Page 1

WORK SAFELY!

Installation of this safety bellhousing requires working

underneath vehicle. USE EXTREME C AU TION W H E N

WORKING UNDERNEATH THE VEHICLE. Never get

near or underneath the vehicle until you are confident

that it is safely supported and will not move or fall from

its raised position. DO NOT USE A BUMPER JACK!

PREPARATION FOR INSTALLATION

1. Place the vehicle on a solid, level surface such as a

garage floor to ensure safe installation.

2. Raise the vehicle using appropriate lifting device and

support it using automotive approved support stands

having adequate load capacity.

3. Disconnect the negative (-) cable from the battery.

CAUTION: DO NOT BEGIN THIS INSTALLATION UNTIL

YOU ARE CONFIDENT THAT THE VEHICLE IS SECURE

AND SAFELY SUPPORTED!

Installation Instructions

1. Remove driveshaft, starter motor, transmission and

stock bellhousing.

2. Re m o ve pressure plate and clutch disc from flywheel.

3. At this point, we recommend that you check your

Lakewood Safety Bellhousing for proper alignment with

the crankshaft. This is not a difficult procedure.

Detailed instructions outlining the necessary steps a l o n g

with recommendations for correcting any misalignment are

included in these instructions.

4. After checking and correcting bellhousing alignment,

remove flywheel and install blockplate. Use blockplate

as is (the round hole in the blockplate will correctly

locate the starter nose assuring proper alignment).

Install blockplate over the crankshaft flange and place

over dowel pins in the block.

I M P O RTA N T: In order to comply and meet S.F. I .

bellhousing specification 6.1, it is mandatory that the

safety blockplate be installed with this bellhousing and

all containment fasteners supplied be used in their

correct location (see illustration).

5. Reinstall flywheel and clutch assembly. Be sure to

tighten fasteners using manufacturers recommended

torque specifications.

Note: We recommend the use of Mr. Gasket Ultra-Seal

premium fasteners for clutch and flywheel installation.

Flywheel bolts Mr. Gasket #912

Pressure plate bolts Mr. Gasket #910

I M P O R TA N T: Do not reuse the factory cast iron

flywheel! A high performance quality billet flywheel that

meets S.F.I. specifications is recommended for safety

purposes. Hays off e r s a complete line of high

performance clutches and flywheels to meet safety

requirements.

6. Remove clutch release bearing fork and pivot ball

from stock bellhousing. Reinstall the pivot ball into the

Lakewood bellhousing and attach fork clip onto the

pivot ball. Note: It is recommended to use Lakewood

#15501 Adjustable Pivot Ball in order to obtain the

proper fork geometry. A Heavy-Duty Clutch Fork #15500

is also available to fit most applications.

7. Position your Lakewood Bellhousing over the flywheel/

clutch assembly and slide onto dowel pins in engine

block. Fasten the bellhousing to the engine block using

the 3/8”-16 x 1” (35 ft lbs of torque) and 1/2” bolts (100110 ft lbs) grade 8 bolts supplied. Secure the blockplate

to the bellhousing using the supplied grade 8 fasteners

installed in the order shown on the illustration.

IMPORTANT: All fasteners must be used in their proper

location for the bellhousing to meet S.F.I. specification 6.1

8. Replace starter motor, transmission and driveshaft.

Attach clutch linkage and check for proper adjustment.

9. Reconnect battery cable.

INSTALLATION INSTRUCTIONS

Lakewood Safety Bellhousing

Oldsmobile, Buick and Pontiac Applications

#15100 and #15120

NOTICE: This safety bellhousing meets S.F.I. (Safety Foundation Institute) specification 6.1 when used

with the enclosed engine block plate and maximum containment fasteners supplied. It is highly

recommended that an S.F.I. approved flywheel and clutch assembly be used in conjunction

with this bellhousing for additional safety precautions.

Page 2

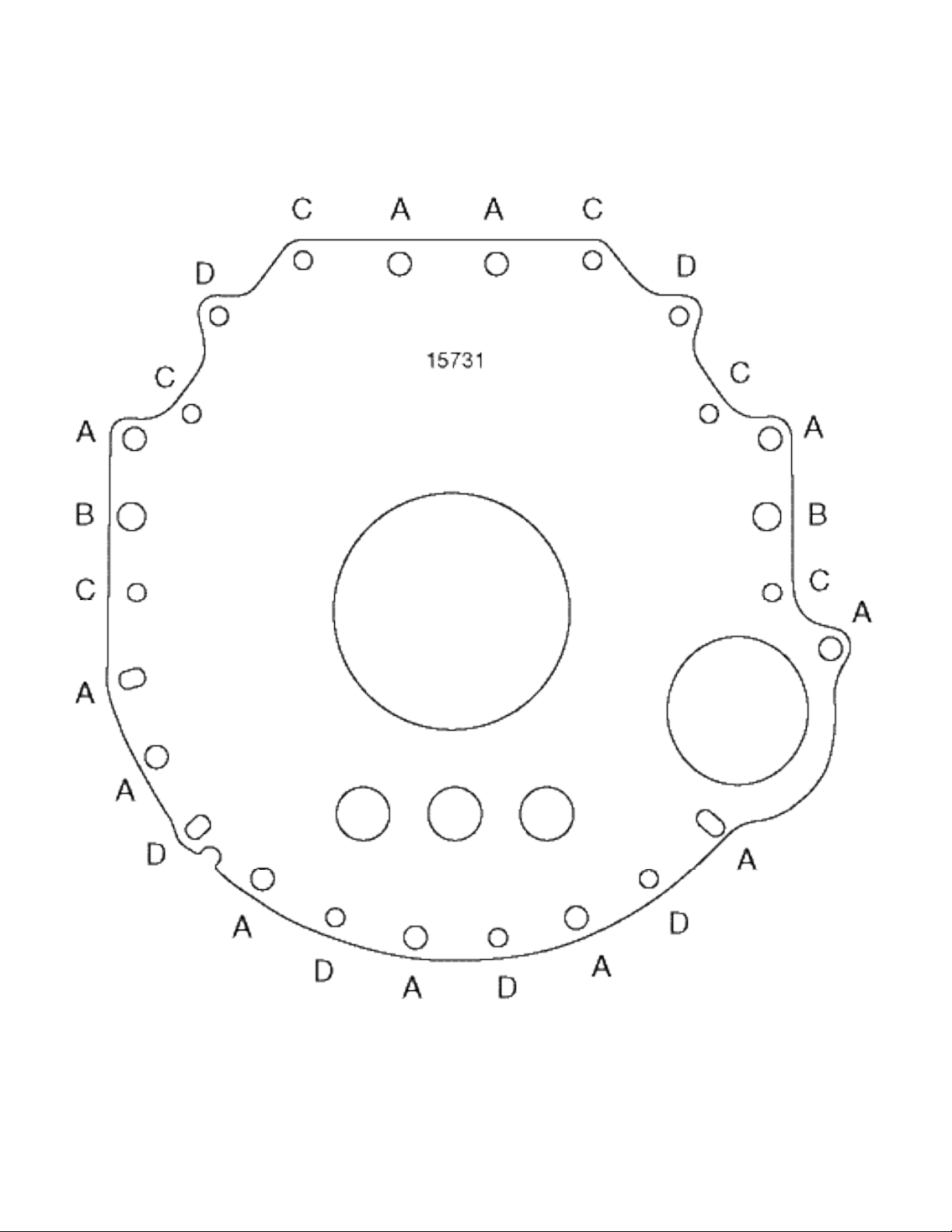

For this product to meet SFI specification 6.1 the fasters listed below must be used.

LAKEWOOD 15120 SERIES FASTENER REQUIREMENT

BUICK 400-455 V8 AND ALL NON CABLE OPERATED RWD V6

A = 1/2-13 X 1” GRADE 8 BOLTS, WASHERS AND NUTS

B = BELLHOUSING LOCATING PINS (NOT INCLUDED)

C = 3/8-16 X 1” GRADE BOLTS AND WASHERS

D = 3/8-16 X 1” GRADE 8 BOLTS WASHERS AND NUTS

Page 3

INSTRUCTIONS

1. Remove clutch assembly from flywheel and install

bellhousing on engine block. (It is easier when yo u

l e a ve the clutch assembly off the flywheel.)

2. Install dial indicator base on the flywheel and adjust

plunger to contact the register bore of the housing.

(See photo.)

3 . Rotate the flywheel and note indicator reading.

Misalignment is one-half of the indicator reading

( m a x i m u m allowable is .005”).

4. To correct off-center condition, select the offset

dowel pin pair that is closest to one-half of the

indicator reading. ( i . e., if reading is .016”,

1/2R=.008” use .007” dowels. If reading is .024”,

1/2R=.012” use .014” dowels).

5. Remove stock dowel pins by driving from back side

or pulling with gripper pliers.

6. Clean engine block dowel holes and coat lightly with

lubricant.

7. L u b r icate dowel pins and install in bl o c k . The slot in the

d o wel pins indicates the direction of maximum offset. T h e y

should be installed parallel to one another, and in pairs

(both .007”or both .014” and .021”).

8. Install and tighten bellhousing securely. R e m o u n t

the dial indicator and recheck the register bore runout

(Repeat step 3).

9. To make small corrections or adjustments to the

alignment, you will need to remove the bellhousing

and dri v e the offset dowels out of the bl o ck .

Reposition the dowels using the slot as a reference

point and re-install. Re-check register bore run-out.

Repeat this procedure until the register bore is

within limits.

NOTE: Always be careful when removing bellhousing

from engine block so that offset dowel pins

do not move or change position.

Total One-Half Size Dowel Lakewood

Indicator Total Indicator To Be Offset Dowel

Reading Reading Used Part Number

GM Ford/Mopar

.012” to .020” .006” to .010” .007” #15920 #15950

.022” to .034” .011” to .017” .014” #15930 #15960

.036” to .052” .018” to .026” .021” #15940 #15970

WELD-ON DOWEL LOCATING KIT

Designed for use on race cars that are frequently dis-assembled, this

kit eliminates the need to “ d i a l - i n ” the bellhousing after each remova l .

For Ford or Mopar vehicles with .500” d o wel holes use #15980. Fo r

GM vehicles with .622” d o wel holes use #15981.Welding is required.

Clean paint inside bore.

LAKEWOOD BELLHOUSING

Alignment Procedure

Due to manufacturers’ machining tolerances of engine blocks in relationship to dowel pin

location, it is quite possible for the crankshaft centerline and bellhousing bore to be misaligned. With the

transmission installed in a misaligned condition, several problems can occur, such as pilot bearing and main shaft

bearing wear, difficulty in shifting, and in extreme cases breakage of transmission gears and cases. While most

housings will fall within the allowable limits, it is good insurance to check for register bore runout whenever any

housing or engine block is installed. Most factory service manuals will outline the checking pro c e d u r e, but will not

give correctional measures necessary to ensure tro u b l e - f r ee standard transmission operation, short of trial and

error with switching of various O.E. housings.

O f fset dowel pins are available from Lakewood Industries to ensure correct adapter housing installation. For checking,

you will need a dial indicator (preferably with a magnetic base), a few simple tools and close attention to detail

to give you accurate installation results.

OFFSET DOWEL PIN CHART

Page 4

RECOMMENDED OPTIONAL LAKEWOOD & HAYS PRODUCTS

• Adjustable Clutch Fork Pivot Ball. This handy item allows adjustment of the clutch fork height when

clutch assemblies are changed.

Lakewood Part #15501

• Safety Block Plates.These plates are exact replacements for those provided in our Lakewood

Bellhousing kits. A must for block protection. These plates are required to meet S.F.I. requirements

for racing.

Please see your Lakewood catalog for one of our many Block Plate part numbers.

• Offset Dowel Pins. Adjustable dowel pins correct for improper alignment of bellhousing to engine

block. A must when accurately dialing in your bellhousing. Please see your Lakewood catalog for

one of our many Offset Dowel Pin part numbers.

• Bellhousing Locating Kit. This kit is used to dial in a misaligned register bore which could cause a

missed shift or premature pilot bearing failure. (Welding required.)

Lakewood Part #15981

• Self-Aligning Throwout Bearing. Designed specifically for installations with clutch to transmission

misalignment resulting in noise and vibration. The Hays bearing minimizes these conditions by

finding the center line.

Please see your HAYS catalog for one of our many Throwout Bearing part numbers.

• Street/Strip Clutch Kits for GM. Designed for high performance and drag racing. This kit features a

pressure plate with heavier springs and centrifugal assist to reduce slippage. The disc features as

aggressive friction material with a high burst strength lining.

Please see your HAYS catalog for one of our many Clutch Kit part numbers.

• Steel & Aluminum Flywheels. All flywheels meet or exceed S.F.I. specifications. Flywheels are

available in a variety of weights, sizes, applications and bolt patterns.

Please see your HAYS catalog for part numbers.

RETAIN THIS INSTRUCTION SHEET FOR FUTURE REFERENCE.

LAKEWOOD IS A DIVISION OF PRESTOLITE PERFORMANCE

10601 MEMPHIS AVE. #12, CLEVELAND, OH 44144

216.688.8300 FAX 216.688.8306

FORM 97140247

11/08

Made in U.S.A.

Printed in U.S.A.

Loading...

Loading...