Mandik MSD Square, MSD Round User Manual

TPM 109/15

These technical specifications state a row of manufactured sizes and models of multi smoke dampers (further only

dampers) MSD. It is valid for production, designing, ordering, delivery, maintenance and operation.

I. CONTENT

II. GENERAL INFORMATION 2

1. Description.........................................................................................................................

2. Design................................................................................................................................

3. Communication and control devices.................................................................................... 8

4. Dimensions, weights........................................................................................................... 9

5. Placement and Assembly.................................................................................................... 24

III. TECHNICAL DATA 30

6. Pressure loss...................................................................................................................... 30

7. Coefficient of local pressure loss......................................................................................... 31

8. Noise data..............….…………………………………......................................................... 32

IV. MATERIAL, FINISHING 34

9. Material............................................................................................................................. 34

V. INSPECTION, TESTING 34

10. Inspection, testing............................................................................................................. 34

VI. TRANSPORTATION AND STORAGE 34

11. Logistic terms.................................................................................................................... 34

2

3

VII. ASSEMBLY, ATTENDANCE, MAINTENANCE AND REVISIONS 34

12. Assembly.......................................................................................................................... 34

13. Entry into service and revisions......................................................................................... 35

14. Spare parts....................................................................................................................... 35

VIII. PRODUCT DATA 36

15. Ordering key...................….…..........................................................................................

36

IX. ORDERING INFORMATION 37

16. Ordering key.....................................................................................................................

37

1

TPM 109/15

II. GENERAL INFORMATION

1. Description

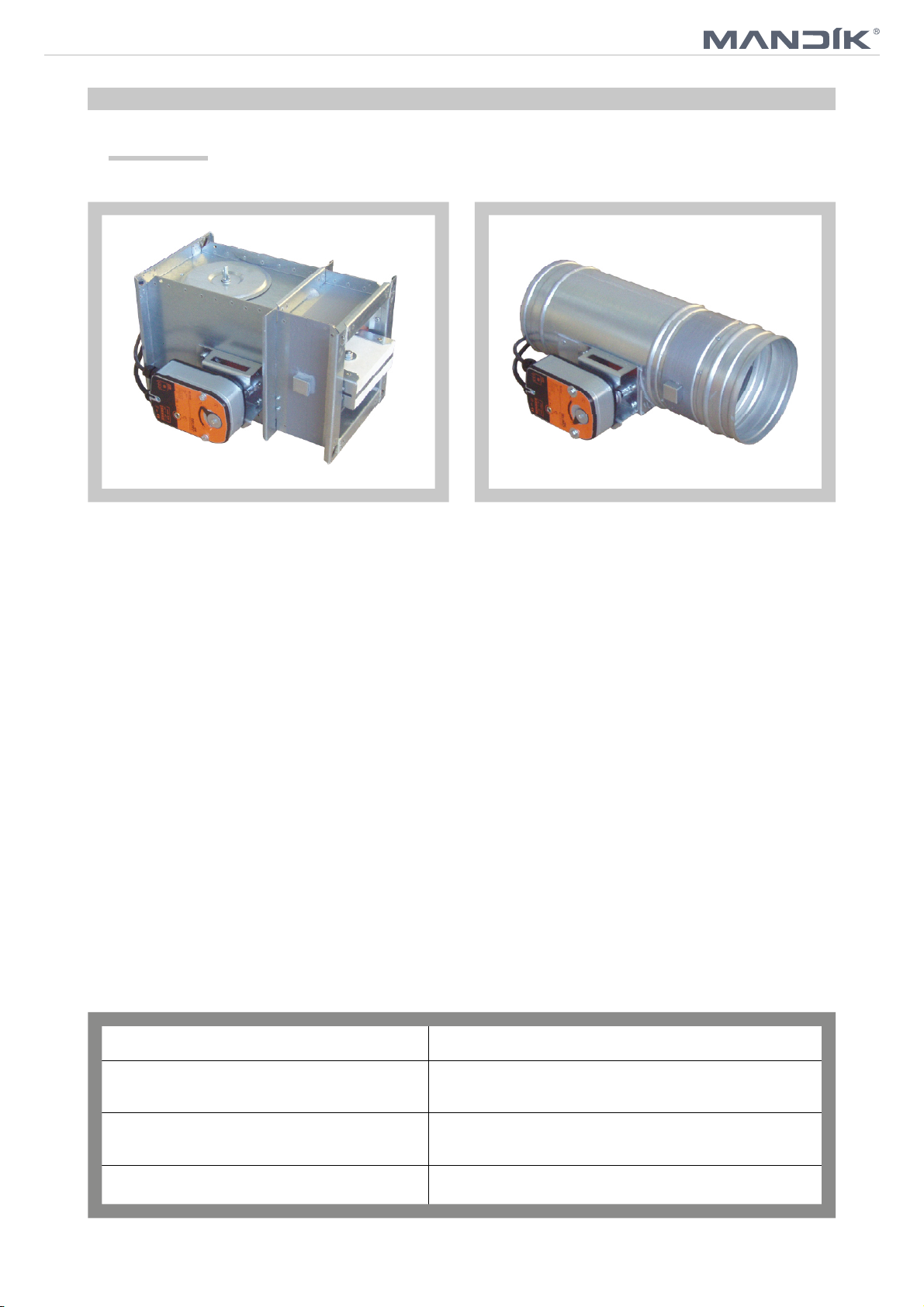

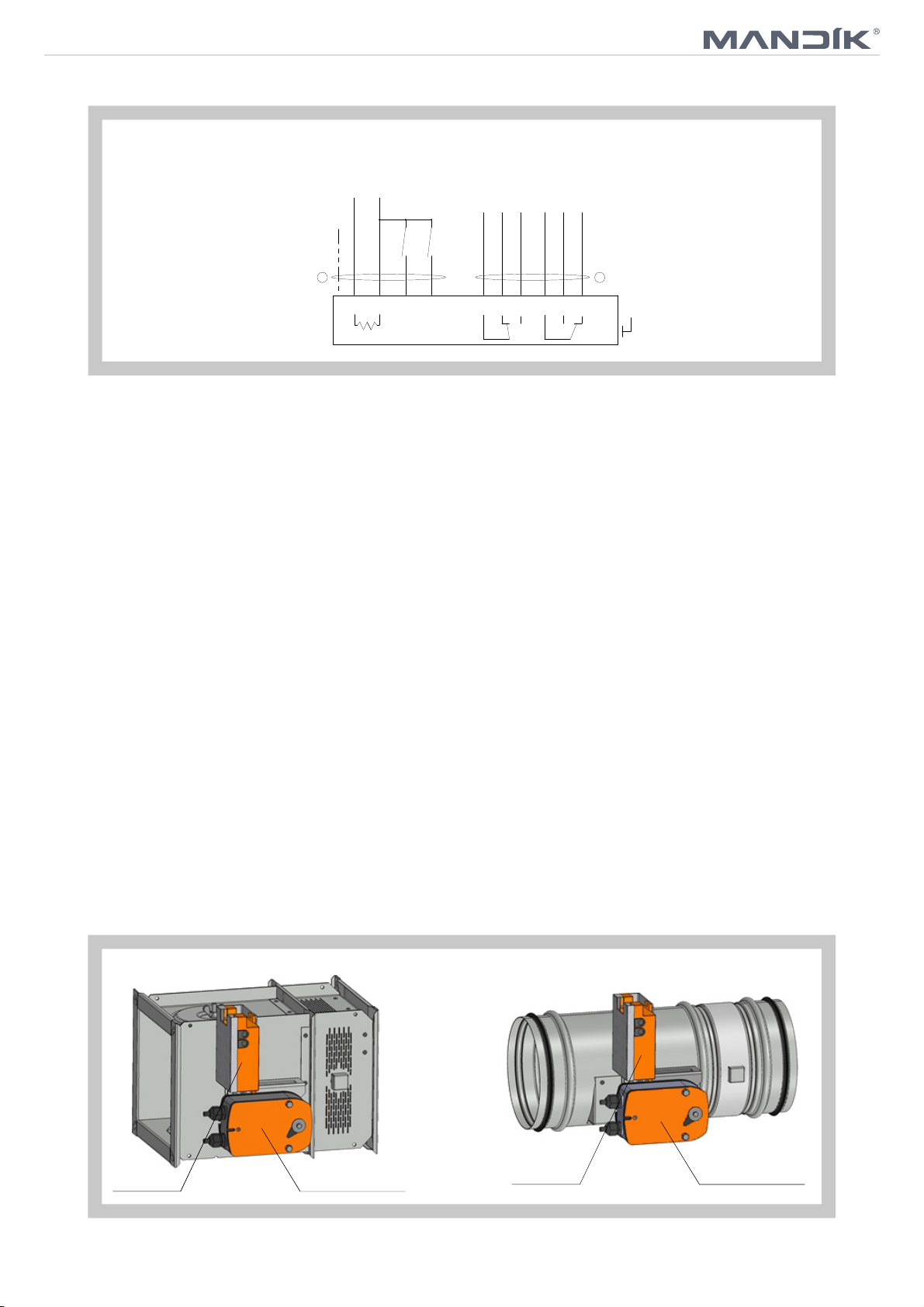

Fig. 1 Damper MSD - square Fig. 2 Damper MSD - round

1.1. Multi smoke dampers are shutters in the smoke exhaust duct systems. The dampers are

designed to remove heat and combustible products (e.g. smoke) from effected fire compartments.

In the event of fire the Smoke and Fire ventilation system opens the damper in the affected

section and removes combustion products and heat from this section.

The damper blade is controlled by electrical actuating mechanism.

Dampers are fire resistant and are intended for systems with automatic activation.

Dampers can be installed in construction of the fire compartment.

1.2. Damper characteristics

• CE certified acc. to EN 12101-8

• Tested in accordance with EN 1366-10

• Classified acc. to EN 13501-4+A1

• Fire resistance according Tab. 1.2.1

• External casing leakage class min. C acc. to EN 1751

• Internal leakage: round dampers - class min. 2, diameters from 560 mm to 630 mm min.

class 3 acc. to EN 1751

square dampers - class min. 2, for max. dimension 1500 x 800 mm min.

class 3 acc. to EN 1751

• Cycling test in class C 10000 acc. to EN 15650 (design MSD-W is tested without load)

• ES Certificate of conformity No. 1391-CPD-2015/0057 for MSD

• ES Certificate of conformity No. 1391-CPD-2015/0058 for MSD-W

• Declaration of Perfomance No. CDM/MSD/001/15

Tab. 1.2.1. Classification of Dampers

Supporting Construction Classification

Porous concrete ceiling construction,

thickness 150 mm

Porous concrete wall construction,

thickness 100 mm

EI 120 (how - i↔o) S1500C

EI 120 (vew - i↔o) S1500C

10000

10000

AAmulti

AAmulti

Gypsum wall, thickness 125 mm

EI 120 (v

- i↔o) S1500C

ew

10000

AAmulti

2

TPM 109/15

1.3. Working conditions

Exact damper function is provided under the following conditions:

a) maximum air velocity 15 m.s

-1

b) underpressure max. -1500 Pa or overpressure max. 500 Pa.

Dampers can be installed in arbitrary position (horizontal or vertical blade axis).

Dampers are designed for macroclimatic areas with mild climate according to EN 60 721-3-3.

Temperature in the place of installation is permitted to range from - 20°C to + 50°C.

2. Design

2.1. Design with actuating mechanism

Design .44 and .54

MSD (MSD-W) is equipped by actuating mechanism Belimo BLE24(BE24-12) for 24V supply or

BLE230(BE230-12) for 230V supply. MSD with big dimensions is equipped by actuating

mechanism Schischek InMax 50.75-S (dual supply 24V or 230V).

After being connected to power supply the actuating mechanism displaces the damper blade into

operation position "OPEN" or „CLOSED“ (according to method of connection, see connection

diagram). Running time is max. 60s. If is power supply cut off, actuating mechanism is stopped

in actual position. The crank handle supplied with the actuator allows it to be operated manually.

Signaling of the damper blade positions "OPEN" and "CLOSED" is provided by means of two

integrated, invariably set terminal switches.

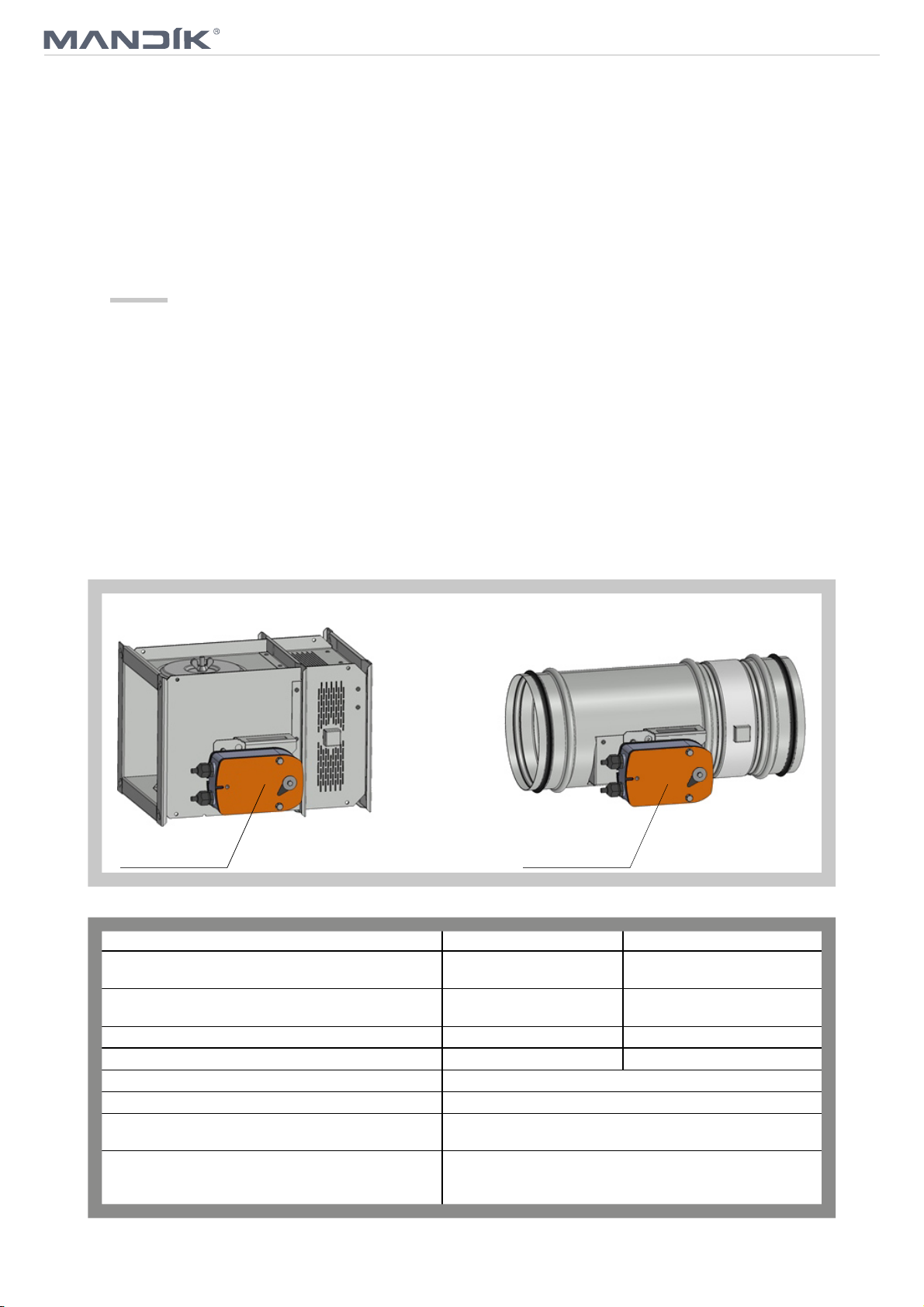

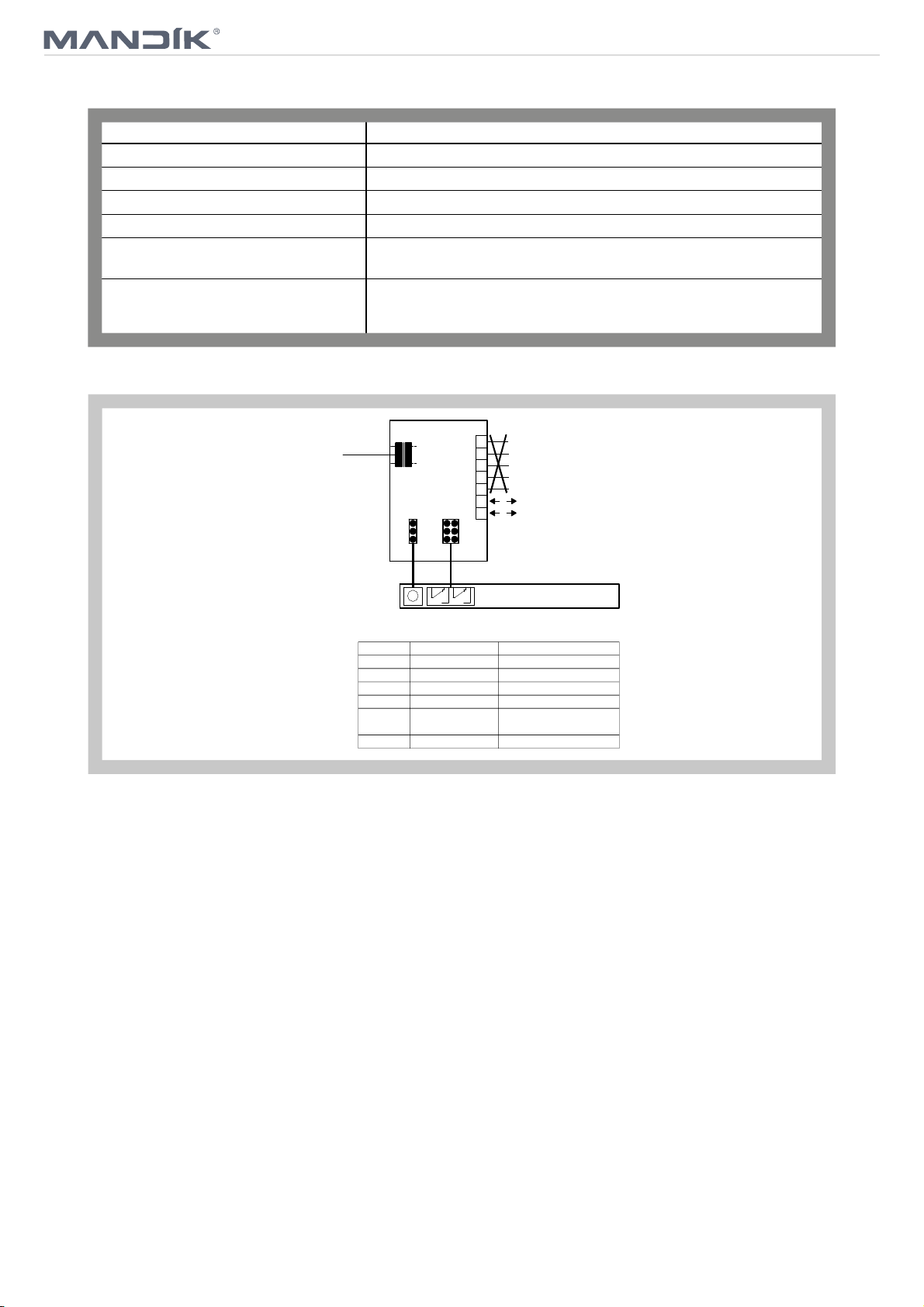

Fig. 3 Damper with actuating machanism

Actuating mechanism

Tab. 2.1.1. Actuating mechanism BELIMO BLE 24(-ST), BLE 230

Actuating mechanism BELIMO BLE 24(-ST) BLE230

Nominal voltage AC 24V 50/60Hz

Power consumption - motoring

- holding

Dimensioning 9 VA (Imax 2,7 A @ 5 ms) 12 VA (Imax 6 A @ 5 ms)

Protection class III II

Degree of protection IP 54

Running time for 95° < 30 s

Ambient temperature range

Non-operating temperature

Connecting - motor

- auxiliary switch

Actuating mechanism

AC 230 V 50/60Hz

DC 24 V

7,5 W

< 0,5 W

- 30 °C … + 50 °C

- 40 °C … + 80 °C

cable 1 m, 3 x 0,75 mm

cable 1 m, 6 x 0,75 mm

(BLE 24-ST) with plug-in connectors

5W

< 1 W

2

2

3

TPM 109/15

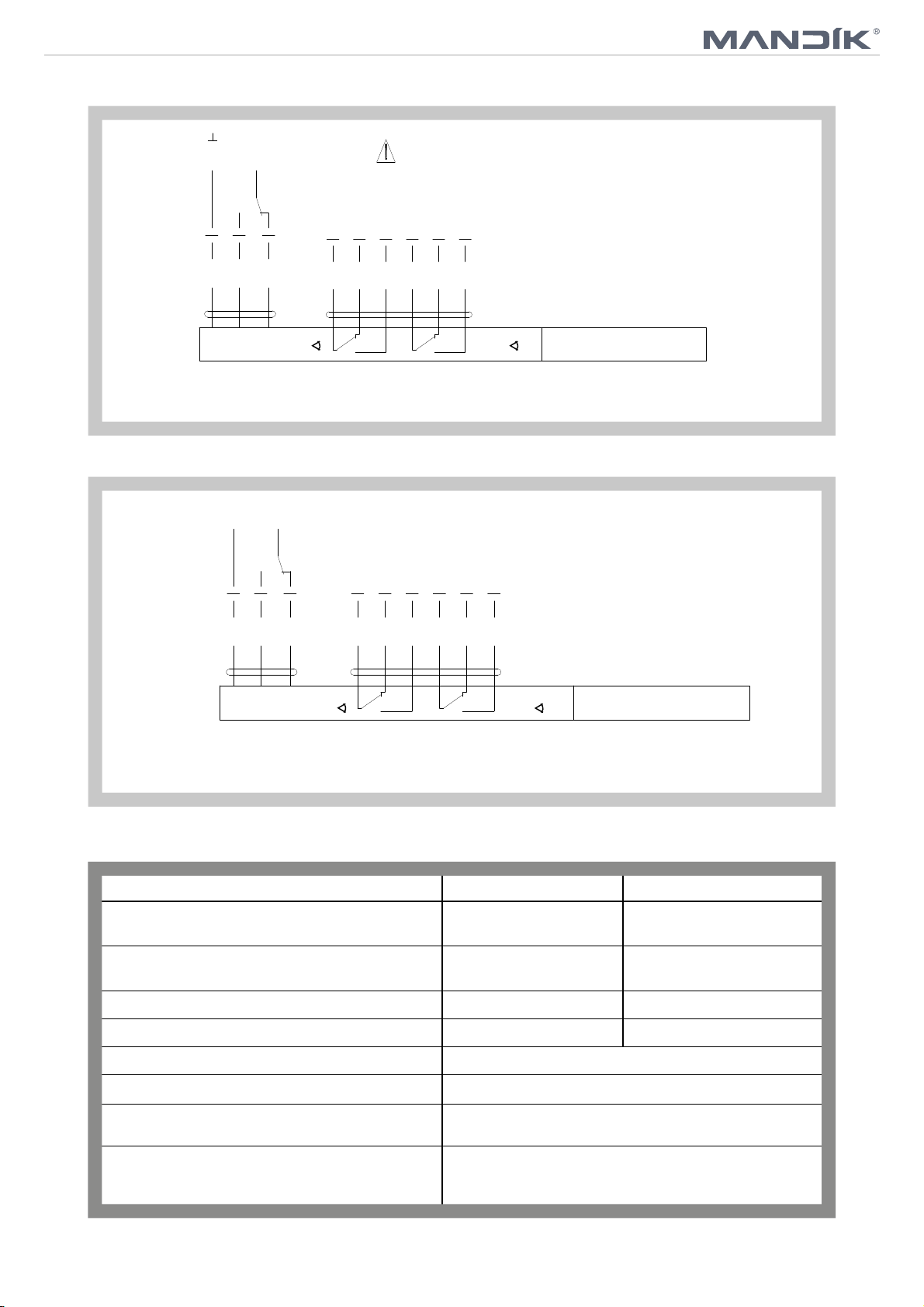

Fig. 4 Actuating mechanism BELIMO BLE 24(-ST)

~

AC 24 V

DC 24 V

+-

Connection through

an insulation transformer.

BLE24-ST: Design with connector plugs for communication

to network and communication device BKNE230-24

213

<3°

Fig. 5 Actuating mechanism BELIMO BLE 230

N

L1

1

2

3

S2S1 S3 S5S4 S6

AC230 V

<3° <87°

S3S2S1 S6S5S4

<87°

Parrallel connection of other driver is possible.

Pay attention to the power input data.

BLE24 (-ST)

BLE230

Parrallel connection of other driver is possible.

Pay attention to the power input data.

Tab. 2.1.2. Actuating mechanism BELIMO BE 24-12(-ST), BE 230-12

Actuating mechanism BELIMO BE 24-12 (-ST) BE230-12

Nominal voltage AC 24V 50/60Hz

DC 24 V

Power consumption - motoring

- holding

Dimensioning 18 VA (Imax 8.2 A @ 5 ms)

Protection class III

Degree of protection IP 54

Running time for 95° < 60 s

Ambient temperature range

Non-operating temperature

Connecting - motor

- auxiliary switch

12 W

0,5 W

- 30 °C … + 50 °C

- 40 °C … + 80 °C

cable 1 m, 3 x 0,75 mm

cable 1 m, 6 x 0,75 mm

(BE 24-ST) with plug-in connectors

AC 230 V 50/60Hz

8W

0,5 W

15 VA (Imax 7.9 A @ 5 ms)

II

2

2

4

TPM 109/15

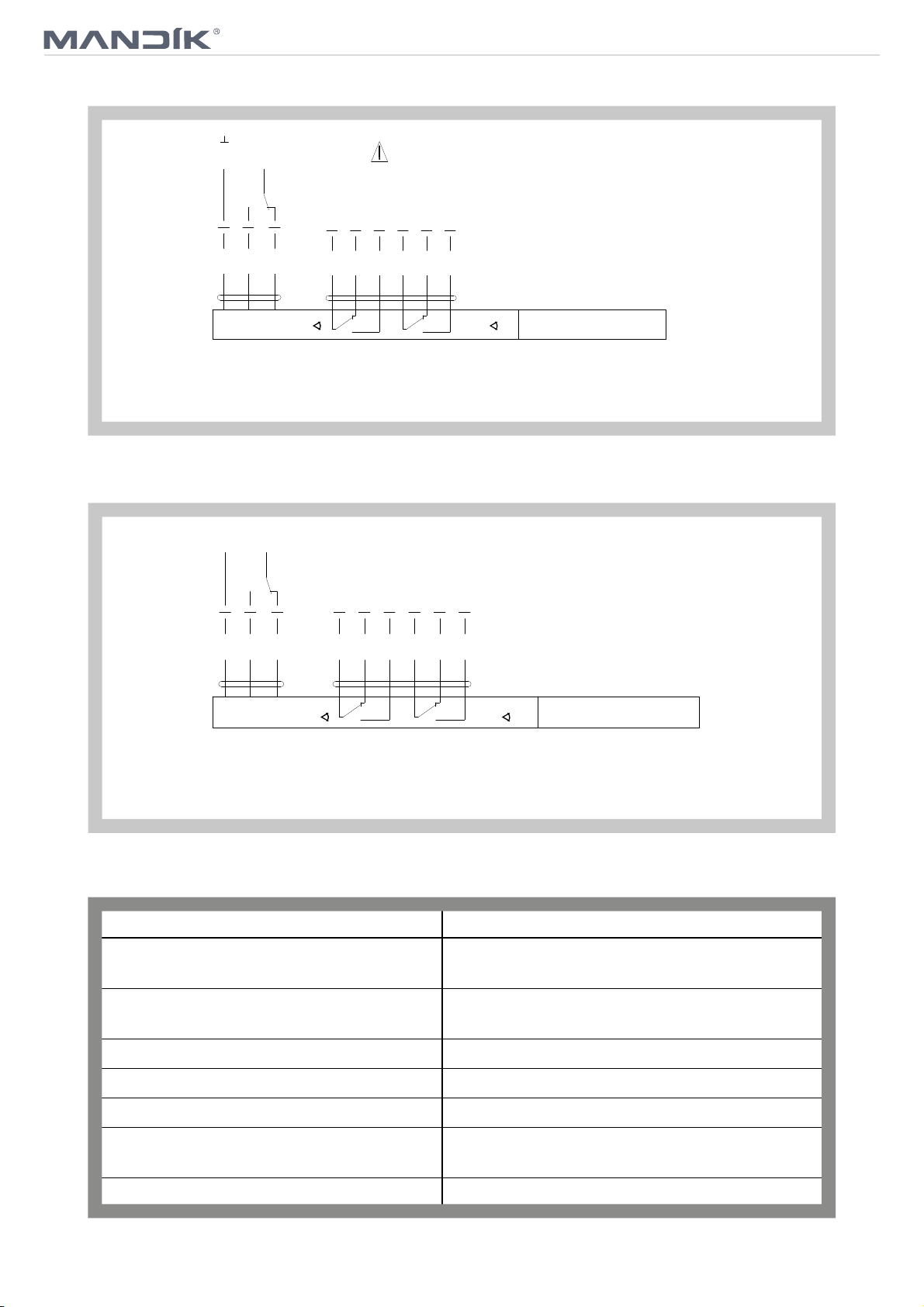

Fig. 6 Actuating mechanism BELIMO BE 24-12(-ST)

~

+-

AC 24 V

DC 24 V

Connection through

an insulation transformer.

BE24-12-ST: Design with connector plugs for communication

to network and communication device BKNE230-24

213

<3° <87°

Fig. 7 Actuating mechanism BELIMO BE 230-12

N

L1

1

2

3

S2S1 S3 S5S4 S6

AC230 V

S3S2S1 S6S5S4

BE24-12 (-ST)

Parrallel connection of other driver is possible.

Pay attention to the power input data.

<3° <87°

Tab. 2.1.3. Actuating mechanism SCHISCHEK InMax 50.75-S

Actuating mechanism SCHISCHEK

Nominal voltage

Power consumption - motoring

- heating

BE230-12

Parrallel connection of other driver is possible.

Pay attention to the power input data.

InMax 50.75-S

24-240 VAC/DC 50/60Hz

10 W

16 W (start at -20°C)

Protection class I

Degree of protection IP 66

Running time for 95° < 60 s

Ambient temperature range

Non-operating temperature

- 40 °C … + 50 °C

- 40 °C … + 70 °C

Connecting cable 1 m, 0,5 mm

5

2

TPM 109/15

Fig. 8 Actuating mechanism SCHISCHEK InMax 50.75-S

24...230 VAC/DC

+-

~

~

Integrated aux. switches

max 24V/3A, 240V/0,25A switching

at 5° and 85°.

<5°

>85°

PE

a

b

A B

1

heater

2 3

4

1

2 3

4 5

6

PA

2.2. Design with the communication and supply device

Design .66

Design with the communication and supply device BKNE230-24 and the actuating mechanism

BLE24(BE24-12)-ST.

BKNE230-24 functions as a decentralized network device for supplying the actuating mechanism

BLE24(BE24-12)-ST on one hand and on the other hand it transmits signals from communication

and control device BKSE24-6.

It simplifies electrical wiring and interconnection of dampers. It facilitates on site check and

enables central control and checks of fire damper by means of a simple 2-conductor wiring.

BKNE230-24 signals the damper position „OPEN“/„CLOSED“ (from switches on the actuator)

and any fault alarms to the BKSE24-6 unit. It also receives positioning commands from the

control unit and triggers the actuator to the required position. The last control command is

retained troughout temporary power failures.

The BKNE230-24 unit monitors the positions of the switches on the actuator, its running time and

the exchange of data with the control and monitoring unit BKSE24-6. It also monitors the actuator

current and the power supply. In order to make installation as simple as possible the smoke

extraction damper actuators ...-ST are fitted with plug connectors that can be inserted directly into

the BKNE230-24 unit.

The 2-wire conductor must be connected to screw terminals 6 and 7. It is recommended that a

fire alarm signal cable suitable for the application be used for the 2-wire conductor. It is essential

to ensure the correct polarity. More information in catalogue Belimo.

Design .66 is not available by using actuating mechanism InMax 50.75-S

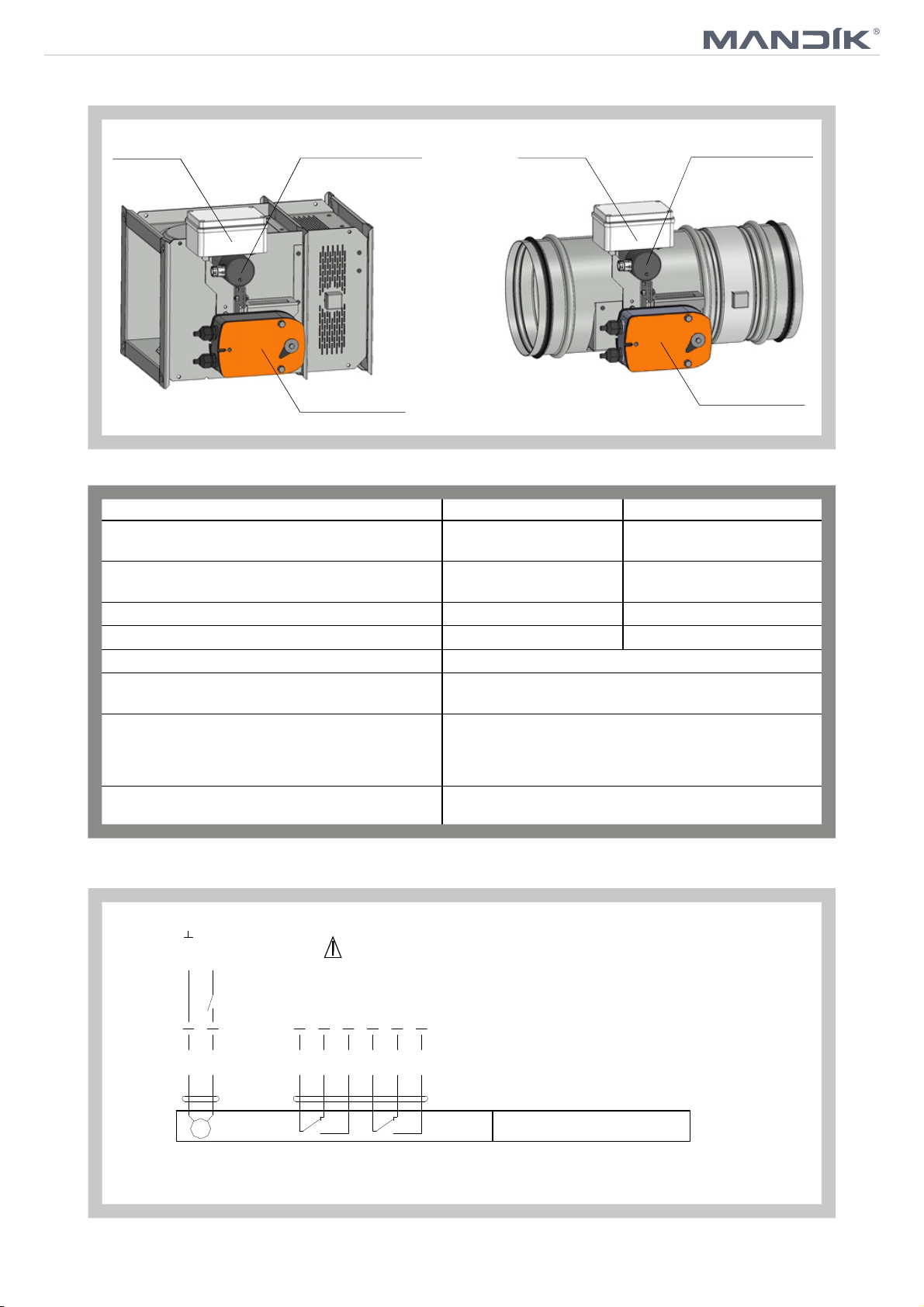

Fig. 9 Damper with actuating mechanism and BKNE230-24

Actuating mechanismBKNE230-24

BKNE230-24

Actuating mechanism

6

TPM 109/15

Tab. 2.2.1. Communication and supply device BKNE 230-24

Communication and supply device BKNE 230-24

Nominal voltage AC 230V 50/60Hz

Power consumption 10 W (including actuating mechanism)

Dimensioning 19 VA (including actuating mechanism)

Degree of protection II

Ambient temperature range

Non-operating temperature

Connecting - net

- actuator

- terminal board

Fig. 10 Communication and supply device BKNE 230-24

6-pole connector, 3-pole connector

screw terminals for cable 2x1,5 mm

- 30 °C … + 50 °C

- 40 °C … + 80 °C

cable 1 m without plug

2

AC 230 V

BKNE230-24

M

Displays

LED Stav Funkce

yellow flashing light damper moving to OPEN

yellow steady light damper open

green flashing light damper moving to CLOSED

green steady light damper closed

yellow flashing at double

or

green frequency

yellow dark power failure

+green

1

2

Nothing must be assigned

3

to terminals 1 to 5

4

5

a

2-wire conductor

6

to BKSE24-6

b

7

BE(G)24-ST, BE24-12-ST

fault

2.3. Design with electric actuating mechanism with emergency function and electromagnet

Design .4M0, .4M1, .5M0 and .5M1

MSD-W is always equipped by electric actuating mechanism BLF 230-T, BLF 24-T, DAF2.20S or

DAF1.20S (further only "actuating mechanism") and is complemented with initiation by means of

an electromagnet (solenoid). After being connected to power supply AC/DC 24V or 230V, the

actuating mechanism displaces the damper blade into operation position "CLOSED" and at the

same time it pre-stretches its back spring. When the actuating mechanism is under voltage, the

damper blade is in the position "CLOSED" and the back spring is pre-stretched. Time needed for

full closing of the flap blade from the position "OPEN" to the position "CLOSED" is maximum

60 sec. This possition is secured by initional lever. If the actuating power supply is cut off damper

is still in the position "CLOSED". After activation of electromagnet is released initiation lever and

the back spring displaces the damper blade into the breakdown position "OPEN". The time of

displacing the blade from the position "OPEN" to the position "CLOSED" takes maximum 16 sec.

In case that the power supply is restored again (the blade can be in any position), the actuating

mechanism starts to re-displace the damper blade into the position "CLOSED".

By voltage AC 230 V is damper equipped by electromagnet EM230. By voltage AC/DC 24 V is

damper equipped by electromagnet EM230 with pre-pulse switch SIEM24. SEIM24 activates the

electromagnet after capacitor charge witch is placed inside of SIEM24. It takes about 10 sec.

Charging time depends on the current supply. For reliable operation is necessary connect to

electromagnet or pre-pulse switch appropriate supply for 2 sec (230 V) or 20 to 30 sec (24 V).

7

TPM 109/15

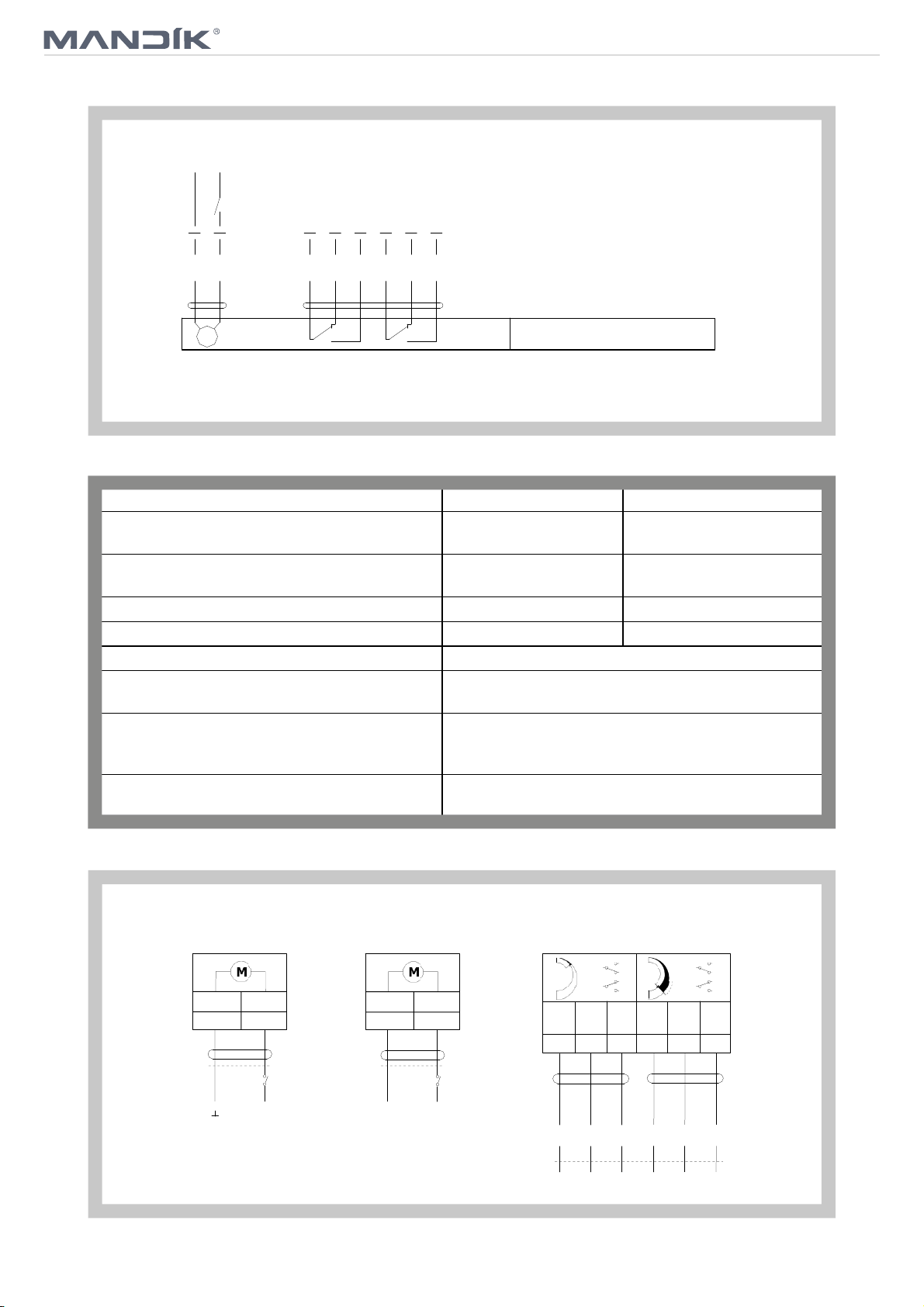

Fig. 11 Electric actuating mechanism with emergency function and electromagnet

Pulse switch

Tab. 2.3.1. Actuting mechanism BELIMO BLF 24, BLF 230

Electromagnet (solenoid) Pulse switch

Actuating mechanism

Electromagnet (solenoid)

Actuating mechanism

Actuting mechanism BELIMO BLF 24 BLF230

Nominal voltage AC 24V 50/60Hz

AC 230 V 50/60Hz

DC 24 V

Power consumption - motoring

- holding

5 W

2,5 W

Dimensioning 7 VA (Imax 5,8 A @ 5 ms)

Protection class III

7 VA (Imax 150 mA @ 10 ms)

5W

3W

II

Degree of protection IP 54

Running time - motor

- spring return

< 120 s

~ 16 s

Ambient temperature

- normal duty

- safety duty

- non-operating temperature

Connecting - motor

- auxiliary switch

The safe position will be attained up to max. 75°C

- 30 °C … + 50 °C

- 40 °C … + 50 °C

cable 1 m, 2 x 0,75 mm

cable 1 m, 6 x 0,75 mm

2

2

Obr. 12 Actuting mechanism BELIMO BLF 24

~

AC 24 V

DC 24 V

+-

1

2

M

<5° <80°

Connection through

an insulation transformer.

S2S1 S3 S5S4 S6

BLF24

Parrallel connection of other driver is possible.

Pay attention to the power input data.

8

TPM 109/15

Obr. 13 Actuting mechanism BLF 230

L1

2

M

AC230 V

S3S2S1 S6S5S4

<5° <80°

N

1

Tab. 2.3.1. Actuting mechanism Joventa DAF2.20S a DAF1.20S

For separation from the mains, a device that

insulates polar conductors must be at disposal

(Minimum distance between contacts - 3 mm).

BLF230

Parrallel connection of other driver is possible.

Pay attention to the power input data.

Actuting mechanism Joventa DAF2.20S DAF1.20S

Nominal voltage AC 24V 50/60Hz

AC 230 V 50/60Hz

DC 24 V

Power consumption - motoring

- holding

26 VA (AC); 15,6 W (DC)

9,3 VA (AC); 2,6 W (DC)

Dimensioning 14 VA

Protection class II

0,15 A

0,09 A

14 VA

II

Degree of protection IP 54

Running time - motor

- spring return

24…57 s

11…15 s

Ambient temperature

- normal duty

- non-operating temperature

Connecting - motor

- auxiliary switch

Obr. 14 Actuting mechanism Joventa DAF2.20S a DAF1.20S

DAF2.20S DAF1.20S LIMIT SWITCHES

M

BLK1RED

2

~

+-

AC 24 V

M

BLK

RED

1

2

N L1

AC230 V

DC 24 V

- 40 °C … + 55 °C

- 65 °C … + 85 °C

cable 1,2 m halogen-free; 2-wires

cable 1,2 m halogen-free; 6-wires

BLK/

RED

21

COM

S1

BLK/

BLU

22

NC

21

22

23

21

BLK/

GRY

23

NO

WHT/

RED

24

COM

S2

WHT/

BLU

25

NC

24

24

25

26

WHT/

GRY

26

NO

9

TPM 109/15

Tab. 2.1.2. Elektromagnet EM230

Elektromagnet EM230

Jmenovité napětí AC 230 V / 50 Hz

Zátahový proud 1,2 A

Krytí IP 40

Teplota okolí provozní -10 °C … +40 °C

Obr. 15 Elektromagnet EM230

Připojení kabel 1m, 3x0,75mm

2

3. Communication and control devises

3.1. BKSE24-6 indicates operating status and fault signals for the smoke extraction dampers. The

auxiliary contacts that are incorporated also allow functions to be signaled or passed on to

higherlevel control systems. The signals from the BKNE230-24 unit are received by the

BKSE24-6 unit and evaluated individually. All BKNE230-24 units are triggered simultaneously. To

BKSE24-6 can be connected max. 6 BKNE230-24.

Communication is via the 2-wire conductor. Correct operation of the dampers is indicated by

means of two LEDs. The operating status of the SBSE-Control system and any faults are also

indicated by this LED and the corresponding fault LED.

The BKSE24-6 unit can be clipped directly to a 35 mm DIN mounting rail and connected by means

of two 9-pole plug-in terminals.

Tab. 3.1.1. Communication and control devices BKSE 24-6

Communication and control devices

BKSE 24-6

Nominal voltage AC 24 V 50/60Hz

Power consumption 3,5 W (operating position)

Dimensioning 5,5 VA 18 VA (Imax 6.4 A @ 2.5 ms)

Protection class III

Degree of protection IP 20

Ambient temperature range 0 … + 50 °C

Connecting screw terminals for cable 2x1,5 mm

2

10

TPM 109/15

Fig. 16 Communication and control devices BKSE 24-6

SMOKE EXTRACTION

CEASE SMOKE EXTRACTION

AC 24 V

Connection through

an insulation transformer.

4. Dimensions, weights

~

AUTO

Input 1

10

11

12

COM

Delay 0 s (Fan)

Delay 60 s (Fan)

OPEN

CLOSED

*Fault (Error)

*Inverted output: fault = contact open

13

14

15

16

17

18

BKSE24-6

9

8

7

6

5

4

3

2

1

+

-

Input 2

(isolated)

U

a1...a6

a1...a6

BKNE230-24

4.1. Dimensions

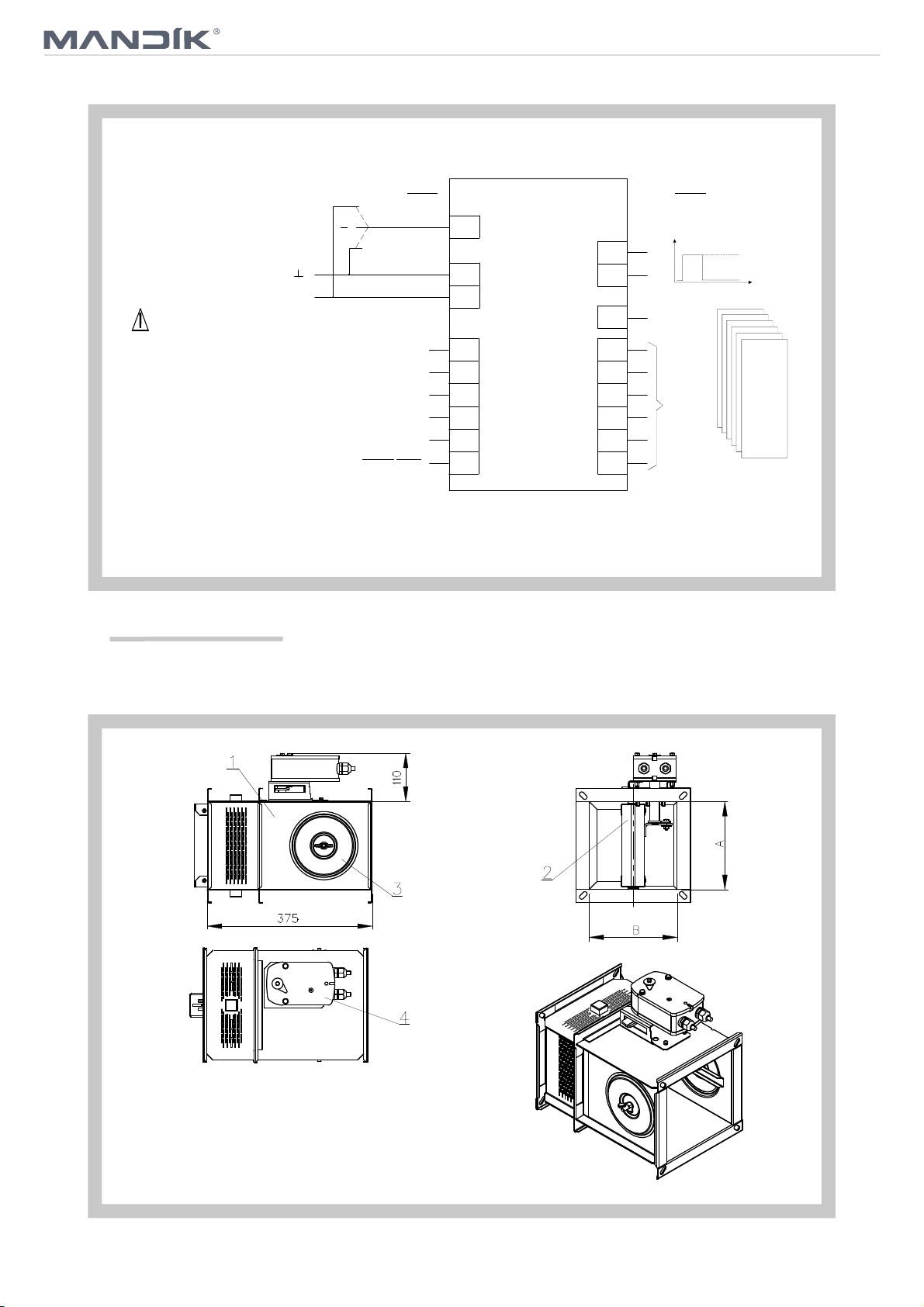

Fig. 17 Square MSD (MSD-W) - design with actuating mechanism

Position:

1 Damper body 3 Inspection hole covering

2 Damper blade 4 Actuating mechanism

11

Loading...

Loading...