Page 1

FACTORY

BRACKET

FORM 97140188 02/11

INSTALLATION INSTRUCTIONS

#20188

1964-77 GM (A-BODY)

COIL SPRING TRACTION BAR

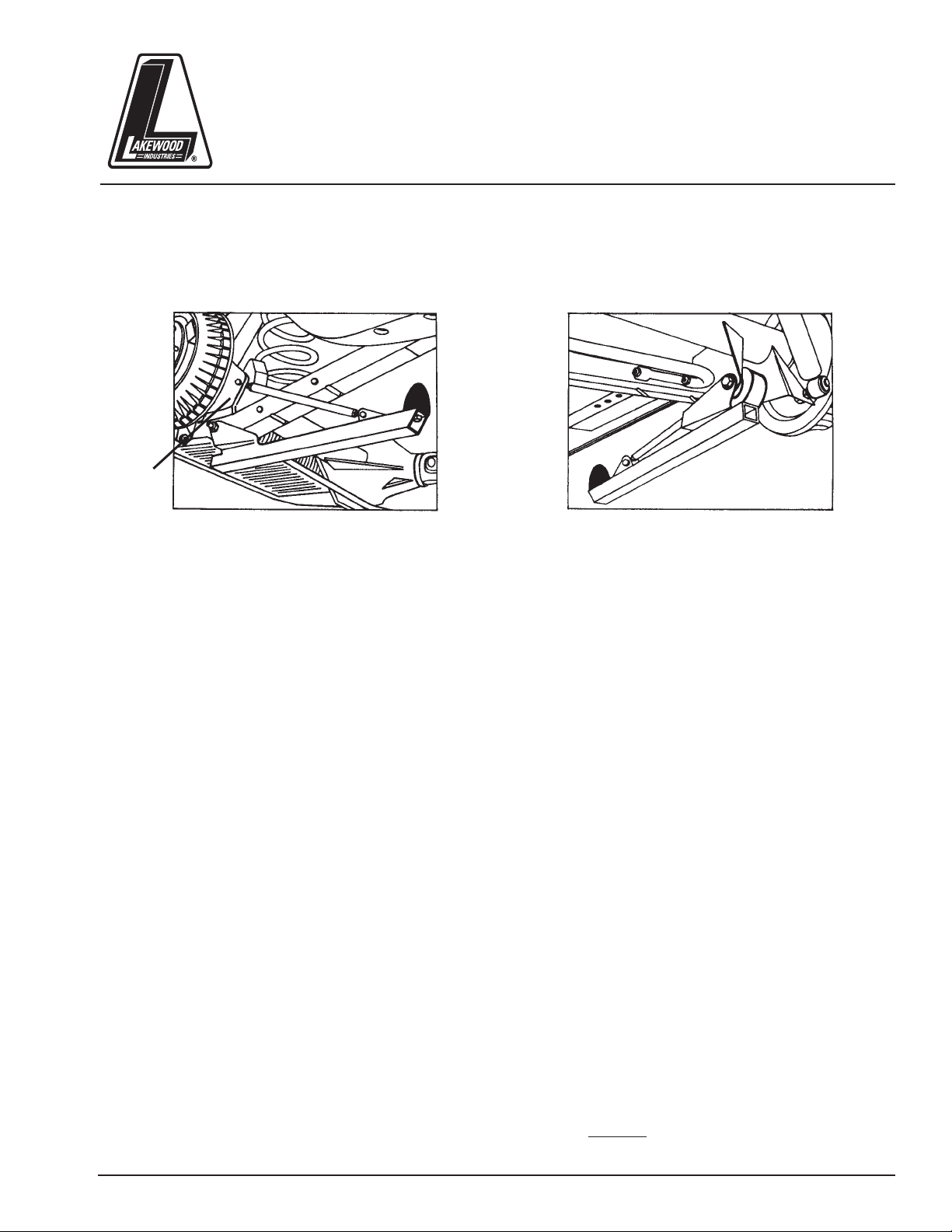

Congratulations! You have just purchased one of the finest

sets of traction bars on the market today. Whether it be

strictly street or professional competition, Lakewood

Industries has the proven engineering it takes for all

racing applications.

NOTE:

For best overall performance we recommend removing

the factory stabilizer bar (if equipped) when installing

these traction bars. If stabilizer bar is retained, inner

corner of traction bar mounting bracket may need to be

filed to provide adequate clearance on some applications.

This will not weaken the traction bar in any way.

WORK SAFELY!

Installation of traction bars requires working underneath

vehicle and should only be performed one side at a time.

USE EXTREME CARE AND CAUTION WHEN WORKING

UNDERNEATH VEHICLE. Never get near or under vehicle

until you are confident that it is safely supported and will

not move or fall from its raised position. DO NOT USE A

BUMPER JACK.

1. Place vehicle on solid level surface such as a garage

floor to insure safe installation.

2. Place wheel blocks or wedges in front of and behind

both front wheels to prevent movement in either

direction.

NOTE: ONLY WORK ON ONE SIDE AT A TIME.

3. Carefully place floor jack under rear differential

housing. Be careful not to damage seal or

companion flange shield with jack.

Lift rear of car up with floor jack and place auto-motive

4.

approved support stands under frame in front of rear

wheels far enough forward so that traction bar installation

will not be interrupted and the wheels do not touch

the ground. Lower floor jack to set vehicle on support

stands.

5. When you are confident that vehicle is secure, raise

differential housing up approx. 1” with floor jack.

Remove rear trailing arm bolt (one side only). If bolt

binds while removing, raise or lower differential housing

with floor jack until bolt can be easily removed.

6. Determine correct bar (right or left) for side you are

working on (when mounted properly traction bar will

be parallel with frame and snubber will align directly

under frame).

7. Attach rubber snubber to front of traction bar as

shown using lock washer and nut (supplied). Tighten

securely.

8. Place traction bar in proper position as shown. Align

trailing arm bolt hole, rear end bracket bolt hole and

traction bar bolt hole. Install 1/2” or 12mm bolts with

self locking nut (supplied) and secure only finger

tight. Your car will either use the 12mm x 90 bolts or

use 1/2”-20 x 4-1/2” long bolts.

9. AT THIS TIME, REPEAT STEPS 5 THRU 8 TO

INSTALL OPPOSITE SIDE.

10. When installation of both traction bars is complete,

lower and remove floor jack to gain easy access to

factory axle rubber snubbers located at front top of

axle housing bracket near rear wheels.

NOTE:

11. Remove factory axle snubbers by prying out of

bracket.

12. Assemble adjustable link using one rod end and jam

nut on each end as shown.

NOTE: DO NOT ATTACH ADJUSTABLE LINK TO

PERFORM STEPS 11 AND 12, ONE SIDE

AT A TIME.

TRACTION BAR BRACKET AT THIS TIME.

LAKEWOOD www.lakewood-industries.com

1

Page 2

13.

Attach both link assemblies to the rod end brackets

as

shown. Carefully remove support stands and lower

vehicle to the ground. You will need car on its own

weight to adjust.

14. Swing traction bar up until air gap between snubber

and frame is approximately 1/8”, then adjust link

length by turning rod ends in or out until lower rod

end will align with bolt hole in welded bracket on

traction bar. Attach with 1/2-20 x 1-1/2” bolt and

self locking nut (supplied) and secure only finger

tight. (Repeat for opposite side).

NOTE: WE RECOMMEND AN 1/8” AIR GAP AS

A GOOD STARTING POINT. GAP CAN

BE ADJUSTED TO SUIT YOUR DRIVING

REQUIREMENTS (SEE TUNING TIPS).

TUNING TIPS

Your rear suspension can be fine tuned for street or

strip. For a good ride, the snubber air gap should be

increased. For a firm competition ride, the snubber air

gap can be decreased. If vehicle torque steers (pulls to

left or right) under acceleration (due to the traction bars),

the snubber air gap can be adjusted to eliminate this

problem.

NOTE: For best results on most vehicles, passenger side

snubber air gap should be less than the drivers side air gap.

After proper adjusting has been completed, your Lakewood

traction bars will be a definite advantage in all of your

acceleration contests.

16. With proper traction bar snubber clearance and

all bolts in place, raise vehicle, place on support

stands, and tighten ALL bolts and nuts securely.

Finally, re-insert the stock axle snubbers over axles

with lubricating oil on tabs for easy installation.

17. Remove support stands and lower vehicle to the

ground. This completes the installation.

It is usually not necessary to weld any of the factory

housing brackets or axle tubes, but it is strongly

recommended for added strength and dependability.

Be sure to keep this instruction sheet for future reference.

Replacement Snubbers are available for your traction bars

from your local Lakewood retailer.

CATALOG #20530 – Rubber Snubbers (2/set)

CATALOG #20730 – Urethane Snubbers (2/set)

For the ultimate in traction performance, use Lakewood

Drag Shocks. Whether its Professional Competition,

Street/Strip, Pro Street, Street Machine or a Muscle

Car, Lakewood has the shock you need. Lakewood

Drag Shocks will provide superior operation over any

other Drag Shock on the market today. See your local

Lakewood retailer for application and price information.

TECHNICAL SERVICE

A highly trained Technical Service Department is maintained by Lakewood Industries to answer your technical

questions, provide additional product information and offer various recommendations. See your local retailer of Lakewood

products for specific prices.

For best results, Technical Service calls, correspondence and warranty questions should be directed to the following

address:

Lakewood Industries Phone: 216.688.8300

10601 Memphis Ave. #12 8:30 A.M. - 5:00 P.M. EST

Cleveland, OH 44144 www.lakewood-industries.com

LAKEWOOD IS A TRADEMARK OF PRESTOLITE PERFORMANCE

10601 MEMPHIS AVE. #12, CLEVELAND, OH 44144

216.688.8300 • WWW.LAKEWOOD-INDUSTRIES.COM

2

www.lakewood-industries.com LAKEWOOD

FORM 97140188

02/11

Loading...

Loading...