Mallickinrodt Gem-Stat User manual

COMPREHENSIVE

SERVICE

MANUAL

Mallinckrodt

Ann

Arbor,

48108-3248

1

(800)

262-3654

313-973-7000

Sensor

Michigan

U.S.A.

or

Systems,

WWEALLINCKROD

Sensor

Inc

Syster

GEM:

Stat

PORTABLE

ELECTROLYTE,

ANALYZER

COMPREHENSIVE

BLOOD

AND

SERVICE

HEMATOCRIT

GAS,

MANUAL

(B

OPERATED

SYSTEM

IF

ABOVE

ACCURACY

IS

95°F

WARNING

NOT

IS

OR

(35°C)

Mallinckrodt

1590

Ann

Arbor,

A

AT

BELOW

GUARANTEED.

Sensor

Eisenhower

MI

48108

(800)

262-3654

(313)

973-7000

TEMPERATURE

(15°C),

60°F

Systems

Place

USA

350140A

No.

Part

1993

May

350138B

**

IMPORTANT

NOTICE

**

This

Voltage)

Appendix 6 is

pages

manual

Models, a 120V,

If

you

have

If

you

have

in

Please

refer

contains

instrument.

the

applicable.

the

this

manual

to

Which

60

120V,

Dual

Appendix 6 now

Model

service

Hz

instrument,

60

Hz

Please

Voltage

with

the

information

Instrument,

Instrument,

appropriate

GEM

for

Stat

for

and a 120/230V,

the

ignore

instructions.

Appendix

you

pages

do

you

two

different

entire

must

that

own?

GEM

50/60

manual

6.

substitute

are

Hz (Dual

EXCEPT

in

Appendix

Stat

some

of

the

6.

This

manual

technicians.

e

Chapter

e

Chapter

installation,

e

Chapter

quality

e

Chapter

operation

component

e

Chapters,

diagnostic

e

Chapter

various

provides

Operators

7,

2,

3,

control

4,

of

messages

6,

systems.

detailed

can

Introduction.

Installation

startup

Operation . Provides

Theory

the

and

Trouble-Shooting.

System

and

optional

procedures

of

Operation.

various

functional

and

Checkout.

GEM

Stat

refer

also

Explains

and

Preparation.

custom

and

an

systems.

systems.

Outlines

recommends

Provides

SCOPE

operating

"GEM

the

to

the

purpose,

Discusses

setup

step

by

step

explanation

Provides

Includes

detailed

block

procedures

appropriate

procedures

and servicing

Operators

Stat

application

storage

procedures.

instructions

of

its

special

information

diagram

and

for

trouble-shooting.

service

to

check

information

Manual".

and

general

requirements,

for

normal

features.

detailed

procedures.

the

operation

relative

performance

for

qualified

specifications.

unpacking,

including

to

the

internal

descriptions

Explains

of

by

the

major

e

Chapter

instructions.

e

Chapter

electrical

layout

e

Chapter

debris

‧

Appendix

Alphanumeric

e

Appendix

via.

RS232

e

Appendix

information

e

Appendix

major

e

Appendix

and

shows

‧

Appendix

pages

instrument.

7,

Mechanical

Contains

8,

Electrical

systems

drawings

9,

in

the

1.

2.

3.

4.

components

§.

how

6.

as

listed

operation.

followed

Cleaning.

fan

filter.

Display

display

Transmission

port.

RS232

and

communication

Electromechanical

and

Printouts,

they

Dual

on

page

See

"Important

Disassembly.

explosion

Circuits.

by an

Provides

Messages.

with

views

Contains

electronic

an

explanation

Reports.

Communication

parameters

systems.

Provides

are

affected

Voltage

Substitute

one

of

the

Notice"

Provides

of

all

Provides

schematics,

component

instructions

Complete

of

Provides

detailed

major

detailed

for

cleaning

list

of

what

they

numerous examples

Specifications.

via

RS232

Specifications.

numerous

by

optional

manual

in

front

setup

pages.

IF

you

of

examples

Substitute

are

manual.

disassembly

subassemblies

electronic

wiring

lists.

display

Lists

items

using

description

diagrams,

blood

from

messages

mean.

Explains

port.

RS232

electromechanical

of

printouts

and

sensor

these

the

115/230V,

and

reassembly

and

complete

of

the

printed

the

instrument

that

may

transmission

connector

specifications

during

pages

normal

faults.

for

the

50/60

parts

major

circuit

board

and

appear

of

pin-out

operation

appropriate

Hz

list.

on

the

reports

for

Information

Mallinckrodt

not

be

copied

without

and

Sensor

or

prior

written

PROPRIETARY

descriptions

Systems.

reproduced

permission

contained

Such

by

any

MATERIAL

herein

information

means,

of

disseminated

Mallinckrodt

are the

and

Sensor

property

descriptions

of

may

or

distributed

Systems.

TABLE

OF

CONTENTS

CHAPTER

1.1

PRODUCT

1.2

OPERATION

1.3

EQUIPMENT

1.4

EOUIPMENT

SEPARATELY.

1.5

OPTIONAL

1.6

DESCRIPTION

GEM

GEM

GEM

GEM

GEM

Reusable

1.7

SPECIFICATIONS

Applicable

Environmental

Environmental

Physical

Power

Quality

Measured

Derived

Miscellaneous

1;

INTRODUCTION

DESCRIPTION

SUMMARY..

SUPPLIED

REOUIRED

OF

Stat

(Product

Statpak

Sampler

Check

crit

requirements

control

GEM

GEM

(Product

(Product

(Product

Check

Case

safety

specifications.

parameters

parameters..

(Product

(Product

standards

conditions

conditions

solutions

Check...

crit

Check

specifications

WITH

FOR

=

THE

GEM

Number

Number

Number

Number

Number

Number

............

....

for

for

specifications.

..

.

EACH

OPERATION,

STAT

4300, 4400, 4500, 4600,

4301)..

4305)

2306)....

operation

storage

..

GEM

COMPO

2309).

84009)

STAT

BUT

INSTRUMENT..

PURCHASED

S.

4700)

D

D

D D

D

ND

&

0

6

0 6%

ER BR

ER

RE

ouumeE

CHAPTER

2.1

STORAGE

2.2

Customers

Customers

2.3

2.4

INSTRUMENT

2.5

2.6

2.7

2.8

2.9

2.10

How

Mandatory

2;

INSTALLATION

INSTRUCTIONS

UNPACKING

INSPECTION

INSTALLING

INSTALLING/CHANGING

GEM

STAT

INSERTING A NEW

GEM

STAT

CUSTOMIZING

to

change

INSTRUCTIONS

with

the

reusable

without

POWER

WARM-UP/HYDRATION

quality

reusable

OF

COMPONENTS..

THE

GEM

FRONT

UP

CARTRIDGE

SYSTEM,

THE

the

hidden

control

AND

PREPARATION

....

carrying

carrying

STAT

PANEL

THE

INSTRUCTIONS.

key

case..

.…

DISPLAYS

PRINTER

.........

"HIDDEN"

status

case.

MODE

.

AND

PAPER

KEY

KEYPAD

..

FUNCTIONS

FUNCTIONS.

POIANA

Mandatory

Date

format.

Counts...

Units

of

measurement

Sample

Analytes

Cal

labeling......................

(Gas/Electrolyte/Hct)

Stats

ID..

for

blood

gas

partial

pressures

.

CHAPTER

8.1

OPERATION

Ready

Standby

QC

3.2

HOW

1.

2.

3.

4.

5.

3.3

OPERATOR

人

Quality

3.4

RECORD

Printing

To

To

3.5

MISCELLANEOUS

Paper

Cartridge

Temperature

Standby

下

3.6

POWER

3.7

CARTRIDGE

3;

OPERATING

SUMMARY

mode...

mode

mode........

TO

Collect

Enter

patient

Aspirate

Interpret

Sample

Derived

Normal

Description

Correcting a calibration

Reasons

How

Control

How

дирйсае

reprint a copy

reprint

feed......

How

How

How

How

How

PROCESS

the

blood

and

the

sample..

the

printout:

printouts

parameters

physiological

PERFORMANCE

to

initiate a 2-point

(QC)......................

to

analyze a QC

KEEPING

QC

records,

status.

to

print

correction

to

temperature

mode.....................

to

enter

to

exit

to

change

INTERRUPTION.

REMOVAL...

A

operator

of

calibration

to

Initiate a 2-point

AND

гесога$.....................

of

the

FUNCTIONS

the

standb:

standby.

INSTRUCTIONS

BLOOD

SAMPLI

identification

with

missing

....

blood

rang

CHECK

failure

failure.

calil

calibration:

solution

REPRINTING:

last

sample

blood

analyses,

cartridge

correct a blood

...

the

date

analysi:

.

status.

and/or

numbers

values

.

.

detection.

or

calibration

sample.

time

records.

CHAPTER

4.1

OVERVIEW

4.2

MAJOR

GEM

GEM

4.3

DESCRIPTION

Sensing

Calibration

Isolated

Heater

Processing

Fluid

4;

THEORY

COMPONENT

Statpak

Stat

instrument

Buffer

Analog-Digital

Thermal

Display

Keypads...........

Power

Pump

Valve

Door

Lock

RS-232

Software

Interface

systems

Hematocrit

Calcium,

Oxygen

system

analog

Block

thermal

and

system

Pump

Valve

...

Actuator

OF

cartridge

.....

amplifier

printer.

assembly

and

circuit

Supply

motor..............

motorin

port

assembly.

and

cartridge

......................

operating

switches...

OF

MAJOR

..

Sodium,

..

power

Internal

System

system

control

System

OPERATION

DESCRIPTION

..

heater

board

block

assembiy.......

lock-out

system

Potassium,

Loop

communication

Carbon

assemb!

solenoid

Dioxide

system

and

pH

+

HA

+4DOLOVONIININIDODIDONNA

oo

CHAPTER

5.1

TROUBLE-SHOOTING

5.2

INOPERATIVE

Instrument

Instrument

Alpha-Numeric

5.3

Printer

Paper

Printer

5.4

5.5

5.6

CRC

RAM

Sample

Valve

5;

TROUBLE-SHOOTING

INSTRUMENT...

inoperative:

inoperative:

display

PRINTER

KEYBOARD

HEATER

ALPHA-NUMERIC

PROBLEMS/FAILURE.....................

inoperative - no

will

not

feed

out

feeds

paper,

PROBLEMS/FAILURE

BLOCK

failed...............

failed

message

error.........

failed

(Also

but

FAILURE

DISPLAY

prints

SUMMARY.

no

visible

display

stays

printing

although

does

on

contains

at

"INSERT

or

it

not

..........

ERROR

print

power

paper

sounds

print.

out

if

paper

.

scattered

CART".

does

not

like

its

MESSAGES

is

installed)

LED

segment:

advanc:

working...

vn

www

5.7

SAMPLING

Sample

Cartridge

Display

Display

5.8

CALIBRATION

Multiple

5.9

QC

QC

Values

QC

Printout

PO2

Multiple

QC

Values

Display

Display

5.10

MISCELLANEOUS

Instrument

Display

Display

Display

Display

PROBLEMS...

will

not

values

reads,

reads,

parameter

PROBLEMS

are

Values

failed

OC

parameter

are

reads,

reads,

will

reads,

reads,

reads,

reads,

aspirate.....

do

not

compare

"OP000000000"

"PA000000000"

PROBLEMS

failures

OR

not

displayed

are

(other

values

displayed

"BAD

"MUST

not

go

"NO

GOOD

"PLEASE

"RECOVERING"

"REMOVE

with

FAILURES......................

Blank

values

failed

and

LOT

NUM"

DO

QC".

PROBLEM

into

Standby

DATA"

WAIT"

CART"

with

the

lab.

and

sample

and

sample

OR

FAILURES......

multiple

on

the

followed

are

within

QC..............

reported

.

(remove

cartridges

instrument

by

a

range).

on

patient

cartridge)

won't

aspirat

won't

aspirate

.

questi

sample

printout

.

CHAPTER

6.1

PURPOSE

6.2

EQUIPMENT

6.3

BASIC

Power-up

Real-Time

Printer

Power

Functional

Diagnostic

Test

CHAPTER

6;

BASIC

REQUIRED.

OPERATION

test.......

clock

test........

fail

test

diagni

1.

Keyboard

2.

Display

3.

Cartridge

4.

Pump

5.

Printer

6.

Thermal

7.

Simulator

keypad

form

7;

MECHANICAL

SYSTEM

OPERATION

TESTS

test

Test.

Test...

Motor

Test.

Test.

Valve

Actuator

Speed

Cartridge

definitions...

DISASSEMBLY

Test

Test.

TEST

=

Test.

OMDNFAAHRAWOWNNNN=]

7.1

OVERVIEW

7.2

TOOLS

7.3

GENERAL

7.4

MAJOR

REQUIRED

FOR

DISASSEMBLY

SUBASSEMBLY

DISASSEMBLY.

PROCEDUR

DIAGRAMS...

7.5

COMPLETE

GEM

STAT

PARTS

LIST...

17

CHAPTER

8.1

Isolated

Main

Parts

8.2

8.3

ANALOG-DIGITAL

Recent

Unused

Electrode

Analog

Low

Voltage

Microprocessor

Parts

8.4

Device

Numerical

Intelligent

LED

Parts

8.5

8.6

DOOR

Parts

8.7

8.8

REAR

8;

ELECTRICAL

POWER

power

power

DC

Power

Motor

Signal

list

HEATER

changes

circuitry

multiplexer

pass

to

Central

Read-Oniy

Random-access

RS-232

Address

Motor

Printer

Display

Light

Keyboard

System

System

Opto-Isolator

List

DISPLAY

Select

Driver.

list

PRINTER

LOCK,

list

INNER

WALL

PANEL

CIRCUITS

SUPPLY.

supply

Power

Control

for

power

BLOCK

differential

filter

frequency

control

emitting

for

A/D

CIRCUIT

Displays

Alphanumeric

for

display

ELECTRONICS

for

solenoid

supply.

.....

Supply.

fail

detect

Interconnection

AND

to

on

.....

circuitry......

processing

memory

port

bus

interface

control

interface.....

Status

real

board

Decoder.................

SOLENOIDS

ELECTRONIC

ELECTRICAL

circu

Circuitry

supply

TEMPERATURE

(A/D)

A/D

board

the

P.C.

amplifiers

converter

on

...

board

CIRCUIT

......

board

.

uni

(ROM)

memory

............

decoder.

time

DESCRIPTION

and

board

signals..

diode

Signals.

and

driver

..

(LED)

calendar

solid

2...

Display

Display

nes

assembly

DESCRIPT

(K1 8 K2),

board

CIRCUITRY

CIRCUITRY

state

..

(RAI

Drivers...

..

the

Power

BOARD

Supply

CONTRO!

control

clock

............

..

relay

drive..

ns

SOLENOID

.

Board..

14

22

DR

CHAPTER

9.1

BLOOD

Materials

Method

9.2

9;

CLEANING

CLEANING

CLEANING

required

for

Cleaning

FAN

PROCEDURES

PROCEDURES

for

cleaning

up

Blood

FILTER...

..

blood.

APPENDIX

APPENDIX

REPORT

OPERATING

Gases

Sample

Temperature

Calibration

EXAMPLES

Sample

Sample

Sample

Sample

Sample

QC

QC

1-Point

2-Point

Last

Sample

Sample

Raw

Report

Status

Status

2-Point

disabled)...

2-Point

1;

DISPLAY

2;

FORMATS

TRANSMISSION

MODE

only,

labeling..........

SELECTIONS..........

electrolytes

correction.

data

reporting

OF

REPORT

report

report

report

report

report

report

report

CAL

CAL

CAL

report

report

count

after

report

report

CAL

CAL

(electrolytes

(Gases

(Temperature

(labeling

(longest)......

(electrolytes

(gases

report

and

report

report

(Electrolytes

(Gases

(electrolytes

(after

(Flawed

value

report

power

completion

failure

(all

electrodes

(after

several

pl

MESSAGES

OF

TRANSMISSION

DESCRIPTION..

only,

or

both

.

TRANSMISSIONS

only)

only).......

enabled)

only)...

electroly

Corrected)

.

Only)..

and

Electrolytes

only)

several

electrodes

sample

..

message

test)........

operational).

calibration

g

REPORTS

modes.

:

.

with

CAL

…………………………………

had

CAL

failures)

failures)

(no

electrode

..

failures,

STAT

CAL

enabled)..

STAT

0 D À

D

NN

& &

En GC

1

©

©

©

HN

HN

©

©

© ©

=

=

APPENDIX

GENERAL

CONNECTOR

BAUD

DATA

APPENDIX

POWER

3;

RS-232

DESCRIPTION

AND

SIGNAL

RATE,

FORMAT,

TRANSMISSION

4;

ELECTROMECHANICAL

SUPPLIES..

COMMUNICATIONS

DESCRIPTION

AND

HANDSHAKING

PROTOCOL

SPECIFICATION

...

SPECIFICATIONS

ELECTRODE

ELECTRODES)

OXYGEN

HEMATOCRIT

DIFFERENTIAL

HEATER

ANALOG-TO-DIGITAL

CARTRIDGE

PUMP

MICROPROCESSOR

RS232

BATTERY

REAL

PRINTER

ISOLATION

MOTOR/ROTOR

PORT...

TIME

Dielectric

Maximum

Physical

BUFFER

CHANNEL

CHANNEL..

GAIN

BLOCK

BACK

.............

THERMOSETTING..

VALVE

CLOCK

AND

LEAKAGE

withstand

leakage

spacing.

AMPLIFIERS

STAGES,

CONVERSION

STEPPER

SYSTEM...

TIME

voltage

currents

PH,

MOTOR

BASE

CURRENTS...

..

.

(REF,

CA++,

PH,

NA+,

CA++,

K+,

NA+,

CO

Kt

AND

CO?

가

나 가

가

D

D

D

D

D D

D

00

00

00

00 00

600

APPENDIX

GENERAL

PRINTOUT

Gases

Sample

Calibration

MISCELLANEOUS

DATE

STANDBY

Temperature

Cartridge

RECORD

APPENDIX

50/60

IMPORTANT

INNER

REAR

COMPLETE

POWER

POWER

WIRING

KEEPING

HZ

MODEL.

PANEL

SOLENOID

SOLENOID

INNER

INNER

REAR

REAR

5;

PRINTOUTS

INFORMATION

OPTIONS

only,

Electrolytes

labeling............

data

and

TIME

mode

STATUS

PAGES

6;

NOTICE;

PANEL

ΘυΡΡΙΥ

SUPPLY

DIAGRAM

WALL

WALL

PANEL

PANEL

ASSEMBLY...

ASSEMBLY...

GEM

DRIVER

DRIVER

WIRING

SCHEMATIC

WIRING

SCHEMATIC.

ACCESSED

reporting.

FUNCTIONS'

....

...

correc!

report

REPRINTS

AND

TO

HOW

STAT

«ιν

ASSEMBLY

PARTS

...................uin

BOARD

BOARD

DIAGRAM

DIAGRAM.

only,

FROM

or

both

AFFECT

SUBSTITUTE

USE

TO

LIST

SCHE

PARTS

SCHEMATIC..

.....

HIDDEN

ON

IF

APPENDIX

THIS

LIST..

FUNCTION

PRINTOUTS.

USING

THE

MENU..

110/220

PRESSURE

V,

Fig.

2-1,

Fig.

2-2,

Fig. 3-1,

Fig. 3-2,

Fig.

3-3,

Fig. 3-4,

Fig.

3-5,

Fig.

3-6,

Fig.

3-7,

Fig.

3-8,

Fig.

3-9,

Fig.

3-10,

Fig.

3-11,

Fig. 4-1,

Fig. 4-2,

Fig.

4-2,

Fig.

5-1,

Fig.

5-2,

Fig. 6-1,

Fig.

6-2,

Fig.

6-3,

Fig.

6-4,

Fig. 6-5,

Fig.

6-6,

Fig. 7-1,

Fig.

7-2,

Fig.

7-3,

Fig. 7-4,

Fig.

7-5,

Fig.

7-6,

Fig.

7-7,

Fig. 7-8,

Fig.

7-9,

Fig.

7-10,

Fig.

7-11,

Fig.

7-12,

Fig.

7-13,

Fig.

7-14,

Fig.

7-15,

Fig.

7-16,

Fig.

8-1,

Fig.

8-2,

Fig.

8-3,

Fig.

8-4,

Front

Panel

Displays

Adding

Make

Immerse

Cancelled

Normal

Sample

2-Point

2-Point

Location

Aspirating

Status

Temperature

GEM

GEM

GEM

Location

Location

Printout,

Power

Printout

Simulated

Simulated

Test

Removing

Removing

Removing

Disconnecting

Removing

Removing

Disconnecting

Removing

Removing

Removing

Inner

Front

Rear

Cover

Cartridge

Printer

Detailed

Power

Power

A/D

Printer

sure

the

the

Sample

Sample

printout

CAL

CAL

of

Lot

solution

Report

Stat

System,

Stat,

major

Stat,

major

of

switch

of

switch

printer

fail

test

diagnostic

auto

sample

result

form

the

the

the

the

the

the

the

the

Panel

Panel

Panel

Assembly

Door

Assembly

Electrical

Supply

Supply

Board

(MSS # 480006)

GEM

Sampler

Message....

Stat

Corrected

printout

Cover

A/D

A/D

the

Printer

Front

Main

Power

Rear

Assembly

Assembly

Assembly

Assembly

Assembly

FIGURES

and

Keypads

Paper.................

Sampler

in

blood

Message

printout..

with

No.

components

components

test...

sample

.......

Main

Assembly

O7

Report.

on

OC

from

printout..

Simple

SW1.

SW3.

Print

test

limits.

Assembly

board

board

Printer

and Inner

Transformer

Supply

Panel

Transformer

.

.

......

........

Block

stop

line

is

then

press

Sensor

OC

Test

problem.

ampule

Block

Insulator

power

.........

Diagram.

(MSS

(MSS # 500018)

..

Se

Diagram

(1

of

2).

(2

of

2).

cable

Panel

cable

and

..................

#500018)

flush

with

the

START

.

Wire

.

Schematic

the

cartridge

keypad

Harness

.

from

Power

Supply..

7-7

Fig.

8-5,

Fig. 8-6

Fig.

8-7,

Fig.

8-8,

Fig.

8-9,

Fig.

8-10,

Fig.

8-11,

Fig.

8-12,

Fig.

8-13,

Fig.

8-14,

Fig.

8-15,

Fig.

8-16,

Fig.

8-17,

Fig.

A5-1,

Fig.

A5-2,

Fig.

A5-3,

Fig.

A5-4,

Fig.

A5-5,

Fig.

A5-6,

A/D

Board

A/D

Board

A/D

Board

Main

Hamess

Display

Display

SW1,

Solenoid

Solenoid

Inner

Inner

Rear

Rear

Board

SW3

Wall

Wall

Panel

Panel

Sample

QC

Reports

2-Point

2-Point

Temperature

Status

Reports

Schematic

(MSS # 480006)

(MSS # 480006)

Schematic

(MSS # 480006)

(MSS + 500023)

Board

(MSS + 500023)

and K1

Driver

Driver

Wiring

Schematic

Wiring

Schematic

Report

CAL

CAL

Wiring

Board

Board

Diagram

Diagram

....

Reports

Reports

Corrected

.

.

(Cal

Schematic

Schematic

..

.

Schematic

Diagram

PCB

Layout

Schematic

Stat

ON)

(Cal

Stat

OFF)

Report

.

(1

(2

(3

..

of

of

of

3)

3)

3)

Table

Table

Table

Table

Table

Table

Table

Table

Table

Table

1-1,

Physical

1-2,

GEM

1-3,

Measured

1-4,

Derived

2-1,

"Hidden

3-1,

Measured

3-2,

Normal

3-3,

Reprint

4-1,

CAL-A

GT

Dao6ostcKeypadioncHons

Specifications,

Stat

Model

Parameters

Parameters

Key”

Defaults

Parameters

expected

Options

and

CAL-B

List

values

..

GEM

and

Power

.

used

to

for

whole

"preset"

Values

TABLES

Stat,

GEM

Reguirements

calculate

Derived

blood

Statpak

parameters

point

CHAPTER

1;

INTRODUCTION

PRODUCT

1.1

The

hematocrit

GEM

disposable

three

The

system

partial

(K+),

Bicarbonate

Saturation

OPERATION

1.2

Insert

1

automatic

system

about

2.

Insert a GEM

cc

DESCRIPTION

GEM

Stat

analyzer.

Sampler.

cartridge.

days,

lonized

whole

or

performs

pressure

(SAT)

the

will

45

minutes)

blood

system

It

Calibration

The

50

analyses,

automatic

(PCOp),

Calcium

(HCOg3),

(iCa++),

Total

are

calculated

SUMMARY

disposable

"warm-up".

let

you

know

Sampler

sample

is a portable,

aspirates

fluids, a waste

cartridge

whichever

Oxygen

Carbon-dioxide

GEM

Statpak

The process

when

into

the

to

the

self-contained

blood

is

calibrations

partial

and

Hematocrit

from

the

it

is

end

instrument,

from a syringe

bag,

and

inserted

comes

pressure

measured

cartridge

is

as

ready.

of

the

into

first.

and

self-checks.

(Hct)

(TCO),

into

simple

(Total

cartridge.

then

blood

the

(PO),

parameters.

as

time

gas,

via a piece

electrodes

instrument

Sodium

are

measured

Base

excess

the

instrument

loading a video

for

this

Present a heparinized

push

the

SAMPLE

electrolyte,

of

tubing---the

are

housed

and

lasts

pH,

Carbon

(Na+),

(BE),

warm-up

Potassium

directly.

and

to

initiate

cassette.

period

button.

and

in

a

for

dioxide

Oxygen

the

The

is

0.5

8.

EQUIPMENT

1.3

The

system

display

Leave

blood

updates

GEM

depleted,

used

and

the

samples

Stat

solutions

Нет

Stat

GEM

Operators

Printer

*

Paper

Refer

will

automatically

print

them

cartridge

can

remaining

show

throughout

simply

throw

are

SUPPLIED

Instrument

Manual

Table

1-2

in

less

inserted

be

shift

collected

for

for

analyzed,

time

changes,

away

it

WITH

complete

aspirate

than

as

and

and

the

in

EACH

two

long

each

sample

24

insert

sealed

the

minutes.

as

yielding

hours

GEM

Quantity

ea.

1

1ea.

rolls

2

Stat

GEM

sample,

72

capacity,

new

a

cartridge,

STAT

process

hours.

eleven

all

day.

a

cartridge.

INSTRUMENT

Part

4X00

380019

2308

model

number

the

During

parameters.

making

When

Since

clean-up

no

Number

*

list.

results,

time,

that

convenient

it

cartridge

the

blood

all

required.

is

then

50

to

up

Status

use

to

is

and

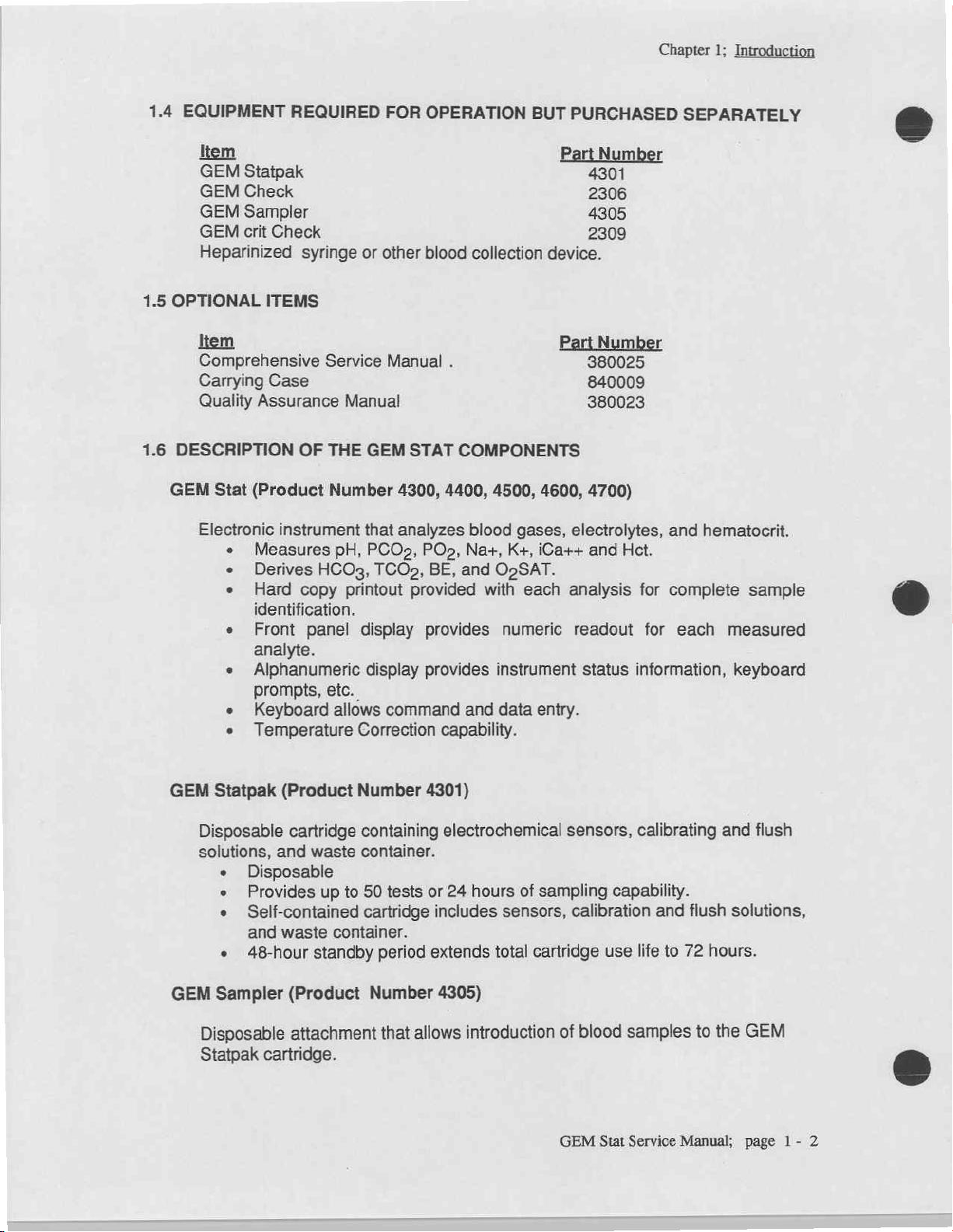

1.4

EQUIPMENT

REQUIRED

FOR

OPERATION

BUT

PURCHASED

Chapter

1;

SEPARATELY

Introduction

ltem

GEM

GEM

GEM

GEM

Heparinized

1.5

OPTIONAL

item

Comprehensive

Carrying

Quality

1.6

DESCRIPTION

GEM

Electronic

Statpak

Check

Sampler

crit

Check

ITEMS

Case

Assurance

Stat

(Product

instrument

e

Measures

e

Derives

«

Hard

identification.

«

Front

analyte.

«

Alphanumeric

prompts,

+

Keyboard

»

Temperature

syringe

Service

Manual

OF

THE

Number

pH,

HCOa,

copy

printout

panel

etc.

allows

or

other

blood

Manual

GEM

STAT

4300,

that

analyzes

PCO2,

TCO»,

POs,

BE,

provided

display

display

Correction

provides

provides

command

collection

.

COMPONENTS

4400, 4500,

blood

Na+,

and

gases,

K+,

O2SAT.

with

each

numeric

instrument

and

data

capability.

Part

Number

4301

2306

4305

2309

device.

Part

Number

380025

840009

380023

4600,

iCa++

4700)

electrolytes,

and

analysis

readout

status

entry.

and

hematocrit.

Het.

for

complete

for

each

information,

sample

measured

keyboard

GEM

Statpak

Disposable

solutions,

e

«

e

e

GEM

Sampler

Disposable

Statpak

(Product

cartridge

and

waste

Disposable

Provides

Self-contained

and

waste

48-hour

(Product

Number

containing

container.

up

to

50

cartridge

container.

standby

attachment

cartridge.

tests

period

Number

allows

that

4301)

electrochemical

or

24

hours

includes

extends

4305)

of

sampling

sensors,

total

cartridge

introduction

sensors,

calibration

blood

of

GEM

calibrating

capability.

use

life

samples

Stat

Service

and

to

Manual;

flush

72

hours.

the

to

and

flush

solutions,

GEM

page

1-

2

Chapter

1;

Introduction

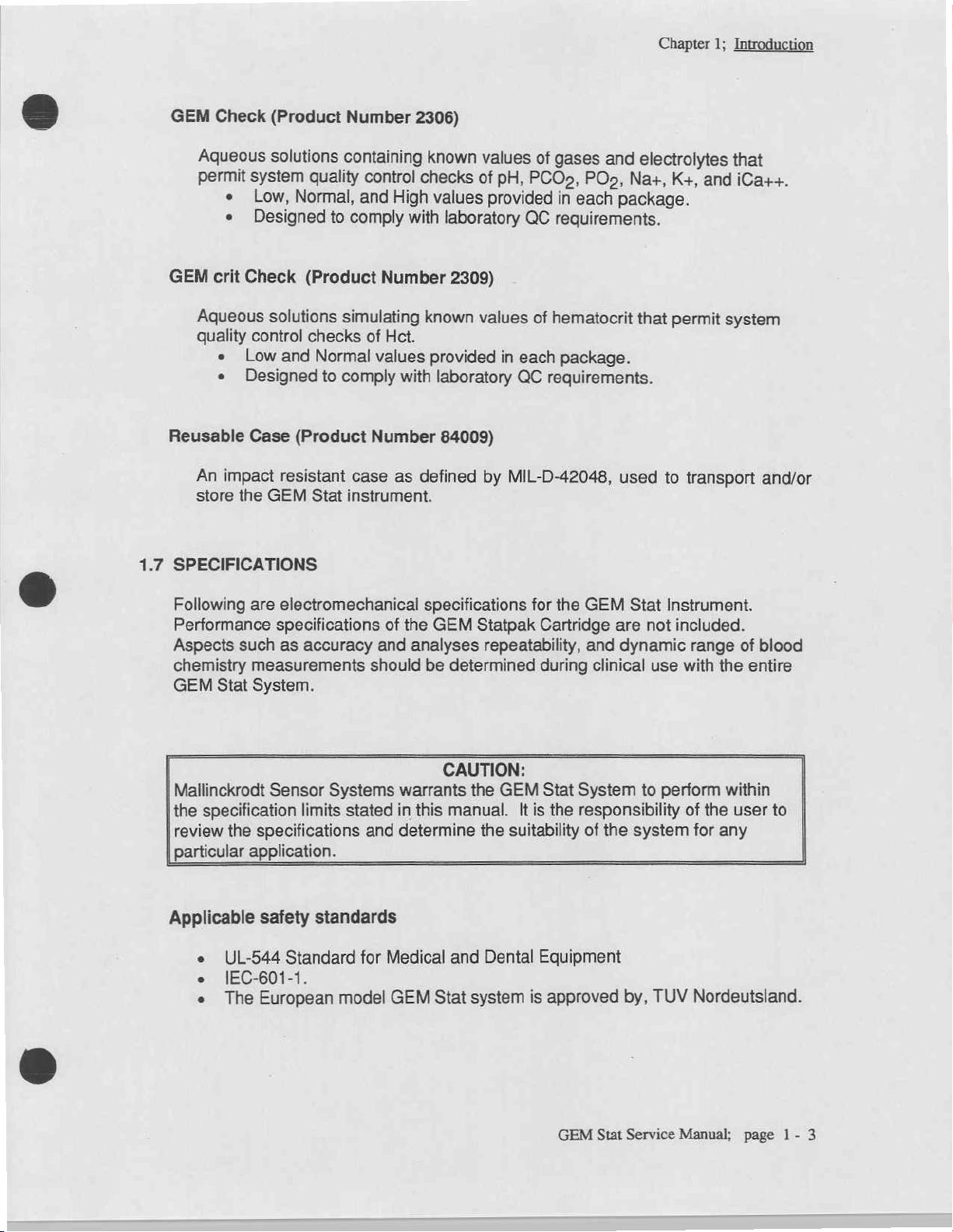

a

GEM

Check

Aqueous

permit

e

«

GEM

crit

Aqueous

quality

e

+

Reusable

An

impact

store

1.7

SPECIFICATIONS

(Product

solutions

system

Low,

Normal,

Designed

Check

solutions

control

and

Low

Designed

Case

(Product

resistant

GEM

the

Number

containing

quality

(Product

checks

Normal

Stat

control

and

to

comply

simulating

of

comply

to

case

instrument.

2306)

checks

High

with

Number

Hct.

values

with

Number

as

defined

known

values

known

provided

values

of

provided

laboratory

2309)

values

laboratory

84009)

by

of

gases

pH,

PCO»,

QC

of

each

in

QC

MIL-D-42048,

PO»,

in

each

requirements.

hematocrit

package.

requirements.

and

electrolytes

Na+,

package.

that

used

to

K+,

and

permit

system

transport

that

iCa++.

and/or

+

Following

Performance

Aspects

chemistry

GEM

Mallinckrodt

the

specification

review

particular

are

such

measurements

Stat

System.

the

application.

Applicable

«

UL-544

IEC-601-1.

+

The

electromechanical

specifications

as

accuracy

should

Sensor

specifications

safety

European

Systems

limits

stated

standards

Standard

model

and

for

specifications

of

the

GEM

and

analyses

be

CAUTION:

warrants

in

this

determine

Medical

GEM

Stat

for

Statpak

Cartridge

repeatability,

determined

the

manual.

the

and

Dental

system

during

GEM

It

is

suitability

Equipment

is

the

GEM

Stat

are

and

dynamic

clinical

Stat

System

the

responsibility

of

the

system

approved

by,

Instrument.

not

included.

range

use

with

to

perform

of

the

for

TUV

Nordeutsland.

of

blood

the

entire

within

user

any

to

GEM

Stat

Service

Manual;

page

1-

3

Chapter

1;

Introduction

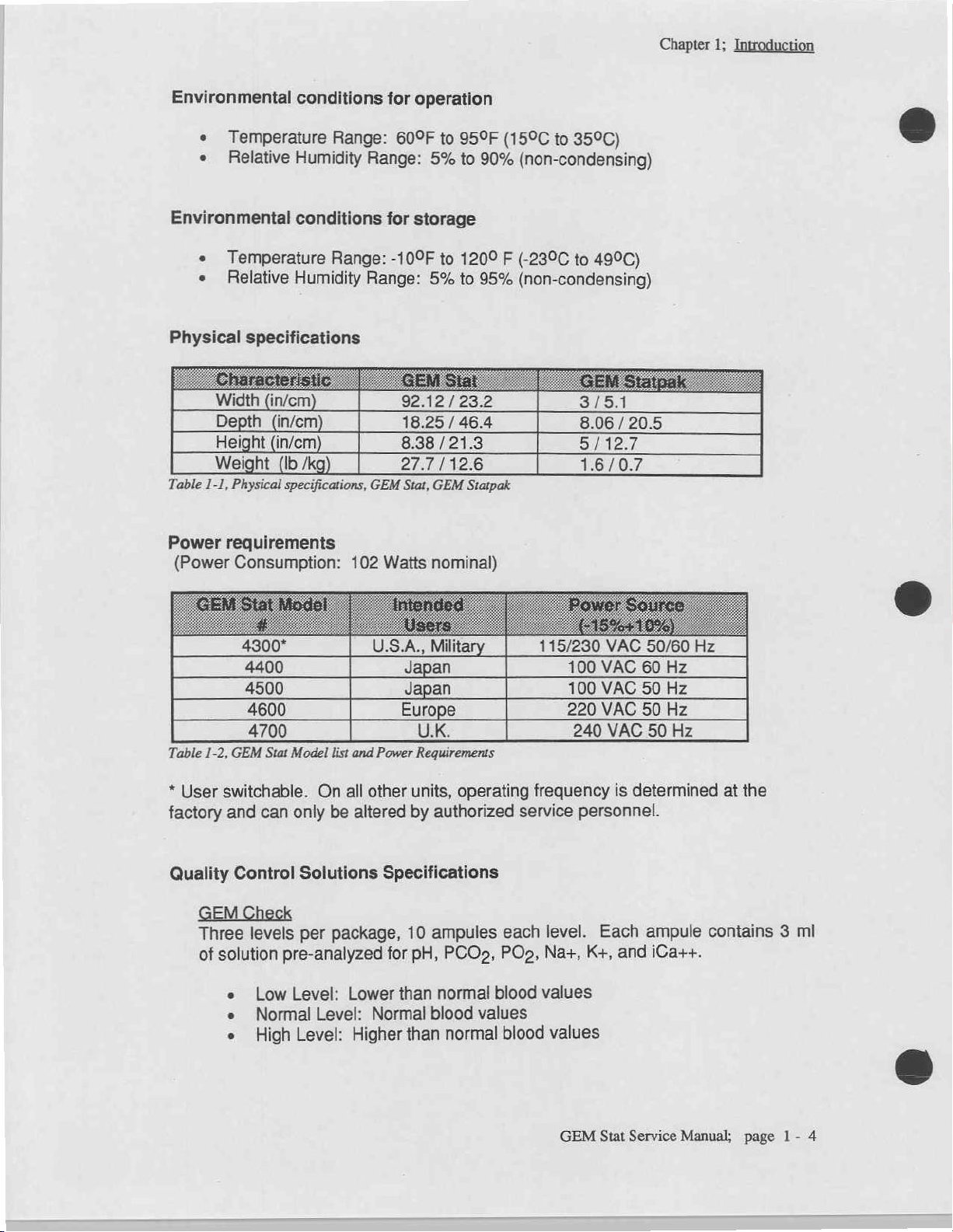

Environmental

e

Temperature

・

Relative

Environmental

«

Temperature

«

Relative

Physical

Table

Power

(Power

specifications

Width

De

Height

Weight

1-1,

(in/cm

Physical

requirements

Consumption:

conditions

Range:

Humidity

conditions

Range:

Humidity

in/cm

(in/em

(Ib

specifications,

Range:

Range:

GEM

102

for

60°F

for

-10°F

92.12 / 23.2

18.25 / 46.4

8.38 / 21.3

27.7 / 19.6

Stat,

Watts

operation

to

95°F

5%

to

90%

storage

to

120° F (-23°C

5%

to

95%

GEM

Statpak

nominal)

(15°C

to

35°C)

(non-condensing)

to

49°C)

(non-condensing)

3/51

8.06 / 20.5

5/12.7

1.6/0.7

Table

1-2,

GEM

*

User

switchable.

factory

Quality

and

GEM

Three

of

solution

e

e

e

4300*

4400

4500

4600

4700

Stat

can

Control

Check

levels

pre-analyzed

Low

Normal

High

Model

list

and

On

all

only

be

Solutions

per

package,

Level:

Level:

Lower

Level:

U.S.A.,

Power

other

altered

Specifications

Normal

Higher

Mili

Japan

Japan

Europe

U.K.

Requirements

units,

by

authorized

10

ampules

for

pH,

than

normal

blood

than

operating

each

PCO2,

normal

PO2,

blood

values

blood

115/230

100

100

220

240

frequency

service

personnel.

level.

Na+,

values

values

VAC

VAC

VAC

VAC

VAC

Each

K+,

is

and

50/60

60

50

50

50

determined

ampule

Hz

Hz

Hz

Hz

Hz

contains 3 ml

iCa++.

at

the

GEM

Stat

Service

Manual;

page

1-

4

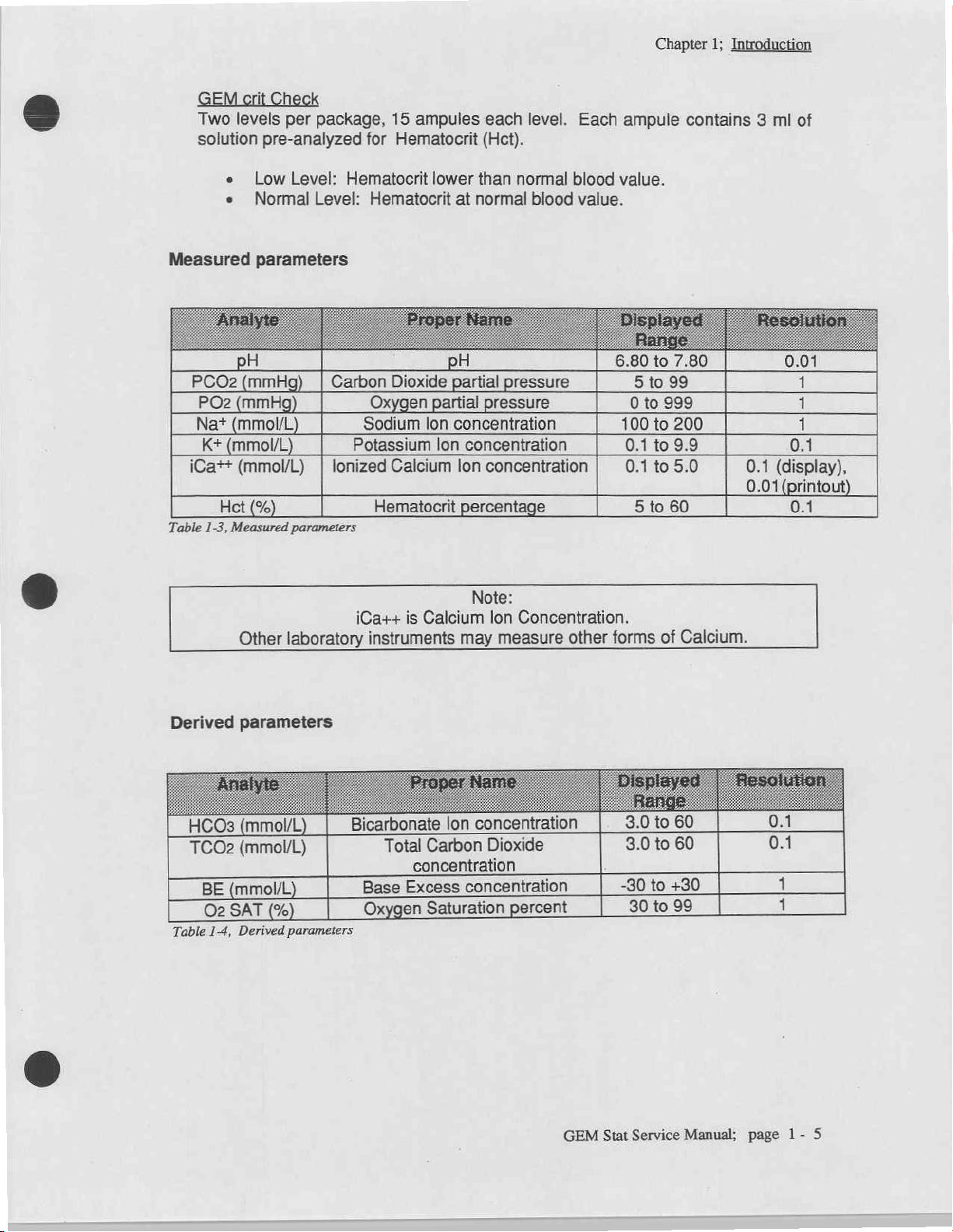

Two

levels

solution

+

Low

e

Normal

per

package,

pre-analyzed

Level:

Hematocrit

Level:

15

ampules

for

Hematocrit

lower

Hematocrit

(Hct).

than

at

normal

each

level.

normal

blood

Each

blood

value.

Chapter

ampule

value.

1;

Introduction

contains 3 ml

of

Measured

É

pH

PCO2

iCa*+

Table

(mmHg)

PO2

(mmHg)

Na+

(mmol/L)

K+

(mmol/L)

(mmol/L) | lonized

Het

1-3,

Measured

Other

parameters

=.

(%)

_|

parameters

laboratory

Z

Carbon

Oxygen

Sodium

Potassium

Hematocrit

iCa++

instruments

Dioxide

partial

lon

lon

Calcium

is

Calcium

_

pH

partial

concentration

pressure

pressure

concentration

lon

concentration

percentage

Note:

lon

Concentration.

may

measure

other

forms

.80

5

0

100

0.1

0.1

5

to

to

to

to

to

to

to

7.

99

999

200

9.9

5.0

60

of

0.1

0.01

Calcium.

.

0.01

1

1

1

0.1

(display),

(printout)

0.1

Derived

HCOs

TCOz

BE

O2

Table

1-4,

parameters

(mmol/L)

(mmol/L)

(mmol/L)

(%

SAT

Derived

parameters

Bicarbonate

Total

Base

lon

Carbon

concentration

Excess

Saturation

en

concentration

Dioxide

concentration

percent

GEM

3.0

3.0

-30

30

Stat

Service

to

to

to

to

60

+30

99

60

Manual;

page

1-

5

Chapter

1;

Introduction

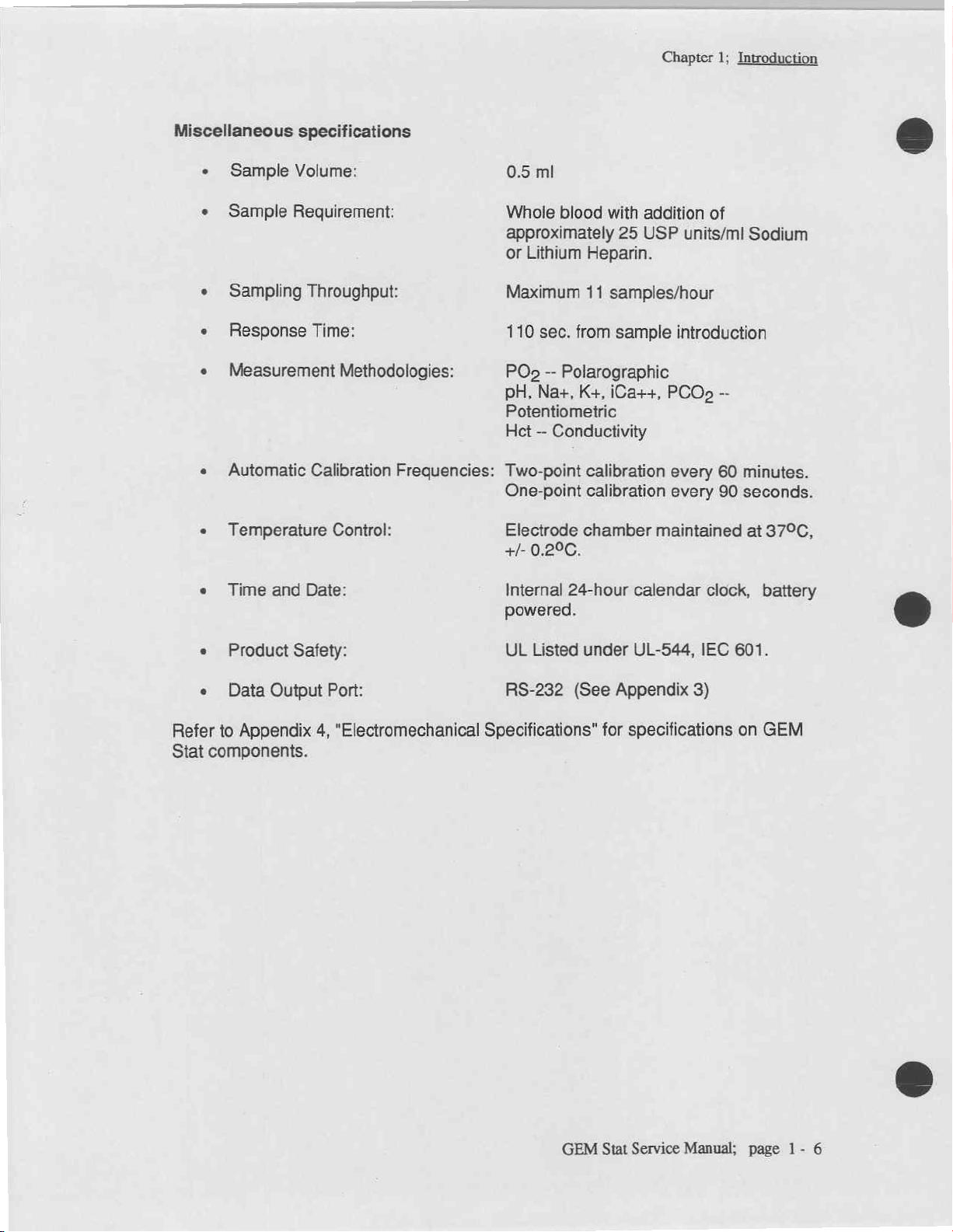

Miscellaneous

Sample

Sample

Sampling

Response

Measurement

Automatic

Temperature

specifications

Volume:

Requirement:

Throughput:

Time:

Methodologies:

Calibration

Frequencies:

Control:

0.5

ml

Whole

approximately

or

Maximum

110

PO»

pH,

Potentiometric

Het

Two-point

One-point

Electrode

+/-

blood

Lithium

sec.

Na+,

--

Heparin.

11

from

--

Polarographic

K+,

Conductivity

calibration

calibration

chamber

0.29С.

with

25

samples/hour

sample

iCa++,

addition

USP

of

units/ml

introduction

PCOp

every

every

--

60

90

maintained

Sodium

minutes.

seconds.

at

37°C,

Refer

Stat

to

components.

Time

and

Product

Data

Output

Appendix

Date:

Safety:

Port:

4,

"Electromechanical

Internal

powered.

UL

RS-232

Specifications"

24-hour

Listed

under

(See

for

calendar

UL-544,

Appendix

specifications

clock,

IEC

3)

battery

601.

on

GEM

GEM

Stat

Service

Manual;

page

1-

6

da

2.1

CHAPTER

STORAGE

2;

INSTALLATION

INSTRUCTIONS

AND

PREPARATION

a

These

reagent

Keep

desiccant

doors

instructions

cartridge

the

instrument

packets

within

Temperature:

Humidity:

Altitude:

Use a waterproof

Minimize

No

temperature

Under

2.2

UNPACKING

Customers

(Refer

case)

movement

periodic

these

the

to

apply

or

quality

in

its

within

the

following

-109F

5% - 95%

Unaffected

covering

between

adjustments

and

humidity

conditions

INSTRUCTIONS

with

the

reusable

printed

laminated

to

the

instrument

control

original

the

plastic.

limits:

to

+1200F

by

to

protect

high

or

inspections

ranges.

the

life

of

carrying

panel

solutions.

packaging,

In

the

(-230C

altitude

the

packaged

and

low

are

the

GEM

case

the

on

only,

not

to

the

with

plastic

original

to

temperatures

required

Stat

inside

packaging,

+490C).

instrument

if

the

is

indefinite.

cover

disposable

around

to

instrument

of

the

it

can

from

prevent

reusable

the

moisture.

GEM

Statpak

instrument

be

stored

condensation.

is

within

carrying

and

out-

these

Open

1.

2.

Open

Remove

3.

paper

Remove

4.

Customers

Open

=

Remove

2.

box.

Remove

3.

surround

Remove

Remove

Keep

pon

original

of

top

the

the

carrying

Service

the

from

the

instrument

the

without

the

top

of

Operators

the

instrument

the

instrument

the

foam

the

instrument

original

packaging

materials

carton

the

case.

Manual,

carrying

reusable

the

carton.

Manual,

caps

end

from

when

remove

and

Operators

case.

carrying

the

from

carrying

the

from

remain

will

from

protective

materials.

transporting

case

printer

box.

with

instrument.

the

plastic

Always

the

reusable

the

Manual,

case.

paper,

The

the

detachable

and

protective

as

unit

bag.

repackage

instrument.

carrying

cord,

detachable

end

foam

pulled

is

it

instrument

the

case.

line

caps

from

and

cord

that

the

printer

the

from

box.

the

in

2.3

INSPECTION

OF

COMPONENTS

Chapter

2;

Installation

and

Preparation

Inspect

be

clean

the

delivering

Warranty

Department

that

a

If

you

feel

component

Authorization

Mallinckrodt

1590

Ann

Phone:

or

2.4

INSTALLING

Install

cord

the

the

to

back

packing

and

without

does

or

proper

(313)

claim

service

should

(RGA)

Eisenhower

Arbor,

(800)

973-7000

THE

GEM

any

grounded,

panel

case

blemishes.

carrier

within

not

cover

an

Authorized

may

is

necessary,

be

number.

Sensor

MI

48108

262-3654

GEM

Stat

by

properly

of

the

instrument.

and

instrument

10

damage

Agent

be

filed.

repaired

Systems

Place

STAT

simply

placing

If

damage

days.

due

will

contact

or

replaced,

Ship

product

wired

for

external

Although

to

shipping,

assist

Customer

you

to:

it

in

any

outlet

that

damage.

has

occurred,

the

Mallinckrodt

our

you

in

determining

Service.

will

be

convenient

meets

All

components

a

claim

must

Sensor

Customer

issued a Return

i

location.

the

voltage

If

it

Service

the

is

decided

Attach

rating

should

be

filed

Systems

damages

that

Goods

the

stamped

with

so

a

line

on

Place

operation.

whether

space

about 6 inches

pull

leave

Operating

Operating

Do

the

you

no

in

cooling

space

not

place

In

order

GEM

Comfortable

larger

temperature

relative

to

Stat

operate

than

behind

air.

Both

nearby

next

to

humidity

prevent

connected

on a level

operation

the

15

inches

the

are

for

the

heating

surface

unit

while

instrument

located

disposable

or

range:

range:

electrical

to a

properly

such

is

on a counter

sitting

wide

by

to

on

the

cartridges and

cooling

WARNING

shock

hazard

wired

as a cart,

or

standing).

20

inches

reach

the

back

devices.

60°F

to

5%

to

90%

to

grounded

counter,

34" - 54"

deep

power

of

the

95°F

(non-condensing).

operator,

high

The

analyzer

by 12

switch

instrument.

quality

control

(15°C

this

receptacle.

or

bench

(depending

requires

inches

to

device

high.

and

allow

It

is

solutions.

35°C).

must

top

during

on

a

Leave

the

fan

advisable

to

be

to

GEM

Stat

Service

Manual:

page 2 -

2

Chapter

2;

Installation

and

Preparation

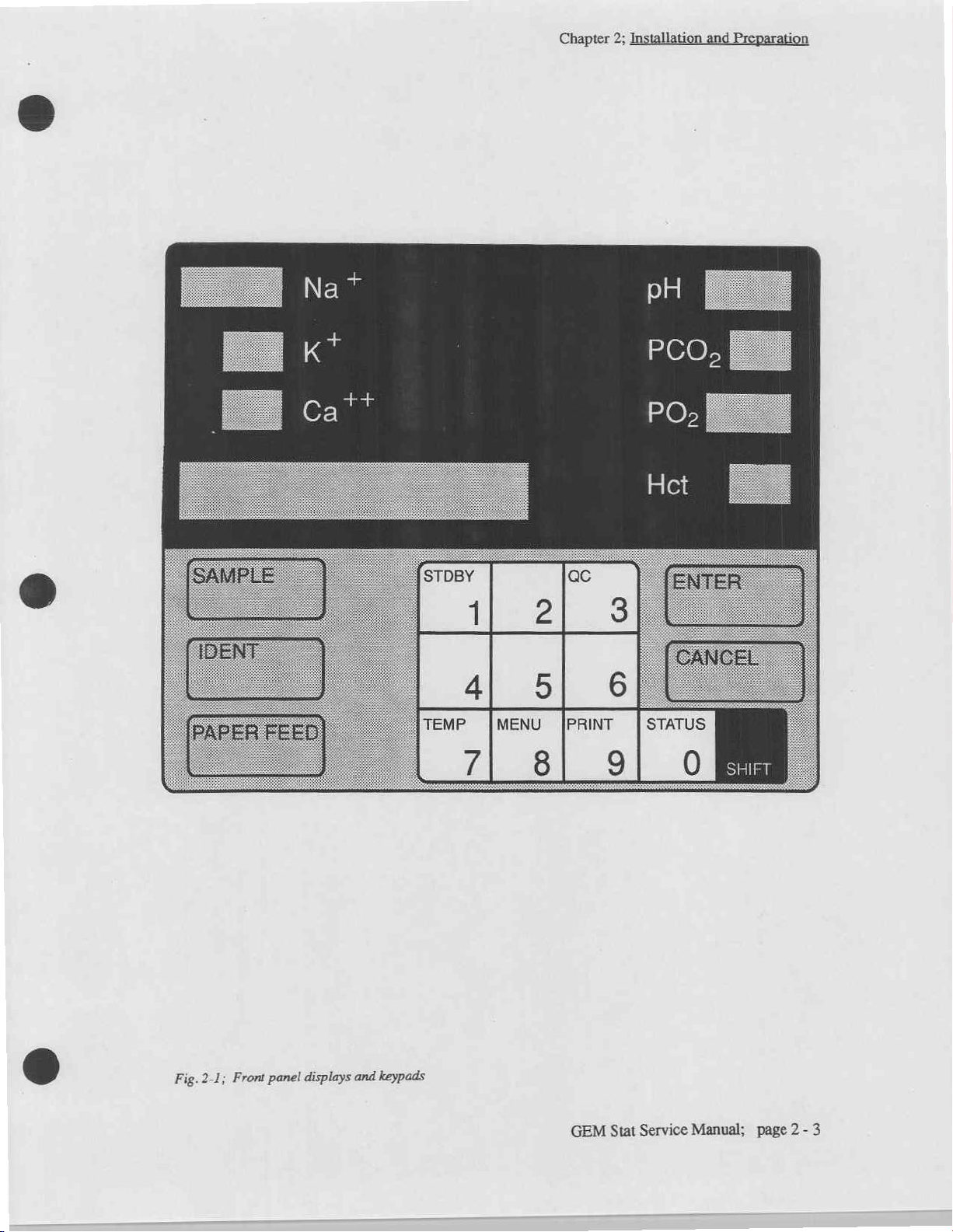

STATUS

a

Fig.2-1;

Front

displays

panel

keypads

and

GEM

Stat

Service

Manual;

page

2-3

2.5

INSTRUMENT

FRONT

PANEL

DISPLAYS

AND

Chapter

KEYPAD

2;

Installation

FUNCTIONS

and

Preparation

|

Keypad / Dis!

Numeric

Na+,

PO2,

Alphanumeric

Primary

Sample

Identification

Paper

Enter

Cancel

Window

K+,

Ca++,

Het.

Keypads:

Feed

Displays:

pH,

PCO2

Display

아이오

Displays

Shows

user

Press

Press

Feeds

Used

Aborts

GEM

supplied

to

to

paper.

to

current

values

Stat

information.

aspirate

enter

Patient

Used

confirm

function.

for

each

analyte

status,

Sample

selections

or

to

start

messages

or

Operator

QC

new

and

and

solution.

ID.

roll.

numbers.

Numeric

Secondary

1/STBY

3/QC

7/TEMP

8/MENU

9/PRINT

O/STATUS

Keypads

Keypads:*

(Standby)

(Quality

Control)

(Temperature)

Press

SHIFT

to

keypad

initiate

secondary

Used

to

enter

Initiates

Initiates

Initiates

Displays

Reprints

Prints

then

or

QC

Temperature

Options

last

Status

*

Note:

appropriate

keypad

numeric

exits

Standby

Test

Sample

Report

values.

Mode

Correction

Menu

Report

numeric

functions.

keypad

feature

GEM

Stat

Service

Manual;

page

2-4

2.6

INSTALLING/CHANGING

THE

PRINTER

PAPER

Chapter

2;

Installation

and

Preparation

When

.

Open

side

.

Remove

cardboard

.

Place

and

until

ring).

.

Thread

shown

1

.

Press

located

matically

a

red

and

slide

roll

inch

stripe

feet

of

printer

the

front

remaining

spool

paper

into

"PAPER

over

new

"seats"

paper

in

Figure

the

on

front

complete

appears

paper

doors

located

of

printer

from

the

paper

(just

through

2-2.

Printer

FEED"

panel

the

on

the

remaining,

on

the

the

GEM

Stat.

paper

spindle.

top

of

the

roll

onto

spindle

past

retaining

printer

Feed

mechanism.

keypad

to

paper

as

the

auto-

thread.

Note:

edge

or

enough

and

roll

paper

of

the

for

paper,

5-6

sample

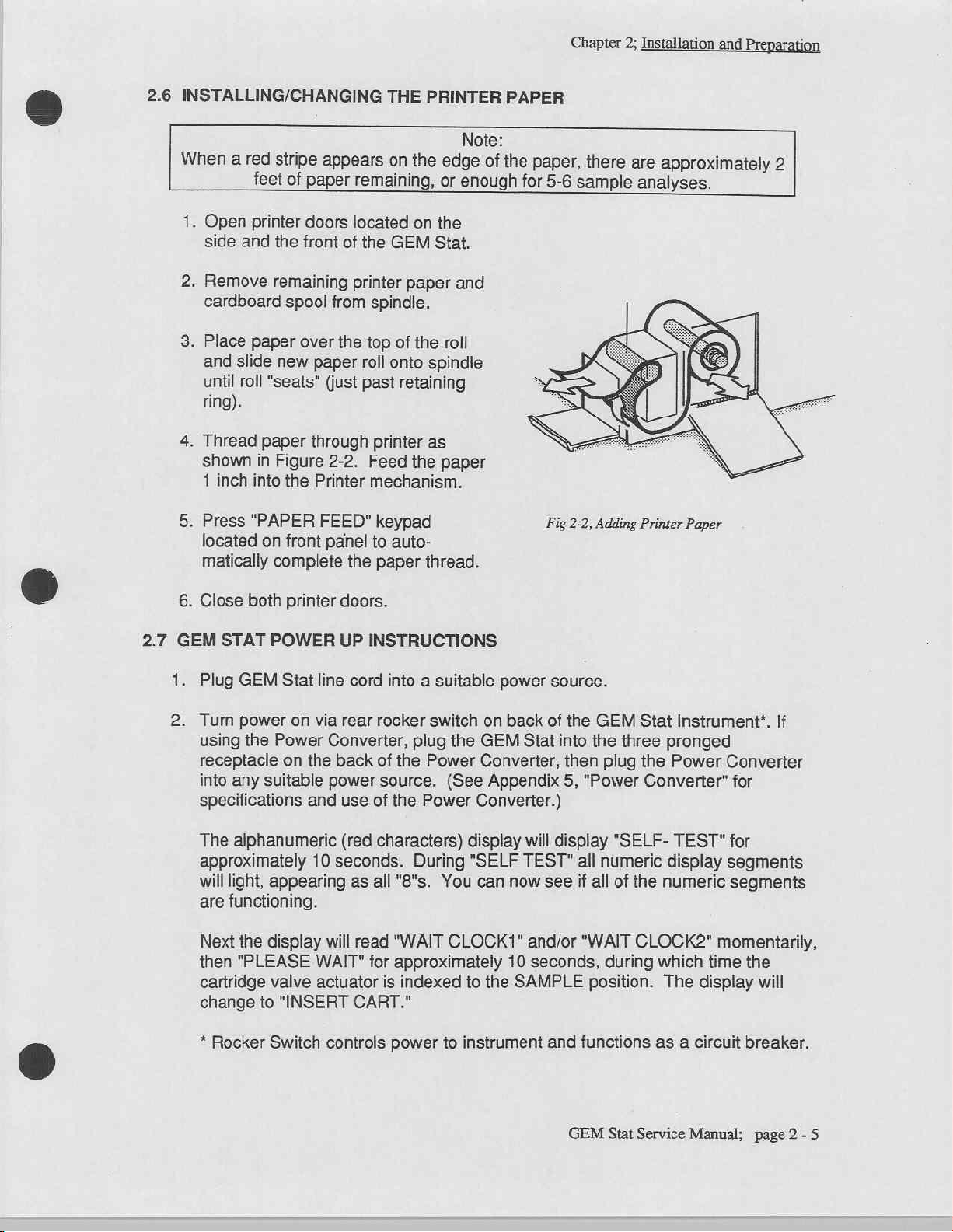

Fig

2-2,

there

Adding

are

approximately

analyses.

Printer

Paper

2

2.7

6.

Close

GEM

т.

Plug

2:

Turn

using

receptacle

into

specifications

The

approximately

will

are

Next

then

cartridge

change

*

both

STAT

GEM

power

the

any

alphanumeric

light,

functioning.

the

"PLEASE

Rocker

printer

POWER

Stat

line

on

via

Power

on

the

suitable

and

10

appearing

display

WAIT"

valve

to

Switch

actuator

"INSERT

doors.

UP

INSTRUCTIONS

cord

into a suitable

rear

rocker

Converter,

back

of

the

power

will

controls

source.

use

of

the

(red

characters)

seconds.

as

all

"8"s.

read

"WAIT

for

approximately

is

CART."

power

indexed

switch

plug

the

Power

(See

Power

During

You

CLOCK1"

to

power

on

back

GEM

Stat

Converter,

Appendix

Converter.)

display

"SELF

can

to

instrument

the

will

TEST"

now

and/or

10

seconds,

SAMPLE

source.

of

the

into

the

then

5,

"Power

display

all

see

if

all

"WAIT

position.

and

functions

GEM

Stat

three

plug

the

Converter"

"SELF-

numeric

of

the

CLOCK2"

during

Instrument”.

pronged

Power

TEST"

display

numeric

which

The

as a circuit

Converter

for

for

segments

segments

momentarily,

time

the

display

breaker.

If

will

GEM

Stat

Service

Manual;

page

2-5

3.

4.

Verify

Verify

do

this

a.

b.

If

the

fan

that

that

the

Fan

in

one

of

two

Hold a piece

instrument.

Hold

your

hand

is

not

operating,

the

date

is

operating

ways:

of

paper

near

and

time

near

the fan

refer

are

quietly

to

correct.

and

the

fan

and

Chapter

Chapter

blowing

and

make

feel

the fan

5,

"Trouble-Shooting".

2;

into

the

sure

pulling.

Installation

GEM

it

is

and

Stat.

pulled

Preparation

You

toward

can

the

Press

DISPLAY

displayed

display

been

set,

correct,

format

If

either

the

date

The

Date

2.8

INSERTING A NEW

It

takes

can

1.

Instrument

about

be

processed.

Examine

exceeded.

SHIFT-MENU

SHOWS

in

the

alphanumeric

will

show

the

display

then

press

hh/mm/ss)

the

date

and

time,

and

Time

and

45

minutes

the

GEM

then

repeatedly

"DATE/TIME?".

mm/dd/yy

will

the

with

or

time

refer

can

the

(month/day/year).

show

"ENTER"

seconds

is

incorrect

to

Section

only

alphanumeric

CARTRIDGE

from

the

Statpak

to

verify

press

Press

display.

dd/mm/yy

key.

incrementing

be

time a new

it

should

3.5

Note:

set

when

that

If

the

(day/month/year).

Time

"Date

display

its

the

MENU

ENTER.

U.S.

should

at 1 second

be

and

there

cartridge

expiration

The

format

If

the

International

now

reset.

Time".

is

no

reads

is

KEY

UNTIL

date

has

Check

be

displayed

intervals.

For

details

cartridge

INSERT

inserted

date has

THE

should

been

CART.

be

set,

the

format

if

the

(in

on

changing

is

in

the

until a sample

not

been

has

date

24

hour

is

2.

Remove

product

of

moisture.

there

If

package

the

GEM

and

the

is

appears

Statpak

packaging

moisture

any

fresh

GEM

pink

from

its

are

completely

CAUTION

inside

(blue

is

Statpak

protective

on

or

bag

normal),

and

do

call

Customer

package.

dry.

Do

not

cartridge

not

use

GEM

Make

use

or

sure

if

there

dessicant

the

cartridge.

Service.

Stat

Service

that

are

Open

Manual;

the

any signs

a

page 2 -

6

2.9

3.

Check

power

4.

Open

knob

5.

Remove

into

one

6.

Close

lock.

GEM

STAT

As

soon

display

period,

chamber

that

the

message

off

and

start

the

hinged

on

the top

the

the

cartridge

You

must

minute

the

door.

Display

WARM-UP/HYDRATION

as

the

shows

calibration

and

left

of

protective

insert

of

removing

solutions

Turn

should

door

"WARM-UP

solution

for

display

over from

cartridge

the

door

cover

compartment,

the

knob

read

is

locked,

44:38",

"B"

30

minutes.

GEM

door

counterclockwise

from

cartridge

the

do

not

counterclockwise

"WARMUP

the

(Cal. B solution)

reads

"INSERT

Stat

power-up,

on

the front

the

aligning

of

GEM

Statpak

it

according

CAUTION:

into

the

GEM

protective

leak

system

and

This

cover

from

the

MM:SS".

MODE

goes

into

begins a count-down.

is

soaking

period

Chapter

CART".

Section

the

instrument

and

pulling

and

to

Stat

instrument

to

ensure

cartridge.

and

the

door

the

warm-up

pumped

hydrates

2;

Installation

If it

does

2.7.

by

the

door

immediately

the

labeling.

within

that

calibration

will

automatically

mode.

During

into

the

electrode

the

electrodes.

and

Preparation

not,

turn

turning

down.

insert

The

the

warm-up

the

the

it

After

soaking

calibration

1.

After

the

that

Chapter

which

Cal. B solution

seconds

equilibrium).

The

№

stored.

Air

is

Cal. A solution

Po

seconds.

The

The

ou

determine

Air

is

Cal. B solution

øn

aspirated

successful

a

GEM

5,

"Trouble-Shooting".

the

electrodes

involves

is

(during

electrical

flushed

electrical

stored

flushed

response

through

is

response

values

sensor

through

or

until

warm-up,

ready

is

Stat

for

the

pumped

which

pumped

for

response

is

pumped

next

to

30

minutes,

following:

into

the

time

the

of

all

sensors

to

clear

the

into

the

of

all

sensors

the

Cal. B and

line

to

clear

the

into

the

automatic

GEM

the

process

the

system

electrode

sensors

to

chamber.

electrode

to

Cal. A measurements

slopes.

chamber.

chamber

calibration

display

Stat

samples.

chamber

come

the

Cal. B solution

chamber

Cal. A solution

and

occurs.

reads,

this

If

performs a two

and

held

to

chemical

and

held

values

remains

until

"READY

case,

the

not

is

point

for

and

thermal

values

for

are

are

used

sample

37°C’,

refer

90

are

90

stored.

to

is

indicating

to

GEM

Stat

Service

Manual;

page 2 -

7

2.10

CUSTOMIZING

The

GEM

system.

Stat

The

has

name

THE

SYSTEM,

"Hidden

and

default

"HIDDEN"

Key

Functions"

setting

of

these

KEY

that

allow

functions

Chapter

FUNCTIONS

the

2;

Installation

user

are

shown

to

customize

in

and

Preparation

the

Table

2-1.

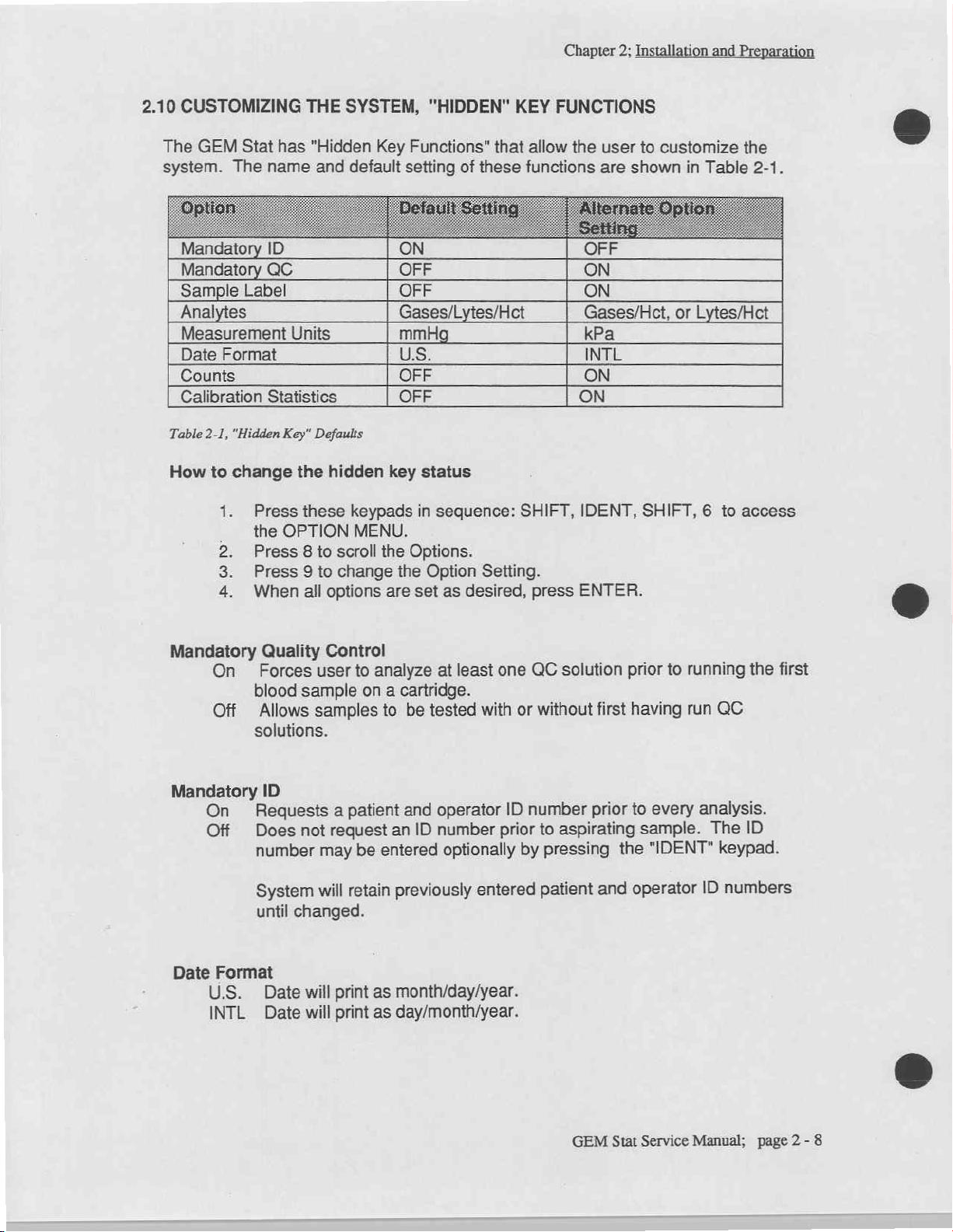

Mandatory

Mandatory

Sample

Analytes

Measurement

Date

Counts

Calibration

Table

2-1,

How

to

1.

Mandatory

On

Off

ID

QC OFF ON

Label

Format

Statistics

"Hidden

change

Press

the

Press 8 to

Press 9 to

When

SS

Quality

Forces

blood

Allows

solutions.

Units

Key"

Defaults

the

hidden

these

OPTION

all

options

Control

user

sample

samples

TON

OFF ON

Gases/Lytes/Hct

mmH

U.S.

OFF ON

OFF

key

status

keypads

MENU.

scroll

change

to

on a cartridge.

in

the

Options.

the

Option

are

set

analyze

to

be

tested

sequence:

Setting.

as

desired,

at

least

one

with

SHIFT,

press

QC

or

without

OFF

Gases/Hct,

kPa

INTL

ON

IDENT,

ENTER.

solution

prior

first

having

or

SHIFT,

to

running

run

Lytes/Hct

6 to

access

the

QC

first

Mandatory

On

Off

Date

Format

U.S.

INTL

ID

Requests a patient

not

Does

number

System

changed.

until

Date

Date

request

may

will

will

print

will

print as

an

be

entered

retain

as

previously

month/day/year.

day/month/year.

and

ID

operator

number

optionally

ID

prior

entered

number

aspirating

to

by

pressing

patient

prior

GEM

the

and

Stat

to

every

sample.

"IDENT"

operator

Service

Manual;

analysis.

ID

The

keypad.

numbers

ID

page 2 -

8

Counts

(Used

On

Off

for

functional

Raw

V/F

electrode

diagnose

Raw

V/F

diagnostic

counts

signals

a

counts

for

problem.

all

channels

are

digitized.

will

not

tests,

refer

be

printed.

to

Chapter

digitized

Turn

this

Chapter

will

feature

2;

6)

be

printed

Installation

ON

only

and

each

if

you

Preparation

time

the

need

to

Units

Sample

Analyte

of

Measurement

kPa

mmHg

Labeling

On

Off

selection

Toggling

"Printouts").

Gases/Lytes/Hct

Gases/Hct

Lytes/Het

for

Blood

Blood

gas

measurements

|

Blood

gas

measurements

"Art 1 Ven2"

you

enter

you

enter

Appendix 6 “Printouts”,

System

labeled.

with

will

be

"1"

the

sample

"2"

the

printout

will

not

prompt

(Gases/Lytes/Hct)

the

"9"

key

Prints

and

Prints

Prints

and displays

and

Gas

displayed

)

for

selects

and

hematocrit.

displays

Partial

will

be

will

be

upon

printout

will

Arterial

displays

values

values

be

one

will

labeled

of 3

Pressures

reported

reported

pressing

be

of

Venous

combinations.

values

for

blood

for

electrolytes

the

labeled

"Venous"

label.

for

blood

gases

in

kilo-pascal

in

millimeters

SAMPLE

"Arterial"

at

the

Printout

(See

gases,

and

hematocrit

and

hematocrit

units.

of

mercury.

keypad.

at

the

top.

(See

will

Appendix

electrolytes,

If

top.

not be

6.

only.

only.

If

Cal

Stats

On

Off

Calibration

setting.

later

desired.

Calibration

each

One-Point

electrode

Calibration

slope

statistics

Therefore,

point

in

the

Refer

to

statistics

statistics

the

cartridge

Section

Cal.

and

for

each

system

will

every

drift

will

life

3.4.

print

following

30

minutes.

values

not

cartridge

the

as

print.

is

can

be

operated

calibration

each

well

as

(See

Appendix

stored

statistics

hourly

The

information

measured

regardless

with

the

can

GEM

Stat

Two-Point

will

bag

values.

6,

"Printouts")

of

the

Cal

Stat

be

printed

Service

Manual;

Cal.

and

include

Cal

Stat

off,

then

out

if

page 2 -

ata

9

Loading...

Loading...