1

1. Description.........................................................................................................................

2

2. Damper Design..….............................................................................................................

3

3. Dimensions, weights...........................................................................................................

4

4. Placement and Assembly....................................................................................................

5

5. Statement of installations....................................................................................................

7

6. Pressure loss and noise data..............................….............................................................

13

7. Coefficient of local pressure loss.......................................................................................

14

8. Material............................................................................................................................. 15

9 Inspection, testing............................................................................................................. 15

15

10. Logistic terms....................................................................................................................

15

11. Assembly..........................................................................................................................

15

12. Entry into service and revisions.........................................................................................

16

13. Data label..........................................................................................................................

16

14 Quick review.....................................................................................................................

16

17

15. Ordering key.................................................................................................................….

17

These technical specifications state a row of manufactured sizes and models of fire dampers (further only dampers)

CFDM. It is valid for production, designing, ordering, delivery, assembly and operation.

2

Fire dampers are shutters in duct systems of air-conditioning devices that prevent spreading the

fire and combustion products from one fire segment to the other one by means of closing the air

duct in the points of fire separating constructions.

Dampers blade automatically closes air duct using a shutting spring.

The damper is sealed with a plastic foam packing against smoke penetration after closing the

blade. At the same time, the damper blade is bedded in a material which enlarges its capacity

and air´proofs the air duct.

Damper characteristics

• CE certified acc. to EN 15650

• Tested in accordance with EN 1366-2

• Classified acc. to EN 13501-3+A1

• Fire resistance EIS 120, EIS 90, EIS 60

• Internal leakage class 2 acc. to EN 1751, external leakage is equal to ducting system

• Corrosion resistant acc. to EN 15650

• ES Certificate No. 1391-CPR-2016/0082

• Declaration of Perfomance No. PM/CFDM/01/16/1

Working conditions

Exact damper function is provided under the following conditions:

a) Maximum air circulation speed: 12 m.s

Maximum pressure difference: 1500 Pa

b) The air circulation in the whole damper section must be secured as steady on whole

surface.

Operation of the damper does not depend on the direction of air circulation. The dampers can

be located in an arbitrary position.

Dampers are suitable for ventilation systems, where air does not content any abrasive, chemical

or adhesive particles.

3

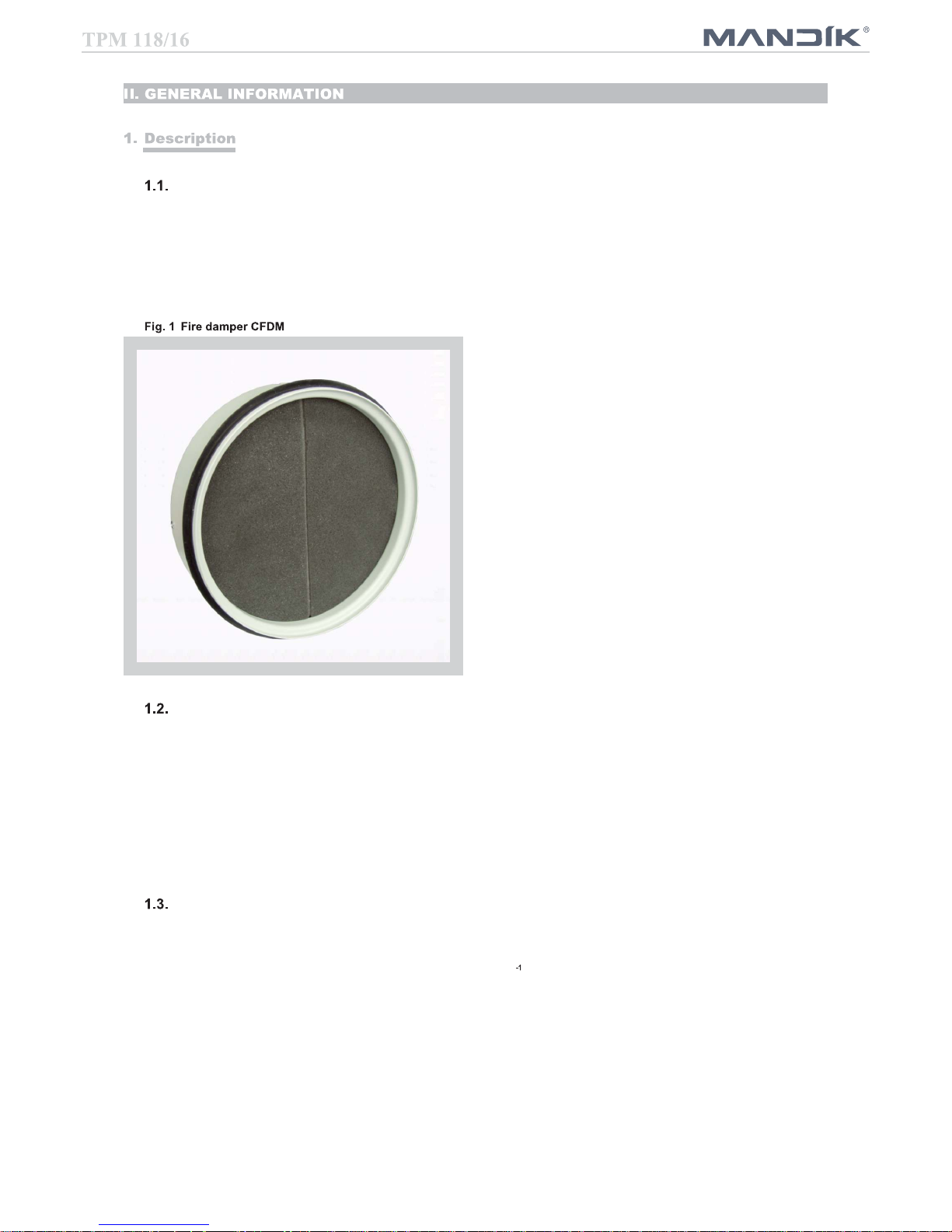

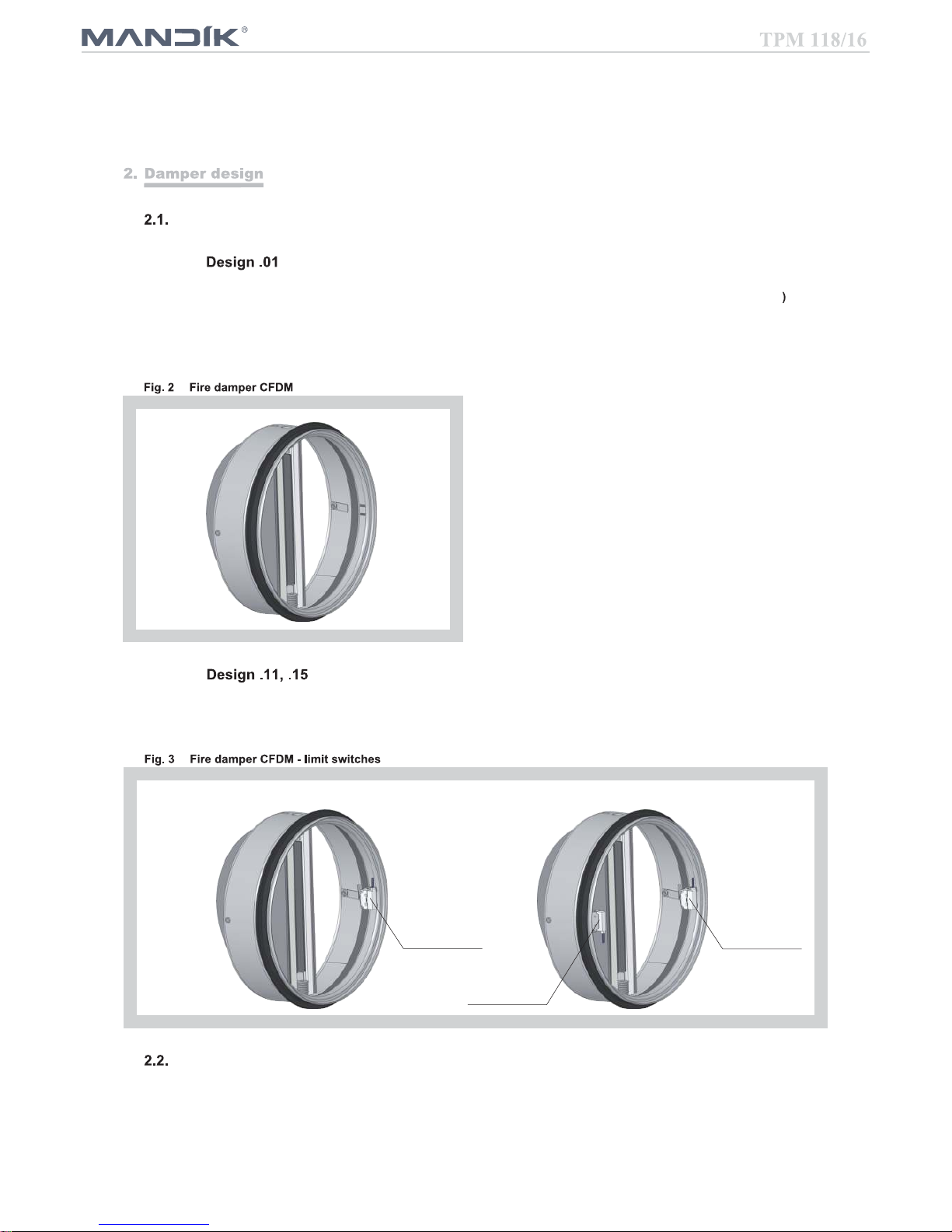

Design .01 with mechanical control can be equipped by one or two limit switches signalling

position of the damper blade "CLOSED". Limit switch is connected via duct.

Design .11 Design .15

Limit switch

“CLOSED”

Limit switch

“CLOSED”

Limit switch

“CLOSED”

Design according to fire resistance

● EIS 120

● EIS 90

● EIS 60

Dampers are designed for macroclimatic areas with mild climate according to EN 60 721-3-3.

Temperature in the place of installation is permitted to range from - 20°C to + 50°C.

Design with mechanical control

Design with mechanical control with a thermal protective fuse (inner mechanical control which

actuates the shutting device within 120 seconds at latest after the nominal start temperature

72 °C has been reached. Automatic initiation of the shutting device is not activated if the

temperature does not exceed 70 °C.

4

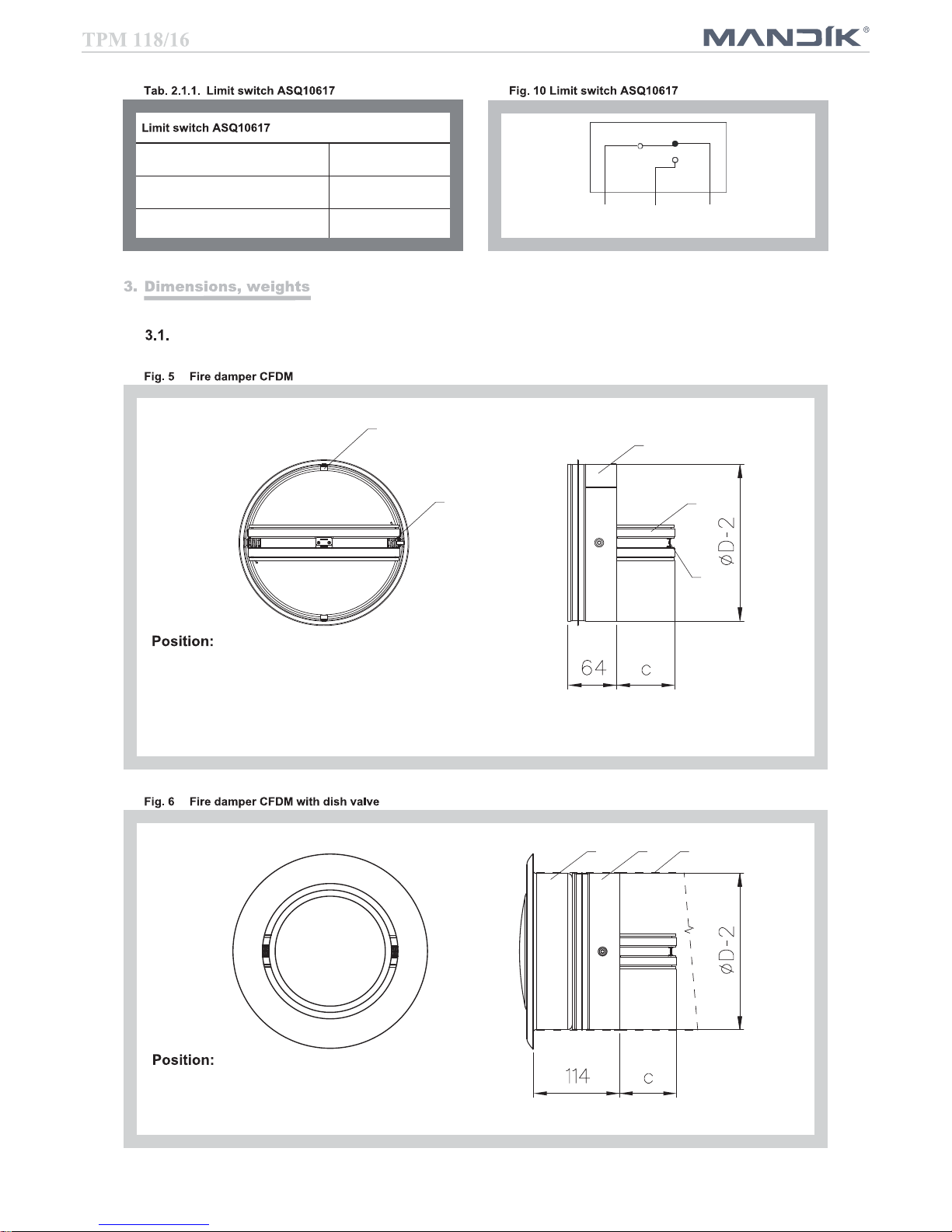

Dimensions

1 Damper casing

2 Damper blade

3 Shutting spring

4 Thermal fuse

5 Locking planchet

1 Fire damper CFDM

2 Dish valve

3 Duct

COM

black

NO

red

NC

white

Nominal voltage, current DC 30 V; 0,1 A

Degree of protection IP 67

Ambient temperature -40 °C … 85 °C

1

2

4

3

5

12 3

5

Weights and effective area

0,3 0,0027 15,5

0,4 0,0056 28

0,55 0,0115 45,5

0,75 0,0206 72,5

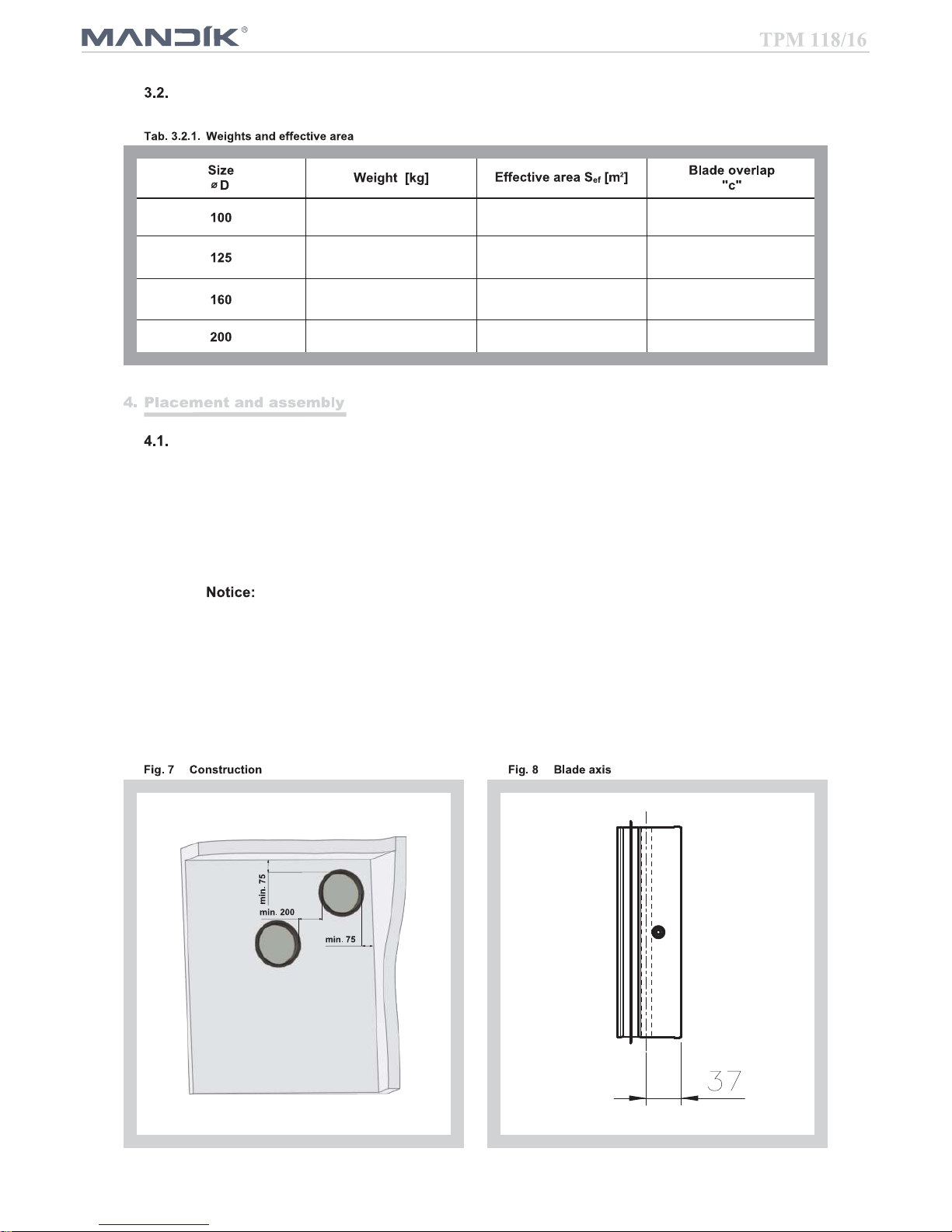

Fire dampers are suitable for installation in arbitrary position in vertical and horizontal passages

of fire separating constructions. Duct assembly procedures must be done so as all load transfer

from the fire separating constructions to the duct in the placement of fire damper installation is

absolutely excluded. Installation gap must be filled by approved material perfectly in all the

installation space volume (installation gap).

To provide needed access space to the control device, all other objects must be situated at least

350 mm from the control parts of the damper. Inspection hole must be accessible.

Damper has to be accessible for regular checks and maintenance.

Fire damper is inserted inside the duct. Blade has to be inside of fire separating

construction (after closing).

The distance between the fire damper and the construction (wall, ceiling) must be at least 75 mm.

In case that two or more dampers are supposed to be installed in one fire separating construction,

the distance between the adjacent dampers must be at least 200 mm according to EN 1366-2

paragraph 13.5.

6

Installation opening dimensions (see Fig. 9-11)

Examples of fire damper installing

The fire damper can be integrated into a solid wall construction made e.g. of normal concrete/

masonry, porous concrete with minimum thickness 100 mm or into solid ceiling construction made

e.g. of normal concrete with minimum thickness 110 mm or porous concrete with minimum

thickness 125 mm.

The fire damper can be integrated into a gypsum wall construction with fire classification

EI 120 or EI 90.

7

Wet mortar or gypsum 12

Dry

mineral wool boards with fire resistant

coating

13

Wet mortar or gypsum 14

Dry

mineral wool boards with fire resistant

coating

15

Wet mortar or gypsum 16

Dry

mineral wool boards with fire resistant

coating

17

Statement of installations the fire dampers CFDM

25

≥ 100

Position:

1 Fire damper CFDM

2 Solid wall construction

3 Mortar or gypsum

4 Duct

Make installation

Opening

Install duct in

the Opening

Fill gap Insert damper

in the duct

8

≥ 100

Position:

1 Fire damper CFDM

2 Solid wall construction

3

Fire resistant board

4

Fire stop coating thickness 1 mm

5 Glass fiber felt with aluminium foil width

50 mm, thickness 5 mm

6 Duct

Used materials - example*:

3 - Hilti CFS-CT B 1S 140/50

4 - Hilti CFS-CT

* Fire resistant board and fire stop coating can be

replaced by another approved fire sealing system for

damper installation with equivalent material properties.

D+60 to 800

max. 1650

D+60 to 800

max. 2050

Make installation

Opening

Install duct in

the Opening

Fill gap and cover

duct by fire resistant

coating

Insert damper

in the duct

≥ 50

≥ 50

9

25

≥ 100

Position:

1 Fire damper CFDM

2 Solid wall construction

3 Mortar or gypsum

4 Duct

Installation opening has to be reinforced by

profile (UW, CW). Profil is fixed by screws

≥3,5 mm with corresponding length.

Distance between screws ≤200 mm.

Make installation

Opening

Install duct in

the Opening

Fill gap

Insert damper

in the duct

10

≥ 100

* Fire resistant board and fire stop coating can be

replaced by another approved fire sealing system for

damper installation with equivalent material properties.

D+60 to 800

max. 1650

D+60 to 800

max. 2050

Installation opening has to be reinforced by

profile (UW, CW). Profil is fixed by screws

≥3,5 mm with corresponding length.

Distance between screws ≤200 mm.

Make installation

Opening

Install duct in

the Opening

Fill gap and cover

duct by fire resistant

coating

Insert damper

in the duct

Position:

1 Fire damper CFDM

2 Gypsum wall construction

3

Fire resistant board

4

Fire stop coating thickness 1 mm

5 Glass fiber felt with aluminium foil width

50 mm, thickness 5 mm

6 Duct

Used materials - example*:

3 - Hilti CFS-CT B 1S 140/50

4 - Hilti CFS-CT

≥ 50

≥ 50

11

Position:

1 Fire damper CFDM

2 Solid wall construction

3 Mortar or gypsum

4 Duct

≥ 25

150*

Install duct in

the Opening

Insert damper

in the duct

Make installation

Opening

Fill gap

* min. 110 - Concrete/ min. 125 - Aerated concrete

12

150*

* min. 110 - Concrete/ min. 125 - Aerated concrete

* Fire resistant board and fire stop coating can be

replaced by another approved fire sealing system for

damper installation with equivalent material properties.

D+60 to 800

max. 2050

D+60 to 800

max. 1650

Make installation

Opening

Install duct in

the Opening

Fill gap and cover

duct by fire resistant

coating

Insert damper

in the duct

Position:

1 Fire damper CFDM

2 Ceiling wall construction

3

Fire resistant board

4

Fire stop coating thickness 1 mm

5 Glass fiber felt with aluminium foil width

50 mm, thickness 5 mm

6 Duct

Used materials - example*:

3 - Hilti CFS-CT B 1S 140/50

4 - Hilti CFS-CT

≥ 50

≥ 50

13

Install duct together with

construction edge

Insert damper in distance 50

mm from the edge in the duct

50

Insert valve housing in the duct

and screw to the construction

Insert valve in the housing

Pressure loss calculation

p

=

w

2

p [Pa] pressure loss

w [m.s ] air flow speed in nominal damper section

[kg.m ] air density

[-] coefficient of local pressure loss for the nominal damper section

(see Tab. 7.1.1.)

14

1,836 1,083 0,7407 0,4167

Given data Fire damper CFDM 200

V = 600 m .h

= 1,2 kg.m

Tab. 3.2.1. Sef = 0,0206 m

Calculation:

w [m.s ] = (V [m .h ] / 3600) / Sef [m ]

w = 8,09 m.s

Tab. 7.1.1. =

0,4167

Calculation: p = . . (w /2) = 0,4167 . 1,2 . (8,09 /2) = 16,4 Pa

Diagram 6.2.1. LWA =

52 dB

Determination of pressure loss by using diagram 9.2.1. = 1,2 kg.m and noise data

Coefficient of local pressure loss (-)

15

Damper casing are supplied in the design made of galvanized sheet without any other surface

finishing.

Damper blades are made of fire resistant asbestos free boards made of mineral fibres.

Damper controls are made of stainless steel with no other surface finish.

Springs are made of stainless steel.

Thermal protective fuses are made of sheet brass, thickness = 0,5 mm.

Fasteners are galvanized.

According to the customer's requirements damper casing can be finished by color acc. RAL.

The appliance is constructed and preset by the manufacturer, its operation is dependent on

proper installation and adjustment.

Dampers are transported by box freight vehicles without direct weather impact, there must not

occur any sharp shocks and ambient temperature must not exceed + 40 °C. Dampers must be

protected against mechanic damages when transported and manipulated. During transportation,

the damper blade must be in the "CLOSED" position.

Dampers are stored indoor in environment without any aggressive vapours, gases or dust. Indoor

temperature must be in the range from -5 °C to +40 °C and maximum relative humidity 80 %.

Dampers must be protected against mechanic damages when transported and manipulated.

All effective safety standards and directives must be observed during fire damper assembly.

To ensure reliable fire damper function it is necessary to avoid blocking the closing mechanism

and contact surfaces with collected dust, fibre and sticky materials and solvents.

Before entering the dampers into operation after their assembly and by sequential checks, the

following checks must be carried out.

Visual inspection of proper damper integration, inside damper area, damper blade, contact

surfaces and silicon sealing.

16

It is recommended to provide periodical checks, maintenance and service actions on Fire

Equipment by Authorized persons schooled by Producer.

Data label is placed on the casing of fire damper.

EI90 (ve, ho-i o)S

Dobříšská 550

267 24 Hostomice

MANDÍK, a.s.

Czech Republic

1391

Požární klapka / Fire damper /

Klasifikace / Classification / Feuerwiederstand / Classification

Rozměr / Size / Grösse / Taille

Výr. číslo / Serial number / Fert. Nr. / Numéro de serie

SAMPLE

Provedení / Design / Ausführung / Conception

.01

Certifikace / Certificate / Zulassungs-Nr. / Certifikat

Hmotnost / Weight / Gewicht / Poids

1391-CPD-2016/0082

16

200

0,5

EN 15650:2010

TPM 118/16

Brandschutzklappe / Clapet coupe-feu

100 Mortar or gypsum

EIS 120

EIS 90

EIS 60

12

100

Mineral wool boards with fire resistant

coating

EIS 90

EIS 60

13

100 Mortar or gypsum

EIS 120

EIS 90

EIS 60

14

100

Mineral wool boards with fire resistant

coating

EIS 90

EIS 60

15

150 Mortar or gypsum

EIS 90

EIS 60

16

150

Mineral wool boards with fire resistant

coating

EIS 90

EIS 60

17

17

Thermal with inner mechanical control .01

Thermal with inner mechanical control and limit switch („CLOSED“) .11

Thermal with inner mechanical control and two limit switches („CLOSED“) .15

technical specifications

TVO - disch valve outlet

TVP - disch valve inlet

60 - EIS60

90 - EIS90

120 - EIS120

design acc. Tab. 17.1.1.

size

type

18

The producer reserves the right for innovations of the product. For actual product information see

www.mandik.com

MANDÍK, a.s.

Dobříšská 550

26724 Hostomice

Czech Republic

Tel.: +420 311 706 706

Fax: +420 311 584 810, 311 584 38

E-Mail: mandik@mandik.cz

www.mandik.com

Loading...

Loading...