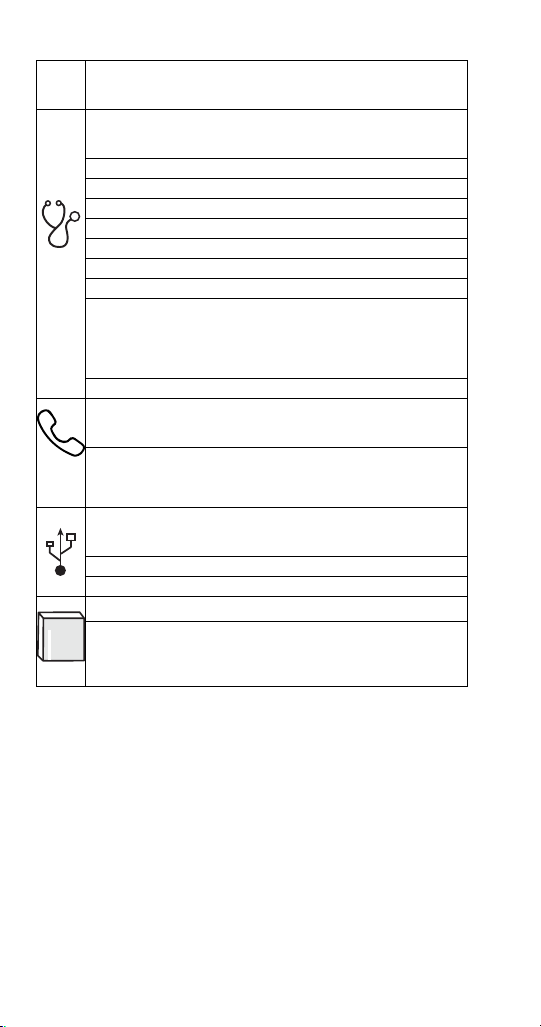

HOME SCREEN ICON DESCRIPTIONS

i

Icon Description

Home Screen Pressing this icon at any time will return the

display to the home screen.

State of ice Machine is the center portion of the

screen which displays the current condition of

the ice machine - Making ice, bin full, program

mode or machine off

Alert Alert icon with number of messages. Pressing

this icon will display the alert log which will

3

allow viewing and resetting of alerts

Message Message icon with umber of messages. Pressing

this icon will display the routine maintenance

3

reminder screen which will allow viewing and

resetting of the reminder

Menu Menu icon will take you to the main menu.

Note: This icon changes to a lock if the

touchscreen lock has been selected.

Information Information icon provides model and serial

number, installation date and other information

specific to the ice machine.

Service Locator Provides contact information for your local

service support - Default is the Manitowoc Ice

website service locator

Lock/Unlock Indicates if screen is locked or unlocked.

The icon is only visible when the screen is

locked.

LuminIce Only visible when a LuminIce II accessory is

connected.

Blue S - Normal operation

S

Red S - Replace bulb

Red/Blue alternating - Incorrect bulb installed

“Part Number: 000015431 Rev01 5/19” 71

Page 72

Icon Description

iAuCS This icon appears when the iAUCS activates

during a programed cleaning cycle.

72 “Part Number: 000015431 Rev01 5/19”

Page 73

Setup Wizard

Screens will automacally advance aer a selecon is made or press the

arrows to advance/go back one screen. All sengs can be accessed and

changed without the wizard by using menu screen navigaon.

Setup Description

Press ON/OFF

Button

Select

Language

Start Wizard

Date and Time

Configuration

Set Local Time Use arrows to set local time.

Verify Date Use arrows to set date for your location.

Accessory

Detection

Optional

USB Settings

Download

Configure Units Select standard or metric.

Set Brightness

Optional Ice

Program

Optional

Cleaning

Reminder

Optional Clean

Air Filter

Air-cooled

models only

Optional Water

Filter Reminder

Water Usage

Option

Congratulations Setup wizard is complete

Turn On Ice

Machine

On/Off button is used to start/stop ice making.

Default is English. Scroll to select a different

language.

Setup wizard will guide ice machine

programming.

Select Month/Day/Year or Day/Month/Year.

Select 12 hour or 24 hour time format.

Detects if Ice Level Sensor, LuminIce II or iAuCS

are connected.

Checkmark = yes - X = no

Only used when setup features have been

transferred to a USB drive. Skip screen by

selecting right arrow.

Configure screen brightness during normal

operation.

Program ice machine run times or press right

arrow to skip this setup.

Set clean and sanitize reminder or press right

arrow to skip.

Set to ON for self-contained air cooled models.

Select Yes or No.

Factory default - or - Use less water for reverse

osmosis systems (see “Reverse Osmosis or

Deionized Water Usage” on page 140) -

or - Use more water to improve clarity for

unfiltered water

Turn on ice machine by pressing the On/Off

button.

“Part Number: 000015431 Rev01 5/19” 73

Page 74

Menu Navigation Overview

SETTINGS MENU SCREEN NAVIGATION

Select SETTINGS Icon from the Home Screen to access

Main Menu screen. The main menu screen contains four

main headings, which allow access to subheadings under

each main heading.

Energy

Ice Program

Continuous Mode - Default, No Program

Time Program - Select Daily On/Off times

Weight Program - Select Daily Production Weight

Water Usage

Use Factory Default

Use Less Water With Reverse Osmosis

Use More Water To Improve Ice Clarity