Page 1

1

ACCEL www.accel-motorcycle.com

ACCEL COIL KIT # 140405

FORM 3-501-87 01/10

ACCEL’s 140405 high output coil for the Harley V-Twins

is designed to yield higher spark energy output than the

stock coils.

This kit comes complete with adjustable angle clamps and

brackets as well as extra heavy-duty ACCEL 8.8 silicone

insulated suppression core wires that are compatible with

the O.E.M. Harley-Davidson electronic ignition as well as

points-triggered ignition. For maximum output for the

Harley-Davidson engines from 1965-1979, using pointstriggered ignition, ACCEL recommends using ACCEL 8.8

Stainless Steel/Copper Core conductor. See an ACCEL

catalog for your specific application.

NOTE: DO NOT USE STAINLESS STEEL/COPPER CORE CONDUCTOR

WIRES WITH HARLEY-DAVIDSON MODELS THAT UTILIZE A FACTORY

ELECTRONIC IGNITION MODULE AS IGNITION MODULE DAMAGE MAY

RESULT.

NOTE: THE DESIGN CHARACTERISTICS OF THIS COIL REQUIRE

EXTRA LONG LAMINATIONS WHICH MAY REQUIRE THE REMOVAL

OR MODIFICATION OF SOME COIL COVERS. DO NOT REMOVE ANY

MATERIAL FROM THE LAMINATIONS.

Step 1

Be sure the ignition switch is in the “OFF” position.

Step 2

Remove original coil and mount ACCEL coil bracket clamps

and the coil itself with the towers in approximately the same

direction as the original coil. Tighten coil clamps snugly

enough to permit rotation of the coil body insuring that there

is no possibility that the coil’s molded shell or towers or towers

could come in contact with the frame, fuel tank, etc. under

vibration when running.

Step 3

Attach primary leads from the ignition switch and ignition

pick-up to either of the brass lead studs. These can be

installed to either stud without negatively affecting the system.

Step 4

Now install the 90° plug end boot of the ACCEL 8.8 wires to

each spark plug and route them as directly as possible to the

coil tower allowing slack to keep tension off each wire. Either

wire can be attached to either coil tower.

Step 5

Estimate how much excess wire should be cut from the

unterminated end. (Fig. A)

Step 6

Slide coil boot onto spark plug wire. (Fig. B)

Step 7

Strip 1/2” of insulation away from the spark plug wire conductor

core. Be very careful not to cut or nick the conductor core when

stripping away. (Fig. C)

Step 8

Fold conductor core back along wire. (Fig. D)

Step 9

Put coil terminal over conductor and crimp into place. (Fig. E)

Step 10

Apply a light coat of high dielectric lube (enclosed) to the inside

of the straight coil end boots and the angled spark plug boots

before they are installed. This prevents possible voltage leakage

around the boots.

Step 11

With the coil and wires mounted, be sure coil towers are

adjusted to insure maximum frame or tank clearance and

tighten clamps firmly. After use, check and retighten clamps

to insure coil is secure. We suggest using Loctite on the

clamp nut threads and checked periodically.

Step 12

We also suggest that spark plug readings be taken and that

carburetion jetting be checked after installation.

INSTALLATION INSTRUCTIONS

Page 2

ACCEL MOTORCYCLE IS A DIVISION OF PRESTOLITE PERFORMANCE

10601 MEMPHIS AVE #12, CLEVELAND, OH 44144

216.688.8300 FAX 216.688.8306

FORM 3-501-87

01/10

Printed in U.S.A.

2

www.accel-motorcycle.com ACCEL

CUT

Figure A

STRAIGHT COIL BOOT

Figure B

STRIP

Figure C

FOLD

Figure D

Place bottom half of crimping

tool in vise.

Place wire in tool as shown with upper half of

crimping tool over tabs. Strike with hammer until

a firm crimp is achieved.

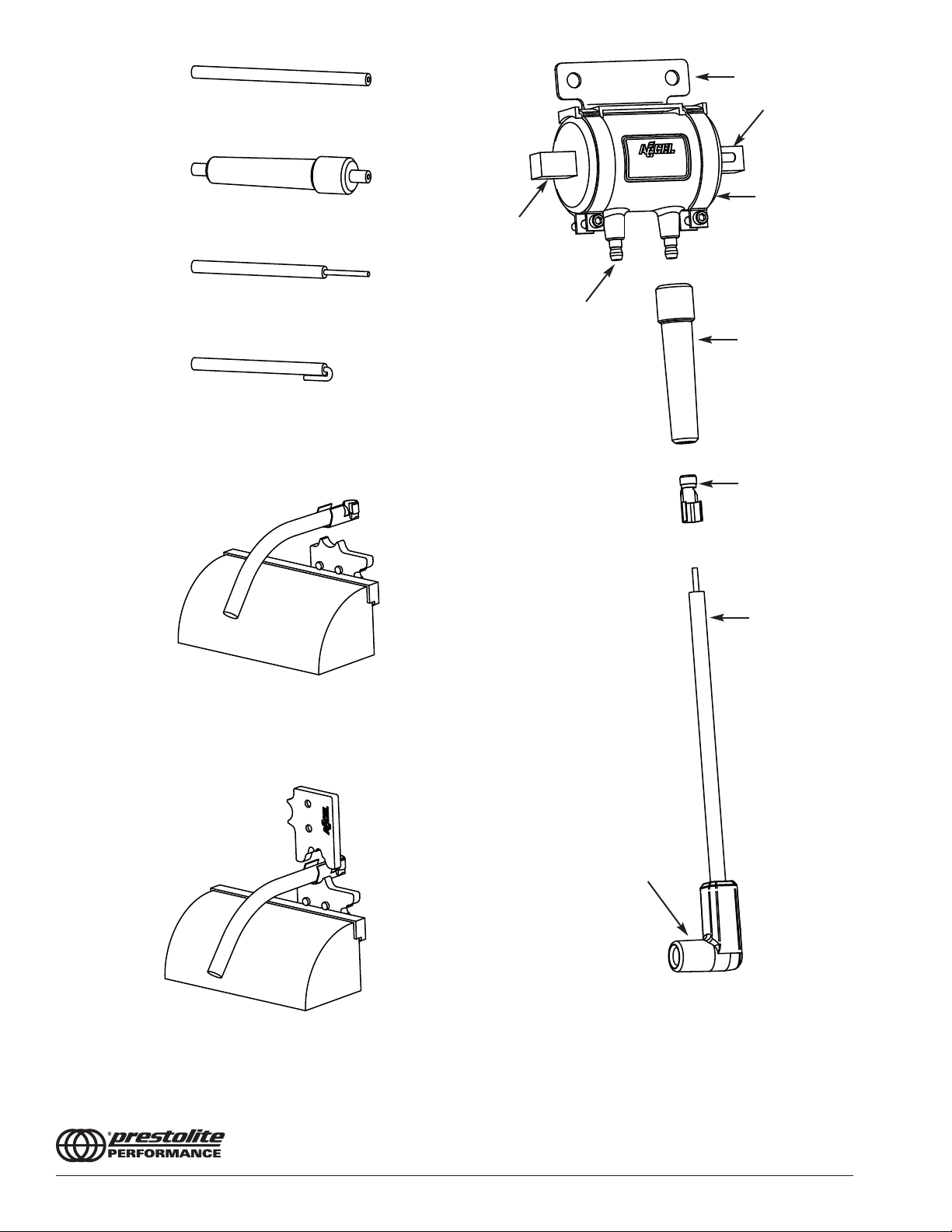

COIL BRACKET

PRIMARY

TERMINAL

STUD

MULTI-ANGLE

CLAMPS

LAMINATIONS

COIL TOWER

STRAIGHT SILICONE

COIL TOWER BOOT

STAINLESS STEEL COIL

TOWER TERMINAL

ACCEL 8.8

SILICONE WIRE

FACTORY TERMINATED

90O SILICONE PLUG BOOT

Loading...

Loading...