Instruction Manual

Manfred Weber

Metra Mess- und Frequenztechnik in Radebeul e.K.

Meissner Str. 58 - D-01445 Radebeul

Phone +49-351 836 2191 Fax +49-351 836 2940

Email: Info@MMF.de Internet: www.MMF.de

8 Channel

IEPE

Conditioner

M208B

Manfred Weber

Metra Mess- und Frequenztechnik in Radebeul e.K.

Meissner Str. 58

D-01445 Radebeul

Phone +49-351-836 2191

Fax +49-351-836 2940

Email Info@MMF.de

Internet www.MMF.de

Notice: The current version of this document can be downloaded from

http://www.mmf.de/product_literature.htm

Specifications subject to change without prior notice.

© 2009 Manfred Weber Metra Mess- und Frequenztechnik in Radebeul e.K.

No part of this document may be reproduced without the prior written consent of Metra.

May/ 16

Contents

1. Application............................................................................................................4

2. The Instrument at a Glance....................................................................................4

2.1. Connectors and Controls................................................................................4

2.2. Menu Structure...............................................................................................5

3. What is IEPE?........................................................................................................5

4. Description of the Instrument ...............................................................................7

5. Power Supply.........................................................................................................8

6. Inputs and IEPE Supply.........................................................................................9

7. Outputs..................................................................................................................9

8. Grounding and Avoiding Ground Loops .............................................................10

9. Operation ............................................................................................................10

9.1. Gain Selection..............................................................................................10

9.2. IEPE Indicators............................................................................................10

9.3. Overload Indicators......................................................................................10

10. Filters and Integrators........................................................................................11

10.1. Filters .........................................................................................................11

10.2. Integrators..................................................................................................13

10.3. Replacing Filter Modules ..........................................................................15

10.4. Switching Off the High Pass Filters............................................................16

10.5. Switching the IEPE Supply On or Off........................................................17

10.6. Loading Default Settings............................................................................17

11. Calibration.........................................................................................................17

12. Hardware and Software Version ........................................................................18

13. Technical Data...................................................................................................19

Appendix: Warranty

CE Declaration of Conformity

Thank you for using a vibration instrument from Metra!

1. Application

The 8 Channel IEPE Conditioner M208B was designed for piezoelectric accelerometers, force transducers, pressure transducers and measuring microphones with IEPE

output. The instrument has the following functions:

• Constant current supply of up to eight sensors

• Gain ranges of 0, 20, 40 and 60 dB

2. The Instrument at a Glance

2.1. Connectors and Controls

4

Figure 1: Front and rear panels

Display

LEDs for gain indication

Overload LED

Constant current LED

Output socket (channel 8)

Input socket (channel 8)

Shared output (channels 1 to 8)

Arrow keys for menu navigation

Escape key for leaving menus

OK key for confirming selections

Key for setup menu

Front Panel:

Rear Panel:

Ground socket

Power supply socket

Reset key

POWER

On/Off switch

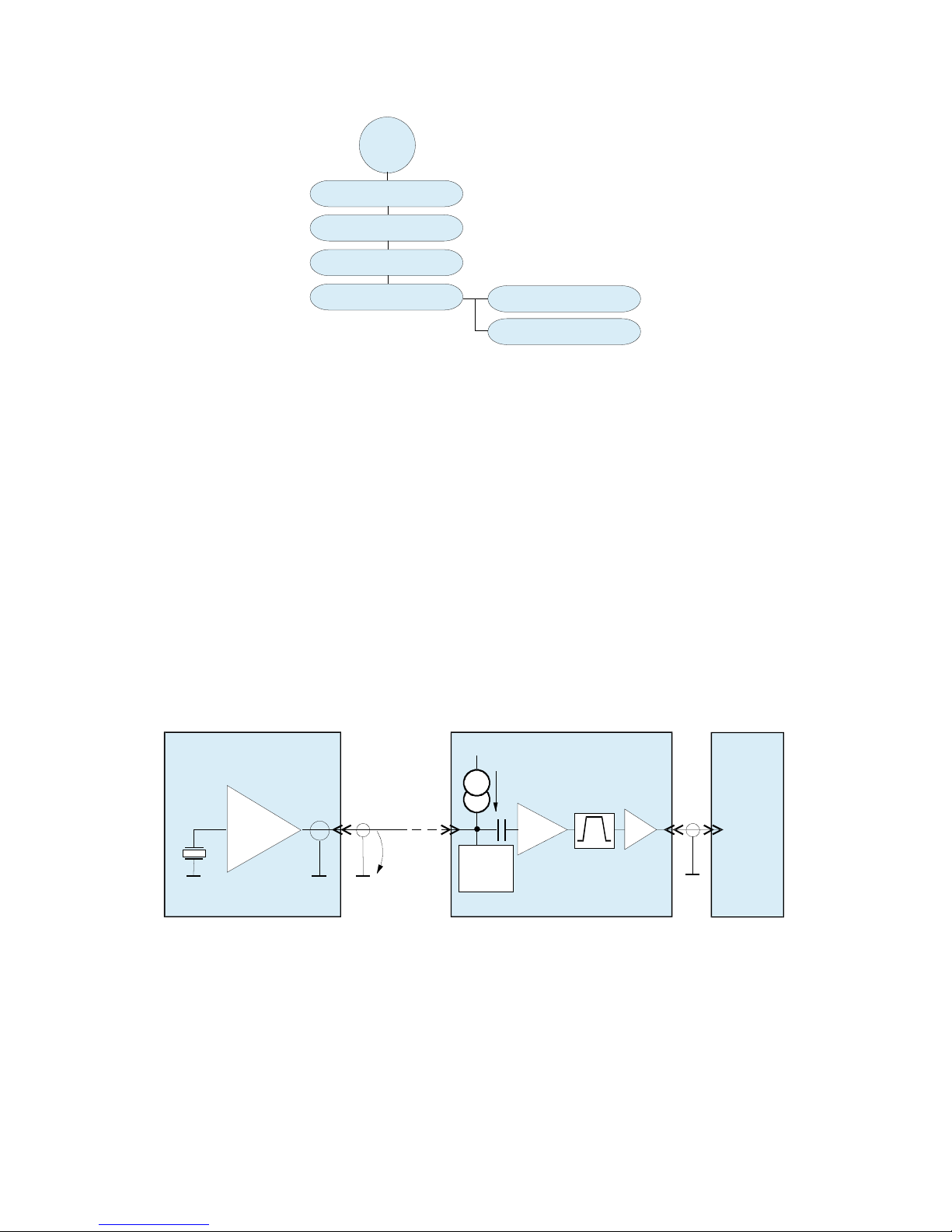

2.2. Menu Structure

3. What is IEPE?

The M208B is a signal conditioner for sensors with IEPE output. The abbreviation

stands for Integrated Electronics Piezo Electric and is a common industrial standard

for the output of piezoelectric sensors and microphones. Proprietary brand names,

like ICP®, Isotron®, Deltatron®, Piezotron® etc., are also used for the same purpose.

An electronic circuit inside the sensor transforms the high-impedance signal of the

sensing element into an output signal with low impedance, which can more easily be

transmitted and processed.

A distinctive feature of IEPE is the transmission of supply current and measuring

signal via one single wire, so an IEPE transducer is connected via a coaxial cable.

Figure 2 shows the principle circuit of an IEPE measuring chain. To supply the sensor electronics, constant current is used (not to be confused with 4-20 mA current

loops). The constant current is fed into the signal cable by the signal conditioner. A

coupling capacitor keeps the DC components away from the AC signal path.

When constant current is fed into the sensor, a positive DC voltage, called bias voltage, arises at the sensor terminals. Depending on model and manufacturer, the bias

voltage can be in the range from 5 to 14 V. The bias voltage is modulated with the

measuring signal u

sensor

. The sensor output can never become negative. The minimum

output voltage is approximately 1 V, the saturation voltage of the sensor output

stage. The upper voltage limit is determined by the supply voltage of the constant

5

MENU

1/4: Highpass

2/4: IEPE supply

3/4: Load defaults

4/4: Factory setup

1/2: LED test

2/2: Gain calibration

(password protected)

Figure 2: IEPE principle

Integated electronics

U = 24VDC

I

= 4mA

const

s

Q

U

Sensing element

I

const

Constant supply current

U

s

Supply voltage of constant current source

Coaxial cable

> 100 m

IEPE Sensor

M208B

U

bias

+u

sensor

LED

sensor

indication

Filter

Amplifier

Buffer

Readout unit

0 - 60dB

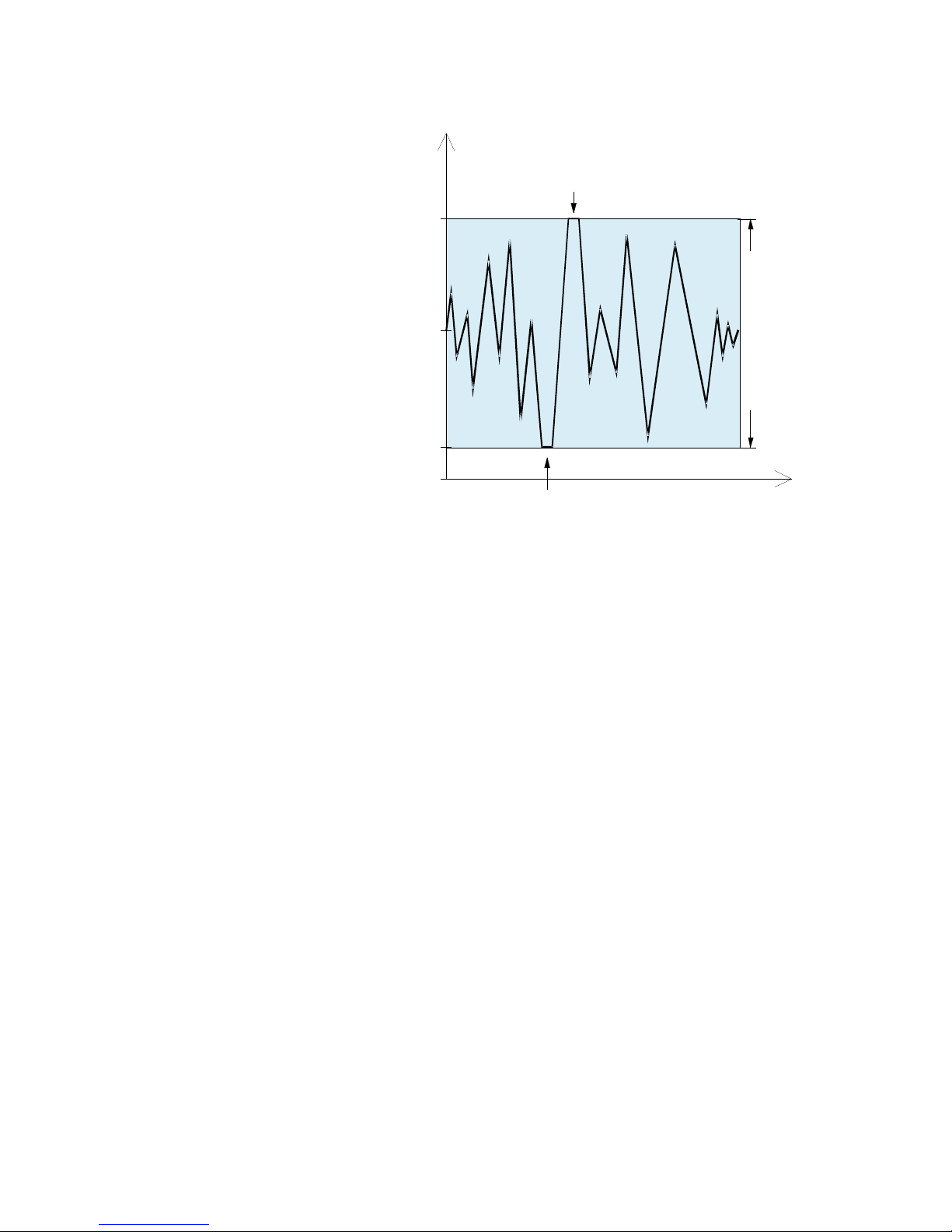

current source, also called compliance voltage. The M208B uses 24 V. Figure 3

shows the dynamic range of an IEPE transducer.

The M208B features a circuit for sensor check. It can detect the following conditions, based on the sensor output voltage:

• No sensor: yellow LED off

• Sensor connected: yellow LED on

The constant current supply can be switched off for each channel (see section 10.5.

on page 17). The sensor detection will then also be deactivated.

6

Figure 3: Dynamic range of IEPE sensors

Max. sensor output =

supply voltage of constant current source

(24 V with M208)

Sensor saturation voltage

(approx. 1 V)

Sensor bias voltage

(see data sheet)

negative overload

0V

positive overload

Sensor dynamic range

4. Description of the Instrument

Figure 4 shows the block diagram of the M208B. The instrument includes eight

identical analog signal paths for amplification and filtering. A micro controller unit

controls the analog part, provides digital interfaces, key control and display functions.

The sensor signals enter the M208B via BNC sockets on the front panel. The IEPE

constant current sources may be switched off individually. The input is followed by

an amplifier stage with selectable gains of 0 or 20 dB. High pass and low pass filters

are designed as plug-in modules. The high pass can be switched off. There are also

single and double integrator modules which may be plugged in instead of the filters.

A selectable attenuator stage is followed by a digital-to-analog converter for gain

calibration. Before the output there is another selectable amplifier stage and a buffer.

Splitting the gain before and after the filters helps to avoid overload at frequencies

in the filter stop band. The output is accessible on the front panel via BNC sockets.

There is a shared output which can be switched to channels 1 to 8.

The M208B is powered from a DC voltage source.

7

Figure 4: Block diagram

I

const

Input 1

BNC

DAC

Output 1

20dB

I

const

Input 8

BNC

DAC 20dB

Channels 1 - 8

Shared

output

MUX

1-8

BNC

Output 8

BNC

BNC

Control Unit

Overload

indication

Micro

Controller

Lowpass

module

Highpass

module

-20/0dB

0/20dB

0/20dB

-20/0dB

0/20dB

0/20dB

1

8

Highpass

module

Lowpass

module

Keypad Display

Micro

Controller

Keypad Display

5. Power Supply

The M208B is powered by an external DC supply voltage between 10 and 28 V.

This could be a supplied mains adapter or a car battery, for example. Current consumption is below 1.5 A. The supply voltage is connected by a circular power connector to DIN 45323. Figure 5 shows the polarity of this socket.

The M208B is protected against false polarization.

There is a fuse inside the instrument. For replacing the fuse, remove the four screws

holding the cover plate and open the case. The location of the fuse holder is shown

in Figure 6. The fuse must be rated 2 A (slow).

Unplug the power supply before replacing the fuse!

Ground your hands before touching electronic components inside!

Use only fuses with the appropriate rating!

8

Figure 5: Polarity of the

supply socket

0 V +10 - 28 V

Figure 6: Location of the fuse holder

6. Inputs and IEPE Supply

The M208B has eight identical measuring channels. Sensors are connected via BNC

sockets marked “IN” on the front panel. The input impedance is approximately

4 MΩ. The input overload limit is ±10 V. The inputs can withstand voltages of up

to ±25 V.

For the operation with IEPE sensors constant current sources must be switched to

the inputs (see 10.5 on page 17). By default the M208B is equipped with 4 mA constant current sources which is a practical value for most applications. For extremely

long sensor cables and high frequencies to be measured, the instrument can also be

equipped with 8 mA sensor supplies. The constant current source module can be replaced by the user. Open the cover plate after removing four screws (see Figure 7).

Unplug the power supply before replacing the module!

Ground your hands before touching electronic components inside!

7. Outputs

The eight outputs are accessible via BNC sockets (“OUT”) on the front panel.

The outputs are short-circuit-proof. Their output impedance is 100 Ω.

In addition to the channel outputs there is a shared output which can be connected to

one of the channels. It is accessible via the BNC socket “SWITCHED OUTPUT” on

the front.

The shared output is always connect to the channel which is flashing in the gain

menu (see section 9.1). You may change the channel by pressing the ◄ ►keys.

9

Figure 7: Location of the constant current source module

Display

8. Grounding and Avoiding Ground Loops

All inputs and outputs are referred to the same ground potential. Ground is also

available at the socket (“GND”) on the rear panel.

The negative supply Terminal (-) is also connected to ground.

To prevent ground loops it is recommended that additional connections are not made

between the sensor cases via the test object. This can be avoided by using sensors

with isolated base or isolating pads which are available as accessory parts.

9. Operation

9.1. Gain Selection

The instrument has four gain ranges of 0, 20, 40 and 60 dB (1, 10, 100 and 1000),

which may be set for each channel individually.

After switching it on, the M208B displays the gain menu (Figure 8).

The selected gain ranges are shown over the respective channel numbers. The flashing value can be changed by the ▲▼ keys. You may select between 0, 20, 40 and

60 dB. Change to another channel by ◄ ►. The active gains are also indicated by

the LEDs over the output sockets:

0 dB: LEDs off

20 dB: orange LED (“20”)

40 dB: green LED (“40”)

60 dB: orange and green LED

The gain settings remain stored when you disconnect the M208B from power.

Note: The flashing channel in the gain menu is also the channel connected to the

shared output (see section 7).

9.2. IEPE Indicators

The yellow “IEPE” LED of an amplifier channel will light up when you connect a

sensor to its input provided that the IEPE supply was switched on.

IEPE constant current indication is based on the measurement of the sensor bias

voltage. If this voltage drops below 20 V the LED lights up.

9.3. Overload Indicators

Each channel has a red overload LED. The signal path is monitored for overload

condition at the sensor and at the amplifier output to make sure that signal components which do not pass the filter but overload the input stage are properly indicated.

The threshold for the overload indicators is 10 V (peak). At this magnitude the signal is still undistorted.

10

Figure 8: Gain selection

Reduce the gain range when the overload LED starts flashing.

Please note that the dynamic range of most IEPE transducers is less than ±10 V so

that in the 0 dB range the signal may become clipped even if no overload is indicated.

10. Filters and Integrators

10.1. Filters

The M208B has replaceable high pass and low pass filter modules. The following

frequencies are available:

High pass filters: Low pass filters:

3 dB frequency limit Model 3 dB frequency limit Model

3 Hz FB3-3Hz 0.1 kHz FB2-0.1kHz

5 Hz FB3-5Hz 0.3 kHz FB2-0.3kHz

10 Hz FB3-10Hz 0.5 kHz FB2-0.5kHz

30 Hz FB3-30Hz 1 kHz FB2-1kHz

50 Hz FB3-50Hz 3 kHz FB2-3kHz

100 Hz FB3-100Hz 5 kHz FB2-5kHz

300 Hz FB3-300Hz 10 kHz FB2-10kHz

500 Hz FB3-500Hz 30 kHz FB2-30kHz

1000 Hz FB3-1000Hz 50 kHz FB2-50kHz

100 kHz FB2-100kHz*

* With the low pass FB2-100kHz at 60 dB gain and frequencies over 50 kHz the

output peak voltage should not exceed ±3V to avoid distortion.

The high pass modules are second order Butterworth filters. The low pass modules

are fourth order Butterworth filters.

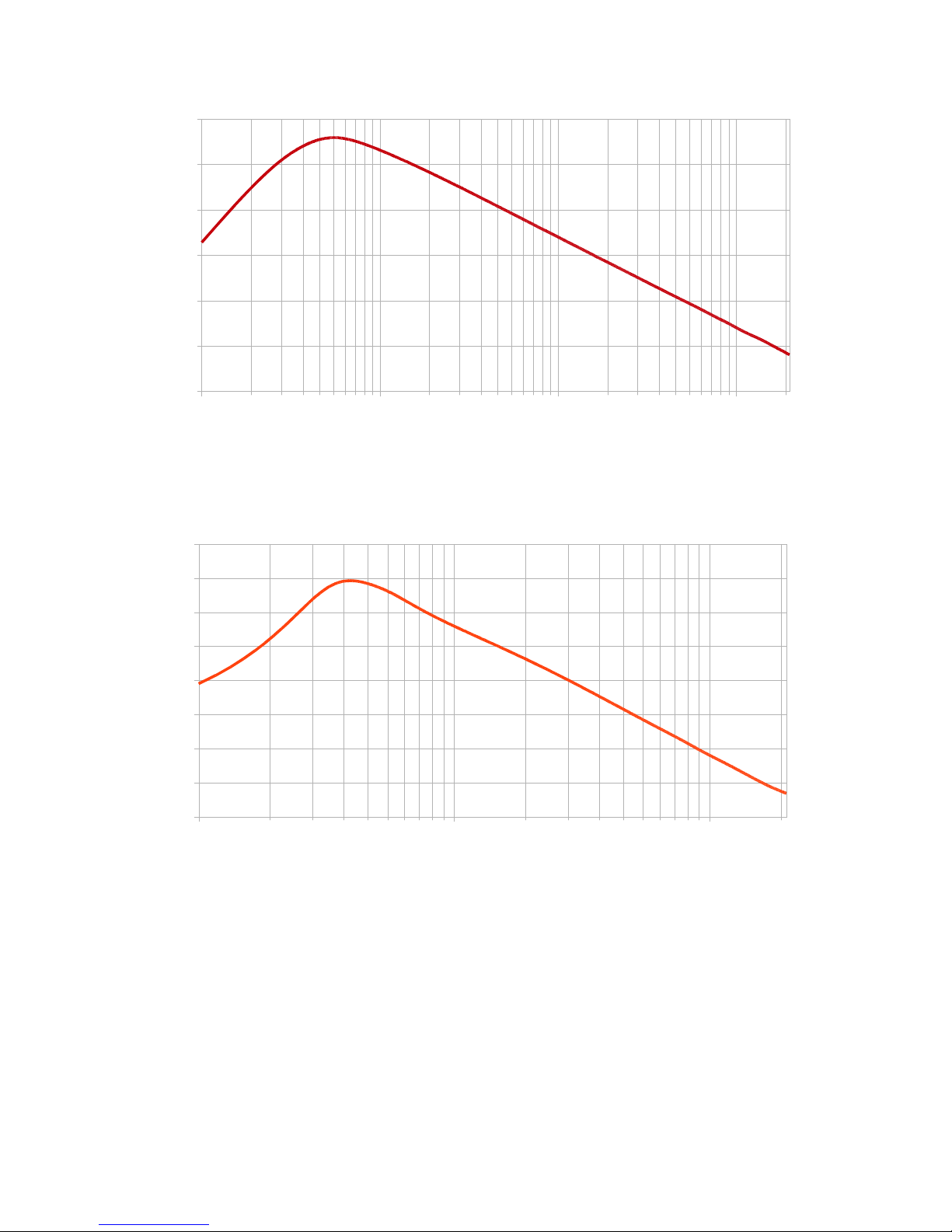

The following diagrams show the frequency and phase response curves of the high

pass and low pass filters.

11

Figure 9: Frequency response of M208B with different high pass filters FB3-...

Figure 10: Frequency response of M208B with different low pass filters FB2-...

12

10

100 1000 10000 100000 1000000

-45

-40

-35

-30

-25

-20

-15

-10

-5

0

FB2-0,1

FB2-0,3

FB2-0,5

FB2-1

FB2-3

FB2-5

FB2-10

FB2-30

FB2-50

FB2-100

f [Hz]

A [dB]

0,01 0,1 1 10 100 1000 10000

-25

-20

-15

-10

-5

0

HP off

FB3-3

FB3-5

FB3-10

FB3-30

FB3-50

FB3-100

FB3-300

FB3-500

FB3-1000

f [Hz]

A [dB]

Figure 11: Phase response of M208B with different high pass filters FB3-...

Figure 12: Phase response of M208B with different low pass filters FB2-...

10.2. Integrators

Integrators are useful to calculate vibration velocity or displacement from an acceleration input.

Single or double integrator modules can be plugged in instead of filters. Mixed filter

operation is also allowed.

The single integrator FBV includes a second order 3 Hz high pass filter.

The double integrator FBD includes a second order 5 Hz high pass filter.

Figures 13 and 14 show the frequency response curves of the integrators.

13

0,1

1 10 100 1000 10000

0

20

40

60

80

100

120

140

160

180

HP aus

FB3-3Hz

FB3-5Hz

FB3-10Hz

FB3-30Hz

FB3-50Hz

FB3-100Hz

FB3-300Hz

FB3-500Hz

FB3-1000Hz

f [Hz]

Phase [°]

10

100 1000 10000 100000 1000000

-180

-160

-140

-120

-100

-80

-60

-40

-20

0

FB2-0,1

FB2-0,3

FB2-0,5

FB2-1

FB2-3

FB2-5

FB2-10

FB2-30

FB2-50

FB2-100kHz

f [Hz]

Phase [°]

The following explanation is given to understand the relationship between the measured mechanical quantity and the integrated output of the M208B with an accelerometer:

The calculations show how the M208B output u

out

corresponds to the three vibration quantities. The selected gain range of the M208B is G (1, 10, 100 or 1000) and

the accelerometer sensitivity (see transducer data sheet) is Bua.

14

Figure 13: Frequency response of the M208B with the single integrator FBV

1,00 10,00 100,00 1000,00

-50

-40

-30

-20

-10

0

10

f [Hz]

A [dB]

Figure 14: Frequency response of the M208B with the double integrator FBD

1,00 10,00 100,00

-50

-40

-30

-20

-10

0

10

20

30

f [Hz]

A [dB]

Vibration acceleration a (without integration):

a=

u

out

G⋅B

ua

(a in m/s²; u

out

in mV; B

ua

in mV/ms-2)

Vibration velocity v (single integration):

v=

u

out

G⋅B

ua

⋅10 s

(v in mm/s; u

out

in mV; B

ua

in mV/ms-2; s = seconds)

Vibration displacement d (double integration):

d =

u

out

G⋅B

ua

⋅100 s

2

(d in µm; u

out

in mV; B

ua

in mV/ms-2; s = seconds)

Example:

Vibration velocity is measured using an accelerometer with a sensitivity of Bqa= 5 mV/ms-2.

The M208B is operated in the range G = 100. Its output voltage is 300 mV

rms

. What is the

corresponding vibration velocity?

Solution:

v=

300 mV

100⋅5mV / ms

− 2

⋅10 s=6 mm / s

eff

When a direct connection between the output voltage of the M208B and the measured physical quantity should be desired (for example “1 mV corresponds to

1 mm/s”), you may may normalize the M208B output in the measuring equipment

connected to its output or in the software.

The frequency range is limited to approximately 6 to 2000 Hz for single integration

and 6 to 200 Hz for double integration. At the upper end of the frequency range only

a poor signal-to-noise ratio can be achieved. This is the consequence of the frequency characteristic of electronic integrators.

It is not recommended to switch off the high pass function (see section 10.4) if

integrator modules are used. The high pass filters inside the integrator modules

have been designed in order to suppress low frequency noise which would appear at the amplifier output.

10.3. Replacing Filter Modules

For replacing filters or integrators, remove the four screws of the cover plate and

open the case.

Unplug the power supply before replacing filters!

Ground your hands before touching electronic components inside!

Figure 15 shows the filter and integrator modules. Each channel has a high pass and

a low pass module. Instead of the high pass and a low pass module an integrator

module can be inserted. Pull out the modules carefully without bending their pins.

15

When inserting the filter or integrator, make sure that the “Pin 1” mark (▼) faces to

the correct side.

For proper function of the M208B it is necessary that all filters or integrators are inserted.

10.4. Switching Off the High Pass Filters

The high pass filters can be switched off separately for each channel. The M208B

will then work with its lower frequency limit of approximately 0.1 Hz. Press the

MENU key and select “1/4: Highpass”. Use the keys ▲▼◄ ► to switch off (○) or

activate (●) the high pass filter for the respective channel. Confirm with OK or press

ESC to quit without changes.

Notice: When the high pass filter is switched off, low frequency noise from the

sensor electronics and the constant current source may pass the signal path. It

may appear as a fluctuating voltage at the amplifier output.

It is not recommended to switch off the high pass function if integrator mod-

ules are used. The high pass filters inside the integrator modules have been de-

16

Figure 15: Location of the filter and integrator modules

Figure 16: Switching high pass filters

on or off

signed in order to suppress low frequency noise which would appear at the amplifier output.

10.5. Switching the IEPE Supply On or Off

IEPE transducers need a constant current supply for operation (compare section 3 on

page 5). For measurements with other sensor types or for using the M208B as AC

amplifier, it may be necessary to switch off the constant current sources. This can be

done for each channel separately. Press the MENU key and open the menu “2/4:

IEPE supply”.

Use the keys ▲▼◄ ► to disable (○) or enable (●) the constant current source of

the respective channel. Confirm with OK or press ESC to quit without changes.

When the IEPE supply is switched off, the M208B works as voltage amplifier with

the gains 0 / 20 / 40 / 60 dB.

It is recommended that the IEPE supply of unused channels be kept switched

on in order to terminate the inputs. Otherwise electromagnetic interference via

the unterminated inputs could induce noise in other channels.

10.6. Loading Default Settings

The M208B can be reset to its factory default settings in the menu “3/4: Load defaults”. The following settings will be changed:

• Gain for all channels 0 dB

• All high pass filters switched off

• All IEPE constant current sources switched off

Calibration data is not changed.

11. Calibration

This section is intended only for users with sufficient experience in the field of the

measurement of low AC signals and with precise measuring equipment of traceable

accuracy.

We recommend a factory re-calibration at Metra after two years when the M208B

was used under normal environmental conditions.

The M208B can be calibrated without opening the case. There are no adjustment

points inside.

Click the MENU key to open the menu „4/4: Factory setup“. This menu is password protected to avoid unwanted alteration. Enter the following password: “1410”.

After opening the calibration menu the IEPE constant current sources and the high

pass filters will be automatically switched off.

17

Figure 17: Switching the IEPE supply

on or off

In some cases it may be desired to reset all calibration values to 0.0 % before calibration. This can be done by holding the MENU key while pushing the RESET key

on the rear panel. Erasing the calibration values must be confirmed by OK.

Calibration is performed by feeding a sine-wave generator signal into all eight in puts simultaneously. No inputs must be left unterminated. Use “T” couplers and

short BNC cables to interconnect the inputs. The generator frequency shall be 80 Hz

and the RMS value 5.000, 50.00, 500.0 or 5000 mV, depending on the gain range to

be calibrated. In addition to the generator, a calibrated RMS voltmeter should be

connected to the inputs.

The amplifier output voltage of all channels is measured at the connector “

SWITCHED OUTPUT” with a second calibrated RMS voltmeter. The signal quality

at the outputs should also be monitored with an oscilloscope.

Select the channel to be calibrated (“Channel No.:”, 1 to 8) and the gain range

(“Gain range”, 0/20/40/60 dB) by the ▲▼keys. Feed in the generator signal according to the display of the M208B, for example 50.00 mV in the gain range 40 dB.

The M208B will display the previously entered calibration value in percent, for example “-0.3%”. Change this value by the ▲▼ keys in steps of 0.1 % until the output voltage is exactly 5000 mV (RMS). Limits for calibration are ±2 %. Press OK to

save your adjustment and to switch to the next channel or gain range.

12. Hardware and Software Version

The version number of your M208B is displayed for two seconds after switching on

power.

The format of the version number is xxx.yyy with the hardware version xxx and the

firmware version yyy. The line beneath shows the firmware upload date.

18

Figure 18: Version number

13. Technical Data

Inputs

8 voltage inputs; single-ended; R

I

= 4 M

AC coupled; IEPE compatible; BNC sockets

± 10 V without clipping at 0 dB gain

± 25 V peak input voltage

IEPE sensor supply 3.8 to 5.6 mA constant current; switchable

compliance voltage > 22 V

constant current indication by LED

Suitable sensors IEPE compatible accelerometers, force transducers,

pressure transducers and measuring microphones

Gains 0 / 20 / 40 / 60 dB

Gain accuracy < 0.3 % of nominal value at T = 15 to 25 °C;

Ua = 1 to 5 V (RMS); f = 80 Hz; high pass off; low pass 100 kHz

Noise (wide band)

Noise densities

< 10 mV

RMS

(0.1 Hz - 30 kHz)

1 Hz: 600 µV/√Hz

10 Hz: 150 µV/√Hz

100 Hz: 60 µV/√Hz

1000 Hz: 60 µV/√Hz

Cross-talk attenuation > 80 dB

Frequency range 0.1 to 100 000 Hz (-3 dB);

max. ± 3 V output at 60 dB and > 50 kHz

High pass filters Plug-in modules: 3 / 5 / 10 / 30 / 50 / 100 / 300 / 500 / 1000 Hz

frequency tolerance ± 10%; 2nd order Butterworth filter

Low pass filters Plug-in modules: 0.1 / 0.3 / 0.5 / 1 / 3 / 5 / 10 / 30 / 50 / 100 kHz

frequency tolerance ± 10%; 4th order Butterworth filter

Integrators Single integrator module FBV; double integrator module FBD

Outputs 8 buffered channel outputs; ± 10 V;100 Ω, BNC

1 buffered shared output; ± 10 V;100 Ω; BNC

output offset voltage: < 3 mV

Overload indication at sensor input and at at output by LEDs; threshold ± 10 V

Warm-up time 5 min

Power supply 10 to 28 V DC; < 1.5 A; DIN 45323 power connector

Operating temperature

range

-10 to 50 °C

Dimensions 483 mm (19”) x 44 mm (1 HU) x 124 mm

Weight 1.7 kg

19

Limited Warranty

Metra warrants for a period of

24 months

that its products will be free from defects in material or workmanship

and shall conform to the specifications current at the time of shipment.

The warranty period starts with the date of invoice.

The customer must provide the dated bill of sale as evidence.

The warranty period ends after 24 months.

Repairs do not extend the warranty period.

This limited warranty covers only defects which arise as a result

of normal use according to the instruction manual.

Metra’s responsibility under this warranty does not apply to any

improper or inadequate maintenance or modification

and operation outside the product’s specifications.

Shipment to Metra will be paid by the customer.

The repaired or replaced product will be sent back at Metra’s expense.

Declaration of Conformity

According to EMC Directive 2014/30/EC

Product: 8 Channel IEPE Conditioner

Type: M208B (from Ser. no. 160000)

It is hereby certified that the above mentioned product complies

with the demands pursuant to the following standards:

DIN EN 61326-1: 2013

DIN EN 61010-1: 2011

DIN 45669-1: 2010

The producer is responsible for this declaration

Metra Mess- und Frequenztechnik

in Radebeul e.K.

Meißner Str. 58, D-01445 Radebeul

declared by

Michael Weber

Radebeul, April 22, 2016

Loading...

Loading...