Page 1

1

1964-1972 (All GM A-Bodies) & 1978-1987 (All GM G-Bodies)

INSTALLATION INSTRUCTIONS

LAKEWOOD INDUSTRIES

LAKEWOOD

“TRACTION...ACTION” LIFT BARS

Part Number #21312 / 21313

WORK SAFELY!

For maximum safety, perform this installation on a

clean, level surface and with the engine turned off.

Place blocks or wedges in front of, and behind both

rear wheels to prevent movement in either direction.

CAUTION: To avoid any possibility of bodily injury or

damage to vehicle, do not attempt installation until

you are confident that the vehicle is safely secured

and will not move.

PREPARATION TIPS FOR INSTALLATION

1. Place vehicle on a solid level surface to ensure safe

installation.

2. Place wheel blocks in front of and behind both front

wheels to prevent movement in either direction.

3. Raise rear of vehicle and support axle housing using

approved automotive support stands having adequate

load capacity (6” inside from each control arm).

4. With a paint scraper, scrape all the undercoating

and rust off the inside of the frame and rear end lift

bar mounting areas.

GM LIFT BAR INSTALLATION

1. On a work bench, drive the grease fittings into the

1/4” holes in the front and rear of bars as follows:

Use a 1/4” deep well socket and a small hammer.

Place a small amount of bearing grease on the ball

end of each grease fitting so that the fitting will

temporarily stick to the end of the 1/4” socket.

Place the fitting into the hole, then one at a time,

drive them in.

2. Grease the ends of the front bar bushings and align

the nylon washers over the steel inner bushing. The

grease will hold the washers in place temporarily.

Also grease the inside of the front frame lift bar

mounting brackets.

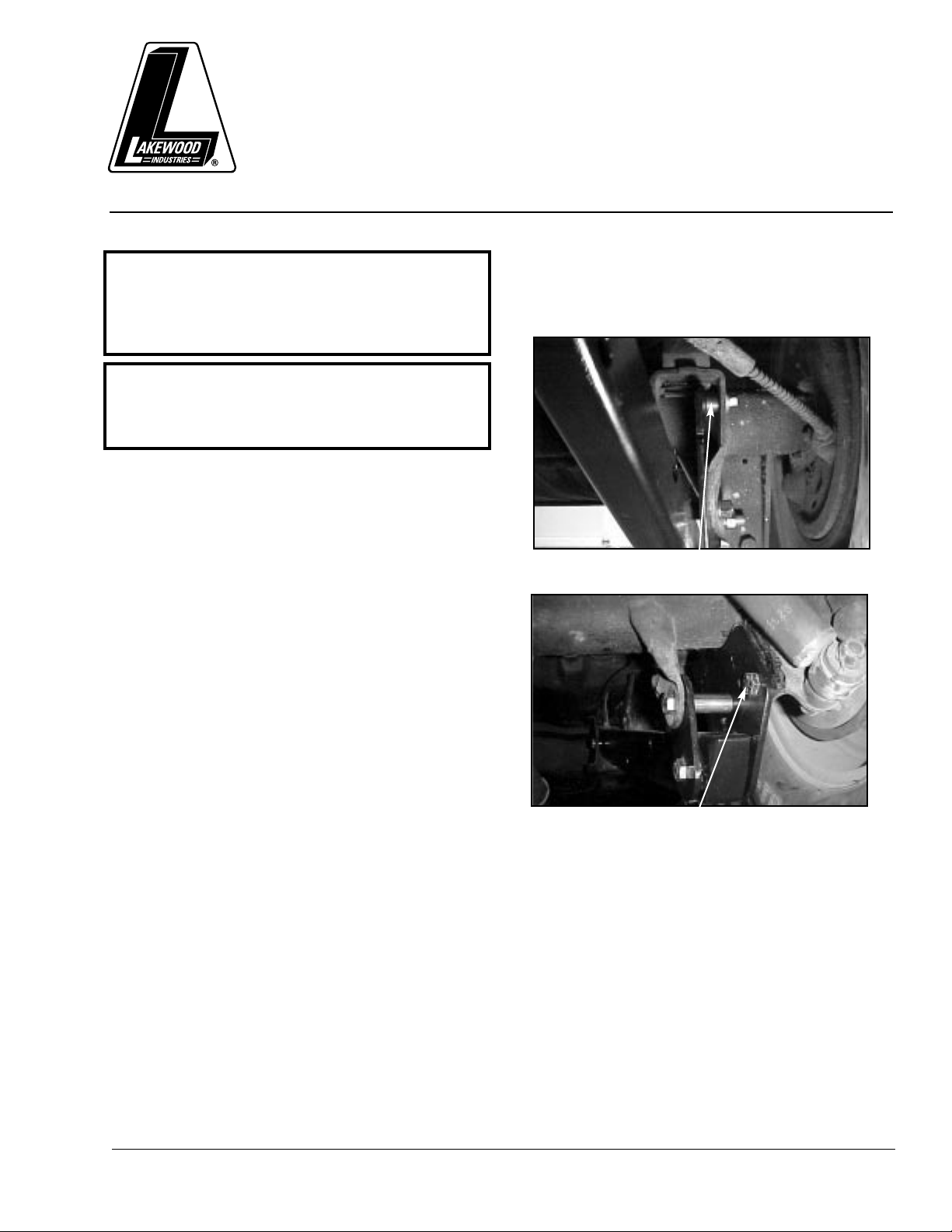

3. Place each lift bar into front frame brackets , align

bolt holes and insert the correct bolt supplied, from

the inside of the frame. Place self locking nut into

socket with extension then attach through the

outer frame holes.

4. Attach rear lift bar mounting plates as shown. use

the hardware supplied at the stock GM

lower control arm bolt holes. Place proper bolts

through these bolt holes and secure lock washers

and hex nuts. If preferred, thread locking liquid can

be used. Do not tighten fasteners yet.

5. Grease the ends of the rear bar bushings and place

nylon washers over the steel bushings just like in

step 2. Swing lift bars up between rear mounting

plates. Align the bolt holes and insert proper bolts

supplied. Attach lock washers and hex nuts and

tighten all bolts and nuts.

6. The pinion angle must now be checked and

adjusted if necessary. The angle between the drive

shaft and the rear end yoke must be between 4 and

6 degrees down. See pinion angle explanation sheet.

(SEE NUMBERS 1, 2, 3, 4 ON THE NEXT PAGE.)

7. With pinion angle set, tighten all fasteners securely.

8. A hole must be drilled through one of the rear lift

bar brackets (if not already drilled in)and through

(SEE NUMBER 4 ON THE NEXT PAGE.)

GM A-BODY

Small bushing used on the 21312 only

GM A-BODY. 64-72

GM A-BODY

Bolt here if not welding.

Page 2

LAKEWOOD INDUSTRIES

2

the housing brackets on each side. Using a hand

drill with a 1/2” chuck, drill 1/2” holes through the

rear mounting plates then through the factory lower

control arm housing brackets. Spot drill using a

1/4” drill, then change to a 1/4” drill size. Drill through

with the 1/4” drill bit then drill through with a 3/8” drill

bit and last with a 1/2” drill bit. CAUTION: Be very

careful when drilling through that the drill bit does not

grab and whip the drill around out of your hands.

9. Insert short 1/2” bolts, lock washers and nuts then

tighten securely.

10.Grease the four fittings in the bars through the

holes in bottom of bars.

11.If the anti-roll bar is going to be used, it can be

attached to the holes provided in the lift bars.

Place the spacers between the anti-roll bar and lift

bars (if necessary) on each side and use factory

GM bolts and nuts. tighten securely. NOTE: for

drag racing use, we recommend not using the

anti-roll bar.

12.Place car back on the ground and you are ready

to test.

CAUTION: TO USE YOUR LIFT BARS ARMS TO

ADJUST YOUR REAR END PINION ANGLE,

FOLLOW DIRECTIONS BELOW.

1. Remove car from jack stands. now place car upon

blocks or car ramps so that the car weight is on all

(4) wheels, keeping the car level, but making sure

you still have room to work under the car to make

your adjustments.

2. With the car up in the air you will need to check the

pinion angle of the rear end and drive shaft. Read

the attached sheet on setting pinion angle. You will

need to aquire a magnetic protractor (angle finder)

to do this operation.

3. Read this before performing the next operation ! !

Using a magnetic protractor (angle finder) check the

pinion angle. If you can’t obtain the desired 4-6

degree pinion angle, then loosen the 4 lower bolts

and pry between the shock stud and control arm to

adjust angle. Tighten all bolts securely while

checking pinion angle.

4. Do not attempt to drive the car with out securing

the lift bar plate to the axle housing plate welded or

bolted. Center punch and drill starting with 3/16” as

a pilot hole then step up the sizes using 1/4”, 5/16”,

3/8” and finishing with 1/2” for final size. Then

install the 1/2” bolts, lockwashers and nuts and

tighten. (torque to 65 ft lbs.)

5. Remove car from the support stands or car ramps

and place it on the ground. You are now ready to

Rock & Roll!!

PLEASE NOTE

1. Be sure to check the bolts frequently. make sure

they are tight and always stay tight. you can use

thread lock if you wish.

2. Welding is recommendedf (but not required) to

secure the lower plates to the lower axle brackets.

3. These lift bars are legal for use in NHRA stock

eliminator classes as a bolt on application only!

(no welding is allowed).

GM A-BODY

Sway bar holes.

GM G-BODY

2 bolts here if not welding.

Sway bar.

GM G-BODY

2 bolts here if not welding

Sway Bar

Sway Bar spacer bushings

Page 3

3LAKEWOOD INDUSTRIES

PINION ANGLE

Pinion angle affects the efficiency of power

transmission from the driveshaft to the rearend. The

pinion angle is the difference between the pinion

centerline and the driveshaft centerline. for maximum

performance, the ideal is to have a slight pinion down

angle (min. 2 degrees) under full power. Obviously, the

pinion angle changes as power is applied, so the axle

housing begins to twist as the pinion tries to drive the

ring gear. Rear axle wind-up can take some of the

intial energy or “hit” away from the launch. As a

general rule, a leaf spring rear suspension should

have between 5-7 degrees of static pinion angle

(pinion down); and a factory four-link should be set

between 4-6 degrees.

Keep in mind that these pinion angles are for

competition. If you primarily drive your car on the

street, you shouldn’t have more than a 5 degree

angle, max. The u-joints are designed to run at this

angle, which allows the cups to rotate, avoiding

premature wear and failure. This doesn’t affect leaf

spring supension, since it runs well within this

tolerance.

You will need to have the car level, up on (4) car

ramps or blocks of equal heights, so you have room

to work under the car when checking the pinion

angle. Also, both the front and rear suspensions need

to be loaded to get accurate readings. The height of

the rearend (relative to the rest of the driveline) will

affect the pinion angle. Using an angle finder, which is

a tool the combines a bubble level and protractor, to

determine the correct pinion angle for your car.

Position the angle finder on the driveshaft and record

the measurement, and then place the angle finder on

the pinion (the u-joint yoke rotated to vertical position

will give an accurate reading) and record the

measurment. The pinion angle is a combination of the

two measurements.

EXAMPLES:

(pinion 0 degrees & driveshaft 6 degrees = 6 degrees total )

(pinion 2 degrees & driveshaft 4 degrees = 6 degrees total )

(pinion 3 degrees & driveshaft 3 degrees = 6 degrees total )

(pinion 4 degrees & driveshaft 2 degrees = 6 degrees total )

(pinion 6 degrees & driveshaft 0 degrees = 6 degrees total )

OTHER SUSPENSION TIPS!

THE FOLLOWING ARE FINE TUNING TIPS FOR

YOUR SUSPENSION

You can purchase shocks that are 3 position

adjustable for both front and rear applications. These

shocks are available from your local speed shop, or

other suppliers. If you can’t find shocks designed for

your specific application, you’ll have to check in a

shock catalog for O.E. applications. You may have to

use shocks from another make or model that has the

same mounts at each end, and the same length, or an

inch or two longer, which won’t hurt, because it allows

for more suspension travel, so you don’t hit the end of

your shock travel and pull the rear wheels off the

ground.

LEAF SPRING REAR SUSPENSION

With Lakewood lift bars, there are shims supplied with

the bars that are used to put more preload in the bars.

When installing the bars always put one more shim on

the right side (pass. side) than the left side (drivers

side). This extra shim helps to counteract engine

torque wanting to lift the left front corner. Use 90/10

front shocks on small blocks, 80/20 or 70/30 with big

blocks and high horsepower small blocks. use 50/50

shocks on the rear.

COIL SPRING REAR SUSPENSION

Use 90/10 front shocks on small block cars, 80/20 or

70/30 on big blocks cars, and high horsepower small

blocks. Except on short wheel base cars like

Mustangs and Capri’s, use the 80/20 or 70/30

settings. Use 50/50 rear shocks along with an air bag

in the right rear coil spring only (4-8 lbs. air), this you

will have to play with to find the best setting for your

car. The air bag is used to counteract the engine

torque wanting to lift the left front corner.

CHASSIS WORK

To help the effects of the lift bars, a minimum of six

point cage to stiffen the chassic up would help. That

way the chassis is not absorbing the energy hit or the

bars, and all the energy will be directed to the tires, to

help lay out a bigger footprint.

**NOTE: THIS DRAWING IS AN

EXAGGERATION.

THE PINION ANGLE IS THE RELATION

BETWEEN THE PINION CENTERLINE

AND THE DRIVESHAFT CENTERLINE.

Page 4

Recommended chassis modifications:

For serious drag racing, we recommend

reinforcing the upper and lower control arm

chassis mounts. They are only spot welded

in place from the factory but should be fully

welded to the floor pan for added strength.

T uning Tips:

These traction bars can be attached to the axle

housing brackets in 1 of 2 positions. The lower

holes will cause the rear tires to “plant” harder

than the upper holes. If you have too much

traction, move the rear attachment to the upper

holes of the axle housing brackets.

Illustration #2

shows what happens to the

instant center (imaginary intersection point

between the upper and lower control arms)

when the lower control arms are attached to

each of the two optional mounting holes in the

axle housing brackets.

When the differential pinion gear is turned by

the drive shaft, which is driven by the engine,

the pinion gear turns the ring gear causing the

axle housing to rotate, pulling back on the upper

control arms and pushing forward on the lower

control arms. These forces theoretically meet

at the instant center point (as shown on the

illustration). The shorter the instant center point

is, the more the tires will separate from the body

upon launch.

IMPORTANT!

Periodically check to make sure that all mounting

hardware is securely tightened. Use a good

quality chassis grease to keep bushings and

sleeves properly lubricated.

TECHNICAL SERVICE

A highly trained technical service department is

maintained by Lakewood Industries to answer your

technical questions, provide additional product

information and offer various recommendations. See

your local retailer of Lakewood products for specific

prices. For best results, technical service calls,

correspondence and warranty questions should be

directed to the following address:

Lakewood Industries

10601 Memphis Ave. #12

Cleveland, Ohio 44144

Phone 216-688-8300

8:30 A.M.-5:00 P.M. EST

www .mrg asket.com

Recommended Optional

Lakewood Products:

• For drag racing, the factory rear shocks

should be replaced with a 50/50 ratio shock

absorber available for 1982-92 model years

(#40301).

• Replacement Bushing Set for Traction Bars

(#20538).

• Front Drag Struts are also available for

1982-92 model years in ratios of 70/30

(#40500) or 90/10 (#40510).

• Bolt-in Safety Drive Shaft Loop available for

1982-92 model years (#18020), 1993-2002

model years (#18022).

See your local retailer of Lakewood products

for specific prices.

LAKEWOOD IS A DIVISION OF THE MR. GASKET PERFORMANCE GROUP

10601 MEMPHIS AVE. #12, CLEVELAND, OH 44144 • 216.688.8300 EXT. 500

VISIT US ON THE WEB AT: www.mrgasket.com or via e-mail at tech@mrgasket.com

Made in U.S.A.

Printed in U.S.A.

Form# 97140080

STOCK

LOCATION

B

A

LOWER CONTROL ARM ATTACHING POINT

ILLUSTRATION #2

Loading...

Loading...