Page 1

iAuCS®

Automatic Cleaning System

Installation, Operation and Maintenance Manual

Original Document

Part Number 000009036 Rev03 6/18

Caution

,

Read this instruction before operating this equipment.

Page 2

Page 3

Safety Notices

Safety Notices

Read these precautions to prevent personal injury:

• Read this manual thoroughly before operating,

installing or performing maintenance on the

equipment. Failure to follow instructions in this manual

can cause property damage, injury or death.

• Routine adjustments and maintenance procedures

outlined in this manual are not covered by the

warranty.

• Proper installation, care and maintenance are

essential for maximum performance and troublefree operation of your equipment. Visit our website

www.manitowocice.com for manual updates,

translations, or contact information for service agents

in your area.

• This equipment contains high voltage electricity and

refrigerant charge. Installation and repairs are to be

performed by properly trained technicians aware of

the dangers of dealing with high voltage electricity and

refrigerant under pressure. The technician must also

be certified in proper refrigerant handling and servicing

procedures. All lockout and tag out procedures must be

followed when working on this equipment.

• This equipment is intended for indoor use only. Do not

install or operate this equipment in outdoor areas.

DEFINITIONS

DANGER

Indicates a hazardous situation that, if not avoided, will

result in death or serious injury. This applies to the most

extreme situations.

Warning

n

Indicates a hazardous situation that, if not avoided, could

result in death or serious injury.

Caution

,

Indicates a hazardous situation that, if not avoided, could

result in minor or moderate injury.

Notice

Indicates information considered important, but not

hazard-related (e.g. messages relating to property

damage).

Warning

n

Follow these electrical requirements during installation of

this equipment.

• All field wiring must conform to all applicable codes of

the authority having jurisdiction. It is the responsibility

of the end user to provide the disconnect means to

satisfy local codes. Refer to rating plate for proper

voltage.

• This appliance must be grounded.

• This equipment must be positioned so that the plug is

accessible unless other means for disconnection from

the power supply (e.g., circuit breaker or disconnect

switch) is provided.

• Check all wiring connections, including factory

terminals, before operation. Connections can become

loose during shipment and installation.

Warning

n

Follow these precautions to prevent personal injury

during installation of this equipment:

• Installation must comply with all applicable equipment

fire and health codes with the authority having

jurisdiction.

• To avoid instability the installation area must be

capable of supporting the combined weight of the

equipment and product. Additionally the equipment

must be level side to side and front to back.

• Ice machines require a deflector when installed on

an ice storage bin. Prior to using a non-OEM ice

storage system with this ice machine, contact the

bin manufacturer to assure their ice deflector is

compatible.

• Do not damage the refrigeration circuit when installing,

maintaining or servicing the unit.

• Connect to a potable water supply only.

• Some 50 Hz models may contain up to 150 grams

of R290 (propane) refrigerant. R290 (propane)

is flammable in concentrations of air between

approximately 2.1% and 9.5% by volume (LEL lower

explosion limit and UEL upper explosion limit). An

ignition source at a temperature higher than 470°C is

needed for a combustion to occur. Refer to nameplate

to identify the type of refrigerant in your equipment.

Only trained and qualified personnel aware of the

dangers are allowed to work on the equipment.

NOTE: Indicates useful, extra information about the

procedure you are performing.

Page 4

Warning

n

Follow these precautions to prevent personal injury while

operating or maintaining this equipment:

• Read this manual thoroughly before operating,

installing or performing maintenance on the

equipment. Failure to follow instructions in this manual

can cause property damage, injury or death.

• Crush/Pinch Hazard. Keep hands clear of moving

components. Components can move without warning

unless power is disconnected and all potential energy is

removed.

• Moisture collecting on the floor will create a slippery

surface. Clean up any water on the floor immediately to

prevent a slip hazard.

• Objects placed or dropped in the bin can affect human

health and safety. Locate and remove any objects

immediately.

• Never use sharp objects or tools to remove ice or frost.

Do not use mechanical devices or other means to

accelerate the defrosting process.

• When using cleaning fluids or chemicals, rubber gloves

and eye protection (and/or face shield) must be worn.

DANGER

Do not operate equipment that has been misused, abused,

neglected, damaged, or altered/modified from that of

original manufactured specifications. This appliance is

not intended for use by persons (including children) with

reduced physical, sensory or mental capabilities, or lack

of experience and knowledge, unless they have been

given supervision concerning use of the appliance by a

person responsible for their safety. Do not allow children

to play with, clean or maintain this appliance without

proper supervision.

DANGER

Follow these precautions to prevent personal injury

during use and maintenance of this equipment:

• It is the responsibility of the equipment owner to

perform a Personal Protective Equipment Hazard

Assessment to ensure adequate protection during

maintenance procedures.

• Do Not Store Or Use Gasoline Or Other Flammable

Vapors Or Liquids In The Vicinity Of This Or Any Other

Appliance. Never use flammable oil soaked cloths or

combustible cleaning solutions for cleaning.

• All covers and access panels must be in place and

properly secured when operating this equipment.

• Risk of fire/shock. All minimum clearances must be

maintained. Do not obstruct vents or openings.

• Failure to disconnect power at the main power supply

disconnect could result in serious injury or death. The

power switch DOES NOT disconnect all incoming power.

• All utility connections and fixtures must be maintained

in accordance with the authority having jurisdiction.

• Turn off and lockout all utilities (gas, electric, water)

according to approved practices during maintenance or

servicing.

• Units with two power cords must be plugged into

individual branch circuits. During movement, cleaning

or repair it is necessary to unplug both power cords.

• Never use a high-pressure water jet for cleaning on

the interior or exterior of this unit. Do not use power

cleaning equipment, steel wool, scrapers or wire

brushes on stainless steel or painted surfaces.

• Two or more people are required to move this

equipment to prevent tipping.

• Locking the front casters after moving is the owner’s

and operator’s responsibility. When casters are

installed, the mass of this unit will allow it to move

uncontrolled on an inclined surface. These units must

be tethered/secured to comply with all applicable

codes.

• The on-site supervisor is responsible for ensuring that

operators are made aware of the inherent dangers of

operating this equipment.

• Do not operate any appliance with a damaged cord

or plug. All repairs must be performed by a qualified

service company.

Page 5

Safety Notices

Section 1

General Information

Section 2

Installation

Section 3

Operation

Table of Contents

Safety Notices ................................................................................................................... 3

Definitions ....................................................................................................................... 3

Compatible Ice Machine Models........................................................................................ 7

Model Compatibility........................................................................................................7

Indigo® NXT ....................................................................................................................... 7

iAuCS® Location ................................................................................................................. 7

Warranty Information........................................................................................................ 7

General ............................................................................................................................. 9

Electrical Service ............................................................................................................... 9

General ............................................................................................................................ 9

iAuCS® Installation ............................................................................................................9

Location/Mounting .........................................................................................................9

Height Requirement ......................................................................................................10

Distance Requirement ...................................................................................................10

Mounting.......................................................................................................................10

Connection to Ice Machine ........................................................................................... 11

Determine Type of Solution Needed ................................................................................ 15

Manitowoc Ice Machine Cleaner ..................................................................................15

Manitowoc Ice Machine Sanitizer .................................................................................15

Installing/Replacing Cleaner or Sanitizer Bottles .............................................................. 15

Indigo® NXT Model Procedures ....................................................................................... 16

Indigo® NXT Automatic Operation ................................................................................16

Indigo® NXT Setting Frequency of Cleaning ..................................................................16

Indigo® NXT Hose Priming .............................................................................................16

Indigo® NXT Manual Start Operation ............................................................................17

Indigo® NXT Changing the Solution Type ......................................................................17

Indigo® Model Procedures ............................................................................................... 18

Indigo® Model Automatic Operation ............................................................................18

Setting Frequency of Cleaning Indigo® Models .............................................................18

Indigo® Model Hose Priming ......................................................................................... 18

Indigo® Model Changing the Solution Type ..................................................................19

Indigo® Model Manual Start Operation ........................................................................19

Changing Switch Position During Operation .................................................................19

Removal from Service/Winterization ............................................................................... 20

Part Number 000009036 Rev03 6/18 5

Page 6

Table of Contents (continued)

THIS PAGE INTENTIONALLY LEFT BLANK

6 Part Number 000009036 Rev03 6/18

Page 7

Section 1

General Information

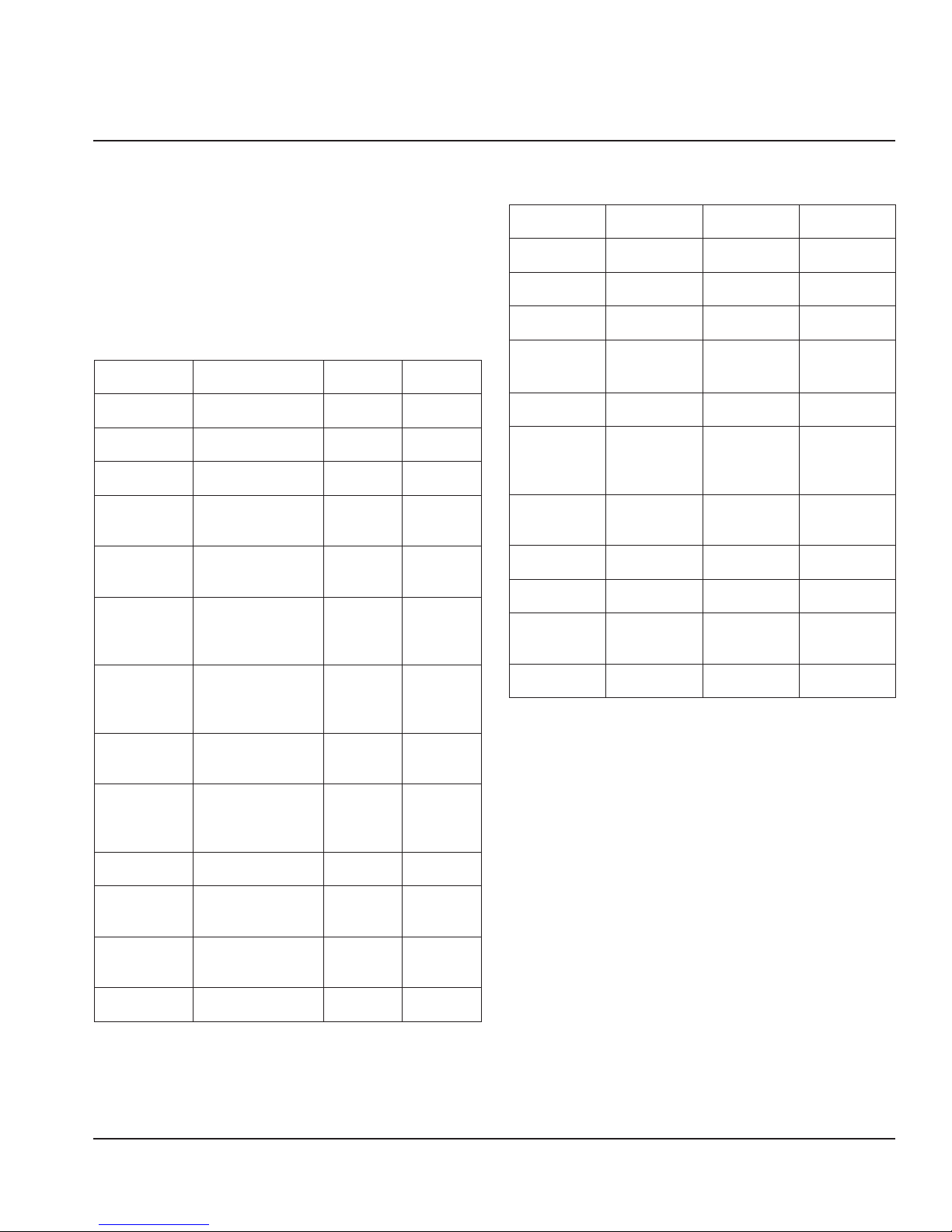

Compatible Ice Machine Models

The iAuCS® accessory can be used on Manitowoc Indigo®

Series ice machines.

NOTE: Automatic Cleaning Systems are not compatible

with S3000 Series, Flake/Nugget, NEO or SM50 model ice

machines.

MODEL COMPATIBILITY

Indigo®

Self-Contained

Air-Cooled

ID0302A

IY0304A

ID0322A

IY0324A

ID0452A

IY0454A

IR0500A

ID0502A

IY0504A

IR0520A

ID0522A

IY0524A

ID0602A

IY0604A

----

---IR0850A

ID0852A

IY0854A

---IR0906A

ID0906A

IY0906A

ID1002A

IY1004A

----

---ID1202A

IY1204A

ID1402A

IY1404A

---IR1800A

ID1802A

IY1804A

----

----

Self-Contained

Water-Cooled

ID0303W

IY0305W

ID0323W

IY0325W

ID0453W

IY0455W

IR0501W

ID0503W

IY0505W

IR0421W

ID0423W

IY0425W

ID0603W

IY0605W

----

---IR0851W

ID0853W

IY0855W

---IR0906W

ID0906W ID0906WM

IY0906W IY0906WM

ID1003W

IY1005W

ID1003WM

---ID1203W

IY1205W

ID1403W

IY1405W

ID1403WM

IR1801W

ID1803W

IY1805W

----

----

Remote

----

----

----

----

----

---IR0590N

ID0592N

IY0594N

----

----

---ID0692N

IY0694N

----

---IR0890N

ID0892N

IY0894N

---IR0996N

ID0996N

IY0996N

ID1092N

IY1094N

----

----

----

---ID1492N

IY1494N

---IR1890N

ID1892N

IY1894N

----

----

QuietQube

Models

----

----

----

----

----

----

----

----

----

----

----

---ID0682C

IY0684C

IB0694YC

IB0692DC

ID0872C

IY0874C

IB0894YC

IB0892DC

ID0976C

IY0976C

---ID1072C

IY1074C

IB1094YC

IB1092DC

ID1272C

IY1274C

ID1472C

IY1474C

ID1872C

IY1874C

---ID2172C

IY2174C

Indigo® NXT

Self-Contained

Air-Cooled

IDF0300A

IYF0300A

IDT0420A

IYT0420A

IDT0450A

IYT0450A

IDT0500A

IYT0500A

IRT0500A

IDF0600A

IYF0600A

IDT0620A

IYT0620A

IRT0620A

IDP0620A

IDF0900A

IYF0900A

IRF0900A

IDT1200A

IYT1200A

IDT1500A

IYT1500A

IDT1900A

IYT1900A

IRT1900A

----

----

Self-Contained

Water-Cooled

IDF0300W

IYF0300W

IDT0420W

IYT0420W

IDT0450W

IYT0450W

IDT0500W

IYT0500W

IRT0500W

IDF0600W

IYF0600W

IDT0620W

IYT0620W

----

---IDF0900W

IYF0900W

---IDT1200W

IYT1200W

IDT1500W

IYT1500W

IDT1900W

IYT1900W

----

----

----

Remote

----

----

----

----

----

---IDT0500N

IYT0500N

---IDF0600N

IYF0600N

----

----

----

---IDF0900N

IYF0900N

---IDT1200N

IYT1200N

IDT1500N

IYT1500N

IDT1900N

IYT1900N

IRT1900N

----

----

QuietQube

Models

----

----

----

----

----

----

----

----

----

IYF0600C

IBF0620C

----

----

---IBF0820C

IYF0900C

IBT1020C

IDT1200C

IYT1200C

IDF1400C

IYF1400C

IDF1800C

IYF1800C

---IDF2100C

IYF2100C

iAuCS® Location

The iAuCS® is mounted on the wall near the ice machine, or

on the bin with the included bracket and hardware.

The iAuCS® must be installed by a trained and qualified

technician.

Warranty Information

Visit www.manitowocice.com for:

• Warranty Verification

• Warranty Registration

• View and download a copy of your warranty

Part Number 000009036 Rev03 6/18 7

Page 8

General Information Section 1

THIS PAGE INTENTIONALLY LEFT BLANK

8 Part Number 000009036 Rev03 6/18

Page 9

Section 2

Installation

General

These instructions are provided to assist the qualified

installer. Check your local Yellow Pages for the name of the

nearest distributor, or contact Manitowoc Ice for information

regarding start-up services.

Please contact you local Manitowoc Distributor or contact

Manitowoc Ice for assistance if you encounter a problem that

is not covered by this manual.

Notice

Failure to follow these installation guidelines may affect

warranty coverage. Improper installation will affect

dispensing rate. Install only within the parameters

outlined in this installation manual.

Electrical Service

GENERAL

Warning

n

A trained and qualified technician must install the iAuCS®.

Voltage Phase Cycle Amperage

115/1/60 0.3

208-230/1/60 0.1

Line voltage is obtained from the ice machine. Refer to the

Model/Serial plate on the ice machine and iAuCS® to verify

both voltages are the same.

iAuCS® Installation

LOCATION/MOUNTING

Warning

n

All wiring must conform to local, state and national codes.

Warning

n

The ice machine and iAuCS® must be grounded in

accordance with national and local electrical codes.

Important

Observe correct polarity of incoming line voltage.

The location selected must meet the following criteria. If any

of these criteria are not met, select another location.

• The location must be free of airborne and other

contaminants.

• The air temperature must be at least 40°F (4°C), but must

not exceed 110°F (43°C).

• The location must not be near heat-generating

equipment or in direct sunlight.

Notice

The iAuCS® accessory must be protected if it will be

subjected to temperatures below 32°F (0°C). Failure

caused by exposure to freezing temperatures is not

covered by the warranty. See “Removal from Service/

Winterization” on page 20.

Part Number 000009036 Rev03 6/18 9

Page 10

Installation Section 2

HEIGHT REQUIREMENT

Either the base or the top of the iAuCS® accessory must

be within 2" (5 cm) of the base of the ice machine. Do not

mount the iAuCS® unit too high or too low.

Notice

The cleaner or sanitizer may siphon (or dispense

improperly) into the ice machine water trough if the

iAuCS® unit is mounted too high or too low.

DISTANCE REQUIREMENT

The iAuCS® unit must be mounted within 9 feet (2.7 m)

of the ice machine to accommodate the low voltage

communication wire and tubing. The tubing may be

shortened to accommodate a run of less than 9 feet (2.7 m).

Notice

Do not extend the length of the 9-foot (2.7 m) low voltage

communication wire or tubing. The correct amount of

solution will not dispense.

Base of Ice

Machine

MOUNTING

Parts

1/2" PVC Conduit

Fitting

Hose Clamps

Locknut

Bumper

Foam Tape

2"

(5 cm)

Box Base or Box Top Must

Be Within 2"

(5 cm) of Ice Machine

Base

Bracket

Notice

The iAuCS® unit may be mounted to the bin or dispenser

only when permitted by local electrical codes.

Mounting to Bin or Dispenser

NOTE: The ice machine’s serviceability may be reduced when

the iAuCS® unit is mounted to the bin or dispenser. Wall

mounting is recommended.

1. Set the mounting bracket over the bin top rail at desired

location.

2. Remove the backing from the foam adhesive tape. Apply

tape to mounting bracket, and along the entire bin rail.

3. Align the iAuCS® key slots with the mounting bracket

tabs. Verify the tabs are at the top of the key slots and

that the iAuCS® unit is level.

10 Part Number 000009036 Rev03 6/18

Page 11

Section 2 Installation

4. Remove the backing from the adhesive bumpers. Attach

bumpers to the mounting bracket directly above the

iAuCS® control box. This eliminates upward movement

and stops the tabs from disengaging the key slots.

Mounting

Bracket

Bumper

Gasket

Mounting to Ice Machine

Mounting to Wall

The iAuCS® is mounted to the wall using the two key slots in

the back wall of the accessory. Screw fasteners (not supplied)

must hold the entire weight of the iAuCS® (approximately 10

lbs. [4.5 kg]).

6.56"

(16.6 cm)

CONNECTION TO ICE MACHINE

Electrical Connections

1. Check electrical code for your area.

• When local code allows, the included wire and strain

relief can be used for line voltage wiring. Remove

knockout from ice machine and install strain relief

and wire.

• When conduit is required, remove strain relief and

ice machine electrical knockout. Install conduit as

required by your electrical code.

Warning

n

Disconnect the electrical power supply to the ice machine

at the electrical disconnect before proceeding.

• Connections on ice machines vary. Refer to the

diagram for the ice machine you are working on.

2. Remove the front, top, and right side panels from the ice

machine.

3. Route line voltage wires through control box line voltage

Heyco fitting. Connect line voltage wires to incoming

power supply of contactor and ground screw.

NOTE: On QuietQube Ice Machines the power connection

is made at the incoming power supply (L1 and L2). Cut-off

yellow terminal (L2) and purple terminal (L1) on iAuCS®

harness. Strip insulation back 1/2" and connect.

Key Slot Dimensions

Low Voltage

Heyco

Fittings

Connect

ground wire

to ground

screw

Line Voltage

Heyco

Fittings

Connect to incoming

power supply of

contactor observing

proper polarity for

115V

Part Number 000009036 Rev03 6/18 11

Page 12

Installation Section 2

Communication Wire and Vinyl Tubing

The communication wire and vinyl tubing must be installed in

conduit to protect them from damage.

1. Remove the 7/8" knockout hole plug located on the back

of the ice machine.

2. Install conduit from the iAuCS® unit to the ice machine.

A pulling elbow is recommended for easier routing of

the vinyl tubing and modular wire.

3. Route low voltage communication wire and vinyl tubing

together through the conduit.

4. Route modular wire through control box low voltage

Heyco fitting. Do not route with line voltage wiring, as

erratic operation could result. Connect modular wire to

control board.

5. Connect the communication wire to the iAuCS® control

board.

iAuCS®

Communication

Plug Connection

Vinyl Tubing Connection

1. Remove the water trough.

A. Depress tabs on right and left side of the water

trough.

B. Allow front of water trough to drop as you pull

forward to disengage the rear pins.

2. Locate the water inlet tube on the right hand side (see

below) of the ice machine base.

• After serial number 1101246915 - Use a screwdriver

to remove membrane.

• Before serial number 1101246915 - Press up on the

plug until it is out.

Control Board

Press up on

bottom of plug

to pop out

Plug Location

Water Inlet

Tubing

After Serial Number

1101246915 use

screwdriver to remove

membrane

12 Part Number 000009036 Rev03 6/18

Page 13

Section 2 Installation

3. Locate and remove either the membrane material or the

plug from the ice machine.

4. Apply food grade silicone and install Y connector through

the hole in the ice machine base. Connect the clear vinyl

tubing to one side of the Y branch. The other side is for

the plug removed in step 3 or the plug provided with the

iAuCS®.

Route tubing

to this area

Insert Y

connector

with tubing

Top View

5. Determine the amount of tubing required in the iAuCS®

control box and cut off the excess tubing.

6. Slide the tubing on the iAuCS® pump.

Slide the tubing

on the iAuCS®

pump

Install plug

provided with

iAuCS®

or

plug removed in

Step 3

Connect

Tubing

Into Base of

Ice Machine

Y-Connector

Part Number 000009036 Rev03 6/18 13

Page 14

Installation Section 2

THIS PAGE INTENTIONALLY LEFT BLANK

14 Part Number 000009036 Rev03 6/18

Page 15

Section 3

Operation

Determine Type of Solution Needed

Caution

,

Use only Manitowoc approved Ice Machine Cleaner

& Sanitizer. It is a violation of Federal law to use these

solutions in a manner inconsistent with their labeling.

Read and understand all labels on the bottles before use.

The iAuCS® accessory will dispense Cleaner OR Sanitizer. It

cannot dispense both at the same time.

MANITOWOC ICE MACHINE CLEANER

Part Number 9405463

Ice Machine Cleaner is used to control buildup and to remove

lime scale or other mineral deposits. It will not “sanitize” the

ice machine.

It is recommended for use in places that have lime scale or

other mineral deposits, but no problems with slime.

Model Amount of Cleaner Dispensed

22" or 30"

Ice Machine

48" Ice Machine 6 oz (177 ml)

3 oz (88 ml)

Important

Using the iAuCS® accessory is supplemental to regular

cleaning and sanitizing. The iAuCS® accessory will clean

surfaces that come in contact with the water distribution

system. Periodic maintenance must be performed every

six months that includes sanitizing the bin (or dispenser)

and adjacent surface areas, which cannot be contacted

by the water distribution system. Refer to the ice machine

installation operation and maintenance manual for

cleaning/sanitizing procedures.

Installing/Replacing Cleaner or Sanitizer Bottles

Caution

,

Do not mix Cleaner and Sanitizer solutions together. It

is a violation of Federal law to use these solutions in a

manner inconsistent with their labeling.

1. Remove left iAuCs®panel.

MANITOWOC ICE MACHINE SANITIZER

Part Number 9405653

Ice Machine Sanitizer is used for sanitizing and controlling

algae buildup (slime) and other bacterial growth. The ice

machine (and bin or dispenser) must be sanitized on a

regular schedule, following Manitowoc recommendations

and local regulations.

It is recommended for use in places such as pizzerias, bars,

bakeries, etc., that have airborne bacteria (yeast). Sanitizing

is also recommended in places that do not have lime scale

(or other mineral deposit problems).

Model Amount of Sanitizer Dispensed

22" or 30"

Ice Machine

48" Ice Machine 6 oz (176 ml)

3 oz (88 ml)

2. Unscrew nozzle/tubing from bottle, then remove bottle.

3. Remove bottle cap and foil seal from new bottle.

4. Install nozzle/tubing on new bottle.

5. Reinstall left panel.

Unscrew cap and remove bottle

Remove cap and foil seal from new

bottle and install

Part Number 000009036 Rev03 6/18 15

Page 16

Operation Section 3

Indigo® NXT Model Procedures

INDIGO® NXT AUTOMATIC OPERATION

The following occurs when the ice machine is in ice making

mode:

• A cleaning sequence starts when the time interval equals

the Frequency of Cleaning setting of the iAuCS®.

• When the clean sequence is complete

(approximately 35 minutes depending on model), ice

making resumes until the next cleaning setpoint.

INDIGO® NXT SETTING FREQUENCY OF CLEANING

1. Navigate to iAuCs® on the touchscreen:

Menu/Settings/iAuCs®.

2. Use the arrows to select the frequency of cleaning - from

once a month, up to once every six months.

3. Select On, then press the Home icon. Priming the pump

is required if initial installation or the dispense hose does

not contain cleaner or sanitizer.

INDIGO® NXT HOSE PRIMING

The dispense pump requires priming after initial installation,

or if the hose between the iAuCS® reservoir and pump has

been pumped dry or the tubing between the iAuCS® pump

and the ice machine has been pumped dry.

Warning

n

Do not blow into or suck on the hose in an attempt to

prime it.

Important

iAuCS® does not operate when the CLEAN button is used

to start a clean cycle. To prime the hose, activation is

required through the Service Menu/iAuCS® icon.

Perform the following procedure:

1. Remove all ice from the evaporator(s) before priming.

2. Place a bottle of cleaner or sanitizer in the

iAuCs®cabinet. Insert the pump inlet hose into the bottle

and verify the pump outlet hose is correctly attached to

the ice machine. Refer to “Installing/Replacing Cleaner

or Sanitizer Bottles” on page 15.

3. Navigate to iAuCs® on the touchscreen:

Menu/Service/iAuCs®.

4. Select On - A cleaning cycle will start by purging the

water in the water trough. When the water trough refills

and water contacts the water level probe, the iAuCs®

pump will energize and prime the pump (touchscreen

displays step 4).

NOTE: After the iAuCs® pump dispenses, the washing, rinsing

and flushing cycles must complete before an ice making cycle

can start.

16 Part Number 000009036 Rev03 6/18

5. The ice machine will turn off at the end of the cycle.

To automatically start ice making when the cycle is

complete, press the power button Off, then On during

either the wash or rinse cycles. The clean cycle will

resume from the beginning of either the washing

or rinsing/flushing cycle, depending on the point of

interruption.

Page 17

Section 3 Operation

INDIGO® NXT MANUAL START OPERATION

Step 1 Ice must not be on the evaporator during the

clean/sanitize cycle. Follow one of the methods below:

• Press the power switch at the end of a harvest cycle after

ice falls from the evaporator(s).

• Press the power switch and allow the ice to melt.

• Use the touchscreen to initiate a manual harvest cycle

Menu/Service/Manual harvest/press to start harvest.

Step 2 Navigate to iAuCs® on the touchscreen:

Menu/Service/iAuCs®/Select On

A cleaning cycle will start by purging the water in the water

trough. When the water trough refills and water contacts

the water level probe, the iAuCs® pump will energize

(touchscreen displays step 4).

NOTE: After the iAuCs® pump dispenses, the washing, rinsing

and flushing cycles must complete before an ice making cycle

can start.

Step 3 The ice machine will turn off at the end of the

cycle. To automatically start ice making when the cycle

is complete, press the power button Off, then On during

the wash cycle (step 5 Washing is displayed). The clean

cycle will resume from the beginning of the washing cycle

and automatically start ice making when the clean cycle is

complete.

INDIGO® NXT CHANGING THE SOLUTION TYPE

Caution

,

Wear rubber gloves and safety goggles (and/or face

shield) when handling Cleaner and Sanitizer.

Caution

,

Do not mix Cleaner and Sanitizer solutions together. It

is a violation of Federal law to use these solutions in a

manner inconsistent with their labeling.

Notice

Do not use 1 gallon bottles of Cleaner or Sanitizer on the

iAuCS® accessory.

Use the following procedure to flush the system prior to

changing from Cleaner to Sanitizer or from Sanitizer to

Cleaner.

1. Remove all ice from the evaporators before proceeding.

2. Remove the bottle of Cleaner or Sanitizer from the

iAuCS®. Flush the bottle thoroughly, then fill with water.

3. Repeat the following a minimum of two times:

A. Navigate to iAuCs® on the touchscreen and select :

Menu/Service/iAuCs®.

Important

Opening the curtain switch will interrupt the clean

sequence. The sequence will resume from the point of

interruption when the curtain re-closes.

B. A cleaning cycle will start by purging the water in

the water trough. When the water trough refills and

water contacts the water level probe, the iAuCs®

pump will energize and prime the pump

4. Install a new bottle of cleaner or sanitizer solution.

Refer to “Installing/Replacing Cleaner or Sanitizer

Bottles” on page 15.

Part Number 000009036 Rev03 6/18 17

Page 18

Operation Section 3

Indigo® Model Procedures

INDIGO® MODEL AUTOMATIC OPERATION

The following occurs when the ice machine is in ice making

mode:

• A cleaning sequence starts when the time interval equals

the Frequency of Cleaning setting of the iAuCS®.

• When the clean sequence is complete

(approximately 25 minutes depending on model), ice

making resumes until the next cleaning setpoint.

SETTING FREQUENCY OF CLEANING INDIGO® MODELS

The iAuCS® unit is factory-set to initiate and complete a clean

sequence approximately once every two weeks.

iAuCS®

For less frequent cleaning, use the controller to select an

interval.

1. Press Menu.

2. Scroll to Setup and press right arrow.

3. Scroll to iAuCS Runtime and press right arrow.

Display reads:

iAuCS on

iAuCS off

Set interval

Exit

4. Select iAuCS on and press check mark.

5. Select Set interval. Display reads:

.5 mo

1 mo

2 mo

3 mo

4 mo

5 mo

6 mo

Exit

6. Select desired time period and press check mark

(15 days, 1 month, 2 months, etc.).

7. Press left arrow repeatedly to exit to Main screen.

INDIGO® MODEL HOSE PRIMING

The dispenser pump requires priming after initial installation,

or if the hose between the iAuCS® reservoir and pump has

been pumped dry or the tubing between the iAuCS® pump

and the ice machine has been pumped dry.

Warning

n

Do not blow into or suck on the hose in an attempt to

prime it.

Perform the following procedure:

1. Press the CLEAN button.

2. The water pump and dump valve will turn on. The dump

valve will shut off after approximately 45 seconds.

3. The control waits until water contacts the water level

probe then energizes the iAuCS® pump (22" or 30" ice

machines - 30 seconds, 48" ice machines - 60 seconds).

4. Allow the ice machine to complete the cleaning or

sanitizing cycle.

Important

The priming procedure starts the automatic cleaning

mode. After starting an ice making cycle, the ice machine

will run through 6 rinse and dump cycles before making

ice.

18 Part Number 000009036 Rev03 6/18

Page 19

Section 3 Operation

INDIGO® MODEL CHANGING THE SOLUTION TYPE

Caution

,

Wear rubber gloves and safety goggles (and/or face

shield) when handling Cleaner and Sanitizer.

Caution

,

Do not mix Cleaner and Sanitizer solutions together. It

is a violation of Federal law to use these solutions in a

manner inconsistent with their labeling.

Notice

Do not use 1 gallon bottles of Cleaner or Sanitizer on the

iAuCS® accessory.

Use the following procedure to flush the system prior to

changing from Cleaner to Sanitizer or from Sanitizer to

Cleaner.

1. Remove the bottle of Cleaner or Sanitizer from the

iAuCS®. Flush the bottle thoroughly then fill with water.

2. Repeat the following until the water bottle is empty

(approximately 8 times):

A. Press the CLEAN button.

B. The water pump and dump valve will turn on.

The dump valve will shut off after approximately

45 seconds.

C. The control waits until the water contacts the water

level probe then energizes the iAuCS® pump (22" or

30" ice machines - 30 seconds, 48" ice machines - 60

seconds).

D. Press the POWER button after step C is completed.

3. Install a new bottle of cleaner or sanitizer solution.

INDIGO® MODEL MANUAL START OPERATION

Step 1 Press the power button after ice falls from the

evaporator at the end of a Harvest cycle. Or, press the power

button and allow the ice to melt off the evaporator.

Notice

Never use anything to force ice from the evaporator.

Damage may result.

Step 2 To start the automatic cleaning system, press the

CLEAN button. The water will flow through the water dump

valve and down the drain. The clean light will turn on to

indicate the ice machine is in Clean Mode.

The iAuCS® pump energizes automatically to add cleaner or

sanitizer to the ice machine.

Step 3 The ice machine will automatically time out a wash

cycle, followed by rinse cycles, and stop. This entire cycle

lasts approximately 24 minutes for Indigo® Series.

Step 4 The ice machine will start and finish the clean

sequence, then automatically start ice making again.

CHANGING SWITCH POSITION DURING OPERATION

If a clean cycle is started and then stopped before the water

inlet valve energizes or the water pump starts (45 seconds

into the cycle), the clean cycle will be aborted.

If a clean cycle is started and then stopped after the water

inlet valve energizes (more than 45 seconds into the cycle)

and is then switched to:

ICE MAKING The clean sequence resumes from the point of

interruption. After completion of the cleaning

sequence, the counter resets and the ice

machine starts making ice.

CLEAN The clean sequence resumes from the point of

interruption.

After the clean cycle is complete, the ice

machine will stop and wait until either Ice

Making or Clean is manually selected.

Part Number 000009036 Rev03 6/18 19

After the iAuCs® pump energizes, the ice machine must

complete the wash and rinse cycles before ice making can

start.

Page 20

Operation Section 3

Removal from Service/Winterization

Notice

Leaving solutions in the iAuCS® in freezing temperatures

may result in severe damage to the dispensing pump. A

failure of this nature is not covered by the warranty.

If the iAuCS® is to be removed from service for extended

periods, or if it is to be exposed to ambient temperatures

32°F (0°C) or below, follow this procedure:

1. Remove the Cleaning or Sanitizing solution bottle.

2. Follow the instructions for your model ice machine to

pump all of the solution out of the dispensing pump and

lines:

• “Indigo® NXT Hose Priming” on page 16

• “Indigo® Model Hose Priming” on page 18

20 Part Number 000009036 Rev03 6/18

Page 21

Page 22

Page 23

Page 24

MANITOWOC ICE

2110 SOUTH 26TH STREET, MANITOWOC, WI 54220

WWW.MANITOWOCICE.COM

844-724-2273

Welbilt provides the world’s top chefs, and premier chain operators or growing independents with industry leading equipment and soluons.

Our cung-edge designs and lean manufacturing taccs are powered by deep knowledge, operator insights, and culinary experse.

All of our products are backed by KitchenCare® – our aermarket, repair, and parts service.

CLEVELAND

CONVOTHERM®

©2017 Welbilt Inc. except where explicitly stated otherwise. All rights reserved.

Part Number 000009036 Rev03 6/18

DELFIELD®

FITKITCHEN™

FRYMASTER®

GARLAND

KOLPAK®

LINCOLN

WWW.WELBILT.COM

MANITOWOC®

MERCO®

MERRYCHEF®

MULTIPLEX®

Loading...

Loading...