Page 1

Tools for Safe, Fast, Accurate Fabrication of

1 in. and 1-1/2 in. Fiberglass Ductboard

We’ll Show you

Step-by-Step!

FABRICATING SYSTEM

FABRICATING SYSTEM

MALCO PRODUCTS INC. • 14080 HWY 55 NW • PO Box 400

Annandale, MN 55302 •

www.malcotools.com

• Engineered for Superior Performance / Limited Lifetime Warranty

• Conçu pour fournir des performances exceptionnelles / Garantie limitée à vie

• Diseñado para un desempeño superior / Garantía de vida útil limitada

SL17156A

Page 2

2 3

VEE-GROOVE KITS

SHIPLAP KITS

Introduction .......................................................4

SETTING UP TOOLS

Adjusting FasGroov Square ............................... 9

Hand Tool blade height adjustment ................. 10

Blade removal / replacement .......................... 14

Shiplap Fabrication ......................................... 16

Vee-Groove Fabrication ................................... 20

Related Tools and Accessories ........................ 24

The duct fabrication procedures outlined in this manual

pertain to two common methods of one-piece duct construction in standard 1” OR 1-1/2” ductboard. For applications requiring ductwork larger than that which can be

constructed from a single piece of ductboard, consult

the NAIMA Fibrous Glass Duct Construction Standards

Manual or your ductboard manufactures fabrication

manual for information on the two-piece “U”, two piece

“L”, and four-piece construction methods.

KIT CONTENTS

FGVK

Vee Kit for

1 in. (25.4 mm)

Ductboar

d

Silver Tools

FGVKL

Vee Kit for

1-1/2 in. (38.1 mm)

Ductboar

d

Gold Tools

FGSLK

Shiplap Kit for

1 in. (25.4 mm) Ductboard

Silver Tools

FGSLKL

Shiplap Kit for

1-1/2 in. (38.1 mm)

Ductboar

d

Gold Tools

FABRICATING SYSTEM

1 inch Kit 1-1/2 inch Kit

Cat. No. Cat No. Description

FGVK FGVKL Vee-Groove Kit with following:

FGV1 FGL1 #1 Tool

FGV FGLV Vee Tool

FGV5 FGL5 #5 Tool

FGV6 — #6 Tool

FGS FGS Square

FGK FGK Duct Knife

FGM FGML Male Shiplap Knife

FGF FGFL Female Shiplap Knife

FGC FGC Tool Case

1 inch Kit 1-1/2 inch Kit

Cat. No. Cat No. Description

FGSLK FGSLKL Shiplap Kit with following:

FGV1 FGL1 #1 Tool

FGV24 FGL24 #2/4 Tool

FGV3 FGL3 #3 Tool

FGV5 FGL5 #5 Tool

FGV6 — #6 Tool

FGS FGS Square

FGK FGK Duct Knife

FGM FGML Male Shiplap Knife

FGF FGFL Female Shiplap Knife

FGC FGC Tool Case

Page 3

INTRODUCTION

Shiplap Method

Vee-Groove Method

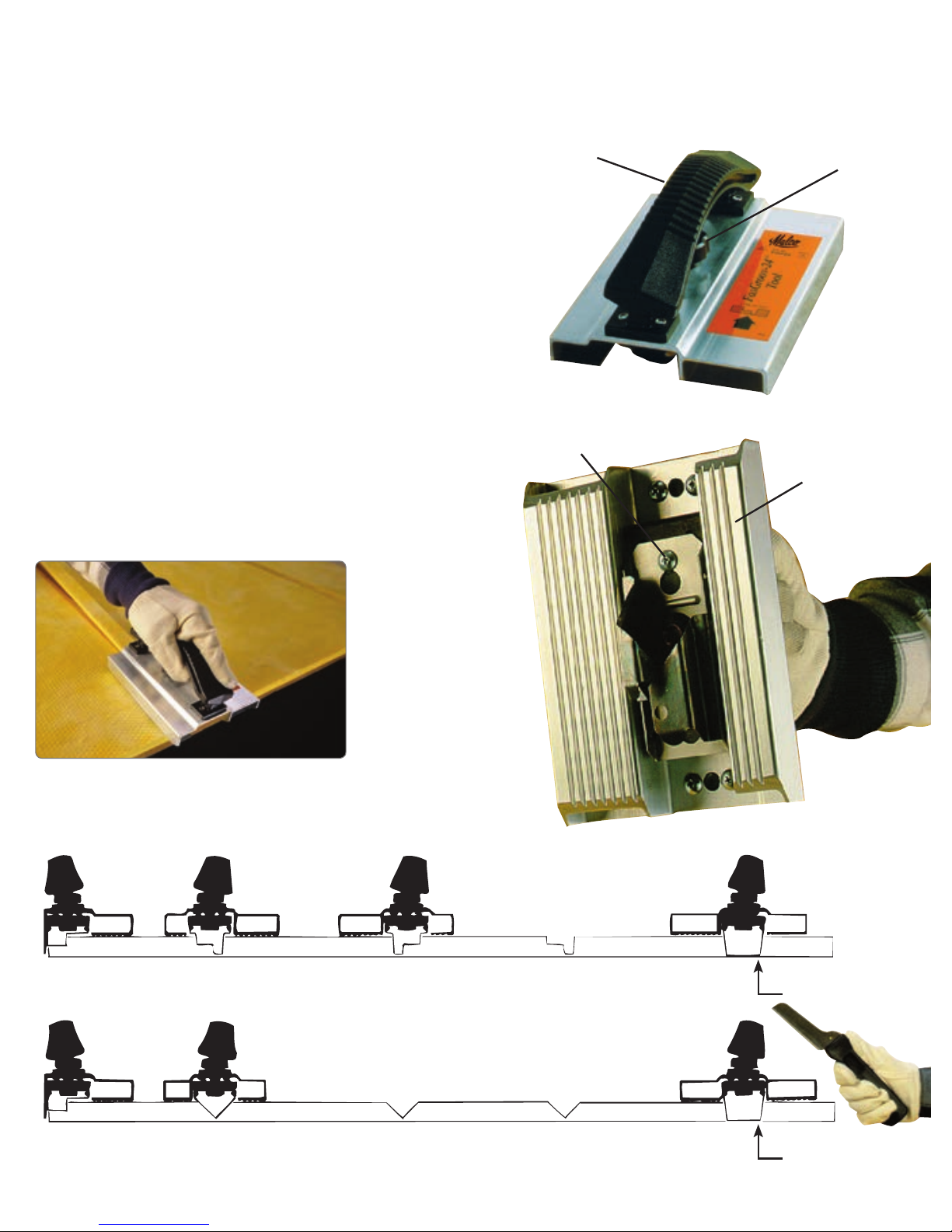

Tool Features:

• FasGroov Tool identification incorporates

both the numbering system of fabrication

machines and the traditional hand tool color

coding system. FasGroov Tools are available for

both shiplap and vee-groove fabrication methods.

• Easy, turn-the-knob, blade height adjustment.

Scrap lifts cleanly out of groove. Blades are also

easily removed without removing screws.

• Molded plastic handles are ergonomically

designed to fit angle of grip and reduce arm

and hand fatigue on-the-job.

• Extruded, anodized, aluminum body is

durable and lightweight. Grooved surface on

sled bottom facilitates easy sliding.

#1

GRAY

#2/4

DARK

ORANGE

#3

ORANGE

#5

BLUE

#1

GRAY

VEE

RED

#5

BLUE

Sled glides

easily and

cleanly removes

scrap piece out

of groove.

Molded handles

ergonomically

designed to

reduce arm

and hand

fatigue.

Blades remove

without removing

screws.

Grooved sled

bottom facilitates

easy sliding.

Patent No’s.

5,040,297

5,077,899

Easy turn-the-knob

blade height adjustment

compensates for thickness

variations in standard

1 and 1-1/2 inch board.

4 5

CUT FLAP

CUT FLAP

Page 4

Use #6 Tool

to shorten

length of

duct section,

by measuring

from outside

edge of material

to be scrapped.

Use knob under

handle to raise

or lower blade

and adjust

depth of cut.

• 1” FasGroov kits also include a #6 tool (Tan color

coded FGV6) for creating duct sections less than

standard 4 foot lengths. The #6 replaces a shiplap

knife for making a shiplap groove at fitting end

prior to closure of duct section. The #6 may also

be used for two-piece and four-piece ductboard

fabrication.

1/2”

FGV6

FGV6

Easy one-piece layout:

• FasGroov Square permits fast and accurate

layout without marking cuts or calculating

add-on dimensions. Lay out ductboard as you

cut. Simply align dimension on FasGroov Square

with right edge of previous cut and move across

the board. Square is also easily adjustable for

angled cuts.

Single blade knives:

• Single blade FasGroov Knives are safer to

use and also feature comfortable molded

handles. Male and Female Shiplap Knives can

be used on closed duct sections.

FGK

Duct Knife

use this point to

cut fiberglass without

tearing ductboard skin.

6 7

Page 5

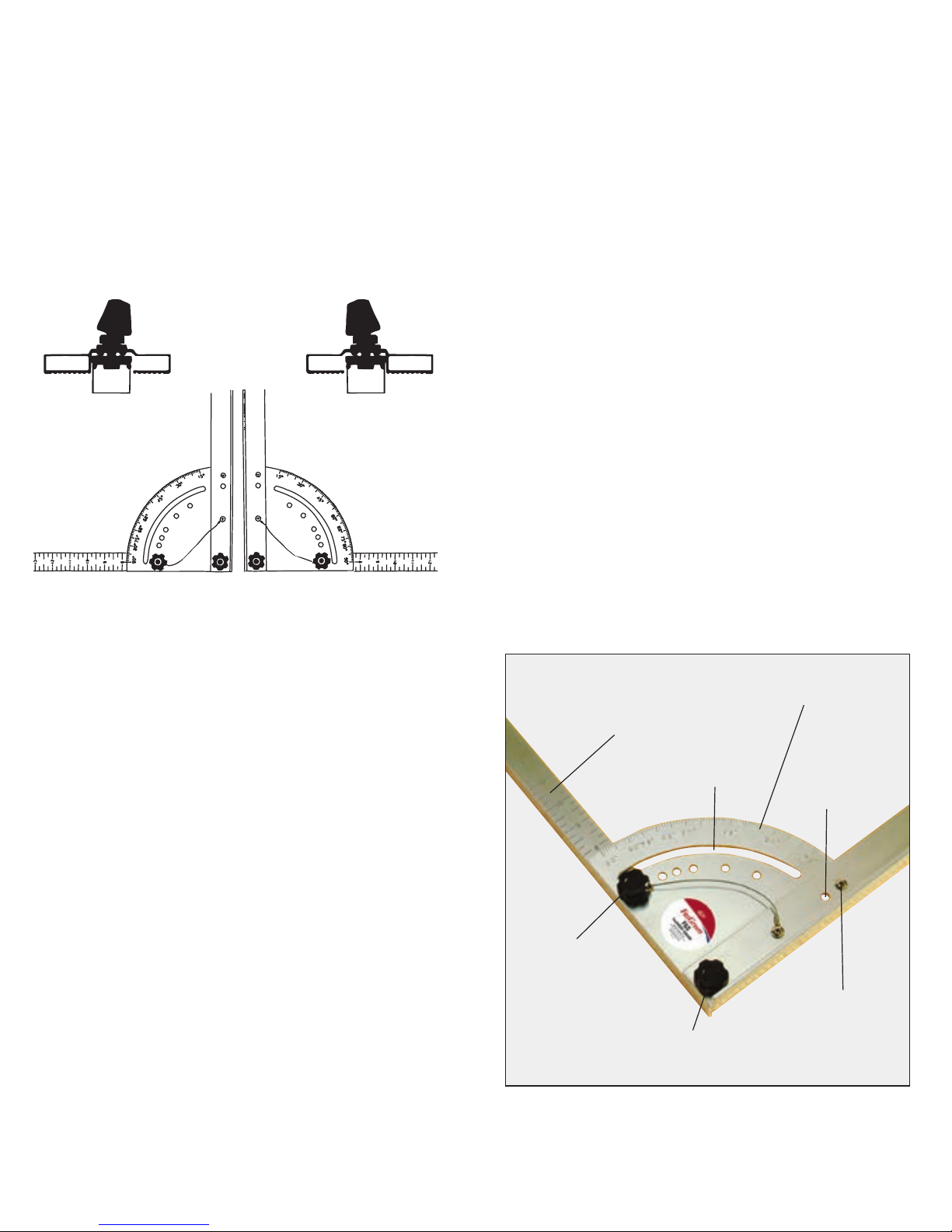

For right or left hand use:

• Right hand orientation of 1” kits is easily changed

by converting #5 Tool and FasGroov Square for left

hand fabrication. Tool handles may also be turned

around to provide left hand grip angle.

Right hand

operation.

Left hand

operation.

CONVERTING FASGROOV

SQUARE FOR LEFT HAND USE.

1. Remove the angle adjustment knob and the end pivot knob.

2. Position the ruler stamped leg so that the 3 holes are to

your left. (Rule reads left to right.)

3. Remove the protractor for the “L” shaped leg by removing

the two screws.

4. Flip the protractor over and install on the opposite end of the

“L” shaped leg.

5. Place the “L” leg/protractor assembly on top of the ruled leg.

6. Align the pivot knob holes and install the pivot knob.

7. Install the angle adjustment knob in any of the fixed positions

or the sliding position.

8. After converting your square for left hand use, double check

the accuracy in the fixed 90° position with a roofing square.

Built-in manufacturing hole tolerances will allow you

to true the square.

Note: 1-1/2” Kits cannot be converted for left hand use.

SETTING UP TOOL

Adjusting Fasgroov Square:

PREDETERMINED SETTINGS

Place adjustment knob into hole corresponding

to most used angles.

OTHER ANGLES

Place adjustment screw into protractor

adjustment slot and tighten at desired angle.

STORAGE

Step 1:

Remove angle adjustment knob and

fold ends of FasGroov Square together.

Step 2:

Place angle adjustment knob into the

storage hole and tighten.

Ruler stamped leg.

Pivot knob.

Angle adjustment

knob shown here in

90° predetermined

hole setting.

Adjustment slot

for other angles.

Storage Hole

for angle

adjustment knob.

Screws holding

protractor to “L”

shaped leg.

Protractor scale etched 2 sides

for right or left hand use.

8 9

Page 6

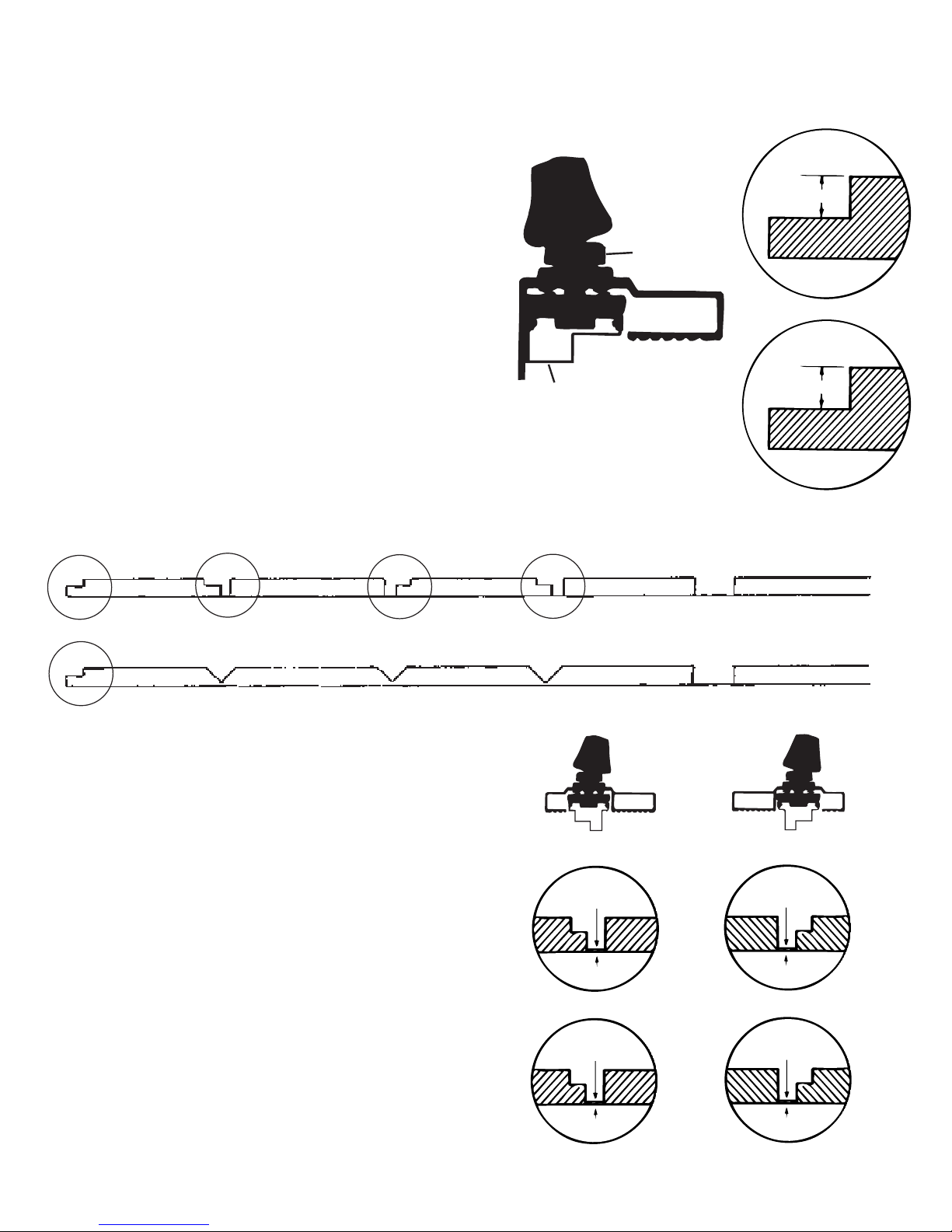

Hand Tool blade

height adjustment:

FASGROOV #1 TOOL

Push the FasGroov #1 Tool along the left edge of a test

piece of ductboard. Measure the depth of cut of the

female shiplap groove, it should be half the thickness

of the ductboard (see illustration).

If adjustment is needed: (1) Turn the blade adjustment

knob counterclockwise to lower the blade for a deeper

cut or (2) Turn the blade adjustment knob clockwise to

raise the blade for a shallower cut. Repeat adjustment

until the proper depth of cut is achieved.

FASGROOV #2/4 and #3

TOOLS

Push the FasGroov #2/4 Tool and FasGroov #3 Tool

through a test piece of ductboard. Measure the amount

of fiberglass remaining between the foil backing and

the deepest part of the shiplap cut (see illustration).

If adjustment is needed: (1) Turn the blade adjustment

knob counterclockwise to lower the blade for a deeper

cut or (2) Turn the blade adjustment knob clockwise to

raise the blade for a shallower cut.

Repeat adjustment until the proper depth of cut

is achieved.

#1 TOOL

FGV1

FGL1

Adjustment

knob

Blade

1”

1-1/2”

1/2”

3/4”

1/16”

FGV24

1/16”

FGV3

1/8”

FGL24

1/8”

FGL3

1”

1-1/2”

1”

1-1/2”

#2/4 TOOL #3 TOOL

#1 #2/4 #3 #2/4

#1

10 11

Page 7

FGV

1-3/4”

FGLV

2-5/8”

1”

1-1/2”

VEE TOOL

FASGROOV-VEE TOOL

Push the FasGroov-Vee Tool through a test piece of

ductboard.

Measure the amount of fiberglass remaining between

the foil backing and the deepest part of the vee-groove

cut. There should be 1/8” of fiberglass remaining (see

illustration for width of cut.)

If adjustment is needed: (1) Turn the blade adjustment

knob counterclockwise to lower the blade for a deeper

cut or (2) Turn the blade adjustment knob clockwise to

raise the blade for a shallower cut.

Repeat adjustment until the proper depth of cut is

achieved.

FASGROOV #5 TOOL

Push the FasGroov #5 Tool through a test piece of

ductboard.

The blade should cut deep enough to skin all of

the fiberglass off the foil backing. By using more

pressure on the FasGroov #5 Tool, any remaining

fiberglass may be cleaned off the foil.

If adjustment is needed: (1) Turn the blade adjustment knob counterclockwise to lower the blade for

a deeper cut or (2) Turn the blade adjustment knob

clockwise to raise the blade for a shallower cut.

Repeat adjustment until the proper depth of cut is

achieved.

Note: It is important to use this tool according to the

direction arrows on the label.

#5 TOOL

Use FGK Knife

to cut staple flap.

VEE VEE VEE #5

#5

12 13

Page 8

Blade removal, replacement:

Since the blade adjustment mechanism is the same for

all FasGroov Tools, this procedure applies to any tool

requiring blade removal/replacement.

BLACK PLASTIC SUPPORT

BLADE ASSEMBLY

SCREWS

Loosen Screws

Slide and remove worn blade assembly.

Place new blade into the black plastic support and

retighten screws.

Note: Initial cutting friction may be realized due to

rust prevention factory finish on the blade.

Blades remove

without removing

screws.

14 15

Page 9

SHIPLAP FABRICATION

#1

GRAY

#2/4

DARK

ORANGE

#2/4

DARK

ORANGE

FGK

Duct Knife

#3

ORANGE

#5

BLUE

W1

H1

W2

H2

Work left to right facing the factory-made female

shiplap edge as your base edge for a standard

4-foot deep ductboard section.

Set the FasGroov Square on top of the ductboard.

Place the ruled edge of the square flush against the

base edge of the board.

Locate your desired inside duct width dimension (W1)

on the ruled edge of square and move the square

along the board base to align your width dimension

with the right edge of the previous cut made with the

#1 Tool. Place the left side of the FasGroov #2/4 Tool

flush against the arm of the square and push the #2/4

tool along the arm’s length to produce a right hand

shiplap groove.

Place the FasGroov #1 Tool flush against the left

edge of the ductboard. Push the tool along length of

left edge to produce a female shiplap groove.

#1 TOOL

#2/4 TOOL

16 17

CUT

FLAP

Locate your desired inside duct height dimension

(H1) on the ruled edge of the FasGroov Square and

move square to the right along base of ductboard to

align your height dimension with the right edge of the

previous cut made with the #2/4 Tool. Place the left

side of the FasGroov #3 Tool flush against the arm of

the square and push the #3 tool along arm’s length to

produce a left hand shiplap groove.

#3 TOOL

Page 10

Insert the FGK FasGroov Duct Knife into the

right edge of the staple flap cut made with the

#5 Tool. Cut completely through the foil to finish

the grooving process.

Fold the duct Section together. Staple and tape the

flap, join duct sections and install take-offs with

manufacturer-approved products.

18 19

SHIPLAP FABRICATION

#1

GRAY

#2/4

DARK

ORANGE

#2/4

DARK

ORANGE

#3

ORANGE

#5

BLUE

W1

H1

W2

H2

Move the square to the right again to align your width

dimension (W2) with the right edge of the previous cut

made with #3 Tool. Place the left side of the FasGroov

#2/4 Tool flush against the arm of the square and push

the #2/4 along arm’s length to produce a second right

hand shiplap groove.

Move the square one last time to align your height

dimension (H2) with the right edge of the previous

cut made with #2/4 Tool. Place the left side of the

FasGroov #5 Tool flush against the arm of the square

and push the #5 along arm’s length to produce a staple

flap groove.

#5 TOOL

FGK

Duct Knife

CUT

FLAP

Page 11

VEE-GROOVE FABRICATION

#1

GRAY

VEE

RED

VEE

RED

VEE

RED

#5

BLUE

W1

H1

W2

H2

CUT FLAP

Work left to right facing the factory-made female

shiplap edge as your base edge for a standard

4-foot deep ductboard section.

Set the FasGroov Square on top of the ductboard.

Place the ruled edge of the square flush against the

base edge of the board.

Locate your desired inside duct width dimension (W1) on

the ruled edge of square and move the square along the

board base to align your width dimension with the right

edge of the previous cut made with the #1 Tool. Place

the left side of the FasGroov-Vee Tool flush against the

arm of the square and push the Vee Tool tool along the

arm’s length to produce a vee groove.

Place the FasGroov #1 Tool flush against the left

edge of the ductboard. Push the tool along length of

left edge to produce a female shiplap groove.

#1 TOOL

VEE TOOL

VEE TOOL

20 21

Locate your desired inside duct height dimension

(H1) on the ruled edge of the FasGroov Square and

move square to the right along base of ductboard to

align your height dimension with the right edge of the

previous cut made with the Vee Tool. Again place

the left side of the Vee Tool flush against the arm of

the square and push the tool along arm’s length to

produce a vee groove.

FGK Duct Knife

Page 12

VEE-GROOVE FABRICATION

22 23

#1

GRAY

VEE

RED

VEE

RED

VEE

RED

#5

BLUE

W1

H1

W2

H2

Move the square to the right to align your width dimension (W2) with the right edge of the previous cut. Place

the left side of the Vee Tool flush against the arm of the

square and push the tool along arm’s length to produce

a third vee groove.

Move the square one last time to align your height

dimension (H2) with the right edge of the last cut made

with Vee Tool. Place the left side of the FasGroov #5

Tool flush against the arm of the square and push the

#5 along arm’s length to produce a staple flap groove.

#5 TOOL

Insert the FGK FasGroov Duct Knife into the right edge

of the staple flap cut made with the #5 Tool. Cut completely through the foil to finish the grooving process.

Fold the duct section together. Staple and tape the

flap, join duct sections and install take-offs with

manufacturer-approved products.

FGK

Duct Knife

CUT

FLAP

Page 13

24 25

For use with wire-reinforced fiberglass ductboard walls

to restrict duct wall deflection on positive pressure supply

ducts. The volcano profiled reinforced washer seats flush

to the ductboard surface. A 1/8-inch (3.18 mm) diameter

hole accepts 12-gauge wire.

Use for fastening sheet metal components to

fiberglass ductboard. The volcano profiled reinforced

washer seats flush to the ductboard. A 7/32-inch

(5.56 mm) hole accepts a #8 screw.

Galvanized Volcano

Reinforcement Washers

Hole Cutter for

Fiberglass Ductboard

Cat. No.

FLW

Dimensions in. (mm) 2 ½ x 2 ½ x .030 (64 x 64 x 0.76)

Hole Dia. In. (mm) 1/8 (3.18)

Cat. No.

RW732

Dimensions in. (mm) 2 ½ x 2 ½ x .030 (64 x 64 x 0.76)

Hole Dia. in. (mm) 7/32 (5.56)

Fasloop

Washer

Reinforcing

Washer

FLW

FG1

RW732

Cuts 4 to 20” (102 to 508 mm)

diameter holes in both

1” (25.4 mm) and

1-1/2” (38.1 mm)

fiberglass duct.

Operation is fast

and easy.

Supplied with a standard utility knife blade that

safely stores in handle. Hole Cutter can also use

the KBHC replacement blade for cutting

1-1/2” ductboard.

Cat. No. Description Net Weight oz. (g)

FG1 Fiberglass Duct Hole Cutter 7-1/2 (213)

REPLACEMENT 1-1/2” BLADE

KBHC 1-1/2” Blade for FG1 Hole Cutter

KBHC Blade

for 1-1⁄ 2” board.

12045

12761

12047

Page 14

Double edged blade

cleanly pierces duct,

cuts both directions.

Built-in wire cutter

completes the job by

severing wire rib coil.

Cat. No.

FDC1

Length of Cut in. (mm) 4 (102)

Tool Length in. (mm) 11-7/8 (302)

Net Weight oz. (g) 11 (312)

26 27

DK6S

Fine Honed Stainless

Steel Double Edged

Knife Blade

Compound

Leverage

Wire Cutter

Comfortable

Contour

Vinyl Gripped

Handles

FDC1

Ergonomic

cushioned

handle offers

comfortable,

sure grip.

Serrated edge aids cutting

“flex” fiberglass wool duct.

Cuts Ductboard and

Flex Duct!

It also cuts the wire rib coil!

Puncture resistant nylon

sheath included with DK6S

cushion gripped knife.

For cutting flexible fiberglass

wool duct and ductboard.

Double edge blades are ideal

for blind cuts in “flex” duct.

Duct Knife

Flex Duct Cutter

Cat. No.

DK6S

Blade Length in. (mm) 6 (152)

Net Weight oz. (g) 7 (199)

Double edged blade cleanly pierces through outer

skin and fiberglass wool insulation and cuts in

either direction around the duct circumference.

Use the handy built-in wire cutter to cut the

hardened wire rib coil.

U.S. Patent No. 5,225,237

Page 15

The shear’s pointed bottom blade easily pierces duct

to start the cut. The handy wire cutter is located

away from the scissor blade edges. And a thumboperated latch ensures that the blade edges stay

closed when not in use. Double edged blade cleanly

pierces through outer skin and fiberglass wool insulation and cuts in either direction around the duct

circumference. Use the handy built-in wire cutter to

cut the hardened wire rib coil.

Double edged blade cleanly pierces through outer

skin and fiberglass wool insulation and cuts in either

direction around the duct circumference. Use the

handy built-in wire cutter to cut the hardened wire

rib coil. Use the tie tensioning mechanism to install

a nylon tie strap that secures flex to a take-off collar.

Use the wire cutter to cut excess nylon tie tail.

A knife, wire cutter & tie tool!

Multi-Purpose

Flex Duct Tool

Cat. No.

FDC2

Length of Cut in. (mm) 4-3/8 (111)

Tool Length in. (mm) 12-1/4 (311)

Net Weight oz. (g) 13 (369)

Cat. No.

FDC3

Length of Cut in. (mm) 4 (102)

Tool Length in. (mm) 11-7/8 (302)

Net Weight oz. (g) 14 (397)

Thumb

operated

latch

Thumb operated latch ensures that

sharpened blade edges on the FDC2

stay closed when not in use.

Wire Cutter

FDC2

FDC3

Use wire cutter to cut duct’s

rib coil and trim nylon tie tail.

Tie tensioning

mechanism

Thumb

operated

latch

28 29

Scissor action plus wire cutter!

Flex Duct Shear

Page 16

30 31

Gripped TY4G and Un-Gripped TY4 Manual Cut-Off

Models feature comfortable handle openings and

reduced pinch-point. These long-life tools also feature a unique, non-slip, notched gripper to ratchet

and set thick and thin nylon ties.

TY6 Model with Automatic Cut-Off can be set to

engage blade and cut off the nylon tie tail when

desired tension is reached. Designed for continuous

use on thick ties, the TY6 features contoured cushion

gripped handles and a long-life notched gripper.

Non-slip, notched gripper!

Features Automatic Cut-Off!

Manual Cut-Off

Tensioning Tools

Adjustable

High Leverage

Tensioning Tool

Cat. No.

TY4 / TY4G (Gripped)

Tool Length in. (mm) 6 (152)

TY4 — Net Weight oz. (g) 10 (284)

TY4G — Net Weight oz. (g) 11 (312)

Cat. No.

TY6

Tool Length in. (mm) 8-1/2 (216)

Net Weight oz. (g) 15 (425)

U.S. Patent No. 5,048,575 U.S. Patent No. 5,048,575

Cutter

Handles

T Y4

Cutter

Handles

T Y4G

T Y6

Adjustment Knob

Excess Tie

Cutting

Blade

Features hardened steel stampings with

weather resistant nickel chrome finish.

Page 17

Quickly installs on 4-inch to 16-inch diameter flexible

fiberglass wool duct to support a 90° elbow support.

Reduces energy consumption by eliminating air

flow restrictions and increasing air flow efficiency.

Lightweight, 100% recycled polymer construction.

Use with 36-inch and 48-inch nylon ties (Malco TY34

and TY48).

These Outdoor Rated UV Resistant Ties are made of 100% Nylon.

A one-piece adjustable, self-locking design makes them easy to

install for a multitude of outdoor applications.

These Indoor Rated Ties are made of 100% Nylon. A one-piece adjust-

able, self-locking design makes them easy to install for a multitude of

indoor applications. Uses include securing HVAC duct take-offs and

securing/bundling heavy tubing, hoses and cables.

Cat. No.

FDS1

Nom. Dimensions in. (mm) 15 x 11-1/4 x 3 (38.1 x 28.6 x 7.6)

Net Weight oz. (g) 3 (85)

Supports 90°

Flex Duct Elbow!

Flex Duct

Support

32 33

TY11 TY24

Overall Length in. (mm) 11 (279) 24 (610)

Width in. (mm) 3/16 (4.57) 3/8 (9.5)

Thickness in. (mm) 3/64 (1.32) 3/32 (2.29)

Min. Tensile Strength lbs. 50 175

Max. Adjustable Dia. in. (mm) 3-1/16 (78) 7-3/16 (179)

Color Black Black

For Malco Tie Tools TY4, TY4G TY4, TY4G, TY6

TY34 TY48

Overall Length in. (mm) 36 (914) 48 (1219)

Width in. (mm) 3/8 (9.5) 3/8 (9.5)

Thickness in. (mm) 3/32 (2.29) 3/32 (2.29)

Min. Tensile Strength lbs. 175 175

Max. Adjustable Dia.In. (mm) 11 (279) 14-1/2 (368)

Color Natural Gray

For Malco Tie Tools TY4, TY4G, TY6 TY4, TY4G, TY6

T Y11

TY24

UV

UV Resistant

Adjustable Nylon Ties

Jumbo Heavy-Duty

Adjustable Nylon Ties

TY34

TY48

Loading...

Loading...