Mallinckrodt INOMAX DSir Plus Operation Manual

Part No. 20003 Rev - 01

Part No. 20717 Rev-01

2014-07

Operation Manual

(800 ppm INOMAX® (nitric oxide) for inhalation)

Series 3 software

Part No. 20717 Rev-01

2014-07

User Responsibility

This Product will perform in conformity with the

description contained in this operating manual

and accompanying labels and/or inserts, when

assembled, operated, maintained and repaired

in accordance with the instructions provided. This

Product must be checked prior to use following the

Pre-Use Checkout procedure described in section

two. A defective Product should not be used. Parts

that are broken, missing, visibly worn, distorted or

contaminated should be replaced immediately.

Should such repair or replacement become

necessary, the manufacturer recommends that a

telephone request for service advice be made to

the local distributor. This Product or any of its parts

should not be repaired other than in accordance with

written instructions provided by the manufacturer or

local distributor. The Product must not be altered.

The user of this Product shall have the sole

responsibility for any malfunction which results

from improper use, faulty maintenance, improper

repair, damage, or alteration by anyone other than

Mallinckrodt Representatives.

Caution: U.S. Federal and Canadian law restrict

this device to sale by or on the order of a licensed

medical practitioner. Outside the U.S.A. and

Canada, check local laws for any restrictions

that may apply.

Inhaled Nitric Oxide mixtures must be handled

and stored in compliance with federal, state and

local regulations.

These products have unit serial numbers with coded

logic which indicate the year of manufacture and a

sequential unit number for identication.

No license is conveyed, either expressed or implied, with the purchase or usage hereof under any patent or patent application covering this

product. See Patents www.mallinckrodt.com/patents and any respective foreign equivalents thereof.

Open Source Software

A CD-ROM is available upon request containing the full source code to the open source software used within this product.

Portions of this software are copyright © 1996-2002 The FreeType Project (www.freetype.org). All rights reserved.

Korean fonts Baekmuk Batang, Baekmuk Dotum, Baekmuk Gulim, and Baekmuk Headline are registered trademarks owned by Kim Jeong-Hwan.

Mallinckrodt, the “M” brand mark and the Mallinckrodt Pharmaceuticals logo are trademark of a Mallinckrodt company. Other brands are

trademarks of a Mallinckrodt company or their respective owner. ©2016 Mallinckrodt

Important:

Before using the INOmax DS

IR

, read through this manual.

Read through the manuals for the ventilator, humidier and any other accessory items used. Follow the manual

instructions and obey the Warnings and Cautions.

Keep this manual readily available to answer questions.

SN 20051234

The rst four numeric digits indicate the year of product manufacture, and the next

four digits are the sequential unit number produced.

Ref 10007

INOmax DSIR part number

Contents

1/ General Information ........................................................................................................................1-1

Indications for Use..........................................................................................................................1-1

Introduction to this Manual .............................................................................................................1-2

INOmeter Operation .....................................................................................................................1-18

Theory of Operation .....................................................................................................................1-22

Environmental Effects ..................................................................................................................1-26

2/ Automated Pre-Use Checkout ........................................................................................................2-1

Initial connections ...........................................................................................................................2-2

High Pressure Leak Test and Automated Purge ............................................................................2-5

Integrated Pneumatic Backup INOMAX Delivery Test ...................................................................2-7

Performance Test ...........................................................................................................................2-8

INOblender Test .............................................................................................................................2-9

Depressurizing the Regulator Supply Line ...................................................................................2-10

3/ Patient Application .......................................................................................................................... 3-1

INOblender Operation ....................................................................................................................3-4

INOblender Used as a Stand-Alone Device ...................................................................................3-5

INOblender use with the NeoPuff ...................................................................................................3-6

Integrated Pneumatic Backup NO Delivery ....................................................................................3-7

Changing INOMAX Cylinders and Purging the Regulator Assembly ...........................................3-10

Oxygen Dilution Chart ..................................................................................................................3-13

Duration Chart INOMAX Cylinder 88-Size ...................................................................................3-14

Duration Chart INOMAX Cylinder D-Size .....................................................................................3-15

Monitoring the Environment .........................................................................................................3-19

Entering Patient Information .........................................................................................................3-20

Connection to Various Breathing Systems ...................................................................................3-24

Acutronics Medical Systems AG Fabian +nCPAP Evolution ......................................................3-25

Acutronics Medical Systems AG Fabian HFO ............................................................................3-26

A-Plus Medical Babi-Plus Bubble CPAP Circuit .........................................................................3-27

Bagging Systems While Using the Injector Module ....................................................................3-28

Bunnell Life Pulse High Frequency Ventilator Circuit .................................................................3-32

Connecting INOmax DS

Connecting INOmax DS

Circle Anesthesia System ........................................................................................................... 3-34

Dräger Babylog VN500/Innity Acute Care System and Heinen & Löwenstein

Leoni-plus Ventilator ................................................................................................................3-36

Fisher & Paykel Healthcare Bubble CPAP .................................................................................3-37

Fisher & Paykel Healthcare Infant Circuit Nasal Cannula ..........................................................3-38

Fisher & Paykel Healthcare Optiow Breathing Circuit ..............................................................3-39

Hamilton Arabella Nasal CPAP ..................................................................................................3-40

ICU Ventilator Circuit ..................................................................................................................3-41

Sensormedics 3100A/B High Frequency Oscillatory Ventilator with a Filtered Circuit ...............3-42

Sensormedics 3100A/B High Frequency Oscillatory Ventilator with a Rigid or Flexible Circuit .3-43

SLE Life Support SLE5000 ........................................................................................................3-44

Spontaneous Breathing Patient on a Mask Circuit ....................................................................3-45

Spontaneous Breathing Patient on a Nasal Cannula .................................................................3-46

Teleex Medical Comfort Flo Humidication System .................................................................3-47

Vapotherm 2000i ........................................................................................................................3-48

Vapotherm Precision Flow ..........................................................................................................3-49

Viasys Infant Flow CPAP System; Cardinal Airlife nCPAP System ............................................3-50

Viasys Infant Flow SiPAP ...........................................................................................................3-52

Sample Tee to the Bunnell Life Pulse Circuit ...................................3-33

IR

Injector Module to the Bunnell Life Pulse Circuit ..............................3-33

IR

Part No. 20717 Rev-01

2014-07

i

4/ Transport ..........................................................................................................................................4-1

Transport Options ..........................................................................................................................4-1

A. Intrahospital transport (within the hospital) when moving the

INOmax DS

B. Intrahospital transport (within the hospital) when removing the INOmax DS

as a unit (cart and cylinders) .............................................................................4-1

IR

and INOblender

IR

from the cart. .............................................................................................................................4-2

C. When using the INOblender as a stand-alone device. ..............................................................4-6

INOblender Test Using the INOmax DS

to Analyze Output ....................................................4-8

IR

INOblender Stand-Alone Pre-use Checkout ...........................................................................4-10

D. InterHospital Transport (Between Hospitals) when using a separate INOmax DS

and

IR

INOblender for transport ...........................................................................................................4-11

Duration Chart ..............................................................................................................................4-12

INOMAX Cylinder D-Size .............................................................................................................4-12

Transport Regulator/Cap Assembly Application ...........................................................................4-13

Connection to a Dual-Limb Transport Ventilator Circuit .............................................................4-16

Connection to a Single-Limb Transport Ventilator Circuit ...........................................................4-17

Cylinder Leak Check ....................................................................................................................4-19

5/ Alarms ..............................................................................................................................................5-1

Alarm History ..................................................................................................................................5-3

Alarm Help......................................................................................................................................5-5

6/ Calibration ........................................................................................................................................6-1

Low Calibration...............................................................................................................................6-2

Oxygen Sensor High Calibration ....................................................................................................6-4

NO Sensor High Calibration ...........................................................................................................6-7

NO

Sensor High Calibration.........................................................................................................6-11

2

7/ Maintenance .....................................................................................................................................7-1

Cleaning the INOmax DS

Replacing the O

, NO and NO2 Sensors ........................................................................................7-6

2

...........................................................................................................7-2

IR

Replacing the Water Separator Cartridge ......................................................................................7-8

Cylinder Leak Check ....................................................................................................................7-10

Preventative Maintenance .............................................................................................................7-11

Parts and Accessories .................................................................................................................. 7-12

8/ Product Specications....................................................................................................................8-1

Ventilator Compatibility ...................................................................................................................8-1

RS232 Data Output ........................................................................................................................8-7

Electromagnetic Compatibility Information .....................................................................................8-9

9/ Appendix ..........................................................................................................................................9-1

Manual Pre-Use Checkout .............................................................................................................9-1

Initial connections .........................................................................................................................9-2

High Pressure Leak Test ................................................................................................................9-5

Manual Purge and Alarm Verication ...........................................................................................9-6

Integrated Pneumatic Backup INOMAX Delivery Test .................................................................9-7

Performance Test .........................................................................................................................9-7

INOblender Test ...........................................................................................................................9-8

ii

Part No. 20717 Rev-01

2014-07

WARNING:

Warnings tell the user about dangerous conditions that can cause injury to

the operator or the patient if you do not obey all of the instructions in this

manual.

Caution:

Note:

Blue arrow denotes required user action.

WARNING:

Cautions tell the user about how to properly use the equipment and conditions

that could cause damage to the equipment.

Read and obey all warnings and cautions.

Notes provide clarication or supplemental information.

Integrated Pneumatic Backup

• The integrated pneumatic backup is intended for short term use when the electronic

delivery system fails until a replacement NO delivery device can be brought to the

bedside.

• The integrated pneumatic backup delivers a variable concentration of NO to the

patient depending on the ventilator ow being used.

• When using the integrated pneumatic backup with breathing circuit gas ows of

5 L/min, the delivered NO dose will be approximately 40 ppm. Breathing circuit gas

ows less than 5 L/min will deliver an NO dose greater than 40 ppm.

• The integrated pneumatic backup (250 mL/min.) should not be used with the

Bunnell Life Pulse as ventilator ow rates are normally below the recommended

ventilator ows.

Changing Cylinders

• Always secure a cylinder when not using it.

• Never lift a cylinder by its valve or valve protection cap or by using a chain, sling or

magnet.

• Never drop a cylinder.

• Never use a hammer, pry or wedge to loosen a valve or protection cap. The valve

and protection cap should operate by hand.

• Never let oil, grease or other combustible come in contact with a cylinder or valve.

• Never remove or deface cylinder labeling or markings.

• Never modify equipment without rst contacting the manufacturer.

• Never use an adaptor to connect a cylinder to the system.

• Never use equipment not designed to use INOMAX mixtures.

• Never attempt to repair a leak on a cylinder valve or its safety relief device.

• Never operate equipment that is leaking.

• Never ship a leaking cylinder.

• Never store cylinders;

- Where damage can result from the elements, such as standing water or

temperatures over 125 degrees F.

- Where they can experience extreme low temperatures.

- Where they can contact corrosive substances.

- Where they can be cut or abraded by an object.

- Next to a walkway, elevator or platform edge.

- Unless they are properly secured.

Part No. 20717 Rev-01

2014-07

iii

WARNING:

High Frequency Oscillatory and Jet Ventilator Circuits

• Some high frequency ventilator circuits require a one-way valve to prevent high

NO delivery.

• Place the Bunnell Life Pulse in Standby prior to suctioning the patient to avoid

NO delivery transiently exceeding the set dose by up to 30 ppm. Press ENTER to

reestablish ventilation as soon as the catheter is removed from the airway. This

will limit the extent of over delivery above the NO set dose.

• Do not use dose settings above 40 ppm with the Acutronics Fabian HFO

ventilator. Bidirectional ow through the Injector Module may cause over-delivery

which can lead to measured NO values greater than 100 ppm

Maintenance

• For continued protection against hazard, replace the fuses only with the correct

fuse type and rating.

• Handle and dispose of sensors according to facility biohazard policies. Do not

incinerate.

• If the Injector Module has been used in the wet/humidied part of the breathing

circuit, it should be sterilized between each patient use.

• INOmax DS

- 4 kV input to output isolation

- 4 kV input to mains isolation, and

- an internal “reference voltage” “U” (as dened in section 20.3 of IEC60601-

1 ed. 2) of less than or equal to 50 VDC or 50 VRMS and dielectric isolation

certied in accordance with IEC 60601-1. Interface cabling must not go outside of

the room (e.g., into walls where potential isolation issues could exist). Adherence

to the above provides compliance to clause 20.3 “Value of test Voltage” in edition

2 and clause(s) 8.5.4 “Working Voltage” and Clause 8.8.3 “Dielectric Strength" in

edition 3.

• RS232 cable must be shielded. The RS232 cable shield shall have a minimum

of 90% coverage. The shield shall only be connected at one end of the cable to

minimize noise induced by ground currents.

should only be connected to RS-232 ports that have:

IR

Manually Bagging a Patient with an Injector Module

• The hyperination bag will, under some conditions, contain NO

one ppm. Use of large tidal volume breaths may expose the patients to the NO

present in the bag for part of the breath. In general, if the inspiratory ow rate

induced by the manual ventilation does not exceed the fresh gas ow rate,

the patient should not be exposed to the concentrations of NO

hyperination bag.

• Adult and infant hyperination bags generate more NO

minute ventilation. If use of the bag is interrupted (for example to adjust the

tracheal tube), before resuming ventilation of the patient, the user should squeeze

the bag several times to empty residual gas from the bag.

• Because of the potential for inhalation of excessive concentrations of NO

the difculty in monitoring the peak inhaled NO

a hyperination bag or self-inating bag is intended only for short term use.

• The monitoring system within the INOmax DS

within the hyperination bag or self-inating bag devices and the alarms for

excessive NO

iv

2

in excess of

2

present in the

2

when used at lower

2

concentrations, ventilation with

2

will not detect generation of NO2

IR

cannot warn of NO2 produced within the manual bag system.

Part No. 20717 Rev-01

, and

2

2014-07

2

WARNING:

Manually Bagging a Patient with an Injector Module continued

• To minimize the delivered concentration of NO2, the following steps should be

taken for use with the manual resuscitator bags:

- Concentrations greater than 20 ppm NO should not be used because of

excessive NO

generation.

2

- Use the smallest bag adequate to deliver the desired tidal volume.

- Oxygen tubing lengths greater than 72 inches should not be used (between the

injector module and the bag).

- Use the highest fresh gas ow rate (up to 15 L/min) that is practical.

- Use the lowest practical inspired oxygen concentration.

- After starting fresh gas ow, squeeze the bag several times to empty residual

gas in the bag prior to using the system to ventilate a patient.

Manually Bagging a Patient with the INOblender

•

The purge procedure must be followed to help ensure NO

system before the manual resuscitator bag is connected to the patient.

•

The manual bag should be squeezed repeatedly during use to avoid NO

up in the bag.

•

If the bag is not squeezed repeatedly while delivering INOMAX, the bag should

be removed from the patient and the bag purge procedure performed before

continuing.

•

The INOblender should be upright when setting the oxygen owrate for accurate

setting.

•

Do not use pneumatically powered nebulizers with the INOblender. This will result

in signicant over delivery of INOMAX in excess of 80 parts per million (ppm).

- The INOblender outlet pressure has been validated for use up to 400 millibar (5.8

psig) pressure. The amount of back-pressure generated by pneumatic nebulizers

is signicantly greater (20-30 psig) and will result in over delivery of INOMAX

in excess of 80 ppm. The user adjusted dose setting on the INOblender will not

correlate with, or have an effect on the actual delivered dose.

- In addition, the INOblender owmeter is not back-pressure compensated and will

display a lower ow rate than actual when pressure is applied to the outlet.

is purged from the

2

building

2

Purging Cylinders

• A new INOMAX cylinder and regulator must be purged before use to ensure the

patient does not receive an excess level of NO

• If the INOmax DS

depressurize the regulator supply line.

• If the INOmax DS

purge procedure.

• If the INOmax DS

procedure.

Part No. 20717 Rev-01

2014-07

.

2

is not going to be used on a patient within 10 minutes,

IR

is not used and is pressurized for more than 10 minutes, repeat

IR

is depressurized and not used within 12 hours, repeat pre-use

IR

v

WARNING:

Use Outside of Product Labeling

• The INOmax DSIR must only be used in accordance with the indications, usage,

contraindications, warnings and precautions described in the INOMAX (nitric

oxide) drug package inserts and labeling. Refer to this material prior to use.

• The manufacturer does not recommend that the INOmax DS

helium/oxygen mixtures in any situation. The INOmax DS

be utilized with

IR

is intended to deliver

IR

INOMAX therapy gas only in conjunction with the delivery of air and oxygen. The

use of helium/oxygen mixtures will lead to over-delivery of INOMAX which may

lead to interruption of therapy.

• The use of devices which radiate high-intensity electrical elds may affect the

operation of the INOmax DS

. Constant surveillance of all monitoring and life

IR

support equipment is mandatory whenever interfering devices are in operation on

or near a patient.

• Do not connect items which are not specied as part of the system.

• The approved patient population for the INOmax DS

, as specied in the drug

IR

labeling for INOMAX (nitric oxide) for inhalation, is limited to neonates. The

INOmax DS

is not intended to be used in other patient populations.

IR

Transport

• If the INOmax DSIR or INOblender is to be used in a transport vehicle, they should

be afxed to the transport mounting post (part number 10009), which is part of

the transport mounting bracket assembly (part number 50041).

• The transport mounting post and/or the transport mounting bracket assembly

should be secured to the transport isolette/transport gurney in a manner which

will secure the INOmax DS

/INOblender.

IR

Troubleshooting or Calibrating

• If an alarm occurs, safeguard the patient rst before troubleshooting or repair

procedures.

• Use caution when troubleshooting the INOmax DS

in use for a patient. When possible replace the unit in question and perform

troubleshooting procedure once the unit is removed from the patient.

• If changing an NO sensor while delivering NO to a patient, install the NO sensor

only when the NO high range calibration screen is displayed otherwise there is a

risk that the system will shut down.

• INOMAX can be administered during the sensor calibration process. However,

inspired gases are not monitored and gas monitoring alarms are disabled.

• Loss of communication between the INOmax DS

more than one hour will result in interruption of INOMAX delivery.

delivery system while

IR

and the INOMAX cylinder for

IR

vi

Part No. 20717 Rev-01

2014-07

WARNING:

Ventilators and Breathing Devices

• The INOmax DSIR subtracts gas from the breathing circuit via the gas sampling

system at 230 mL per minute which can cause the ventilator to auto-trigger.

Adjusting the ow sensitivity may be necessary. The trigger sensitivity of the

ventilator should be checked after connecting the INOmax DS

circuit.

• Set the INOmax DS

alarm thresholds for the current patient conditions to

IR

monitor any inadvertent changes in treatment.

• Be certain all cables and hoses are positioned to help prevent damaging or

occluding them.

• The use of pediatric and neonatal ventilator settings with adult size breathing

circuits can result in high levels of NO

. Always use the size of breathing circuit

2

that is appropriate for the patient.

• The humidier chamber volume should not be more than 480 mL to prevent

elevated NO

values.

2

• When handling any component of the patient circuit that comes in contact with

patient’s uids wear personal protective equipment (PPE).

• Patient disconnect and high pressure alarms are required for the ventilator.

• Patient circuit pressure and gas loss will result if cap is not in place (secured).

• Use only “Latex-Free” breathing circuits and ventilators when using the

INOmax DS

• If the INOmax DS

.

IR

is to be used in a transport vehicle, it should be afxed to the

IR

transport mounting post.

• Avoid recirculation of gases. Undesired recirculation of gases will occur if fresh

gas ows are less than the patient minute volume and may result in:

- Higher NO

remove NO

levels due to the limited ability of the carbon dioxide absorbent to

2

.

2

- Higher NO concentrations than those set due to NO recirculated through the

absorber.

- Reduction in O

concentration because nitrogen is the balance gas for nitric

2

oxide and will be present in the re-circulated gases.

• Only use parts/accessories designated for use with this system.

to the breathing

IR

Part No. 20717 Rev-01

2014-07

vii

(Intentionally left blank)

viii

Part No. 20717 Rev-01

2014-07

Part No. 20003 Rev - 01

Part No. 20717 Rev-01

2014-07

1/ General Information

General

Information

Part No. 20717 Rev-01

2014-07

1/ General Information

General

Information

1/ General Information

Indications for Use

• The INOmax DSIR (delivery system) delivers INOMAX (nitric oxide for inhalation) therapy gas into the

inspiratory limb of the patient breathing circuit in a way that provides a constant concentration of nitric

oxide (NO), as set by the user, to the patient throughout the inspired breath. It uses a specially designed

injector module, which enables tracking of the ventilator waveforms and the delivery of a synchronized and

proportional dose of NO. It may be used with most ventilators.

• The INOmax DS

comprehensive alarm system.

• The INOmax DS

the absence of an external power source.

• The INOmax DS

which along with user supplied 10 L/min of oxygen provides 20 ppm in the gas ow to a patient's breathing

circuit. It may also use the INOblender for backup.

• The target population is controlled by the drug labeling for INOMAX which is currently neonates; refer to the

drug label for specic information. The primary targeted clinical setting is the Neonatal Intensive Care Unit

(NICU) and secondary targeted clinical setting is the transport of neonates.

provides continuous integrated monitoring of inspired O2, NO2 , and NO and a

IR

incorporates a battery that provides up to six hours of uninterrupted INOMAX delivery in

IR

includes a backup NO delivery capability that provides a xed ow of 250 mL/min of NO

IR

Part No. 20717 Rev-01

2014-07

1-1

Introduction to this Manual

Denitions and abbreviations

Term Denition

% v/v % volume/volume

Breathing circuit Part of ventilator or breathing system that connects to the INOmax DS

Breathing system Non-invasive breathing devices.

Control wheel Rotary control used to change and conrm settings.

®

Cylinder Aluminum cylinder containing INOMAX

HFOV High frequency oscillatory ventilation.

therapy gas.

®

.

IR

INOblender

®

Back up to the INOmax DSIR. Allows manual ventilation of the patient, providing

uninterrupted delivery of INOMAX.

INOMAX Nitric oxide for inhalation.

INOmeter

®

Counter mounted on a cylinder that records the amount of time the INOMAX cylinder

valve is open.

Infrared (

) Infra-red technology by which the INOmax DSIR communicates with the INOmeter

IR

mounted on each cylinder.

N

2

Nitrogen.

NO Nitric oxide.

NO

O

2

2

Nitrogen dioxide.

Oxygen.

ppm Parts per million.

Pre-use circuit Connectors and tubing assembly required for INOmax DS

psig Pounds per square inch gauge.

Set NO Dose of INOMAX set by the user.

for pre-use checkout.

IR

This manual shows the Set NO displays associated with the 0-80 ppm range.

1-2

Part No. 20717 Rev-01

2014-07

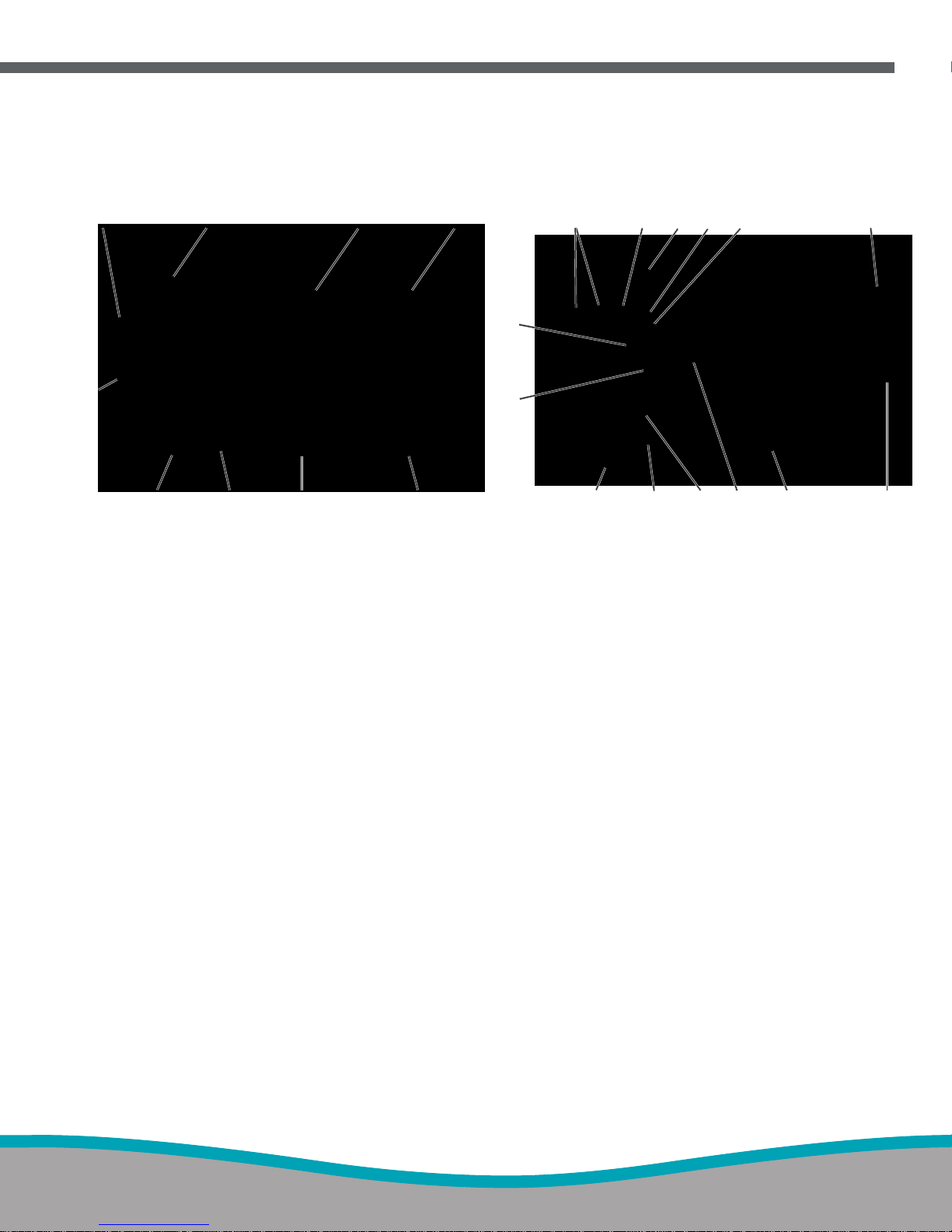

1

2

3

4

11

12

13

14

15

16

10

9

8

7

6

1. Sample Line Inlet

2. Main Power Indicator

3. Display Screen

4. Alarm Speaker (under front label)

5. Integrated Pneumatic Backup Switch

6. Control Wheel

7. Injector Module Tubing Outlet

8. Injector Module Cable Inlet

5

9. Water Trap Bottle

10. Purge Port

11. INOMAX Gas Inlets

12. Blender Gas Outlet

13. Ethernet Port

14. Infrared Connector

15. USB Port

16. Water Separator Cartridge

23

22

21

20

19

17. Water Trap Bottle

18. Sample Gas Outlet Port

19. Clamp Assembly

20. Electrical Cord Inlet

21. Equipotential T erminal

22. ON/Standby Switch

23. RS232 Port

Figure 1-1 INOmax DSIR Front View Figure 1-2 INOmax DSIR Rear View

18

17

Part No. 20717 Rev-01

2014-07

1-3

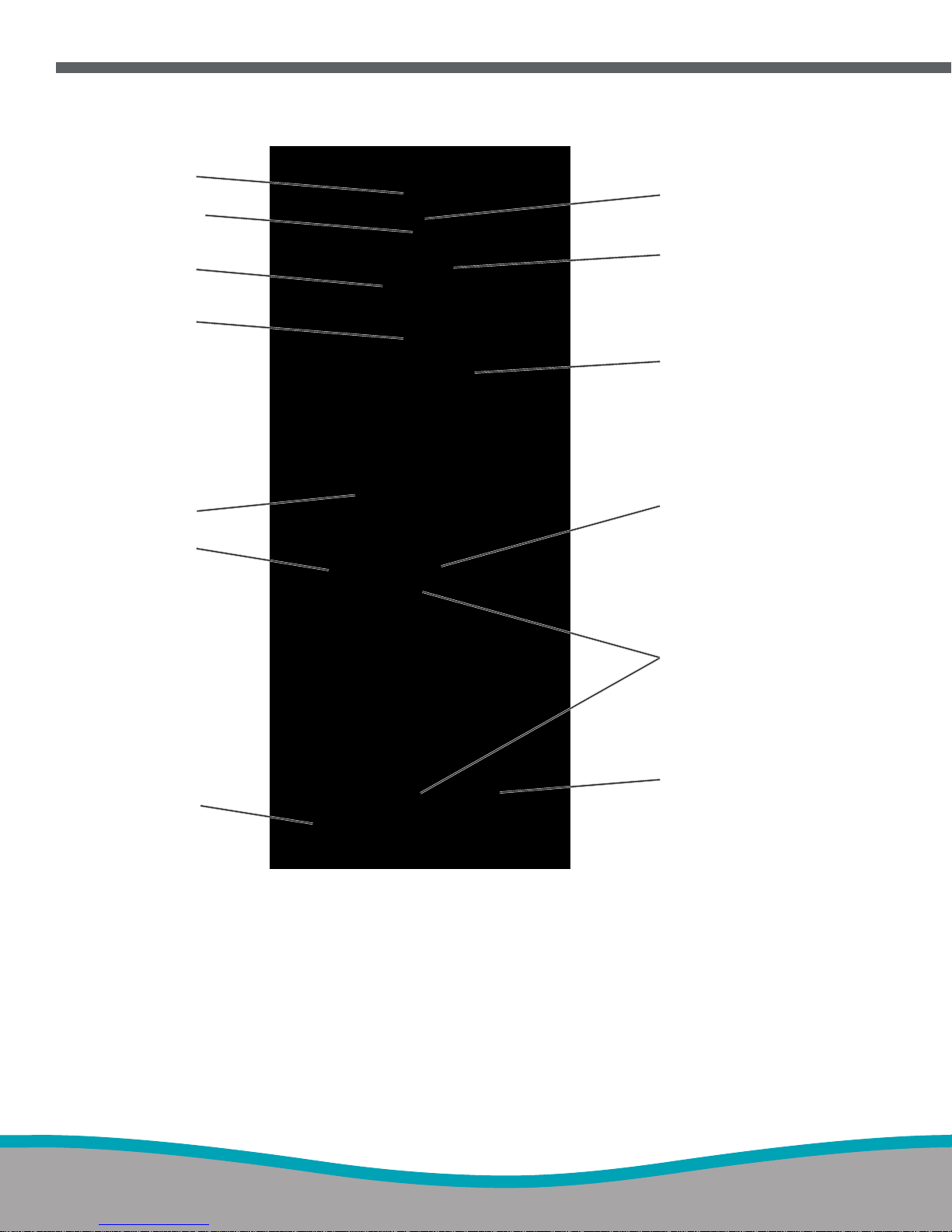

1

2

3

5

6

8

10

4

7

9

11

13

1. INOmax DS

IR

2. INOmax DSIR Mounting Post

3. Clamp Assembly

4. INOMAX Regulator (2)

5. INOblender

6. Small Part Bin

7. INOmeter

8. INOMAX Cylinder

9. Cylinder Holding Bracket

10. Cylinder Mounting Strap

11. Oxygen Cylinder Bracket

12. Caster Lock Lever

13. Caster (4)

Figure 1-3 INOmax DSIR and Cart

1-4

12

Part No. 20717 Rev-01

2014-07

(Intentionally left blank)

Part No. 20717 Rev-01

2014-07

1-5

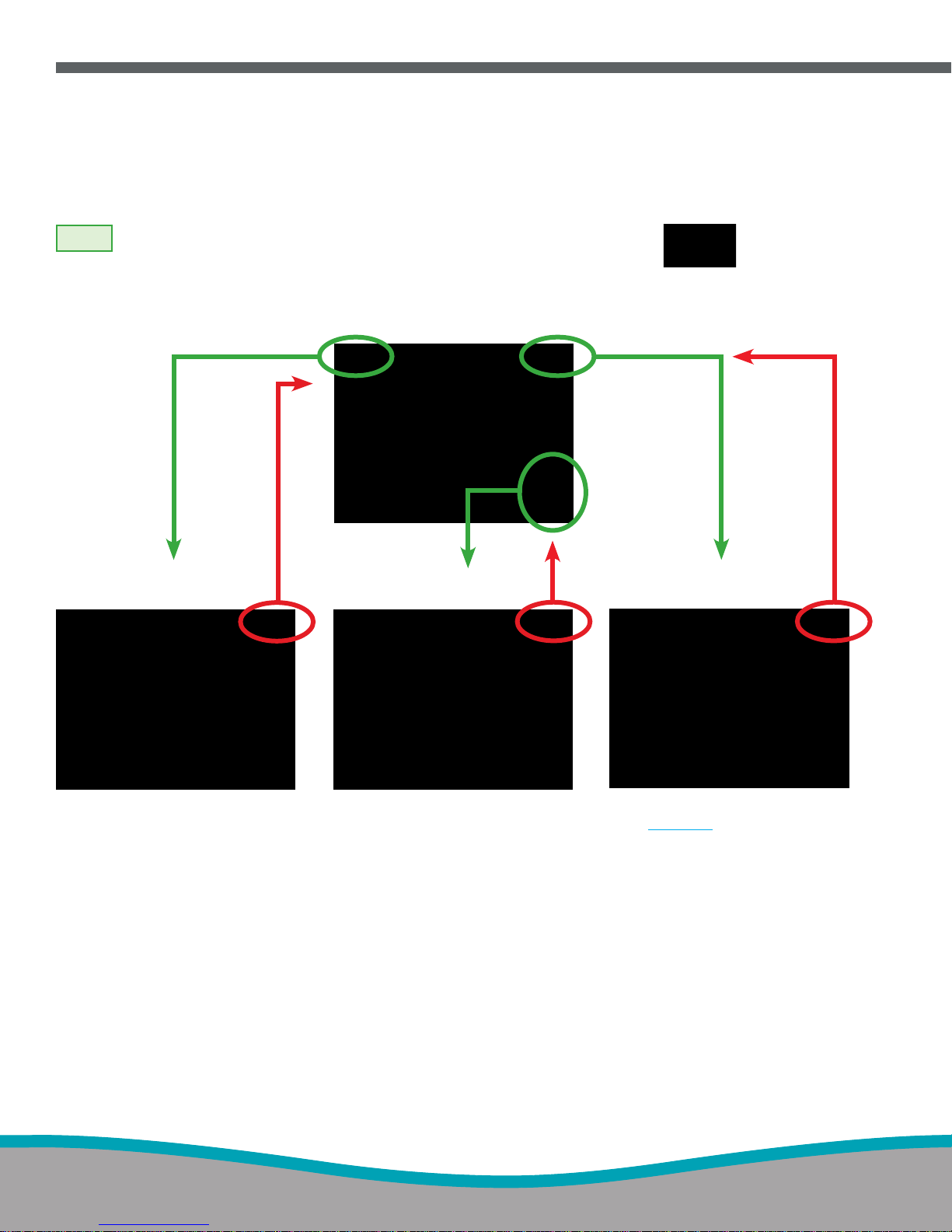

Navigating the Display Screens

Note:

The specic level is identied by the highlighted card on the Menu Button.

The red arrows indicate going back to a previous screen.

Recent Alarms Screen

(second level)

Main Screen (rst level)

Patient Information Screen

(second level)

Menu Screen

(second level)

1-6

Navigating the Menu Screen

(see page 1-8)

Part No. 20717 Rev-01

2014-07

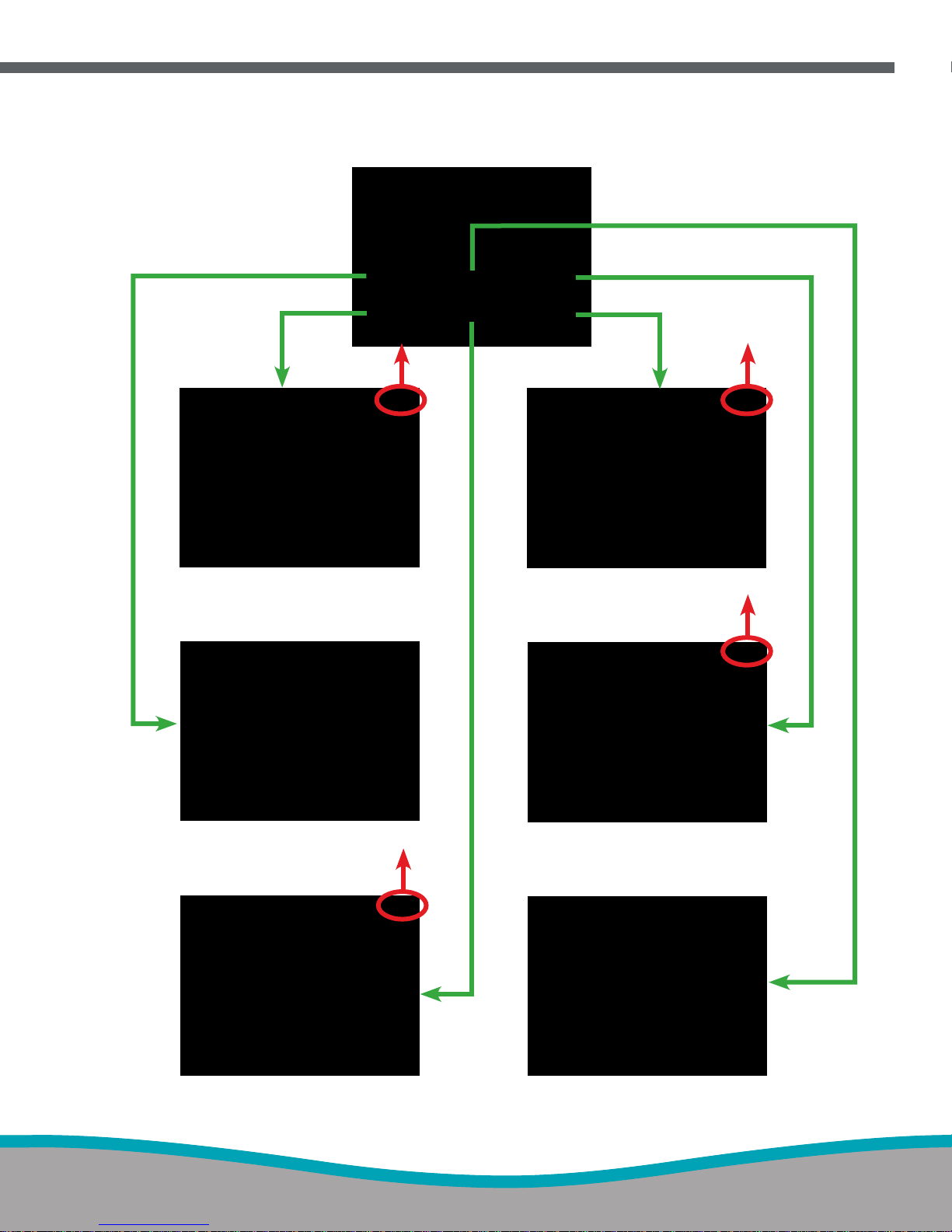

Menu Screen

(second level)

Low Calibration Screen Settings Screen

Pre-Use Wizard Alarm History Screen

High Calibration Screen Automated Purge Screen

Part No. 20717 Rev-01

2014-07

1-7

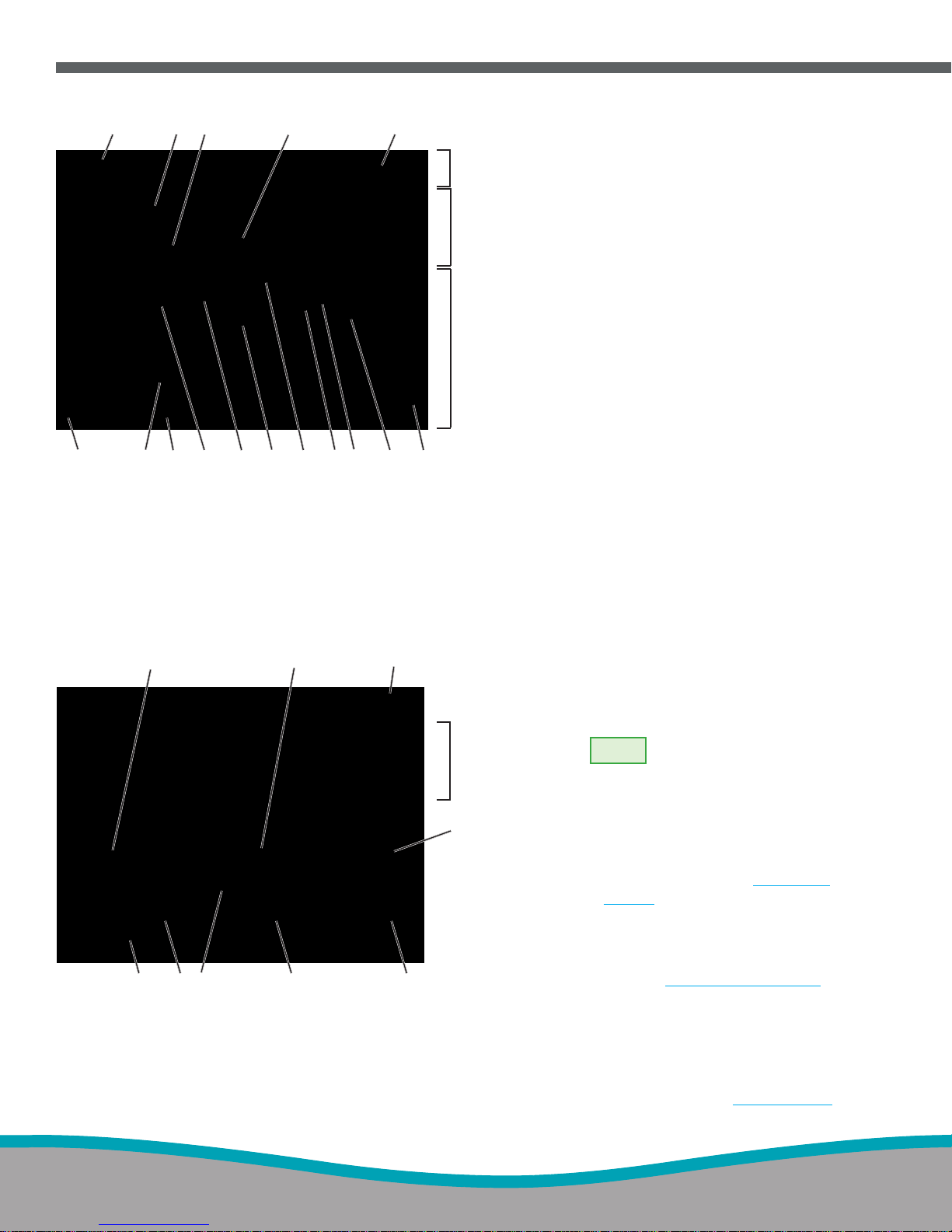

19

1

3

2

4

5

6

Main Display Screen

• On the main screen the user can

7

view alarm messages, monitored

values and graphical information.

• By pressing the “Menu Button” on

the touch screen (top right hand

corner), the user can access the

menu screen (see Figure 1-5 ).

8

10

1718

16

15

14

13

12

11

9

1. Alarm Silence Button

2. Upper Alarm Limit Button

3. Lower Alarm Limit Button

4. Monitored Value

5. Menu Button

6. Text Message Area

7. Monitor Area

8. Graphical Area

9. Patient Information Button

10. Sample Line Icon

11. Water Trap Bottle Icon

12. Inspiratory Limb Icon

Figure 1-4 Main Display Screen

1

8

910

1. Pre-Use Checkout Button

2. Auto Purge Button

3. Return to Previous Level Button

4. Monitor Area

5. Alarm History Button

2

7

6. Settings Button

7. High Calibration Button

8. High Calibration Due Date

9. Low Calibration Button

10. Last Low Calibration Date

Figure 1-5 Menu Screen (second level)

13. Injector Module Icon

14. Delivery Line Icon

15. Integrated Pneumatic Backup Line Icon

16. Integrated Pneumatic Backup Switch Icon

17. Delivery Setpoint Display

18. NO Delivery Setpoint Button

19. Cylinder Icon

Menu Screen (second level)

3

• On the menu screen the user can

access the Pre-Use Checkout

(#1) and the Auto Purge (#2)

wizards.

4

Note:

The Pre-Use Checkout

and Auto Purge buttons

are inactive (greyed out) if

a dose is set.

5

• To review the complete alarm

history, press the Alarm History

button (#5), (refer to Section 5/

Alarms).

• To initiate a low (room air) or high

calibration, press either the Low

Cal (#9) or High Cal (#7) buttons.

6

(refer to Section 6/ Calibration).

• Press the Settings button (#6) to

view circuit ow and calculated

delivery graphs, change display

brightness, change alarm volume,

change time zone and view

software

revision (see

F

igure 1-

6).

1-8

Part No. 20717 Rev-01

2014-07

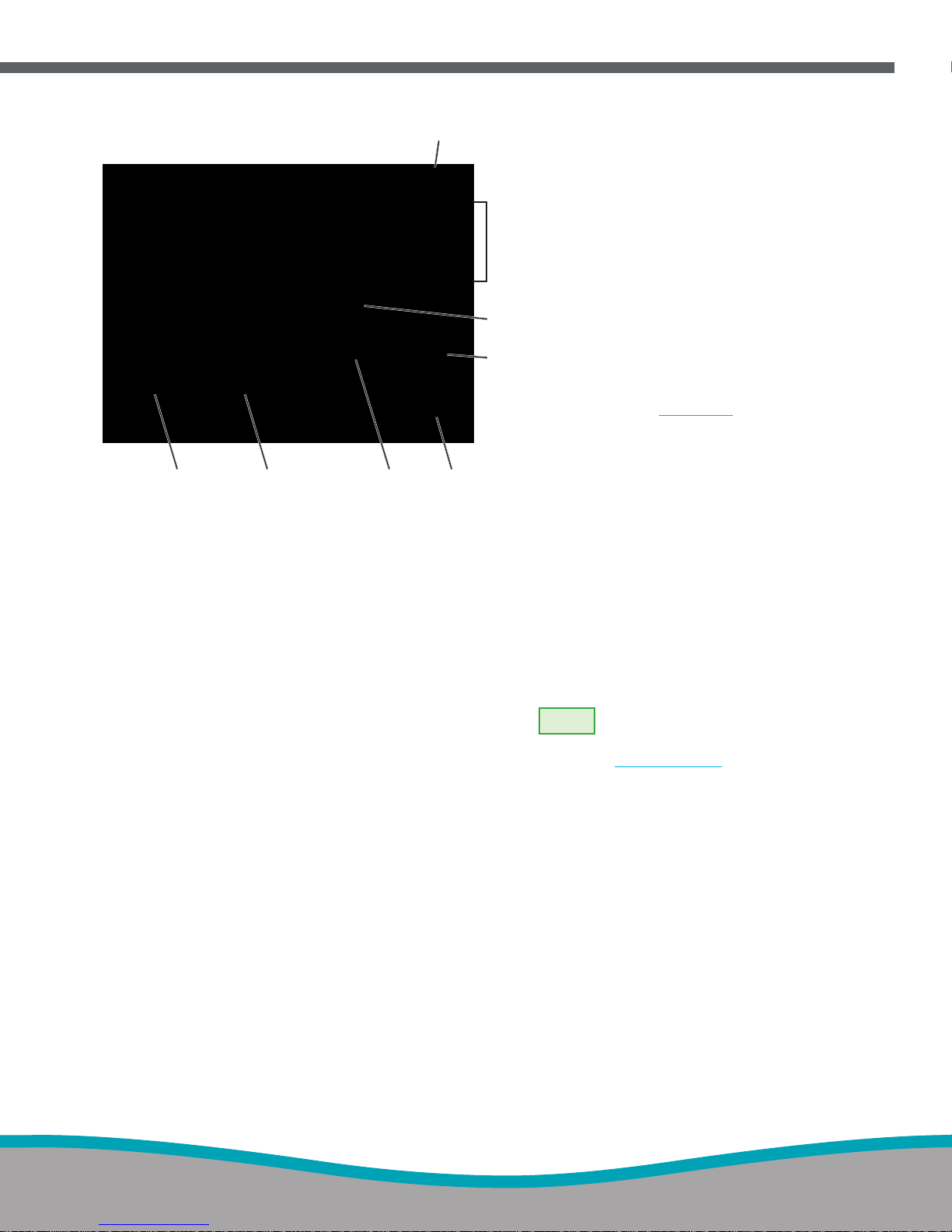

8

1. Return to Previous Level Button

2. Monitor Area

3. Display Brightness Button

4. Time Adjust Button

7

Figure 1-6 Settings Screen

1

2

3

4

6

5. Software Revision

6. Alarm Volume Button

7. Calculated Delivery Graph

8. Circuit Flow Rate Graph

5

Settings Screen (third level)

• The circuit ow graph, combined with

calculated delivery graph, is a user level tool to

ascertain NO delivery system limitations in the

context of mechanical ventilation.

• The circuit ow rate graph displays the

real time peak and average ow rate in the

breathing circuit over a 10 second time period,

as measured by the injector module. The

area in green represents the circuit ow range

where the INOmax DS

system is rated to

IR

deliver NO from 1-80 ppm. (see maximum NO

delivery graph page 1-25). Display graphic

areas in yellow represents where some

inaccuracy of NO delivery is to be expected.

• The calculated delivery graph displays the

delivery subsystem calculated % error in NO

delivery compared to the desired set dose

over a 10 second time period. The green

to yellow transition points are dened to be

NO delivery error of +20% (over-delivery)

to -20% (under-delivery) compared to the

desired NO set dose. High set dose levels,

high peak inspiratory ows and proportional

NO ow control inaccuracies can contribute

to the indicating arrow varying from the ideal

midpoint.

Note:

• If the NO dose is not set, both graphs

will remain inactive.

• See page 1-25 for further explanation

of maximum deliverable NO

concentration.

Part No. 20717 Rev-01

2014-07

1-9

Display and user controls

The INOmax DSIR has a color touch screen display and a control wheel for adjusting and entering user

settings. The buttons on the touch screen and the control wheel perform a variety of functions using a threestep procedure (see “Setting and making changes on the INOmax

The touch screen buttons and control wheel are used to:

• Set the concentration of delivered NO

• Adjust alarm limits

• Silence alarms

• Calibrate the sensors

• Review alarm history

• Dene setup options

• Enter patient information

DSIR” see page 1-12).

Note:

• If a button has been selected and no activity has been sensed within 20 seconds, the display will

return to its previous condition. If a button is greyed out, it is not active.

• Position delivery system so user screen is unobstructed and the speaker is not covered.

When a value is being changed, pressing the

"Cancel Active Status" button during editing will

stop the change and return the parameter to its

original value (similar to the escape key on a

computer).

1-10

Part No. 20717 Rev-01

2014-07

Main Screen

Cylinder icons are not visible and the NO delivery

setpoint button will remain inactive until the

INOmax DS

recognizes an INOMAX cylinder.

IR

Caution:

High frequency and/or high intensity light

emission, in the area of the INOmeter, may

interfere with communication between the

INOmax DS

and the INOmeter on the

IR

INOMAX cylinder (see page 1-15).

The cylinder icons will appear on the main screen in

relation to their position on the cart when the user is

facing the INOmax DS

Note:

When using the transport regulator/cap

.

IR

assembly (PN 10022) only one cylinder

will be displayed.

Part No. 20717 Rev-01

2014-07

When an INOMAX cylinder valve is opened, the

cylinder handle graphic will turn green representing

an open INOMAX cylinder valve.

1-11

Setting and making changes on the INOmax DS

IR

Dose settings

Displayed dose settings are 1, 5, 10, 20, 40, 60 and

80 ppm. Each click on the control knob corresponds

to a known change in dose. The incremental dose

per click corresponds to a value dependent upon

the dose range in which the change is made, as

illustrated in the table at right.

Dose Settings Adjustments

Dose Setting Range Dose Change Per Click

< 1 ppm 0.1 ppm

1 to 40 ppm 1 ppm

40 to 80 ppm 2 ppm

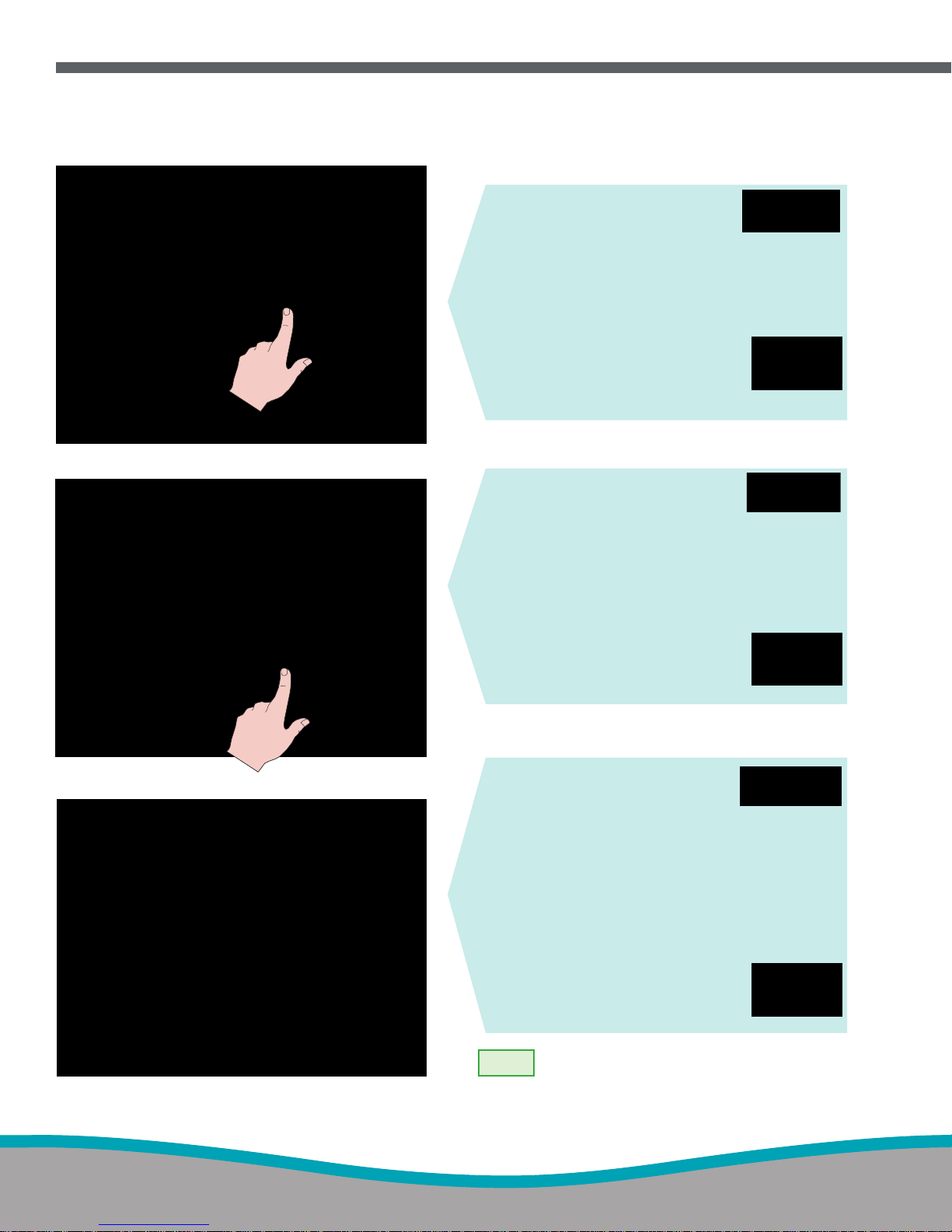

1. SELECT

(press) a button on the touch

screen associated with the

desired function. (An audible

beep will sound when a button

is selected, and the button will

be displayed in inverse video.)

1-12

2. ROTATE

the control wheel clockwise or

counterclockwise to adjust the

value.

Part No. 20717 Rev-01

2014-07

3. CONFIRM

the selection by pressing the

control wheel or the button

associated with the desired

function again.

Note:

• After conrming a desired

dose, the NO alarm

setting (high and low) will

automatically be set for the

rst setting only.

• Any other changes will

require the high and

low alarm settings to be

adjusted.

• Also a two minute lockout

period will prevent the

low NO monitoring alarm

from occurring while the

measured values stabilize.

The Monitor Alarm Delay

Active indicator is not active

following a dose change

from zero.

Part No. 20717 Rev-01

2014-07

1-13

Settings Screen Adjustments

Access the settings screen (third menu level).

Display Brightness setting

1. Push the display brightness

button on the touch screen.

2. Turn the control wheel to indicate the display

brightness level desired. Choices range from

one (darkest) to 10 (brightest).

3. Push the control wheel to conrm the

selection.

4. When nished with the

menu screen, push the return

to previous level button on the

touch screen.

Alarm Volume setting

1. Push the alarm volume

button on the touch screen.

2. Turn the control wheel to

indicate the volume level desired. Choices

range from one (softest) to ve (loudest).

3. Push the control wheel to conrm the

selection.

4. When nished with the

menu screen push the return

to previous level button on the

touch screen.

1-14

Time Adjust setting

1. If the "Time" button is pressed

the Time Adjust screen will

appear.

2. Press the Hour or Minute button on the

touch screen.

3. Turn the control wheel to adjust the

displayed hour or minute.

4. Push the control wheel to conrm the

selection.

5. When nished with the menu

screen push the return to

previous level button on the

touch screen.

Note:

Changing the displayed time does not

impact the time written to the INOmeter

since the time written to the INOmeter is

the GMT time, not the displayed time.

Part No. 20717 Rev-01

2014-07

Infrared Communication between the INOMAX Cylinders and

the INOmax DS

IR

WARNING:

Loss of communication between the INOmax DSIR and the INOmeter for more

than one hour will result in interruption of INOMAX delivery.

The INOmax DSIR has an interface using infrared (IR) technology which allows the INOmax DSIR to

communicate with the INOmeter

INOMAX cylinder for the correct expiration date and cylinder concentration. The INOmax DS

(which is mounted to each INOMAX cylinder). The INOmax DSIR checks the

also transmits

IR

a conrmed patient identier to the INOmeter on any open INOMAX cylinder.

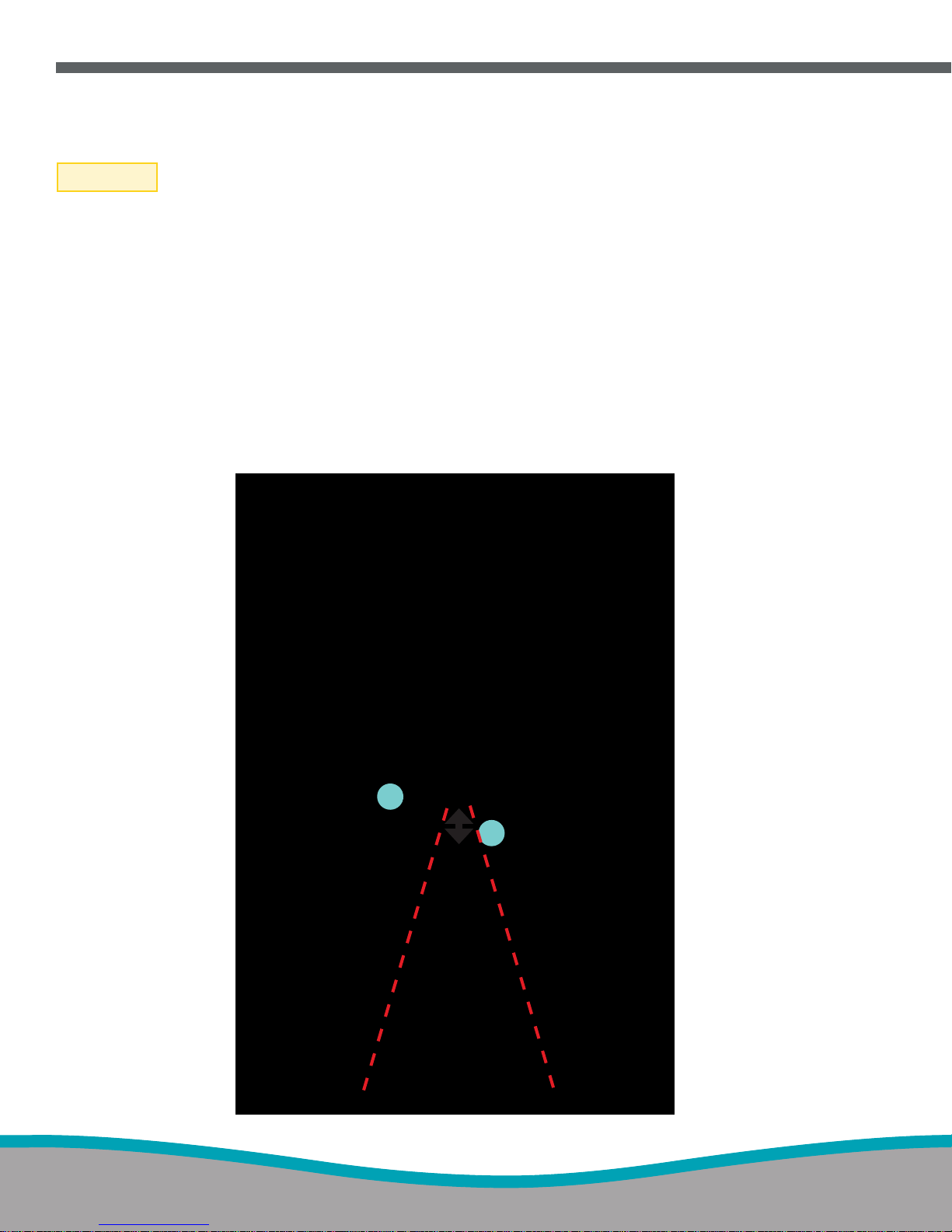

The INOmax DS

cart (PN 10018) has a cover (see Figure 1-7, ) with an infrared transceiver mounted

IR

1

directly above each INOMAX cylinder. When INOMAX cylinders are loaded, communication will take

place between the INOmax DS

INOmax DS

is complete. A cylinder icon will be displayed on the main screen when an INOMAX cylinder is

IR

recognized by the INOmax DS

and the INOmeter (see Figure 1-7, ) after the boot up phase of the

IR

IR

(see “Loading INOMAX Cylinders onto the INOmax DS

Caution:

Nothing should be placed between the INOmeter and the cart to which it is attached.

Cart”, page 1-17).

IR

2

IR Communication Interference

The INOmax DSIR transceiver is located under the cart cover and should be protected from outside IR

sources. The INOmax DS

The INOmax DS

transceiver transmits via a 30 degree transmission cone projecting towards the oor (see

IR

dotted lines in Figure 1-7). The specications of the IR beam call for it to have a range of 20 cm (7.9 in). Based

on these specications it sould not affect other devices in the vicinity of the INOmax DS

cart was designed to protect the INOmeter from external light/IR energy sources.

IR

.

IR

The INOmeter uses a lower energy source which results in a lower IR beam range than the INOmax DS

The INOmeter does not transmit IR signals unless it is mounted on the INOmax DS

Caution:

A strong magnetic eld could affect the ability of the INOmeter to detect if the cylinder valve is

opened or closed. This may affect the ability of the INOmax DS

or closed) of the cylinder valve.

If there is interference with the INOmax DS

will not be displayed and a “Cylinder Not Detected” alarm will activate if there is a set INOMAX dose.

If IR communication interference occurs, we recommend taking the following actions:

• Move the external IR source

• Move the INOmax DS

cart to reduce the external IR source in the area of the INOmeter

IR

• Shield the INOmeter from the suspect IR source

If the actions listed above do not remedy this issue, the transport regulator/cap assembly (PN 10022) may

be utilized.

Part No. 20717 Rev-01

2014-07

cart.

IR

to detect the position (open

IR

/INOmeter communication, the cylinder icon on the user screen

IR

cart.

IR

1-15

External Light Interference

Caution:

High frequency and/or high intensity light emission, in the area of the INOmeter, may interfere

with communication between the INOmax DS

and the INOmeter on the INOMAX cylinder.

IR

If there is interference with the INOmax DSIR/INOmeter communication, the cylinder icon on the user screen

will not be displayed and a “Cylinder Not Detected” alarm will activate if there is a set INOMAX dose.

Test results have demonstrated susceptibility to unintended infrared energy from articial light sources. Most

notably, various compact uorescent lighting xtures that focus or reect light, increasing the light intensity in

the vicinity of the INOmax DS

cart, could affect INOmeter communications.

IR

If external light interference occurs, we recommend taking the following actions:

• Move the interfering light source

• Move the INOmax DS

cart to reduce the high intensity light in the area of the INOmeter

IR

• Shield the INOmeter from the suspect light source

If the actions listed above do not remedy this issue, the transport regulator/cap assembly may be utilized.

Figure 1-7

1-16

1

2

Part No. 20717 Rev-01

2014-07

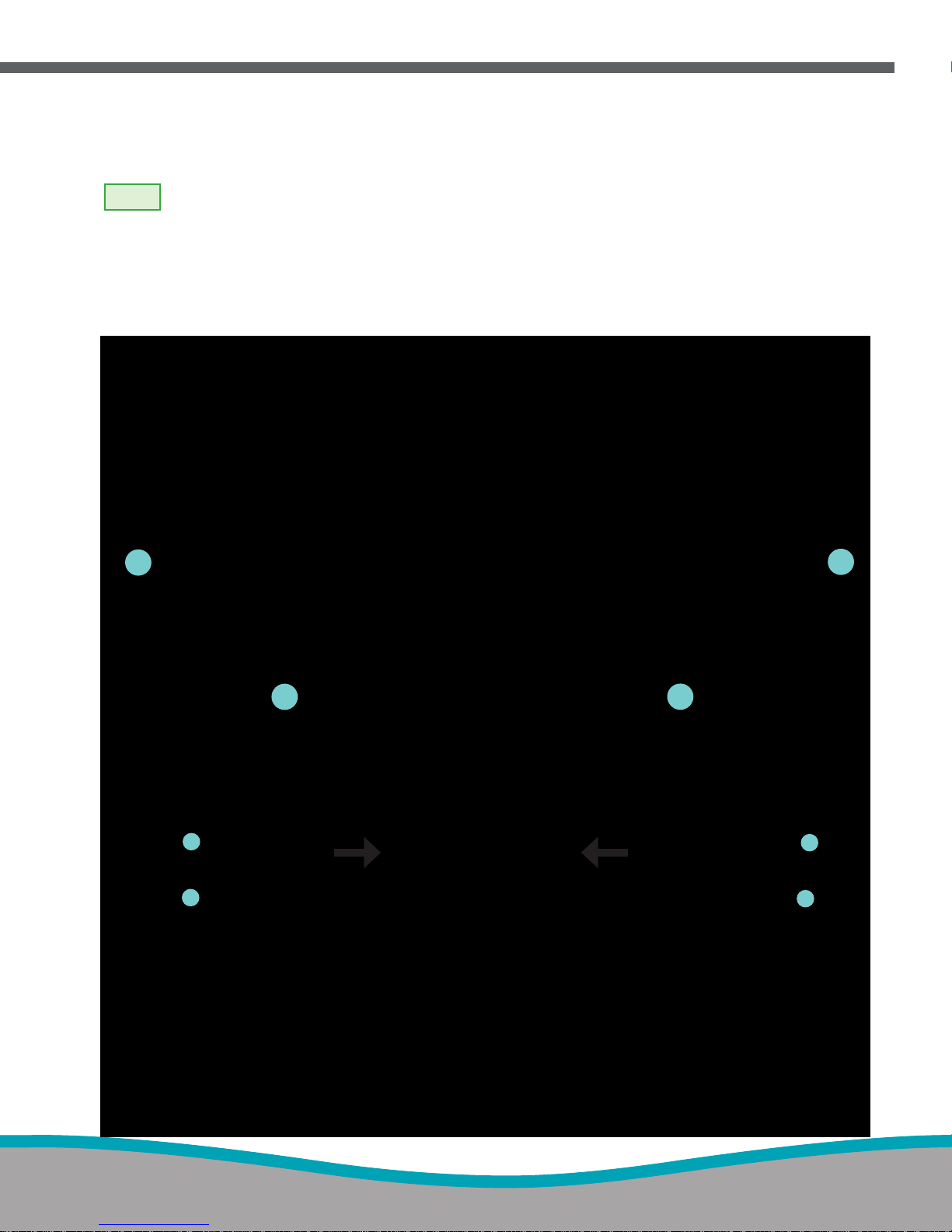

Loading INOMAX Cylinders Onto the INOmax DSIR Cart

Note:

2

Check the INOMAX gas cylinders for the correct product identity labels, cylinder concentration

and expiration date.

4

Loading the rst

INOMAX cylinder

on the cart will

result in a cylinder

icon displayed on

the screen .

1

2

1

3

Loading a second

INOMAX cylinder onto

the cart will result

in a second cylinder

icon displayed on the

screen .

3

4

Part No. 20717 Rev-01

2014-07

1-17

INOmeter Operation

•

Removal of the INOmeter from the cylinder must be performed by authorized personnel. Do not

dispose of the INOmeter.

•

INOmeter battery replacement is only to be performed by authorized personnel.

•

The INOmeter replaces the standard rubberized cylinder valve handle on the INOMAX cylinders and

is used to open and close the cylinder valve. The INOmeter is a time-metric device which records the

amount of time the INOMAX cylinder valve is opened.

•

The INOmeter is designed for use with INOMAX cylinders and with the INOvent, INOmax DS and

INOmax DS

•

When used with INOmax DS

INOmax DS

and the expiration date to the INOmax DS

communicated from the INOmax DS

delivery systems.

IR

, two-way infrared (IR) communication occurs between the

IR

and the INOmeter. The INOmeter communicates the INOMAX cylinder concentration

IR

. Patient ID (when conrmed) and dose information are

IR

to the INOmeter.

IR

Figure 1-8

Note:

• Cylinders are shipped with the

INOmeter covered in a tamper-proof

seal.

• A valve lock is secured to the cylinder

by a lanyard.

• The lock must be removed to open

the cylinder valve for use.

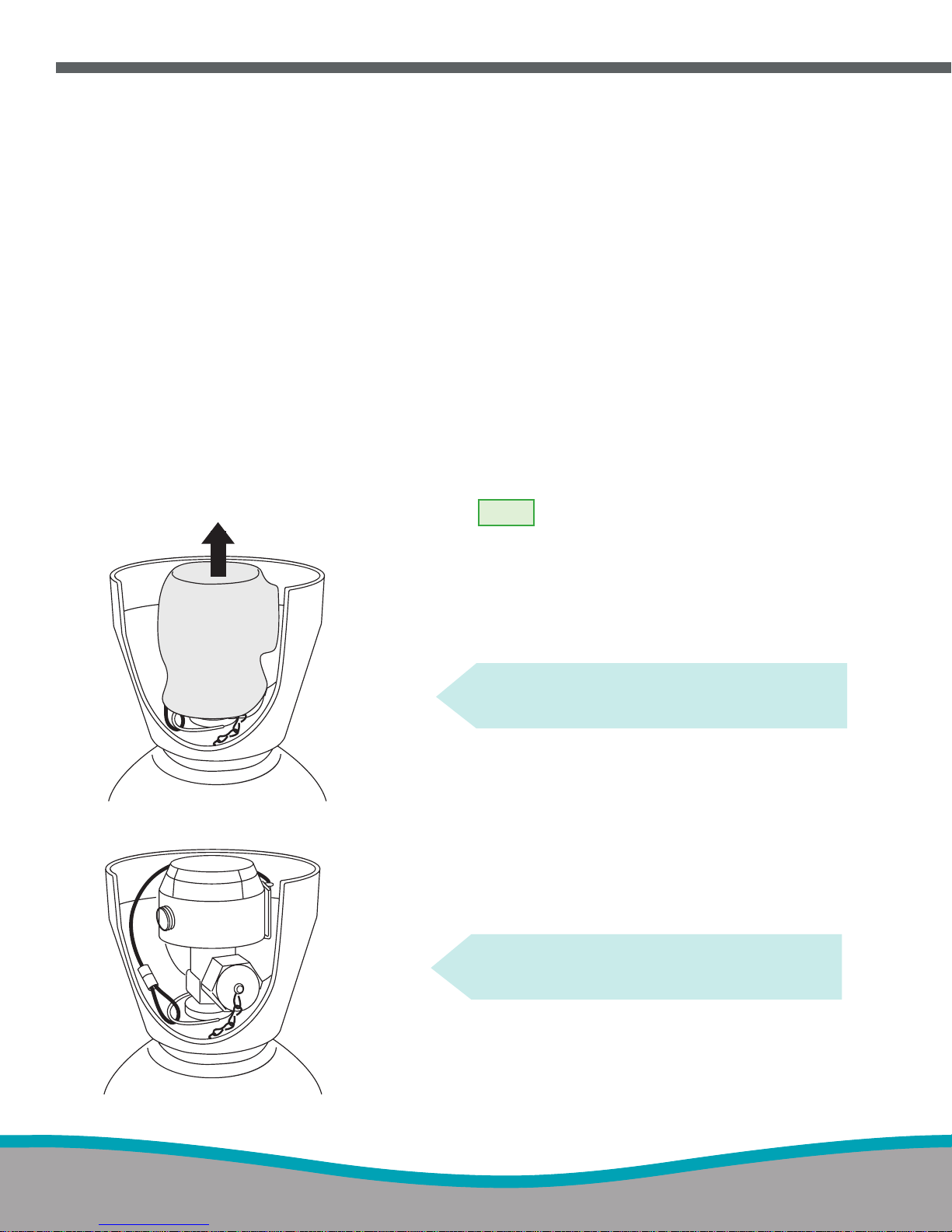

1. Remove and properly dispose of tamper-proof

seal or covering (see Figure 1-8).

2. The lock is secured to the cylinder by a

lanyard (see Figure 1-9).

Figure 1-9

1-18

Part No. 20717 Rev-01

2014-07

Loading...

Loading...