INSTRUCTIONS

FOR SAFE, FAST, ACCURATE

FABRICATION OF 1” AND 1-1/2”

FIBERGLASS DUCTBOARD.

DEVELOPED WITH THE END USER IN MIND, BY THE

COMPANY THAT MEANS HAND TOOLS FOR THE HVACR

INDUSTRY.

www.malcotools.com

1

KIT CONTENTS

VEE-GROOVE

KITS

1 inch 1-1/2 inch Description

Cat. No. Cat No.

FGVK FGVKL Vee-Groove Kit with following:

FGV1 FGL1 #1 Tool

FGV FGLV Vee Tool

FGV5 FGL5 #5 Tool

FGV6 -- #6 Tool

FGS FGS Square

FGK FGK Duct Knife

FGM FGML Male Shiplap Knife

FGF FGFL Female Shiplap Knife

FGC * Tool Case

SHIPLAP KITS

1 inch 1-1/2 inch Description

Cat. No. Cat No.

FGSLK FGSLKL Shiplap Kit with following:

FGV1 FGL1 #1 Tool

FG24 FGL24 Vee Tool

FGV3 FGL3 #3 Tool

FGV5 FGL5 #5 Tool

FGV6 -- #6 Tool

FGS FGS Square

FGK FGK Duct Knife

FGM FGML Male Shiplap Knife

FGF FGFL Female Shiplap Knife

Order FGVLKW

for 1-1/2” Vee Kit

WITHOUT square.

Order FGSLKLW

for 1-1/2” Shiplap Kit

WITHOUT square.

FABRICATING SYSTEM

INTRODUCTION ...................................... 4

SETTING UP TOOLS

Adjusting FasGroov Square ..................... 9

Hand Tool blade height adjustment ....... 10

Blade removal / replacement ................ 14

SHIPLAP FABRICATION .......................... 16

VEE-GROOVE FABRICATION ................... 20

RELATED TOOLS AND ACCESSORIES ..... 24

The duct fabrication procedures outlined in

this manual pertain to two common methods

of one-piece duct construction in standard

1” OR 1-1/2” ductboard. For applications

requiring ductwork larger than that which

can be constructed from a single piece of

ductboard, consult the NAIMA fibrous Glass

Duct Construction Standards Manual or your

ductboard manufactures fabrication manual

for information on the two-piece “U”, two

piece “L”, and four-piece construction method.

2

www.malcotools.com

INTRODUCTION

Tool Features:

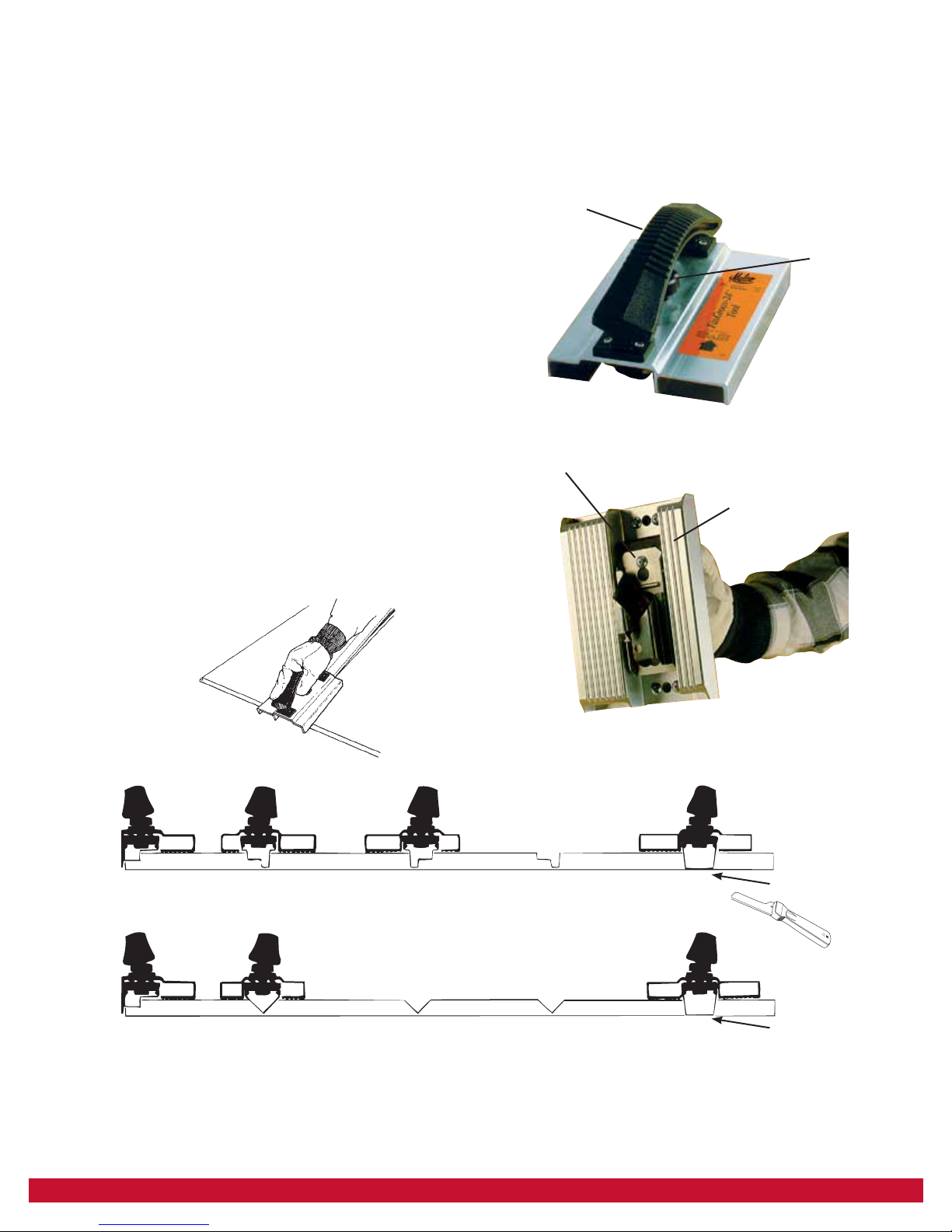

• FasGroov Tool identification incorporates

both the numbering system of fabrication

machines and the traditional hand tool

color coding system. FasGroov Tools are

available for both shiplap and vee-groove

fabrication methods.

• Easy, turn-the-knob, blade height adjust-

ment. Scrap lifts cleanly out of groove.

Blades are also easily removed without

removing screws.

• Molded plastic handles are ergonomically

designed to fit angle of grip and reduce

arm and hand fatigue on-the-job.

• Extruded, anodized, aluminum body is

durable and lightweight. Grooved surface

on sled bottom facilitates easy sliding.

Molded handles

ergonomically

designed to

reduce arm

and hand

fatigue.

Blades remove

without removing

screws.

Easy turn-the-knob

blade height adjustment

compensates for

thickness

variations

in standard

1 and 1-1/2 inch

board.

Patent No’s.

5,040,297

5,077,899

Grooved sled

bottom facilitates

easy sliding.

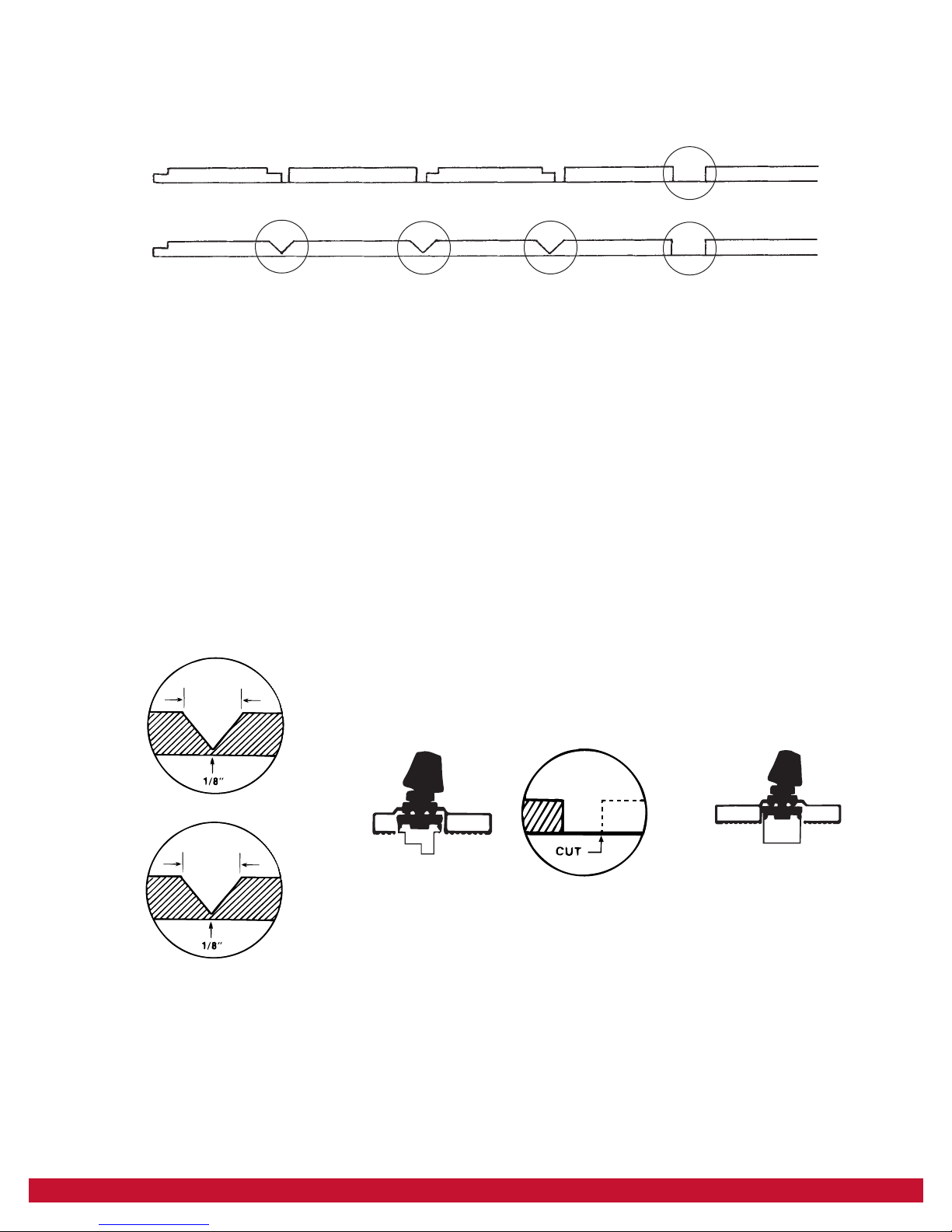

SHIPLAP METHOD

#1

GRAY

VEE-GROOVE METHOD

#1

GRAY

#2/4

DARK

ORANGE

VEE

RED

Easy

sliding,

scrap

lifts

cleanly

out of

groove.

#3

ORANGE

#5

BLUE

CUT FLAP

#5

BLUE

CUT FLAP

3

www.malcotools.com

Use

#6 Tool

to shorten

length of

duct section,

by measuring

from outside

edge of material

to be scrapped.

FGV6

• 1” FasGroov kits also include a #6 tool (Tan

color coded FGV6) for creating duct sections

less than standard 4 foot lengths. The #6

replaces a shiplap knife for making a shiplap

groove at fitting end prior to closure of duct

section. The #6 may also be used for twopiece and four-piece ductboard fabrication.

Easy one-piece layout:

• FasGroov Square permits fast and accurate layout without marking cuts or calculating add-on dimensions. Lay out duct-

board as you cut. Simply align dimension on

FasGroov Square with edge of previous cut

and move across the board. Square is also

easily adjustable for angled cuts.

FGK

Duct Knife

use this point to

cut fiberglass without

tearing ductboard skin.

Use knob

under handle

to raise or

lower blade

and adjust

depth of cut.

1/2”

Single blade knives:

• Single blade FasGroov Knives are safer to

use and also feature comfortable molded

handles. Male and Female Shiplap Knives

can be used on closed duct sections.

4

www.malcotools.com

For right or left hand use:

SETTING UP TOOL

• Right hand orientation of 1” kits is easily changed by converting #5 Tool and

FasGroov Square for left hand fabrication.

Tool handles may also be turned around to

provide left hand grip angle.

Right hand

operation.

Left hand

operation.

CONVERTING FASGROOV SQUARE

FOR LEFT HAND USE.

1. Remove the angle adjustment knob and the end

pivot knob.

2. Position the ruler stamped leg so that the 3 holes

are to your left. (Rule reads left to right.)

3. Remove the protractor for the “L” shaped leg by

removing the two screws.

4. Flit the protractor over and install on the opposite

end of the “L” shaped leg.

5. Place the “L” leg/protractor assembly on top of

the ruled leg.

6. Align the pivot knob holes and install the pivot

knob.

7. Install the angle adjustment knob in any of the

fixed positions or the sliding position.

8. After converting your square for left hand use,

double check the accuracy in the fixed° position

with a roofing square. Built-in manufacturing

hole tolerances will allow you to true the square.

Note: 1-1/2” Kit cannot be converted for left hand use.

Adjusting Fasgroov Square

PREDETERMINED SETTINGS

Place adjustment knob into hole corresponding

to most used angles.

OTHER ANGLES

Place adjustment screw into protractor adjustment slot and tighten at desired angle.

STORAGE

Step 1: Remove angle adjustment knob and

fold ends of FasGroov Square together.

Step 2: Place angle adjustment knob into the

storage hole and tighten.

Ruler

stamped

leg.

Angle

adjustment

knob shown

here in 90°

predetermined

hole setting.

Adjustment slot

for other angles.

Pivot knob.

Protractor scale etched

2 sides for right or left

hand use.

Screws holding

protractor to

“L” shaped leg.

5

www.malcotools.com

Hand Tool blade height

adjustment:

FASGROOV #1 TOOL

#1 TOOL

1/2”

Push the FasGroov #1 Tool along the left edge

of a test piece of ductboard. Measure the depth

of cut of the female shiplap groove, it should be

half the thickness of the ductboard (see illustration).

If adjustment is needed: (1) Turn the blade

adjustment knob counterclockwise to lower the

blade for a deeper cut or (2) Turn the blade

adjustment knob clockwise to raise the blade

for a shallower cut. Repeat adjustment until the

proper depth of cut is achieved.

#1 #2/4 #3 #24

#1

Blade

Adjustment

knob

1”

3/4”

FASGROOV #2/4 AND #3 TOOLS

Push the FasGroov #2/4 Tool and FasGroov #3

Tool through a test piece of ductboard. Measure

the amount of fiberglass remaining between the

foil backing and the deepest part of the shiplap

cut (see illustration).

If adjustment is needed: (1) Turn the blade

adjustment knob counterclockwise to lower the

blade for a deeper cut or (2) Turn the blade

adjustment knob clockwise to raise the blade for

a shallower cut.

Repeat adjustment until the proper depth of cut

is achieved.

#2/4 TOOL #3 TOOL

1/16”

1”

FGV24

1/8”

FGL24

1/16”

FGV3

1/8”

FGL3

1”

6

www.malcotools.com

#5

VEE VEE VEE #5

FASGROOV-VEE TOOL

Push the FasGroov-Vee Tool through a test

piece of ductboard.

Measure the amount of fiberglass remaining

between the foil backing and the deepest part

of the vee-groove cut. There should be 1/8” of

fiberglass remaining (see illustration for width

of cut.)

If adjustment is needed: (1) Turn the blade

adjustment knob counterclockwise to lower the

blade for a deeper cut or (2) Turn the blade

adjustment knob clockwise to raise the blade for

a shallower cut.

Repeat adjustment until the proper depth of cut

is achieved.

FGV

1-3/4”

1”

FASGROOV #5 TOOL

Push the FasGroov #Tool through a test piece of

ductboard.

The blade should cut deep enough to skin all of

the fiberglass off the foil backing. By using more

pressure on the FasGroov #5 Tool, any remaining fiberglass may be cleaned off the foil.

If adjustment is needed: (1) Turn the blade

adjustment knob counterclockwise to lower the

blade for a deeper cut or (2) Turn the blade

adjustment knob clockwise to raise the blade for

a shallower cut.

Repeat adjustment until the proper depth of cut

is achieved.

Note: It is important to use this tool according to

the direction arrows on the label.

FGLV

2-5/8”

1-1/2”

VEE TOOL

Use FGK Knife

to cut staple flap.

www.malcotools.com

#5 TOOL

7

Blade removal, replacement:

Since the blade adjustment mechanism is the

same for all FasGroov Tools, this procedure

applies to any tool requiring blade removal/

replacement.

Blades remove

without removing

screws.

BLACK PLASTIC SUPPORT

BLADE ASSEMBLY

SCREWS

Loosen Screws

Slide and remove worn blade assembly.

Place new blade into the black plastic support

and retighten screws.

Note: Initial cutting friction may be realized due

to rust prevention factory finish on the blade.

8

www.malcotools.com

SHIPLAP FABRICATION

W1

#1

GRAY

H1

#2/4

DARK

ORANGE

W2

#3

ORANGE

Face the factory made female shiplap edge of a

ductboard section. Place the FasGroov #1 Tool

against the left edge of the ductboard. Push the

FasGroov #1 Tool closely along the left edge to

produce a female shiplap groove.

#1 TOOL

#2/4

DARK

ORANGE

H2

#5

BLUE

CUT FLAP

#2/4 TOOL

Set the FasGroov Square on top of the ductboard. Place the ruled edge along the factory

made female shiplap edge. Measure the desired

inside duct width dimension (W1) and align with

the right edge of cut made previously by the

FasGroov #1 Tool. Place the FasGroov #24 Tool

against the slide edge and push along to produce

a right hand shiplap groove.

Move the FasGroov Square to the right and measure the desired inside duct height dimension

(H1). Align dimension with the right edge of cut

previously made by the FasGroov #2/4 Tool.

#3 TOOL

9

www.malcotools.com

Place the FasGroov #3 Tool against the slide

edge and push along to produce a left hand shiplap groove.

Move the FasGroov Square to the right and

measure the desired inside duct width dimension

(W2). Align with the right edge of cut previously made by the FasGroov #3 Tool. Place the

FasGroov #2/4 Tool against the slide edge and

push along to produce a second right hand shiplap groove.

Place the FasGroov Duct Knife on the right edge

of cut previously made by the FasGroov #5 Tool.

Cut completely through the foil to finish the

grooving process.

Move the FasGroov Square to the right one last

time and measure the desired inside duct height

dimension (H2). Align dimension with the right

edge of cut previously made by the FasGroov

#2/4 tool. Place the FasGroov #5 Tool against

the slide edge and push along to produce a staple

flat groove.

#3 TOOL

Fold the duct section together. Staple and tape

the duct section with manufacturer approved

products.

10

www.malcotools.com

VEE-GROOV FABRICATION

W1

#1

GRAY

H1

#2/4

DARK

ORANGE

W2

#3

ORANGE

Face the factory made female shiplap edge of a

standard four foot ductboard section. Place the

FasGroov #1 Tool against the left edge of the

ductboard. Push the FasGroov #1 Tool closely

along the left edge to produce a female shiplap

groove.

#1 TOOL

#2/4

DARK

ORANGE

H2

#5

BLUE

CUT FLAP

VEE TOOL

Set the FasGroov Square on top of the ductboard. Place the ruled edge along the factory

made female shiplap edge. Measure the desired

inside duct width dimension (W1) and align

with the right edge of cut made previously by

the FasGroov #1 Tool. Place the FasGroov VeeTool against the slide edge and push along to

produce a vee groove.

Move the FasGroov Square to the right and measure the desired inside duct height dimension

(H1). Align dimension with the right edge of cut

previously made by the FasGroov Vee-Tool.

#3 TOOL

11

www.malcotools.com

Place the FasGroov-Vee Tool against the slide

edge and push along to produce another vee

groove.

Move the FasGroov Square to the right and

measure the desired inside duct width dimension

(W2). Align dimension with the right edge of

vee groove made in the previous step. Place the

FasGroov-Vee Tool against the slide edge and

push along to produce a third vee groove.

Move the FasGroov Square to the right ,one last

time and measure the desired inside duct height

dimension (H2). Align dimension with the right

edge of cut previously made by the FasGroovVee Tool.

#5 TOOL

Place the Fasgroov #5 Tool against the slide

edge. make sure the blade is turned the proper

way or in the proper set of holes to produce a

staple flap groove in the right handed vee groove

direction. For blade removal/replacement, see

page 14. Push along to produce a staple flap

groove.

Place the FasGroov Duct Knife on the right edge

of cut previously made by the FasGroov #5 tool.

Cut completely through the foil to finish the

grooving process.

Fold the duct section together. Staple and tape

the duct section with manufacturer approved

products.

12

www.malcotools.com

Loading...

Loading...