Page 1

FORM 1434 (REV. C) 1/00

®

COMP STARTER

PART NOS. 3000, 3001, 3002, 3003, 3004, 3005, 3006, 3008

GENERAL INFORMATION

INSTALLATION INSTRUCTIONS

Because Mallory's starter is smaller than stock, and the solenoid can be

rotated to any position, installation of the COMP

than installing a stock starter. However, there are a few things that should be

checked to prevent damage to the starter and/or flywheel.

INSTALLATION

Step 1

Disconnect the negative battery cable from the battery. Remove the stock

starter.

Step 2

Loosen the v-clamp on the COMP® STARTER just enough to rotate the starter

by hand.

Step 3

Hold the starter in place (do not bolt-up yet) and determine the best position for

the solenoid by rotating the starter relative to the nose. Try to leave a minimum

1/2" air gap between the exhaust and the solenoid. Remove the starter and

tighten the v-clamp to lock the solenoid in position.

®

STARTER is usually easier

®

BELLHOUSING MOUNT STARTERS

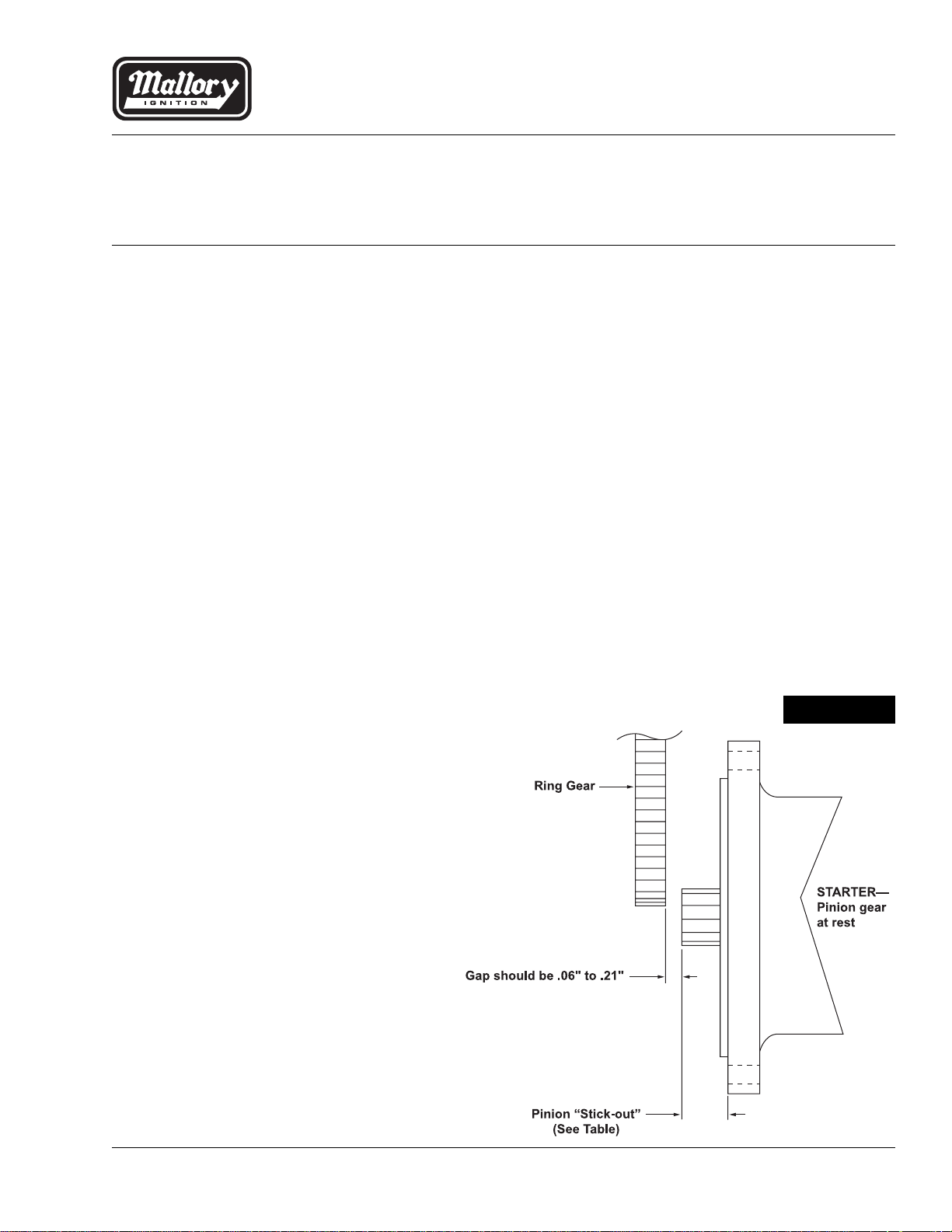

If you cannot see the gap when the starter is installed, measure the distance

from the starter mounting surface to the ring gear and compare that with the

distance the pinion sticks out of the starter. There should be .06" to .21"

difference. See Figure A.

Pinion "stick-out" of Mallory bellhousing mount starters:

Part No. 3002 Ford BB Starter .50"

Part No. 3003 Ford "manual trans" starter .25"

Part No. 3001 Ford "auto trans" starter .62"

Part No. 3005 Mopar starter .94"

Part No. 3006 AMC starter .70"

Part No. 3008 Hemi 4-speed starter 1.13"

If the pinion is too close to the ring gear, the pinion gear can be replaced with

a Mallory "short" gear (PN 3109*), which moves the pinion back .125".

* NOTE: Gear PN 3109 will not fit Mopar Starter PN 3005.

Step 4

Determine the gap between the starter pinion gear and the flywheel ring gear.

NOTE: In most cases, this step is not necessary. However, it is highly

recommended to prevent damage to the starter.

With the pinion gear at rest, there should be .06" to .21" between the pinion gear and the ring gear. In some cases, it is not possible to visually

check the gap, so it must be calculated.

FIGURE A

1

Page 2

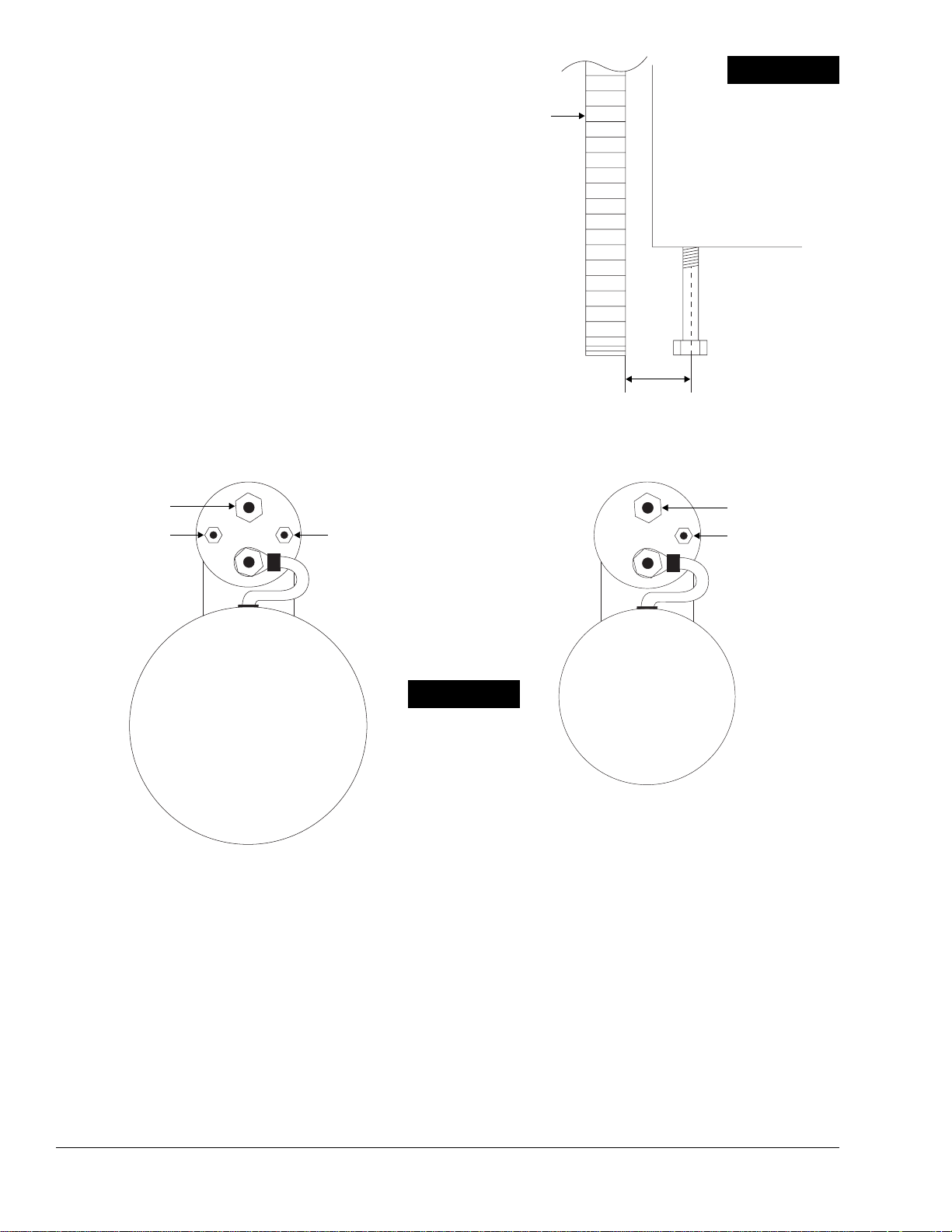

Block Mount Starters

If you cannot see the gap with the starter in place, remove the starter and

screw a starter bolt into the block. Measure from the center of the bolt to the

ring gear. Compare this measurement with the distance that the pinion gear

sticks out past the bolt holes on the starter. See Figure B.

Pinion "stick-out" (past bolt holes) of Mallory starters:

Part No. 3000 Chevy/Buick starter .87"

Part No. 3004 Pontiac/Oldsmobile starter .87"

The difference should be .06" to .21".

FIGURE B

RING GEAR

Step 5

Bolt the starter in place with the solenoid in the desired position. Mallory

Comp® Starters are designed to use the stock type and length starter bolts. If

you do not have the correct bolts, they are available at any auto parts store.

NOTE: GM block mount starter bolts have a knurl on the shank near the

threads. Do not use bolts without the knurl.

WIRING

Step 6

Vehicles without remote solenoid/relay, including most GM/Mopar:

STOCK SOLENOID

(ON STARTER)

B

S

R (Not always used)

NOTE: The position of the

S and R terminals may be

reversed on some starters.

ENGINE BLOCK

C

L

MALLORY SOLENOID

(ON STARTER)

B

S

FIGURE C

"B" Terminal

Remove all wires from the large B terminal (including the battery cable) on the

stock solenoid. Connect all wires to the same terminal on the Mallory solenoid.

"S" Terminal

This is the small terminal that is connected to the starter switch/key. The wire(s)

connected here activate the starter. Remove the wire(s) from the stock

solenoid and connect them to the small terminal on the Mallory solenoid.

NOTE: This terminal may be on the opposite side of the solenoid

compared to the stock starter.

"R" Terminal

Some older cars have one or more wires connected to a second small R

terminal. These wires are not used on a Mallory starter.

2

Page 3

Step 7

Vehicles with remote Solenoid (includes most Ford/AMC):

FIGURE D WITH STOCK STARTER

BATTERY

REMOTE

SOLENOID

Move the starter cable from the current position on the remote solenoid to the

opposite side (same side as battery cable).

Run a 10 gauge or larger wire from the remote solenoid terminal (where the

starter cable used to be) to the small terminal on the Mallory starter solenoid.

STOCK STARTER

STARTER CABLEBATTERY CABLE

NOTE: Mallory does not recommend using a jumper wire on the

solenoid. Installing a jumper wire on a permanent magnet motor can

result in current feedback, which can cause the pinion to remain

engaged with the flywheel after the engine starts. This will result in

eventual starter failure.

FIGURE E WITH MALLORY COMP® STARTER

2 GAUGE OR LARGER

BATTERY

BATTERY CABLE

REMOTE

SOLENOID

STARTER CABLE

10 GAUGE OR LARGER

3

Page 4

Starter Shims

When using a starter that bolts to the engine block, it is sometimes necessary

to shim the starter to get smooth engagement. If the starter grinds (does not

engage ring gear smoothly) when the key is turned, shims may be required.

Mallory Comp

any auto parts store. Start with the thinnest shim. Do not use any more shims

than necessary to get smooth engagement. No more than .093" of total shims

should ever be used. If the starter still does not engage smoothly, check the

ring gear teeth for damage.

NOTE: If the starter engages the ring gear but is noisy while turning

the engine over, too many shims are being used or the ring gear/pinion gear is damaged.

®

Starters are designed to use the stock type shims available at

MALLORY IS A DIVISION OF THE MR. GASKET PERFORMANCE GROUP

550 MALLORY WAY, CARSON CITY, NEVADA 89701

(775) 882-6600 FAX (775) 887-4326

www.mrgasket.com

4

FORM #1434

(REV. C) 1/00

Made in U.S.A.

Printed in U.S.A.

Loading...

Loading...