MALMET ES915, ES935 User Manual

Serial Number:

Purchased from:

Date Installed:

Installed by:

Head Office and Customer Service

Email: info@malmet.com.au

ABN 95 001 717 791

9-11 McKay Avenue

PO Box 373

Leeton NSW 2705

Phone: +61 2 6953 7677

Bedpan / Urinal Bottle Washer

Disinfector

Models ES915, ES935

Detergent Models with Hands Free Operation

Operation, Maintenance and

Installation Manual

Note: Due to Malmet’s policy of continuous product improvement;

design and technical specifications are subject to change without notice.

It is important that the name from whom you purchased your device and the name of the installer are recorded above. The installer is

responsible for the correct installation, start up and demonstrating the operation of this device. They are also responsible for issuing relevant

certificates of compliance (these may differ from state to state).

Issue 3

Malmet Bedpan / Urinal Bottle Washer Disinfector (ES-D)

Detergent Model with Hands Free Operation

Operation, Maintenance and Installation Manual

Table of Contents

Foreword .............................................................................................................................................. 3

Quality Policy........................................................................................................................................ 3

Certifications ........................................................................................................................................ 3

Important Warranty Reminder ............................................................................................................ 3

Malmet Head Office and Factory Contact Details ............................................................................... 3

Safety Instructions - Warnings ............................................................................................................. 4

Design Parameters ............................................................................................................................... 5

Section A – Device Operation ............................................................................................................... 6

Hands Free Operation .......................................................................................................................... 6

Detergent ............................................................................................................................................. 7

Changing the Detergent Bottle ............................................................................................................ 8

Disposal of Empty Detergent Bottles ................................................................................................... 8

Loading Configurations ........................................................................................................................ 9

Cycle of Operation .............................................................................................................................. 11

Sequence of Operation ....................................................................................................................... 12

Display Board ..................................................................................................................................... 17

Section B – Device Maintenance ........................................................................................................ 18

Preventative Maintenance Schedule ................................................................................................. 18

Safety Checks ..................................................................................................................................... 20

Replacement of Safety Devices .......................................................................................................... 20

Fault Finding Guide ............................................................................................................................ 21

Appendix A – Faults ............................................................................................................................ 22

Appendix B – Additional Faults not detected by micro-processor ..................................................... 25

Electrical Diagram – 20 Amp Models (ES915) .................................................................................... 26

Electrical Diagram –10 Amp Models (ES935) .................................................................................... 27

Hydraulic Circuit Diagram ES915/935 ................................................................................................ 28

Section C – Device Installation ........................................................................................................... 29

Service Connections............................................................................................................................ 30

Dimensions and Service Entry Points ................................................................................................. 31

Electrical ............................................................................................................................................. 32

Post Installation Precautions ............................................................................................................. 33

Positioning of Bedpan Washer Disinfector ........................................................................................ 34

Installation and Service Connection Layout Details ........................................................................... 36

Plumbing ............................................................................................................................................ 37

Technical Specifications ..................................................................................................................... 37

Device Specifications .................................................................................................................... 38/39

Warranty Statement .......................................................................................................................... 39

Quick Reference Guide ....................................................................................................................... 43

Issue 3 Page 2 04/10/2019

Malmet Bedpan / Urinal Bottle Washer Disinfector (ES-D)

Detergent Model with Hands Free Operation

Operation, Maintenance and Installation Manual

Foreword

To obtain maximum life and efficiency from your Malmet Bedpan / Urinal Bottle Washer Disinfector and to

ensure safe operation, please read this manual thoroughly and follow all instructions before operating the

device.

This manual provides information on the operation of the device. It is recommended that all persons

operating the device have access to this manual for training purposes.

This unit is not intended for use by any person without the proper training, experience or knowledge.

The specifications supplied in this manual were in effect at the time of publication. However, owing to

Malmet (Australia)’s policy of continuous improvement, changes to these specifications may be made at

any time without notice on the part of Malmet (Australia).

Quality Policy

Malmet’s quality management system is certified to ISO 9001:2015 and ISO 13485:2016 and guarantees

the quality of this product.

Certifications

Electrical Safety: Cert No. CS10847N to IEC 61010-2-040, IEC 61010-1

EMC Compliance: Report T130119 to IEC 60601-1-2

Watermark: Cert No. WMKA21156

Important Warranty Reminder

Should you have any problems with your device, contact the company from whom you purchased it, or

Malmet (Australia) Pty Ltd.

It is important that the name from whom you purchased your device and the name of the installer are

recorded on the front page of this manual. The installer is responsible for the correct installation, start up

and demonstrating the operation of this device. They are also responsible for issuing relevant certificates

of compliance (these may differ from state to state).

Malmet Head Office and Factory Contact Details

Malmet (Australia) Pty Ltd

9-11 McKay Avenue

PO Box 373

LEETON NSW 2705

Telephone: +61 2 6953 7677

E-mail: info@malmet.com.au

Website: www.malmet.com.au

Issue 3 Page 3 04/10/2019

Malmet Bedpan / Urinal Bottle Washer Disinfector (ES-D)

Detergent Model with Hands Free Operation

Operation, Maintenance and Installation Manual

Safety Instructions - Warnings

Please read and understand this manual before using this device, if this device is used in a manner not

specified by the manufacturer protection by the device may be impaired.

Please refer to this manual for information wherever this warning symbol is displayed -

Be aware of 240V Voltage

Disconnect power when servicing

Mains power ISO switch or circuit-breaker must be in an

accessible position, easily reached and not obstructed so device

can be isolated from mains power during service

Only process items listed as per the design parameters in this

manual

Be aware of steam discharge

Goods and racks are hot to handle

Safety gloves and goggles must be worn when changing detergent

Safety clothing with reflective tape can activate the hands free

sensor when device is in standby mode

Be aware of hot surface, pipes and hoses from steam and hot

water

Install temperature probes and element over temperature

protection thermal cut-outs correctly

Plumbing service connection must comply with AS/NZS 3500

Issue 3 Page 4 04/10/2019

Malmet Bedpan / Urinal Bottle Washer Disinfector (ES-D)

Detergent Model with Hands Free Operation

Operation, Maintenance and Installation Manual

Design Parameters

The Malmet Bedpan / Urinal Bottle Washer Disinfector has been designed within the following parameters:

a) A single bedpan with lid and two urinal bottles can be emptied, cleaned and disinfected during each

automatic cycle.

The utensils that can be cleaned in the device are:-

i) Standard size bed pans

ii) Standard commode bowl

iii) Standard male and female urinal bottles

iv) Most plastic urinal bottles including male non-spill and female cervec

v) Small slipper pan

vi) Large slipper pan

b) The cradle is designed to ensure that utensils are not dislodged during the cleaning cycle; the contents

are emptied during door closure.

c) The chamber and door are self-cleaning and do not permit water or soil to remain after a properly

completed cycle. Steam disinfection ensures all internal surfaces are totally clean and safe.

d) The flush and clean stage:

i) Removes the soil

ii) Clears the trap

e) A complete cycle is completed in approximately four (4) minutes for the 20 Amp Bedpan /Urinal Bottle

Washer Disinfector and six (6) minutes and thirty (30) seconds for the 10 Amp Bedpan / Urinal Bottle

Washer Disinfector

Note: Dependant on ambient air temperature.

Note: The first cycle will take longer as the device has to reach the operating water temperature of

90˚C.

f) Malmet Door Obstruction Feature

This is factory set to 12Nm ±10%; causing the door to re-open when an obstruction is detected. This is

designed to protect the integrity of the device and the articles within.

Disconnect power when servicing

Issue 3 Page 5 04/10/2019

Malmet Bedpan / Urinal Bottle Washer Disinfector (ES-D)

Detergent Model with Hands Free Operation

Operation, Maintenance and Installation Manual

Section A – Device Operation

For the safe use of this device the responsible body should ensure that all operators are adequately trained

to operate and maintain the device in its safe use.

Hands Free Operation

Zero Contamination – Totally Hands Free

The Malmet Bedpan / Urinal Bottle Washer Disinfector is fully automatic.

Door open, door close and cycle start can be activated without touching the device.

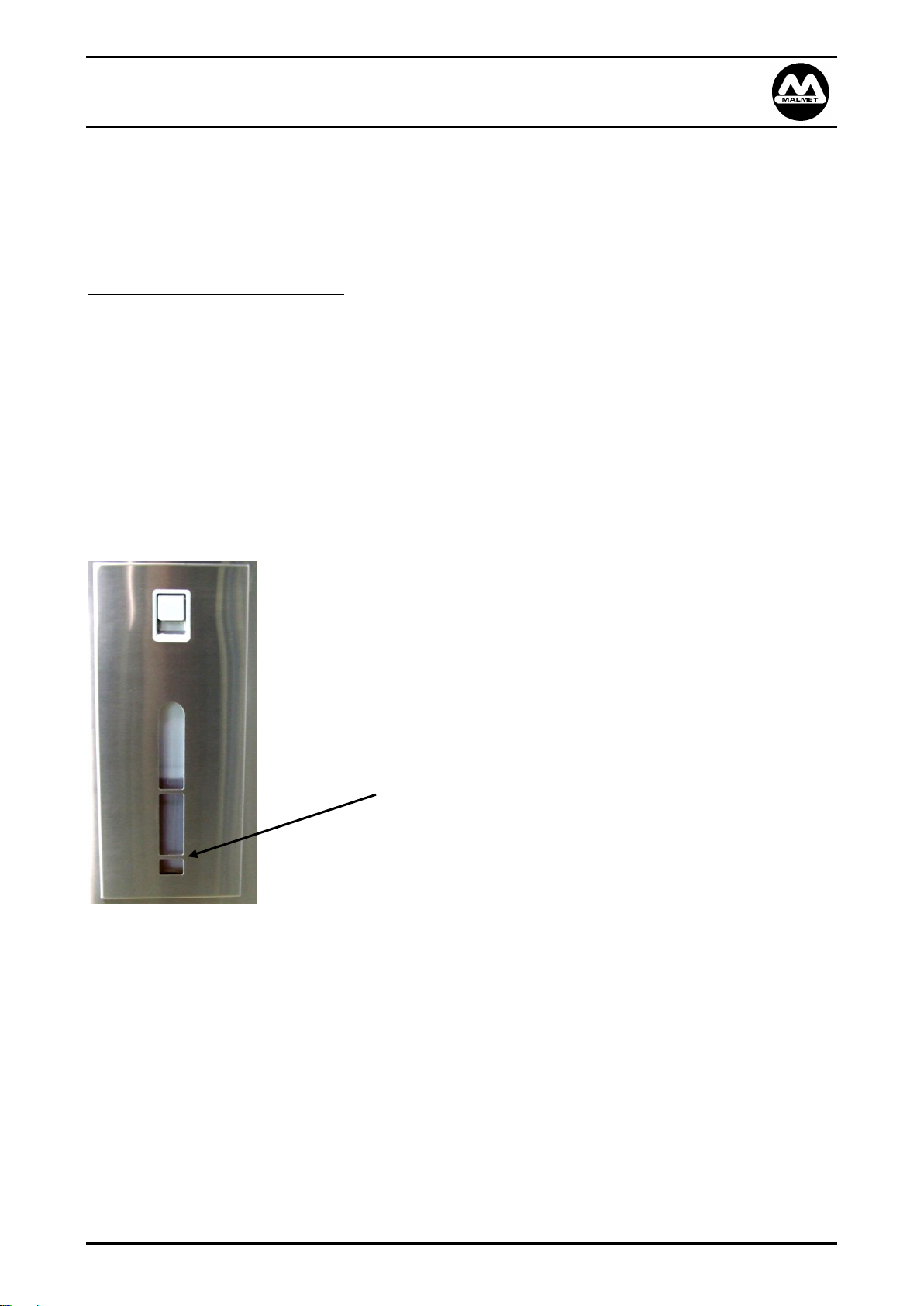

Front View

Manual operation of the door and a manual start button are available.

To Operate

To Open Door – Break Sensor Beam

To Close Door – Break Sensor Beam

To Start Cycle – Break Sensor Beam once when green LED’s flash within 8 seconds after door

closure

Note: If door is opened then closed and cycle has not commenced the beam must be broken twice.

Issue 3 Page 6 04/10/2019

Malmet Bedpan / Urinal Bottle Washer Disinfector (ES-D)

Detergent Model with Hands Free Operation

Operation, Maintenance and Installation Manual

Detergent

The detergent system delivers 30ml of concentrated detergent in the initial wash stage.

Current Safety Data Sheet for Malmet Device Detergent is available in pdf format from Malmet’s website.

www.malmet.com.au

Detergent Out Condition - F 30 Fault

If insufficient detergent is available to deliver the required quantity, the device will display an F 30 dEt fault.

Access to the load will be restricted until the condition is rectified.

To rectify this fault, install a new detergent bottle as per the procedure in this manual “Changing the

Detergent Bottle”.

On completion of changing the detergent bottle, press either the “Manual Door” or “Manual Start” button

to initiate a priming sequence. If priming is successfully the fault will clear and door will open. Inspect the

items, ensuring they have been cleaned sufficiently before unloading. It is recommended the items are

reprocessed in the event of an F 30 dEt Fault.

If priming is unsuccessful, access to the load will continue to be restricted and F 30 dEt fault displayed.

To avoid the detergent out condition check the low level

mark on detergent door, replace detergent when the

detergent level reaches this mark.

Issue 3 Page 7 04/10/2019

Malmet Bedpan / Urinal Bottle Washer Disinfector (ES-D)

Detergent Model with Hands Free Operation

Operation, Maintenance and Installation Manual

WARNING!

SAFETY GLOVES AND GOGGLES MUST BE WORN WHEN

CHANGING DETERGENT AND DISPOSING OF EMPTY CONTAINERS

Current Safety Data Sheet for Malmet Device Detergent is available in pdf format from Malmet’s

website. www.malmet.com.au

Changing the Detergent Bottle

1. Pull latch on detergent door and open.

2. Unscrew cap and pull out with suction hose (let hose hang in detergent chamber).

3. Remove empty bottle and replace with full bottle.

Note: Leave cap on new bottle until in position.

4. Remove cap on new bottle and fit existing hose and cap.

5. Close detergent door.

6. Restart device operation as normal.

Disposal of Empty Detergent Bottles

1. When handling empty containers treat as though container is full and wear appropriate PPE as per

MSD requirements.

2. Triple rinse container and puncture base to render unusable.

3. Dispose of containers as per facility chemical waste handling procedures, and/or local government

requirements.

Issue 3 Page 8 04/10/2019

Malmet Bedpan / Urinal Bottle Washer Disinfector (ES-D)

Push down slipper pan

until it locks into

position

Detergent Model with Hands Free Operation

Operation, Maintenance and Installation Manual

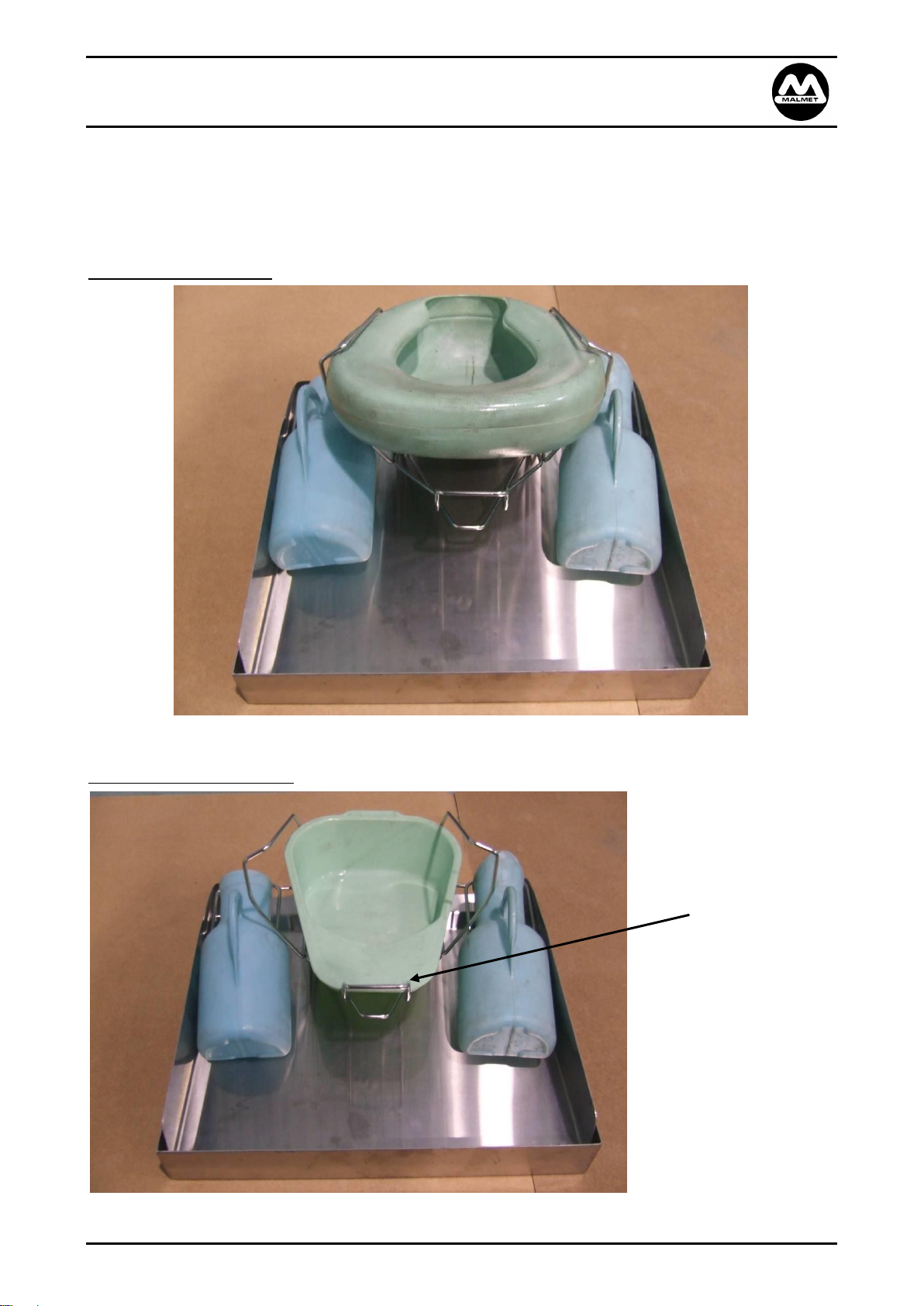

Loading Configurations

The device is intended to be loaded as per the below configurations, please refer to the design parameters

section of this manual for items that this device is designed to process. Part loads or singular items can be

processed but must be loaded in their designated positions as below.

Bed Pan + 2 Urinal Bottles

Slipper Pan + 2 Urinal Bottles

Issue 3 Page 9 04/10/2019

Malmet Bedpan / Urinal Bottle Washer Disinfector (ES-D)

Detergent Model with Hands Free Operation

Operation, Maintenance and Installation Manual

Standard Commode Bowl + 2 Urinal Bottles

Large Commode Bowl + 2 Urinal Bottles

Issue 3 Page 10 04/10/2019

Malmet Bedpan / Urinal Bottle Washer Disinfector (ES-D)

Detergent Model with Hands Free Operation

Operation, Maintenance and Installation Manual

Cycle of Operation

Stage 1 Flushing / Cleaning

One rotating 180° back spray

Two fixed 60° top sprays

Two fixed urinal sprays

Rinse for 10 seconds

Detergent pump on for 7 seconds to add 30ml of concentrate to pump

Main pump on for 3 seconds to apply detergent

Pause for 40 seconds

Rinse for 10 seconds to wash detergent off

Stage 2 Thermal Disinfection

Steam is delivered into the sealed wash chamber

Steam continues to heat the surface temperature of utensils and chamber to a minimum of 90°C

for 60 seconds

Stage 3 Cool Down Rinse

One 60° fine mist top spray delivers cold water direct from mains.

Utensils are cooled to 55°C for safe handling.

In accordance and complies with:

Cleaning Efficacy

AS/NZS 4187:2014, ISO 15883-1, ISO/TS 15883-5

Thermal Disinfection

AS/NZS 4187:2014, ISO 15883-1

Issue 3 Page 11 04/10/2019

Malmet Bedpan / Urinal Bottle Washer Disinfector (ES-D)

Detergent Model with Hands Free Operation

Operation, Maintenance and Installation Manual

Sequence of Operation

1. Once device is installed into position with power and water connected, push power on button.

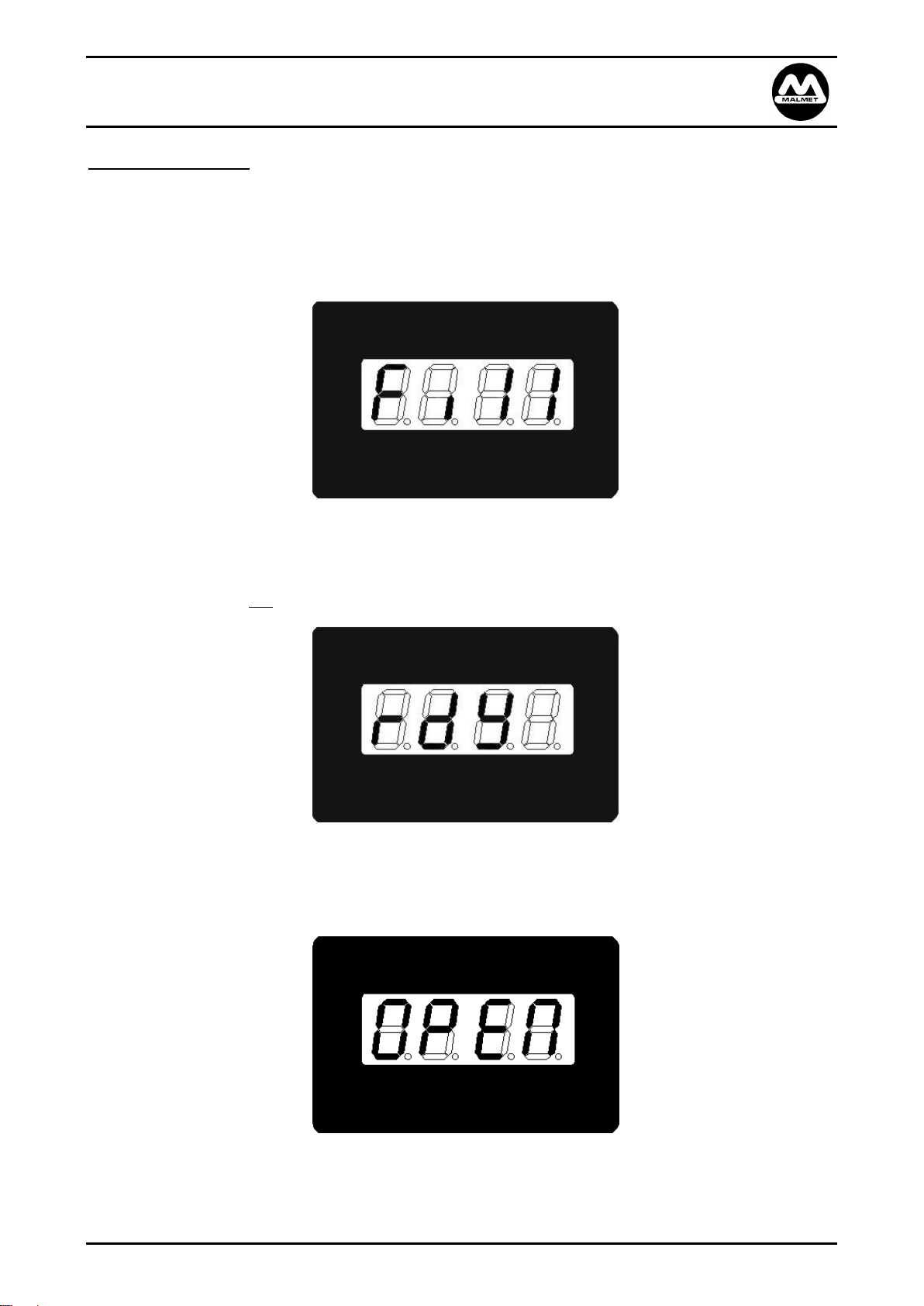

2. When the device is turned on via the display panel the display shows fill indicating steam generator

and cold water tanks are filling to the high water level.

At this stage the device will not commence a cycle until Step 5.

3. Once the steam tank water level probes sense the tank is full it will start heating.

4. The steam tank is heated to temperature 90°C - 92°C. The device is now ready to commence a cycle.

The display shows rdY (ready).

5. The operator breaks the infra-red beam, which opens the door.

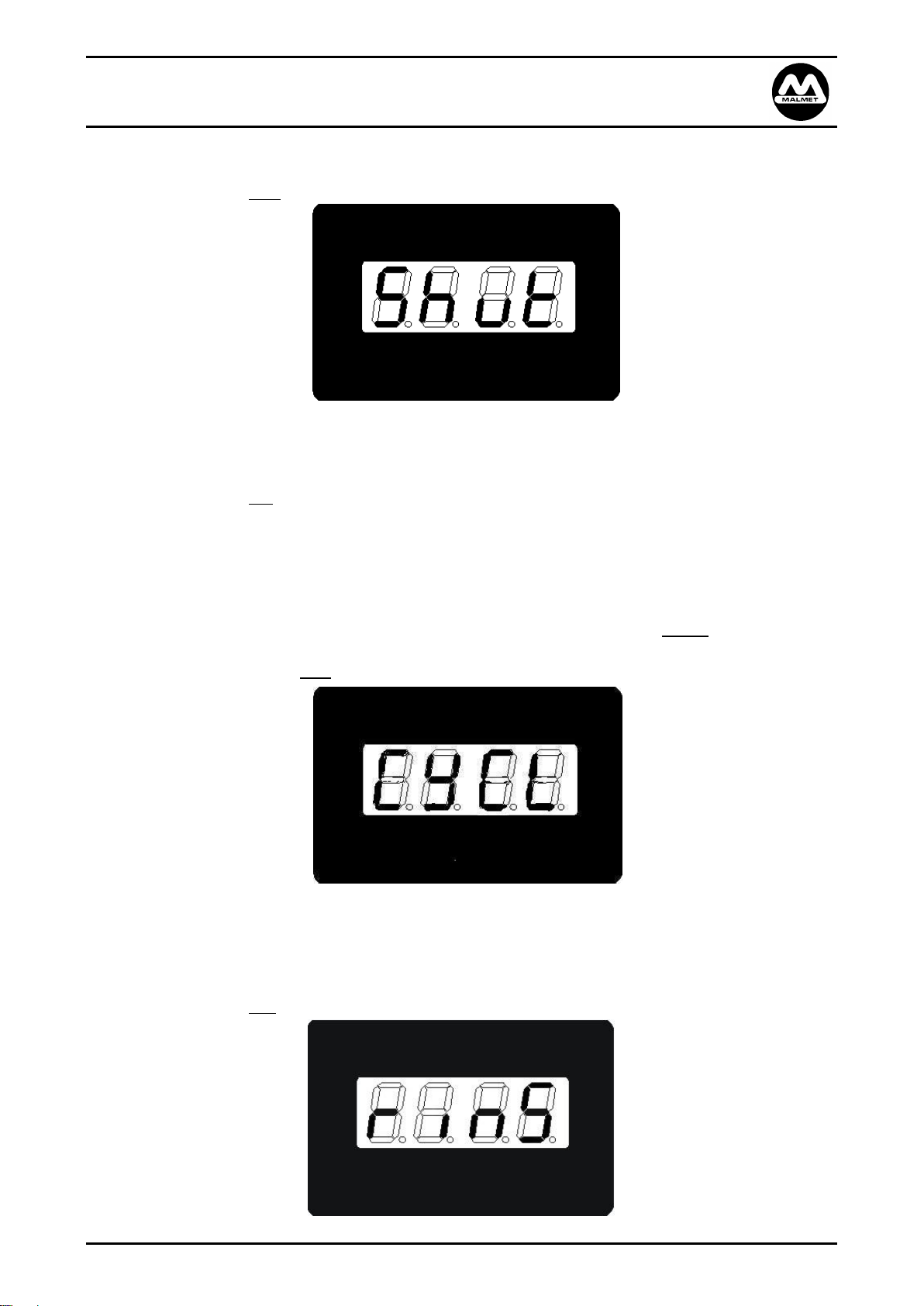

The display shows open.

Note: Whenever the door is opened the elements are in the off mode.

Issue 3 Page 12 04/10/2019

Malmet Bedpan / Urinal Bottle Washer Disinfector (ES-D)

Detergent Model with Hands Free Operation

Operation, Maintenance and Installation Manual

6. Once the device is “loaded” the operator breaks the infra-red beam to close the door.

The display shows Shut

7. When the door is fully closed 2 green LED’s will flash in the infra-red sensor area for 8 seconds to advise

the user to break the beam again to start a cycle.

The display shows rdY

If the 8 seconds has elapsed the flashing LED’s will stop and the device will not start for a cycle. The

operator has to repeat the process from Step 5 (or press manual start).

Note: If this occurs the beam must be broken twice.

Note: On 10A models, if the steam generator temperature is not at 90°C after the beam has been

broken or the manual start button pressed, the display will show “CYCL”. The Green LED’s

will stop flashing and stay on. When the steam generator has reached temperature the

display will show rinS and the wash cycle will start automatically.

8. Once a cycle has been initiated the elements are turned on in the steam tank to start heating the

water.

The wash pump is turned on for 10 seconds for the initial wash.

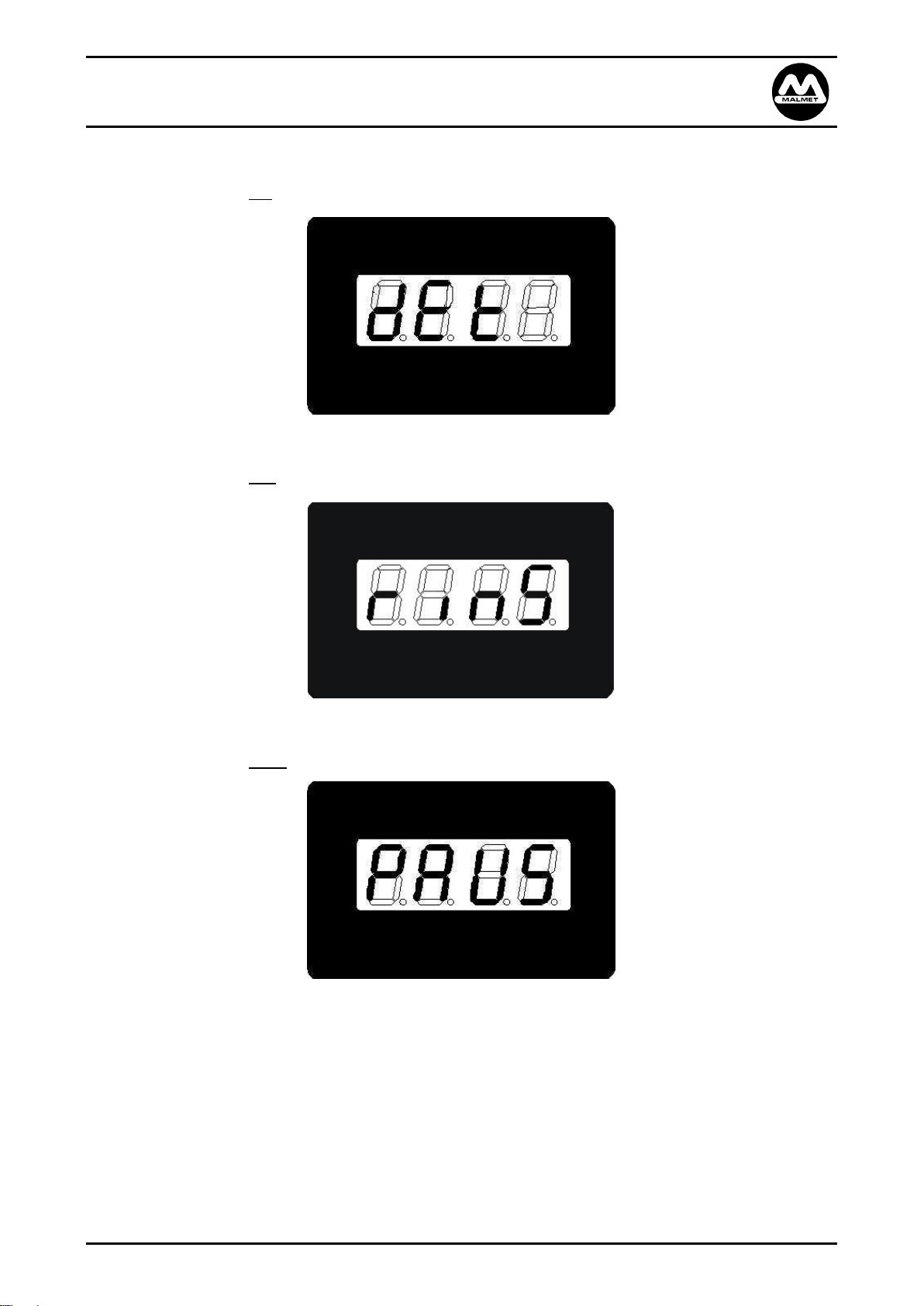

The display shows rinS

Issue 3 Page 13 04/10/2019

Malmet Bedpan / Urinal Bottle Washer Disinfector (ES-D)

Detergent Model with Hands Free Operation

Operation, Maintenance and Installation Manual

9. Detergent pump comes on delivering 30ml of concentrate to rinse pump.

The display shows dEt

10. Rinse pump comes on to distribute detergent over and inside items

The display shows rinS

11. Pause for 40 seconds so detergent can take effect

The display shows PAUS

Issue 3 Page 14 04/10/2019

Loading...

Loading...