Mandik FDMC General Information Manual

TPM 083/12

These technical specifications state a row of manufactured sizes and models of fire dampers (further only dampers)

FDMC. It is valid for production, designing, ordering, delivery, assembly and operation.

I. CONTENT

II. GENERAL INFORMATION 2

1. Description.........................................................................................................................

2. Damper Design..….............................................................................................................

3. Communication and control devices..............….................................................................. 6

4. Dimensions, weights........................................................................................................... 9

5. Placement and Assembly.................................................................................................... 10

6. Statement of installations.................................................................................................... 12

7. Suspension of fire dampers................................................................................................. 18

III. TECHNICAL DATA 21

8. Pressure loss...................................................................................................................... 21

9. Coefficient of local pressure loss......................................................................................... 21

10. Noise data......................................................................................................................... 22

IV. MATERIAL, FINISHING 24

11. Material............................................................................................................................. 24

VI. INSPECTION, TESTING 24

12. Inspection, testing............................................................................................................. 24

2

3

VI. TRANSPORTATION AND STORAGE 24

13. Logistic terms.................................................................................................................... 24

VII. ASSEMBLY, ATTENDANCE, MAINTENANCE AND REVISIONS 24

14. Assembly.......................................................................................................................... 24

15. Entry into service and revisions......................................................................................... 24

VIII. DATA OF PRODUCT 25

16. Data label..........................................................................................................................

17. Quick review.....................................................................................................................

25

25

IX. ORDERING INFORMATION 26

18. Ordering key.....................................................................................................................

26

1

TPM 083/12

II. GENERAL INFORMATION

1. Description

1.1. Fire dampers are shutters in duct systems of air-conditioning devices that prevent spreading the

fire and combustion products from one fire segment to the other one by means of closing the air

duct in the points of fire separating constructions.

Dampers blade automatically closes air duct using a shutting spring or an actuating mechanism

back spring. The back spring of the actuating mechanism is started when the thermoelectrical

starting mechanism BAE 72B-S is activated, when a reset button on BAE 72B-S is pushed or

when a power supply of the actuating mechanism is stopped.

The damper is sealed with a silicon packing against smoke penetration after closing the blade. At

the same time, the damper blade is bedded in a material which enlarges its capacity and air

proofs the air duct.

Dampers have one inspection hole, since the shutting device and the inspection hole can be set

into the most advantageous position (with respect to the operation and manipulation with the

control device).

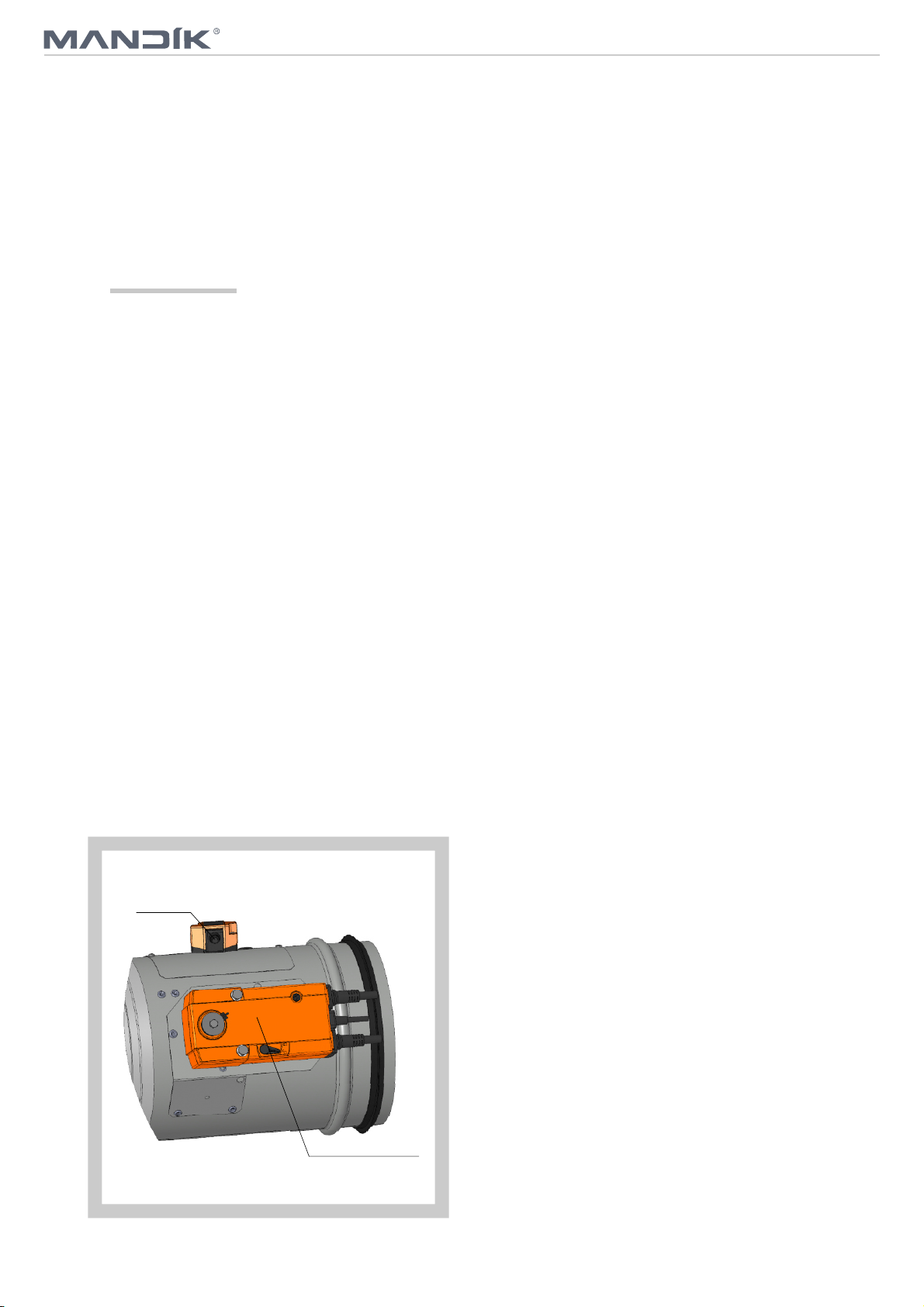

Fig. 1 Fire damper FDMC

1.2. Damper characteristics

• CE certified acc. to EN 15650

• Tested in accordance with EN 1366-2

• Classified acc. to EN 13501-3+A1

• Fire resistance EIS 60

• External Casing leakage class min. C, Internal leakage class 3 (D=200 - 400 mm) and class 2

(D=180 mm) and class 1 (D=100 - 160 mm) acc. to EN 1751

• Cycling test in class C 10000 acc. to EN 15650

• Corrosion resistant acc. to EN 15650

• ES Certificate of conformity No. 1391-CPR-0090/2014

• Declaration of Perfomance No. CDM/FDMC/001/14

• Hygienic assessment of fire dampers - Report No. 1.6/13/16/1

1.3. Working conditions

Exact damper function is provided under the following conditions:

a) Maximum air circulation speed: 12 m.s

-1

Maximum pressure difference: 1500 Pa

b) Dampers could be displaced into position “CLOSED” only in case that ventilator, or Air

Handling Unit is switched off. The goal is the securing of proper closing and safe

function of Fire Damper in case of Fire.

c) The air circulation in the whole damper section must be secured as steady on whole

surface.

2

TPM 083/12

Operation of the dampers does not depend on the direction of air circulation. The dampers can

be located in an arbitrary position.

Dampers are suitable for systems without abrasive, chemical and adhesive particles.

Dampers are designed for macroclimatic areas with mild climate according to EN 60 721-3-3.

Temperature in the place of installation is permitted to range from - 20°C to + 50°C.

2. Damper design

2.1. Design with actuating mechanism

Design .40, .50

Design with an actuating mechanism BFL 230-T or BFL 24-T (further only "actuating mecha-

nism"). After being connected to power supply AC/DC 24V or 230V, the actuating mechanism

displaces the damper blade into operation position "OPEN" and at the same time it pre-stretches

its back spring. When the actuating mechanism is under voltage, the damper blade is in the

position "OPEN" and the back spring is pre-stretched. Time needed for full opening of the flap

blade from the position "CLOSED" to the position "OPEN" is maximum 140s. If the actuating

power supply is cut off (due to loss of supply voltage, activation of thermoelectrical actuating

mechanism or pushing the reset button on the thermoelectrical starting mechanism BAT), the

back spring displaces the damper blade into the breakdown position "CLOSED". The time of

displacing the blade from the position "OPEN" to the position "CLOSED" takes maximum 20 s. In

case that the power supply is restored again (the blade can be in any position), the actuating

mechanism starts to re-displace the damper blade into the position "OPEN".

A thermoelectrical starting mechanism BAT, which contains three thermal fuses Tf1 and Tf2, is a

part of the actuating mechanism. These fuses are activated when temperature +72 °C has been

exceeded (the fuse Tf1 when the temperature around the damper and the fuses Tf2 when the

temperature inside the air-conditioning piping has been exceeded). After the thermal fuse Tf1 or

Tf2 has been activated, the power supply is permanently and irreversibly cut off and the actuating

mechanism, by means of the pre-stretched spring, displaces the damper blade into the

breakdown position "CLOSED".

Signalling of blade positions "OPEN" and "CLOSED" is ensured by two firmly set integrated limit

switches.

Fig. 2 Fire damper FDMC - actuating mechanism

BAT

Actuating mechanism

3

TPM 083/12

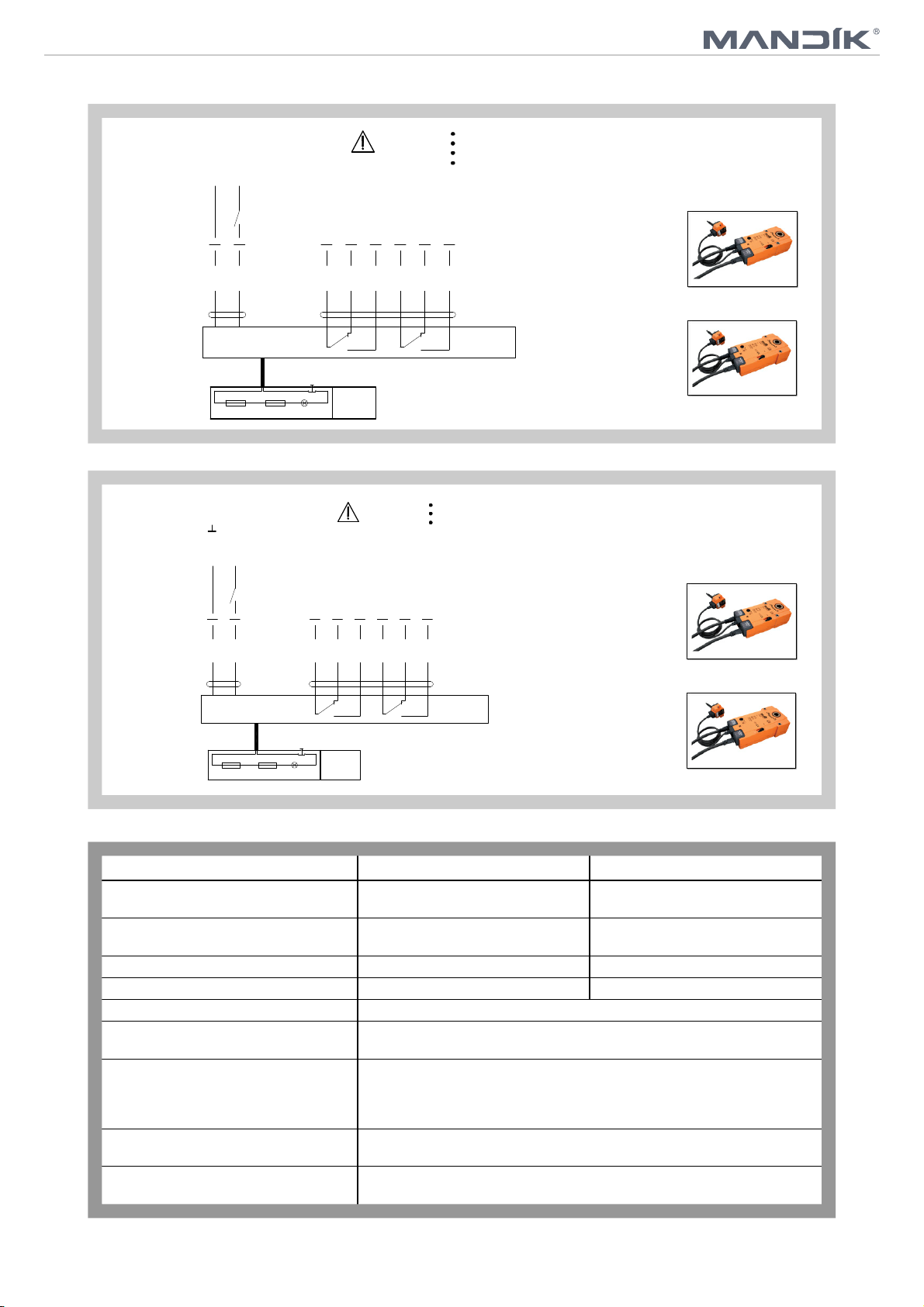

Fig. 3 Actuating mechanism BELIMO BFL 230-T

AC230 V, open-close

N

L1

1

2 S3S1 S2 S5S4 S6

<5° <80°

Tf Tf LED

BAT

Notes

Fig. 4 Actuating mechanism BELIMO BFL 24-T(-ST)

AC/DC 24 V, open-close

Notes

~

- +

Caution: Power supply voltage!

The actuator must be protected by a fuse that does not exceed 16 A.

Parallel connection of other actuators possible. Observe the performance data.

Combination of power supply voltage and safety extra-low voltage not permitted

at the both auxiliary switches.

BFL 230-T

Cable colours:

1 = blue

2 = brown

S1 = violet

S2 = red

S3 = white

S4 = orange

S5 = pink

S6 = grey

Connection via safety isolating transformer.

Parallel connection of other actuators possible. Observe the performance data.

Combination of power supply voltage and safety extra-low voltage not permitted

at the both auxiliary switches.

(-ST)

Plug connection to communication

and power supply units:

Application examples for integration

into monitoring and control systems

or into bus networks can be found in

the documentation of the connected

communication and power supply unit.

BFN 230-T

BFL 24-T

1

2 S3S1 S2 S5S4 S6

<5°

Tf Tf LED

BAT

<80°

Cable colours:

1 = blue

2 = brown

S1 = violet

S2 = red

S3 = white

S4 = orange

S5 = pink

S6 = grey

BFN 24-T

Tab. 2.1.1. Actuating mechanism BELIMO BFL24-T(-ST), BFN 24-T(-ST), BFL 230-T a BFN 230-T

Actuating mechanism BELIMO BFL, BFN 230-T BFL, BFN 24-T(-ST)

Nominal voltage

Power consumption - motoring

- holding

AC 230 V 50/60 Hz

3,5/5 W

1,1/2,1 W

AC 24 V 50/60 Hz

DC 24 V

2,5/4 W

0,8/1,4 W

Dimensioning 6,5/10 VA (Imax 4 A @ 5 ms) 4/6 VA (Imax 8,3 A @ 5 ms)

Protection class II III

Degree of protection IP 54

Running time - motor

- spring return

Ambient temperature

- normal duty

- safety duty

- non-operating temperature

Connecting - motor

- auxiliary switch

Thermal trips

The safe position will be attained up to max. 75°C

cable 1 m, 2 x 0,75 mm (BFL/BFN 24-T-ST) with 3-pin plug-in connectors

cable 1 m, 6 x 0,75 mm (BFL/BFN 24-T-ST) with 6-pin plug-in connectors

2

2

duct outside temperature 72 °C

duct inside temperature 72 °C

<60 s

~ 20 s

- 30 °C … 55 °C

- 40 °C … 55 °C

4

TPM 083/12

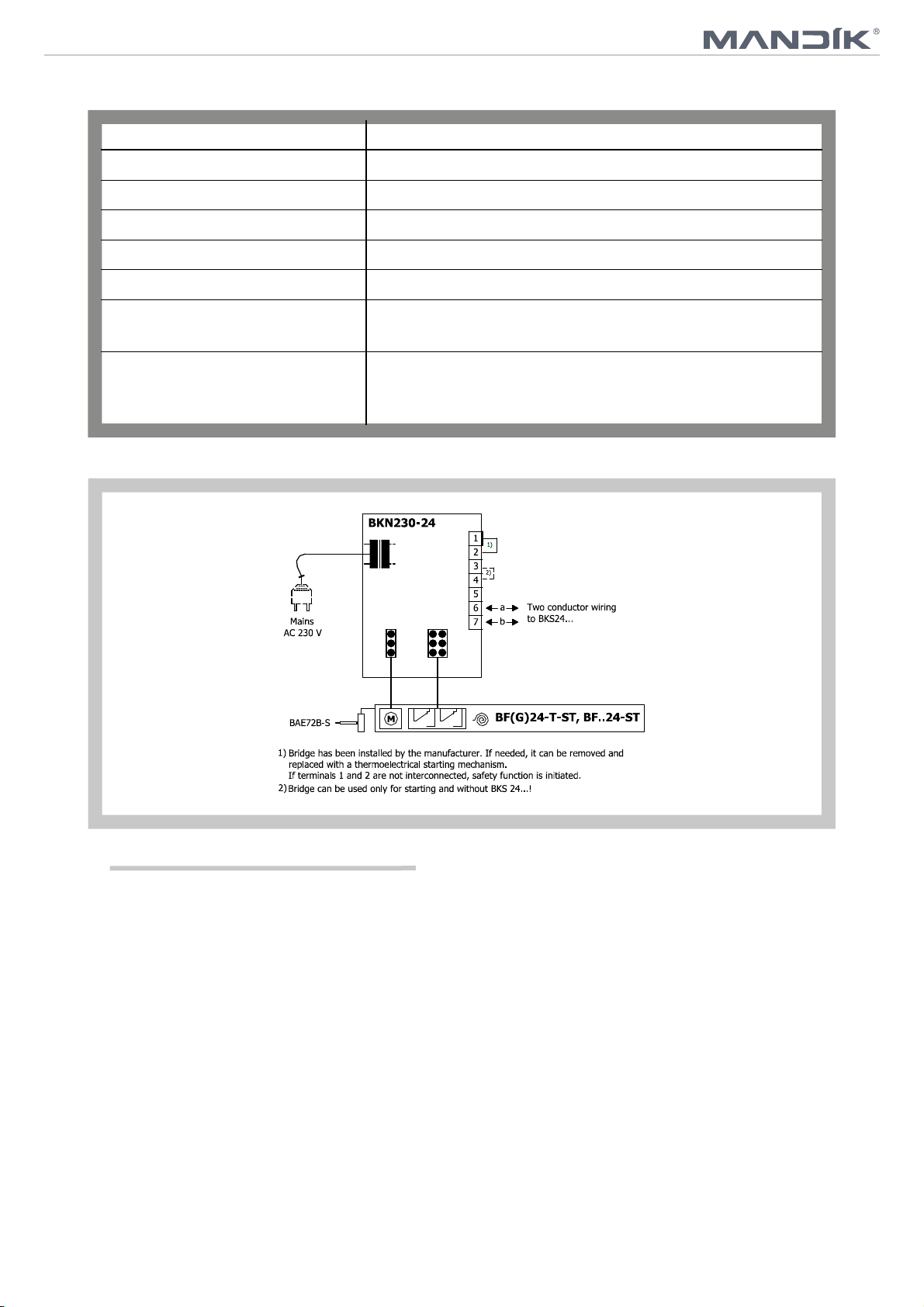

2.3. Design with the communication and supply device

Design .60

Design with the communication and supply device BKN 230-24 and the actuating mechanism

BFL 24-T-ST. It simplifies electrical wiring and interconnection of fire damper. It facilitates on site

check and enables central control and checks of fire damper by means of a simple 2-conductor

wiring.

BKN 230-24 functions as a decentralized network device for supplying the actuating mechanism

BFL 24-T-ST with a spring back drive on one hand and on the other hand it transmits the signal

information about the fire damper position OPERATION and FAILURE through 2-conductor

wiring to the central. Control command SWITCHED ON - SWITCHED OFF from the central

through BKN 230-24 goes through the same wiring to the actuating mechanism.

To simplify the connection, the actuating mechanism BFL 24-T-ST is equipped with connecting

plugs that are inserted directly to BKN 230-24. BKN 230-24 is supplied with a conductor and an

EURO plug to be connected to the 230V mains.

2- conductor wiring is connected to BKN 230-24 by means of terminals 6 and 7.

If the drive is supposed to be controlled without any signal from the central, it can be switched on

by means of a bridge between the terminals 3 and 4. A green LED pilot light on BKN 230-24 is

on when voltage is present in the drive (AC 24V). If the button on BAE 72-S is switched on or if

the power supply (e.g. by a signal from ELECTRICAL FIRE SIGNALISATION) is disconnected,

the fire damper position will be "FAILURE".

Communication and supply device BKN 230-24 has to be placed near the damper. It is necessary

for easy connection of actuating system equipped by BKN 230-24 device.

Fig. 5 Fire damper FDMD with actuating mechanism

and BKN

BAT

BKN

Actuating mechanism

Tab. 2.3.1. Communication and Supply Device BKN 230-24

Communication and Supply Device

Nominal voltage AC 230V 50/60Hz

Power consumption 3,5 W (operating position)

Dimensioning 11 VA (including actuating mechanism)

BKN 230-24

Protection Class II

Degree of protection IP 42

Ambient Temperature

Storage Temperature

Connection - mains

- drive

- terminal board

Cable 0,9 m with EURO plug of 26 type

screw terminals for conductor 2x1,5 mm

- 30 °C … + 50 °C

- 40 °C … + 50 °C

6 pole plug, 3 pole plug

5

2

TPM 083/12

Tab. 2.3.2. Communication and Supply Device BKN 230-24

Communication and Supply Device BKN 230-24

Nominal voltage AC 230V 50/60Hz

Power consumption 3,5 W (operating position)

Dimensioning 11 VA (including actuating mechanism)

Protection Class II

Degree of protection IP 42

Ambient Temperature

Storage Temperature

Connection - mains

- drive

- terminal board

Fig. 6 Communication and Supply Device BKN 230-24

- 30 °C … + 50 °C

- 40 °C … + 50 °C

Cable 0,9 m with EURO plug of 26 type

6 pole plug, 3 pole plug

screw terminals for conductor 2x1,5 mm

2

3. Communication and control devices

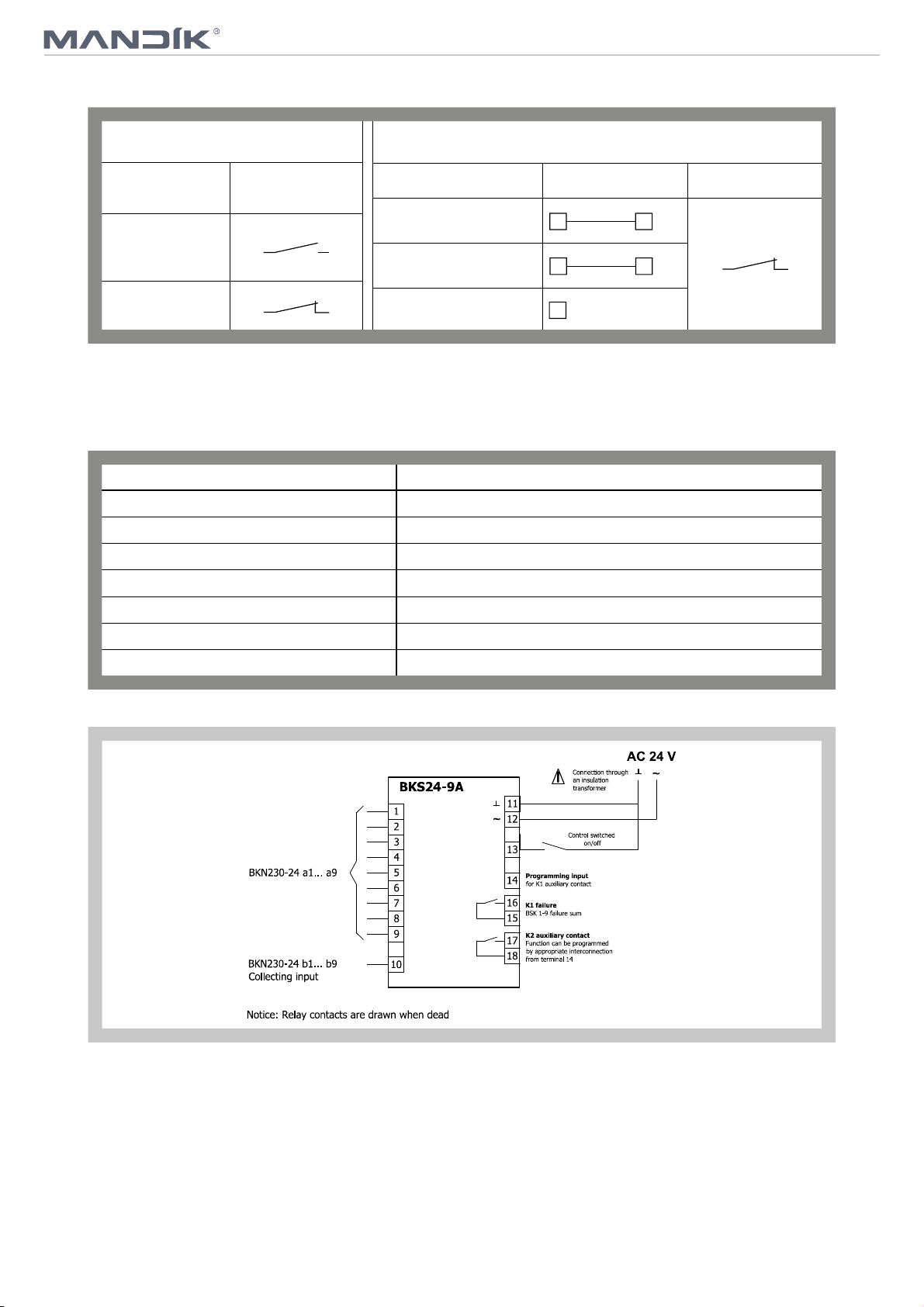

3.1. BKS 24-9A communication and control device is used for group control and checks of 1 to 9 fire

dampers with the actuating mechanism BFL 24-T-ST in connection with the supply and

communication device BKN 230-24. Signalisation of the damper position is individual; the

dampers can be controlled and tested only as a group. BKS 24-9A is intended for use in the

distribution board and displays the operation situations and failure reports of the connected fire

dampers. It is possible to signalise functions such as the damper position and failure reports or to

transmit them further to the system by means of integrated auxiliary switches. BKS 24-9A

receives signals from BKN 230-24 through the two-conductor wiring and issues control

commands. Proper damper operation is indicated by two light LED diodes:

Control ON = position OPERATION

Control OFF = position FAILURE

If the fire dampers do not reach the given position in time tolerable for displacing, the appropriate

light diode FAILURE starts to flash and K1 contact is opened (current failure). In case that the

faulty damper finally reaches its given position, K1 is closed and the failure report lights up shines

(the failure is saved in memory).

K2 - the auxiliary contact - is used for signalisation of the flap position to the master device. Function

of this auxiliary contact can be programmed through the terminal 14 according to the Tab. 3.1.1.

6

TPM 083/12

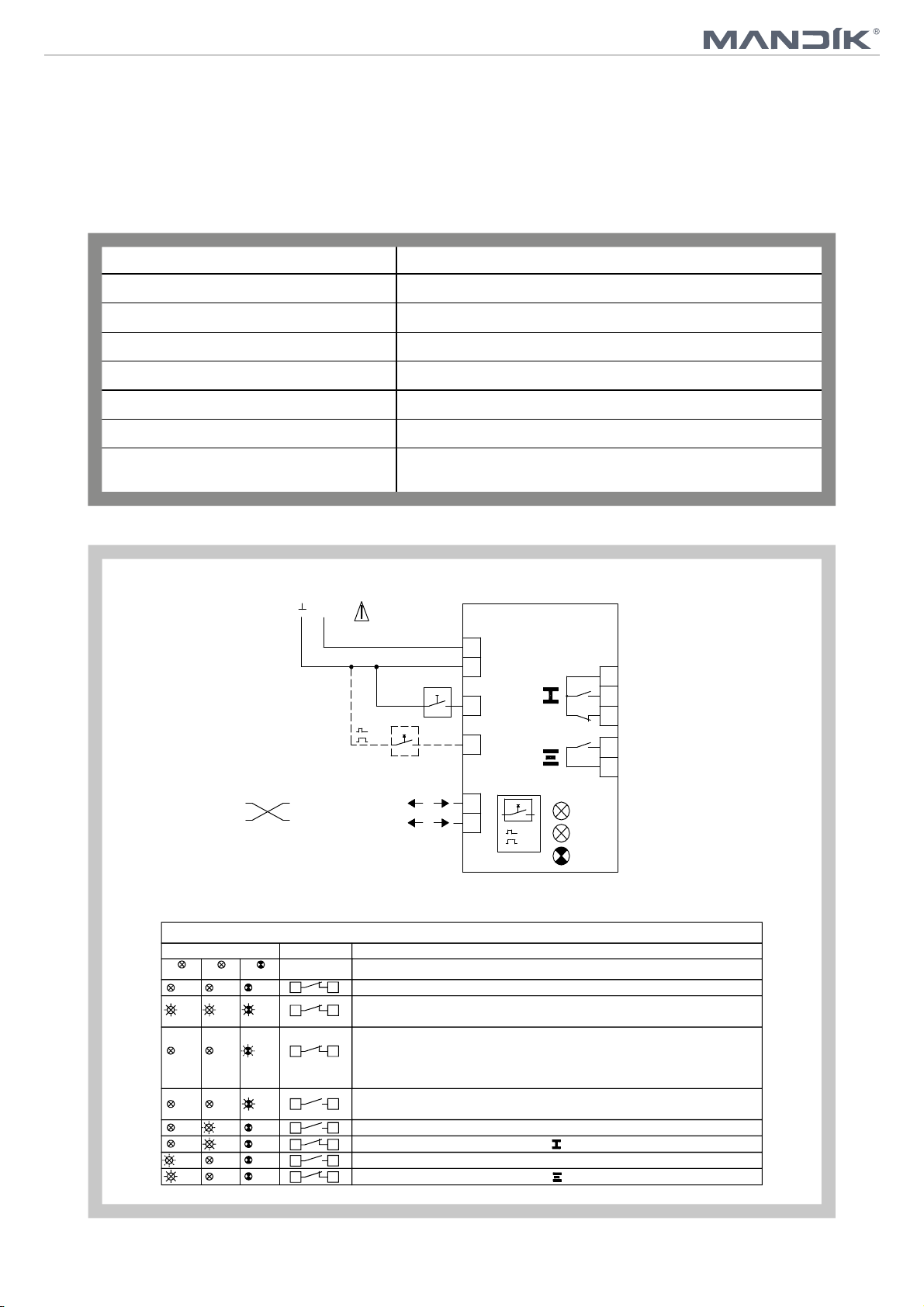

Tab. 3.1.1. BKS 24 -9A contacts K1 and K2

K1 Function Contact

Situation State

Current Failure

No Failure

15 16

15 16

Programming K2 Auxiliary Contact

Function

K2 contact is on if all the

damperss are open

K2 contact is on if the damper

No. 1 is open

K2 contact is on if all the

dampers are closed

Interconnection State

14 11

14 12

14 open

Function check can be done in the position OPERATION by means of pushing the TEST button.

While the button is pushed, the flap blade is turning into the position FAILURE. Fault function is

indicated by a report "FAILURE".

Tab. 3.1.2. Communication and Control Device BKS 24-9A

Communication and Control Device BKS 24-9A

Nominal voltage AC 24 V 50/60Hz

Power consumption 3,5 W (operating position)

Dimensioning 5,5 VA

Protection Class III (safe small voltage)

17 18

Degree of protection IP 30

Ambient Temperature 0 … + 50 °C

Connection Terminals for conductor 2 x 1,5 mm

Fig. 7 Communication and Control Device BKS 24-9A

2

3.2. BKS 24-1B communication and control device is used for control and checks of fire dampers with

the BFL 24-T-ST actuating mechanism in conjunction with the BKN 230-24 supply and

communication device. BKS 24-1B receives information about the situation of the fire damper

through the BKN 230-24 supply and communication device and issues controlling commands.

The device is intended for building in into the distribution board. Light diodes on the front side of

the device indicates the operating situations of the damper and breakdowns of the whole system.

Nonpotential auxiliary contacts enable connection to the master control system (indication of the

damper position, failure reports, release of the ventilators etc.).

7

TPM 083/12

3.3. BKS 24-1B communication and control device is used for control and checks of fire dampers with

the BFL 24-T-ST actuating mechanism in conjunction with the BKN 230-24 supply and

communication device. BKS 24-1B receives information about the situation of the fire damper

through the BKN 230-24 supply and communication device and issues controlling commands.

The device is intended for building in into the distribution board. Light diodes on the front side of

the device indicates the operating situations of the damper and breakdowns of the whole system.

Tab. 3.3.1. Communication and Control Device BKS 24-1B

Communication and Control Device

BKS 24-1B

Nominal voltage AC 24 V 50/60Hz

Power consumption 2,5 W (operating position)

Dimensioning 5 VA

Protection Class III (safe small voltage)

Degree of protection IP 30

Ambient Temperature 0 … + 50 °C

Connection

Fig. 8 Communication and control device BKS 24-1B

Into ZSO-11 connector which is not a part of BKS 24-1B.

ZSO-11 connector has screw terminals 11 x 1,5 mm

AC 24 V

~

Connection through

an insulation

transformer

Control

switched

/off

on

Reset

Test

External buton

optional

10

BKS24-1B

2

AC

24V

1

5

6

damper position

4

breakdown

failure

3

damper position

7

operation

8

2

conection can

be interchanged

2-conductor wiring

to BKN230-24

Notice: Relay contacts are drawn

without power

Signals and diagnosis

light diodes contacts

open closed

closed

open

closed

closed

closed

closed

flashing

open

closed closed

open open

closed

closed

flashing

open

closed

closed

alarm

flashing

open

closed

closed

closed

closed

state

6

6 3

6

6

6 4

6

6 7

6

a

9

b

11

Power supply AC 24V

3

Check test cca 35sec

«Reset/Test» button

Current failure,

or damper failure (at BKN..) • Power supply AC 230V missing • defective

3

thermoelectrical starting • smoke detector activated • exceeded operation time

• damper blocked

Failure saved in memory

3

done

Damper (drive) turning into

Damper (drive) in

4

Damper (drive) turning into

Damper (drive) in

7

not available

, starting with switching AC 24 on or pressing

possible cause: • short circuit or interruption of 2-conductor wiring

breakdown position

operating position

Reset

Test

Description

Cause/Course

• Fault in system signalled, system check should be

the direction

the direction

open

closed

alarm

of breakdown position

of operating position

8

Loading...

Loading...