Manaras Opera-MH, Opera-MJ Installation Manual

r

r

r

r

IInnssttaallllaattiioon

O

p

O

p

Read this manual carefully before

Note:

installing the operator and place this installation

manual in an accessible place near the

operator. For future reference record:

Model #

Date

Wiring Diagram #

Serial #

Project No.

Project Name

Door No. #

e

e

n

& IInnssttrruuccttiioonn

&

a--

a

M

M

H

H

O

O

Maannuuaall

M

p

p

e

e

a--

a

M

M

TM

J

J

®

2

IMPORTANT SAFETY INSTRUCTIONS

WARNING

TO REDUCE THE RISK OF SEVERE INJURY OR DEATH, READ AND FOLLOW ALL INSTRUCTIONS

1. Never allow children to operate or play with or near door.

2. Check to see that the operator is correct for the type, size of door and frequency of use per the

operator specifications.

3. If the door system is near a residential area, or pedestrian traffic is expected near the door system,

additional equipment such as electric reversing edges, photocells, or similar devices must be installed

as part of the system to prevent entrapment.

4. Reversing devices appropriate to the application must be installed as part of the system.

5. Outdoor or easily accessible controls must be of the security type to prevent unauthorized use of the

system.

6. Place controls far enough from the door so that a user cannot touch the door when operating the

controls.

7. Controls should be placed so the user has full view of the door when operating.

8. Always keep moving door in sight and away from people or vehicles until it is completely opened or

closed. NO ONE SHOULD CROSS THE PATH OF THE MOVING DOOR.

9. If a person is trapped under the door, push the "OPEN" control button.

10. Do not overtighten a clutch to compensate for a damaged door.

11. Test door and service monthly. After adjusting the limit travel, retest the door opener. Failure to adjust

the door may cause death or injury.

12. KEEP DOORS PROPERLY BALANCED. See door owner's manual. An improperly balanced door

could cause severe injury. Have a qualified service person make repairs to cables, spring assemblies

and other hardware.

13. If possible, use the emergency release only when the door is closed. Use caution when using this

release with the door open. Weak or broken springs may cause the door to fall rapidly, causing injury

or death.

14. You are responsible for assuring that the owner of the door system understands its basic operation and

safety. In particular, be sure the owner/end-user understands the location and operation of the manual

disconnect.

15. Point out to the owner/end-user of the door system that children or pets should not be allowed to play

on or near the door or any part of the system, and that the safety instructions supplied with this

operator are the responsibility of the owner/end-user.

16. Leave the installation and maintenance manual for this operator as well as any additional information

supplied with this operator or other components of the door system with the owner/end-user.

17. If you have any question about the safety of the door operating system, do not install the operator,

contact us.

WARNING

DO NOT CONNECT POWER SUPPLY WHILE INSTALLING, SERVICING OR ADJUSTING THE ELECTRIC

NOT APPLICABLE FOR RESIDENTIAL USE. ONLY FOR INDUSTRIAL AND COMMERCIAL APPLICATIONS

OPERATOR

WARNING

3

TABLE OF CONTENTS

Page

GENERAL PARTS & SPECIFICATIONS ..................................................................................................4

WEIGHT AND DIMENSIONS .................................................................................................................... 4

PRODUCT APPLICATION.........................................................................................................................5

DELIVERY OF OPERATOR ...................................................................................................................... 5

HARDWARE .............................................................................................................................................. 5

INSTALLATION.....................................................................................................................................6-10

LIMIT SWITCHES ...............................................................................................................................10-11

SUGGESTED WIRE SIZE .......................................................................................................................11

WIRING OF AN Opera........................................................................................................................12-13

B2/C2 WIRING.........................................................................................................................................14

OPTIONAL CONTROL ACCESSORIES ................................................................................................. 15

CONNECTION OF SAFETY EDGE.........................................................................................................16

CLUTCH ADJUSTMENT .........................................................................................................................16

OPERATOR START-UP AND TESTING GUIDE ....................................................................................18

TROUBLESHOOTING GUIDE ...........................................................................................................18-20

SCHEDULED MAINTENANCE................................................................................................................21

Opera-MH exploded view.........................................................................................................................22

Opera-MJ exploded view .........................................................................................................................23

Opera-MH/MJ STANDARD ELECTRICAL DIAGRAM ............................................................................24

Opera-MH/MJ STANDARD ELECTRICAL DIAGRAM………………………………………………………..25

WARRANTY……………………………………………………………………………………………………….26

NOTES ....................................................................................................................................................27

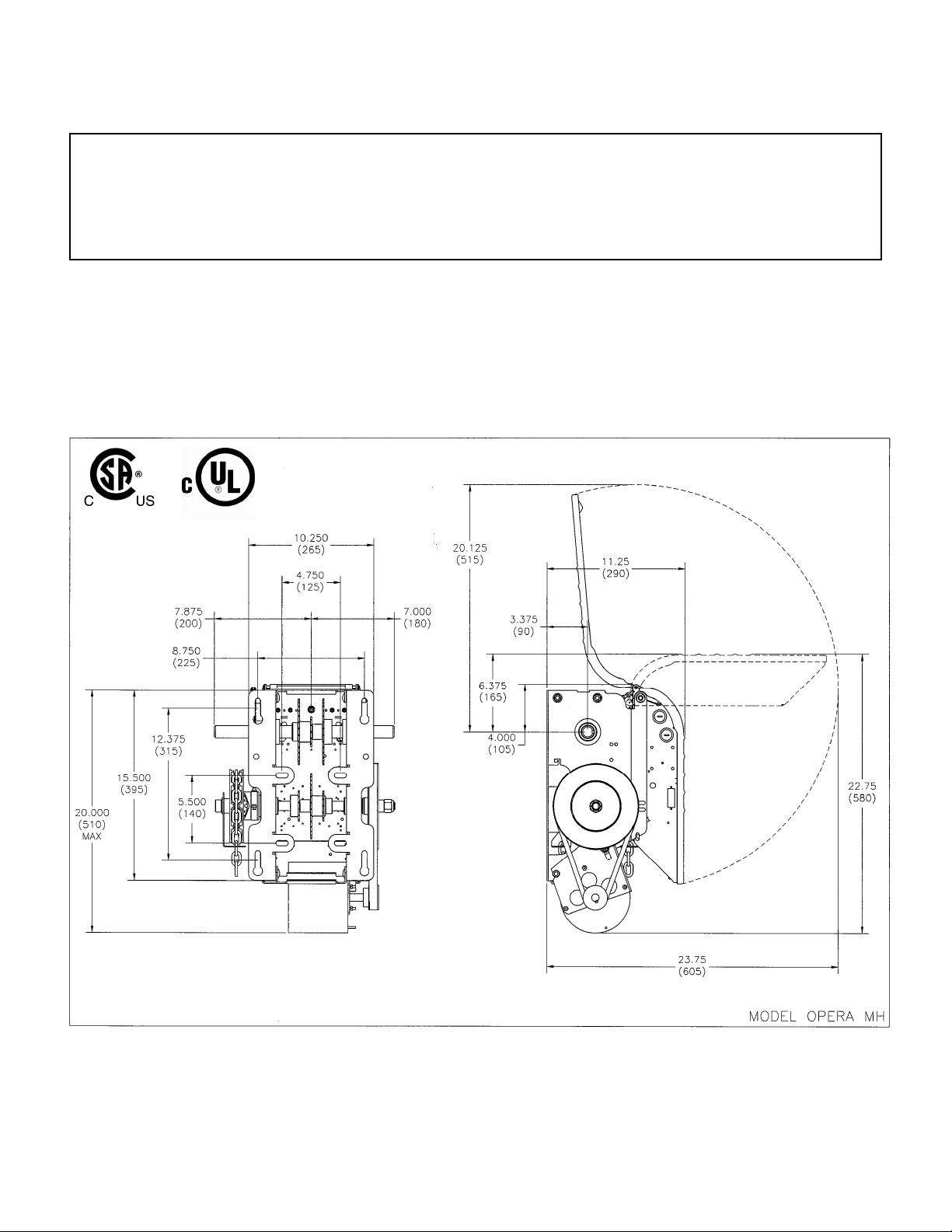

4

SPECIFICATIONS

GENERAL

SUPPLY VOLTAGE………………….. 115 VAC single phase

CONTROL VOLTAGE………………. 24VAC class 2 transformer, 2 amp fuse type ACG

MOTOR………………………………. Intermittent duty ½ Horsepower

OPERATOR OUTPUT SPEED……… 39 RPM

NET WEIGHT (Operator only)……… 71 Lbs (33 Kg) for Opera-MH and 61lbs (28 Kg) for Opera-MJ

STANDARD WIRING TYPE………… C2-momentary contact to open and stop and constant pressure to close

DIMENSIONS

(Opera-MH)

OPERA: MEDIUM DUTY JACKSHAFT OPERATOR

5

IMPORTANT: UPON COMPLETION OF OPERATOR INSTALLATION THIS MANUAL MUST BE GIVEN

TO THE END-USER.

1. PRODUCT APPLICATION

The model OPERA medium duty jackshaft operator is designed for use on commercial or industrial doors

of all types provided that the door has a shaft as basic driving element (sectional doors with high lift, vertical

lift, small rolling doors and grilles). All OPERA door operators are designed and constructed in accordance

with UL325 Standard, and certified by CSA Laboratories.

2. DELIVERY OF OPERATOR

Upon delivery of your medium duty jackshaft operator OPERA, inspect the unit immediately for shipping

damage. Verify that you have received all the hardware parts mentioned in TABLE 1 and shown in Figure 1.

Other items may be present, such as radio controls or other types of optional equipment, if ordered. If any

item is missing or if there is evidence of damage, call the transport company first.

* Check to make sure that the available power supply to be connected to the operator is of the same voltage,

frequency, phase and amperage as indicated on the nameplate of the operator.

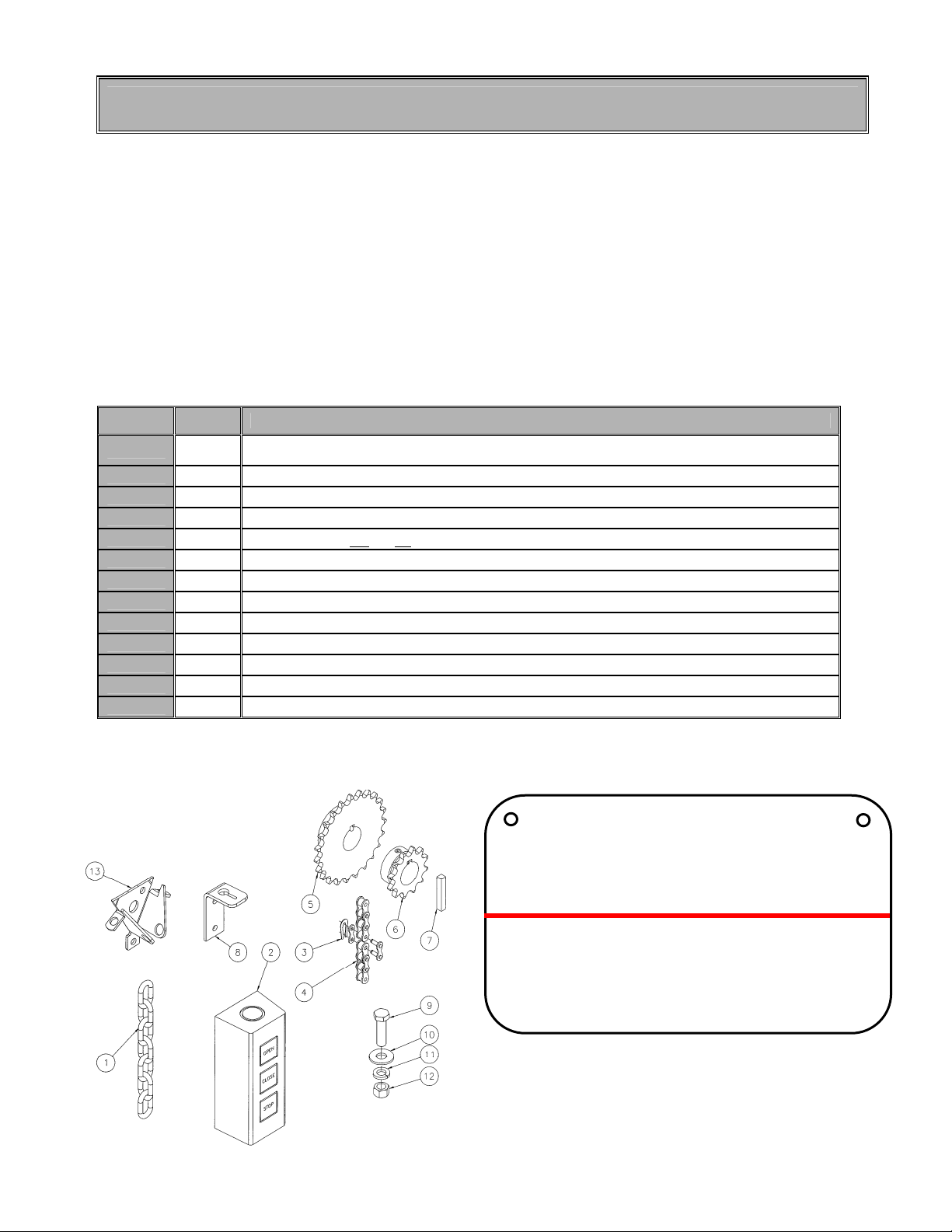

3. HARDWARE

TABLE 1 STANDARD PARTS LIST FOR OPERA JACKSHAFT OPERATOR

PART # QTY DESCRIPTION

1 1

2 1 3-button open/close/stop push-button station

3 1 #41 connecting link

4 1 #41 roller chain x 4'(1.2m) or x 5’ when sprocket is 42 teeth or more.

5 1

6 1

7 1 Square shaft key 1/4" x 1-1/2" L for OPERATM output shaft

8 1 Chain keeper for Opera-MJ only

9 4 3/8" x 1-1/4" bolts

10 4 3/8" washers

11 4 3/8" lock washers

12 4 3/8" nuts

13 1 Chain keeper for Opera-MH only

** See SPECIFICATIONS, DOOR SPEED AND AVAILABLE DOOR ADJUSTMENT

Pocket wheel hand chain (2X door shaft less 4 ft. (1.2m)) for Opera-MH or disconnect chain

(14’) for Opera-MJ

** Sprocket 41B

Sprocket 41B12 x 1,0 " c/w set screws for OPERA

x " c/w set screws for door shaft

TM

output shaft

WARNING

TO PREVENT ENTRAPMENT,

DO NOT START DOOR DOWN UNLESS

DOORWAY IS CLEAR

AVERTISSEMENT

POUR ÉVITER TOUT COINCEMENT, NE

PAS ABAISSER LA PORTE TANT

QUE L’EMBRASURE N’EST PAS LIBRE.

Ensure that the Warning tag supplied with

the operator is properly fixed on the door

and it is visible while the door is moving

Figure 1 Hardware and Warning Tag

6

4. INSTALLATION

All medium duty OPERA jackshaft operators are tested and adjusted at the factory. When installing your

unit, please note that the cams are resting in the center of the cam-shaft.

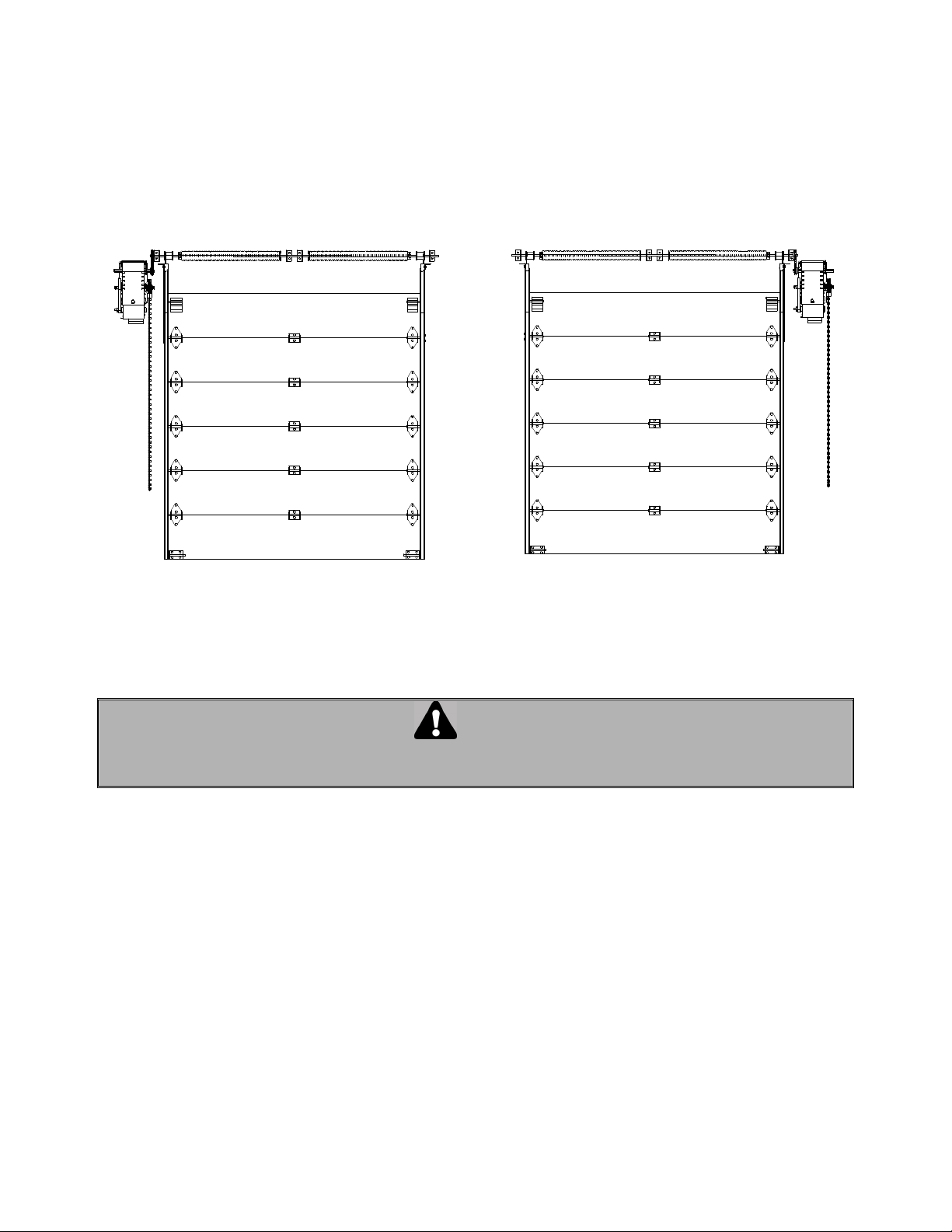

The OPERA operator has a dual output shaft and may be mounted on either the left or right hand side of

a sectional door (see Figure 2 and Figure 3). Place sprocket on either the right or the left end of the

output shaft according to the desired handing.

The Opera-MH comes with a chain hoist located on the right of the operator. If handing requires the

chain hoist to be on the left (rolling doors, left operator hood mounting for ex.), it must be requested at the

time of ordering. Do not attempt to change handing of the chain yourself.

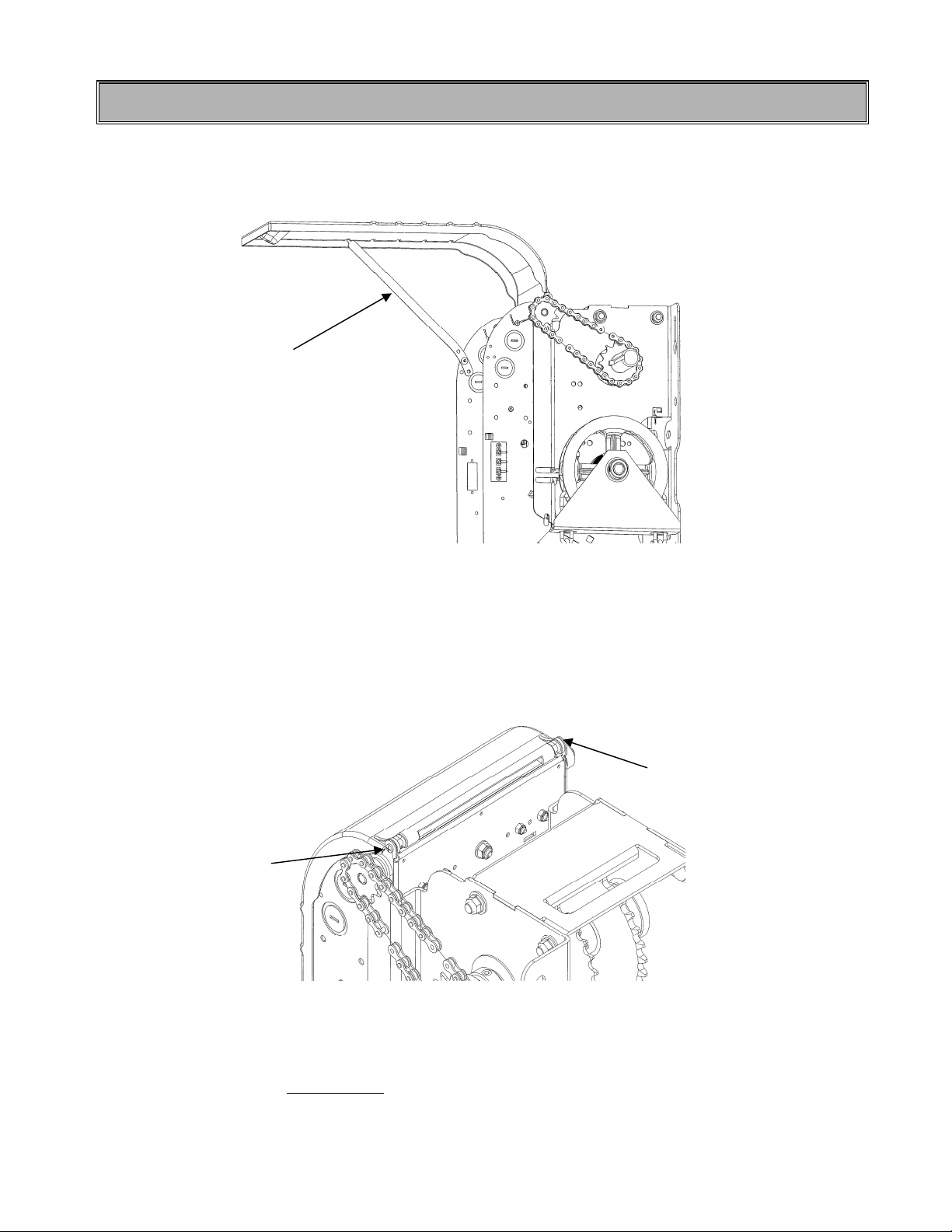

Figure 2 Left side Figure 3 Right side

4.1 IMPORTANT INSTALLATION INSTRUCTIONS

WARNING

TO REDUCE THE RISK OF SEVERE INJURY OR DEATH, READ AND FOLLOW ALL INSTALLATION

INSTRUCTIONS.

1. Installation of this door operator must be done by a qualified installer.

2. Insure that the door is properly installed and works freely in both directions. Do not install the

operator until all door problems have been corrected. If necessary, oil all moving parts (chains,

rollers, guides, etc.).

3. Remove all old accessories (locks, bolts, etc.) before installing door operator.

4. Do not connect the operator to a source of power until instructed to do so.

5. Locate control push-button station within sight of the door, at a minimum height of 5 ft. (1.5 m) so

small children cannot reach it, and away from all moving parts of the door.

7

4.2 INSTALLATION OF OPERA OPERATOR

IMPORTANT NOTE: THIS OPERATOR MUST BE INSTALLED A MINIMUM OF 8 FT. (2.4 m) ABOVE FLOOR.

The OPERA has two sets of mounting holes: outside the frame for wall mounting and inside the frame for

hood mounting.

To open the control box cover, loosen the screw at the base of the cover. If the cover cannot be fully

opened, the retaining arm may be used to hold the cover in other positions (Figure 4).

Retaining

arm

Figure 4 Control box cover opening

After installation, verify that there is no obstacle in the way when opening the control box cover. If so, it is

possible to remove the cover by unscrewing it from the box before putting the operator on the wall or

hood (see Figure 5).

Remove the screw

Remove the screw

Figure 5 Unscrewing the cover from the control box

Locate the four mounting holes. The optimum distance between the door shaft and operator drive shaft is

between 12" and 15". Mount the OPERA unit by fastening it to the wall, bench or hood with 3/8" or 1/2"

thru-bolts or if the wall is of such construction so as to prohibit use of thru-bolts, lag bolts and shields of

sufficient size may be used. Do not tighten.

8

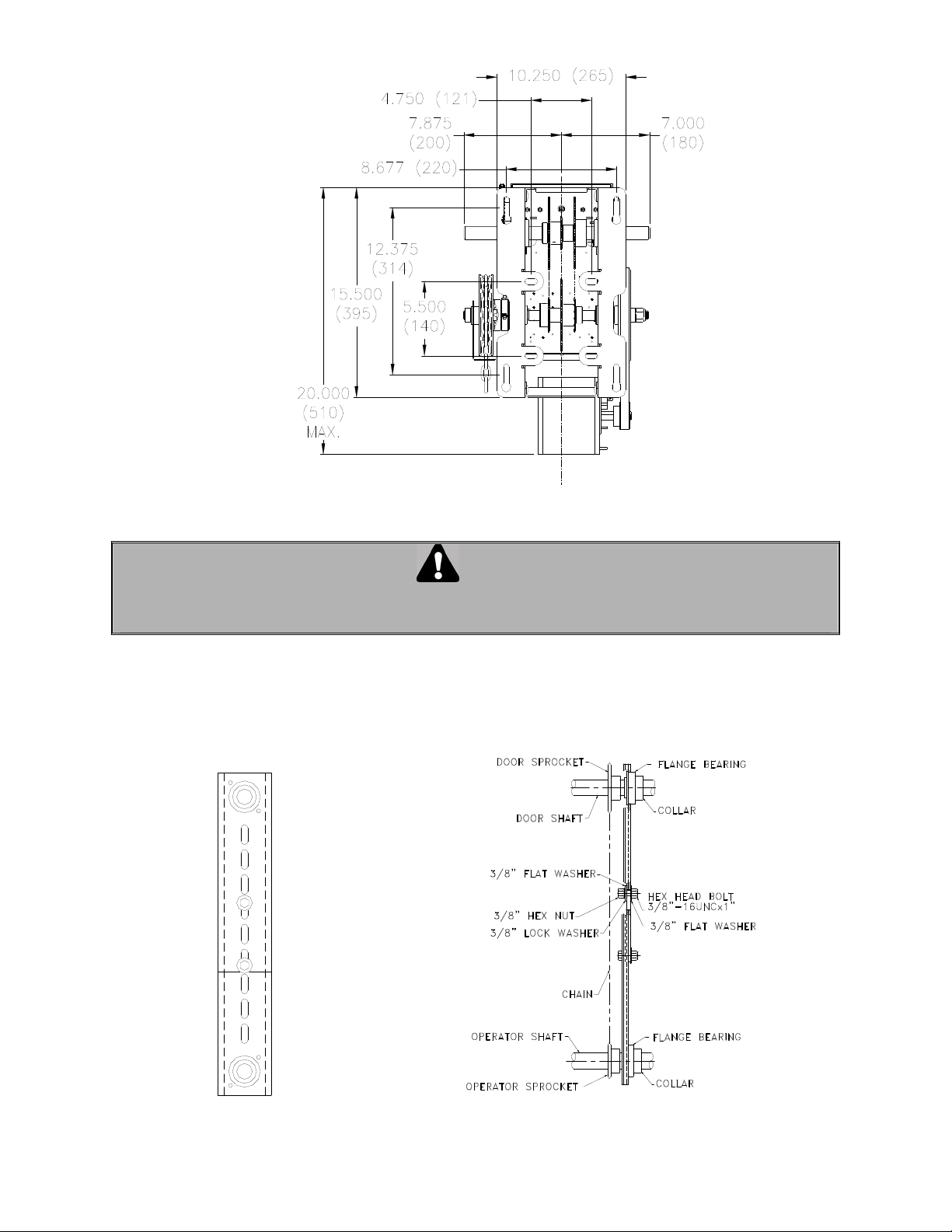

Figure 6 Mounting dimensions for wall or hood

CAUTION

MAKE CERTAIN THAT OPERATOR IS PERFECTLY ALIGNED WITH DOOR SHAFT OTHERWISE

DAMAGE CAN OCCUR

1. Place the driven sprocket on the door shaft loosely and align it with the drive sprocket of the

operator.

NOTE: If a chain spreader has been ordered along with your operator, see Figure 7 and Figure

8 below for installation.

Figure 7 Chain spreader Figure 8 Chain spreader mounted on door and

operator shafts

9

2. Lock the drive and driven sprockets in place by inserting the keys and tightening their respective set

screws.

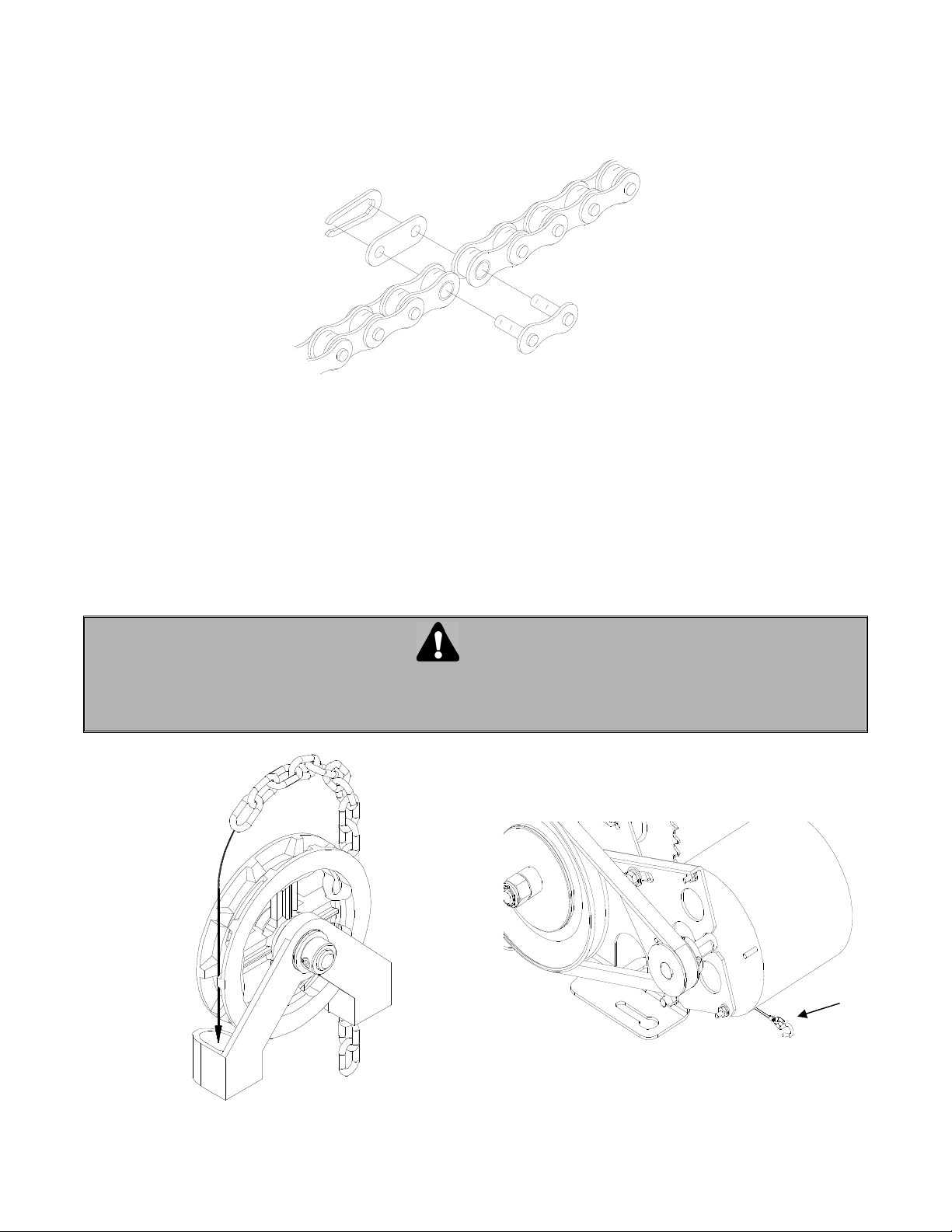

3. Connect the sprockets with the drive chain, shorten to a suitable length and join together with the chain

link provided in the hardware bag. To shorten the chain, punch out the pin that will leave an inside link

nearest to the desired length. Connect the chain around the sprockets using the chain link (Figure 9).

Figure 9 Chain link

4. Slide the operator to tighten the drive chain and then firmly tighten the mounting bolts. Check the

tension on the chain and the set screws on the sprockets (there should be no more than 1/4" slack

when chain is depressed between sprockets

5. Opera-MH: run hand chain through the pocket wheel and through the chain guide outside the frame

(Figure 10A), allow both ends to hang down toward the ground and cut hand chain, if necessary, so

that both ends are approximately 2 feet (0.6 m) from floor. Connect both ends of hand chain.

6. Opera-MJ: link the disconnect chain at the key ring or hook located at the extremity of the disconnect

pull cable (Figure 10B) Place the Opera-MJ chain keeper so that, when pulled and engaged, the

disconnect chain keeps the machine ‘’disconnected’’ and in the manual position.

CAUTION

BEFORE PULLING HAND CHAIN THROUGH POCKET WHEEL OR LIFTING THE DOOR DIRECTLY BY HAND,

PULL CAM PLATE AND SPIN CAM NUTS TO CENTER OF LIMIT SHAFT SO AS TO BE SURE THE CAMS ARE

NOT BEING MECHANICALLY DRIVEN THROUGH THEIR NORMAL LIMIT SWITCH END POSITIONS.

Keyring

or

Hook

Figure 10 A. Installing hand chain on Opera-MH

Figure 10 B. Installing disconnect chain on Opera-MJ

Loading...

Loading...