Page 1

NOTICE:

This safety bellhousing meets S.F.I. (Safety

Foundation Institute) specification 6.1 when

used with the enclosed engine block plate

and maximum containment fasteners

supplied. It is highly recommended that an

S.F.I. approved flywheel and clutch assembly

be used in conjunction with this bellhousing

for additional safety precautions.

WORK SAFELY!

Installation of this safety bellhousing requires working

underneath vehicle. USE EXTREME CAUTION WHEN

WORKING UNDERNEATH THE VEHICLE. Never get near or

underneath the vehicle until you are confident that it is

safely supported and will not move or fall from its raised

position.

DO NOT USE A BUMPER JACK!

PN 97140239 ©2000

SAFETY BELLHOUSING

Ford Applications

INSTALLATION INSTRUCTIONS

Cleveland, Ohio

216.688.8300

www.mrgasket.com

#15210

#15220

PREPARATION FOR INSTALLATION

1. Place the vehicle on a solid, level surface such as a garage

floor to ensure safe installation.

2. Raise the vehicle using appropriate lifting device and

support it using automotive approved support stands

having adequate load capacity.

3. Disconnect the negative (–) cable from the battery.

CAUTION: DO NOT BEGIN THIS INSTALLATION UNTIL

YOU ARE CONFIDENT THAT THE VEHICLE IS SECURE AND

SAFELY SUPPORTED!

Installation Instructions

1. Remove driveshaft, starter motor, transmission and stock

bellhousing.

2. Remove pressure plate and clutch disc from flywheel.

3. At this point, we recommend that you check your

Lakewood Safety Bellhousing for proper alignment with

the crankshaft. This is not a difficult procedure. A detailed

instruction sheet outlining the necessary steps along

with recommendations for correcting any misalignment is

included. Please refer to this sheet now.

4. After checking and correcting bellhousing alignment,

remove flywheel and install blockplate by positioning o ver

crankshaft flange and placing onto dowel pins in engine

block.

IMPORTANT: In order to comply and meet S.F.I. bellhousing

specification 6.1, it is mandatory that the safety blockplate be

installed with this bellhousing and all containment fasteners

supplied be used in their correct location (see illustration).

5. Reinstall flywheel and clutch assembly. Be sure to tighten

fasteners using manufacturers recommended torque

specifications.

Note: We recommend the use of Mr. Gasket Ultra-Seal

premium fasteners for clutch and flywheel installation.

Flywheel bolts Mr. Gasket #912

Pressure plate bolts Mr. Gasket #911

IMPORTANT: Do not reuse the factory cast iron flywheel! A

high performance quality billet flywheel that meets S.F.I.

specifications is recommended for safety purposes. Hays

offers a complete line of high performance clutches and

flywheels to meet safety requirements.

6. Remove clutch release bearing fork and spring wire clip

from stock bellhousing. Remove the pivot fulcrum from

the stock bellhousing and install it in the Lakewood

bellhousing. Reinstall the release arm and spring clip to

the fulcrum.

Note: If you do not have these parts, they may be purchased

from your local Ford dealer parts department.

7. Position your Lakewood Bellhousing over the flywheel/

clutch assembly and slide onto dowel pins in engine block.

Fasten the bellhousing to the engine block using the

7/16"-14 x 1-1/4" grade 8 bolts supplied. Secure the blockplate to the bellhousing using the supplied 1/2"-13 and

3/8"-16 grade 8 fasteners installed in the order shown on

the illustration.

IMPORTANT: All fasteners must be used in their proper

location for the bellhousing to meet S.F.I. specification 6.1.

8. Replace starter motor, transmission and driveshaft. Attach

clutch linkage and check for proper adjustment.

9. Reconnect battery cable.

RETAIN THIS INSTRUCTION SHEET FOR FUTURE REFERENCE.

Page 2

PN 97140239 ©2000

Cleveland, Ohio

216.688.8300

www.mrgasket.com

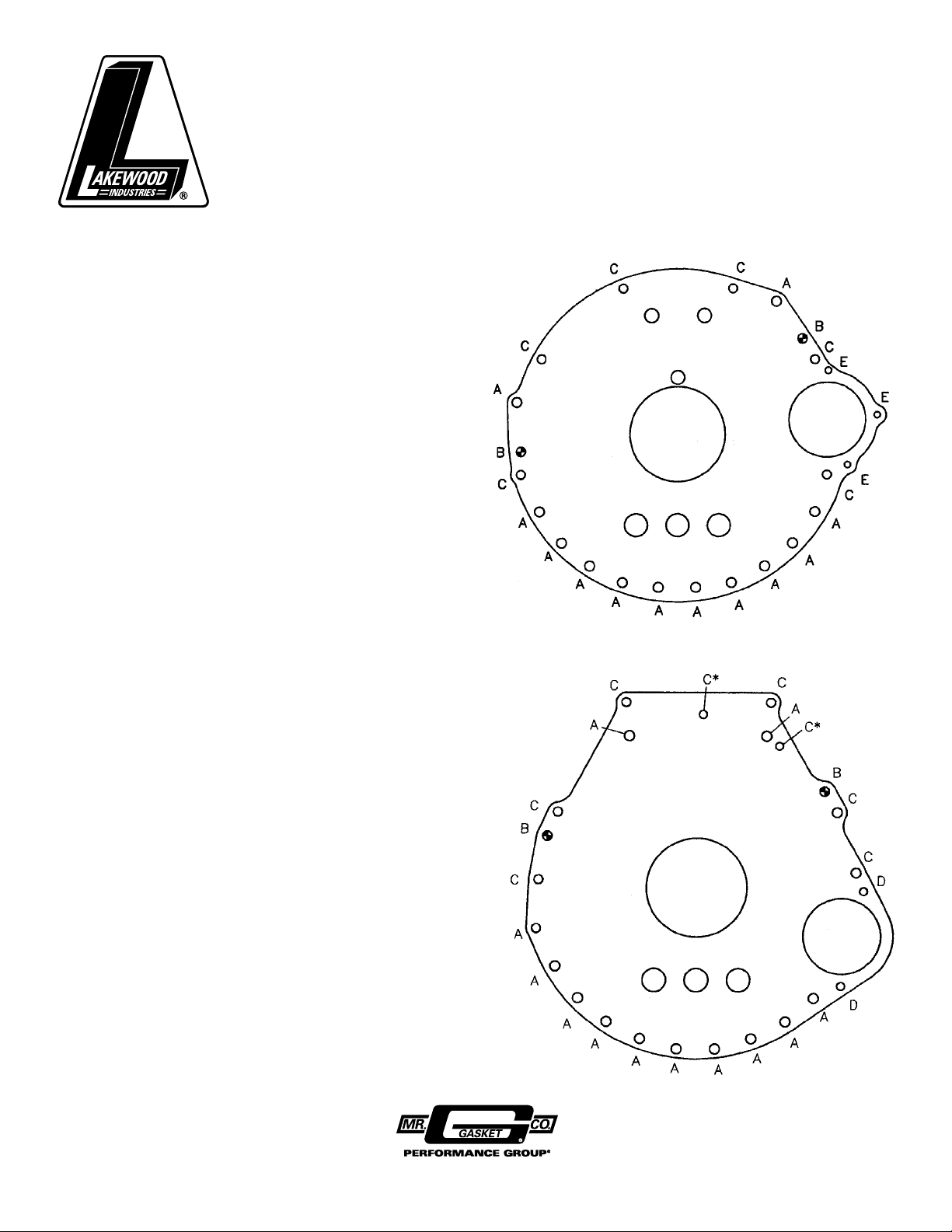

SAFETY BLOCKPLATE FASTENER

REQUIREMENTS AND LOCATION

IMPORTANT: All fasteners must be used in their proper location

for the bellhousing to meet S.F.I 6.1 safety requirements.

LAKEWOOD 15210 SERIES FASTENER REQUIREMENTS

Ford 390, 406, 427 & 428

For this product to meet SFI specification 6.1

the fasteners listed below must be used.

A = 1/2 - 13 x 1" GRADE 8 BOLTS, WASHERS & NUTS.

B = BELLHOUSING LOCATING PINS (NOT INCLUDED).

C = 7/16 - 14 x 1" GRADE 8 CAP SCREWS.

D = 3/8 - 16 x 1" GRADE 8 BOLTS, WASHERS & NUTS.

E = GRADE 5 STARTER BOLTS.

LAKEWOOD 15220 SERIES FASTENER REQUIREMENTS

Ford 351M, 400, 429 & 460

For this product to meet SFI specification 6.1

the fasteners listed below must be used.

A = 1/2 - 13 x 1" GRADE 8 BOLTS, WASHERS & NUTS.

B = BELLHOUSING LOCATING PINS (NOT INCLUDED).

C = 7/16 - 14 x 1" GRADE 8 CAP SCREWS.

D = GRADE 5 STARTER BOLTS.

* These holes may not be present in some blocks. If present, their

use is recommended for additional safety.

15741

15729

Loading...

Loading...