027/12

VALID FROM: 01.10.2013

INSTALLATION INSTRUCTIONS

MULTI COMPARTMENT SMOKE

EXTRACTION DAMPER

2

Content

General information

................................................................................................... 3

Assembly information

................................................................................................ 3

Installation opening.......................................................................................... 4

Statement of installation................................................................................... 4

The Blades Overlaps........................................................................................ 8

The Flanges....................................................................................................... 9

Connection Diagrams

................................................................................................... 9

Service, assembly and revisions

.............................................................................. 11

Dimensions

................................................................................................................... 11

Material

.......................................................................................................................... 12

3

Smoke extract dampers - multi are shutters in the smoke exhaust piping systems. The dampers are

designed to remove heat and combustible products (e.g. smoke) from fire compartments. The

damper blade is controlled by actuating mechanism. The dampers are designed for using in fire

compartments that can be connected to the smoke exhaust ducts (tested according to EN 1366-8)

or they can be installed in or on the construction of the fire compartment.

Dampers are classified according to EN 13501-4.

General information

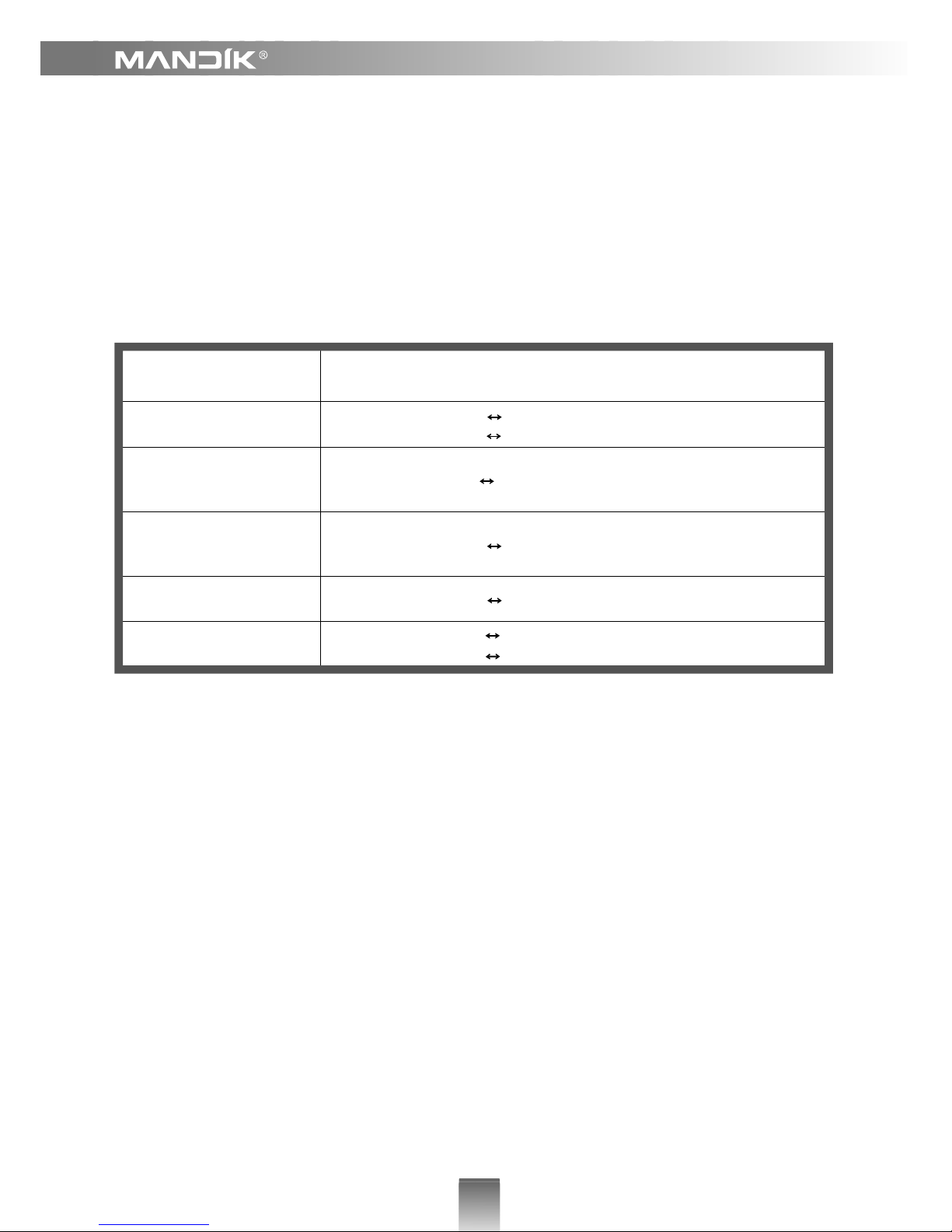

Classification of Dampers

Supporting

Construction

Classification

Horizontal duct system

EI 120 (h

od

- i o) S1000C

10000

HOT 400/30Mamulti

EI 120 (h

od

- i o) S1000C

10000

HOT 400/30AAmulti

Porous concrete ceiling

construction,

thickness 150 mm

EI 90 (h

ow

- i o) S1000C

10000

HOT 400/30AAmulti

Porous concrete wall

construction,

thickness 100 mm

EI 120 (v

ew

- i o) S1000C

10000

HOT 400/30AAmulti

Gypsum wall, thickness

100 mm

EI 120 (v

ew

- i o) S1000C

10000

HOT 400/30AAmulti

Vertical duct system

EI 120 (v

ed

- i o) S1000C

10000

HOT 400/30MAmulti

EI 120 (v

ed

- i o) S1000C

10000

HOT 400/30AAmulti

Assembly information

1. During installation the damper blade must be in position “CLOSED”. The damper body should

not be deformed in the course of bricking in. Once the damper built in, its blade should not grind

on the damper body during opening or closing.

3. During installation the control mechanism must be protect against damaged and pollution.

2.

The installation of more dampers into the fire separating construction must meet the following

requirements:

- the minimum distance between two dampers has to be 200 mm;

- the minimum distance between damper and construction (ceiling / wall) has to be 75 mm;

In the event of fire the Smoke and Fire Ventilation System opens the damper in the affected section

which removes combustion products and heat from this section.

Fire dampers are suitable for installation in arbitrary position (axle of the blade as horizontal or

vertical). The Air Flow (smoke) must be directed from the control device side (see arrow on the

damper body).

Dampers are designed for macroclimatic areas with mild climate according to EN 60 721-3-3 zm.A2.

4

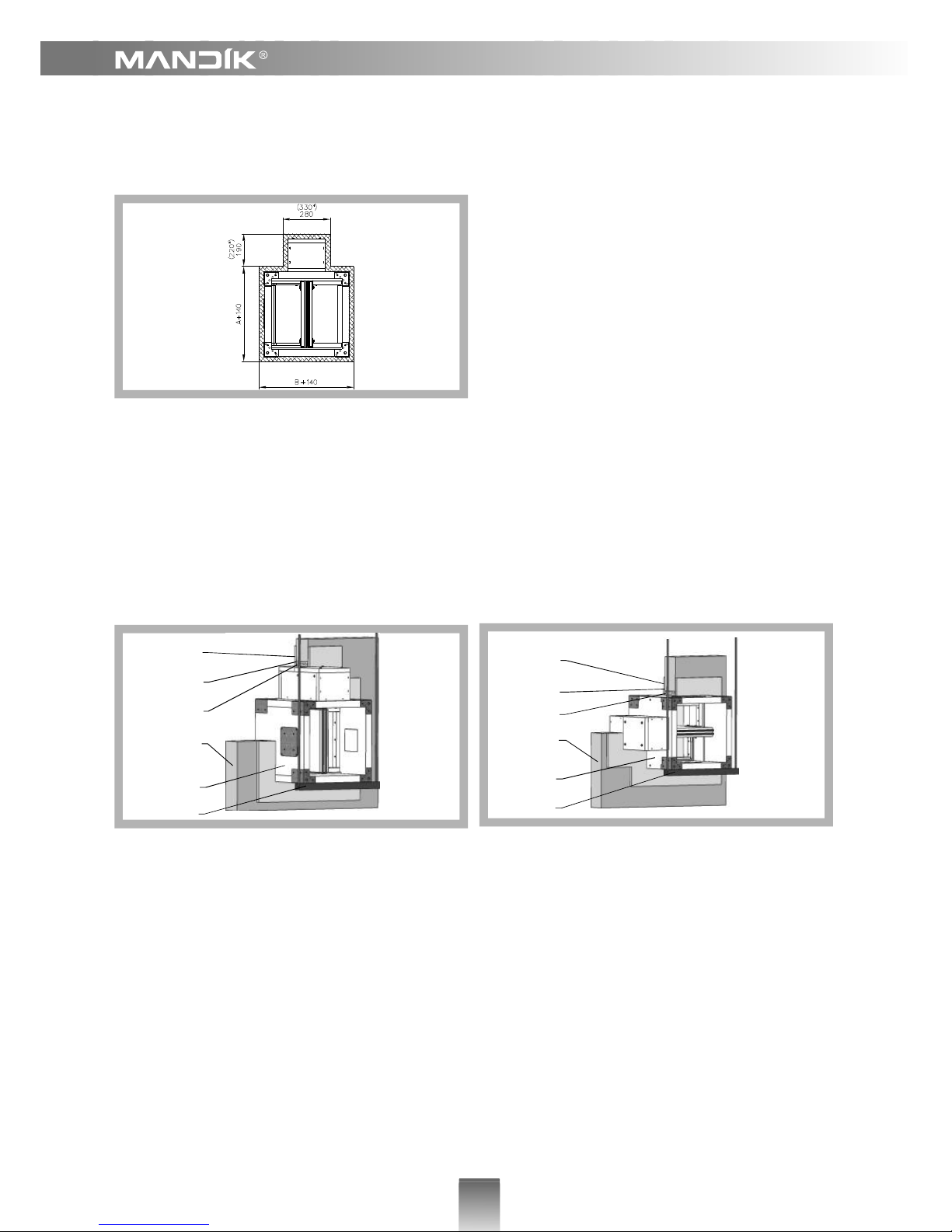

5. Statement of installations

4. Installation opening

NOTICE

*Dime

nsions for damper with actuating

mechanism InMax 50.75

Recommended installation opening

NOTICE

The actuating mechanism cover must be removable after the installation.

Installation in the solid wall (ceiling) construction of fire compartment

Installation in the solid wall construction of fire

compartment. Damper blade is in horizontal position.

Installation in the solid wall construction of fire

compartment. Damper blade is in vertical position.

2

5

4

3

1

6

2

5

4

3

1

6

Position

1 Damper SEDM

2 Solid wall construction

3 Mineral stone wool, density 140 kg/m

3

4 Fire protection mastic, thickness 1 mm

5 Cement lime plate, thickness 15 mm, density 870 kg/m

3

6 Hinges

5

Position

1 Damper SEDM

2 Solid ceiling construction

3 Mineral stone wool, density 140 kg/m

3

4 Fire protection mastic, thickness 1 mm

5 Cement lime plate, thickness 15 mm, density 870 kg/m

3

6 Hinges

2

5

4

3

1

6

Installation in the solid wall construction of fire

compartment

NOTICE

The actuating mechanism cover must be

removable after installation.

Installation in the gypsum wall construction of fire compartment

Position

1 Damper SEDM

2 Gypsum construction

3 Mineral stone wool, density 140 kg/m

3

4 Fire protection mastic, thickness 1 mm

5 Cement lime plate, thickness 15 mm, density 870 kg/m

3

6 Hinges

Installation on gypsum wall construction of fire

compartment

2

5

4

3

1

6

NOTICE

The actuating mechanism cover must be

removable after installation.

6

Installation on the solid wall (ceiling wall) construction

Position

1 Damper SEDM

2 Solid wall construction

3 Ceramic paper

4 Hinges

2

4

1

3

Installation on the solid wall construction of fire compartment Damper blade is in horizontal position.

Installation on the solid wall construction of fire compartment. Damper blade is in vertical position.

2

4

1

3

Position

1 Damper SEDM

2 Solid wall construction

3 Ceramic paper

4 Hinges

7

Installation on the solid ceiling construction of fire compartment - suspension

4

5

1

2

3

Pozice:

1 Damper SEDM

2 Solid ceiling construction

3 Ceramic paper

4 Hinges

5 Cement lime plate

Installation on the solid ceiling construction of fire compartment - mounting from top

1

4

2

3

Position

1 Damper SEDM

2 Solid ceiling construction

3 Ceramic paper

4 Hinges

8

6. Damper assembly procedures must be done so as all load transfer from the fire separating

constructions to the damper body is absolutely excluded. Back-to-back air - conditioning piping

must be hung or supported so as all load transfer from the back-to-back piping to the damper is

absolutely excluded.

Installation in smoke exhaust ducts

Installation in vertical smoke exhaust duct

Installation in horizontal smoke

exhaust duct

7. Flanges

NOTICE

Flanges for square fire dampers are 30 mm

wide with oval hole.

Flanges for SEDM

9

Connection Diagrams

Actuating mechanism BELIMO BLE 24(-ST)

8. Blade overlaps

The overlaps of SEDM

The overlaps of SEDM with flange

AxB

a c e f

Ax180

- - - -

Ax200

- - - -

Ax225

- - - -

Ax250

- - -

Ax280

- - -

Ax300

- - -

Ax315

- - -

Ax355

- 6,5 - -

Ax400

- 29 - -

Ax450

- 54 - 4

Ax500

- 79 - 29

Ax550

104 54

Ax560

- 109 - 59

Ax600

- 129 - 79

Ax630

- 144 - 94

Ax650

- 154 - 104

Ax700

11 179 - 129

Ax710

16 184 - 134

Ax750

36 204 - 154

Ax800

61 229 11 179

Ax900

111 279 61 229

Ax1000

161 329 111 279

NOTICE

The blade of dampers without flange exceeds body of fire damper by the values “a” and “c”.

The blade of dampers with flange exceeds body of fire damper by the values “e” and “f”. There has

to be enough space in dust or installation shaft for blade rotation.

10

Actuating mechanism BELIMO BE 230-12

Actuating mechanism BELIMO BE 24-12(-ST)

Actuating mechanism BELIMO BLE 230

11

5. The adjustment of the blade can be done by connecting the power supply to the actuator (or by

the signal from the Smoke and Fire Ventilation system). The blade is adjusted to the position

"OPENED" and then back to position "CLOSED".

6. Manual operation

Any position of the damper blade can be manually set by using a special key. The functionality

of the damper can be then easily tested.

1.

Assembly, maintenance and damper check can be done

only by qualified persons, i.e.

“AUTHORIZED PERSONS” that have been trained by the manufacturer.

2. All effective safety standards and directives must be observed during fire damper assembly.

3. Before entering the dampers into operation after assembly and after sequential revisions,

checks and functionality tests of all designs including operation of the electrical components

must be done. After entering into operation, these revisions must be done according to

requirement set by national regulations.

Assembly, service and revisions

Visual inspection of proper fire damper integration, inside fire damper area, fire damper blade,

contact surfaces and silicon sealing.

4. After fire damper assembly the following checks must be carried out:

Inspection hole disassembly: release the covering lid by removing the four screws in the

corners of the inspection hole. Then remove lid from its original position.

Actuating mechanism SCHISCHEK InMax 50.75-S

12

1. Damper and blades are made of fire resistant asbestos free boards made of mineral fibres.

Material

2. Fasteners is galvanized.

Dimensions

Damper SEDM

Damper SEDM with flanges

NOTICE

*Dimensions for damper with actuating mechanism InMax 50.75

MANDÍK, a.s.

Dobříšská 550

26724 Hostomice

Czech Republic

Tel.: +420 311 706 706

Fax: +420 311 584 810, 311 584 382

e-mail: mandik@mandik.cz

www.mandik.cz

All rights reserved by Manufacturer. Changes to the product can be applied.

The current product information are available on www.mandik.cz

Loading...

Loading...