Page 1

INSTALLATION INSTRUCTIONS

“TRACTION…ACTION!” SUSPENSION BARS - Part No. 21150

FORM 9744065 07/11

Thank you for your purchase from Lakewood Industries. For

technical assistance, please call 216-688-8300 Monday thru

Friday 8:30 AM to 5:00 PM EST.

CAUTION: INSTALLATION OF THIS PRODUCT REQUIRES WORKING UNDER

THE VEHICLE. IT IS THE RESPONSIBILITY OF THE INSTALLER TO ENSURE

A SAFE WORKING ENVIRONMENT. THE USE OF AN AUTOMOTIVE LIFT IS

RECOMMENDED. MAKE SURE THAT THE VEHICLE IS SAFELY SUPPORTED

AND ALWAYS USE JACK STANDS. ALWAYS WEAR SAFETY GLASSES.

STEP 1

Raise the rear of the car, using as level a floor as possible, and

remove wheels.

STEP 2

Disconnect lower shock absorber attachment. On early Corvettes

and some American Motors it is necessary to remove all factory

traction devices.

A. Sway bars on cars with suspension package may have to

be modified or removed to fit suspension bars.

STEP 3

Support the car at front spring hangers, allowing the axle housing

to rest on the springs.

STEP 4

Remove the stock lower spring clamping plates.

A.

For street use we recommend using GM factory replacement

“U” bolts on Camaro, Chevy II and Firebirds when not

furnished.

B. For model no. 21140, when used with “J” bolt option on

Camaro, Chevy II and Firebird, “T” bolts will be placed in

front holes of suspension bars. (If car was not equipped

with “T” bolt, your GM dealer has replacements.)

C. 1965-68 Mustang, Cougar, Falcon and Fairlane with

necked down axle housing, discard the original equipment

axle housing “U” bolts and replace with 3 ¼ “ center to

center (Ford no. C6DZ-5705A) “U” bolts. On some models

it may be necessary to saw off the outside shock mount tab

using hacksaw, due to backing plate interference.

D. For street model no. 21310, insulator pads must be

removed. The housing locators supplied in kit must be used

by placing them over the bolt used to hold the leaf springs

together. Discard the original shock mounting plates and

the original axle housing “U” bolts and replace them with 3

½” center to center (Chrysler no. 2834928) “U” bolt.

E. For AMC Spirit applications the rubber insulator pads must

be used. The four holes in the housing locator bracket must

be longated up to the upright section of the bracket, next to

the bend, in order for the bar to accept the “U” bolts. Also

the right side locator bracket must be trimmed at the inside

rear corner so the shock can be attached. The outside edge

of the forward “U” bolt bracket (located near the front of

the traction bar) should be trimmed approximately 3/16” for

added tire clearance.

STEP 5

Do not remove insulator pads on GM cars.

WARNING: DUE TO THE TECHNICAL NATURE OF THIS PRODUCT,

AND SPECIALIZED EQUIPMENT, PROFESSIONAL INSTALLATION IS

RECOMMENDED.

IMPORTANT! J BOLT PART NO. 20580 CAN BE USED ON COMPETITION

BARS ONLY, IF DESIRED. USE OF AIR SHOCKS ARE NOT RECOMMENDED

AS THEY MAY CAUSE SHOCK OR SHOCK MOUNT DAMAGE.

STEP 6

Position the bars over the spring center bolt and start nuts on “U”

bolts. Run the nuts up until they are just finger tight.

A. Determine which shock absorber mounts are to be used

and if necessary, remove the mounts that may interfere with

the backing plates. This may be done with a hacksaw.

B. On Ford applications, it may be necessary to use the spring

center bolt spacer provided with the kit, as some of the

center bolts are different diameters.

STEP 7

Position each of the bars so that they are directly under the center

of each spring at the front and tighten the stock “U” bolts around

the axle housing.

STEP 8

Reinstall the wheels and lower the car on a level floor. CHECK THE

TIRE CLEARANCE!

STEP 9

Carefully determine the amount of bumper height necessary to fill

the gap at the front of the bar (bumpers moved). On competition

only cars, it is best to completely fill the gap. On street/strip cars, a

½” gap on the right bumper and a 3/8” gap on the left bumper will

produce a greatly improved ride. (See note below.)

A. Due to the severe arch variations of some springs, it may

be necessary to shim the rear of the bars by using a wedge

(Lakewood part nos. 20500 & 20510) available at your

Lakewood dealer, part no. 20500 for mild arch and part

no. 20510 for severe arch. This wedge is used between the

spring and the suspension bar plate.

STEP 10

Again raise the car and install the bumpers. (It would be wise to

start all bumper height adjustments with the bumper in the rear

hole on the driver’s side and the front hole on the passenger side.)

STEP 11

Do not attempt to level the car with the bumpers as this will cause

radical preloading and considerable torque steer problems.

STEP 12

Support the car with the axle, reinstall the shocks.

A. When applicable, use a sleeve for the shock bolt to bring it up

to the shock bushing size. There are two bushings supplied

with the kit for this purpose. The small diameter being for

American Motors and the large on for Chrysler products.

1LAKEWOOD www.lakewood-industries.com

Page 2

STEP 13

Run the jam nuts up on all the 3/8” “U” bolts that are supplied with

the kit.

STEP 14

Position the “U” bolts all over the spring and through the strap on the

top of each bar. Run the lower nuts up on the “U” bolts. Lock with

upper jam nuts. Do not attempt to adjust bar height with “U” bolts.

RECOMMENDED STARTING ADJUSTMENTS

1. Be sure that both tire pressures are equal.

2. To correct unequal traction, try the following: If the rear

drives harder with the right wheel, raise the left bumper or

move it forward.

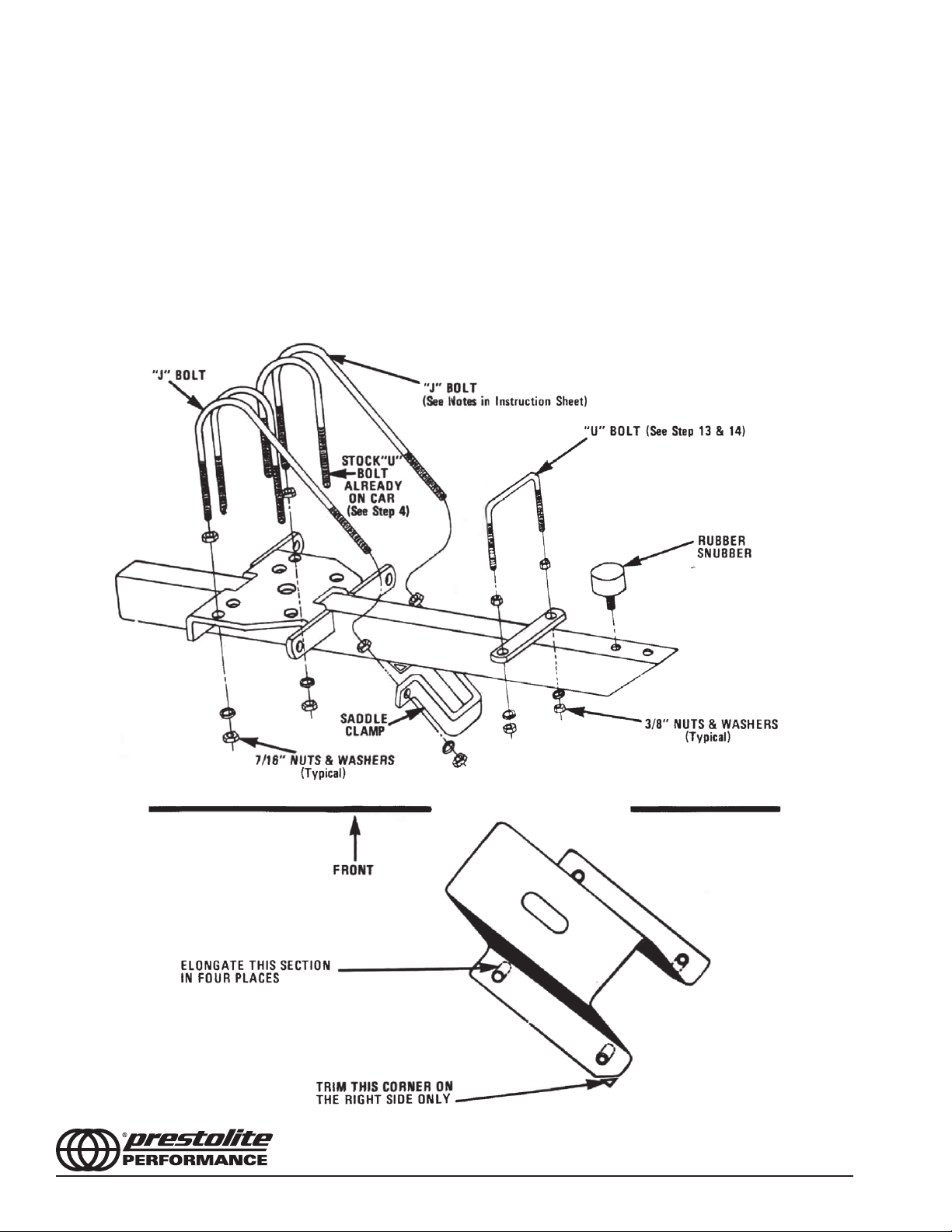

ASSEMBLY INSTRUCTIONS

Typical 21000 Series Traction Bar with 20580 “J” Bolt Option

Figure 1

NOTE: When properly installed, snubber end of traction bar must angle

up or be parallel with chassis: under no circumstances should vehicle be

operated with snubber end angled down. If bar cannot be further adjusted,

use one of Lakewoods suspension bar kits no. 20500, 20502, 20504, or

20510, depending on application.

Lakewood chassis and suspension products are engineered and

manufactured to improve the performance of your vehicle. We

encourage you to enjoy using our products safely at a sanctioned

racing facility. Please obey all traffic laws.

LAKEWOOD IS A TRADEMARK OF PRESTOLITE PERFORMANCE

10601 MEMPHIS AVE #12, CLEVELAND, OH 44144

216.688.8300 FAX 216.688.8306

www.lakewood-industries.com LAKEWOOD2

Figure 2

FORM 9744065

07/11

Loading...

Loading...