Page 1

Q Mo de l

®

AuCS

A Ac c e sso ry

(A uto m a tic C le a ning Syste m)

Insta lla tio n

Use a nd C a re Ma nua l

This Manual Covers Installation, Use and Care Information for the AuCS

We reserve the right to make product improvements at any time.

Specifications and design are subject to change without notice.

®

A Accessory.

Part Number 80-1218-3

Page 2

Sa fe ty No tic e s

Pro c e dura l No tic e s

When installing or using the AuCSA accessory, be

sure to pay close attention to the safety notices in this

manual. Disregarding the notices may lead to serious

injury and/or damage to the ice machine or AuCS

accessory.

Throughout this manual, you will see the following

types of safety notices:

WA RNING

Text in a Warning box alerts you to a potential

personal injury situation. Be sure to read the

Warning statement, and then proceed carefully.

CA UTIO N

Text in a Caution box alerts you to a situation in

which you could damage the ice machine or AuCS

®

accessory. Be sure to read the Caution statement,

and then proceed carefully.

When installing or using the Model AuCSA

accessory, be sure to read the procedural notices in

this manual. These notices supply helpful and

important information.

Throughout this manual, you will see the following

types of procedural notices:

Im po rta nt

Important boxes serve two functions:

They call the operator’s attention to important

information.

They also provide the service technician with

information that may help in performing a

procedure more efficiently. Disregarding this

information may slow down the work.

NOTE: Text set off as a Note provides you with

simple, but useful, extra information.

CA UTIO N

Use only Manitowoc approved Ice Machine

Cleaner (part number 94-0546-3) and Sanitizer

(part number 94-0565-3) with the AuCS

accessory.

Read and understand all information printed on the

bottles before use.

Page 3

Table o f Co nte nts

Ta ble o f C o nte nts

Se c tio n 1 - G e ne ra l Inform a tio n

Freight Damage and Claims Procedure......................................................................................................... 1-1

Model/Serial Number Location ...................................................................................................................... 1-1

Owner Warranty Registration Card.............................................................................................................. 1-2

Warranty Coverage ......................................................................................................................................... 1-2

Component Location and Identification ....................................................................................................... 1-3

Compatible Ice Machine Models ....................................................................................................................1-4

Se c tio n 2 - Installa tio n Instruc tions

General.............................................................................................................................................................. 2-1

Electrical Service.............................................................................................................................................. 2-1

Location/Mounting ..........................................................................................................................................2-2

Connection to Ice Machine.............................................................................................................................. 2-4

Determine Type of Solution Needed............................................................................................................... 2-12

Installing Bottle of Solution ............................................................................................................................2-12

Changing Solution Type.................................................................................................................................. 2-13

Hose Priming ....................................................................................................................................................2-13

Setting Frequency of Cleaning........................................................................................................................ 2-14

Removal From Service/Winterization ...........................................................................................................2-14

Se c tio n 3 - O pe ra tio n

Automatic Operation....................................................................................................................................... 3-1

Manual Start Operation

Q Models........................................................................................................................................................... 3-1

QDUAL ............................................................................................................................................................. 3-3

Changing Switch Position During Automatic Operation

Q Models........................................................................................................................................................... 3-2

Q1400C.............................................................................................................................................................. 3-2

QDUAL ............................................................................................................................................................. 3-3

i

Page 4

Table o f Co nte nts

THIS PAGE INTENTIONALLY LEFT BLANK

ii

Page 5

Se c tio n 1 G e ne ra l Informa tio n

Se c tion 1

G e ne ra l Informa tion

Fre ig ht Dam a g e a nd C la ims Pro c e dure s

1. Shortages

Check the number of cartons delivered against the

quantity shown on your receipt. If the quantities

do not match, have the driver note the shortage

and file your claim with the freight company.

2. No-Fault Claim Procedure

Manitowoc assumes responsibility for all freight

damage claims involving participating carriers,

with the following exceptions:

When the trucking company loses the

equipment.

When fire destroys the equipment en route.

When a traffic accident damages the shipment

en route.

3. Visible Damage

A. If a carton appears damaged in any way, open

the carton and inspect the contents in the

presence of the driver. Note the nature and

extent of the damage on the freight bill.

B. Notify your local Manitowoc distributor to

inspect the merchandise within 15 days of

delivery. Do not attempt to repair the damage.

4. Concealed Damage

A. If damage is noticed at the time of

installation, notify the distributor immediately

and ask for an inspection.

B. Do not destroy packing materials until the

inspection is completed.

These conditions must be met before your claim

can be processed by the distributor.

5. Claims

Manitowoc Ice, Inc. and your local distributor

will arrange to repair or replace the equipment.

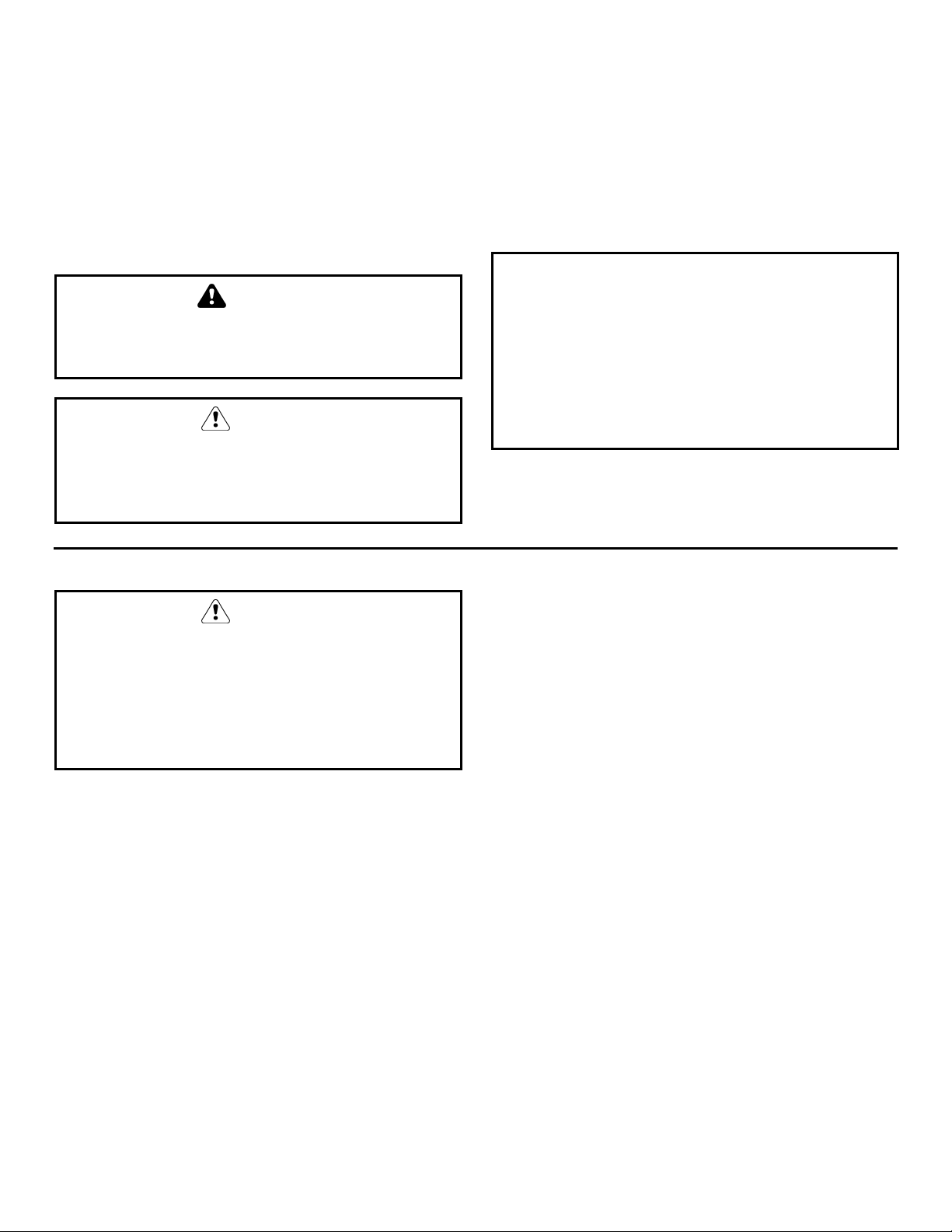

Mo de l/ Se rial Num be r Lo c a tio n

Record the model and serial number of the AuCSA

accessory in the space provided below. These

numbers are required when requesting information

from your local Manitowoc distributor, service

representative, or Manitowoc Ice, Inc.

The model and serial number are listed on the

OWNER WARRANTY REGISTRATION CARD.

They are also listed on the MODEL/SERIAL

NUMBER DECAL affixed to the side of the

AuCS

A accessory.

MODEL AND

SERIAL NUMBER

SV1275

Model/Serial Number Location

Ic e Ma c hine Bin/ Dispe nser

Mo de l Num be r

Serial Numb e r

Re m o te

Co nde nser o r

Co nde nsing Unit

Mo de l Num be r

Serial Numb e r

Ac c e ssory

AuC S

A

1- 1

Page 6

G e ne ra l Informa tio n Se c tio n 1

O wne r Wa rra nty Re g istra tio n C a rd

GENERAL

The packet containing this manual also includes

warranty information. Warranty coverage begins the

day your new AuCSA accessory is installed.

Im po rta nt

Complete and mail the OWNER WARRANTY

REGISTRATION CARD as soon as possible to

validate the installation date.

If you do not return your OWNER WARRANTY

REGISTRATION CARD, Manitowoc will use the

date of sale to the Manitowoc distributor as the first

day of warranty coverage for your new AuCS

A

accessory.

Wa rra nty C ove ra g e

GENERAL

The following Warranty outline is provided for your

convenience.

Contact your local Manitowoc representative or

Manitowoc Ice, Inc. if you need further warranty

information.

PARTS

Manitowoc warrants the AuCS

A accessory against

defects in materials and workmanship, under normal

use and service for three (3) years from the date of

original installation.

LABOR

Labor required to repair or replace defective

components is covered for three (3) years from the

date of original installation.

EXCLUSIONS

The following items are not included in the ice

machine’s warranty coverage:

1. Normal maintenance, adjustments and cleaning as

outlined in this manual.

2. Repairs due to unauthorized modifications to the

ice machine or the AuCS

A accessory, or the use

of non-standard parts without prior written

approval from Manitowoc Ice, Inc.

3. Damage caused by improper installation of the

ice machine, AuCS

A accessory, electrical

supply, water supply or drainage, or damage

caused by floods, storms, or other acts of God.

4. Premium labor rates due to holidays, overtime,

etc.; travel time; flat rate service call charges;

mileage and miscellaneous tools and material

charges not listed on the payment schedule.

Additional labor charges resulting from the

inaccessibility of the ice machine and AuCS

A

accessory are also excluded.

5. Parts or assemblies subjected to misuse, abuse,

neglect or accidents.

6. Damage or problems caused by installation,

cleaning and/or maintenance procedures

inconsistent with the technical instructions

provided in this manual.

AUTHORIZED WARRANTY SERVICE

To comply with the provisions of the warranty, a

refrigeration service company, qualified and

authorized by a Manitowoc distributor, or a

Contracted Service Representative must perform the

warranty repair.

NOTE: If the dealer the ice machine and AuCS

A

accessory were purchased from is not authorized to

perform warranty service, contact the Manitowoc

distributor or Manitowoc Ice, Inc. for the name of the

nearest authorized service representative.

1- 2

Page 7

Se c tio n 1 G e ne ra l Informa tio n

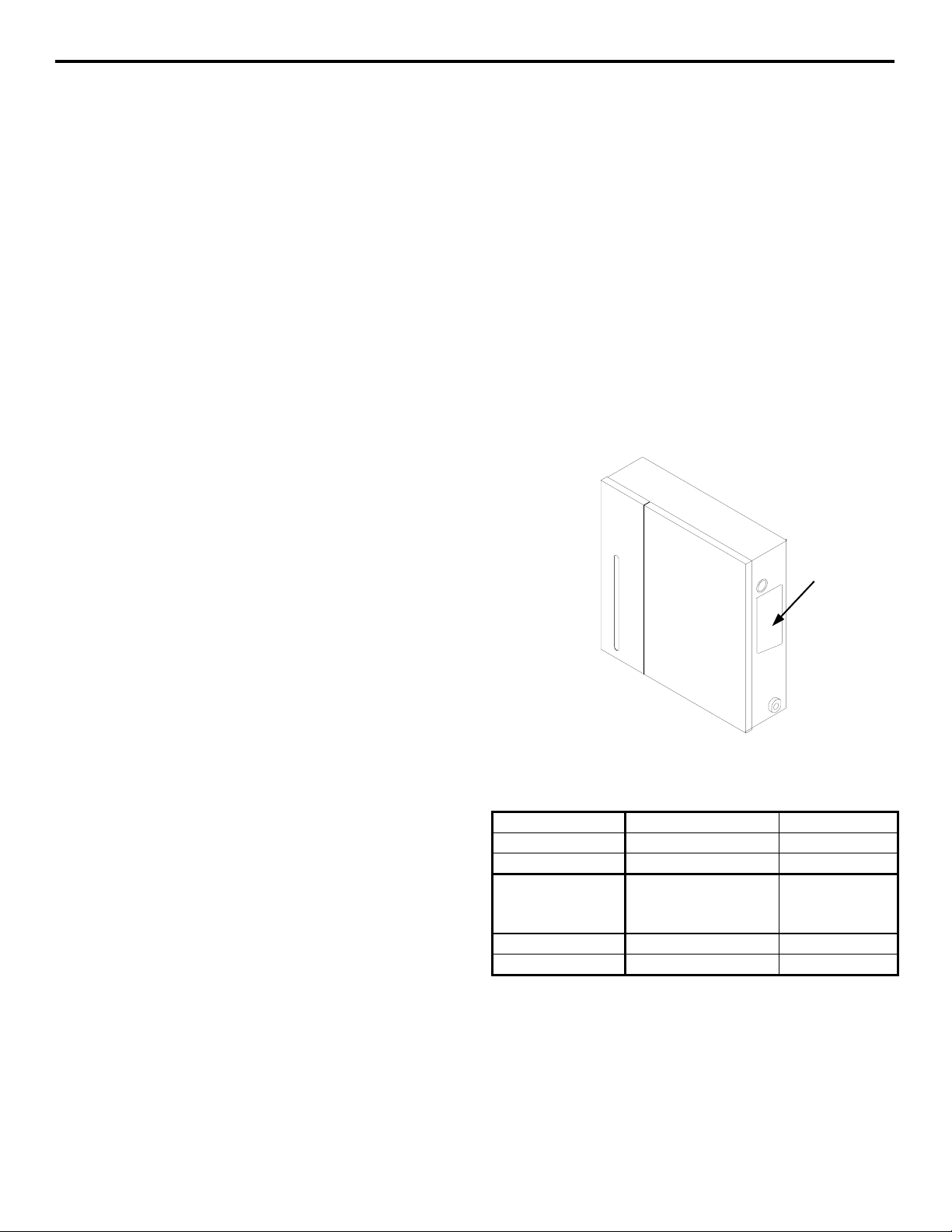

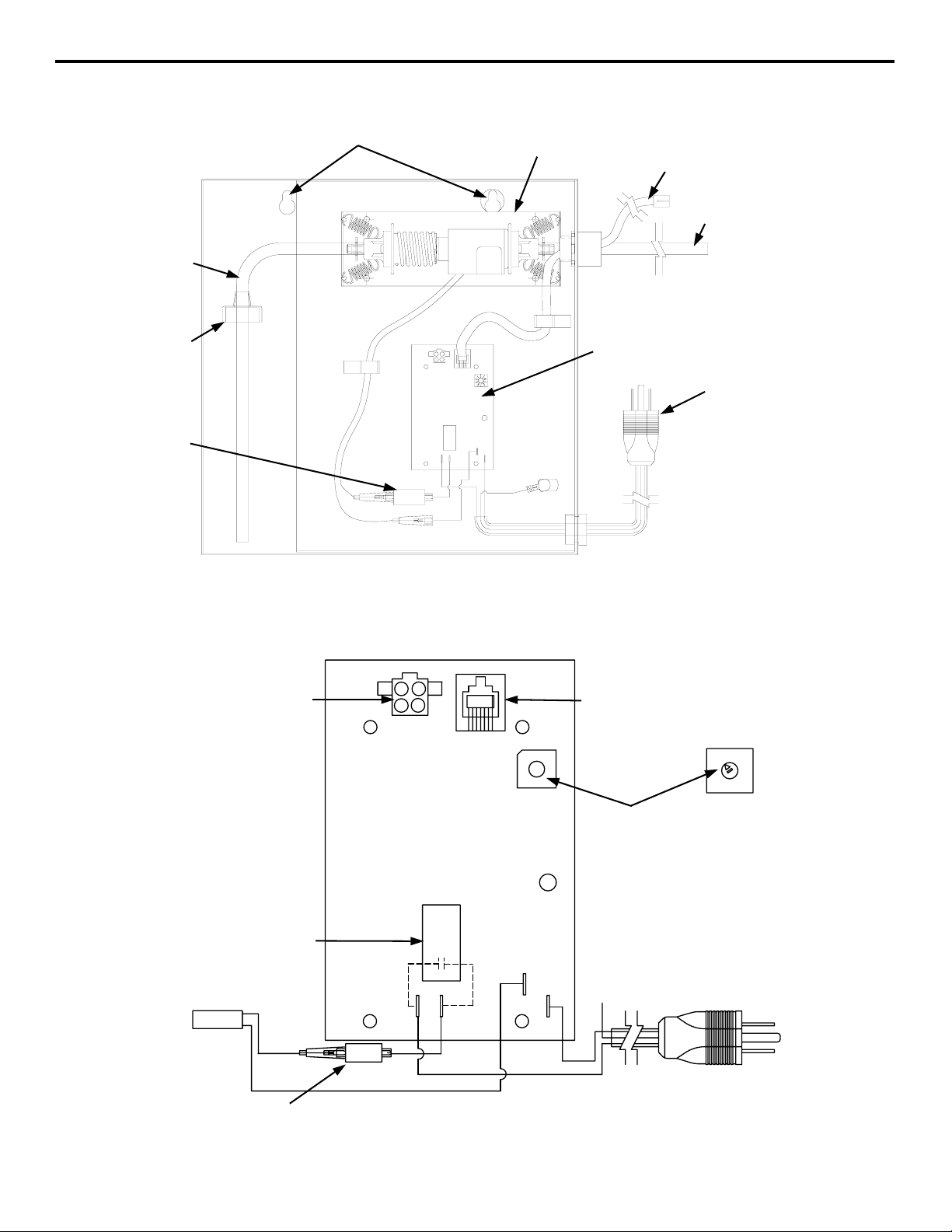

Com po ne nt Loc a tio n a nd Id e ntific a tion

MOUNTING SLOTS

DISPENSING PUMP

COMMUNICATION WIRE

(9 FEET LONG)

VINYL TUBE

(9 FEET LONG)

VINYL TUBE

PLASTIC CAP

PUMP

OSCILLATING

DIODE

CONTROL

BOARD

ELECTRIC POWER CORD

(8 FEET LONG)

SV1630G

COMMUNICATION CONNECTION QDUAL

COMMUNICATION WIRE IS SUPPLIED WITH ICE

MACHINE AND IS LOCATED ON THE BACK OF

THE CONTROL BOX

ELECTRIC CORD TO

DISPENSING PUMP

PUMP OSCILLATING

RELAY

DIODE

CONTROL

BOARD

COMMUNICATION CONNECTION

COMMUNICATION WIRE IS SUPPLIED WITH AUCS

CLEANING FREQUENCY

SELECTOR SWITCH

ELECTRIC CORD FOR

POWER TO AuCS

®

SV3065

1- 3

Page 8

G e ne ra l Informa tio n Se c tio n 1

Com pa tib le Ic e Ma c hine Mo de ls

The AuCSA accessory can be used on all Manitowoc ice machines capable of accepting the AuCS accessory.

Q Model Undercounter (Q130, Q210, Q270) QM model (QM20, QM30, QM45) and Flake Ice Machines

(QF800, QC700, QF400) are not AuCS compatible.

Listed models are compatible with the AuCSA accessory

Q MODELS

Air, Water or Remote Condenser

B150

Q200 J200 B200

J250 B250

Q280

Q320 J320 B320

Q370

Q420 J420 B420

Q450 J450 B450

Q600 J600 B600

Q800 J800 B800

Q1000 J1000 B1000

Q1300 J1300 B1300

Q1600

Q1800 J1800 B1800

Air, Water or Remote Condenser

QUIETQUBE MODELS

Q600C

Q800C

Q1000C

Q1400C

QDUALC

ICE BEVERAGE MODELS

IB600C

IB800C

IB1000C

SU1000C (SerVend UC300 Dispenser)

J MODELS

Air, Water or Remote Condenser

B MODELS

1- 4

Page 9

Se c tio n 2 Insta lla tio n Instruc tio ns

®

®

Se c tion 2

Insta lla tio n Instruc tio ns

G e ne ra l

These instructions are provided to assist the qualified

installer. Check your local yellow pages for the name

of the nearest Manitowoc Ice Machine Distributor or

call Manitowoc Ice, Inc. for information regarding

installation and start-up services.

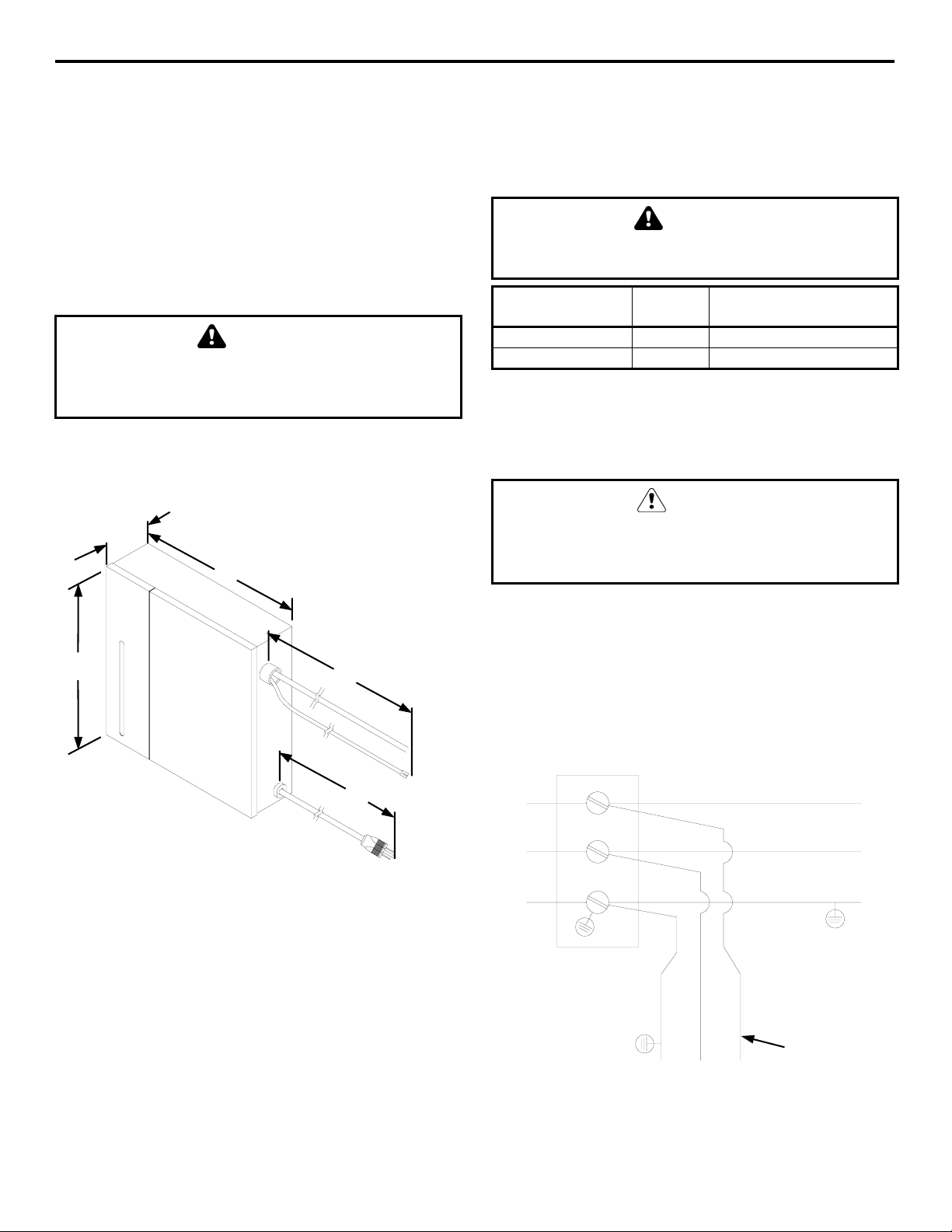

WA RNING

Improper installation will affect dispensing rate.

Install only within the parameters outlined in this

installation manual.

Please contact your local Manitowoc Distributor or

call Manitowoc Ice, Inc. for assistance if you

encounter a problem that is not covered by this

manual.

3.43 "

8.7 CM

12”

30.48 CM

Elec tric a l Se rvic e

WA RNING

All wiring must conform to local, state, and

national codes.

Vo lta g e / C yc le /

Pha se

Runnin

g Am p s

N.E.M.A Elec tric a l Plug

Co nfig ura tion

115/ 60/ 1 .3 5-15P

220/ 240/ 50/ 1 .1 No p lug attac he d

115 VOLT WIRING

The 115/60/1 AuCS has an eight (8) foot cord

which must be plugged into a 15 amp electrical

outlet.

CA UTIO N

Never use an extension cord. If an outlet is not in

reach of the AuCS power cord, have an outlet

installed.

220/240 VOLT WIRING

The 220/240/50/1 AuCS can be wired to:

12.12"

30.78 CM

Dimensions

9’

274.3 CM

8’

243 CM

SV1632G

The terminal block located in the ice machine.

With a separate plug.

To a separate disconnect.

TERMINAL BLOCK LOCATED

PRE-WIRED TO ICE MACHINE

IN ICE MACHINE

L

1

N N

GROUND

PRE-WIRED AT AuCS

N L

ACCESSORY

GROUND

TO SEPARATE FUSE/

CIRCUIT BREAKER.

DISCONNECT ALL POLES.

REFER TO ICE MACHINE

INSTALLATION

INSTRUCTIONS FOR

FUSE RATING.

AuCS

POWER

1

CORD

SV1633G

L

1

220/240/50/1 Wiring

2- 1

Page 10

Insta lla tio n Instruc tio ns Se c tio n 2

Lo c a tio n/ Mo unting

CA UTIO N

Do not install in an area where the air temperature

falls below 35F or exceeds 110F.

The AuCSA must be protected if it will be

subjected to temperatures below freezing. Refer to

“Removal From Service/Winterization.”

HEIGHT REQUIREMENT

3. Align the AuCS

bracket tabs. Verify the tabs are at the top of the

key slots and that the AuCS

4. Remove the backing from the adhesive bumpers

(part D, page 2-4.) Attach bumpers to the

mounting bracket directly above the AuCS

control box. This eliminates upward movement

and stops the tabs from disengaging the key slots.

A key slots with the mounting

A is level.

BRACKET

GASKET

A

(Refer to drawing on page 2-3.) Either the base or the

top of the AuCSA must be within 2” of the base of

the ice machine. Do not mount the AuCSA too high

or too low.

CA UTIO N

The cleaner or sanitizer may siphon (or dispense

BUMPER

improperly)into the ice machine water trough if the

AuCS

DISTANCE REQUIREMENT

(Refer to drawing on page 2-3.) The AuCSA must

be mounted within 9 feet of the ice machine to

accommodate the low voltage communication wire

and tubing. The tubing may be shortened to

accommodate a run of less than 9 feet.

Do not extend the length of the 9-foot low voltage

modular communication wire or tubing. The correct

amount of solution will not dispense.

FASTENING TO BIN OR DISPENSER

A is mounted too high or too low.

CA UTIO N

CA UTIO N

SV1640G

Mounting to Ice Machine

FASTENING TO WALL

The AuCSA is mounted to the wall using the two

key slots in the back wall of the accessory. Screw

fasteners (not supplied) must hold the entire weight

of the AuCSA accessory (approximately 10 lb.).

6.56”

16.6 CM

The AuCSA accessory may be mounted to the bin

or dispenser only when permitted by local electrical

codes.

NOTE: The ice machine’s serviceability may be

reduced when the AuCSA is mounted to the bin or

dispenser. Wall mounting is recommended.

1. Set the mounting bracket (part F, page 2-4) over

the bin top rail at desired location (refer to

figure).

2. Remove the backing from the foam adhesive tape

(part E, page 2-4). Apply tape to mounting

bracket, and along the entire bin rail.

2- 2

Key Slot Dimensions

SV1634G

Page 11

Se c tio n 2 Insta lla tio n Instruc tio ns

BASE OF ICE MACHINE

NO! TOO HIGH

2”

5 CM

2”

5 CM

BOX BASE OR BOX TOP

MUST BE WITHIN 2” (5 CM)

OF

ICE MACHINE BASE

NO! TOO LOW

NOTE: BOX MUST ALSO MOUNT WITHIN REACH OF 9’ TUBING AND LOW VOLTAGE COMMUNICATION WIRE.

SV1639G

Height and Distance Requirements

2- 3

Page 12

Insta lla tio n Instruc tio ns Se c tio n 2

Conne c tion to Ic e Ma c hine

GENERAL

A

B

½” PVC CONDUIT

FITTING

HOSE CLAMPS

LOCKNUT C

BUMPER D

PVC CONDUIT FITTING (A) INSTALLATION

½” LOCKNUT (C)

½” PVC CONDUIT

FITTING (A)

SV1636G

PVC Conduit Fitting (A) Installation

Parts Identification

FOAM TAPE E

BRACKET F

SV1635G

1. Insert the PVC fitting (A) into the AuCSA and

tighten with the lock nut (C).

WA RNING

Disconnect the electric power supply to the ice

machine at the electrical disconnect before

proceeding.

2. If required for access, remove the front, top, and

right side panels from the ice machine.

3. Remove the 7/8” access hole plug located on the

back of the corner post of the ice machine

4. Insert the PVC conduit fitting (Part A) and

tighten with the lock nut (Part C).

2- 4

Page 13

Se c tio n 2 Insta lla tio n Instruc tio ns

Conne c tion to Ic e Ma c hine (c o nt.)

Q320 Q370 Q420

Q600C Q800C Q1000C

1-1/8” DIAMETER

5”

1.5”

ACCESS HOLE

Q200 Q280 Q450

Q600 Q800 Q1000

3”

Q1300 Q1600 Q1800

1-1/8” DIAMETER

1.5”

ACCESS HOLE

½” LOCKNUT (C)

½” PVC CONDUIT

FITTING (A)

½” LOCKNUT (C)

PVC Conduit Fitting (A) Installation

½” PVC CONDUIT

FITTING (A)

SV1637G

2- 5

Page 14

Insta lla tio n Instruc tio ns Se c tio n 2

5.9"

IB600C IB800C IB1000C

3.0"

1-1/8"

DIAMETER

ACCESS

HOLE

7.5"

Q1400C

2"

1-1/8"

DIAMETER

ACCESS

HOLE

7.5"

QDUAL

2"

1-1/8"

DIAMETER

ACCESS

HOLE

2- 6

Page 15

Se c tio n 2 Insta lla tio n Instruc tio ns

Conne c tion to Ic e Ma c hine (c o nt.)

PVC CONDUIT CONNECTION

(NOT SUPPLIED)

Connect the ½” PVC conduit from the AuCSA to

the ice machine.

CA UTIO N

NOTE: AuCS®SHOWN

IS 115 VOLT WITH

POWER CORD

ATTACHED

Install 1/2” conduit to protect the tubing and

modular wire from damage or access.

NOTE: A pulling elbow is recommended for easier

routing of the vinyl tubing and modular wire.

Typical PVC Conduit Installation

SV1638G

2- 7

Page 16

Insta lla tio n Instruc tio ns Se c tio n 2

Conne c tion to Ic e Ma c hine (c o nt.)

WATER INLET

VALVE

ACCESS

HOLE

SV1641G

WATER INLET

BARBED FITTING

Vinyl Tubing Installation

(Typical 22” Ice Machine Shown)

WATER INLET

BARBED FITTING

SV3064

IB600C IB800C IB1000C

2- 8

SV1780

QDUAL

ROUTE TUBING

WATER INLET

BARBED FITTING

ROUTE TUBING AND

CONNECT TO 90

Q1400C

ELBOW

SV1770 RH

Page 17

Se c tio n 2 Insta lla tio n Instruc tio ns

Q1400C ONLY

A. 1/4" DIA x 4" LG VINYL TUBING

B. 1/2" PVC CONDUIT FITTING (QTY 2)

C. 90 THREADED ELBOW

D. 1/4" FERRULE NUT

E. 90 BARBED ELBOW

F. 3/8" HOSE CLAMP (QTY 2)

G. 1/2" LOCKNUT (QTY 2)

A. Slide the 1/4" ferrule nut (part D) onto the 1/4"

tubing (part A)

B. Connect the 1/4" ferrule nut (with 1/4" tubing)

to the 90 threaded elbow (part C) and hand

tighten.

C. Locate the 7/16" diameter hole in the bulkhead

of the ice machine. (See illustration).

D. Remove the plastic plug from the hole.

E. Insert the threaded end of the barbed elbow

(part E) into the hole. Screw the 90 threaded

elbow (part C) to the barbed elbow (part E).

Hand tighten. Be sure the threaded elbow (part

C) outlet tube points downward, toward the

water trough.

2- 9

Page 18

Insta lla tio n Instruc tio ns

Conne c tion to Ic e Ma c hine (c o nt.)

COMMUNICATION WIRE CONNECTION

Insert the low voltage communication wire through

the ½” conduit connecting the AuCSA to the ice

machine.

machine.

A to the ice

CONTROL BOARD

COMMUNICATION

WIRE

GROUND WIRE

(Q1300/Q1800 ONLY)

Se c tio n 2

Plug into the jacks on the ice machine control board

Plug into the jacks on the ice machine control board

and the AuCS

and the AuCSA control board. (Refer to drawing for

routing communication wire in ice machine.)

routing communication wire in ice machine.)

A control board. (Refer to drawing for

ROUTE WIRING

THROUGH

ACCESS HOLES

AS SHOWN

30 AND 48 INCH 22 INCH

COMMUNICATION

WIRE

SV1642G

Low Voltage Communication Wire Connection

QDUAL ONLY: The communication wire is attached to the rear of the ice

machine control box. The communication wire included with the AuCS

A is

not used.

AUCS CONTROL

BOARD

COMMUNICATION

PORT

2- 10

QDUAL

COMMUNICATION

PORT

Page 19

Se c tio n 2 Insta lla tio n Instruc tio ns

Conne c tion to Ic e Ma c hine (c o nt.)

VINYL TUBING CONNECTION

1. Insert the tubing into the ½” conduit from the

AuCS to the ice machine.

2. Slide the 3/8” hose clamp (B) onto the tubing and

connect it to the barbed fitting on the AuCS

WATER INLET

AuCS® INLET

dispenser pump.

3/8” HOSE CLAMP (B)

8’ VINYL TUBING

MODULAR WIRE LEAD

SV1643G

Connecting Vinyl Tubing to Dispenser Pump

Using 3/8” Hose Clamp (B)

3. Route the tubing through the bulkhead heyco

fitting and into the water compartment.

4. Determine the amount of tubing required and cut

off the excess.

5. Slide the 3/8” hose clamp (Part B) onto the tubing

and connect it to the water inlet barbed fitting.

Connecting Vinyl Tubing to

AFTER INSTALLATION

Water Inlet Barbed Fitting

WA RNING

Read and understand this entire manual prior to

operation of the AuCSA accessory. You must

understand all warning and caution statements and

follow all safety precautions to assure proper

operation of the AuCSA accessory.

SV1644G

2- 11

Page 20

Insta lla tio n Instruc tio ns Se c tio n 2

De te rm ine Type O f Solutio n Ne e de d

CA UTIO N

Use only Manitowoc-approved Ice Machine

Cleaner (part number 94-0546-3) or Sanitizer (part

94-0565-3) in the AuCS

A It is a violation of

Federal law to use these solutions in a manner

inconsistent with their labeling. Read and

understand all labels on the bottles before use.

The AuCSA accessory will dispense Cleaner OR

Sanitizer. It cannot dispense both at the same time.

CA UTIO N

Do not mix Cleaner and Sanitizer solutions

together. It is a violation of Federal law to use these

products in a manner inconsistent with their

labeling.

MANITOWOC ICE MACHINE CLEANER

Part Number 94-0546-3

Ice Machine Cleaner is used to control build-up and

to remove lime scale or other mineral deposits. It will

not “sanitize” the ice machine.

Insta lling Bo ttle O f So lutio n

WA RNING

Wear rubber gloves and safety goggles (and/or face

shield) when handling Cleaner or Sanitizer.

CA UTIO N

Follow instructions listed under “Changing

Solution Type” on the next page when changing

from Cleaner to Sanitizer or from Sanitizer to

Cleaner.

1. Place the bottle into the AuCSA accessory.

2. Slide the tube to the bottom of the bottle and

hand-tighten the cap.

It is recommended for use in places that have lime

scale or other mineral deposits built up, but no

problems with slime.

MANITOWOC ICE MACHINE SANITIZER

Part Number 94-0565-3

Ice Machine Sanitizer is used for sanitizing and

controlling algae build-up (slime) and other bacterial

growth. The ice machine should be sanitized on a

regular schedule, following Manitowoc

recommendations and local regulations.

It is recommended for use in places such as pizzerias,

bars, bakeries, etc., that have airborne bacteria

(yeast). Sanitizing is also recommended in places that

do not have lime scale (or other mineral deposit

problems).

Mo de l

Q200 Q 280 Q 320 Q 370 Q 420

Q450 Q 600 Q 600C IB600C

Q800 Q 800C IB800C Q 1000

Q1000C IB1000C SU1000C

Q1400C

Q1300 Q 1600 Q 1800 Q DUAL *4.8 o unc e s (140 ml)

*The disp e nse ra te is a uto ma tic ally c o ntro lle d

Am o unt o f C le a ne r o r

Sanitize r Dispe nse d

*2.4 o unc e s (70 m l)

TUBE MUST BE CLOSE

TO BOTTLE BOTTOM

SV1645

Bottle Installation

WA RNING

Do not use 1 gallon bottles of Cleaner or Sanitizer

on the AuCSA

2- 12

Page 21

Se c tio n 2 Insta lla tio n Instruc tio ns

Chang ing So lutio n Type

CA UTIO N

Do not mix Cleaner and Sanitizer solutions

together. It is a violation of Federal law to use these

products in a manner inconsistent with their

labeling.

Use the following procedure to flush the system prior

to changing from Cleaner to Sanitizer or from

Sanitizer to Cleaner.

1. Remove the bottle of Cleaner or Sanitizer from

the AuCS

A. Insert a 16 oz. bottle of water.

2. Repeat the following until the water bottle is

empty (approximately 8 times):

A. Move the ice machine toggle switch to

CLEAN.

B. The water pump and dump valve will turn on.

The dump valve will shut off after

approximately 45 seconds.

C. The pump will run for 60 seconds and then

dispense for 10 seconds. (The Q1300, Q1600,

Q1800 and QDUAL will dispense for

20 seconds).

D. Move the switch to OFF after step C is

Ho se Prim ing

The dispenser pump requires priming only upon

initial installation, or if the hose between the

AuCS

A and the ice machine has been pumped dry.

WA RNING

Do not blow into or suck on the hose in an attempt

to prime it.

Do not prime the hose until installation is complete.

CA UTIO N

Repeat the following procedure three times:

1. Move the ice machine toggle switch to CLEAN.

2. The water pump and dump valve will turn on.

The dump valve will shut off after approximately

45 seconds.

3. The control waits until the water pump runs for

60 seconds, then energizes the AuCS

A pump for

10 seconds. (The Q1300, Q1600, Q1800, and

QDUAL will energize for 20 seconds).

4. Allow the ice machine to complete the cleaning

or sanitizing cycle.

Refer to Manual Start Operation for details.

completed.

3. Install a new bottle of either Cleaner or Sanitizer

solution. Refer to “Installing Bottle of Solution”

on previous page.

The priming procedure starts the automatic

cleaning mode. Upon moving the ice machine

toggle switch to ICE, the ice machine will run

Im po rta nt

through 6 rinse cycles before making ice.

2- 13

Page 22

Insta lla tio n Instruc tio ns Se c tio n 2

Se tting Fre q ue nc y O f Cle aning s

The AuCSA is factory-set to clean (or sanitize) the

ice machine approximately once every two weeks.

For less frequent cleaning, set the selector switch as

indicated below. (Refer to “Component Location and

Identification” for selector switch location.)

Switc h

Po sition

0 No c le aning (O FF)

1

2

3

Time Be twe en

Clea ning s

Ap pro xim a te ly 2 w e eks

(1120 ha rve sts)

Ap pro xim a te ly 4 w e eks

(2240 ha rve sts)

Ap pro xim a te ly 12 w e e ks

(6720 ha rve sts)

NOTE: Switch positions 4-9 are inoperative. Do not

use them.

Im po rta nt

Using the AuCSA accessory is supplemental to

regular cleaning and sanitizing (per Manitowoc

recommendations and local regulations).

Re m o va l Fro m Se rvic e / Winte riza tion

CA UTIO N

Leaving solutions in the AuCSA in freezing

temperatures may result in severe damage to the

dispensing pump. A failure of this nature is not

covered by the warranty.

If the AuCSA is to be removed from service for

extended periods, or if it is to be exposed to ambient

temperatures of 32F (0C) or below, follow this

procedure:

1. Remove the Cleaning or Sanitizing solution

bottle.

2. Follow the instructions under “Hose Priming” to

pump all of the solution out of the dispensing

pump and line.

2- 14

Page 23

Se c tio n 3 Ic e Ma c hine O pe ra tio n

Se c tion 3

Ic e Ma c hine O pe ra tio n

Autom a tic O p e ra tio n

The following occurs when the toggle switch is in

the ICE position:

The ice machine control board counts the

number of ice harvest cycles.

The AuCS

A accessory interrupts the ice

making mode and starts the cleaning (or

sanitizing) mode when the harvest count equals

the “Frequency of Cleaning” setting of the

AuCS

A

When the automatic cleaning (or sanitizing)

cycle is complete (approximately 25 minutes,

QDUAL 40 minutes), ice making resumes

automatically, and the “Harvest Count” is reset

to zero.

Im po rta nt

Opening the curtain switch will interrupt the

cleaning (or sanitizing) sequence. The sequence

will resume from the point of interruption when

the curtain re-closes.

NOTE: The harvest count is reset after the AuCSA

cycle is completed. It cannot be reset by unplugging

the modular wire, changing the switch position,

power loss, etc.

Ma nua l Sta rt O pe ra tio n

(QDUAL SEE PAGE 3-3)

Step 1 Set the toggle switch to the OFF position

after ice falls from the evaporator at the end of a

Harvest cycle. Or, set the switch to the OFF

position and allow the ice to melt off the

evaporator.

CA UTIO N

Never use anything to force ice from the

evaporator. Damage may result.

Step 2 To start the automatic cleaning system,

move the toggle switch to the CLEAN position. The

water will flow through the water dump valve and

down the drain. The Clean light will turn on to

indicate the ice machine is in Clean Mode.

The AuCS

A pump energizes automatically to add

cleaner or sanitizer to the ice machine.

Step 3 The ice machine will automatically time out

a ten minute cleaning or sanitizing cycle, followed

by six rinse cycles, de-energize the Clean light and

stop. This entire cycle lasts approximately 25

minutes.

Step 4 After the cleaning or sanitizing cycle stops,

move the toggle switch to the ICE position.

Step 5 The ice machine may be set to start and

finish a cleaning (or sanitizing) cycle, then

automatically start ice making again.

You must wait about one minute into the cleaning

cycle (until water starts to flow over the

evaporator), then move the toggle switch from

CLEAN to ICE position.

When the cleaning (or sanitizing) cycle is

completed, an ice making sequence will start

automatically.

Im po rta nt

The Q1400C ice machine can not perform step 5.

The toggle switch position must be changed from

CLEAN to ICE after the AuCS

A cycle has been

completed.

3- 1

Page 24

Ic e Ma c hine O pe ra tio n Se c tio n 3

Chang ing Switc h Po sitio n During Autom a tic O pe ra tio n

Q MODELS/IB MODELS/SU1000C

If the toggle switch is moved to OFF prior to the

pump dispensing (less than 45 seconds into the cycle)

then switched to:

IC E

CLEAN

A no rm a l ic e -ma king mo de b e g ins.

A m a nua l c le an c yc le b e gins.

(Se e “ Ma nua l Sta rt O pe ra tio n,” p a g e 3-1.)

If the toggle switch is moved to OFF after the pump

dispenses (more than 45 seconds into the cycle, but

before rinse cycles begin) then switched to:

IC E

CLEAN

The “ c le an” po rtio n o f the c yc le b e g ins.

Afte r c omp le tio n o f the 10-minute

“ C le a n” a nd 6 rinse c yc le s, the c o unter

re sets and a no rma l ic e -ma king mo de

b e g ins.

A m a nua l c le an c yc le b e gins.

(Se e “ Ma nua l Sta rt O pe ra tio n,” p a g e 3-1.)

Afte r c omp le tio n o f the 10-minute

“ C le a n” a nd 6 rinse c yc le s, the c o unter

re sets and the ic e m a c hine awa its a

c hang e in the tog g le switc h po sitio n.

If the toggle switch is moved to OFF after the 6 rinse

cycles have begun and then switched from off to:

IC E

CLEAN

The rinse po rtio n o f the c yc le re sta rts a nd

c ontinue s.

Afte r c omp le tio n o f the 6 a d ditio na l rinse

c yc le s, the c o unte r re sets and a no rma l

ic e -ma king mo de b e g ins.

A m a nua l c le an c yc le b e gins.

(Se e “ Ma nua l Sta rt O pe ra tio n”.)

Afte r c omp le tio n o f the 10-minute

“ C le a n” a nd 6 rinse c yc le s, the c o unter

re sets and the ic e m a c hine awa its a

c hang e in the tog g le switc h po sitio n.

Q1400C

If the toggle switch is moved to OFF prior to the

pump dispensing (less than 45 seconds into the cycle)

then switched to:

IC E

CLEAN

A no rm a l ic e -ma king mo de b e g ins.

A m a nua l c le an c yc le b e gins.

(Se e “ Ma nua l Sta rt O pe ra tio n,” p a g e 3-1.)

If the toggle switch is moved to OFF after the pump

dispenses (more than 45 seconds into the cycle, but

before rinse cycles begin) then switched to:

IC E

CLEAN

The ic e ma c hine runs 6 rinse c yc le s, re sets

the c o unte r a nd starts a no rm a l ic e ma king m o de .

A m a nua l c le an c yc le b e gins.

(Se e “ Ma nua l Sta rt O pe ra tio n”)

Afte r c omp le tio n o f the 10-minute

“ C le a n” a nd 6 rinse c yc le s, the c o unter

re sets and the ic e m a c hine awa its a

c hang e in the tog g le switc h po sitio n.

If the toggle switch is moved to OFF after the 6 rinse

cycles have begun and then switched from off to:

IC E

CLEAN

The ic e ma c hine runs 6 rinse c yc le s, re sets

the c o unte r a nd starts a no rm a l ic e ma king m o de .

A m a nua l c le an c yc le b e gins.

(Se e “ Ma nua l Sta rt O pe ra tio n”.)

Afte r c omp le tio n o f the 10-minute

“ C le a n” a nd 6 rinse c yc le s, the c o unter

re sets and the ic e m a c hine awa its a

c hang e in the tog g le switc h po sitio n.

Im po rta nt

After solution is dispensed (cleaner or sanitizer),

the Q1400C ice machine must run 6 rinse cycles.

Changing toggle switch position, disconnecting

power, etc will not override the 6 rinse cycles.

Each time the toggle switch is moved from Off to

Ice (or power is interrupted), the six rinse cycles

begin again.

3- 2

Page 25

Q DUA L O NLY

Ic e Ma c hine O pe ra tio nSe c tio n 3

Chang ing Switc h Po sitio n During

Ma nua l Sta rt O pe ra tio n

Step 1 Set the toggle switch to the OFF position

after ice falls from the evaporator at the end of a

Harvest cycle. Or, set the switch to the OFF position

and allow the ice to melt off the evaporator

CA UTIO N

Never use anything to force ice from the

evaporator. Damage may result.

Step 2 To start the automatic cleaning system, move

the toggle switch to the CLEAN position. The water

will flow through the water dump valve and down the

drain. The Clean light will energize to indicate the ice

machine is in the Clean Cycle. Th ice machine will

purge water for two minutes. The water fill valve

will energize and remain energized until water

contacts the water level probe. The AuCS

A will

then automatically add cleaner or sanitizer to the ice

machine.

Step 3 The ice machine will automatically time out a

ten minute cleaning or sanitizing cycle, followed by

six rinse cycles, de-energize the Clean light and stop.

This entire cycle lasts approximately 40 minutes.

Autom a tic O p e ra tio n

If the toggle switch is moved to OFF prior to the

pump dispensing (less than 2 minutes into the cycle)

then switched to:

IC E

CLEAN

A no rm a l ic e -ma king mo de b e g ins.

A m a nua l c le an c yc le b e gins.

(Se e “ Ma nua l Sta rt O pe ra tio n,” p a g e 3-1.)

If the toggle switch is moved to OFF after the pump

dispenses (more than 2 minutes into the cycle, but

before rinse cycles begin) then switched to:

IC E

CLEAN

The “ c le an” po rtio n o f the c yc le b e g ins.

Afte r c omp le tio n o f the 10-minute

“ C le a n” a nd 6 rinse c yc le s, the c o unter

re sets and a no rma l ic e -ma king mo de

b e g ins.

A m a nua l c le an c yc le b e gins.

(Se e “ Ma nua l Sta rt O pe ra tio n,” p a g e 3-

1.)

Afte r c omp le tio n o f the 10-minute

“ C le a n” a nd 6 rinse c yc le s, the c o unter

re sets and the ic e m a c hine awa its a

c hang e in the tog g le switc h p o sitio n.

If the toggle switch is moved to OFF after the 6 rinse

cycles have begun and then switched from off to:

Step 4 After the cleaning or sanitizing cycle stops,

move the toggle switch to ICE position.

Step 5 The ice machine may be set to start and finish

a cleaning (or sanitizing) cycle, then automatically

start ice making again.

You must wait about 2 minutes into the cleaning

cycle (until water starts to flow over the evaporator),

then move the toggle switch from CLEAN to ICE

position.

After the fluid has been dispensed opening the

curtain (bin switch) will interrupt the AuCS

A

sequence. The sequence resumes when the curtain

closes.

When the cleaning cycle (or sanitizing) is completed,

an ice making sequence will start automatically.

IC E

CLEAN

The rinse po rtio n o f the c yc le re sta rts a nd

c ontinue s.

Afte r c omp le tio n o f the 6 a d ditio na l rinse

c yc le s, the c o unte r re sets and a no rma l

ic e -ma king mo de b e g ins.

A m a nua l c le an c yc le b e gins.

Afte r c omp le tio n o f the 10-minute

“ C le a n” a nd 6 rinse c yc le s, the c o unter

re sets and the ic e m a c hine awa its a

c hang e in the tog g le switc h p o sitio n.

3- 3

Page 26

Page 27

Page 28

MA NITO WO C IC E, INC .

2110 South 26th Stre e t P.O. Bo x 1720

Ma nito wo c , WI 54221-1720

Pho ne : (920) 682-0161

Fa x: (920) 683-7585

We b Site - www.ma nito w o c ic e .c o m

2002 Ma nito w o c Ic e , Inc .

Loading...

Loading...