Manitowoc ECG080A, ECG018A, ECG023A, ECS031A,ECS031W, ECS018A Installation Use And Care Manual

...Page 1

Part Number 80-1651-3

Installation Use and Care

EC Series

Ice Machines

This manual is updated as new informati on an d models ar e rel eased. Visit our websit e for the latest man ua l.

www.manitowocice.com

05/10

Page 2

Table of Contents

Table of Contents

Section 1 - Installation Instructions

MODEL/SERIAL NUMBER LOCATION ............................................................................................... 1-1

LOCATION OF ICE MACHINE .............................................................................................................. 1-2

LEVELING THE ICE MACHINE ............................................................................................................ 1-2

ELECTRICAL SERVICE.......................................................................................................................... 1-3

WATER SERVICE/DRAINS ..................................................................................................................... 1-4

ICE MACHINE DIMENSIONS ................................................................................................................ 1-5

INSTALLATION CHECKLIST ................................................................................................................ 1-6

Section 2 – Component identification

EVAPORATOR COMPONENTS ............................................................................................................. 2-1

CONDENSER, CONTROLS, AND AIR FILTER .................................................................................... 2-2

Section 3 – Ice Making Sequence Of Operation

ICE MAKING SEQUENCE OF OPERATION ........................................................................................ 3-1

OPERATIONAL CHECKS ....................................................................................................................... 3-2

Section 4 – Maintenance

MAINTENANCE CHART ......................................................................................................................... 4-1

CLEANING CONDENSER ....................................................................................................................... 4-2

CLEANING PROCEDURE ....................................................................................................................... 4-3

SANITIZING PROCEDURE ..................................................................................................................... 4-4

REMOVAL FOR WINTERIZATION ...................................................................................................... 4-5

BEFORE CALLING FOR SERVICE ....................................................................................................... 4-6

Page 3

Installation Instructions

Section 1

Self-Contained

Air-Cooled

Self-Contained

Water-Cooled

Not Available

Not Available

ECS023A

ECS023W

ECG023A

ECG023W

ECS031A

ECS031W

ECG031A

ECG031W

ECS041A

ECS041W

ECG041A

ECG041W

ECS051W

ECG051A

ECG051W

ECS065A

ECS065W

ECG065A

ECG065W

ECS080A

ECS080W

ECG080A

ECG080W

from that of original manufactu r ed specifications.

installation procedures for yo u.

Ice Machine Model

Ice Cube Size

S - Standard Cube

Ice Machine Series

Condenser Type

A - Air - Cooled

General Information

It is recommen ded that this ice machine be inspect ed and

inst alled by a qual ified ser vi ce technician.

If you do not understand the procedures or the

safety precaut io ns that must be fo llow ed, call your

local service represent ative to perform the necessa ry

WARNING

Model Numbers

Th i s manual cove rs the follo wing mod e l s :

ECS018A

ECG018A

Follow all recommendations and instructions for proper

installation and safe operation of this ice machine.

WARNING

PERSONAL IN JU RY POTENTIA L

Do not operate equipment that has been misused,

abused, neglected, damaged, or altered/modified

ECS051A

Model Numbers Identification

EC S 018 A

G - Large Cube

W - Water- Cooled

1-1

Page 4

Installation Instructions

Section 1

Self-Contained

Air-Cooled

Self-Contained

Water-Cooled

Top/Sides

203 mm (8 in.)*

127 mm (5 in.)*

Back

127 mm (5 in.)*

127 mm (5 in.)*

he ice machine must be protected if it will be

Failure caused by exposure to freezing

THREAD

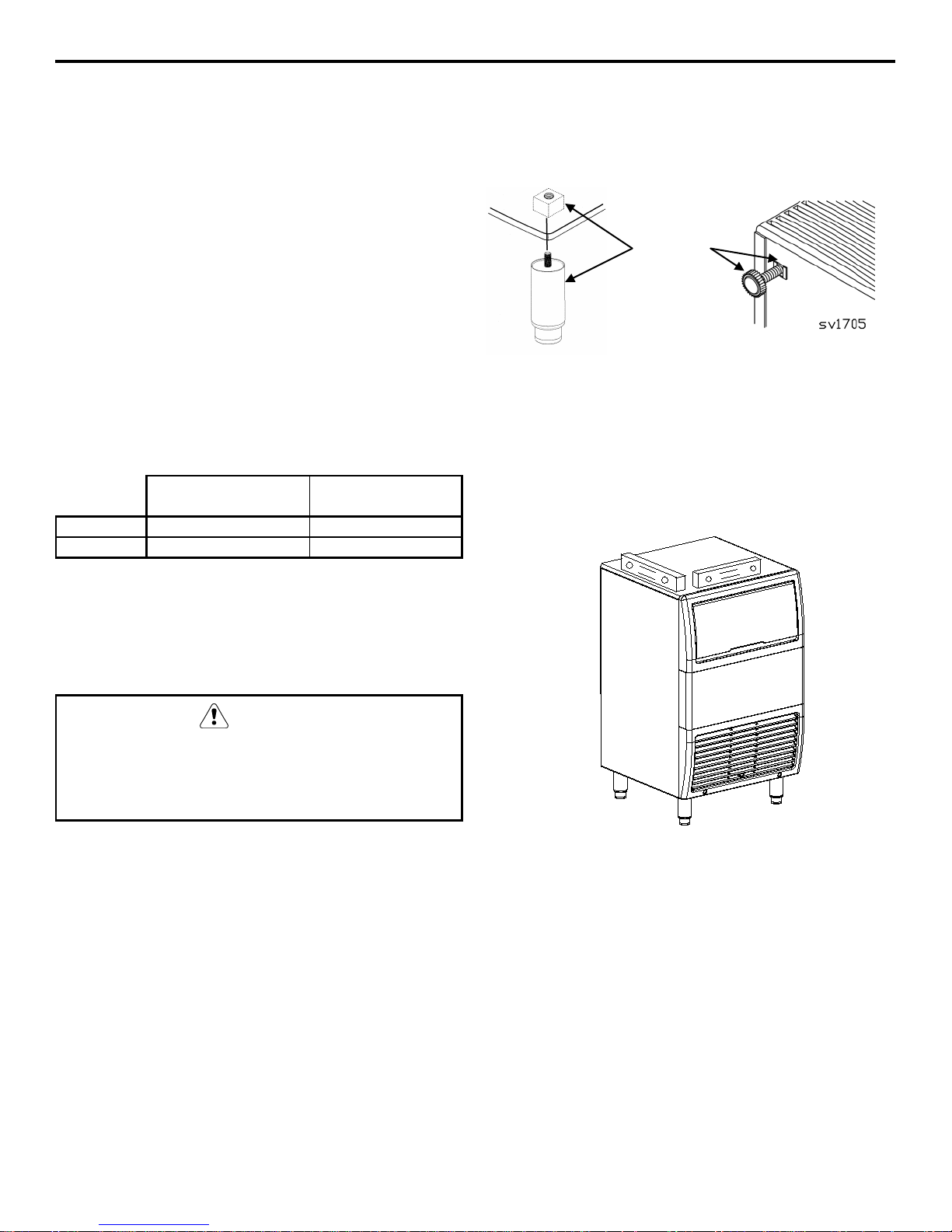

Location of Ice Machine

Leveling the Ice Machine

The loca tion selected for th e ice machine mu st meet the

follo wing crit er ia. If any of these crit er ia are not met, select

another location.

• The location m ust be indoor s.

• The location must be free of airborne and other

contaminants.

• The air temperature must be at least 10°C (50°F), but must

not ex ceed 4 3 °C (110°F).

• The location must not be near heat-generating equipment or

in direct sunl ight.

• The location m ust be ca pable of supp orting the weight of the

ice ma ch ine and a full bin of ice.

• The loca tion must al low enough cl earance for water, dra in

and el ectrical con nection s in th e rear of the ice machine.

• The location must no t obstruct airflow through or a roun d the

ice machine (condenser airflow is in and out the front). Refer

to the ch ar t below for cl earance r ecom mendations.

* NOTE: The ice machine may be built into a ca binet.

There is no minimum clearance requirement for the top or left

and ri ght sides of th e ice machin e. Th e listed valu es are

recomm ended for effi cient oper ation and s er vi cing only.

CAUTION

T

subjected to temperatures below 0°C (32°F).

temperatures is not covered by the warranty.

Leveler s a r e in clud ed wit h all i ce m ach in e. Legs a r e an available

option.

1. Screw the legs or levelers into the bottom of the ice

machine.

LEVELING LEG

INTO BASE OF

CABINET

2. Screw th e foot of each leg or level er in as far as possible.

Move the ice machine into its final position.

3. Level the ice machine correct ly. Use a level on top of the ice

machine. Turn each fo ot as necessary to level the ice

machine from front to

back and side to side.

1-2

Checking Ice Machin e Level

Page 5

Installation Instructions

Section 1

must conform to

local, stat e and national codes.

complete..

Air-Cooled

Water Cooled

Maximum

230/1/50

10 Amp

4.4

10 Amp

4.0

230/1/60

10 Amp

4.4

10 Amp

4.0

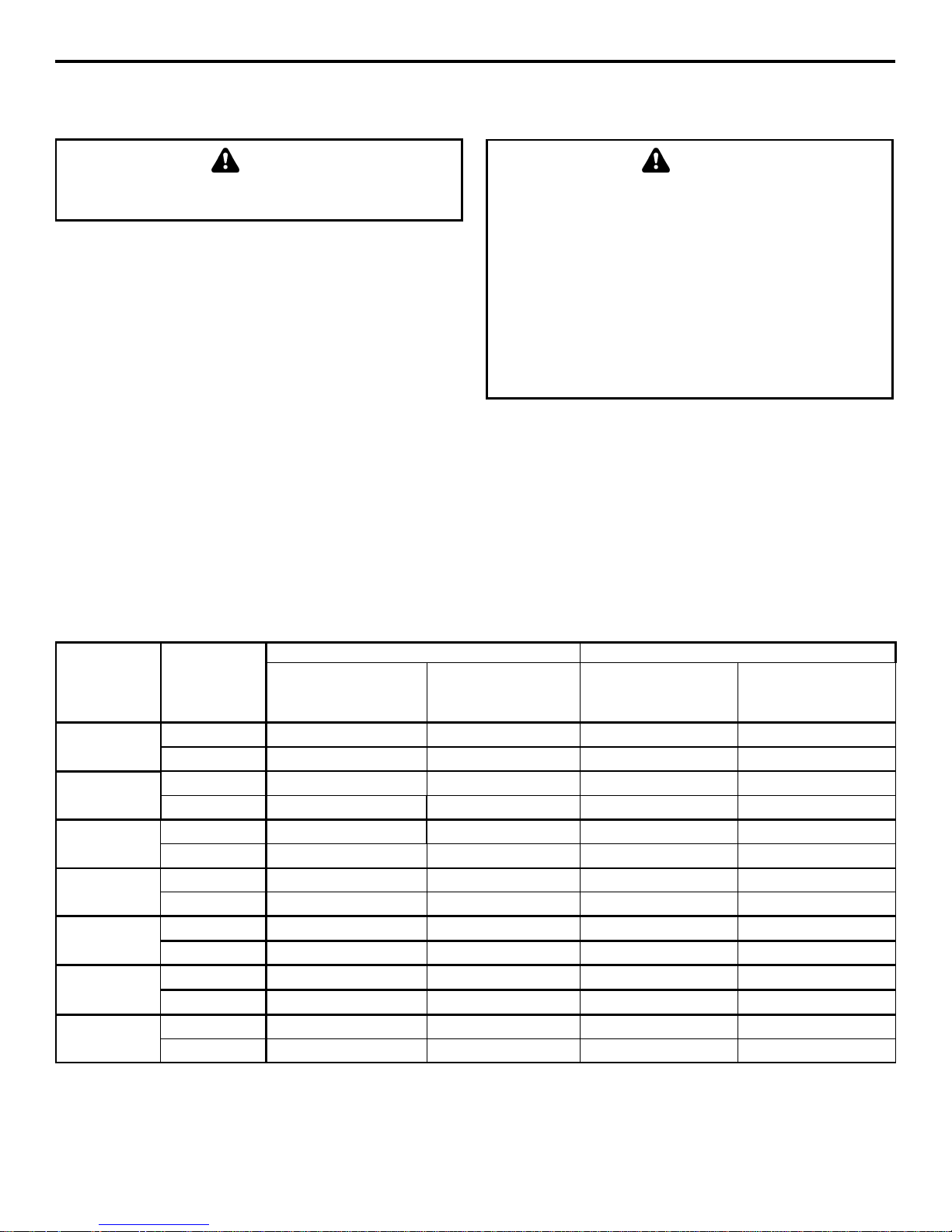

Electrical Servi ce

GENERAL

WARNING

All wiring and ground connections

VOLTAGE

The maximum allowable voltage variation is ± 6% of the rated

volta g e on the ice machine model/serial num ber plate at s tart-up

(when the electrical load is highest).

All ice m achines ar e factory pr e-wired with a 2 meter (6 ft)

power cord, no plug is supplied

FUSE/CIRCUIT BREAKER

A separ at e fu s e/ circuit break er m u st be pr ovi d ed f or each ice

machine. An electr ical di scon nect swit ch mu s t be provided if the

ice machine is hard wired (wired without a plug).

TOTAL CIRCUIT AMPACITY

The tot al circuit ampacity is u sed to help select the wir e si ze of

the electrical s u p p ly.

The wire size (or gauge) is also dependent upon location,

materials used, length of run, etc., This must be determined by a

quali fi ed electrician.

.

WARNING

Risk Of Electri cal Sho ck

This ice machine must be properly grounded and

connected to the field wiring ter minal in

accordance with all applicab le national and local

electrical codes by a qualif ied e lect r ician. Be fore

connecting wires, d isco nnect po wer at the electrical

disconnect and lock out to prevent accidentally

energizing.Con nect all electrical wiring before use do not energize ice mach ine until installation is

1. Connect –the three suppl y lead wir es (Blue, Brown,

and Yellow/Gr een) to t he field wiring terminal, “L”, “N”,

and “G”, the Yellow/Green wir e m ust c onnec t to the

“G”(ground).

2. After connecting the wiring to the terminal strip, the

supply lead must be secured to the cabinet with a

strain relief near the terminal strip.

3. Verify wiri ng is cont ained in the electrical wiring box.

Ice Machine

EC018

EC020

EC030

EC040

EC050

EC065

EC080

Voltage

Phase

Cycle

230/1/50 10 Amp 2.2 N/A N/A

230/1/60 10 Amp 2.2 N/A N/A

230/1/50 10 Amp 2.5 10 Amp 2.3

230/1/60 10 Amp 2.5 10 Amp 2.3

230/1/50 10 Amp 3.4 10 Amp 3.2

230/1/60 10 Amp 3.4 10 Amp 3.2

230/1/50 10 Amp 3.4 10 Amp 3.1

230/1/60

230/1/50 10 Amp 4.0 10 Amp 3.7

230/1/60 10 Amp 4.0 10 Amp 3.7

230/1/50 10 Amp 4.2 10 Amp 3.8

230/1/60 10 Amp 4.2 10 Amp 3.8

Maximum

Fuse/Circuit Breaker

10 Amp 3.4 10 Amp 3.1

Total Amps

Fuse/Circuit Breaker

Total Amps

1-3

Page 6

Installation Instructions

Section 1

Important

cooled condenser.

for water-c ooled condenser.

Water

Pressure

Ice Machine

Fitting

Tubing Size Up to Ice

Machine Fitting

**Drain Connection

18mm (3/4”) Minimum

0.6ºC (33ºF) Min.

32.2ºC (90ºF) Max.

140 kPa (20 Psi) Min.

3/8” Female pipe

15mm (1/2”) Inside

Condenser Water Outlet

1/2” Female pipe

15mm (1/2”) Minimum

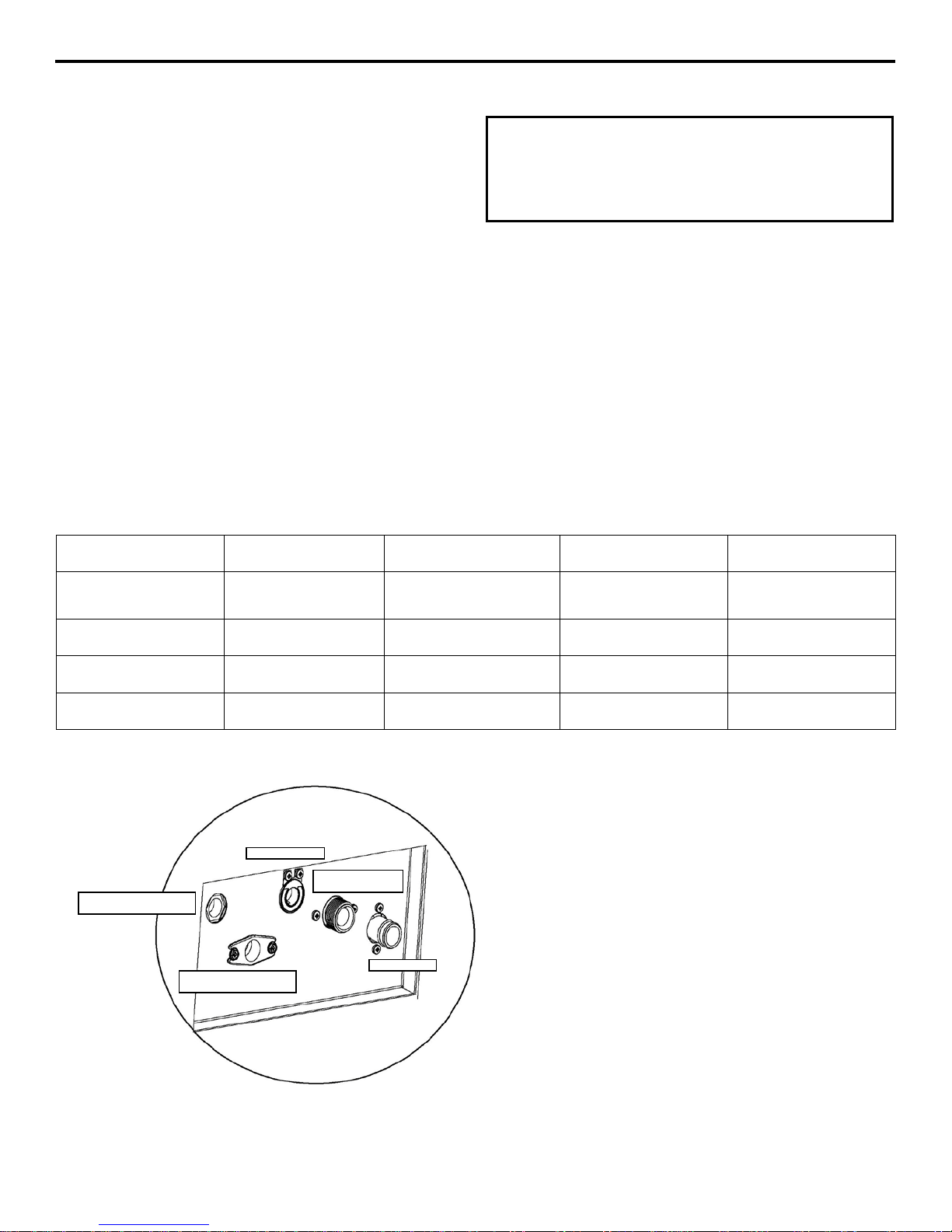

ELECTRICAL

DRAIN

POTABLE WATER

INLET

WATER COOLED

CONDENSER INLET

CONDENSER OUTLET

Water Service/Drains

WATER SUPPLY

Local wa ter cond itions may r eq uire treatment of the water to

inhibit scale formation, filter sediment, remove chlorine, and

impr ove t aste and clarity.

If you are installing a water filter system, make sure that

you use a separate line for waterFilt er life w ill be greatly reduced if filt ered water is u sed

WATER INLET LIN ES

Follow these guidelines to install water inlet lines:

• Do not connect th e ice machine to a hot water suppl y. Be

sure all ho t w ater restrictors install ed for other eq u ipment ar e

working. (Che c k valve s on sink fau c e ts, dishwa sher s, etc.)

• Water pressure t o the machine should be between 1.4 t o 5.5

bar (20 to 80 psi).

• If water pressure ex ceed s t he maximu m 5 bar recommended

press ure, obtain a water pressure re gula tor fr om your

Manitowoc distri butor. Adjust pressur e to 2.5 bar (37 psi).

• Install a wate r shut-off va l ve.

• Connect to a pot able water s upply only.

DRAIN CONNECTIONS

Follow t hese guidelines when installing dra in lines to pr event

drain water from flowing back into the ice machine and storage

bin:

• Dra i n line s must have a 3.8 cm (1 .5 in ch) drop of run for

each meter (3 feet), and must not create traps.

• The floor drain must be lar ge enou gh to ac c ommodate

drainage from all drains.

• Run sep ar ate bin and water-cooled condens er drain lines.

Insulate them to prevent condens ation

WATER SUPPLY AND DRAIN LINE SIZING/CONNECTIONS

.

Water Temperat ure

*Ice Making

Water Inlet

Outlet

Condenser Water Inlet

10ºC (50ºF) Min.

32ºC (90ºF) Max.

-----

----- -----

WATER COOLED

140 kPa (20 Psi) Min.

550 kPa (80 Psi) Max

1030 kPa (150 Psi) Max

3/4” Male Pip e

Thread

----- 7/8” Barb connection

Thread

Thread

* Water inle t hose supplie d with machine.

3/4” Female Pip e Thread/ 2 meters long.

** Drain hose supplied with mach ine.

7/8” (22.2mm) hose/ 2 meters long.

15mm (1/2”) Inside

Diameter Minimum

Inside Diameter

Diameter Minimum

Inside Diameter

1-4

Page 7

Installation Instructions

Section 1

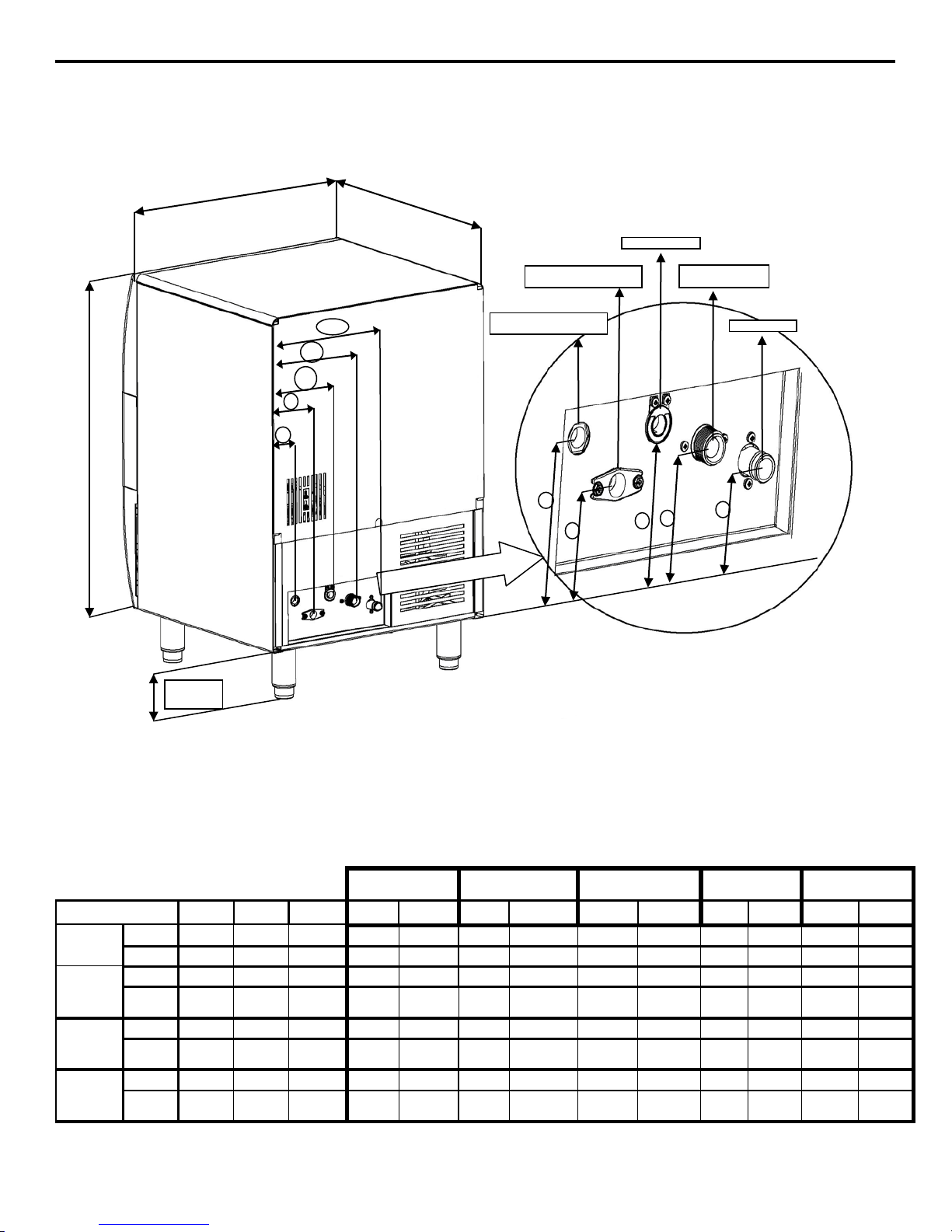

MODEL

H W D 1 6 2 7 4 9 5 10 3 8

MM

635

343

420

NA

NA

NA

NA

63.5

88.9

50.8

140

76.2

38.1

INCH

25.0

13.5

16.5

NA

NA

NA

NA

2.5

3.5

2.0

5.5

3.0

1.5

EC020

EC030

MM

650

450

475

100.5

53.4

45.5

138.4

125.5

118.4

45.3

225

125.5

183.4

EC040

EC050

MM

800

550

550

108

77.5

68

123

87.5

221

68

275

108

168

EC065

EC080

MM

902

700

600

114.3

82.6

76.2

120.7

95.25

222.25

82.6

279.4

120.7

171.5

D

W

H

1 2 4

5 3 6

7 8 9

10

152.4 mm

(6in.)

ELECTRICAL

DRAIN

POTABLE WATER

INLET

WATER COOLED

CONDENSER INLET

WATER COOLED

CONDENSER OUTLET

Dimensions

EC018

Condenser Water

Inlet

Condenser Water

Outlet

Potable Water Inlet Drain Electrical

&

&

&

INCH

INCH

INCH

25.59 17.72 18.7 3.96 2.1 1.79 5.45 4.94 4.66 1.78 8.86 4.94 7.22

31.5 21.65 21.65 4.25 3.05 2.68 4.82 3.44 8.71 2.68 10.83 4.25 6.59

35.5 27.5 23.5 4.5 3.25 3.0 4.75 3.75 8.75 3.25 11.0 4.75 6.75

1-5

Page 8

Installation Instructions

Section 1

Is the ice machin e level ?

Has all of the internal packing been removed?

Have all of t he electr ical and water con nections been

Has th e s upply voltag e been tested and checked ag ainst

Are all components installed as shown in Section 3?

Has th e ice machine been instal l ed where ambi en t

Has th e ice machine been instal l ed where the incoming

Is ther e a s ep ar ate drain line for the wat er-cooled

Are al l el ectrica l l eads free from con tact with

Has th e own er/operator been instructed r eg arding

Has th e own er/operator completed the warr anty

Has th e ice machine an d bin been sanitized?

Has thi s man u al been given to the owner/operat or?

Is the ice -off - wash switch set to the ice position?

from that of original manufactu r ed specifications.

Installation Checklist

Before Starting the Ice Machine

made?

the rating on the nameplate?

Water s pray bar, ice chute, wat er curtain and su mp drain

overflo w t u b e are all in pl a ce?

temperatures will remain in the range of 10° - 43°C

(50° - 110°F)?

water t emperature wi ll remain in the range of 10° - 32°C

(50° - 90°F)?

condenser?

All ice m achines ar e factory-operated and ad ju s ted before

shipment. Normally, new installations do not require any

adjustment.

To ensure proper operation, follow th e Operational Checks in

section 3 of thi s manual. Starting the ice machine and completin g

the Oper ational Checks are th e responsibilities of the

owner/operator.

Adjustments and maintenance

procedures outlined i n this manual

are not covered by the warranty.

WARNING

PERSONAL INJURY POTENTIAL

Do not op erat e equ ipment that has be en misu se d,

abused, neglected, damaged, or altered/modified

refrige r ation lines a nd mo ving equipment?

maintenance an d the use of Manit owo c Cleaner an d

Sanitizer?

regi s tr ation car d ?

1-6

Page 9

Section 2

Component Identification & Removal

AIR COOLED

CONDENSER

ON/OFF/WASH

TOGGLE SWITCH

TOGGLE SWITCH

Component Identification

WATER CURTAIN

WATER SUMP TROUGH

TIMER MECHANISM

ICE CHUTE

EVAPORATOR

SPRAY BAR

SPRAY NOZZLES

2-1

Page 10

Component Identification & Removal

Section 2

REMOVE TWO SCREWS – SLIDE

ALIGN DOOR PINS WITH TRACK SLOTS , THEN LIFT

DOOR OUT OF TRACK

Top Cover

For easiest access t o t he evapor ator compartment, th e top cover

can be r em oved.

1. Remove tw o screws on the rear of the ice machine.

2. Slid e t op cover back to disengag e th e three pins fr om th e

front panel.

COVER BACK TO REMOVE

Bin Door

Allows access to the storage bin.

1. Remove top co v er.

2. Slide door up until rear pins align with slot in door tracks.

3. Lift rear door pins out and slide door up un til fr ont door

pins align with s lot

4. Lift door out of door track.

2-2

Page 11

Section 2

Component Identification & Removal

ICE CHUTE

Water Curtain

The ice curtain is des igned t o keep th e s praying water from

escaping the evapor ator c ompartment. Removal of the bin door

is not r eq uired, but enhances a cces s.

1. Grasp one end of the ice curtain an d li ft up.

2. Pivot water curt ain and disen ga g e r emaining end.

3. To re-install int o ice ma chine , gras p one en d of the water

curtain, install one end, pivot the opposite end and pull

down int o position. Make sure ta bs a re sec ure in grooves.

Ice Chute

The ice ch ute is positioned over the spray noz z les and allows the

ice to easily fall into the bin. It must be firmly positioned on the

Water Distribution Assembly, with the front edge inside the

water trough or t he spr ay noz z les will not be aligned wi t h the

spray holes, and spray water will fall into bin.

1. Gra b protruding spray hol es on on e end and lift up.

2. Pivot ice chute and remove.

3. To re-install ice chute, gr asp protr uding s pray holes a nd

position over Water Distribution Assembly. Make sure rear

supports are ove r Water Di s t ribution Assem bly, and fr ont

edge is inside of water trough.

WATER CURTAIN

2-3

Page 12

Component Identification & Removal

Section 2

OVERFLOW TUBE

Spray Bar

The spray bar supplies water to the individual ice-making cups.

Water from the Water P um p s prays through the nozzl es , located

on the upper portion of the tubes.

Sump Drain Overfl ow Tube

The sump drain overflow tube is located in the evapor ator water

sump.

1. Remove shutters and ice chute.

1. Gra s p one end of the spray bar , lift u p and remove fr om

se a t formed in w ater trough.

2. Remove bot h plastic c lips on water i nlet tubin g by graspin g

both ears on clip and sep arating

3. Apply food grade lubricate to ease re-assembly of spray bar

components when necessary.

4. To re-install spray bar, position water inlet tubing on inlet

por ts, an d squeeze clips until tight.

5. Reposition assembly on water trough seat.

Nozzl es and inser ts can be removed for clean ing by unscrewing

nozzles. Inserts are located inside the spray bar ports. The spray

bar also d isass e mbles for easy cleaning.

2. Lift spr ay bar or dis con nect and rem ove for easiest access.

3. Pul l up on over flow tube to re move.

4. To replace plug, insert in hole, and push with force to make

a tight sea l.

2-4

Page 13

Section 2

Component Identification & Removal

Door Frame

It is not n eces sary to remove the door frame to clea n the ice

machine.

1. Remove top cover and bi n door .

2. Remove two screws (1 on each side of door track).

3. Lift door track out of i c e machine.

REMOVE 2 SCREWS

2-5

Page 14

Section 2

Component Identification & Removal

PAGE INTENTIONALLY LEFT BLANK

2-6

Page 15

Section 3

Ice Machine Operation

Prior to start up of this machine, a thorough

cleaning and sanitization should be performed.

t h is m a n u al.

Ice Machine Operation

Ice Making Sequence of Operation

Important

Follow instructions in the maintenance section of

Initial Start-Up

1. Water Inlet

Turn the toggle switch to wash/fill,the water fill valve and pump

are en ergized, wait for 90 seconds, th en turn the switch to off

position.The water inlet valve on thi s machine energ i zes i n the

harvest cycle, therefore pr i ming the system with water will allow

the system to start up next cycle with a full reservoir of water.

2. Freez e Cyc le

Turn the on/off/wash switch t o on. Th e compre s sor, and wate r

pump wil l start, thu s s tarting th e fr eezing cycle. The pump spr ays

water in to the inverted cups. The water freez es layer by layer,

until an ice cube forms in each cup.

At th e same time the comp ressor star ts, the condenser fan motor

(air-cooled models) is supplied with power throughout th e freeze

and harvest cycles. The freeze cycle continues and t he eva porator

therm ostat reach es the adjust ed s et point.

• EC18/20

A harvest cycle starts.

3. Harvest Cycle

The compressor con tinues to operate an d the water pump is deenergized. The hot gas val ve e nergiz es, allowin g hot gas to ent e r

and warm th e eva porat or .. The water va lve is also ener gized,

aiding with harvest, as well as filling up the sump with fresh

water for a new freeze cycl e.

The ice fa lls from th e cu p s an d i s directed into the bin by the ice

chut e. Th e h arvest cycle c ontinues until:

• EC18/20

The evaporator thermostat changes position.

• EC30/40/50/65/80

The timer reaches the factory setting of 3 minutes.

The hot ga s valve, and water va lve de-energi ze. If ice cubes are

not contacting th e bin thermostat a new freez e cycle is initiated

as the water pump energizes and sprays water into the cups,.

4. Automatic Shut-Off

When th e storage bin is full, the ice will come in contact with the

bin thermostat which is located inside the bin. The machine will

stop after approximately one minute of continuous ice contact

with the bi n thermostat probe.

The ice machine remains off until enough ice has been removed

from the storage bin to allow the ice to fall clear of the bin

therm ostat probe. A s the ice cl ears the probe, the bin ther mostat

warm s up an d the machine starts another freeze cycle.

• EC30/40/50/65/80

The thermostat energizes the tim e d elay relay. When the timer

reach es setpoint (1 0 min u tes factor y setting) th e harvest cycle is

initiated.

3-1

Page 16

Ice Machine Operation

Section 3

Important

It is recommended that adjustments made to this ice machine

seriously affect the life of this ice machine.

40

38

Large cube 32g

Dimple

33

34

Fig. 6

Operational Checks

GENERAL

Your i ce machine was fa ctory-operated an d ad ju s ted before

shipment. Normally, a newly installed ice machine does not

require any adjustment.

To ensure proper operation, always follow these Operational

Check s when starting the ice ma ch ine:

• for the first time

• afte r a prolonged out of service period

• after cleaning and s an itizing

Routine adjustments and maintenance procedures outlined in this

manua l are not cover ed b y the warranty.

be made by a qualified technician. Improper adjustment, may

CUBE SHAPE

The standard cu be has an average wei g ht of 19 grams, while th e large cube ha s an average wei ght of 32 gram s .

Notice t he normal d im ple in the center of the cube.

ICE CUBE THICKNESS CHECK

The ice cu be t hickness is factor y-set to maint ain the ice cube

thickness at the proper size and weight.

1. Allow the ice machine to operate for thr ee com p lete cycles.

The cubes should ha ve a s ma ll dimple in th e cen ter

2. Cycle ti mes vary, according to su r roundin g air and water

inlet temperat ures.

3. If cubes are n ot full (large dimple), turn evaporator

thermostat o ne increme nt towards t he right t o inc rease c ube

size. Allow ice machine to complet e th ree cycles. C heck

cube

4. If cubes are too full, ( no dimple), turn evaporator thermostat

one in cr ement towar d s th e left to decrease cube si z e. Allow

ice ma ch ine to operat e th ree compl ete cycles.

Standard cube 19g

3-2

Page 17

Section 4

Maintenance

Semi

Clean cabinet ext er ior

X X X Sanitize Ice Bin

X X X Clean Evaporator

X S S Sanitize Evaporator

X S S

S

Check I ce Quality

X S S

S

local service representative to perform the

Section 4

Maintenance

General

The end u ser is respon sible for main taining the ice machin e in

accord ance with the instructions in this manual.

procedu res are not covered by the warrant y.

If you do not understand the procedures or the

safety precaut ions that must be fo llowed, ca ll your

necessary maintenance procedures for you.

WARNING

Maintenance Weekly Monthly

Maintenance

Basic hygiene and maintenance of your I ce Mach ine, will

increase its reliability, increase performance, and help save on

water an d power consu mp tion. Ice pr od u ction will be m aintain ed

within the manufacturers guidelines, and unwanted repairs due to

maintenance issues will be minimized.

The char t below is an overvi ew of the maintenance that the en d

user an d service tech nician sh ould perfor m, and the fr equency.

These figures are the minimum required. If the Ice Machine is

supplied with hard water, more frequent evaporator cleaning

should be performed. If the condenser air filter is totally blocked,

after on e week, more frequent cl eaning is recom mended.

Annual

Annual

After pr olonged

shutdown

At Start-up

Clean Condenser Coil X S S

X = End User

S = Service Com p any

4-1

Page 18

Maintenance

Section 4

tch before performing

The condenser fins are sharp. Use care when

cleaning them.

FIN COMB

CONDENSER

Cleaning the Conden ser

WARNING

Disconnect e lectric power to the ice machine at the

electric service swi

maintenance on equipment.

AIR-COOLED CONDENSER

A dirty condenser r es tr icts air fl ow, resulting in excessi v ely high

operating temperatures. This reduces ice production and shortens

component life.

Clean th e condenser at least every six months.

1. Remove Plastic Front Grill removing two Phillips head

screws. C lean Grill opening s before repl a cing.

2. Clean the outside of the condenser with a soft brush or a

vacuum with a brush attachment. Clean from top to bottom,

not sid e to side. Be car eful not to bend the condenser fins.

WARNING

“COMB”

DOWN

ONLY

3. Shine a flashlight through the condenser to check for dirt

between the fins. If dirt remains:

A. Blow compr essed air through the condenser fins. Be

careful not to bend the fan blades.

B. If dirt or grease remains between fins, consult your

service representati ve.

4. Straighten any bent condenser fins with a fin comb.

WATER-COOLED CONDENSER

AND WATER REGULATING VALVE

The water-cooled con d enser and wa ter-regulating valve may

require cleaning due to scale build-up.

Low ice production, high water consumption and high oper ating

temperatures and pressures all may be symptoms of restrictions

in the condenser water circu i t.

Because the clean ing procedures requ ire special pumps and

cleaning solu ti ons, quali fi ed mainten ance or ser vi ce p ersonnel

must perform them.

4-2

Page 19

Section 4

Maintenance

d Ice Machine Cleaner and

and Sanitizer solut ions together

hine Cleaner or

Cleaner

Water

500 ml (16 oz)

4 l (1 gal)

Never use anything to force ice from the

Interior Cleaning and Sanitizing

CLEANING PROCEDURE

GENERAL

Clean and sanitiz e the ice machine every six m on ths for effic ient

opera tion. If th e ice machine r eq u ires more freq u ent cleaning and

sani ti zing, con su lt a qualifi ed s ervice company to test the water

quality and recommend appropriate water treatment.

If requ ired, an extremely dirty ice machine may be tak en apart

for cl ean ing and sani tizing.

CAUTION

Use only approve

Sanitizer. Read and u nderstand all labels printed o n

bottles before use. Do not mix Ice Machine Clean er

WARNING

Wear rubber glo ves and safety goggles (and/o r face

shield) when handling Ice Mac

Sanitizer.

Ice mach ine cleaner is used to remove lime scale or other mineral

deposits. It is not used to remove algae or slime. Refer to

“San itizing Pr ocedure” on the next page for r emoval of alg ae and

slime.

Mix 4 liters of water with 500 ml of cleaner in a plastic or

stain l es s container .

Step 1 Set the toggle switch to the OFF position at the end of a

Harvest Cycle, aft er ice releases from the evapora tor. Or, set th e

switch to the OFF position and allow the ice to melt off the

evaporator.

CAUTION

evaporator. Damage may resu lt.

Step 2 Remove all ice from the bin.

WARNING

Disconnect e lectric power to the ice machine at the

electric switch box before p roc eeding .

Step 3 Remove al l parts as described in S ection 3, Component

Identification & Removal.

4-3

Page 20

Maintenance

Section 4

Sanitizer

Water

60 ml (1 oz)

12 l (3 gal)

Never use anything to force ice from the

Step 4 Take all components to sink and with 2 liters

Clean er/Water mixture clean all comp onents with a soft n yl o n

brush. Disassem ble spray bar, remove nozzles and inserts and

soak for 5 minutes. For heavily scaled parts, soak in solution for

15–20 minutes. Rinse all components with clean water.

Step 5 While components are soaking, use nylon brush to scrub

insi d e of ice bi n. Scrub inside of door, door track, bin, sump

trough, and evaporator moldings. With clean water, rinse all of

these areas thoroughly.

Step 6 Replace s ump overflow tube and pour r e maining 2 lit ers

of mixture into the water sump. Replace all parts.

Step 7 Disconnect the incom i ng ice -making wat er line.

Step 8 To start a cleanin g cycl e, set th e tog g le switch t o the

WASH position.

Step 9 After 10 minutes, set the toggle switch to the OFF

position. Remove water cur tain, ice ch ut e and over flow t u be

from the water sump. Allow all water to drai n from the sump.

Replace drain plug and fill sump with 2 liters of water. Set toggle

switch to Wash and circulate for 10 minutes.

Step 10 After 10 minutes, set toggle switch to off position.

Remove wat er curta in , ice chute, water sump over flow tube.

Drain water from sump and replace tube.

Mix 4 liters of water with 30 ml of sanitizer in a plastic or

stain l es s container .

Step 11 Set the toggle switch to the OFF position at the end of a

harvest cycle, a fter ice rel eases from th e eva p orator. Or, set the

switch to the OFF position and allow the ice to melt off the

evaporator.

CAUTION

evaporator. Damage may resu lt.

Step 12 Remo ve a ll ice from th e bin.

Step 13 Remove Water Curtain and Ice Chute as described in

Section 3, Component Identification & Removal.

4-4

Page 21

Section 4

Maintenance

Step 14 Take all components to sink and with 2 liters

Sanitizer/Water mixture clean all components with a soft nylon

brush. Rinse all Components with clean water .

Step 15 Use brush to scrub ins ide of i c e bin. S crub inside of

door, door track, bin, water sump, water distribution assembly

and eva p orator moldings. With clean water , r inse all of thes e

areas thoroughly.

Step 18 After 10 minutes, set the toggle switch to the OFF

position. Remove water curtain an d ice chute Rem ove ov er flow

tube from water sump. Allow all water to drain from sump.

Replace over flow tube and fill sump with 2 liters of water. Set

toggle switch to Wash and allow circulation for 10 minutes.

Step 19 Repla ce a ll parts. Connect the incoming i ce-making

water line.

Step 16 Replace s ump drain ove r flow tube, and transfer

remaining 2 liters of solution to the sump trough. Replace all

components.

Step 17 To start a sanitizing cycle, set the tog g le switch to the

WASH position.

Step 20 Place t ogg le switch in WASH/FILL f or 90 seconds and

then to ICE position, ice machine will go into ice making cycle.

4-5

Page 22

Section 4

Maintenance

temperatures, severe damage to some

Exterior Cleaning

Clean the area around the ice machine as often as necessary to

maintain cleanliness and efficien t operat ion.

Spong e any dust and dir t off the out side of the ice machine with

mild soap and water. Wipe dry with a clean, soft cloth.

A commercial gra d e st ainless steel cleaner and poli sh may be

used.

Removal f rom Service/ W interization

GENERAL

Specia l precautions must be t aken if the ice machine i s t o be

removed from ser vi ce f or an exten d ed p er iod of time or exposed

to ambient temperatures of 32°F (0°C) or be low.

CAUTION

If water is allowed to remain in the ice machine in

freezing

components cou ld resu lt. Da mage of this nature is

not covered by the warranty.

Follow the appli cable procedure below.

WATER-COOLED ICE MACHINES

1. Perform steps 1-6 under “Air-Cooled Ice Machines.”

2. Disconnect the incoming water and drain lines from the

water-cooled cond enser.

3. Insert a large screwdriver between the bottom spring coils of

the wat er r eg u lating val ve. P ry upward t o open the valve.

AIR-COOLED ICE MACHINES

1. Disconnect the electric p ower at the circu it breaker or the

electric ser vi ce s witch.

2. Turn off the water supply.

3. Drain the water from the water sump and water pump by

disconnecting th e water pump tubing.

4. Disconnect and drain the incoming ice-m aking water line

and disconnect the tubing from the water inlet valve outlet

and allow water to drain.

5. Blow compressed air in the drain opening and water valve

ou t let ho se, then rea t tac h.

6. Make sure water is not trapped in any of the water or drain

lines.

Pry Open the Water Regulating Valve

4. Hold t he valve open and blow compressed air through the

condenser unti l wa ter no longer exits.

SV1624

4-6

Page 23

Section 4

Maintenance

Problem

Cause

Correction

Ice Machine Will Not Run

Toggle switch is not in ice position

Place toggle switch in ice position

No Power – Breaker off, fuse blown,

unplugged

Restore power

Bin Thermostat incor r ectly adjusted

Adjust bin thermostat

Ice machine runs and no ice is

No water to ice machine

Correct water supply

Water sump overflow tube out of

Re pos itio n/ inst al l overf low tube

Evaporator thermostat incorrectly

adjusted or faulty

Adjust or replace evaporator

thermostat

Freeze cycle long – low

Dirty condenser

Clean condenser

Water temperature too high

Connect to a cold water supp ly,

other equipment work properly

Refrigeration problem

Call for se rvice

Freeze Cyc l e

Shallow, incomplete or white

Ice machine is dirt y

Clean & sanitize the ice machine

Water pressure supp ly incorr ect

Verify water pressure is co r r ect

Air temperature around ice machine is

too high

Vent area or move ice machine

Evaporator thermostat incorrectly

adjusted

Adjust evaporator thermostat

Harvest Cycle

Will not initiate a harvest cycle

Evaporator thermostat incorrectly

Adjust or replace evapor ato r

Timer Problem

Call for se rvice

Ice cubes do not release

Ice machine is dirt y

Clean and sanitize the ice mach ine

Low ambient around ice machine

Adjus t t imer or move ice machine

Evaporator thermostat incorrectly

Adjust evaporator thermostat

Before Calling for Service

If a problem arises during oper ation of your ice machine, follow the chart below before ca lling for serv ice.

Routine adjust ments and maintenance procedures are not co vered by the warranty.

produced

position

production

verify check valves in faucet s and

ice cubes

adjusted or faulty

adjusted (cubes too large)

thermostat

to warmer area

4-7

Page 24

Section 4

Maintenance

4-8

Page 25

Owner Warranty Registration Card

Important

Complete and mail the OWNER WARRANTY

GENERAL

The packet containing this manua l also includes

warranty information. Warranty coverage begins the

day you r new ice mac h in e is ins t a lle d.

REGISTRATION CARD as soon as possible to

validate the installation date.

If you do not return your OWNER WARRANTY

REGISTRATION CARD, the date of sale to the

Manitowoc Distributor will be used as the first day of

warranty coverage for your new ice machine.

Warranty Coverage

GENERAL

The follow ing Warranty outline is provided for your

convenience. For a det ailed explanation, read the

warranty bond shipped with each product.

Contact your local Manitowoc representative or

Manitowo c Ice if you need further war r ant y

information.

PARTS

1. Manitowo c warrant s t he ice machine against

defects in materials and wor kmanship, under

norma l us e and service for two (2) years fro m the

date of original installation.

LABOR

1. Labor required to rep air or replace de fective

components is covered for one (1) year from the

date of original installation.

AUTHORIZED WARRANTY SERVICE

To comply with th e prov isions of the warrant y, a

refrigerat ion service co mpa n y qualif ied and

authorized by your distributor must perform the

warranty repair.

EXCLUSIONS

The following ite ms are not included in the ice

machine’s warranty coverage:

1. Normal maintenance, adjustments and cleaning.

2. Repairs due to unautho r ized modifications to the

ice machine or use of non-standard parts without

prior wr itten app roval from t he manufacturer.

3. Damage caused by improp er insta llation of the ice

machine, electrical supply, water supply or

drainage, or damage caused b y floo ds, sto r ms, or

other acts of God..

4. Parts or assemblies subjected to misuse, abuse,

neglect or accidents.

5. Damage or problems caused by inst allation,

cleaning and/or maintenance procedures

inconsistent with the t ech nica l instr uctions

provided in this manual.

6. Premium labor rate s due to holidays, overtime,

etc.; travel time; flat rate service call charges;

mileage and miscellaneo us to ols and material

char ges not lis ted on the payment s chedule.

Additional labor charges resulting from the

inaccessibility o f equip me nt ar e also excluded

SERVICE CALLS

Normal maintenance, adjustments and cleaning as

outlined in this manual are not covered by the

warranty. If you have followed the procedures listed

on the “Before Calling For Service” chart in this

manual, and the ice machine st ill does no t p er form

properly, call your author ized service company.

NOTE: If the dealer you purchased the ice machine

from is not author ized to per for m warranty service,

contact your distributor for the name of the nearest

authorized service repr esentative.

Page 26

We reserve the right to make product improvements at any time.

MANITOWOC ICE

EC DECLARATION OF CONFORMITY

05

Specification s and design are subject to change without noti c e.

We hereb y declare th at our product s , ice machines and Mult iplex refrigerat ion equipm en t com ply with all the essent ial

requirements of the listed EC- directives.

Manufacturer: European Distribu tor:

Mani towoc Ice, Inc. _____________________________________________

2110 South 26

Manitowoc Wisconsin 5421-1720 _____________________________________________

Representati ve Of Manitowoc Ice, Inc: Repres e ntative o f European D istribut or:

Randy Haack, Engineering Manager ______________________________________________

th

Street _____________________________________________

______________________________________________

Model and Serial No. Applied EC Di rectives:

Low Voltage 73/23/EEC

EMC 89/336/EEC

Pressure Equipment 97/23/EC

Applied Standards

EN60335-1 Safet y of hou se hold and si m ilar elect ri c al ap pl iances EN55014 Electrical Mot o r Operated A p pl i an ces (Emis sions)

EN60335-2-24 Part icul a r re quirem ents re frige r ators, fo od freez ers and i ce makers EN55104 Electro magnetic compatibility (Immunity)

EN378-1 to –4 Refrigeration plants

8201043

Website - www.manitowocice.com

2010 Manitowoc Ice

Loading...

Loading...