Page 1

FORM 641 (REV. B) 9/99

®

INSTALLATION INSTRUCTIONS

COMP 9000 90 SERIES

POINT TYPE DISTRIBUTOR

OLD DISTRIBUTOR REMOVAL

1. Disconnect distributor point wire from negative () side of coil.

2. Rotate engine until timing mark on crank balancer lines up with

TDC mark on timing tab.

3. Remove cap from original distributor. Rotor blade should point to

number one spark plug wire terminal of cap. If not, rotate engine

one full turn until timing marks line up again.

4. Note position of rotor blade, remove hold-down clamp at distributor base and remove distributor from engine.

STARTING THE ENGINE

CAUTION: Before starting the engine, be sure all tools, wires

and miscellaneous objects are clear of moving engine parts.

1. Connect a timing light. Find the area with the best view of the

timing marks.

2. Crank the engine. If it fails to start, rotate the distributor in small

increments left or right until engine starts. Do not exceed more

than ten degrees of rotation either way.

3. Set timing as recommended by the engine manufacturer, then

tighten the distributor hold down clamp. Make sure timing is still

correct. If timing has moved, repeat this procedure.

COMP 9000 DISTRIBUTOR INSTALLATION

NOTE: The Comp 9000 adjustment is preset at the factory.

1. Prepare new Comp 9000 distributor by removing the spark

plug wire retainer and distributor cap.

2. Place the Comp 9000 distributor into the engine. Do not install

clamp at this time. Raise distributor housing enough to turn rotor,

point rotor blade in direction of original rotor.

3. Seat distributor fully into engine.

NOTE. It may be necessary to turn the oil pump drive with a

long screw driver to fully seat the distributor.

4. Install distributor hold-down clamp. Leave clamp loose enough to

rotate distributor for timing purposes.

5. Install Comp 9000 distributor cap as follows: move spark plug

wires from old cap to new cap one wire at a time, starting with the

number one cylinder, attach wires to matching terminals on new

cap. Do not attach coil lead at this time.

NOTE: It may be necessary to purchase and install spark plug

wire boots and terminal kit, Mallory part number 669.

6. Install the spark plug wire retainer, then attach coil lead.

7. Attach distributor point harness to negative () side of coil.

MALLORY COMP 9000 SERVICE PARTS

QTY. DESCRIPTION PART NO.

1 WIRE RETAINER WITH SCREWS 29744

1 DISTRIBUTOR CAP ASSEMBLY 29745

1 ROTOR ASSEMBLY, RH ROTATION 29772

1 ROTOR ASSEMBLY, LH ROTATION 29773

1 CAP ADAPTER/SHIELD ASSEMBLY W/SCREWS 29748

2 CONTACT POINT SET WITH SCREWS 102 X

1 CONDENSOR WITH BRACKET AND SCREWS 400

1 POINT WIRE HARNESS 29775

1 DISTRIBUTOR CAM GREASE (1/4 OZ TUBE) 26015

Page 2

MALLORY COMP 9000 DISTRIBUTOR

90 SERIES POINT TYPE

TUNE-UP AND MAINTENANCE INFORMATION

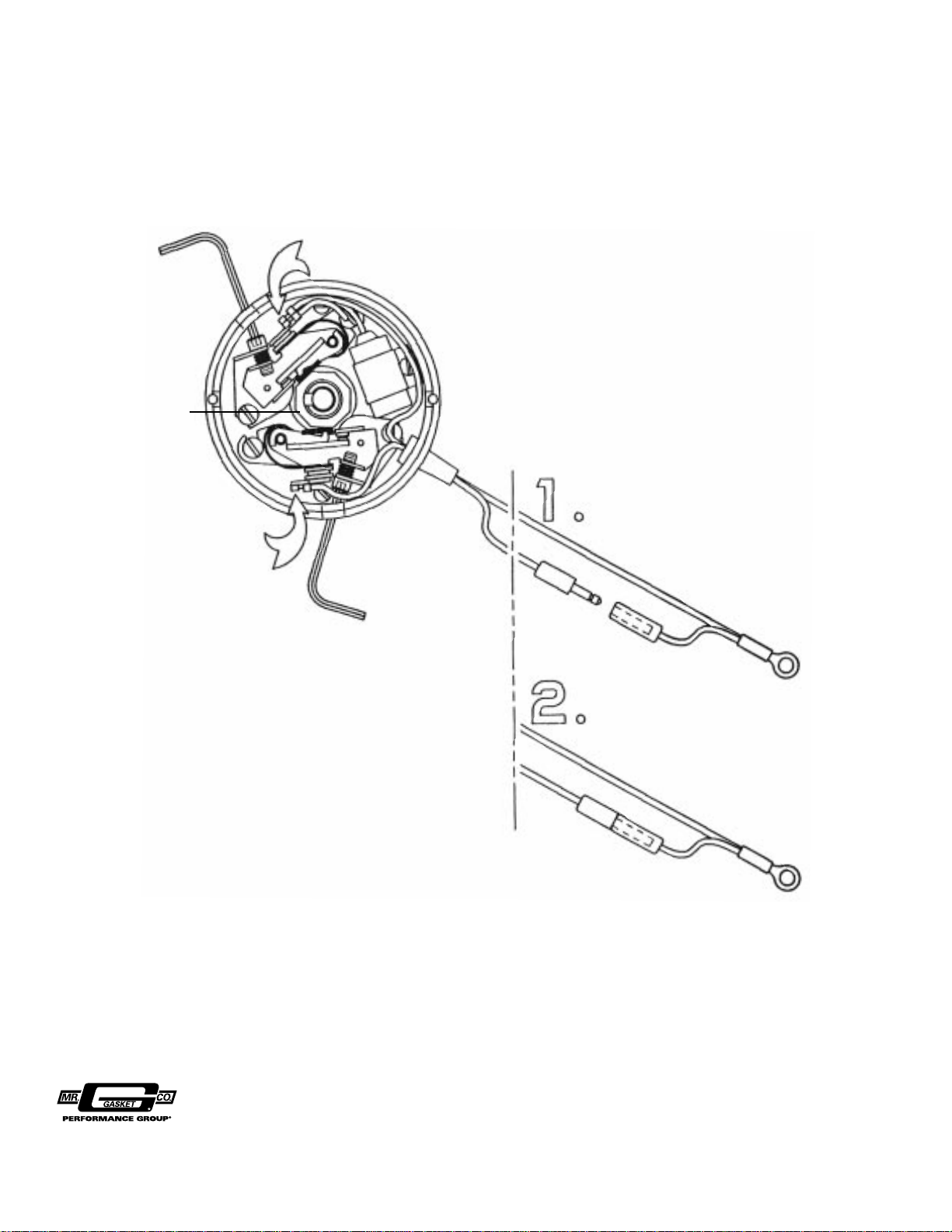

NOTE: Turning wrench

clockwise increases

dwell angle.

IMPORTANT: Apply a light

film of Mallory distributor

cam grease (supplied) on

surface of cam to extend

point life.

POINT NO. 2

Connect black point harness lead only to

this point to ensure proper distributor adjustment and performance.

POINT NO. 1

Both the red point harness lead and the orange condensor lead

must connect to this point when distributor is in this point.

MALLORY COMP 9000

POINT ADJUSTMENT PROCEDURE

NOTE: If dwell meter is not available, set each

point gap at .018 .020

OR

With connector unplugged, using the 8-cyl scale

on your dwell meter, adjust the setting to read

26º 28º dwell angle. Proceed to Step 2 to attain

total dwell setting.

NOTE: Turning wrench

clockwise increases

dwell angle.

MALLORY IS A DIVISION OF THE MR. GASKET PERFORMANCE GROUP

550 MALLORY WAY, CARSON CITY, NEVADA 89701

(775) 882-6600 FAX (775) 887-4326

www.mrgasket.com

After reinserting plug connector, adjust the second set of points to the total dwell angle setting

of 34º 36º, again using the 6-cyl scale on your

dwell meter.

Once these two steps have been completed, you

must reset your ignition timing.

FORM #641

(REV. B) 9/99

Made in U.S.A.

Printed in U.S.A.

Page 3

FORM 664A

®

NOTICE

This distributor is equipped with an O-ring. If the original distributor has a steel

gasket, discard it and use only the O-ring supplied with the Mallory distributor.

FORM 664A

®

NOTICE

This distributor is equipped with an O-ring. If the original distributor has a steel

gasket, discard it and use only the O-ring supplied with the Mallory distributor.

FORM 664A

®

NOTICE

This distributor is equipped with an O-ring. If the original distributor has a steel

gasket, discard it and use only the O-ring supplied with the Mallory distributor.

FORM 664A

®

NOTICE

This distributor is equipped with an O-ring. If the original distributor has a steel

gasket, discard it and use only the O-ring supplied with the Mallory distributor.

FORM 664A

®

NOTICE

This distributor is equipped with an O-ring. If the original distributor has a steel

gasket, discard it and use only the O-ring supplied with the Mallory distributor.

Loading...

Loading...