Page 1

1MALLORY TECHNICAL SUPPORT (216) 688-8300

COMP PUMP SERIES 110FI IN-LINE

ELECTRIC FUEL PUMP PART NO. 11106M

INSTALLATION INSTRUCTIONS

FORM INST11106M (Rev A) 05/10

Parts included in this kit:

1 - Comp Pump 100FI Series electric in-line fuel pump

2 - Mounting brackets

Please read these instructions completely before

installing your new fuel pump. Installation of this pump

requires detailed knowledge of repair and modifications

to a high performance fuel system. We recommend that

a qualified automotive technician perform the installation

procedure.

NOTE: DO NOT RUN THIS PUMP WITHOUT FUEL (EXCEPT FOR

A BRIEF PERIOD WHILE PRIMING)

CAUTION: Please make sure to wear appropriate safety apparel.

Work in a well ventilated area. Extinguish any open flames

and eliminate any source of ignition or sparks in the area.

WARNING: The fuel system operates under pressure. Do not

open the fuel system until the pressure has been relieved.

Please refer to your appropriate service manual for the correct

procedure to relieve the fuel system pressure. Fuel leakage

will occur when loosening any fuel system connections. Be

sure to be ready to safely contain any fuel leakage.

PERFORMANCE SPECIFICATIONS

Outlet Pressure/Flow:

110 gph free flow with 12.5 volts

85 gph @ 45 PSI with 12.5 volts

60 gph @ 65 PSI with 12.5 volts

Maximum recommended operating pressure: 65 PSI

continuous, 90 PSI intermittent

Mallory part no. 11106M fuel pump is rated for both

gasoline and gasoline/ethanol blends up to E85.

Mallory part no. 11106M fuel pump utilizes port style

O-ring fittings; -8 AN inlet and -6 AN outlet. Mallory part

no. 30606 and 30808 fittings or their equivalents are

recommended. DO NOT use pipe thread of thread sealant

with these fittings.

A high capacity fuel pre-filter with a 40 micron to no

greater than 100 micro rated element must be installed in

the fuel line between the tank and the fuel pump inlet.

Mallory part no. 3175 or equivalent is recommended.

PERFORMANCE SPECIFICATIONS

A by-pass or return style fuel pressure regulator MUST

be used with this fuel pump. We recommend the Mallory

part no. 4305M for systems running from 30 to 90 PSI.

Gravity feed this pump by mounting it as low and as

close as possible to the fuel tank. The installation of either

a rear mount reservoir style sump or a high flow capacity

fuel tank pickup in your stock tank is highly recommended.

These will insure that the fuel pump is able to self prime

and avoid pump starvation and cavitation. Failure to follow

these recommendations will result in poor fuel system

performance and drastically shorten the fuel pumps life.

Improper fuel pump installation will void all product warranties.

INSTALLATION

1. Wait for the engine to cool. Make sure the ignition system

is off or disconnect the negative battery cable. Relieve

the fuel system pressure.

2. Raise and secure the vehicle to allow working access

under the vehicle. Following the appropriate service

manual procedure to; disconnect the existing fuel

pump lines, plug all open fuel lines to keep fuel from

draining and debris from entering, remove the existing

fuel pump.

3. Install either the after-market fuel tank rear mount

sump or high flow capacity fuel tank pickup per the

manufactures instructions.

4. Assemble the mounting brackets onto the fuel pump.

Determine the new fuel pump mounting location.

Remember it needs to be as low and as close to the

fuel tanks as possible.

5. Make sure that the fuel pump location will accommodate

the mounting brackets. Also make sure that the fuel

pump, lines and pre-filter locations will be free from

any interference with the exhaust system as well as

clear of any moving suspension system or drive train

components. Keep the fuel pump clear of any road

obstacles or debris that can be kicked up by the tires.

Make sure you have access to the pre-filter so that the

element can be periodically cleaned and/or changed.

Page 2

2 MALLORY IGNITION www.malloryperformance.com2

FORM INST11106M (Rev A) 05/10

Printed in U.S.A.

MALLORY IS A DIVISION OF PRESTOLITE PERFORMANCE

10601 MEMPHIS AVE. #12, CLEVELAND, OH 44144

216.688.8300 FAX 216.688.8306

6. Use the mount brackets as a template, mark and drill

the four mounting holes.

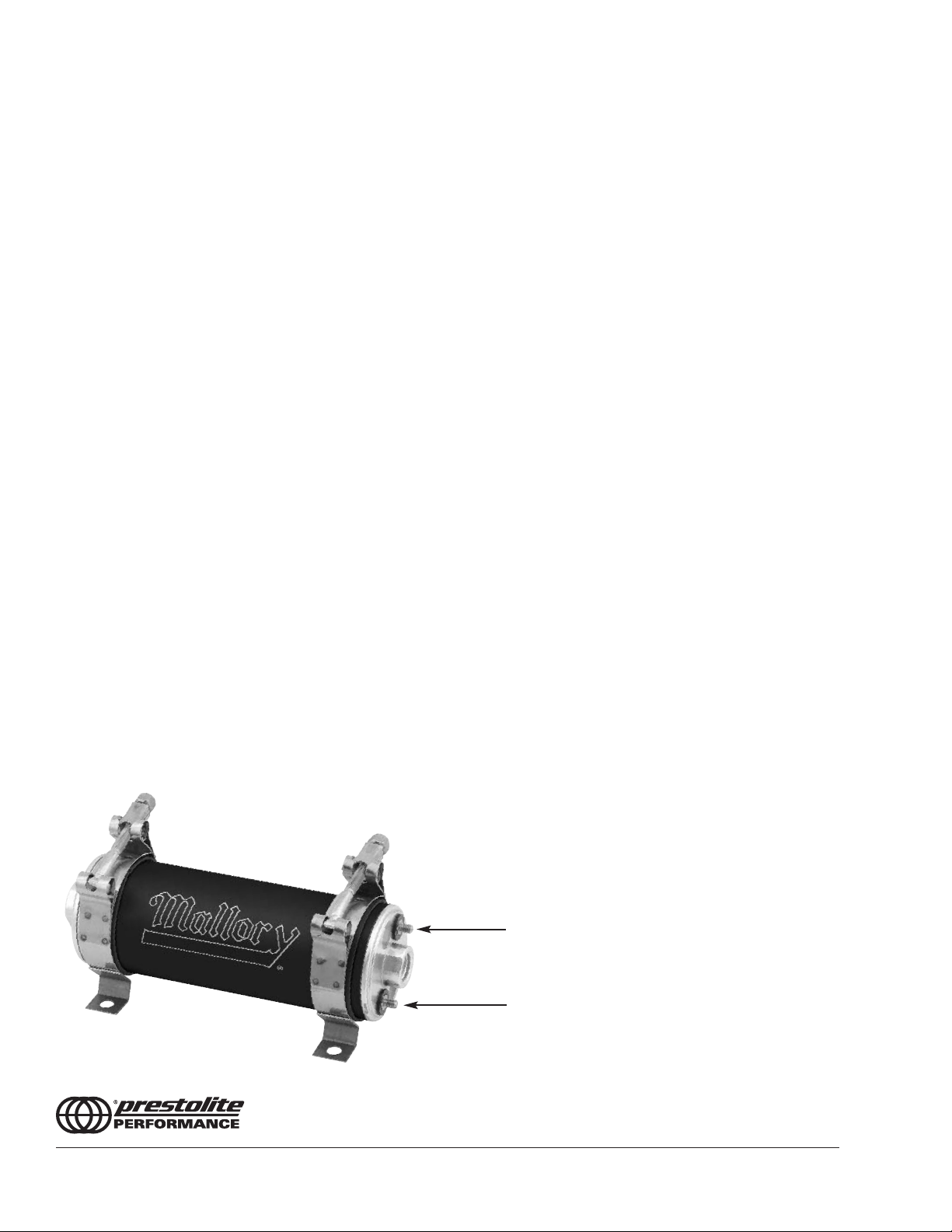

7. Install the fuel pump making sure the fuel pump is facing

the correct direction. The outlet side is the same side

as the fuel pump’s electrical connections.

8. Install the inlet and outlet fittings. Connect the fuel

tank pickup line to the pre-filter and the fuel pre-filter

to the fuel pump inlet. The pre-filter can be directly

mounted to the fuel pump inlet or via a short section of

fuel line if necessary. Make sure that if you must use

angled fittings, that they are of a sweep design to

minimize any flow restrictions. Most fuel system problems

are due to flow restrictions on the inlet side of the fuel

pump. If at all possible do NOT use forged hard

angled fittings.

9. Make sure you are using a correctly rated high pressure

fuel line from the fuel pump forward. Make sure that

you are using a high flow 10 micro fuel filter between

the fuel pump and the fuel pressure regulator. We

recommend the Mallory part no. 3160 fuel filter or

equivalent. Make sure you are using a return style fuel

pressure regulator.

10. Fuel pump wiring – We recommend that you use a 30

amp universal electric fuel pump relay and harness

installation kit. Please fellow the wiring kit’s installation

instructions. If you are not using a relay harnesses kit,

connect a 12ga BLACK wire to the negative (-) terminal

on the fuel pump and to a quality ground location

such as an engine ground or the negative battery

terminal to chassis ground location. Connect a RED

12ga wire from a 12v key-on switched connection,

such as a 30 amp relay to the positive (+) terminal on

the fuel pump. Use a 30amp inline fuse. Double check

to make sure the power to the pump is only on when

the ignition key is on.

11. Check for leaks – Turn the ignition key to the “Run”

position without starting the engine. This will power

up the fuel pump. Check for any fuel leaks at all the

connections. Fix and repair any leaks immediately

before operating the vehicle.

If you have any questions or problems, please contact our

Technical Service department at 216.688.8300 8:00am- 5:00pm

Monday- Friday EST.

When installing the pump, do not over tighten the nuts

on the electrical posts. These need to be a

snug fit

only

. Over tightening these connections can result in

damaging internal connections and create a no run

condition. This is considered damage at installation

and not warrantied.

Loading...

Loading...