Page 1

1MALLORY TECHNICAL SUPPORT 216.688.8300 www.malloryracing.com

MAX-FIRE AND E-FIRE ELECTRONIC DISTRIBUTORS

NOTE: This product is applicable to pre-1966 California and pre-1968 federally certified passenger cars. It is

also applicable to non-emission controlled trucks and similar vehicles. It is not applicable or intended for use

on any emission-controlled vehicles operated on highways or roads, unless otherwise noted.

INSTALLATION INSTRUCTIONS

FORM 1330 (REV. A) 6/08

WARNING

Mallory’s Max-Fire and E-Fire distributors are

not compatible with positive ground or 6-volt

vehicle electrical systems.

PARTS INCLUDED IN THIS KIT:

1 Electronic Distributor

1 Distributor Wire Harness

1 12-Volt Power Supply Harness

GENERAL INFORMATION

Advance Curves

This distributor is equipped with 7 preprogrammed RPM based advance curves.

Changing the advance curve is accomplished

by accessing the switches on the circuit board

once the cap is removed. You also have the

ability to design your own custom advance

curve by utilizing the optional software available

from Mallory. You may also adjust the vacuum

advance utilizing the same software.

Ignition Coils

The Max-Fire and E-Fire distributors are

designed to work with most aftermarket high

performance ignition coils. For optimum

performance, we recommend using one of

Mallory’s performance coils such as part numbers

29440 and 30440.

Capacitive Discharge or Inductive Ignition

Amplifiers (boxes)

The Max-Fire Distributor is equipped with its

own internal capacitive discharge system and

does not need any additional ignition accessories.

The E-Fire is compatible with most popular

Mallory HyFire Ignitions.

Spark Plug Gaps

For street applications, use your engine

manufacturer’s specifications. For racing

applications, start with your engine manufacturers

specifications, then experiment with and closely

monitor various gaps and heat range spark

plugs to achieve maximum performance.

Electric Welding

Unplug the distributor wire harness before welding

on the vehicle.

Spark Plug Wires

YOU MUST USE suppression type (carbon core;

spiral core; radio suppression core) spark plug

wire. We recommend spiral core ignition wire,

such as Mallory PRO SIDEWINDER

®

Ignition

Wire. Suppression type spark plug wires prevent

false triggering and the possibility of premature

ignition or accessory failures. DO NOT USE

solid core (copper core; stainless steel core)

spark plug wire with any electronic ignition

system or accessory. Solid core spark plug wire

causes radio frequency interference (ignition

noise; static). Radio frequency interference

causes false triggering (preignition; spark scatter)

and premature ignition or accessory failures.

IMPORTANT

This distributor requires 12 volts to operate correctly. If the vehicle is equipped with an ignition ballast

resistor (or loom resistance wire) in the wire between the ignition switch and the coil (+) terminal, you

will need to run a new wire from the ignition switch which will supply 12 volts. Check a service manual

for your vehicle to locate the ignition ballast resistor (or loom resistance wire). These are most common

in vehicles that were originally equipped a point type or some early electronic distributors.

Page 2

OLD DISTRIBUTOR REMOVAL

Step 1

Disconnect the trigger wire from the coil

negative (-) terminal.

Step 2

Locate the spark plug wire on the original

distributor cap that the engine timing is set

from. See a service manual for these locations.

Mark the distributor cap and the distributor

housing, in line with this spark plug wire position

on the distributor cap.

Step 3

Turn the engine crankshaft in the direction of

rotation until the timing mark lines up with the

top dead center (TDC) mark on the timing tab.

See a service manual for these locations.

NOTE: Removing the spark plugs may make it

easier to turn the crankshaft.

Step 4

Remove the distributor cap from the distributor.

Do not remove the spark plug wires or coil wire

at this time. The rotor blade should point to the

mark made on the distributor housing (from

Step 2). If it is not, turn the engine crankshaft in

the direction of rotation one full turn (repeating

Step 3) until the timing mark lines up (again)

with the TDC mark on the timing tab.

NOTE: Once you are finished with Step 4,

DO NOT turn the crankshaft until the new

distributor is installed.

Step 5

Note the direction the rotor is pointing. Remove

the distributor hold down clamp and remove the

distributor from the engine.

DISTRIBUTOR INSTALLATION

Step 1

Prepare the distributor by removing the

distributor cap.

Step 2

Place the distributor in the engine with the rotor

pointing in the same general direction as the

original distributor.

NOTE: The distributor must be fully seated into

the engine. It may be necessary to turn the oil

pump drive, or turn the engine crankshaft in the

direction of rotation two full turns until the timing

mark lines up (again) with the TDC mark on the

timing tab, to allow the distributor to seat fully.

MALLORY TECHNICAL SUPPORT 216.688.8300 www.malloryracing.com

2

Step 3

Rotate the distributor housing in the

opposite direction of rotor rotation until the leading

edge of the blade portion of the trigger wheel is

centered in the Hall sensor pickup gap. This will

generally put timing close enough for starting

purposes. Put the distributor hold down clamp

in place and tighten slightly, leaving it loose

enough to turn the distributor. Make a mark on

the distributor housing where the rotor points.

Step 4

Install the distributor cap. Remove the spark

plug wire on the original distributor cap that the

engine timing is set from, and install it onto the

distributor cap post above the mark on the

distributor housing where the rotor had pointed.

Continue installing each remaining spark plug

wire, one at a time, from the original distributor

cap to the distributor cap in the same sequence.

NOTE: It may be necessary to purchase and

install distributor boots and terminals for the

spark plug wires to correctly fit the distributor cap.

DISTRIBUTOR WIRING

There are three harnesses coming from the

distributor body:

4-PIN SQUARE CONNECTOR – this is the

data connector for the PC or external handheld

programmer. It is only used when adjusting the

distributor with an external controller or PC.

3 PIN FLAT CONNECTOR – this is the power

connector.

BLACK WIRE- connects to the vehicle ground

(engine block). Make sure the surface is free of

dirt, grease and paint.

RED WIRE- connects to the 12 volt ignition

wire from the key switch (there should not be

any ballast resistors or loom resistance wire in

this wire). Refer to a service manual’s wiring

diagram to determine the correct wire. Make

sure the wire supplies 12 volts when the switch

is in the start position and the run position.

WHITE WIRE- this wire is NOT USED with the

22 Series E-Fire inductive storage distributor. It

is used as a 12v square wave tach output with

the 12 Series MAX-Fire. Verify the series you have

by the first 2 digits of the distributor part number.

2 PIN FLAT CONNECTOR–this is the coil connector

ORANGE WIRE-connects to the coil + terminal

BLACK WIRE-connects to the coil – terminal

Page 3

Additional Connections

There is a brass fitting extending from the bottom

of the distributor bowl. This fitting should be

attached to the ported vacuum source so that the

vacuum advance and boost retard features will

work. If you are NOT using either of these, this

fitting does not need to be connected. If you are

using the existing vacuum hose from the original

distributor, check is for cracks or an oily coating

on the inside. Replace it as necessary.

SETTING THE DISTRIBUTOR

12 Series MAX-Fire Distributors

There are three ways of setting up the

distributor: The switches on the circuit board,

using a PC with the EA_Comm software, or the

optional hand held LCD display control (HHC)

part number 29124.

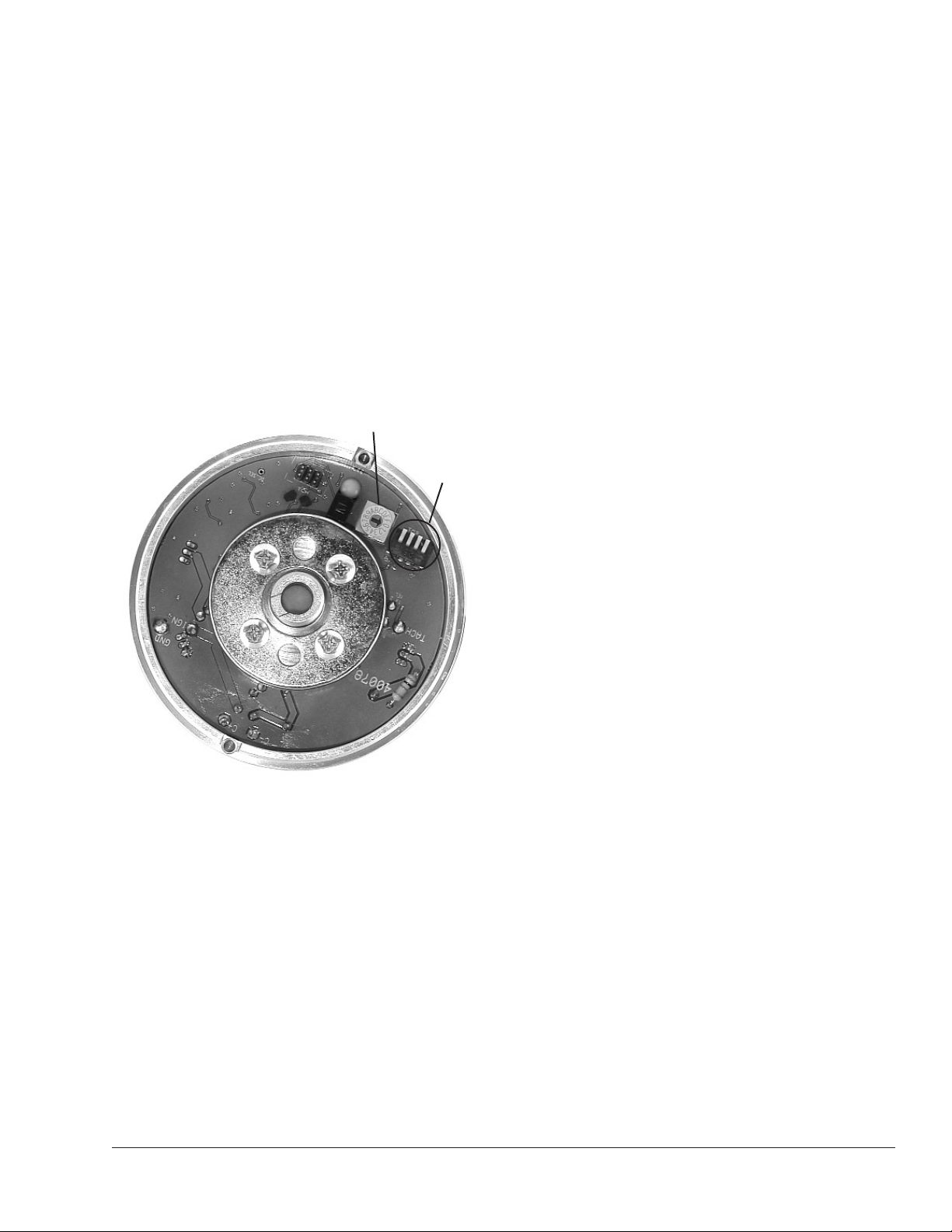

The MAX-Fire Distributor allows you to select

advance curve, vacuum advance sensitivity, and

RPM limiter with a combination of rotary and

DIP switches on the PC board. See Photo #1.

The rotary switch selects the RPM limiter, where

“1” is 4500 RPM, and “F” is 8000 RPM in 250

RPM steps.

NOTE: Setting the rotary switch to “0” allows

the rev limiter to be set by using either a PC

with the EA_Comm software or using the hand

held controller.

The DIP switches are located just to the right of

the RPM rotary switch. DIP switch #1 is located

at the left next to the RPM rotary switch. DIP

switch #4 is located on the far right next to

distributor bowl. For the DIP switches, the UP

position is “ON” and the down position is “OFF”.

3MALLORY TECHNICAL SUPPORT 216.688.8300 www.malloryracing.com

The DIP switches only move about 1/16”

between the UP and DOWN positions. These

DIP switches are VERY delicate and you do NOT

need to use a crow bar to move them – a very

small eye glass type screw driver and very light

pressure works well. DIP switches 1-3 select

one of the seven pre-programmed curves,

according to the table below.

DIP switch 4 selects a high or low vacuum advance

sensitivity. DIP switch 4 “OFF” results in a vacuum

advance where advance starts at 4” of vacuum,

and reaches a maximum of 10 degrees at 10” of

vacuum. If DIP switch 4 is “ON”, the vacuum

advance starts at 8” of vacuum, and reaches a

maximum of 10 degrees at 16” of vacuum.

NOTE: To use either the external programming

methods, the RPM limiter rotary switch needs to

be set at “0” position and all four DIP switches

need to be “OFF” position.

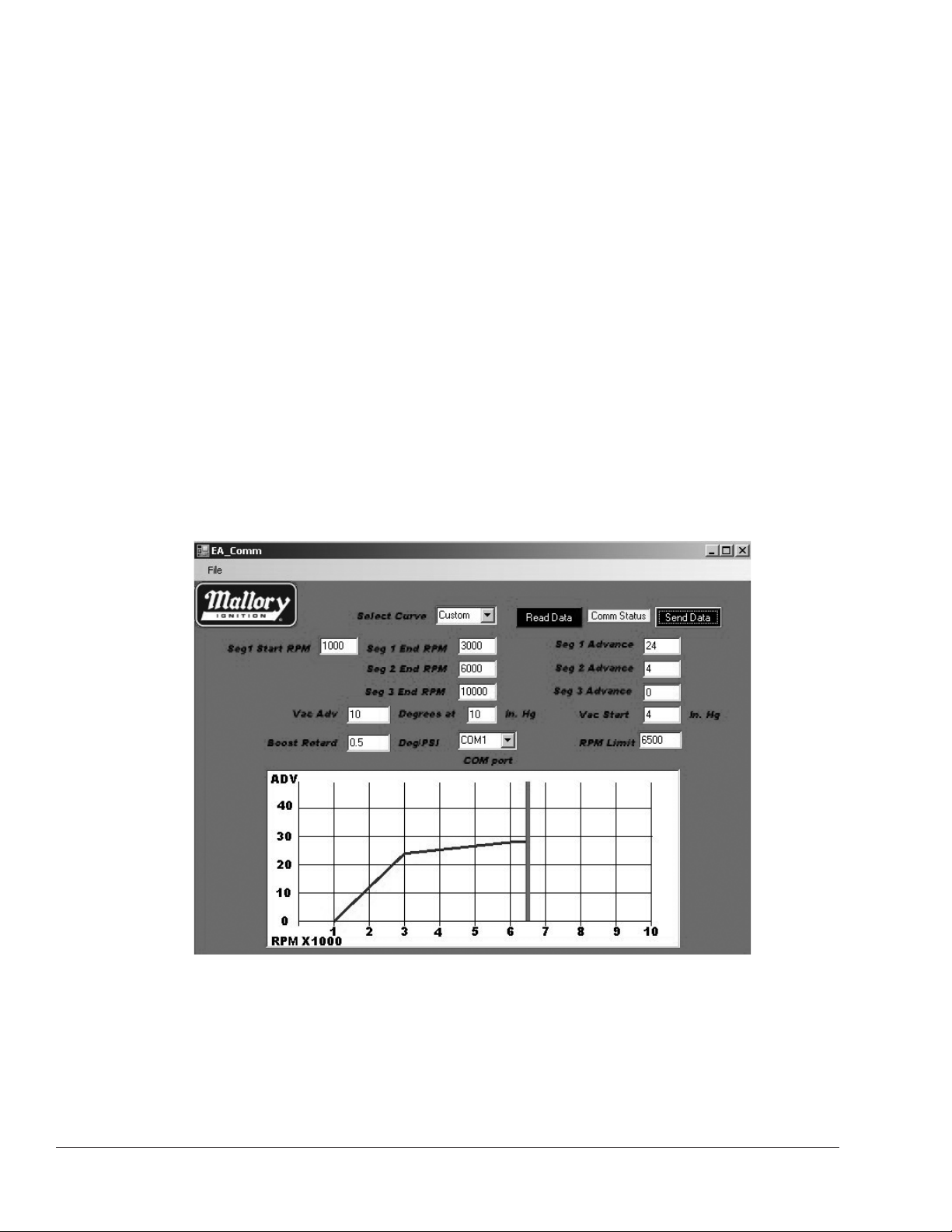

The EA_Comm software allows you to use the

drop down menu to select a preprogrammed

advance curve or design you own 3 segment

custom advance curve by simply filling in the

open windows in the program. In addition, you

can design you own vacuum advance curve by

inputting the total number of degrees of

advance you desire, the inches of vacuum at

which you have full advance, and the inches of

vacuum you want zero vacuum advance.

You can also utilize the Boost Retard feature by

selecting the number of degrees of retard (in 10ths

of a degree) per pound of boost. The rev limiting

feature is used by inputting your desire rev limit.

NOTE: We recommend you hit “Read Distributor”

to verify the current adjustments prior to making

changes. Once you hit the send button the new

adjustments will appear on the graph.

The optional Hand Held Controller or HHC has 4

buttons: Mode up/down, and Value up/down. To

adjust a particular setting, press the Mode up or

down switch until that area is displayed on the

LCD readout, then use the Value up or down

buttons to change the value. If you hold the buttons

down, after a short interval they will auto-repeat.

22 Series E-Fire Distributors

The E-Fire distributor can be adjust 3 different

ways- The switches on the circuit board, using

a PC with the EA_Comm software, or the

optional hand held LCD display control (HHC)

part number 29124. Please see Photo #2.

PHOTO #1

DIP

Switches

RPM Rotary Switch

Page 4

MALLORY TECHNICAL SUPPORT 216.688.8300 www.malloryracing.com

4

NOTE: The DIP switches are located just to the

right of the Hall Effect trigger. DIP switches are

labeled #1, #2 and #3. For the DIP switches,

the forward position is “ON” as labeled and the

backward position is “OFF”. The DIP switches

only move about 1/16” between the forward and

backward positions. These DIP switches are

delicate and you do NOT need to use a crow

bar to move them – a very small eye glass

type screw driver or a pick tool and very light

pressure works well.

The E-Fire Distributor a 3 position DIP switch on

the circuit board. When all of the switches are

off, the advance curve can be set by using the

external HHC or PC software. If any of the

switches are set to “ON”, then the selected

curve will be one of the seven pre-programmed

curves, according to the table below:

Advance Curve Theory And Setup

These distributors have a total of 8 selectable

advance curves. Seven are preprogrammed,

and can’t be changed, and there is the “custom”

selection, which allows you to select up to three

separate curve segments. Each segment has a

start RPM, an end RPM, and an advance

amount. For segments two and three, the start

RPM is automatically set to the end RPM of the

previous segment, so the settings will show only

an end RPM and an advance amount.

PHOTO #2

SWITCH #1-OFF #2-ON #3-OFF

SWITCH #1-OFF #2-OFF #3-ON

SWITCH #1-OFF #2-ON #3-ON

SWITCH #1-ON #2-OFF #3-OFF

SWITCH #1-ON #2-ON #3-OFF

SWITCH #1-ON #2-OFF #3-ON

SWITCH #1-ON #2-ON #3-ON

DIP

Switches

Page 5

5MALLORY TECHNICAL SUPPORT 216.688.8300 www.malloryracing.com

To make a custom curve, first sketch out what

you want your advance curve to look like, showing

advance vertically, and RPM horizontally. You

can have up to three straight line segments in

the curve. After doing this, note the RPM and

change of advance for each segment. Select

“Manual” from the Advance curve mode. Then,

starting at the “Seg 1 start” mode, enter the

RPM and change of advance for each segment.

Remember that the start RPM of segments 2

and 3 will be the end RPM of the previous

segments. See the example picture, below:

The maximum recommended total advance (RPM

based and vacuum) is 45 degrees, so keep this

in mind when determining advance curves.

Vacuum Advance Setting

The vacuum advance is set up with three modes:

Vacuum start tells the distributor where to start advancing the timing.

Vacuum max tells the distributor where to stop advancing the timing.

Vacuum advance tells the distributor how many degrees to advance the timing at the

vacuum max setting. See the example, below:

NOTE: For reference purposes only, noted

below is the standard “street performance”

mechanical advance curve that most Mallory

distributors come with from the factory;

0 degrees @ 1200 RPM

12 degrees @ 1600 RPM

18 degrees @ 2400 RPM

24 degrees @ 3200 RPM

Page 6

MALLORY TECHNICAL SUPPORT 216.688.8300 www.malloryracing.com6

Boost Retard Setting

Boost retard will retard the timing by the number

or degrees shown, per pound of boost. For

example, if you set the boost retard to .5, then

for every pound of boost, you will retard the

timing by 1/2 degree. 10 psi boost would cause

5 degrees of retard. If you are not using boost,

this setting has no effect.

PC Software

The PC software, EA_Comm, allows you to set

the distributor and see the advance curve on a

graph. You can also save and recall different

advance curves. EA_Comm has an advance

curve graph that shows the result of changes

made in the curve settings. The Screen Shot #1

below shows the user interface:

When you first start the software, the values

boxes will be blank. Make sure that your distributor

is connected to a COM port on your computer,

and powered up.

NOTE: Many laptops do not have external COM

ports. If this is your situation, there are readily

available USB to COM port adapters that will

work. Once the adapter is plugged into a USB

port and recognized by the computer, the COM

port will show up in the list in EA_Comm. Click

on the “COM port” arrow, and select the COM

port that is connected to your distributor. Then,

click “Read Data” to get the current distributor

program information. A progress bar will show

up over the curve graph as data are being read.

Once the distributor has been read, the screen

should look similar to Screen Shot #1.

SCREEN SHOT #1

Page 7

7MALLORY TECHNICAL SUPPORT 216.688.8300 www.malloryracing.com

The blue lines indicate the advance curve, and

the red line shows the RPM limiter setting. The

vacuum advance and boost retard are not

shown on the graph, but the programmed

values are shown in the boxes above. If the

distributor is set to one of the “built-in” advance

curves, the values in the boxes will be “grayed

out”, which means that they can’t be changed.

See Screen Shot #2.

If you want to set the distributor to a preset

curve, select the curve from the “Select Curve”

box. Enter the desired RPM limit and vacuum

advance settings, then click the “Send Data”

button. This will transfer the data to the distributor,

then read it back and show the graph to confirm

the transfer. If you want to put in a custom

curve, select “Custom” from the “Select Curve”

box, and click the “Send Data” button. This will

tell the distributor that you want the custom

curve settings, and read the data presently

programmed in. Once the graph shows the

existing distributor programming, you can enter

the custom curve settings you want, then click

the “Send Data” button to update the distributor.

Saving and Opening Distributor Curve Files

In the upper left corner of the EA_Comm

window is the “File” menu bar item. Clicking on

this brings down a menu with a choice of

“Open”, “Save”, or “Quit”.

Selecting “Quit” closes the EA_Comm

application. Selecting “Save” brings up a

standard Windows dialog box that allows you

to save a custom distributor file. These files

have an .ead suffix. The “Open” dialog box

allows you to read a file in. Once the file has

been read into EA_Comm, the graph will show

SCREEN SHOT #2

(Blue)

(Red)

Page 8

8 www.malloryracing.com

MALLORY IS A DIVISION OF PRESTOLITE PERFORMANCE

10601 MEMPHIS AVE. #12, CLEVELAND, OH 44144

216.688.8300 FAX 216.688.8306

FORM 1330

(REV. A) 6/08

Made in U.S.A.

Printed in U.S.A.

the curve. Click the “Send Data” button to send

these new settings to the distributor. One area

where this feature comes in handy is if you see

that there is a pre-programmed curve that is

almost what you want. By selecting that and

saving it, you can then recall it and treat it as

another custom curve.

NOTE: The pre-programmed curves in the

distributor cannot be changed. File saving and

recalling allow you to use the “Custom” curve

select option to load a modified version of the

pre-programmed curve.

While it is possible to run the EA_Comm

software with the distributor while the engine

is running, we DO NOT recommend this, as the

electrical noise from the spark plug wiring can

cause errors in communication. It is best to

have the engine stopped when modifying the

distributor programming.

Loading...

Loading...