Page 1

OPERATOR MANUAL

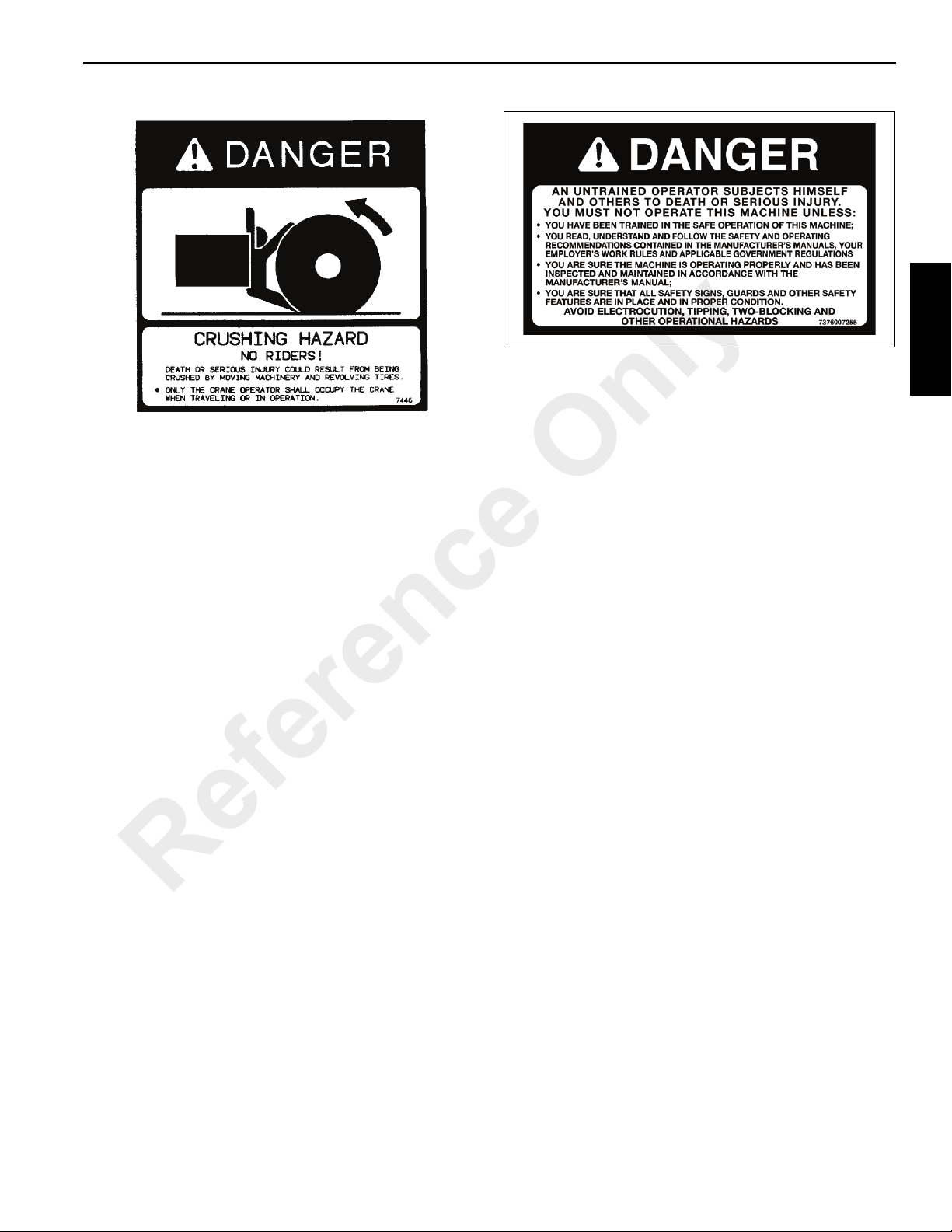

An untrained operator subjects himself and others to death or

serious injury. Do not operate this crane unless:

• You are trained in the safe operation of this crane. Manitowoc is not

responsible for qualifying personnel.

• You read, understand, and follow the safety and operating

recommendations contained in the crane manufacturer’s manuals and

load charts, your employer’s work rules, and applicable government

regulations.

• Y ou are sure that all safety signs, guards, and other safety features are

in place and in proper condition.

• The Operator Manual and Load Chart are in the holder provided on

crane.

DANGER

!

Supplement

Crane Warm-up Procedures

Reference Only

© 2015 Manitowoc

Published 3-10-2015, Control # 571-00

Page 2

SECTION CONTENTS

Crane Warm-up Procedures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Engine. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Transmission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Hoist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Swing Drive and Turntable Bearing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Axles. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Hydraulic Oil System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Reference Only

Page 3

This Supplement provides information regarding the proper

warm-up procedures for operating the crane in colder

temperatures. The information pro vided her e sup plements

the Operator and Service Manuals and must b e used in

conjunction with these manuals.

CRANE WARM-UP PROCEDURES

The following procedures detail the actions that must be

taken to properly warm the different crane components

before operating the crane.

NOTE: For temperatures below -9°C (15°F) refer to arctic

lubricants and conditions in th e Operator and

Service Manuals.

Before starting the crane, ensure the appropriate lubricants

are used to provide lubrica tion for th e prevailing ambient

temperatures in which the crane will operate in (a list of

lubricants and their temperature ranges can be found in the

Lubrication section of your crane’s Operator Manual, by

contacting your local Manitowoc distributor, or by contacting

Manitowoc Crane Care directly).

Operating the transmission with a sump temperature below

normal operating temperature is limited to:

• operating in the neutral gear or

• driving with an unloaded crane while not exceeding

1500 engine RPM and not exceeding half throttle.

Alternate Warm-up Procedures for Tr uck Mount (TM/

TMS) Cranes:

1. Setup the crane on outriggers.

2. Engage the transmission and allow crane to run at idle

until the temperature of the transmission sump reaches

normal operating temperature.

Hoist

Performing a warm-up procedure is recommended at every

startup and is required at ambient temperatures below 4°C

(40°F).

Warm-up Procedures:

1. Without operating the hoist function, warm the hydraulic

oil (see Hydraulic Oil System, page 2).

CAUTION

Crane Damage Hazard!

Operating the crane with the inc orrect lubricants and

fluids for the prevailing ambient temperature and/or fail ing

to adequately w arm the crane prior to cold weather

operation can lead t o a f ailu re o f a crane co mpo ne nt o r

system.

Always use Manitowoc recom mended lubrica nts and

fluids for the prevailing ambient temperature and properly

start and warm the crane using the cold weather

procedures found in this Operator Manual and

supplement before operating the crane at full load.

Engine

NOTE: For National Crane engine warm-up procedures,

refer to chassis manufacturer’s manual.

Warm-up Procedures for All Temperature Ranges:

1. Upon startup, allow the engine to idle for 3 to 5 minutes

before operating with a load.

2. Cold Engine Startup: After allowing the engine to warm

by idling it for 3 to 5 minutes, slowly increase the engine

speed to provide adequate lubrication to the bearings

and to allow the oil pressure to stabili ze.

Reference Only

T ransmission

NOTE: For National Crane transmission warm-up

procedures, refer to chassis manufacturer’s

manual.

2. Once the hydraulic system is warm, operate the

unloaded hoist, in both directions, at low speeds several

times to prime all hydraulic lines with warm hydraulic oil

and to circulate gear lubricant through the planetary

gear sets.

Swing Drive and T urnt able Bearing

Warm-up Procedures for Temperatures Above -7°C

(20°F):

1. Setup the crane on fully extended outriggers, with the

boom fully retracted and near maximum lift angle with no

load applied.

2. Rotate the superstructure at a speed of less than one

RPM for at least one complete revolution in one

direction, then rotate the superstructure at a speed of

less than one RPM for at least one complete revolution

in the opposite direction.

Warm-up Procedures for Temperatures Below -7°C

(20°F):

1. Ensure the boom is fully retracted and near maximum lift

angle with no load applied.

2. Rotate the superstructure at a speed of less than onehalf RPM for at least two complete revolutions in one

direction, then rotate the superstructure at a speed of

less than one-half RPM for at least two complete

revolutions in the opposite direction.

National Crane Published 3-10-2015, Control# 571-00 1

Page 4

Axles

NOTE: For National Crane axle warm-up procedures, refer

to chassis manufacturer’s manual.

Hydraulic Oil System

Operating Limits and Warm-up Procedures:

• From 4°C to -10°C (40°F to 15°F): Crane operation

without

medium function speed (joystick position) until the fluid

reaches at le a st 10 °C ( 50°F). It is th e n r eco mm en de d

that all crane functions be cycled to remove cold fluid

from all components and cylinders of the hydraulic

system. If there is any unusual sound coming from the

a load is allowed with medium engine RPM and

crane’s hydraulic pumps or motors, s top the ope ra tion

and engine immediately and contact a Manitowoc

distributor.

• From 10°C to 4°C (50°F to 40°F): Crane operation with

a load is allowed with medium engine RPM and medium

function speed (joystick position) until the fluid reaches

at least 10°C (50°F).

• From 95°C to 10°C (200°F to 50°F): Crane operation

with a load is allowed with no restrictions.

• Above 95°C (200°F): No crane operation is allowed. Let

the crane’s hydraulic oil cool by running the engine at

idle with no functions actuated.

Reference Only

2 Published 3-10-2015, Control# 571-00

Page 5

An untrained operator subjects himself and others to death or

serious injury. Do not operate this crane unless:

• You are trained in the safe operation of this crane. Manitowoc is not

responsible for qualifying personnel.

• You read, understand, and follow the safety and operating

recommendations contained in the crane manufacturer’s manuals and

load charts, your employer’s work rules, and applicable government

regulations.

• Y ou are sure that all safety signs, guards, and other safety features are

in place and in proper cond

ition.

• The Operator’s Manual and Load Chart are in the holder provided on

crane.

DANGER

!

1

2

3

4

5

6

National Crane

OPERATOR MANUAL

This manual has been prepared for and is considered part of the

500E2

This Manual is divided into the following sections:

SECTION 1 INTRODUCTION

SECTION 2 SAFETY PRECAUTIONS

SECTION 3 OPERATING CONTROLS AND PROCEDURES

SECTION 4 SET-UP

SECTION 5 LUBRICATION PROCEDURE AND CHARTS

SECTION 6 MAINTENANCE CHECKLIST

NOTICE

The crane serial number is the only me thod your distribu tor or th e factor y

has of providing you with correct parts and service information.

The crane serial number is identified on the builder’s decal att ached to the

right side of the turret. Always furnish crane serial number when

ordering parts or communicating service problems with your distributor or

the factory.

Reference Only

© 2011 Manitowoc

10-20-2011 Control # 111-05

Page 6

CALIFORNIA

PROPOSITION 65 WA RNING

Diesel engine exhaust and some of its constituents are

known to the State of California to cause cancer, birth

defects, and other reproductive harm.

CALIFORNIA

PROPOSITION 65 WA RNING

Battery posts, terminals, and related accessories contain

chemical lead and lead compounds, chemicals known to

the State of California to cause cancer, birth defects or

other reproductive harm. Wash hands after handling.

Reference Only

Page 7

500E2 OPERATOR’S MANUAL TABLE OF CONTENTS

1

SECTION 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Introduction

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Supplemental Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Safety Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

New Owner. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

SECTION 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Safety Precautions

Safety Messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

General. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Safety Alert Symbol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

Signal Words. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Accidents. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Operator’s Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Operator’s Qualifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

Operational Aids . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Load Moment Indication (LMI) Systems (If Equipped) . . . . . . . . . . . . . . . . . . . . . . . 2-4

Anti-Two-Blocking Device. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Work Area Definition System (WADS) (If Equipped) . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Crane Stability/Structural Strength . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

Load Charts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-6

Work Site . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-6

Wind Forces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Lifting Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Counterweight. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Outrigger Lift Off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-8

Multiple Crane Lifts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Electrocution Hazard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-8

Set-Up and Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

Electrocution Hazard Devices. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

Electrical Contact . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Special Operating Conditions and Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Personnel Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-11

Environmental Protection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

Service and Repairs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

Tires . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

Wire Rope. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

Sheaves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

Batteries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

Engine. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

Transporting the Crane . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

Travel Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

Reference Only

Work Practices. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

Personal Considerations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

Crane Access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

Job Preparation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

Working. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

Lifting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-19

Hand Signals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-20

Boom Extension. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-22

Parking and Securing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-22

Shut-Down. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-22

Cold Weather Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-22

Temperature Effects on Hydraulic Cylinders. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-23

National Crane 1-1

Page 8

TABLE OF CONTENTS OPERATOR’S MANUAL 500E2

Overload Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-25

Boom Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-26

Superstructure Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-28

Carrier Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-30

SECTION 3 . . . . . . . . . . . . . . . . . . . . . . . .Operating Controls And Procedures

Truck Cab Controls. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Power Take-Off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Park Brake. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Cold Weather Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Unattended Crane . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Crane Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Turn . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Swing Speed Adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Boom . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Boom Telescope . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Hoist. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Stabilizers Up/Down . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Stabilizers Extend/Retract . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Outriggers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Foot Throttle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Emergency Stop Switch. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Horn. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Hydraulic Capacity Alert System (HCA) Load Range Gauge . . . . . . . . . . . . . . . . . 3-3

HCA Overload Light. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Anti-Two-Block/Jib Overload Light. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Key Override Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Override Button . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Load Chart. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Boom Angle Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Boom length Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Outrigger Status Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Hoist System Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Using Multiple Part Lines. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

General Rules When Operating Hoist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Lifting the Load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Optional Hoist Burst of Speed (BOS). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Anti-Two Block System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Outrigger Monitoring System (OMS) (Optional—Standard in North America) . . . . . . . . 3-6

Hydraulic Capacity Alert System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

System Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Indicator Lights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

HCA Load Range Gauge. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

HCA System Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Pressure Sensing Switch. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Reference Only

Jib Load Limiting Device. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

System Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

System Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Three Section Boom Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Anti-two-block Weight Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

Installing Cable On The Hoist. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

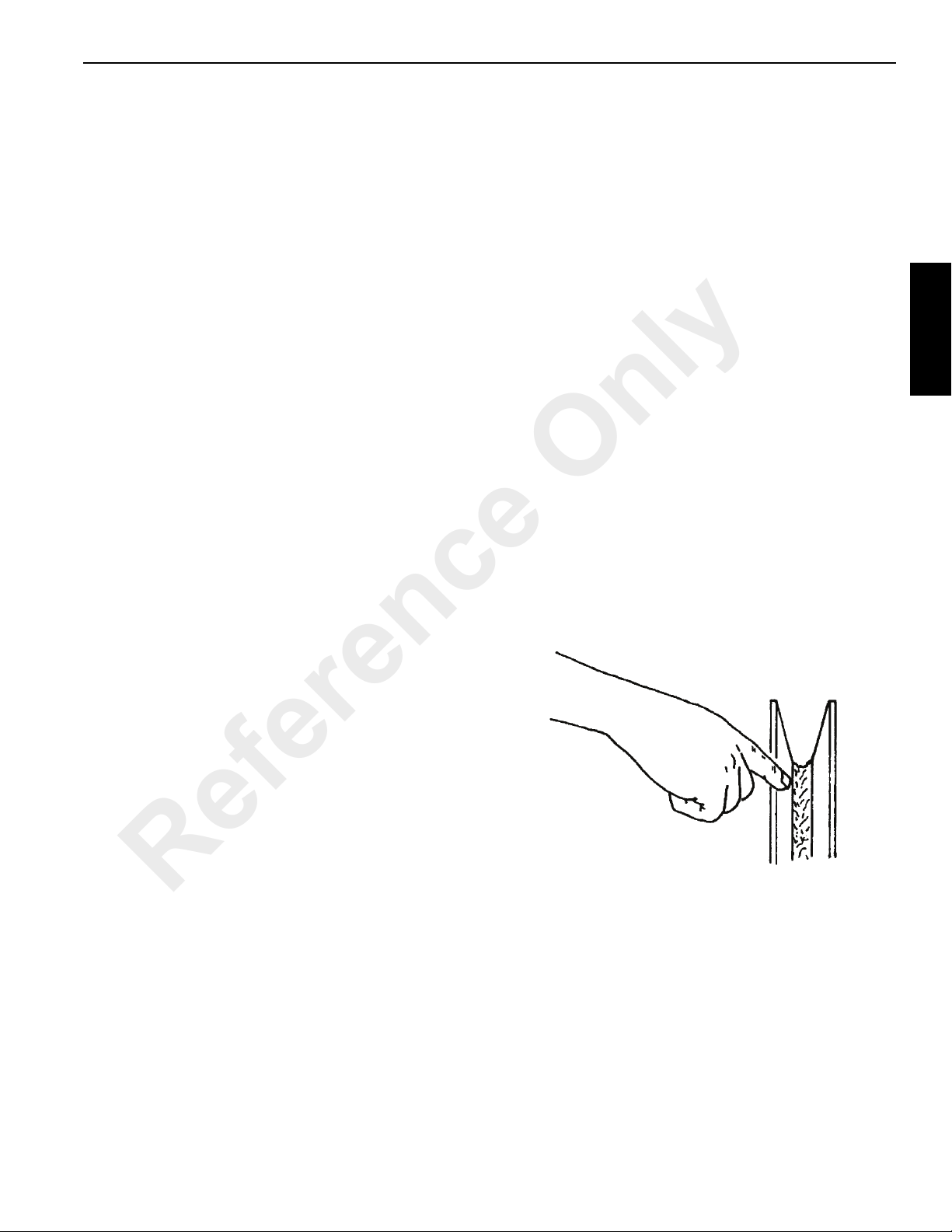

Wedge Socket Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

1-2

SECTION 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Set-Up

Equipment Familiarization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Equipment Checks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Pre-Operation Inspection and Calibration Verification. . . . . . . . . . . . . . . . . . . . . . . 4-1

Page 9

1

500E2 OPERATOR’S MANUAL TABLE OF CONTENTS

Work Site Selection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Before Leaving the Cab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Lifting Over the Rear. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Lifting Over the Front with a Front Stabilizer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Before Making the Lift. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Reading and understanding the load Charts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Set-Up. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Definitions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Determining Load Capability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Load Determination Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Jib Operation Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Side Folding-Swing Around Jib Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

Deployment Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

Stowing Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-10

Jib Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

Jib Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

Jib Jack Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

Adjustable Swing Speed Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

SECTION 5 . . . . . . . . . . . . . . . . . . . . . . . . . Lubrication Procedure and Charts

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Lubricants . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Arctic Conditions Below -18°C (0°F). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Chassis Grease. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

Extreme Pressure Multipurpose Gear Lubricant (EPGL) . . . . . . . . . . . . . . . . . . . . . 5-1

Open Gear Lubricant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-2

Chassis Grease Low Temp. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Anti-wear Additives. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Hydraulic OIL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Standard Hydraulic Oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Intermediate Hydraulic Oil. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Wide Range Intermediate Hydraulic Oil.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Arctic Hydraulic Oil.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Lubrication Points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Surface Protection for Cylinder Rods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Internal Cable Sheave Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

Inner Boom Pad Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-5

Side and Bottom Boom Wear Pad Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-5

Hoist Gearbox Oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Hoist Brake Oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Hydraulic Oil Reservoir Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-7

Wire Rope Lubrication. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

Reference Only

SECTION 6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Maintenance Checklist

Crane Inspection And Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Daily Inspections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Weekly Inspections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Monthly Inspections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Periodic/Annual Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-3

Special Boom Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-3

Stability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-3

Hoist Cable Inspection and Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Keeping Records . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-3

Environmental Conditions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Dynamic Shock Loads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

National Crane 1-3

Page 10

TABLE OF CONTENTS OPERATOR’S MANUAL 500E2

Precautions and Recommendations During Inspection. . . . . . . . . . . . . . . . . . . . . . 6-4

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Wire Rope Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

Care of Wire Rope. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

Rope Construction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

Crane Adjustments and Repairs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

Jib Jack Service and Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

Adding Oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

Changing Oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

Lubrication. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

Rust Prevention. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

Oil Cooler Service and Maintenance (Optional). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

Jib Load Limiting Device. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

Single Character Display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

Hydraulic System Trouble Diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

Jib Jack Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-11

Tire Load And Inflation Table. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-12

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-15

Hydraulic Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-15

Hydraulic System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-15

Reservoir . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-15

HCA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-15

Hoist Speed and Pull. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-15

Crane Operating Speeds. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-16

Reference Only

1-4

Page 11

500E2 OPERATORS MANUAL INTRODUCTION

1

SECTION 1

INTRODUCTION

SECTION CONTENTS

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Supplemental Information. . . . . . . . . . . . . . . . . . . 1-1

GENERAL

This manual has been compiled to assist you in properly

operating and maintaining your Model 500E2 Series

National Crane.

Before placing the crane in service, all operators and

persons working around the crane must thoroughly read and

understand the contents of the manual pertaining to Safety,

Operation and Maintenance. Before moving a vehicle

equipped with the crane, information relating to transporting

the vehicle must be read and observed.

This manual must be retained with the machine for use by

subsequent operating personnel.

Information in this manual does not rep lac e fe de ra l, state or

local regulations, safety codes or insurance requirements.

The National Crane has been designed for maximum

performance with minimum maintenance. With proper care,

years of trouble-free service can be expected.

Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

New Owner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

parts for options such as remote controls, augers, varying

control configurations, baskets, grapples, etc. is included in

separate sections of this manual, if applicable.

Engine operating procedures and routine maintenance

procedures are supplied in a separate manual with each

crane, and should be referred to for detailed information.

Whenever a question arises regarding your National product

or this publication, please consult your National Dealer for

the latest information. Your National Dealer is equipped with

the proper tools, necessary National parts and trained

service personnel to properly maintain and service your

crane.

DANGER

Failure to observe all the instructions contained in this

manual will result in death or serious injury to the operator

or bystanders or damage to the equipment.

Constant improvement and engineering progress makes it

necessary that we reserve the right to make specification

and equipment changes without notice.

National Crane and our Dealer Network want to ensure your

satisfaction with our products and customer support. Your

local dealer is the best equipped and most knowledgeable to

assist you for parts, service and warranty issues. They have

the facilities, parts, factory trained personnel, and the

information to assist you in a timely manner. We request that

you first contact them for assistance. If you feel you need

factory assistance, please ask the dealer’s service

management to coordinate the contact on your behalf.

Reference Only

Supplemental Information

Supplemental Information regarding Safety and Operation,

Specifications, Service and Maintenance, Installation, and

National Crane Published 10-20-2011 Control # 111-05 1-1

Safety Information

A Safety Compact Disc (CD) which includes sections on

Operation, Safety and Maintenance for Nation al Crane

operators and owners is supplied when the crane is

purchased new. Additional copies are available from your

local distributor.

New Owner

If you are the new owner of a Manitowoc crane, please

register it with Manitowoc Crane Care so we have the ability

to contact you if the need arises. Go to:

www.manitowoccranes.com/MCG_CARE/Includes/EN/

changeOfOwnership.cfm and complete the form.

Page 12

INTRODUCTION OPERATORS MANUAL 500E2

Item Component

1Hoist

2 Boom

3 Sheaves

4 Boom Rest

5 Stabilizers

6 Hydraulic Reservoir

7 Control Console

8 Outriggers

Item Component

NOTICE TO OWNER/USER

Should this crane become involved in a property damage accident,

please contact your local National distributor immediately and relate

details of incident including serial number of crane. The Dealer will notify

National Crane Corporation.

If accident involves personal injury notify your local distributor and

immediately contact the National Crane Corporation Manager of

Product Safety and Reliability at the contact numbers listed in the front

of this Handbook.

500E2 Series Major Components

Reference Only

1-2 Published 10-20-2011 Control # 111-05

Page 13

2

500E2 OPERATORS MANUAL SAFETY PRECAUTIONS

SECTION 2

SAFETY PRECAUTIONS

SECTION CONTENTS

Safety Messages. . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

General. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Safety Alert Symbol . . . . . . . . . . . . . . . . . . . . . . . 2-1

Signal Words . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Accidents. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Operator’s Information. . . . . . . . . . . . . . . . . . . . . . 2-2

Operator’s Qualifications. . . . . . . . . . . . . . . . . . . . 2-3

Operational Aids. . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Load Moment Indication (LMI) Systems

(If Equipped) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Anti-Two-Blocking Device. . . . . . . . . . . . . . . . . . . 2-4

Work Area Definition System (WADS)

(If Equipped) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Crane Stability/Structural Strength. . . . . . . . . . . . 2-5

Load Charts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Work Site . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Wind Forces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Lifting Operations . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Counterweight. . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Outrigger Lift Off . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Multiple Crane Lifts. . . . . . . . . . . . . . . . . . . . . . . . 2-8

Electrocution Hazard . . . . . . . . . . . . . . . . . . . . . . . 2-8

Set-Up and Operation. . . . . . . . . . . . . . . . . . . . . 2-10

Electrocution Hazard Devices. . . . . . . . . . . . . . . 2-10

Electrical Contact . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Special Operating Conditions and Equipment . . 2-11

Personnel Handling . . . . . . . . . . . . . . . . . . . . . . . 2-11

Environmental Protection. . . . . . . . . . . . . . . . . . . 2-12

Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

Service and Repairs . . . . . . . . . . . . . . . . . . . . . . 2-13

Lubrication. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

Tires. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

Wire Rope . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

Sheaves. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

Batteries. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

Transporting the Crane. . . . . . . . . . . . . . . . . . . . . 2-16

Travel Operation . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

Work Practices. . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

Personal Considerations . . . . . . . . . . . . . . . . . . . 2-18

Crane Access . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

Job Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

Working . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

Lifting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-19

Hand Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-20

Boom Extension . . . . . . . . . . . . . . . . . . . . . . . . . . 2-22

Parking and Securing . . . . . . . . . . . . . . . . . . . . . . 2-22

Shut-Down . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-22

Cold Weather Operation . . . . . . . . . . . . . . . . . . . . 2-22

Temperature Effects on Hydraulic Cylinders . . . 2-23

Overload Inspection . . . . . . . . . . . . . . . . . . . . . . . 2-25

Boom Inspection . . . . . . . . . . . . . . . . . . . . . . . . . 2-26

Superstructure Inspection . . . . . . . . . . . . . . . . . . 2-28

Carrier Inspection . . . . . . . . . . . . . . . . . . . . . . . . 2-30

SAFETY MESSAGES

Reference Only

safety alert symbol and a signal word to identify the hazard’s

degree of seriousness.

General

Safety Alert Symbol

The importance of safe operation and maintenance cannot

be overemphasized. Carelessness or neglect on the part of

operators, job supervisors and planners, rigging personnel,

and job site workers can result in their death or injury and

costly damage to the crane and property.

To alert personnel to hazardous operating practices and

maintenance procedures, safety messages are used

throughout the manual. Each safety message contains a

National Crane Published 10-20-2011 Control # 111-05 2-1

Become alert - your safety is involved! Obey all safety

messages that follow this symbol to avoid possible death

or injury .

This safety alert symbol means ATTENTION!

Page 14

SAFETY PRECAUTIONS OPERATORS MANUAL 500E2

Signal Words

DANGER

Identifies hazards that will result in death or serious injury

if the message is ignored.

WARNING

Identifies hazards that may result in death or serious

injury if the message is ignored.

Identifies hazards that could result in minor or moderate

injury if the message is ignored.

CAUTION

CAUTION

Without the safety alert symbol, identifies hazards that

could result in property damage if the message is ignored.

NOTE: Emphasizes operation or maintenance

procedures.

failure or misuse and should not be relied upo n in place of

good operating practices.

You are the only one who can be relied upon to assure the

safety of yourself and those ar ou nd you. Be a professional

and follow the rules of safety.

Remember, failure to follow just one safety precaution could

cause an accident that results in death or serious injury to

personnel or damage to equipment. You are responsible for

the safety of yourself and those around you.

ACCIDENTS

Following any accident or damage to equipment, the

Manitowoc dealer must be immediately advised of the

incident and consulted on necessary inspections and

repairs. Should the dealer not be immediately available,

contact should be made directly with Manitowoc Product

Safety at the address below. The crane must not be returned

to service until it is thoroughly inspected for any evidence of

damage. All damaged parts must be repaired or replaced as

authorized by your Manitowoc dealer and/or Manitowoc

Crane Care.

If this crane becomes involved in a property damage and/or

personal injury accident, immediately contact your

Manitowoc dealer. If the dealer is unknown and/or cannot be

reached, contact Product Safety at:

The Manitowoc Company, Inc.

1565 East Buchanan Trail

Shady Grove, PA 17256-0021

GENERAL

It is impossible to compile a list of safety precautions

covering all situations. However, there are basic principles

that must be followed during your daily routine. Safety is

your primary responsibility, since any piece of equipment

is only as safe as the person at the controls.

Read and follow the information located in Model Specific

Information near the end of this section.

This information has been provided to assist in promoting a

safe working atmosphere for yourself and those around you.

It is not meant to cover every conceivable circumstance

which could arise. It is intended to present basic safety

precautions that should be followed in daily operation.

Because you are the only part of the crane that can think and

reason, your responsibility is not lessened by the addition of

operational aids or warning devices. Indeed, you must guard

against acquiring a false sense of security when using them.

They are there to assist, not direct the operation. Operational

aids or warning devices can be mechanical, electrical,

electronic, or a combination thereof. They are subject to

Reference Only

Phone: 888-777-3378 (888-PSR.DEPT)

Fax: 717-593-5152

E-mail: product.safety@manitowoc.com

OPERATOR’S INFORMATION

You must read and understand this Operator’s Manual and

the Load Chart before operating your new crane. You must

also view and understand the supplied safety video. This

manual and Load Chart must be readily available to the

operator at all times and must remain in the cab (if equipped)

or operator’s station while the crane is in use.

The Operator’s Manual supplied with and considered part of

your crane must be read and completely understood by each

person responsible for assembly, disassembly, operation

and maintenance of the crane.

No personnel shall be allowed to climb onto the crane or

enter the crane cab or operator’s station unless performance

of their duties require them to do so, and then only with

knowledge of the operator or other qualified person.

Allow No One

while the crane is operating or moving, unless they are

seated in a two-man cab.

other than the operator to be on the crane

2-2 Published 10-20-2011 Control # 111-05

Page 15

2

500E2 OPERATORS MANUAL SAFETY PRECAUTIONS

An untrained operator subjects himself and others to death

or serious injury.

Y ou must not operate this machine unless:

Do not remove the Load Chart, this Operator’s Manual, or

any decal from this crane.

Inspect the crane every day (before the start of each shift).

Ensure that routine maintenance an d lubricat ion are being

dutifully performed. Don’t operate a damaged or poorly

maintained crane. You risk lives when operating faulty

machinery - including your own.

If adjustments or repairs are necessary, the operator shall

notify the next operator.

OPERATOR’S QUALIFICATIONS

Qualified person is defined as one who by reason of

knowledge, training and experience is thoroughly familiar

with crane operations and the hazards involved. Such a

person shall meet the operat or qualif ications s pecified in

Occupational Safety and Health Administration (OSHA)

Regulations (United States Federal Law), in ASME B30.5

American National Standard, or in any other applicable

federal, state or local laws.

Ensure that all personnel working around the crane are

thoroughly familiar with safe operating practices. You must

be thoroughly familiar with the location and content of all

placards and decals on the crane. Decals provide important

instructions and warnings and must be read prior to any

operational or maintenance function.

You must be familiar with the regulations and standards

governing cranes and their operation. Work practice

requirements may vary slightly between governme nt

regulations, industry standards, and employer policies so a

thorough knowledge of all such relevant work rules is

necessary.

Reference Only

• You have been trained in the safe operation of this

machine.

• You read, understand, and follow the safety and

operating recommendations contained in the

manufacturer’s manuals, your employer’s work rules,

and applicable government regulations.

• You are sure the machine has been inspected and

maintained in accordance with the manufacturer’s

manuals and is operating properly .

• You are sure that all safety signs, guards, and other

safety features are in place and in proper condition.

Do not attempt to operate the crane unless you are trained

and thoroughly familiar with all operational functions.

Controls and design may vary from crane to crane; therefore,

it is important that you have specific training on the particular

crane you will be operating.

Training is ESSENTIAL for proper crane operation. Never

jeopardize your own well-being or that of others by

attempting to operate a crane on which you have not been

trained.

You must be mentally and physically fit to operate a crane.

Never attempt to operate a crane while under the influen ce

of medication, narcotics, or alcohol. Any type of drug could

impair physical, visual and mental reactions, and

capabilities.

As operator of this crane, you are granted the authority to

stop and refuse to lift loads until safety is assured.

OPERATIONAL AIDS

Manitowoc remains committed to providing reliable products

that enable users and operators to safely lift and position

loads. Manitowoc has been an industry leader in the

incorporation of operational aids into the design of its cranes.

Federal law requires that cranes be properly maintained and

National Crane Published 10-20-2011 Control # 111-05 2-3

Page 16

SAFETY PRECAUTIONS OPERATORS MANUAL 500E2

kept in good working condition. The manuals that Manitowoc

provides that are specific for each crane and the

manufacturer’s manuals for the operational aids shall be

followed. If an operational aid should fail to work properly , the

crane user or owner must assure that repair or recalibration

is accomplished as soon as is rea sonably possible. If

immediate repair or recalibration of an operational aid is not

possible and there are ex ceptional circu mstances whic h

justify continued short-term use of the crane when

operational aids are inoperative or malfunctioning, the

following requirements shall apply for continued use or

shutdown of the crane:

• Steps shall be taken to schedule repairs and

• When a Load Indicator, Rated Capacity Indicator, or

• When a Boom Angle or Radius Indicator is inoperative

• When an Anti-Block Device, Two-Blocking Damage

• When a Boom Length Indicator is inoperative or

• When a Level Indicator is inoperative or malfunctioning,

Load Moment Indication (LMI) Systems (If

recalibration immediately. The operational aids shall be

put back into service as soon as replacem ent parts, if

required, are available and the repairs and recalibration

can be carried out. Every reasonable effort must be

made to expedite repairs and recalibration.

Rated Capacity Limiter is inoperative or malfunctioning,

the designated person responsible for supervising the

lifting operations shall establish procedures for

determining load weights and shall ascertain that the

weight of the load does not exceed the crane ratings at

the radius where the load is to be handled.

or malfunctioning, the radius or boom angle shall be

determined by measurement.

Prevention or Two-Block Warning Device is inoperative

or malfunctioning, the designated person responsible for

supervising the lifting operations shall establish

procedures, such as assigning an additional signal

person to furnish equivalent protection . This d oes not

apply when lifting personnel in load-line supported

personnel platforms. Personnel shall not be lifted when

anti-two-block devices are not functioning properly .

malfunctioning, the designated person responsible for

supervising the lifting operations shall establish the

boom lengths at which the lift will be made by actual

measurements or marking on the boom.

Reference Only

other means shall be used to level the crane.

Equipped)

Your crane may be equipped with an LMI system wh ich is

intended to aid the operator. Test daily for proper operation.

Never interfere with the proper funct ioning of opera tional

aids or warning devices.

Under no condition should it be relied upon to replace the

use of Load Charts and operating instructions. Sole reliance

upon these electronic aids in place of good operating

practices can cause an accident.

Know the weight of all loads and always check the capacity

of the crane as shown on the Load Chart before making any

lifts.

NEVER exceed the rated capacity shown on the Load Chart.

Always check the Load Chart to ensure the load to be lifted

at the desired radius is within the rated capacity of the crane.

For detailed information concerning the operation and

maintenance of the load moment indicating system installed

on the crane, see the manufacturer’s manual supplied with

the crane.

Anti-T wo-Blocking Device

This crane should have a functional Anti-Two-Block and

Control Lock-Out System. T est daily for proper operation.

Two-blocking occurs when the load block (hook block,

headache ball, rigging, etc.) comes into physical contact with

the boom (boom nose, sheaves, boom extension, etc.). Twoblocking can cause hoist lines (wire rope), rigging, reeving,

and other components to become highly stressed and

overloaded in which case the wire rope may fail allowing the

load, block, etc. to free fall.

Two-blocking is more likely to occur when both the main and

auxiliary hoist lines are reeved over the main boom nose and

boom extension nose respectively. An operator,

concentrating on the specific line being used, may telescope

or lower the boom allowing the other hoist line attachment to

contact the boom or boom extension nose, thus causing

damage to the sheaves, or causing the wire rope to fail,

dropping the lifting device to the ground and possibly injuring

personnel working below.

Caution must be used when lowering the boom, extending

the boom or hoisting up. Let out load line(s) simultaneously

to prevent two-blocking the boom tip(s) and the hook block,

etc. The closer the load is carried to the boom nose the more

important it becomes to simultaneously let out wire rope as

the boom is lowered. Keep load handling devices a minimum

of 42 in (107 cm) below the boom nose at all times.

Two-blocking can be prevented. Operator awareness of the

hazards of two-blocking is the most important factor in

preventing this condition. An Anti-Two-Block System is

intended to assist the operator in preventing dangerous twoblock conditions. It is not a replacement for operator

awareness and competence.

Never interfere with the proper functioning of operational

aids or warning devices.

2-4 Published 10-20-2011 Control # 111-05

Page 17

500E2 OPERATORS MANUAL SAFETY PRECAUTIONS

2

Work Area Definition System (W ADS) (If Equipped)

If your crane is equipped with a WADS, you must read and

understand the manufacturer’s Operator’s Manual before

operating the system. Become familiar with all proper

operating procedures and with the identification of symbol

usage.

The work area definition system is intended as an aid to the

operator. It is not a substitute for safe crane operating

practices, experience and good operator judgements.

CRANE STABILITY/S TRUCTURAL STRENGTH

To avoid death or serious injury, ensure that the crane is on a

firm surface with load and crane’s configuration within

capacity as shown on the crane’s Load Chart and notes.

Ensure all pins and floats are properly installed and outrigger

beams are properly extended before lifting on outriggers. On

National Crane Published 10-20-2011 Control # 111-05 2-5

Reference Only

models equipped with outriggers th at ca n be pinn ed at the

mid-extend position (vertical strip, if applicable), the

outriggers must also be pinned when operating from the midextend position.

Use adequate cribbing under outrigger floats to distribute

weight over a greater area. Check frequently for settling.

Page 18

SAFETY PRECAUTIONS OPERATORS MANUAL 500E2

Read and follow the following safety decal for cranes with

center front stabiliers.

Carefully follow the procedures in this Operator’s Manual

when extending or retracting the outriggers. Death or serious

injury could result from improper crane setup on outriggers.

The operator must select the proper Load Chart and Load

Moment Indicating (LMI) System program for the outrigger

position selected.

Before swinging the superstructure over the side when the

outriggers are retracted, check the Load Chart for backwards

stability.

Long cantilever booms can create a tipping condition when

in an extended and lowered position. Retract the boom

proportionally with reference to the capacity of the applicable

Load Chart.

Check crane stability before lifting loads. Ensure the

outriggers (or tires if lifting on rubber) are firmly positioned on

solid surfaces. Ensure the crane is level, brakes are set, and

the load is properly rigged and attached to the hook. Check

the Load Chart against the weight of the load. L ift the load

slightly off the ground and recheck the stability before

proceeding with the lift. Determine the weight of the load

before you attempt the lift.

Unless lifting within On Rubber capacities, outrigger beams

and jack cylinders (plus center front stabilizer, if equipped)

must be properly extended and set to provide precise

leveling of the crane. Tires must be clear of the ground

before lifting on outriggers.

Reference Only

KEEP THE BOOM SHORT. Swinging loads with a long line

can create an unstable condition and possible structural

failure of the boom.

Load Charts

Load Charts represent the absolute maximum allowable

loads, which are based on either tipping or structural

limitations of the crane under specific conditions. Knowing

the precise load radius, boom length, and boom angle

should be a part of your routine planning and operation.

Actual loads, including necessary allowances, should be

kept below the capacity shown on the applicable Load Chart.

Load Chart capacities are based on freely suspended loads.

You must use the appropriate Load Chart when determining

the capability of the crane in the configuration required to

perform the lift.

Maximum lifting capacity is available at the shortest radius,

minimum boom length, and highest boom angle.

Do not remove the Load Charts from the crane.

Work Site

Prior to any operation, you must inspect the entire work site,

including ground conditions, where the crane will travel and

operate. Be sure that the surfaces will support a load greater

than the crane’s weight and maximum capacity .

Be aware of all conditions that could adv ersely affect the

stability of the crane.

Wind Forces

Wind can have a significant affect on loads that may be lifted

by a crane. Wind forces act differently on a crane depending

2-6 Published 10-20-2011 Control # 111-05

Page 19

500E2 OPERATORS MANUAL SAFETY PRECAUTIONS

2

upon the direction from which the wind is blowing (e.g., wind

on the rear of the boom can res ult in decrea sed forward

stability, wind on the underside of the boom can result in

decreased backward stability, wind on the side of the boom

can result in structural damages, etc.). To assist you in

determining prevailing wind conditions, refer to Table 2-1.

Wind forces can exert extreme dynamic loads. Manitowoc

recommends that a lift not be made if the wind can cause

T able 2-1

Wind Force

Beauford

Scale

Zero (0) Calm less than 1 (<2) No wind; smoke rises vertically

1 Light Air 1-3 (2-5) Wind direction seen by smoke but not by wind vanes

2 Light Breeze 4-7 (6-11) Wind felt on face; leaves rustle; wind vane moves slightly

3 Gentle Breeze 8-12 (13-19) Leaves/small twigs in constant motion: wind extends flag

4

Reduce crane load ratings and operating parameters at 20 mph (32 km/h)

5 Fresh Breeze 19-24 (31-39)

6 Strong Breeze 25-31 (40-50)

Cease all craning operations at 30 mph (48 km/h); lower & retract boom

7 Moderate Gale 32-38 (52-61) Whole trees in motion; walking against wind is inconvenient

Designation

Moderate

Breeze

Wind V elocity

mph (km/h)

13-18 (21-29) Raises dust & loose paper; moves small branches

Small trees in leaf begin to sway; on ponds, crested wavelets

form

Large branches in motion; telegraph wires whistle; umbrellas

used with difficulty

a loss of control in handling the load. Manitowoc

recommends that, if the wind speed (velocity) is between 20

mph (32 km/h) to 30 mph (48 km/h), the load capacities shall

be reduced to account for the size and shape of the load and

the wind direction in relation to the machine for all boom and

boom extension lengths. Further, operation of the crane in

wind velocities over 30 mph (48 km/h) is not recommended.

Visible Indicator

Effects of wind as observed on land

Lifting Operations

Before lifting, position the crane on a firm surface, properly

extend and set the outriggers, and level the crane.

Depending on the nature of the supporting surface,

adequate cribbing may be required to obtain a larger bearing

surface.

The crane is equipped with a bubble level that sh ould be

used to determine whether the crane is level. The load line

can also be used to estimate the levelness of the crane by

checking to be sure it is in-line with the center of the boom at

all points on the swing circle.

If the boom extension, or auxiliary boom nose is to be used,

ensure the electrical cable and the weight f or the An ti-TwoBlock Switch are properly installed and the LMI is

programmed for the cran e conf igura tion. Refe r to the LM I

handbook supplied with the crane.

Verify the crane’s capacity by checking the Load Chart

against the weight of the load. Then, lift the load slightly at

first to ensure stability before proceeding with the lift.

Be sure the load is properly rigged and attached. Always

determine the weight of the load be fo re you a tte mpt to lift it

Reference Only

and remember that all rigging (slings, etc.) and lifting devices

(hook block, boom extension, etc.) must be considered part

of the load.

Measure the load radius before making a lift and stay within

approved lifting areas based on the range diagrams and

working area diagrams on the crane’s Load Chart.

Always keep the load as near to the cra ne and as close to

the ground as possible.

Do not overload the crane by exceeding the capacities

shown on the appropriate Load Chart. Death or serious

injury could result from the crane tipping over or failing

structurally from overload.

The crane can tip over or fail structurally if:

• The load and crane’s configuration is not within the

capacity as shown on the applicable Load Chart and

notes.

• The ground is soft and/or the surface conditions are

poor.

• Outriggers are not properly extended and set. On

models equipped with outriggers that can be pinned at

National Crane Published 10-20-2011 Control # 111-05 2-7

Page 20

SAFETY PRECAUTIONS OPERATORS MANUAL 500E2

the mid-extend position, the outriggers must also be

pinned when operating from the mid-extend position.

• Cribbing under the outrigger pads is inadequate.

• The crane is improperly operated.

Do not rely on the crane’s tippin g to dete rmine y our lifting

capacity.

Be sure the hoist line is vertical before lifting. Do not subject

the crane to side loading. A side load can tip the crane or

cause it to fail structurally.

Load Chart capacities are based on freely suspended loads.

Do not pull posts, pilings, or submerged articles. Be sure the

load is not frozen or otherwise attached to the ground before

lifting.

If you should encounter a tipping condition, immediately

lower the load with the hoist line and retract or elevat e the

boom to decrease the load radius. Never lower or extend the

boom; this will aggravate the condition.

Use tag lines whenever possible to help control the

movement of the load.

When lifting loads, the crane will lean toward the boom and

the load will swing out, increasing the load radius. Ensure the

crane’s capacity is not exceeded when this occurs.

Do not strike any obstruction with the boom. If the boom

should accidentally contact an object, stop immediately.

Inspect the boom. Remove the crane from service if the

boom is damaged.

Never push or pull with the crane boom.

Avoid sudden starts and stops when moving the load. The

inertia and an increased load radius could tip the crane over

or cause it to fail structurally .

Use only one hoist at a time when lifting loads.

Always use enough parts-of-line to accommodate the load to

be lifted. Lifting with too few parts-of-line can result in failure

of the wire rope.

Counterweight

On cranes equipped with removable counterweights, ensure

the appropriate counterweight sections are properly installed

for the lift being considered.

Do not add material to the count erweight to increase

capacity. United States Federal law prohibits modification or

additions which affect the capacity or safe operation of the

equipment without the manufacturer’s written approval.

[29CFR 1926.1434]

Outrigger Lift Off

Regarding “lifting” of an outrigger pad during craning

activities, be advised that the rated loads for these cranes,

Reference Only

as indicated on the crane’s Load Chart, do not exceed 85%

of the tipping load on outriggers as determined by SAE J765

OCT80 “Cranes Stability Test Code.” An outrigger pad may

lift off the ground during operation of the crane within the

capacity limits of the Load Chart, yet the crane will not have

reached instability. The “balance point” for stability testing

according to SAE and Manitowoc criteria is a condition of

loading wherein the load moment acting t o overturn the

crane is equal to the maximum moment of the crane

available to resist overturning. This balance point or point of

instability for a crane does not depend on “lifting” of an

outrigger but rather on comparison of the “opposing” load

moments.

The occurrence of an outrigger lifting from the ground is often

attributed to the natural flex in the crane’s frame. This may

happen when lifting a load in certain configurations within the

capacity limits of the Load Chart and is not necessarily an

indication of an unstable condition.

Provided the crane is properly set up, the crane is in good

working condition, that all operator ’s aids are properly

programmed, that the qualified crane o perator a dheres to

the instructions found in the applicable Load Chart,

Operator’s Manual and decals on the crane, the crane

should not be unstable.

Multiple Crane Lifts

Multiple crane lifts are not recommended.

Any lift that requires more that one crane must be precisely

planned and coordinated by a qualified engineer .

If it is necessary to perform a multi-crane li ft, the operator

shall be responsible for assuring that the following minimum

safety precautions are taken:

• Secure the services of a qualified engineer to direct the

operation.

• Use one qualified signal person.

• Coordinate lifting plans with the operators, engineer, and

signal person prior to beginning the lift.

• Maintain communication between all parties throughout

the entire operation. If possible, provide approved radio

equipment for voice communication between all parties

engaged in the lift.

• Use cranes and rigging of equal capabilities and use the

same boom length.

• Use outriggers on cranes so equipped.

• Be certain cranes are of adequate lifting capacity.

• Calculate the amount of weight to be lifted by each crane

and attach slings at the correct points for proper weight

distribution.

2-8 Published 10-20-2011 Control # 111-05

Page 21

500E2 OPERATORS MANUAL SAFETY PRECAUTIONS

2

• Ensure the load lines are directly over the attach points

to avoid side loading and transfer of loading from one

crane to the other.

• Do not travel. Lift only from a stationary position.

ELECTROCUTION HAZARD

To avoid deat h or s eriou s in jury, keep all parts of the crane,

rigging and load at least 20 feet (6 meters) away from any

energized power line. You must follow the OSHA

requirements set forth in 29CFR 1926.1407 through

1926.1411.

This crane is not designed or equipped for use within 10 feet

(3 meters) of energized power lines [Refer to

29CFR1926.1410 Table A]. If operation within 10 feet (3

meters) of any power lines cannot be avoided, the power

utility must be notified and the power lines must be deenergized and grounded before performing any work.

If contact is ever accidentally made with a power line and any

part of this crane, its rigging or load, never touch the crane or

even approach or come near the crane.

Electrocution can occur even without direct contact with the

crane.

Crane operation is dangerous when close to an energized

electrical power source. Exercise extreme caution and

prudent judgement. Operate slowly and cautiously when in

the vicinity of power lines.

Before operating this crane in the vicinity of electrical power

lines or equipment, notify the power utility company. Obtain

positive and absolute assurance that the power has been

turned off.

This crane is not insulated. Always consider all parts of the

load and the crane, including the wire rope, hoist cable,

pendant cables, and tag lines, as conductors. You, the

operator, are responsible for alerting all personnel of

dangers associated with electrical power lines and

equipment. Do not allow unnecessary personnel in the

vicinity of the crane while operating. Permit no one t o le an

against or touch the crane. Permit no one, including riggers

and load handlers, to hold the load, load lines, tag lines, or

rigging gear.

National Crane Published 10-20-2011 Control # 111-05 2-9

Reference Only

If the load, wire rope, boom, or any portion of the crane

contacts or comes too close to an electrical power source,

everyone in, on, and around the cra ne can be serio usly

injured or killed.

Most overhead power lines are not insulated. Treat all

overhead power lines as being energized unless y ou ha ve

reliable information to the contrary from the utility company

or owner.

The rules in this Operator’s Manual must be followed at all

times, even if the electrical power lines or equipment have

been de-energized.

The safest way to avoid electrocution is to stay away from

electrical power lines and electrical power sources.

It is not always necessary to contact a power line or power

source to become electrocuted. Electricity, depending on

magnitude, can arc or jump to any part of the load, load line,

or crane boom if it comes too close to an electrical power

source. Low voltages can also be dangerous.

Page 22

SAFETY PRECAUTIONS OPERATORS MANUAL 500E2

Thoroughly read, understand, and abide by all applicable

federal, state, and local regulations.

Set-Up and Operation

During crane use, assume that every line is energized (“hot”

or “live”) and take the necessary precautions.

Set up the crane in a positio n su ch that t he loa d, b oom, or

any part of the crane and its attachment s cannot be moved to

within 20 ft (6 m) of electrical power lines or equipment. This

includes the crane boom (fully extended to maximum height,

radius, and length) and all attachments (boom extensio ns,

rigging, loads, etc.). Overhead lines tend to blow in the wind

so allow for lines’ movement when determining safe

operating distance.

A suitable barricade should be erected to physically restrain

the crane and all attachments (including the load) from

entering into an unsafe distance from electrical power lines

or equipment.

Plan ahead and always plan a safe route before traveling

under power lines. Rider poles should be erected on each

side of a crossing to assure sufficient clearance is

maintained.

Electrocution Hazard Devices

The use of insulated links, insulated boom cages/guards,

proximity warning devices, or mechanic al limit sto ps does

not assure that electrical contact will not occur . Even if codes

or regulations require the use of such devices, failure to

follow the rules listed here may result in serious injury or

death. You should be aware that such devices have

limitations and you should follow the rules and precautions

outlined in this manual at all times even if the crane is

equipped with these devices.

Insulating links installed into the load line afford limited

protection from electrocution hazards . Links are limited in

their lifting abilities, insulating properties, and other

properties that affect their performance. Moisture, dust, dirt,

oils, and other contaminants can cause a link to conduct

electricity. Due to their capacity ratings, some links are not

effective for large cranes and/or high voltages/currents.

The only protection that may be afforded by an insulated link

is below the link (electrically downstream), provided the link

has been kept clean, free of contamination, has not been

scratched or damaged, and is periodically tested (just before

use) for its dielectric integrity .

Boom cages and boom guards afford limited protection from

electrocution hazards. They are designed to cover only the

boom nose and a small portion of the boom. Performance of

boom cages and boom guards is limited by their physical

size, insulating characteristics, and operating environme nt

(e.g. dust, dirt, moisture, etc.). The insulating characteristics

of these devices can be compromised if not kep t cle an , fr ee

of contamination, and undamaged.

Proximity sensing and warning devices are available in

different types. Some use boom nose (localized) sensors

and others use full boom length sensors. No warning may be

given for components, cables, loads, and other attachments

located outside of the sensing area. Much reliance is placed

upon you, the operator, in selecting and properly setting the

sensitivity of these devices.

United States OSHA regulations require a flagman when

operating in close proximity to energized power lines.

Appoint a reliable and qualified signal person, equipped with

a loud signal whistle or horn and voice communication

equipment, to warn the operator when any part of the crane