Page 1

LAKEWOOD “TRACTION . . . ACTION” LIFT BARS

INSTALLATION INSTRUCTIONS

Part #21700

Fits 1982-2001 Camaro/Firebird

Features:

• Legal for NHRA Stock Eliminator Classes

• Completely bolt-on. No welding required

• “Adjustable” load control strut link to allow

right or left suspension pre-load for fine tuning

the chassis under various track conditions

• Polyurethane bushings for positive suspension

control and stability

IMPORTANT!

Read this instruction sheet completely

so that you thoroughly understand it

and can become familiar with the procedure

before attempting installation.

WORK SAFELY!

Installation of these traction bars requires

working underneath vehicle.

USE EXTREME CARE AND CAUTION WHEN

WORKING UNDERNEATH VEHICLE.

Never get near or under vehicle until you are

confident that it is safely supported and will

not move or fall from its raised position.

DO NOT USE A BUMPER JACK.

PREPARATION FOR INSTALLATION

1. Place vehicle on a solid level surface to ensure

safe installation.

2. Place wheel blocks in front of and behind

both front wheels to prevent movement in

either direction.

2. Apply lubricant (supplied) to polyurethane

bushings and steel sleeves, then install into

eyelet ends as shown.

3. Assemble load control strut links using ball rod

ends and hex jam nuts supplied.

Note:

There are right and left hand thread ball rod

ends, use the correct ball rod end and hex

jam nut on each end of the strut link.

TRACTION BAR INSTALLATION

Note:

We recommend working on only one side

at a time. The traction bars should be

installed with the load control strut bracket

facing down and positioned toward the

front chassis mount.

CAUTION:

DO NOT BEGIN THIS INSTALLATION UNTIL

YOU ARE CONFIDENT THAT VEHICLE IS

SECURE AND SAFELY SUPPORTED!

1. Remove both rear wheels.

2. Apply penetrating oil or rust release lubricant

to front and rear mounting bolts of lower

control arms, lower shock absorber studs and

stabilizer bar hardware.

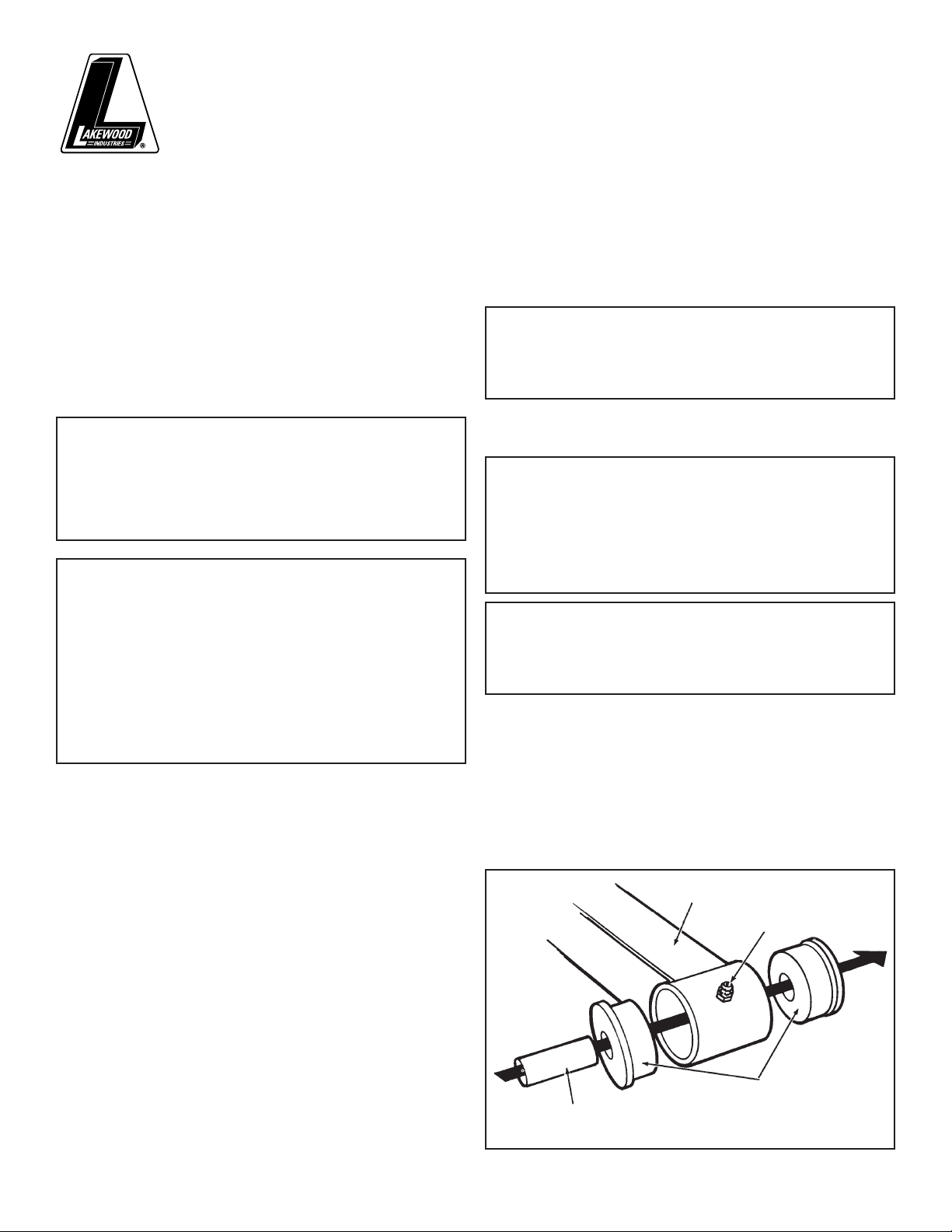

ILLUSTRATION #1

TRACTION

BAR

GREASE

FITTING

3. Raise rear of vehicle and support axle housing

using approved automotive support stands

having adequate load capacity.

TRACTION BAR ASSEMBLY

1. Install grease fittings (supplied) into each end

of traction bar by driving fittings into drilled

hole of bushing eyelet using a hammer and

either a 9/32” or 7mm socket. Use care not to

damage fittings

THE MR. GASKET PERFORMANCE GROUP • CLEVELAND • OHIO • WWW.MRGASKET.COM ©2001 REVISION 2

(see illustration #1)

.

STEEL

SLEEVE

URETHANE

BUSHINGS

Page 2

3. Remove lower shock absorber nut and lock

washer. Compress shock slightly to facilitate

removal of shock stud from axle housing

bracket.

Caution:

Shock absorbers are pressurized with gas,

use care when removing stud from bracket.

Carefully release shock allowing it to

extend all the way out.

4. Remove stabilizer bar from axle housing only

and let hang until new traction bars are

installed.

5. Remove factory lower control arm. DO NOT

discard the front bolts and nuts, they will be

reused.

Note:

If vehicle is equipped with emergency brake

cable bracket mounted to the factory

control arm bracket, let cable and bracket

hang temporarily.

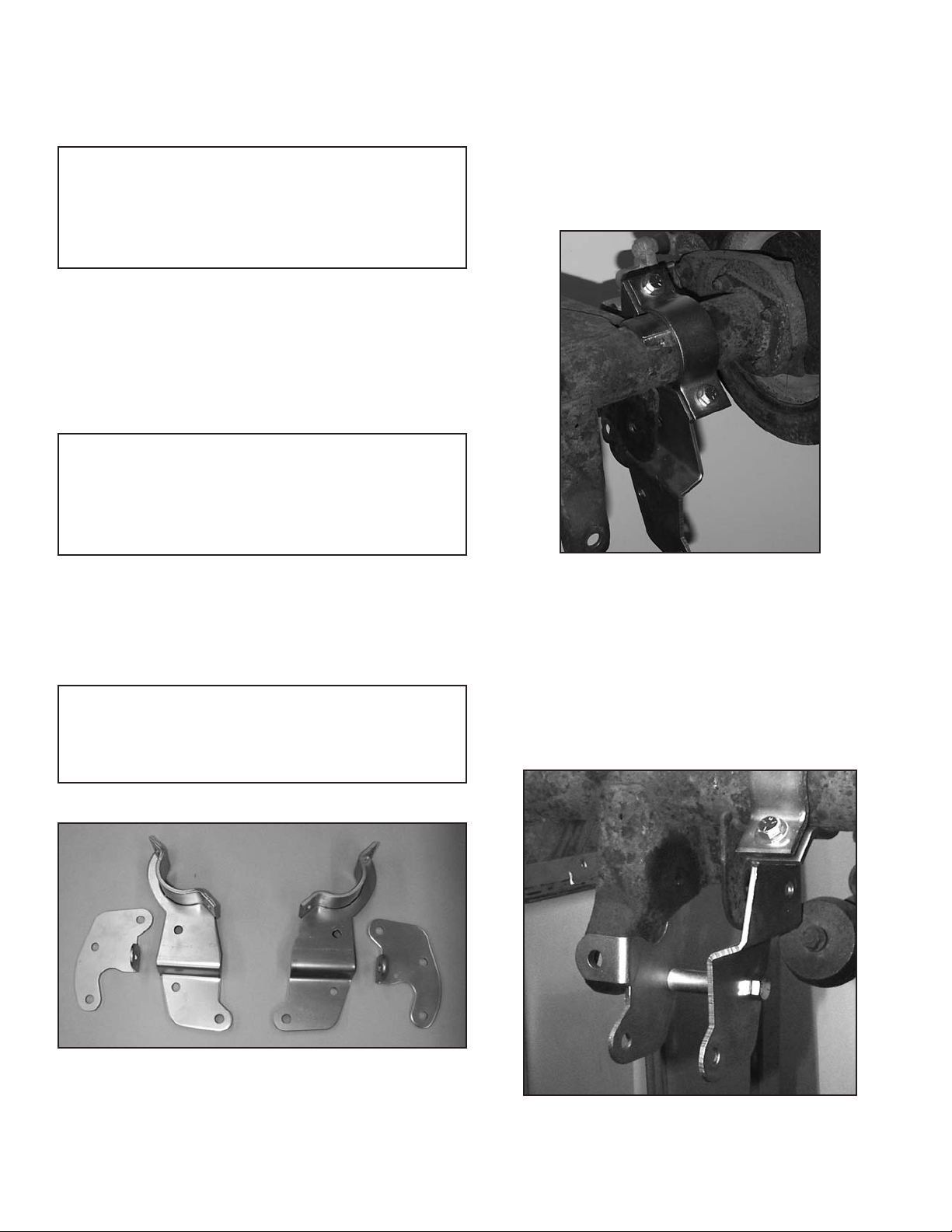

6. Place outer traction bar bracket into position on

the side of existing factory control arm bracket

located on the axle housing (upper part of

bracket will be spaced approximately 1” away

from the factory mounting bracket).

Note:

There are right and left-hand

inner/outer brackets.

Refer to photo # 1 for identification.

Install upper axle housing clamp and align

the clamp bolt holes with the lower bracket.

(See photo # 2)

. Install the 7/16-14 x 1-3/4”

hex head bolts (supplied). Thread on the 7/16-14

self-locking hex nuts and tighten only snug.

Use the supplied flat washers between the bolt

heads/hex nuts and bracket clamp surface.

7. Place inner traction bar bracket into position

on the side of the factory control arm bracket.

Align mounting holes for shock absorber

stud. Re-attach shock absorber stud to mount

hole and fasten with hex nut and lock washer

previously removed. DO NOT tighten securely

at this time

(see photo #3)

.

PHOTO #1

PHOTO #3

PHOTO #2

Right Hand Side Left Hand Side

Left Hand Driver’s Side Shown – Front View

Left Hand Driver’s Side Shown – Front View

Page 3

8. Install the front end of the Lakewood

Traction Bar to the front chassis mount using

the mounting hardware previously removed. DO

NOT tighten securely at this time.

Note:

Either end of the strut link may be connected

to the traction bar.

Note:

The traction bar should be installed with the load

control strut bracket facing down and positioned

toward the front.

9. Swing the rear of the bar up into the stock

factory mounting brackets. Align the holes in

the new mounting brackets with the existing

holes in the factory mounting brackets. Place

and align the 3/4” spacer and flatwasher

(supplied) between the factory outer bracket

and new outer bracket before installing the

mounting bolt

Factory

Outer

Bracket

Flat

Washer

(see photo #4)

PHOTO #4

.

Attach other end of strut link to lower holes

of new brackets on axle housing using a 15/16”

spacer (supplied) on each side of the ball rod

end (adjust load control strut to either shorten

or lengthen in order to align mounting holes

keeping the same amount of thread exposed

on each end of the strut). Fasten to the brackets

using the 1/2-20 x 4” hex head bolt and self

locking hex nut (supplied). Tighten only snug

at this time

(see photo #5).

PHOTO #5

Spacer

New

Outer

Bracket

Note:

If vehicle is equipped with emergency brake

cable bracket (previously removed),

DO NOT use the flatwasher. Use the spacer as

instructed above and position the cable

bracket over the new inner bracket and the

factory outer axle bracket. Cable bracket

will need to be spread apart slightly

in order to fit properly (see photo #4)

.

Install the new metric 12mm x 1.75 x 120mm

hex head bolt (supplied). Thread on the new

metric hex nut (supplied) and tighten only

snug at this time.

10. Attach the load control strut link to the bracket

on the traction bar using the

1/2-20 x 1-1/2” hex head bolt and self

locking hex nut (supplied). Tighten securely.

11. Position the long spacer tube between the new

brackets and align with the remaining holes

below the traction bar mount. Install the

1/2-20 x 4” hex head bolt (supplied) through

the bracket and spacer and thread on the self

locking hex nut

(as seen in photo #6)

.

Tighten securely.

Note:

If vehicle is equipped with emergency brake

cable bracket, use flat washers supplied

between 15/16” spacer and bracket and the

long spacer and bracket. If the vehicle does not

use emergency brake bracket DO NOT use the

flat washers supplied (see photo #6).

12. Securely tighten all traction bar mounting

bracket hardware at this time. Tighten front

and rear traction bar mounting bolts to

80 ft./lb. torque.

Page 4

RETAIN THIS INSTRUCTION SHEET

FOR FUTURE REFERENCE.

P/N 97144052 Rev. 12/01

13. Follow the same above procedure for

installation of Lakewood Traction Bar on

other side of vehicle.

14. When both traction bars are installed, re-

attach the stabilizer bar to the axle housing.

Tighten securely.

15. Lubricate both ends of the traction bars with a

good quality chassis grease.

16. Install wheels and properly tighten lug nuts to

wheel manufacturers specifications.

17. Carefully remove support stands and lower

vehicle to ground.

18. With vehicle on level surface, load control

strut links should be adjusted so that front

ball rod end mount has no load on it.

Adjust load control strut to either shorten

or lengthen in order to align mounting holes

so that bolt can be installed or removed

without any bind.

19. Tighten ball rod end mounting bolt and ball

rod end hex jam nuts securely.

This completes the installation. You can now

test drive the vehicle and will notice a big

improvement in traction control.

Important:

Periodically check to make sure that all

mounting hardware is securely tightened.

Use a good quality chassis grease to keep

bushings and sleeves properly lubricated.

Chassis Tuning Tips for Drag Racing

The stabilizer bar is not recommended for drag

racing. It is used to control body roll under

road handling conditions.

Recommended optional

Lakewood products:

• For drag racing, the factory rear shocks

should be replaced with a 50/50 ratio shock

absorber available for 1982-92 model years

(#40301).

• Replacement Bushing Set for Traction Bars

(#20538).

• Front Drag Struts are also available for

1982-92 model years in ratios of 70/30

(#40500) or 90/10 (#40510).

• Bolt-in Safety Drive Shaft Loop available for

1982-92 model years (#18020), 1993-2002

model years (#18022).

See your local retailer of Lakewood products

for specific prices.

TECHNICAL SERVICE

A highly trained technical service department is

maintained by Lakewood Industries to answer your

technical questions, provide additional product

information and offer various recommendations.

See your local retailer of Lakewood products for

specific prices. For best results, technical service

calls, correspondence and warranty questions

should be directed to the following address:

Lakewood Industries

10601 Memphis Ave., #12

Cleveland, Ohio 44140

Phone 216.688.8300

8:30 A.M.-5:00 P.M. EST

www.mrgasket.com

PHOTO #6

Left Hand Driver’s Side Shown – Rear View

Flat

Washers

Needed

Loading...

Loading...