Manitowoc Granitore 1, Granitore 1 FF, Granitore 2, Granitore 2 FF, Granitore 3 Service Manual

...Page 1

Single, Dual and Triple Granita Machine

INSTALLATION & SERVICE GUIDE

Part Number 020001173

Manitowoc Beverage Equipment

2100 Future Drive Sellersburg, IN 47172-1868

Tel: 812.246.7000, 800.367.4233 Fax: 812.246.9922

www.manitowocbeverage.com

In accordance with our policy of continuous product development and

improvement, this information is subject to change at any time without notice.

January 03, 2007 REV1

Page 2

FOREWORD

Manitowoc Beverage Equipment (MBE) developed this manual as a reference guide for the owner/

operator, service agent, and installer of this equipment. Please read this manual before installation

or operation of the machine. A qualified service technician should perform installation and startup of this equipment, consult the

If you cannot correct the service problem, call your MBE Service Agent or Distributor. Always have your model and

serial number available when you call.

Your Service Agent___________________________________________________________________

Service Agent Telephone Number ______________________________________________________

Your Local MBE Distributor ___________________________________________________________

Distributor Telephone Number _________________________________________________________

Model Number ______________________________________________________________________

Serial Number _______________________________________________________________________

Installation Date _____________________________________________________________________

Troubleshooting Guide

within this manual for service assistance.

UNPACKING AND INSPECTION

Note: The unit was thoroughly inspected before leaving the factory. Any damage or irregularities should

be noted at the time of delivery.

WARRANTY INFORMATION

Consult your local MBE Distributor for terms and conditions of your warranty. Your warranty specifically

excludes all beverage valve brixing, general adjustments, cleaning, accessories and related servicing.

Your warranty card must be returned to Manitowoc Beverage Equipment to activate the warranty on this

equipment. If a warranty card is not returned, the warranty period can begin when the equipment leaves

the MBE factory.

No equipment may be returned to Manitowoc Beverage Equipment without a written Return Merchandise

Authorization (RMA). Equipment returned without an RMA will be refused at MBE’s dock and returned to

the sender at the sender’s expense.

Please contact your local MBE distributor for return procedures.

Page 3

TABLE OF CONTENTS

FOREWORD ........................................................................................................ 2

UNPACKING AND INSPECTION......................................................................... 2

WARRANTY INFORMATION ............................................................................... 2

SAFETY ............................................................................................................... 5

IMPORTANT SAFETY INSTRUCTIONS ........................................................................... 5

CARBON DIOXIDE WARNING ......................................................................................... 5

QUALIFIED SERVICE PERSONNEL ................................................................................ 5

SHIPPING, STORAGE, AND RELOCATION ..................................................................... 5

ADDITIONAL WARNINGS ................................................................................................ 5

GROUNDING INSTRUCTIONS ........................................................................................ 6

GENERAL SAFETY RULES ............................................................................................. 7

STOP FUNCTIONS ........................................................................................................... 7

PLATES ............................................................................................................................ 7

GENERAL INFORMATION .................................................................................. 8

MANUFACTURER ............................................................................................................ 8

AUTHORIZED PERSONS ................................................................................................ 8

LAYOUT OF THE MANUAL ............................................................................................. 8

PURPOSE AND CONTENTS ............................................................................................ 8

WHO MUST READ THE MANUAL ................................................................................... 8

HOW TO KEEP THE MANUAL......................................................................................... 9

SYMBOLS USED ............................................................................................................. 9

INSTALLATION .................................................................................................. 10

LIST OF ACCESSORIES PROVIDED ............................................................................. 10

POSITIONING ................................................................................................................. 10

DISPOSAL OF PACKING MATERIALS .......................................................................... 10

ELECTRICAL CONNECTION ..........................................................................................11

OPERATION ...................................................................................................... 11

CONTROL PANEL ...........................................................................................................11

USE OF THE MACHINE ................................................................................................. 12

MAIN COMPONENTS .................................................................................................... 12

TECHNICAL DATA ......................................................................................................... 12

PACKAGING .................................................................................................................. 13

Page 4

TABLE OF CONTENTS

CONVEYANCE AND HANDLING ................................................................................... 13

STORAGE ...................................................................................................................... 13

PREPARING THE PRODUCT ......................................................................................... 14

STARTING A GRANITORE ............................................................................................. 15

ADJUSTING GRANITA CONSISTENCY......................................................................... 16

INDICATIONS FOR CORRECT USE ............................................................................. 17

EMERGENCY SITUATIONS ........................................................................................... 17

ACCESSORY (OPTIONAL) (LOCKING SYSTEM).......................................................... 17

USER MAINTENANCE ...................................................................................... 17

PREVENTATIVE MAINTENANCE .................................................................................. 17

EMPTYING THE BOWLS ............................................................................................... 19

DISASSEMBLING THE DISPENSING TAP .................................................................... 19

REMOVING THE BOWL ................................................................................................. 20

WASHING AND SANITIZING THE COMPONENTS ....................................................... 20

REASSEMBLING THE WASHED COMPONENTS ......................................................... 21

RINSING CYCLE ............................................................................................................ 22

CLEANING THE DRIP TRAY .......................................................................................... 22

LIGHTED LID MAINTENANCE ....................................................................................... 23

BULB REPLACEMENT .................................................................................................. 23

CLEANING THE CONDENSER ...................................................................................... 23

CLEANING THE GRANITORE 1/1FF CONDENSER ...................................................... 24

CLEANING GRANITORE 2/2 FF - 3/3 FF COND ............................................................ 24

SCRAPPING ................................................................................................................... 25

TROUBLESHOOTING .................................................................................................... 25

EXPLODED VIEWS, PARTS & DIAGRAMS ..................................................... 26

GRANITORE 1 - 1 FF WIRING........................................................................................ 26

GRANITORE 2 - 2FF WIRING ........................................................................................ 27

GRANITORE 3 - 3FF 230V WIRING ............................................................................... 28

GRANITORE 3 - 3FF 115V WIRING................................................................................ 29

GRANITORE 1FF EXPLODED VIEW ............................................................................. 30

GRANITORE 2FF EXPLODED VIEW ............................................................................. 32

GRANITORE 3FF EXPLODED VIEW ............................................................................. 34

INDEX................................................................................................................. 39

Page 5

Installation and Service Manual

SAFETY

IMPORTANT SAFETY INSTRUCTIONS

Carefully read all safety messages in this manual. Learn how to operate the Chillz unit properly.

Do not allow anyone to operate the unit without proper training and keep it in proper working

condition. Unauthorized modifications to the Chillz unit may impair function and/or safety and

affect the life of the unit.

CARBON DIOXIDE WARNING

DANGER: Carbon Dioxide (CO2) displaces oxygen. Exposure to a high concentration of CO2 gas

causes tremors, which are followed rapidly by loss of consciousness and suffocation. If a CO2 gas leak

is suspected, particularly in a small area, immediately ventilate the area before repairing the leak. CO

lines and pumps should not be installed in an enclosed space. An enclosed space can be a cooler or

small room or closet. This may include convenience stores with glass door self serve coolers. If you

suspect CO2 may build up in an area, venting of the B-I-B pumps and / or CO2 monitors should be utilized.

QUALIFIED SERVICE PERSONNEL

WARNING: Only trained and certified electrical and plumbing technicians should service this unit.

All wiring and plumbing must conform to national and local codes.

2

SHIPPING, STORAGE, AND RELOCATION

CAUTION: Before shipping, storing, or relocating this unit, syrup systems must be sanitized. After

sanitizing, all liquids (sanitizing solution and water) must be purged from the unit. A freezing environment causes residual sanitizing solution or water remaining inside the unit to freeze, resulting

in damage to internal components.

ADDITIONAL WARNINGS

Installation and start-up of this equipment should be done by a qualified service technician. Operation,

maintenance, and cleaning information in this manual are provided for the user/operator of the equipment.

Save these instructions.

5

Page 6

Installation and Service Manual

SAFETY

GROUNDING INSTRUCTIONS

WARNING: Risk of electrical shock. Connect to a properly grounded outlet only.

This appliance must be grounded. In the event of malfunction or breakdown, grounding provides

a path of least resistance for electric current to reduce the risk of electric shock. This appliance is

equipped with a cord having an equipment-grounding conductor and a grounding plug. The plug

must be plugged into an appropriate outlet that is properly installed and grounded in accordance

with all local codes and ordinances.

DANGER – Improper connection of the equipment-grounding conductor can result in a risk of

electric shock. The conductor with insulation having an outer surface that is green with or without

yellow stripes is the equipment grounding conductor. If repair or replacement of the cord or plug

is necessary, do not connect the equipment-grounding conductor to a live terminal. Check with a

qualified electrician or serviceman if the grounding instructions are not completely understood, or

if in doubt as to whether the appliance is properly grounded. Do not modify the plug provided with

the appliance – if it will not fit the outlet, have a proper outlet installed by a qualified electrician.

WARNING – When using electric appliances, basic precautions should always be followed, including the following:

a) Read all the instructions before using the appliance.

b) To reduce he risk of injury, close supervision is necessary when an appliance is used

near children.

c) Do not contact moving parts.

d) Only use attachments recommended or sold by the manufacturer.

e) Do not use outdoors.

f) For a cord-connected appliance, the following shall be included:

• Do not unplug by pulling on cord. To unplug, grasp the plug, not the cord.

• Unplug from outlet when not in use and before servicing or cleaning.

• Do not operate any appliance with a damaged cord or plug, or after the appliance

malfunctions or is dropped or damaged in any manner. Return appliance to the

nearest authorized service facility for examination, repair, or electrical or mechanical

adjustment.

g) For a permanently connected appliance – Turn the power switch to the off position

when the appliance is not in use and before servicing or cleaning.

h) For an appliance with a replaceable lamp – always unplug before replacing the lamp.

Replace the bulb with the same type.

i) For a grounded appliance – Connect to a properly grounded outlet only. See Grounding

Instructions.

SAVE THESE INSTRUCTIONS

6

Page 7

SAFETY

GENERAL SAFETY RULES

Installation and Service Manual

• Carefully read the whole instruction manual.

• The connection to the electricity mains must comply

with the current safety standards in the user’s country.

• The machine must be connected to an electric outlet

that is:

- compatible with the plug provided with the machine;

- of dimensions conforming to the data shown on

the rating plate on the side of the machine.

- properly grounded;

- connected to a system provided with a differential switch and circuit breaker.

• The power cord must not be:

- allowed to come into contact with any kind of liquid: danger of electric shocks and/or fire;

- crushed and/or brought into contact with sharp

surfaces;

- used to move the machine;

- used if it shows any damage;

- handled with damp or wet hands;

- wound into a coil when the machine is on.

- tampered with.

• DO NOT:

- install the machine in a manner other than that

described in Chap. 5.

- Install the machine in a place where it may be

exposed to sprays of water.

- use the machine near inflammable and/or explosive substances.

- leave plastic bags, polystyrene, nails etc. within

children’s reach, since they are potential sources

of danger.

- allow children to play near the machine.

- use spare parts other than those recommended

by the manufacturer.

- make any technical changes to the machine.

- immerse the machine in any kind of liquid.- spray

water on the machine to wash it.

- use the machine other than as directed in this

manual.

- use the machine when not in full possession of

your mental and physical faculties: under the influence of drugs, alcohol, etc.

- install the machine on top of other equipment.

- use the machine in an explosive or aggressive

atmosphere or in the presence of a high concentration of dust or oily substances suspended in

the air;

- use the machine in a place where there is a

risk of fire;

- use the machine to dispense substances that are

not compatible with the machine’s specifications;

• Before cleaning the machine, make sure that it is unplugged; do not clean the machine with gasoline and/

or solvents of any kind.

• Repair work may be performed only by a Service Center authorized by the Manufacturer and/or specialized,

trained personnel.

• Do not obstruct the grill vents on the side of the machine.

• Do not position the machine near heating equipment

(stoves or radiators).

• In case of fire, use carbon dioxide (CO2) extinguishers. Do not use water or powder extinguishers.

In the event of improper use, all warranty rights will be forfeited and the manufacturer will accept no liability for injury

or damage to persons and/or property.

The following are to be considered improper use:

- any use other than the intended use and/or with

methods other than those described herein;

- any operation on the machine that is in contrast

with the directions provided herein;

- use of the machine after any components have

been tampered with and/or safety devices have

been changed;

- use of the machine after it has undergone repair

with components not authorized by the manufacturer;

- outdoor installation of the machine.

STOP FUNCTIONS

The machine is shut down by turning off the main switch.

PLATES

None of the plates or labels applied on the machine must be removed, covered or damaged, especially

those relating to safety.

7

Page 8

Installation and Service Manual

GENERAL INFORMATION

MANUFACTURER

The manufacturer’s details are shown on the identification plate, illustrated on first and/or last page of the manual.

AUTHORIZED PERSONS

Two types of persons may access the machine for different purposes.

User

A person who has adequate technical training to prepare the products the machine uses to dispense granita, in

observance of current standards of hygiene. After reading this manual, he will be capable of:

• Carrying out normal product loading and/or replacement operations;

• Properly dispensing the product;

• Cleaning and sanitizing the machine.

Specialized technician

A person who has examined this manual and has specific training in the installation, use and servicing of the

granita machine:

• He must be able to carry out repairs in the event of serious faults and be well acquainted with this manual and

all the information regarding safety;

• He must be able to understand the contents of the manual and correctly interpret drawings and diagrams;

• He must be familiar with the most important sanitary, accident prevention, technological and safety standards;

• He must have specific experience in servicing granita machines;

• He must know how to behave in case of emergency, where to find individual safety equipment and how to use

it properly.

Persons who do not meet the above requirements must not be allowed to use the machine.

LAYOUT OF THE MANUAL

The Purchaser must very carefully read the information contained in this manual.

PURPOSE AND CONTENTS

The purpose of this manual is to provide the Purchaser with all the necessary information regarding the installation,

maintenance and use of the granita machine.

Before carrying out any operation on the machine, users and specialized technicians must carefully read the instructions herein.

Should you have any doubts as to the correct interpretation of these instructions, contact the manufacturer to

request the necessary explanations.

You should not carry out any type of operation until you have read and thoroughly understood the

contents of this manual.

WHO MUST READ THE MANUAL

This manual is aimed at users and specialized technicians.

Users must not attempt to carry out any operations restricted to qualified technicians.

The manufacturer will not be liable for any damage or injury caused as a result of failure to comply with this rule.

The instruction manual is an integral part of the product purchased and must therefore be handed over to any

subsequent owners.

8

Page 9

Installation and Service Manual

GENERAL INFORMATION

HOW TO KEEP THE MANUAL

This instruction manual must be kept in the immediate vicinity of the machine. Due precautions should be taken to

ensure that the manual is maintained intact and legible over time:

• Use the manual in such a way as to avoid damaging any of its contents.

• Do not for any reason remove, tear or rewrite parts of the manual.

• Keep the manual in a place that is protected against humidity and heat in order to preserve the quality of the

print and the legibility of all its parts.

If the present instruction manual is damaged or lost, another copy should be immediately requested

from the manufacturer or authorized distributor in the user’s country.

SYMBOLS USED

GENERAL DANGER WARNING

It indicates a danger which may also place the User at mortal risk. In such cases utmost care is required

and every precaution must be taken in order to operate safely.

DANGERS OF ELECTROCUTION

It warns the personnel concerned that the operation described may result in an electric shock unless all the

necessary safety precautions are taken

IMPORTANT

It indicates a cautionary note, a note about key functions or useful information. Very close attention should

be paid to the portions of text marked with this symbol

PROHIBITED

This symbol is used to indicate operations that must absolutely be avoided since they create hazards for

the User and any other individuals present in the vicinity.

DO NOT EXTINGUISH FIRES WITH WATER

The presence of this symbol warns against attempting to extinguish fires with water or any substance

containing water.

PERSONAL PROTECTION

When this symbol appears alongside a description it means that personal safety equipment must be used,

as there is an implicit risk of accidents.

SPECIALIZED TECHNICIAN

It identifies operations that may be performed only by qualified technical personnel.

MOVING MACHINE PARTS

It identifies the danger due to moving parts existing in the machine. Turn off the machine before carrying

out any operation.

9

Page 10

Installation and Service Manual

s

INSTALLATION

All of the operations described may be carried out exclusively by specialized technicians, who must organize all the operational sequences and use suitable equipment, in strict compliance with the applicable

regulations currently in force. The machine must be installed indoors in a well-lit and well-ventilated room

with a firm, solid, level floor (slope less than 2°).

The machine is of the attended type, and must be installed in places where it can be monitored by trained

personnel. The machine may only operate in places with an ambient temperature ranging between 20°C

and 32°C.

LIST OF ACCESSORIES PROVIDED

The following items of equipment are supplied with the

standard model of the machine:

• Padlock and key (1 for each bowl of the granita

machine): to lock the bowl during normal use and

prevent its opening by unauthorized persons.

POSITIONING

The installer must check that:

• the site has been duly prepared for machine installation;

• the surface the machine will be installed on is firm,

flat and solid;

• the room is adequately lit, ventilated and hygienic

and an electric outlet is within easy reach.

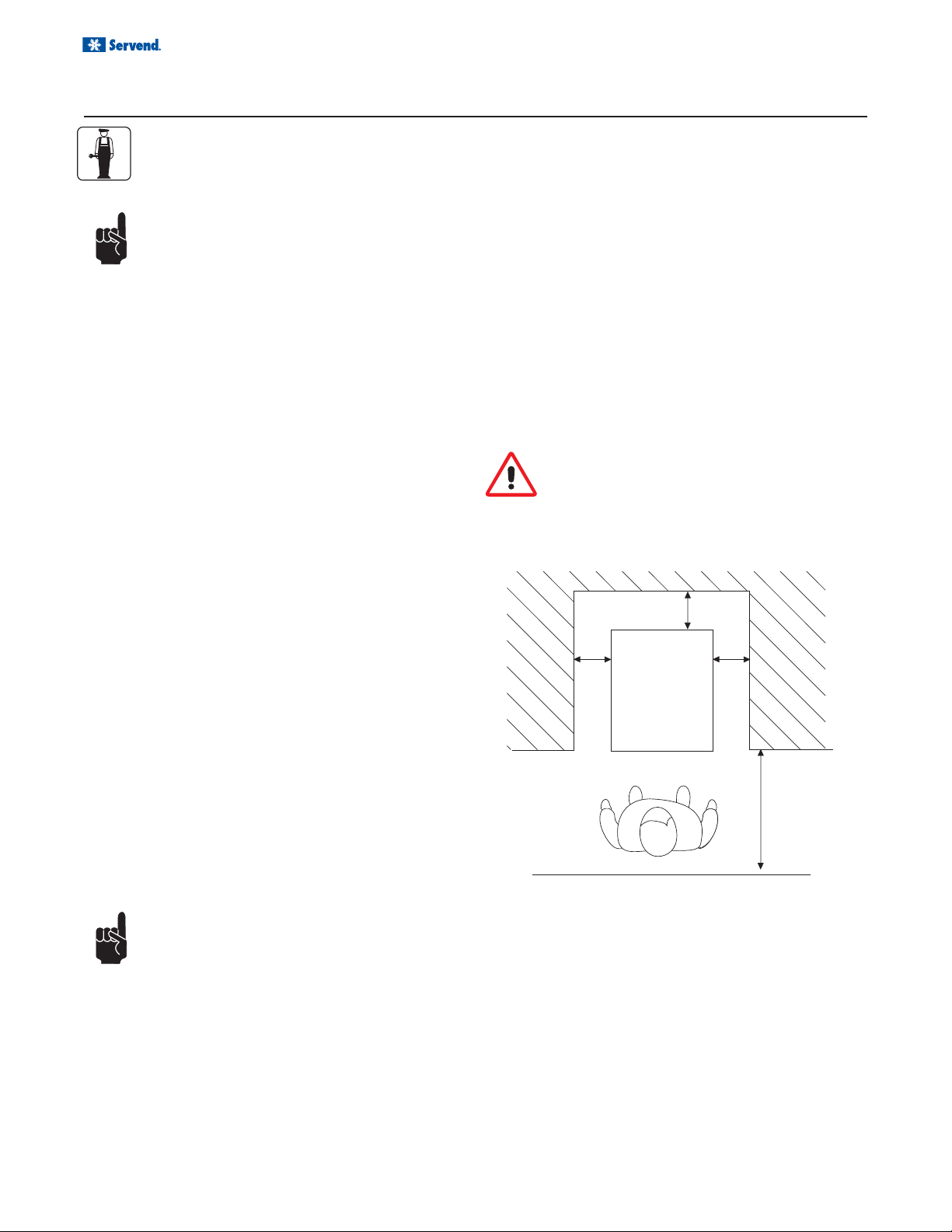

The figure indicates the space required for accessing:

• the control panel on the right side;

• machine parts so that they may be serviced in the

event of a fault.

After positioning the packing container in the vicinity of

the installation site, proceed as follows:

1. cut the straps securing the box;

2. lift the cardboard box;

3. then lift the machine and position it on the prepared site.

• Food Grade Lubricant: to lubricate all of the parts

indicated in this manual after washing and sanitization operations.

Adequate clearance must be left around the

machine to enable personnel to work without any constraints and also to leave the

work area immediately in case of need. The

figure below shows the minimum clearances for installation

25 cm

10 inches

25 cm

10 inches

25 cm

10 inches

150 cm

60 inche

Note: Leave a 25 cm (10 inches) space in the upper part.

Before the machine is used for the first time, its components must undergo thorough cleaning and the

parts that will come into contact with the granita must be sanitized; for further details see the relevant

section herein.

DISPOSAL OF PACKING MATERIALS

After opening the box, make sure to separate the packing materials according to type and dispose of them in

accordance with the current regulations in the user’s country. We recommend keeping the box for future conveyance or transport

10

Page 11

Installation and Service Manual

INSTALLATION

ELECTRICAL CONNECTION

This job may be performed only by specialized technical personnel. Before plugging in the machine, make

sure that the main switch is on “0”. The Purchaser is responsible for making the electrical connection. The

machine must be connected to the electricity mains by means of the plug fitted on the power cord. Be sure

to comply with:

• the technical regulations and standards in

force at the time of installation;

Warning: the electric outlet must be situated in a place easily within reach of the user, so that no

effort is required in order to disconnect the machine from the power supply when necessary.

If the power cord is damaged, you must have it replaced either by the manufacturer or a specialized technician.

It is forbidden:

• the data shown on the rating plate on the side of

the machine.

• to use extension cords of any type;

• to replace the original plug;

The machine controls are located on the side control panel

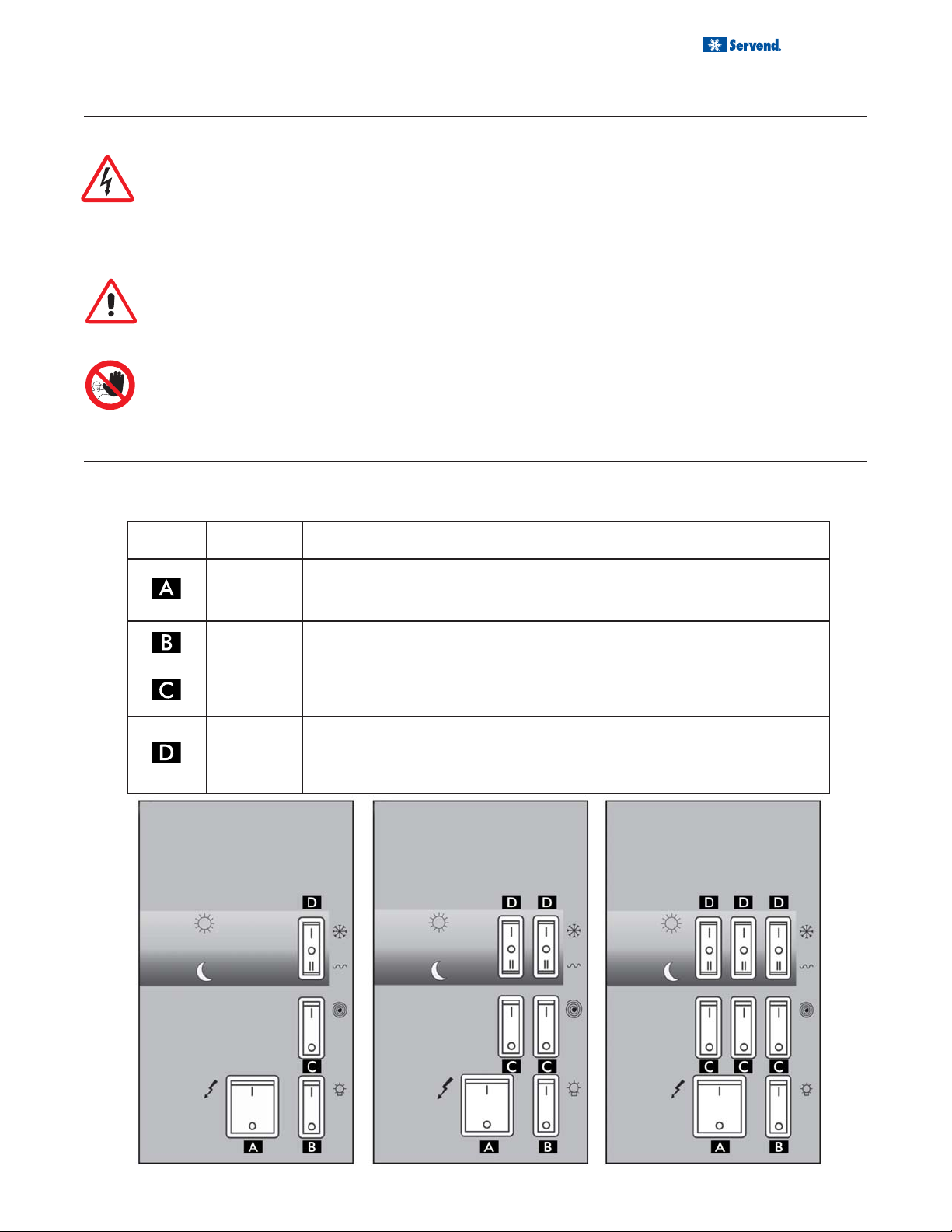

COMMAND MODEL FUNCTION

ALL

ALL

ALL

ALL

Main switch: its function is to command:

- the starting of the machine;

- the switching off of all the functions present on the machine.

Lid light switch: to turn on/off light (if present) on the bowl lids.

Bowl mixing switch (one per bowl): its function is to turn on and off the gearmotor aimed at operating the auger of the

relevant bowl.

Refrigeration system changeover switch (one per bowl):

- in position “0”, the refrigeration system is deactivated;

- in position “I”, the refrigeration system is activated for the production of granitas;

- in position “II”, the refrigeration system is activated for the production of cold drinks.

• to use adaptors.

OPERATION

CONTROL PANEL

11

Page 12

Installation and Service Manual

The machine you have purchased is intended to prepare granita and cold drinks.

OPERATION

USE OF THE MACHINE

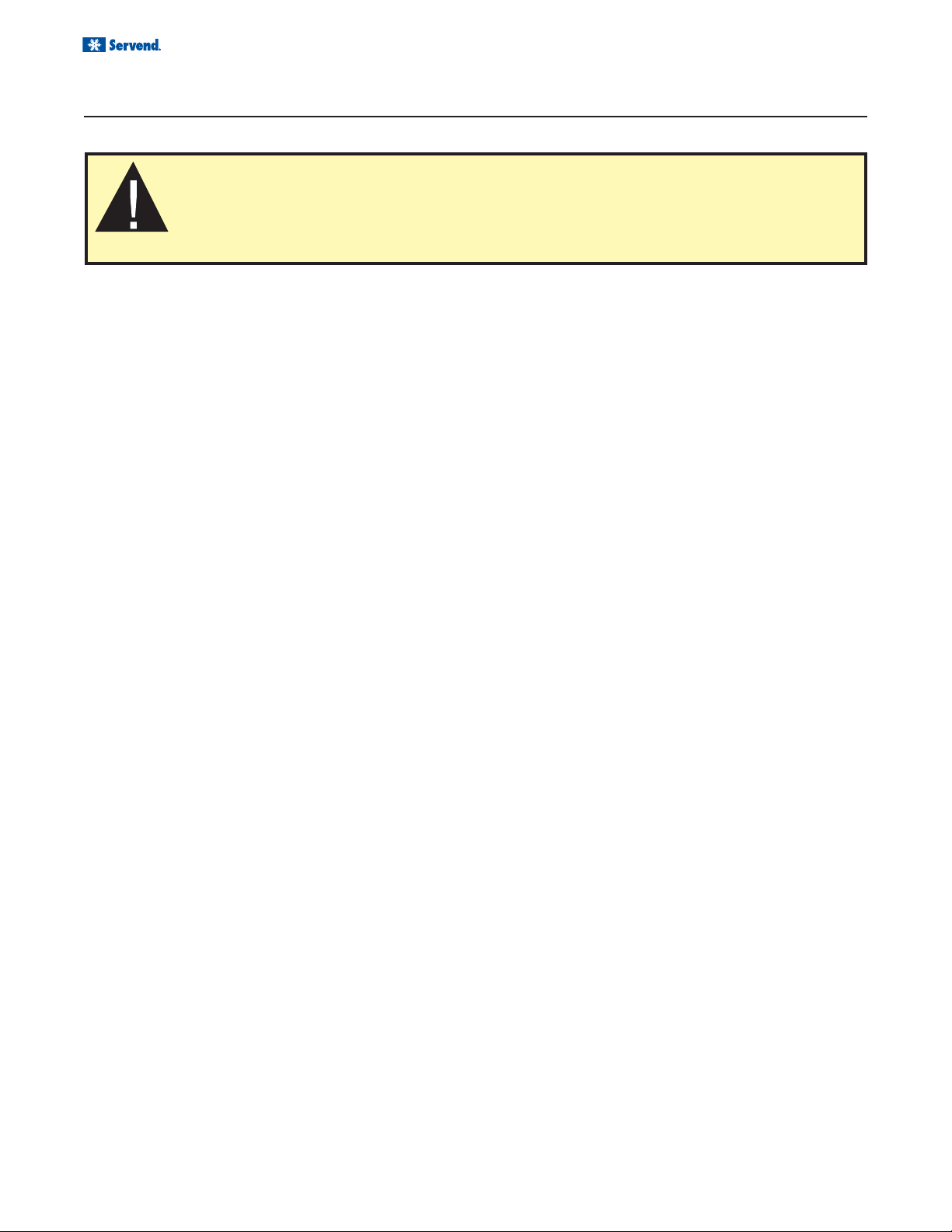

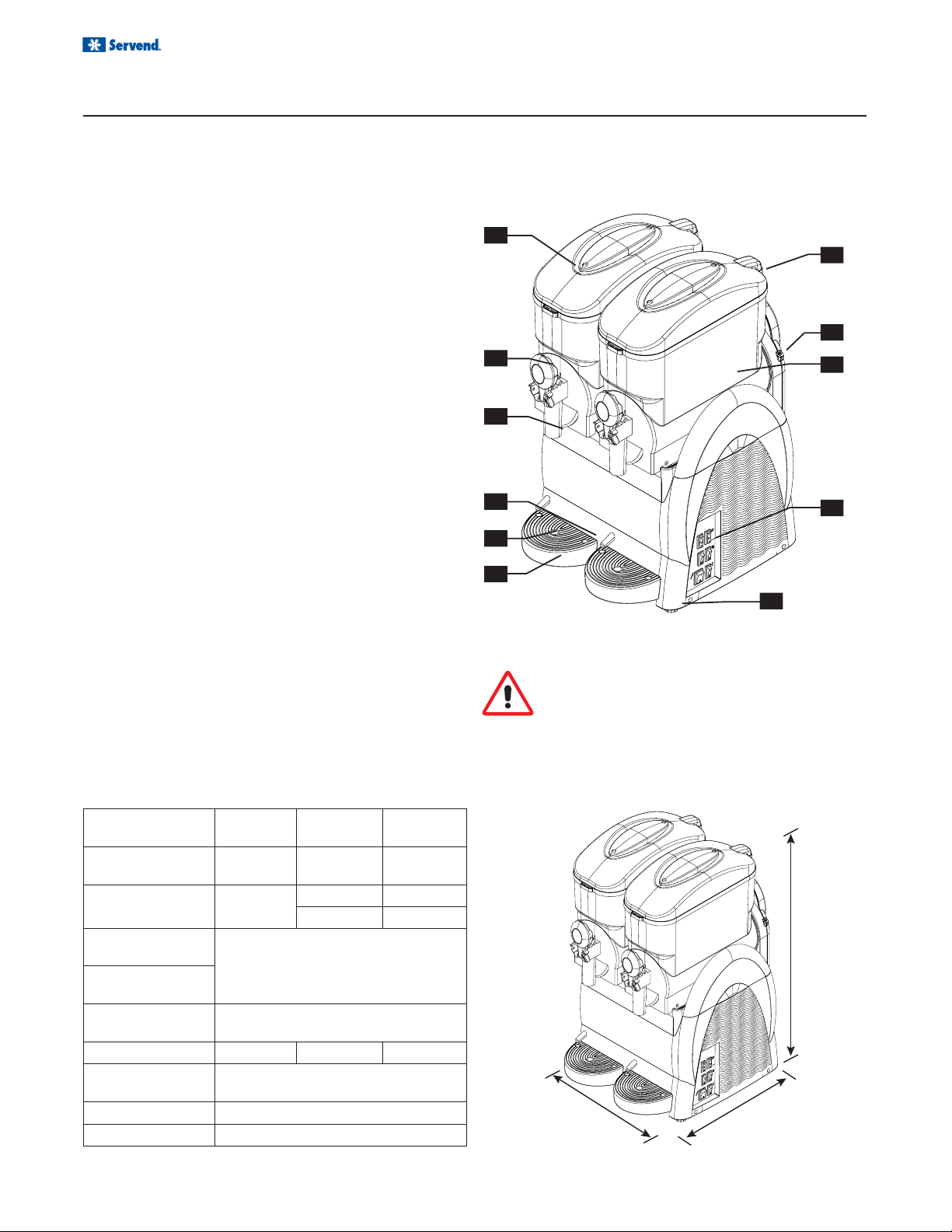

MAIN COMPONENTS

The main components making up the machine are:

1. Bowl lid

2. Bowl locking device

3. Thickness regulator

4. Bowl

5. Control panel

6. Drip tray

7. Grid

8. Float (overflow indicator)

9. Product dispenser

10. Product dispensing lever

11. Feet

To make the instructions easier to read, the following

abbreviations are used herein:

Granitore 1 - a Granita machine with one (1) bowl;

Granitore 2 - a Granita machine with two (2) bowls;

Granitore 3 -a Granita machine with three (3) bowls;

Granitore 1 FF - identifies a Granita machine with one (1)

bowl and Fast Freeze refrigeration system;

Granitore 2 FF - identifies a Granita machine with two (2)

bowls and Fast Freeze refrigeration system;

Granitore 3 FF - identifies a Granita machine with three

(3) bowls and Fast Freeze refrigeration system.

1

2

3

10

4

9

8

5

7

6

11

Note: The manufacturer reserves the right to make

changes to the machine without notice.

Important! Any changes and/or additions of accessories must be explicitly approved and implemented by the Manufacturer.

TECHNICAL DATA

The technical data and features are listed below

Model

Dimensions

L x P x A - (cm).

Weight (kg)

(bowl empty)

Maximum Electrical

Input (W)

Operating voltage

(V).

Operating temperature.

Number of bowls. 1 2 3

Capacity of each

bowl (l.)

Sound pressure level << 70 dB

Class. N

Granitore 1

Granitore 1 FF

27 x 52 x 81 42 x 52 x 81 67 x 52 x 81

29

See rating plate on side of machine

12

Granitore 2

Granitore 2 FF

47 62

56 70

Min. 20°C

Max. 32°C

12

A

Granitore 3

Granitore 3 FF

A

L

P

Page 13

Installation and Service Manual

OPERATION

All the operations described may be carried out exclusively by technicians who are also specialized in the lifting

and handling of packed or unpacked machines. They must organize all the operational sequences and use

suitable equipment, according to the characteristics and weight of the object to be handled and in strict compliance with the applicable regulations currently in force.

PACKAGING

The machine is shipped ready for use in a cardboard box. The cardboard box comprises a base and a cover, which

are secured together with two nylon straps.

Dimensions and weight of packing container

H

L

Width (L) Depth (P) Height (H) Weight

Granitore 1 270 mm 540 mm 910 mm 31 kg

Granitore 1 FF 270 mm 540 mm 910 mm 31 kg

Granitore 2 540 mm 570 mm 1010 mm 51 kg

Granitore 2 FF 540 mm 570 mm 1010 mm 60 kg

Granitore 3 760 mm 580 mm 1040 mm 67 kg

Granitore 3 FF 760 mm 580 mm 1040 mm 75 kg

P

Note: the dimensions and weight of the packing container are approximate.

CONVEYANCE AND HANDLING

Make sure that no one is stationed within range

of lifting and handling operations. In difficult

conditions, specialized personnel should be

appointed to oversee the movements of the

machine.

Manual handling of the machine requires at least two

people. The machine must be moved into an upright

position, only after every bowl has been emptied of

product.

Lift the box and carefully convey it, avoiding routes with

obstacles. Pay attention to the overall dimensions and any

parts sticking out.

Warning: Do not make any additional cuts on

the packing container. The warranty does not

cover damage caused to the machine during

its conveyance and handling. The Purchaser

will bear the cost of repairing or replacing damaged parts.

STORAGE

Before the machine is placed in storage and whenever the machine is started up again after a period of

storage, it must be thoroughly cleaned and sanitized.

Warning: Do not store more than two machines stacked on top of one another.

If the machine is to remain unused for a long period of

time, due precautions must be taken with respect to the

place and duration of storage:

• store the machine in a closed place;

• protect the machine from shocks and stresses;

• protect the machine from humidity and large temperature fluctuations;

• prevent the machine from coming into contact with

MAX

13

Page 14

Installation and Service Manual

OPERATION

Before the machine may be started up for the first time, specialized technical personnel must check that it functions

properly.

PREPARING THE PRODUCT

Warning: Product may be poured into the

bowl only when the machine is off and unplugged.

Dilute and mix the CONCENTRATE with WATER in a

suitable container, following the manufacturer’s directions. THE MIXTURE OBTAINED MUST HAVE A MINIMUM SUGAR CONTENT OF 13° BRIX - A lower concentration may damage the augers and/or gear motors.

NEVER INTRODUCE HOT LIQUIDS

(with temperatures exceeding 25°c)

NEVER USE ONLY WATER

To remove the lid from the bowl, follow these instructions:

1. remove any device which may block the lid;

2. lift the rear part of the lid;

3. extract the lid from the retainer placed in the

front side.

Pour the product into the bowl taking care

that it never goes above the max level.

After pouring the product into the bowl, close the lid on

top of the bowl itself and apply the padlock provided as

shown. Each bowl must be padlocked

Warning: never switch on the machine if the padlock is missing from the lid. Before removing

the padlock, switch off the machine and unplug

it. The padlock keys must be kept safely by the

user .

14

Warning: do not force the lid opening in case of

difficulty.

Warning: There are some moving parts inside

the bowl, which may cause injuries; turn off and

unplug the machine before carrying out any

operation inside the bowl.

It is forbidden to operate the machine if the padlock is not correctly positioned on the bowl lid.

Page 15

OPERATION

STARTING A GRANITORE

For the sake of simplicity only the operation of the right

bowl will be illustrated; to operate the other bowls simply

carry out the same sequence of steps on the switches of

the bowl in question.

Switch in position “I”: machine powered.

Installation and Service Manual

To dispense Cold Drinks:

Change over switch : in position “II” refrigeration system on

(cooling mode).

Each bowl is controlled by a switch and a change over

switch, which must be operated as follows:

Switch in position “I”: mixer on.

To dispense Granita:

Change over switch : in position “I” refrigeration system

on (freeze mode).

Press the switch to turn on the machine lid light.

15

Page 16

Installation and Service Manual

OPERATION

ADJUSTING GRANITA CONSISTENCY

The consistency of the granita may be adjusted (+/-) by

means of the screw shown in the figure

+: thicker consistency, -: thinner consistency.

The adjustment may be made by hand or with the aid

of a screwdriver, depending on the type of pin inserted.

DISPENSING GRANITA

To dispense the beverage, pull the tap lever.

16

Page 17

Installation and Service Manual

OPERATION

INDICATIONS FOR CORRECT USE

When the level of granita in the bowl is below the mid of the

mixing auger, in order to prevent the product from becoming too thick, it is necessary to stop the refrigeration system by selecting “O” on the change over switch , or it is

necessary to fill the bowl. For safety reasons, each time

you fill bowls, switch the mixer off. If the machine is

switched off at night with the bowls even partially full, an ice

layer can build up at the surface: this is the natural effect

EMERGENCY SITUATIONS

Warning: in every emergency situation, to shut down the machine, firmly press the main switch

into position -0-.

In case of freezing, switch off the machine and contact a service center or specialized technician.

If a fire breaks out, the area must be immediately cleared to make way for trained personnel provided with suitable safety equipment. Always use approved extinguishers, never use water or substances of dubious nature.

which results due to the separation of the non-mixed product. Should this occur, before restarting the machine, remove the ice layer so as to prevent any mixer damage. To

access the THERMOSTAT (cold drink temperature only)

and FUSES, remove the side grate on the control panel

side, adjust and check as necessary, then fit the grate correctly back in place.

Note: The main supply fuses are optional for models

220/240V 50/60 hz.

ACCESSORY (OPTIONAL) (LOCKING SYSTEM)

Use the new tap locking system as follows:

Fig. A: When using the machine, place the rod “R” as

showed in the picture.

Fig. B: To lock the handle, insert the rod “R” in its hole

and place the padlock as showed in the picture.

USER MAINTENANCE

PREVENTATIVE MAINTENANCE

Preventative maintenance is a vital part of keeping your Chillz unit in top condition. Following the guidelines below will

assist you in continued trouble free operation of your unit. Contact MBE at 1-800-367-4233 for more information

about our ProActive Maintenance Program.

1. Conduct daily maintenance of the machine.

2. Perform monthly maintenance of the machine.

3. Perform periodic maintenance and sanitizing of beverage system.

17

Page 18

Installation and Service Manual

USER MAINTENANCE

Before undertaking any cleaning and maintenance of external machine components, make sure

that the main switch is positioned on -0- and that the machine is unplugged.

Before performing any cleaning and maintenance operation on the machine, wear the personal

protections (gloves, glasses, etc.), which are recommended by the safety standards in force in the

country where the machine is used.

When performing the Cleaning and Maintenance operations, follow these instructions:

• wear protection accident-proof gloves;

• do not use solvents or inflammable materials;

• take care to avoid dispersing liquids in the surrounding area;

• do not wash machine components in a dishwasher;

• do not dry parts of the machine in a conventional and/or microwave oven;

• do not immerse the machine in water;

Cleaning and sanitization are operations that must be performed with utmost care and on a regular basis to guarantee the quality of the beverages dispensed and compliance with mandatory hygiene standards.

Each bowl must be cleaned and sanitized for a product change at least every 2 (two) days in compliance with the current hygiene regulations in the user’s country. The stainless materials, plastic

and rubber used to manufacture said parts, as well as their particular shape, make them easy to

clean but do not prevent the build-up of germs and mold in the event of inadequate cleaning.

• do not expose the machine to direct sprays of

water;

• for cleaning use only lukewarm water and a

suitable sanitizing agent (conforming to current

regulations in the user’s country) that will not

risk damaging machine components;

• on completing work, make sure that all protective covers and guards that have been removed

or opened are set back in place and properly

secured.

It is forbidden to clean or service the machine when it is plugged in and the main switch is positioned

on -1- .

To carry out maintenance and cleaning of the machine,

it is possible to remove the upper parts of the side protections, if necessary. Lift the upper part to remove them.

Once finished, fit the part in the side position again.

18

Page 19

USER MAINTENANCE

EMPTYING THE BOWLS

Before a bowl may be cleaned, it must be emptied of the

previously prepared product.

For the sake of simplicity only the operation of the right

bowl will be illustrated; to operate the other bowls simply

carry out the same sequence of steps on the switches of

the bowl in question.

Installation and Service Manual

With the machine switched on, put the freeze/cool change

over switch on “O”, and empty the bowl of all its contents.

After that, turn off both the main switch and mixer switch

and unplug the machine.

DISASSEMBLING THE DISPENSING TAP

Before removing the bowl it is recommended to disassemble the tap. After cleaning, the tap must not be reapplied

until the bowl has been correctly positioned in its seat. Disassemble the tap and remove the pin (F) from its seat to

release all the other parts. The parts are under spring tension and may pop out.

These components may be placed in a basin containing

hot water (approx. 50°C); they must later be treated as

described in section.

Never disassemble the tap if the product or any

other liquid is present inside the bowl.

19

Page 20

Installation and Service Manual

USER MAINTENANCE

REMOVING THE BOWL

Removal of every machine bowl is fundamental to ensure correct machine cleaning and sanitization. To remove a

bowl correctly proceed as follows:

1. remove the padlock and take off the lid.

2. raise the front part of the bowl to release it;

3. remove the bowl from its seat by pushing and

tapping lightly on the rear part;

4. take out the auger and remove the seals (a and b).

WASHING AND SANITIZING THE COMPONENTS

All of the previously disassembled and removed components must be thoroughly washed and sanitized.

Important: the sanitizing solution must comply with the regulations in force at the time

the machine is used.

To carry out the procedure correctly, please use the following instructions:

1. Fill a container with a sanitizer solution mixed in water

(2% of sodium hypochlorite mixed in water).

2. Thoroughly wash the tank, lid and evaporator with a

sponge soaked in the sanitizer solution.

3. Thoroughly wash again with clean water.

4. Fill another container with a sanitizer solution.

5. Dip the dismantled components into the sanitizer

solution.

Warning: do not submerge lids equipped with

lighting in any type of liquid.

6. Leave the dismantled components to soak in the solution for 30 minutes.

7. Thoroughly wash again with clean water.

8. Place the components on a clean surface and dry

them.

9. Assemble the machine as described.

10. Before using the machine again carry out the rinsing

cycle with clean water .

20

Page 21

USER MAINTENANCE

REASSEMBLING THE WASHED COMPONENTS

All of the washed and sanitized components must be carefully reassembled. Some components must be adequately

lubricated in order to ensure that they work efficiently. Apply the seal (A) on the auger as shown in the illustration on

the right.

Important Note: always check the seal integrity; should

it be worn, replace it with a new one. Replace the seal

(A) once a year at least.

Using the food grade lubricant provided, lubricate the seal

(A) in the areas shown.

Installation and Service Manual

Introduce the auger, engaging head (c) with shaft (D).

Note: rotate the auger to engage it.

Set the bowl back in place; slightly raise head (c) of the

auger so that it meets the seat provided (E) in the bowl.

Apply seal (B), lubricating the entire surface indicated by

the arrows with food grade lubricant.

Press the bowl downward until it engages the surface as

shown in the figure.

21

Page 22

Installation and Service Manual

USER MAINTENANCE

REASSEMBLING THE WASHED COMPONENTS

Follow these instructions to refit the tap:

1. Using the food grade lubricant provided, adequately

lubricate the cap (Y), and refit the components;

2. Introduce the pin (F) while keeping the tap lever steady.

Note: Correctly install the components as shown in

the figure.

Note: The non-lubrication of the cap may cause product leakage from the tap.

RINSING CYCLE

Before starting up the machine, you must carry out the rinsing cycle. Proceed as follows:

1. Fill the tank with a sanitizer solution mixed in water

(2% of sodium hypoclorite mixed in water).

2. Let the machine on for 5 minutes in the “agitation” mode only.

3. Turn off the machine and empty the tank by opening the tap.

CLEANING THE DRIP TRAY

The drip tray should be emptied and cleaned daily.

Note: All of the drip trays present in the machine

should be cleaned. The drip tray should be emptied

and cleaned every time the red float installed in the

grid rises into view.

Holding the drainage hose firmly, lift the tray with the

grid on top of it and pull it out.

Wash the tray and grid separately with lukewarm water.

Dry all of the components.

Reposition the grid on top of the tray. Position the drainage hose in the opening provided.

Fit the tray back in place and press down to secure it to

the machine.

22

Page 23

USER MAINTENANCE

LIGHTED LID MAINTENANCE

Warning! Any intervention on the lid must be

only be made by hand. Never use any kind of

tool which could damage the integrity of the

lid or its components.

To carry out the maintenance operations of the lighted lid,

remove the lid from the machine and unplug the connector.

Clean the lid contacts using a wet cloth, and dry carefully.

Always carry out this operation when the machine is off.

BULB REPLACEMENT

Remove the protection caps; undo both screws to split

the lighted lid sections; use a proper screwdriver for this

operation.

Installation and Service Manual

Remove the bulb “U” from the socket “T”, and replace it

with a new one. Refit the lid, and tighten both screws.

CLEANING THE CONDENSER

The condenser may be cleaned solely by a specialized technician, who must organize all of the operational sequences and use suitable equipment, in strict compliance with the applicable regulations currently

in force.

Periodically clean the condenser situated inside the machine.

Warning: Removing safety guards will expose some sharp surfaces of the machine. A dirty condenser will

impair machine performance. To access the condenser remove the safety guards. It is forbidden to use the

machine when even only one panel (front, rear or side) is not set properly in place.

It is prohibited for the operator to clean the condenser.

23

Page 24

Installation and Service Manual

USER MAINTENANCE

CLEANING THE GRANITORE 1/1FF CONDENSER

The safety guards must be removed by means of a suitable screwdriver.

After removing the guard, use a dry brush to remove the

dust that has built up over time with use.

Remove the rear guard after taking out the screws securing it to the frame (the screws are positioned on the left and

right sides).

CLEANING GRANITORE 2/2 FF - 3/3 FF COND

To remove the protection, undo the screws placed on

its base.

After removing the screws, extract outwards the protection with no hesitation .

Once the condenser has been thoroughly cleaned, fit all

the safety guards back in position.

After removing the guard, use a dry brush to remove the

dust that has built up over time with use.

Once the condenser has been thoroughly cleaned, fit all

the safety guards back in position.

24

Page 25

Installation and Service Manual

USER MAINTENANCE

SCRAPPING

Electric and electronic equipment must be disposed of in accordance with European Directive

2002/96/Ec.

Such equipment may not be disposed of as normal municipal solid waste but must rather be separately

collected to optimize recovery and recycling of the materials used to manufacture them.

All products are marked with the crossed out wheeled bin symbol as a reminder of separate collection

obligations. Correct observance of all of the provisions for the disposal of end-of-life products will contribute to

safeguarding the environment.

TROUBLESHOOTING

PROBLEM CAUSE REMEDY

The machine

does not turn on.

The tap leaks.

Product leaks

from the rear

part of the bowl.

The auger does

not turn

The main switch is off (positioned on “O”). Press the switch into position “I”.

The machine is not plugged in. Insert the plug in a suitable outlet.

The tap plug is not lubricated. Lubricate the plug.

The plug is defective. Replace the plug.

The bowl is not fitte correctly in place . Check the positioning of the bowl.

The bowl seal is not lubricated. Lubricate accordingly.

The seal is defective. Replace the seal.

The switch is positioned on"O". Press the switch into position "I".

There are blocks of ice inside the bowl. Empty the bowl and remove the blocks

of ice; check that the product has been

correctly diluted.

The switch is positioned on "O". Press the switch into position"I".

The machine is near sources of heat.

Install the machine in a suitable place.

The machine

There is insufficien ventilation.

does not make

granita.

The condenser is dirty. Call in a specialized technician to clean

the condenser.

The auger is

The consistency has not been adjusted

correctly.

The front seal has been applied

incorrectly.

Correctly adjust the consistency.

Check that the seal is applied correctly.

noisy.

The seal is not lubricated. Lubricate the seal accordingly.

If the machine malfunctions due to causes other than those listed in this table or the proposed remedies

do not solve the problem, contact a specialized technician.

25

Page 26

Installation and Service Manual

EXPLODED VIEWS, PARTS & DIAGRAMS

230 Volt

GRANITORE 1 - 1 FF WIRING

F

N

115 Volt

Tx

I.G

0

I

0

I

MV2MV1

M

I

0

I.M

MTx

Fc

Fc.Tx

D.G.B

Tm

IL

0

I

I

II

0

t°

P

L.MC

MC

L.P.

TR.L

(12 V a.c.)

Fu

L.L

26

Item Description

DGB

Fc

FcTx

Fu

FuA

I.G

I.L

I.M

L.L.

M

SLUSH/DRINK SWITH

LIMIT SWITCH ADJUSTMENT

TIMER LIMIT SWITCH

FUSE (5A)

AUXILIARY FUSE

MAIN SWITCH

LIGHTED COVER SELECTOR (OPTIONAL)

MIXING MOTOR SWITCH

LIGHTED COVER LAMP (OPTIONAL)

MIXING MOTOR

Item Description

MC

MTx

MV1

MV2

Tm

TR.L

Tx

P

L.P.

L.MC

COMPRESSOR MOTOR

TIMER MOTOR

FAN MOTOR 1

FAN MOTOR 2

THERMOSTAT (OPTIONAL)

TRANSFORMER (OPTIONAL)

TIMER (OPTIONAL)

PRESSURE GAUGE (OPTIONAL)

PRESSURE GAUGE LAMP (OPTIONAL)

COMPRESSOR LAMP (OPTIONAL)

Page 27

230 Volt

Installation and Service Manual

EXPLODED VIEWS, PARTS & DIAGRAMS

GRANITORE 2 - 2FF WIRING

F

N

115 Volt

I.G

0

I

0

I

P

R.Mc

L.P.

MC

Item Description

DGB.1

DGB.2

EV1

EV2

Fc1

Fc2

Fu

FuA

I.G

I.L

I.M1

I.M2

L.L.1

L.L.2

TANK 1 SLUSH/DRINK SWITH

TANK 2 SLUSH/DRINK SWITH

TANK 1 SOLENOID VALVE

TANK 2 SOLENOID VALVE

TANK 1 LIMIT SWITCH ADJUSTMENT

TANK 2 LIMIT SWITCH ADJUSTMENT

FUSE (5A)

AUXILIARY FUSE

MAIN SWITCH

LIGHTED COVER SELECTOR (OPTIONAL)

TANK 1 MIXING MOTOR SWITCH

TANK 2 MIXING MOTOR SWITCH

TANK 1 LIGHTED COVER LAMP (OPTIONAL)

TANK 2 LIGHTED COVER LAMP (OPTIONAL)

IL

Fu.A

L.L.1 L.L.2

M2M1

DGB .2

I

00

I.M.2I.M.1

EV2

Fc.2 Tm.2

IIII II

TR.L

(12Va.c.)

I

EV1

MV

Fc.1 Tm.1

DGB .1

Tx

Item Description

M1

M2

MC

MV

Tm1

Tm2

TR.L

Tx

P

L.P.

R.Mc

TANK 1 MIXING MOTOR

TANK 2 MIXING MOTOR

COMPRESSOR MOTOR

FAN MOTOR

TANK 1 THERMOSTAT (OPTIONAL)

TANK 2 THERMOSTAT (OPTIONAL)

TRANSFORMER (OPTIONAL)

TIMER (OPTIONAL)

PRESSURE GAUGE (OPTIONAL)

PRESSURE GAUGE LAMP (OPTIONAL)

COMPRESSOR RELAY (USED ON MODELS EQUIPPED WITH

T2155GK AND T2168GK COMPRESSORS)

27

Page 28

Installation and Service Manual

EXPLODED VIEWS, PARTS & DIAGRAMS

(GRANITORE 3) / 230V

GRANITORE 3 - 3FF 230V WIRING

(GRANITORE 3FF) / 230V

DGB.1

DGB.2

DGB.3

EV1

EV2

EV3

Fc1

Fc2

Fc3

Fu

FuA

I.G

I.L

I.M1

I.M2

I.M3

L.L.1

28

Item Description Item Description

TANK 1 SLUSH/DRINK SWITH

TANK 2 SLUSH/DRINK SWITH

TANK 3 SLUSH/DRINK SWITH

TANK 1 SOLENOID VALVE

TANK 2 SOLENOID VALVE

TANK 3 SOLENOID VALVE

TANK 1 LIMIT SWITCH ADJUSTMENT

TANK 2 LIMIT SWITCH ADJUSTMENT

TANK 3 LIMIT SWITCH ADJUSTMENT

FUSE (5A)

AUXILIARY FUSE

MAIN SWITCH

LIGHTED COVER SELECTOR (OPTIONAL)

TANK 1 MIXING MOTOR SWITCH

TANK 2 MIXING MOTOR SWITCH

TANK 3 MIXING MOTOR SWITCH

TANK 1 LIGHTED COVER LAMP (OPTIONAL)

L.L.2

L.L.3

M1

M2

M3

MC

MV

MV1

MV2

Tm1

Tm2

Tm3

TR.L

Tx

P

L.P.

R.Mc

TANK 2 LIGHTED COVER LAMP (OPTIONAL)

TANK 3 LIGHTED COVER LAMP (O

TANK 1 MIXING MOTOR

TANK 2 MIXING MOTOR

TANK 3 MIXING MOTOR

COMPRESSOR MOTOR

FAN MOTOR

FAN MOTOR 1

FAN MOTOR 2

TANK 1 THERMOSTAT (OPTIONAL)

TANK 2 THERMOSTAT (OPTIONAL)

TANK 3 THERMOSTAT (O

TRANSFORMER (OPTIONAL)

TIMER (OPTIONAL)

PRESSURE GAUGE (OPTIONAL)

PRESSURE GAUGE LAMP (OPTIONAL)

C

OMPRESSOR RELAY

PTIONAL)

PTIONAL)

Page 29

EXPLODED VIEWS, PARTS & DIAGRAMS

GRANITORE 3 - 3FF 115V WIRING

I

00

I.M.1 I.M.2

I.G

0

I

EV1

I

M2 M3

EV2

I

0

I.M.3

EV3

Installation and Service Manual

IL

Fu

115 Volt

0

I

L.P.

DGB.1

Tx

Tm.1Fc.1

IIIII II II

DGB.2

Fc.3 Tm.3Tm.2Fc.2

DGB.3

TR.L

(12Va.c.)

L.L.2L.L.1

L.L.3

Item Description Item Description

DGB.1

DGB.2

DGB.3

EV1

EV2

EV3

Fc1

Fc2

Fc3

Fu

FuA

I.G

I.L

I.M1

I.M2

I.M3

L.L.1

TANK 1 SLUSH/DRINK SWITH

TANK 2 SLUSH/DRINK SWITH

TANK 3 SLUSH/DRINK SWITH

TANK 1 SOLENOID VALVE

TANK 2 SOLENOID VALVE

TANK 3 SOLENOID VALVE

TANK 1 LIMIT SWITCH ADJUSTMENT

TANK 2 LIMIT SWITCH ADJUSTMENT

TANK 3 LIMIT SWITCH ADJUSTMENT

FUSE (5A)

AUXILIARY FUSE

MAIN SWITCH

LIGHTED COVER SELECTOR (OPTIONAL)

TANK 1 MIXING MOTOR SWITCH

TANK 2 MIXING MOTOR SWITCH

TANK 3 MIXING MOTOR SWITCH

TANK 1 LIGHTED COVER LAMP (OPTIONAL)

L.L.2

L.L.3

M1

M2

M3

MC

MV

MV1

MV2

Tm1

Tm2

Tm3

TR.L

Tx

P

L.P.

R.Mc

TANK 2 LIGHTED COVER LAMP (OPTIONAL)

TANK 3 LIGHTED COVER LAMP (O

PTIONAL)

TANK 1 MIXING MOTOR

TANK 2 MIXING MOTOR

TANK 3 MIXING MOTOR

COMPRESSOR MOTOR

FAN MOTOR

FAN MOTOR 1

FAN MOTOR 2

TANK 1 THERMOSTAT (OPTIONAL)

TANK 2 THERMOSTAT (OPTIONAL)

TANK 3 THERMOSTAT (O

PTIONAL)

TRANSFORMER (OPTIONAL)

TIMER (OPTIONAL)

PRESSURE GAUGE (OPTIONAL)

PRESSURE GAUGE LAMP (OPTIONAL)

C

OMPRESSOR RELAY

29

Page 30

Installation and Service Manual

EXPLODED VIEWS, PARTS & DIAGRAMS

GRANITORE 1FF EXPLODED VIEW

30

Page 31

Installation and Service Manual

EXPLODED VIEWS, PARTS & DIAGRAMS

GRANITORE 1FF EXPLODED VIEW

Item Code DESCRIPTION

1 SL320001244 Topper - upper part

2 SL320000011 Bulb holder support

3 SL320001421 Bulb holder

4 SL38LA10WG4 Bulb

5 SL320001348 Light topper

6 SL320001384 Cover bung

7 SL320001245 Undercover

8 SL3GS82013A Spigot tap holder

9 SL320001401 Cylindrical spring cock

10 SL320001243 Spigot handle

11 SL310000367 Spigot pin

12 SL320001629 Spigot piston

13 SL320001550 Cover light contacts

14 SL320001759 Spigot sealing plug

15 SL320000054 Drain pipe

16 SL320001599 Auger spiral

17 SL340001092 Left panel

18 SL320001398 Front panel

19 SL340000885 Drip tray assy - Grey

20 SL340000884 Complete illuminated cover

21 SL320001537 Timer motor 110V 60Hz

22 SL37TBH1411 Fan motor “120x120x38” 115V 60Hz

23 SL300951610 Condenser

24 SL320001235 External condensation union

25 SL320001234 Internal condensation union

26 SL340000999 Bowl 12 Litres

27 SL320001241 Evaporator support Pz 1 - Grey

28 SL300951869 Evaporator support Pz 2 - White

29 SL320001598 Evaporator/bowl rear gasket

30 SL300951752 Shaft supporting bushing

31 SL300951200 Evaporator

32 SL320001630 Evaporator/auger spiral rubber

33 SL320001342 Evaporator tray bung - Grey

34 SL3GS12036A Hardness control pin catch

35 SL3GS12035A Hardness control pin

36 SL320001553 Evaporator support cover - Grey

37 SL3GS12037B Hardness control pin bushing

38 SL3MS4M015C Gear motor 115V 60Hz

39 SL3GS12031A Bushing spindle conn.

Item Code DESCRIPTION

40 SL300006076 Seeger-ring

41 SL3GS12038A Torque compression spring (1,2)

42 SL3GS12030A Drive shaft for spiral

43 SL340000876 Evaporator support assy - Grey

44 SL340000315 Limit switch

45 SL320001373 Evaporator tray - Grey

46 SL330000119 Cover protection for switch 11 x 30

47 SL320000391 Dryer

48 SL320001399 Rear panel

49 SL330000096 Cover protection for switch 22 x 30

50 SL320001162 Chassis

51 SL320000464 Thermostat

52 SL320001636 Extension inox H100 for foot

53 SL300951357 Foot H. 40 mm

54 SL320001154 Black transformer support

55 SL320001155 Thermostat/cyclic timer support

56 SL340001091 Right panel

57 SL340000858 Condenser group assy

58 SL330000209 Switch 11x30 - Black

59 SL330000208 Light main switch 22x30 - Green

60 SL320000395 Receiver

61 SL300951469 Compressor NE2125GK 115/60

62 …………… Kit electric 115V 60Hz “NE2125GK”

63 SL320001557 Power cable with USA plug

66 SL320001507 Rear panel support

67 SL3GS12734C Transformer 110V - 12V

68 SL38WZC0005 Fuse 5x20 L250V F5A (mod. 115V 60Hz)

69 SL300970373 Compressor Spacer

70 SL320001397 Side panel support

71 SL320001351 Control panel

72 SL320001387 Control board adhesive

73 SL320001390 Complete control panel

74 SL3GS82016A Spigot closing rod

75 SL3GS24118A Padlock

76 SL340001093 Side panel cover

77 SL330000210 Cange-over switch 11x30 - Black

78 SL320001593 Panel support

79 SL320001400 Front panel spacer

81 SL320001653 Bracket condensate

31

Page 32

Installation and Service Manual

EXPLODED VIEWS, PARTS & DIAGRAMS

GRANITORE 2FF EXPLODED VIEW

32

Page 33

Installation and Service Manual

EXPLODED VIEWS, PARTS & DIAGRAMS

GRANITORE 2FF EXPLODED VIEW

Item Code DESCRIPTION

1 SL320001244 Topper - upper part

2 SL320000011 Bulb holder support

3 SL320001421 Bulb holder

4 SL38LA10WG4 Bulb

5 SL320001348 Light topper

6 SL320001384 Cover bung grey

7 SL320001245 Undercover

8 SL3GS82013A Spigot tap holder

9 SL320001401 Cylindrical spring cock

10 SL320001243 Spigot handle

11 SL310000367 Spigot pin

12 SL320001629 Spigot piston

13 SL320001550 Cover light contacts

14 SL320001759 Spigot sealing plug

15 SL320000054 Drain pipe

16 SL320001599 Auger spiral

17 SL340001092 Left panel

18 SL320001374 Front panel

19 SL340000885 Drip tray assy - Grey

20 SL340000884 Complete illuminated cover

24 SL320001235 External condensation union

25 SL320001234 Internal condensation union

26 SL340000999 Bowl 12 Litres

27 SL320001241 Evaporator support Pz 1 - Grey

28 SL300951869 Evaporator support Pz 2 - White

29 SL320001598 Evaporator/bowl rear gasket

30 SL300951752 Shaft supporting bushing

31 SL300951200 Evaporator

32 SL320001630 Evaporator/auger spiral rubber attachment

33 SL320001342 Evaporator tray bung - Grey

34 SL3GS12036A Hardness control pin catch

35 SL3GS12035A Hardness control pin

36 SL320001553 Evaporator support cover - Grey

37 SL3GS12037B Hardness control pin bushing

38 SL3MS4M015C Gear motor 115V 60Hz

39 SL3GS12031A Bushing spindle conn.

40 SL300006076 Seeger-ring

41 SL3GS12038A Torque compression spring (1,2)

42 SL3GS12030A Drive shaft for spiral

43 SL340000876 Evaporator support assy - Grey

Item Code DESCRIPTION

44 SL340000315 Limit switch

45 SL320001380 Evaporator tray - Grey

46 SL330000119 Cover protection for switch 11 x 30

47 SL300970232 Evaporator tray support

48 SL340000917 Rear panel

49 SL330000096 Cover protection for switch 22 x 30

50 SL320001170 Chassis

51 SL320000464 Thermostat

52 SL320001636 Extension H100 inox for foot

53 SL300951357 Foot H. 40 mm

54 ……………. Kit electric 115V 60Hz “T2155GK”

55 SL320001382 Rear panel spacer

56 SL340001091 Right panel

57 SL340000785 Condenser group assy

58 SL330000209 Switch 11x30 - Black

59 SL330000208 Light main switch 22x30 - Green

60 SL340000786 Receiver

61 SL38EAD18GL Ev-coil - gas 115V 60HZ

62 SL3GS24711D Double solenoid valve assy 115V 60Hz

63 SL300970233 Condenser

64 SL3GS36815A Dryer

65 SL320001267 Thermostat support

66 SL3GS24060A Transformer 110V - 12V

67 SL37ZG12155 Compressor T2155GK 115/60

68 SL300000233 Fan blade VA ø254/28º

69 SL320001379 Side panel support

70 SL37TKU1N16 Fan motor 110V 60Hz

71 SL320001352 Control panel

72 SL320001388 Control board adhesive

73 SL320001391 Complete control panel

74 SL3GS82016A Spigot closing rod

75 SL3GS24118A Padlock

76 SL340001093 Side panel cover

77 SL330000210 Cange-over switch 11x30 - Black

78 SL320001589 Panel support

79 SL320001383 Front panel spacer

80 SL38WZC0005 Fuse 5x20 5A (mod. 115V 60Hz)

81 SL320001542 Relay support

82 SL38CD65311 Relay

83 SL320001574 Power cable with USA plug

84 SL320001653 Bracket condensate

33

Page 34

Installation and Service Manual

EXPLODED VIEWS, PARTS & DIAGRAMS

GRANITORE 3FF EXPLODED VIEW

34

Page 35

Installation and Service Manual

EXPLODED VIEWS, PARTS & DIAGRAMS

GRANITORE 3FF EXPLODED VIEW

Item Code DESCRIPTION

1 SL320001244 Topper - upper part

2 SL320001384 Cover bung grey

3 SL320001421 Bulb holder

4 SL38LA10WG4 Bulb

5 SL320001348 Light topper

6 SL320000011 Bulb holder support

7 SL320001245 Undercover

8 SL3GS82013A Spigot tap holder

9 SL320001401 Cock cylindrical spring

10 SL320001243 Spigot handle

11 SL310000367 Spigot pin

12 SL320001629 Spigot piston

13 SL320001550 Cover light contacts

14 SL320001759 Spigot sealing plug

15 SL320000054 Drain pipe

16 SL320001599 Auger spiral

17 SL340001092 Left panel

18 SL320001375 Front panel

19 SL340000885 Drip tray assy - Grey

20 SL340000884 Complete illuminated cover

24 SL320001235 External condensation union

25 SL320001234 Internal condensation union

26 SL340000999 Bowl 12 Litres

27 SL320001241 Evaporator support Pz 1 - Grey

28 SL300951869 Evaporator support Pz 2 - White

29 SL320001598 Evaporator/bowl rear gasket

30 SL300951752 Shaft supporting bushing

31 SL300950585 Evaporator

32 SL320001630 Evaporator/auger spiral rubber attachment

33 SL320001342 Evaporator tray bung - Grey

34 SL3GS12036A Hardness control pin catch

35 SL3GS12035A Hardness control pin

36 SL320001553 Evaporator support cover - Grey

37 SL3GS12037B Hardness control pin bushing

38 SL3MS4M015C Gear motor 115V 60Hz

39 SL3GS12031A Bushing spindle conn.

40 SL300006076 Seeger-ring

41 SL3GS12038A Torque compression spring (1,2)

42 SL3GS12030A Drive shaft for spiral

43 SL340000876 Evaporator support assy - Grey

44 SL340000315 Limit switch

Item Code DESCRIPTION

45 SL320001381 Evaporator tray - Grey

46 SL330000119 Cover protection for switch 11 x 30

47 SL300970232 Evaporator tray support

48 SL340000918 Rear panel

49 SL330000096 Cover protection for switch 22 x 30

50 SL320001173 Chassis

51 SL320000464 Thermostat

52 SL320001636 Extension inox H100 for foot

53 SL300951357 Foot H. 40 mm

54 ……………. Kit electric 115V 60Hz “T2178GK”

56 SL340001091 Right panel

57 SL340000827 Condenser group assy

58 SL330000209 Switch 11x30 - Black

59 SL330000208 Light main switch 22x30 - Green

60 SL300951935 Receiver

61 SL38EAD18GL Ev-coil - gas 115V 60Hz

62 SL3GS36711D Double solenoid valve assy 115V 60Hz

63 SL300970233 Condenser

64 SL3GS36815A Dryer

65 SL320001271 Thermostat support

66 SL3GS24060A Transformer 110V - 12V

67 SL300951256 Compressor T-2178GK 115/60

68 SL300000233 Fan blade VA ø254/28º

69 SL320001379 Side panel support

70 SL37TKU1N16 Fan motor 110V 60HZ

71 SL320001353 Control panel

72 SL320001389 Control board adhesive

73 SL320001392 Complete control panel

74 SL3GS83016A Spigot closing rod

75 SL3GS24118A Padlock

76 SL340001093 Side panel cover

77 SL330000210 Cange-over switch 11x30 - Black

78 SL320001589 Panel support

79 SL320001383 Front panel spacer

80 SL38WZC0005 Fuse 5x20 5A (For mod. 115V 60Hz)

81 SL320001542 Relay support

82 SL38CD65311 Relay

83 SL320001575 Power cable with USA plug

84 SL300950035 Condenser

85 SL37TBH1411 Fan motor 120X120X38 110/50-60

87 SL320001653 Bracket condensate

35

Page 36

Page 37

Page 38

Page 39

INDEX

B

brixing ....................................... 2

C

Carbon Dioxide ......................... 5

Cleaning .................................... 2

CO2 ........................................... 4

CO2 monitors ............................ 4

D

damage ..................................... 2

delivery ...................................... 2

Diagrams

26, 27, 28, 29, 30, 31, 32, 33, 34, 35

Distributor ................................. 2

distributor .................................. 2

E

Exploded Views

26, 27, 28, 29, 30, 31, 32, 33, 34, 35

F

FOREWORD ............................ 2

I

INSPECTION ............................ 2

Installation Date ........................ 2

irregularities .............................. 2

M

MBE .......................................... 2

Model Number .......................... 2

modifications ............................. 5

O

Operation .................................. 5

P

Parts

26, 27, 28, 29, 30, 31, 32, 33, 34, 35

Q

Qualified Service Personnel ..... 5

R

Relocation ................................. 5

return procedures ..................... 2

RGA .......................................... 2

S

SAFETY ........................... 5, 6, 7

sanitizing ................................... 4

Serial Number ........................... 2

Service Agent ............................ 2

service assistance .................... 2

Service Personnel ..................... 5

Shipping .................................... 5

Shipping, Storage, Relocation .. 5

start-up ...................................... 5

Storage ..................................... 5

T

TABLE OF CONTENTS ............ 4

Telephone Number ................... 2

U

UNPACKING ............................. 2

W

Warning ..................................... 5

WARRANTY ............................. 2

WARRANTY INFORMATION ... 2

water-to-syrup ratio.

See

brixing

Page 40

Manitowoc Beverage Equipment

2100 Future Drive Sellersburg, IN 47172-1868

Tel: 812.246.7000, 800.367.4233 Fax: 812.246.9922

www.manitowocbeverage.com

In accordance with our policy of continuous product development and

improvement, this information is subject to change at any time without notice.

020001173 January 03, 2007 REV1

Loading...

Loading...