Mallory Ignition 20144, 20149, 20154 User Manual

Features:

• Heavy gauge steel eliminates flex increasing traction

• Completely bolt-on, no welding required

• Polyurethane bushings for positive suspension

control and stability

• Completely adjustable to set up your suspension

IMPORTANT!

Read this instruction sheet completely so that

you thoroughly understand it and are familiar

with the procedure before attempting installation.

WORK SAFELY!

Installation of these control arms requires

working underneath vehicle.

USE EXTREME CARE AND CAUTION WHEN

WORKING UNDERNEATH VEHICLE.

Never get near or under vehicle until you are

confident that it is safely supported and will not

move or fall from its raised position.

DO NOT USE A BUMPER JACK.

PREPARATION FOR INSTALLATION

1. Place vehicle on a solid level surface to ensure

safe installation

2. Place wheel blocks in front of and behind both front

wheels to prevent movement in either direction.

3. Raise rear of vehicle and support flat area of chassis

in front of lower control arm attaching point using

approved automotive support stands having

adequate load capacity. DO NOT put support stands

under the axle housing. Note: Raise vehicle high

enough to allow adequate clearance for coil

spring removal.

CAUTION

DO NOT BEGIN THIS INSTALLATION UNTIL YOU ARE

CONFIDENT THAT VEHICLE IS SECURE AND SAFELY

SUPPORTED!

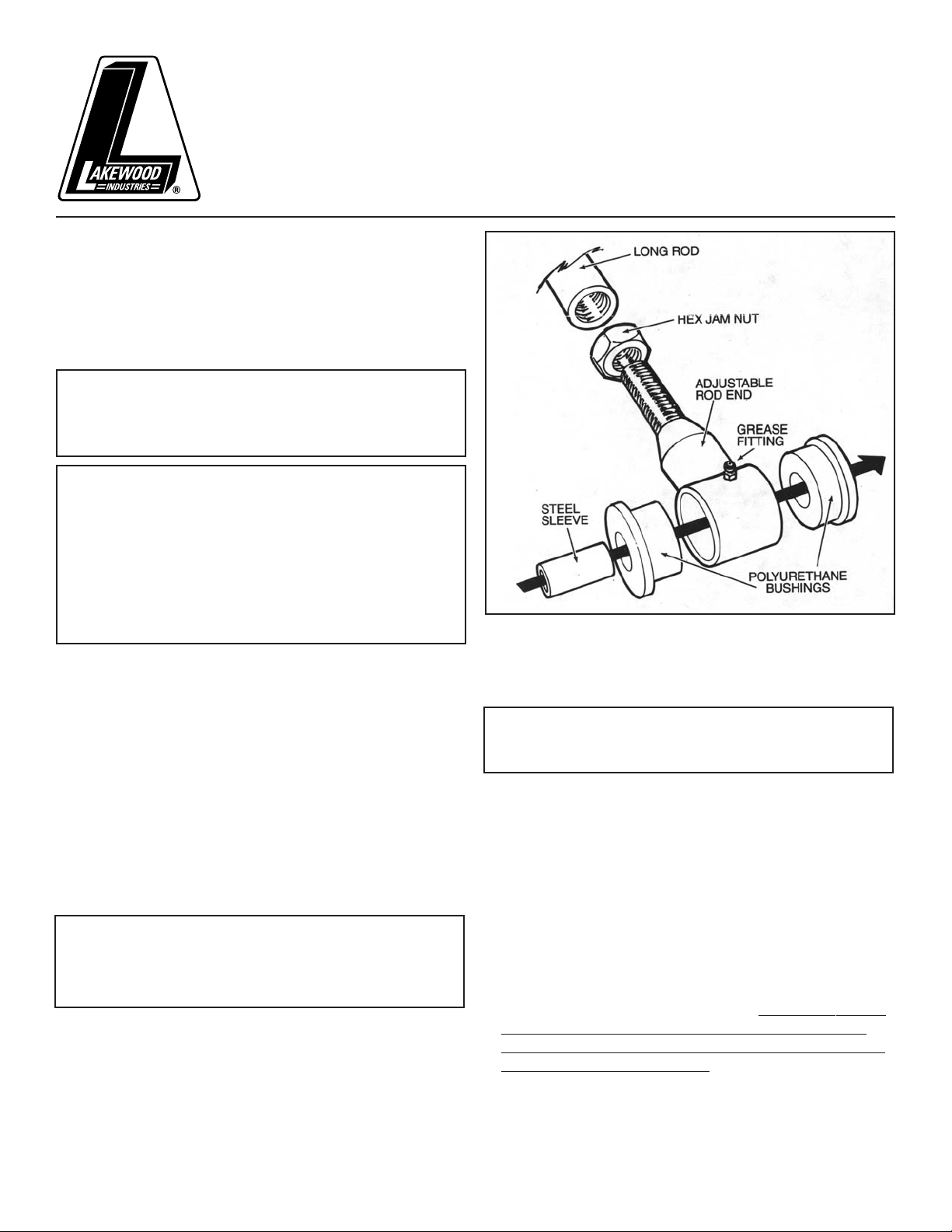

CONTROL ARM ASSEMBLY

1. Install grease fittings (supplied) into each end of

control arm by threading fittings into drilled hole of

bushing eyelet. Use care not to damage fittings

(see illustration)

.

2. Apply lubricant to polyurethane bushings and steel

sleeves, then install into eyelet ends as shown.

CONTROL ARM INSTALLATION

NOTE

We recommend working on

only one side at a time.

1. Remove both rear wheels.

2. Apply penetrating oil or rust release lubricant to

front and rear mounting bolts of upper control arms.

3. Raise axle housing up approximately 2"

(a hydraulic floor jack is recommended for

this procedure).

4. Using a wrench, remove one upper control arm. DO

NOT discard the bolts and nuts, they may be reused.

5. Lightly lubricate threads of short adjustable end.

Install hex jam nut, and assemble. Adjust Lak

ewood

control arms to same length as factory arm using

center to center location of mounting bushing holes

as your measurement point.

6. Install the new control arm to chassis and axle

housing brackets using the stock factory mounting

bolts and nuts previously removed.

ADJUSTABLE REAR UPPER CONTROL ARMS

INSTALLATION INSTRUCTIONS

Part #20144, #20149, #20154

LAKEWOOD INDUSTRIES IS A DIVISION OF MR. GASKET INC. • CLEVELAND • OHIO • WWW.LAKEWOOD-INDUSTRIES.COM ©2006

Note: Clean and lubricate axle and chassis control

arm mounting brackets with a good quality chassis

grease to ease installation.

7. Tighten front and rear control arm mounting bolts to

80 ft./lb. torque.

Note: The adjustable feature of this arm enables you

to correctly locate the rear end in relation to the

chassis and to compensate for altered ride heights.

8. Follow the same above procedure for installation

of Adjustable Control Arm on other side of vehicle.

9. Lubricate control arm bushings with a good quality

chassis grease.

10. Once arms are installed you can begin to adjust.

11. The pinion angle must now be checked and adjusted if

necessary. The angle between the drive shaft and the

rear end yoke must be between 4 and 6 degrees down.

12. With pinion angle set, tighten all fasteners securely.

13. Install wheels and properly tighten lug nuts to

wheel manufacturers specifications.

14. Carefully remove support stands and lower vehicle

to ground.

THIS COMPLETES THE INSTALLATION.

YOU CAN NOW ROCK-N-ROLL!

IMPORTANT!

Periodically check to make sure that all mounting

hardware is securely tightened. Use a good

quality chassis grease to keep bushings and

sleeves properly lubricated.

TECHNICAL SERVICE

A highly trained technical service department is

maintained by Lakewood Industries to answer your

technical questions, provide additional product

information and offer various recommendations. See

your local retailer of Lakewood products for specific

prices. For best results, technical service calls,

correspondence and warranty questions should be

directed to the following address:

Lakewood Industries

10601 Memphis Ave. #12

Cleveland, Ohio 44144

Phone 216-688-8300

8:30 A.M.-5:00 P.M. EST

www.lakewood-industries.com

Recommended Optional Lakewood Products for Ford:

• For drag racing, use Lakewood Traction… Action Lift

Bars for 1979-98 Mustangs #21900, for 1999-03

Mustangs #21901

• For drag racing, the factory rear shocks should be

replaced with a 50/50 ratio shock absorber (1979-1993

Mustangs) #40301

• Front Drag Struts are also available for

1979-93 model years in ratios of 70/30 #40501, or

90/10 #40511. Also 1994-2003 Mustangs 70/30 #40506,

and 90/10 #40516

• Rear Lower Control Arms with polyurethane bushings

to reduce flex and provide stability for 1779-98

Mustangs #20150, and 1999-03 Mustangs #20151

• Ford Lower Control Arms

1979-1993 Ford Mustang, Capri, #21314

1980-1985 Ford Thunderbird, Cougar #21314

1978-1982 Ford Fairmont #21314

1981-1982 Ford Granada, Monarch, Zephyr #21314

• Replacement Bushing Set. Bushings for all Lakewood

Control Arms and Traction Bars #20538

• Bolt-in Drive Shaft Safety Loop for 1979-03 Mustangs

#18017

Recommended Optional Lakewood Products for GM:

• For drag racing, the factory rear shocks should be

replaced with a 50/50 ratio shock absorber available

for 1982-92 model years (#40301).

• Replacement Bushing Set for Traction Bars (#20538).

• Front Drag Struts are also available for

1982-92 model years in ratios of 70/30 (#40500) or

90/10 (#40510).

• Bolt-in Safety Drive Shaft Loop available for 1982-92

model years (#18020), 1993-2002 model years

(#18022).

• GM Lower Control Arms

1964-1972 GM A-Body Cars: Chevelle, GTO,

Cutlass, Skylark, G.S., 442 #21312

1978-1987 GM G-Body Cars: Regal, G.N.,

Monte Carlo, Cutlass, Grand Prix #21313

• GM No-Hop Traction Bars

1964-72 Skylark, Chevelle, Cutlass, 442, Grand Prix,

GTO, Lemans, Malibu, Monte Carlo #21609

1978-87 Chevelle, Cutlass, 442, Grand Prix, Malibu,

Monte Carlo, Regal #21610

See your local retailer of Lakewood products

for specific prices.

RETAIN THIS INSTRUCTION SHEET FOR FUTURE REFERENCE.

LAKEWOOD INDUSTRIES IS A DIVISION OF MR. GASKET INC. • CLEVELAND • OHIO • WWW.LAKEWOOD-INDUSTRIES.COM ©2006

97140057

Loading...

Loading...