Mandam Hybro 3, Hybro 6, 0 H, Hybro 4, Hybro 8 Instruction Manual

P.P.H. MANDAM Sp. z o.o.

ul. Toruńska 2 44-100 Gliwice, Poland

e-mail: mandam@mandam.com.pl

Tel.: 032 232 26 60 Fax: 032 232 58 85

NIP (VAT no.): 648 000 16 74

REGON (Registration no.): P – 008173131

INSTRUCTION MANUAL

HYBRO weeder

1

CE DECLARATION OF CONFORMITY

FOR A MACHINE

Pursuant to the Ordinance of the Ministry of Economy of 21 October 2008 (Journal of Laws No. 199,

item 1228) and the Directive of the European Union no. 2006/42/EC of 17 May 2006

Przedsiębiorstwo Produkcyjno-Handlowe „MANDAM” Sp. z o.o.

ul. Toruńska 2

44-100 Gliwice, Poland

hereby declares at its sole responsibility that the following machine:

under this declaration, complies with:

the Ordinance of the Ministry of Economy of 21 October 2008 on fundamental

requirements for machinery (Journal of Laws No. 199, item 1228)

and the Directive of the European Union 2006/42/EC of 17 May 2006.

The persons responsible for the technical documentation for the machine:

Jarosław Kudlek, Łukasz Jakus,

ul. Toruńska 2, 44-100 Gliwice, Poland

For assessment of compliance the following standards have been applied:

PN-EN ISO 13857:2010,

PN-EN ISO 4254-1:2009,

PN-EN ISO 12100-1:2005/A1:2009,

PN-EN ISO 12100-2:2005/A1:2009

PN-EN 982+A1:2008

This EC Declaration of Conformity shall be cancelled

if the machine is modified or redesigned without consent of the manufacturer.

Gliwice, 18 April 2014 ………………………………………

Place and date of issue Surname, first name, position

and signature of the

authorised person

HYBRO WEEDER

type/model: ……………………………..

year of manufacture: ……………………

serial number: …………………………..

2

Table of Contents

1. SAFETY SIGNS AND INSCRIPTIONS ............................................................ 3

1.1. SAFETY SIGNS AND INSCRIPTIONS ..................................................... 4

1.2. Hybro weeder design ................................................................... 6

2. Intended use of the Hybro weeder .......................................................... 7

3. General safety information ................................................................... 8

3.1. Attaching the tractor ................................................................... 8

3.2. Hydraulic system ........................................................................ 9

3.3. Transport on public roads .............................................................. 9

3.4. Description of residual risk ........................................................... 10

3.5. Residual risk assessment .............................................................. 10

4. General operation instructions ............................................................. 10

4.1. Before using the Hybro weeder ...................................................... 11

4.2. Adjustments ............................................................................. 12

4.3. Protection of the hydraulic system .................................................. 13

4.4. Operating the Hybro weeder ......................................................... 14

4.5. Maintenance............................................................................. 14

4.6. Replacement procedures .............................................................. 16

5. Storage ......................................................................................... 16

6. Transport ....................................................................................... 16

7. Disassembly and withdrawal from service ................................................ 17

8. Technical data of the Hybro weeder ....................................................... 18

9. General warranty terms ..................................................................... 19

Warranty card .................................................................................... 20

3

1. Introduction

Congratulations on your purchase of the HYBRO weeder.

This instruction manual contains the information on hazards that may occur during work

with the device, technical data and the most important guidelines and

recommendations to be known and applied to ensure a proper operation. Keep this

manual for future reference. Should you have any problems with understanding any

statement in the instruction manual, please contact the manufacturer.

The following mark indicates the guidelines that are important due to safety reasons:

The machine is provided with a name plate to be found on the main frame. The name

plate presents basic data allowing the identification of the machine:

Type Number

Weight Year of manufacture

The warranty for the HYBRO weeder is valid for 24 months and runs from the date of

sale.

The warranty card can be found at the end of the manual.

The warranty card constitutes an integral part of the machine.

Whenever you request any information on spare parts, provide the serial number.

For more information on spare parts:

• please visit our website at: http://mandam.com.pl/parts/

• or call us at +48 668 662 239

• e-mail: czesci@mandam.com.pl

Machine identification

Identification data of the HYBRO weeder, including basic information on the

manufacturer and the machine and CE marking, can be found on the rating plates placed

on the load-bearing frame.

4

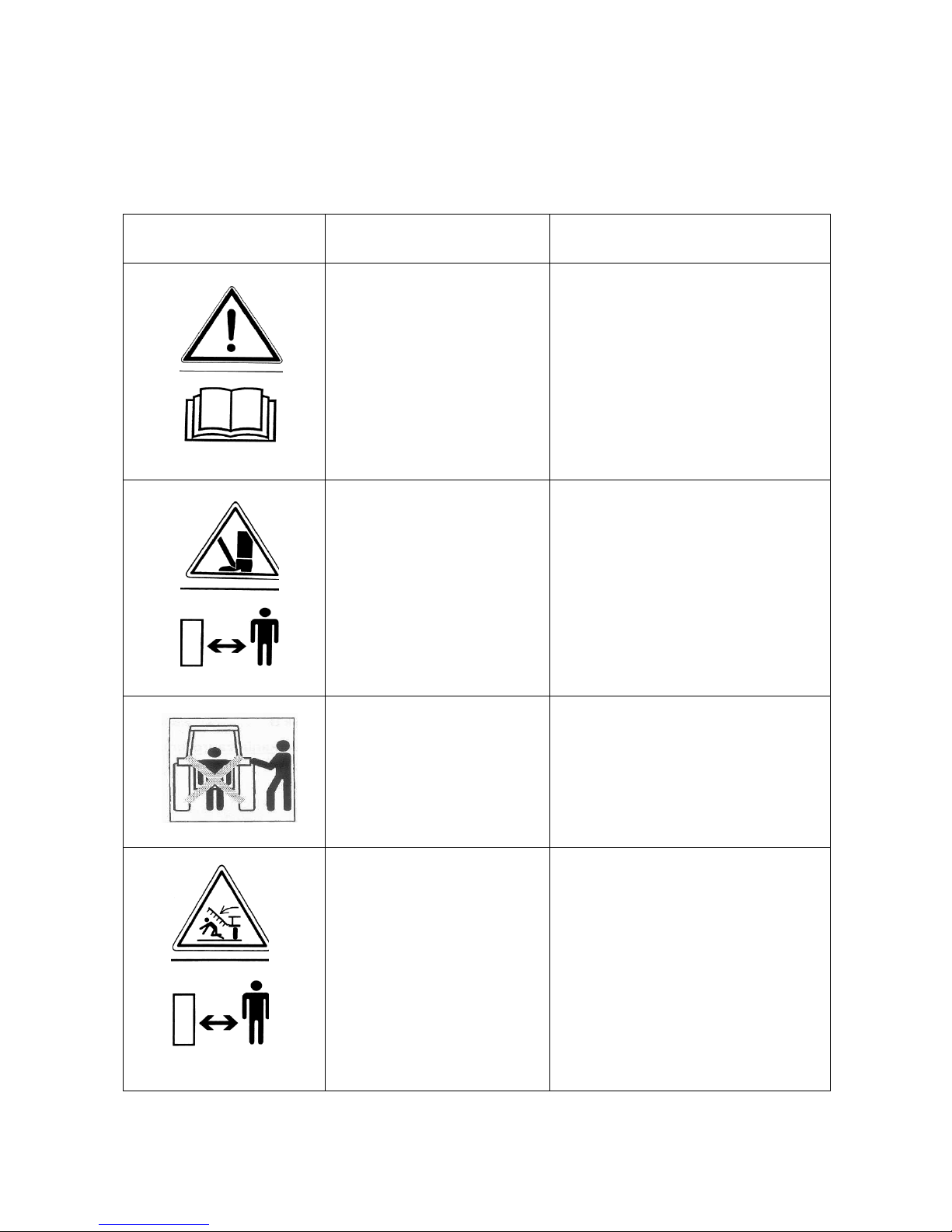

1.1 SAFETY SIGNS AND INSCRIPTIONS

The following signs and inscriptions can be found on the machine. Protect the signs and

safety inscriptions so that they cannot be lost or become illegible.

If lost or illegible, replace the signs and inscriptions with new ones.

Table 1. Information and warning signs

Safety sign

Meaning of the safety sign

Location on the machine

Read the instruction

manual prior to

operating the

machine.

Weeder frame adjacent to

the mounting of the upper

fastener

Danger of toe or foot crush

Weeder frame adjacent to

the mounting of the upper

fastener

Keep clear from lift bars

while controlling the lift

Weeder frame adjacent to

the mounting of the upper

fastener

Keep clear from foldable

and moving parts of the

machine

Front part of the mid frame

adjacent to side frames

5

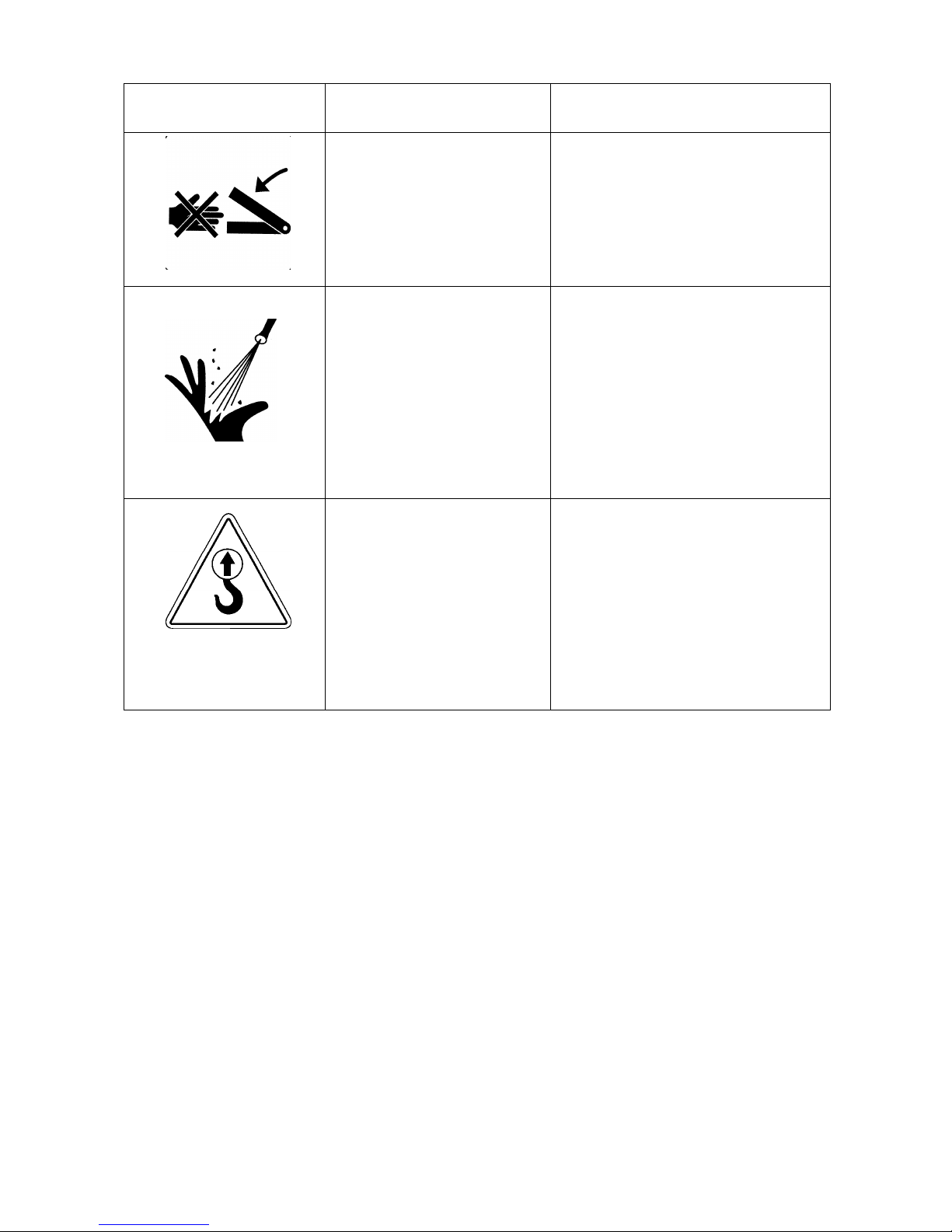

Safety sign

Meaning of the safety sign

Location on the machine

Do not reach into the

crushing zone if the

elements can move

Mid frame adjacent to side frames

Liquid jet under pressure –

injury

Cylinders

Fixing point for

transport belts

Upper part of the drawbar (upper

fastener bolt)

Rear part of the frame:

• rigid frame (adjacent to

the roller depth

adjustment)

• foldable frame (adjacent

to the upper fastener

bolt on the mid frame)

6

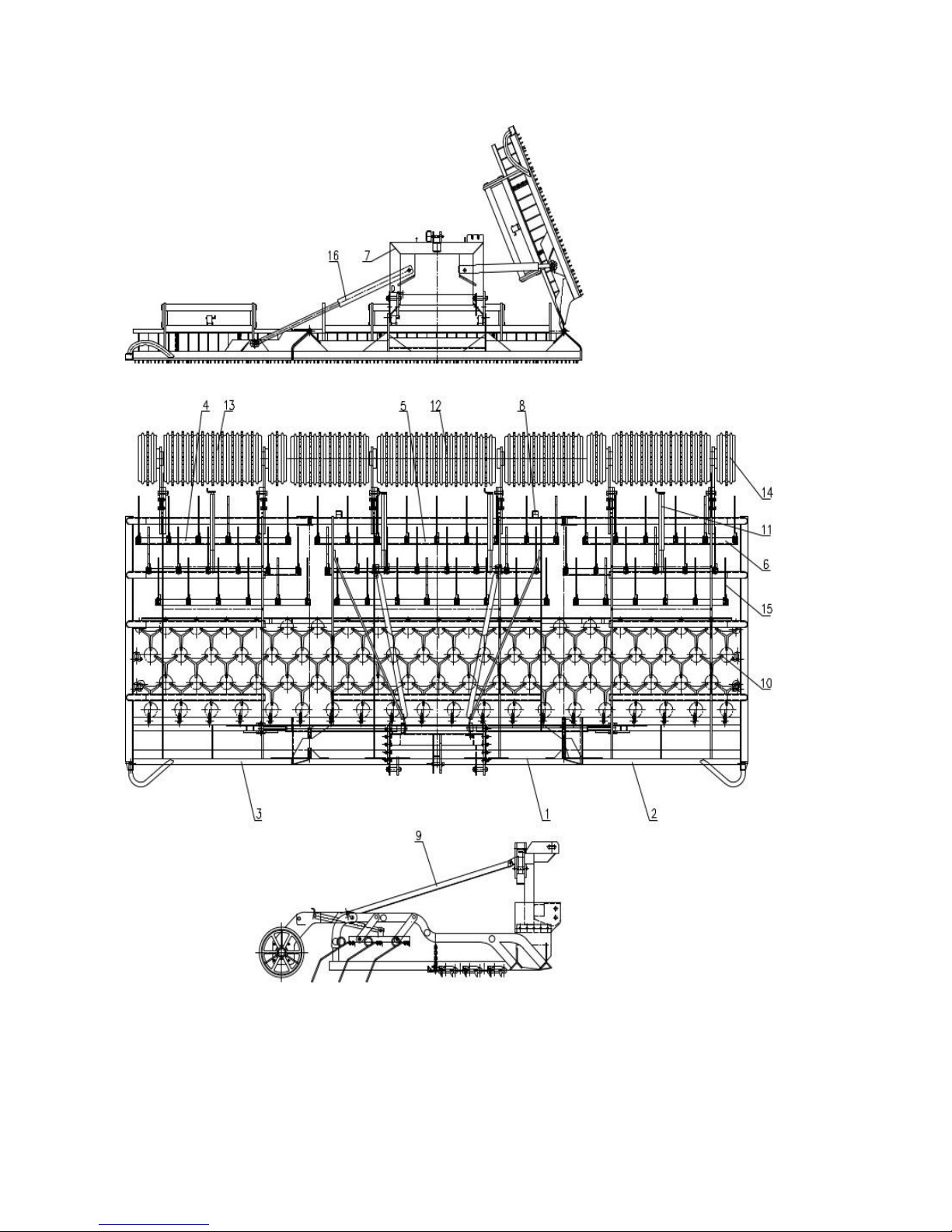

1.2. Hybro weeder design

Fig. 1 Design of the HYBRO weeder: 1 - central frame, 2 - right side frame, 3 - left side

frame, 4 - right side tool section, 5 - central tool section, 6 - left side tool section, 7 drawbar, 8 - foot, 9 - strip, 10 - weeder grid, 11 - section adjustment mechanism, 12 central cast iron shaft Ø525, 13 - right side cast iron shaft Ø525, 14 - left side cast iron

shaft Ø525, 15 - spring tine, 16 - hydraulics

Loading...

Loading...