Malabar 795 Owner's Manual

Date: June 7, 2006

MALABAR

INTERNATIONAL

AIRCRAFT MAINTENANCE & SUPPORT EQUIPMENT

OWNER’S MANUAL FOR MALABAR MODEL

795

READ

AND

SAVE

THIS

INSTRUCTION

MANUAL

Property of American Airlines

SINGLE STAGE FIXED HEIGHT

HYDRO - MECHANICAL

AVIATION TRIPOD JACK

* GENERAL DESCRIPTION

* OPERATION

* SERVICE

* PARTS BREAKDOWN

For Service & Spare

Parts, Please Contact: Malabar International

220 W. Los Angeles Avenue

Simi Valley, California 93065

Phone: (805) 581-0116

Fax: (805) 584-1624

E-mail: sales@malabar.com

Web site: http://www.malabar.com

OVER 65 YEARS OF SERVICE & EXPERIENCE

2002 Malabar International. All rights reserved. Permission to reproduce all or part of this material must be obtained from Malabar International.

GENERAL DESCRIPTION, OPERATION, SERVICE AND PARTS BREAKDOWN

MALABAR MODEL 795

SINGLE STAGE FIXED HEIGHT

HYDRO-MECHANICAL AVIATION TRIPOD JACK

CAUTION: AIRCRAFT MANUFACTURER’S SPECIFICATIONS AND INSTRUC-

TIONS MUST BE FOLLOWED. IN THE EVENT OF CONTRADICTION

BETWEEN AIRCRAFT MANUFACTURER’S SPECIFICATIONS AND

MALABAR’S, AIRCRAFT MANUFACTURER’S SPECIFICATIONS WILL

PREVAIL.

SPECIFICATIONS:

Rated Capacity---------------------------------------------------------------------------------- 100 tons (90.7 m. tons)

Side Load----------------------------------------------------------------------------------------- 15% of vertical load

Roll Under Height------------------------------------------------------------------------------- 98.5 inches (2502 mm)

Low Height---------------------------------------------------------------------------------------- 97 inches (2464 mm)

Hydraulic Lift ------------------------------------------------------------------------------------- 72 inches (1829 mm)

Extension Screw-------------------------------------------------------------------------------- 24 inches (610 mm)

Total Extended Height

Oil Pressure at Rated Capacity------------------------------------------------------------- 3140 psig (221 kg/sq cm)

Safety Pop-off Valves

System Relief Valve set at-------------------------------------------------------------- 110 tons (99.8 m. tons)

Thermal Relief Valve set at------------------------------------------------------------- 125 tons (113.4 m. tons)

Hydraulic Caster Relief Valves set at

Proof Load---------------------------------------------------------------------------------------- 150 tons (136.1 m. tons)

Reservoir Capacity----------------------------------------------------------------------------- 26 gallons (98.4 liters)

Hydraulic Fluid----------------------------------------------------------------------------------- MIL-H-5606 or equivalent

Maximum Towing Speed--------------------------------------------------------------------- 5 mph (8 km/h)

Approximate Jack Net Weight -------------------------------------------------------------- 3800 lbs (1724 kg)

Input power--------------------------------------------------------------------------------------- 230/460V, 60Hz

Pump motor / starter----------------------------------------------------- 2 HP, 3 PH, 1725 RPM, explosion proof with

------------------------------------------------------------------------- 193 inches (4902 mm)

------------------------------------------------ 900 psig (63.3 kg/sq cm)

red and green indicator lights

GENERAL DESCRIPTION:

The Malabar Fixed Height Tripod Jack Model 795 is a 100 ton capacity single stage hydraulic jack

designed primarily for use in aircraft maintenance. It consists of a tripod structure, hydraulic cylinder

assembly, reservoir, valve block assembly, hand pump assembly, tow handle, swivel casters and the

following optional equipment:

*Air pump

*Electric motor operated hydraulic pump

*Load gauge

*Adjustable swivel foot

*Adjustable swivel foot with hydraulic caster

*Ladder

*Remote control (platform operated)

The jack tow handle readily connects to tow vehicle for ease of transport. The jack should never be used

as a personnel carrier while being towed or in motion. On jacks equipped with spring loaded swivel

casters, the jack leg pads are raised off the ground. The casters will retract and the pads rest on the

ground when a load is applied to the jack. On jacks equipped with adjustable swivel foot, the jack leg

Property of American Airlines

**Shock absorber for hydraulic caster option

- 1 -

pads have adjustable leveling feet for slightly uneven or sloping floors. On jacks equipped with hydraulic

casters, leveling of the jack is faster and easier by selectively extending or retracting the caster plungers

utilizing the caster hand pump or release valve. Extending the casters also increases the towing ground

clearance. For extended towing over rough surfaces, a hydro-pneumatic shock absorber is provided to

cushion against towing loads and improve caster life.

PREPARATION FOR USE:

Disregard the following erection procedure if the jack is shipped fully assembled. If the jack is shipped

partially assembled, erection is accomplished by following the suggested sequence below (also see

figures 1A & 1B):

1. Install sling under tripod head of cylinder assembly and support from a crane or forklift capable of

lifting 6000 pounds to a height of 12 feet.

2. Install legs, tripod head pins and retaining rings.

3. Install braces.

4. Tighten all bolts.

If jack is equipped with adjustable swivel feet, perform the following procedure to calibrate bubble level:

1. Hang 2 plumb bobs (at 90°) from the tripod head with the plumb bob strings approximately parallel to

the cylinder assembly (dial indicator magnetic bases work well as supports for the plumb bobs).

2. Stand on jack footpads and screw the footpad locknuts up to the end of the legs, continue turning

footpad locknuts until weight of jack is off casters (one end of the pump handle fits into the footpad

locknuts to provide extra leverage if required). Adjust footpad locknuts so both plumb bob strings are

parallel to the cylinder assembly (carefully measure top and bottom from cylinder assembly to

strings). Alternately, if jack is equipped with hydraulic casters, operate hydraulic caster hand pumps

and/or release valves to extend or retract casters until both plumb bob strings are parallel to the

cylinder assembly.

3. Remove cover from bubble level and adjust screws to center bubble. Lock adjustment screws and

replace cover. Tag with date of calibration.

4. Raise footpads fully to stow position and reinsert pump handle in handle holder. Remove plumb bobs.

5. Bubble level should be checked periodically as directed by cognizant quality control department.

Before placing jack in operation, perform the following procedure:

1. Remove filler cap from the filler spout located at the side of the reservoir.

2. Fill jack reservoir to mark on dipstick with MIL-H-5606 hydraulic fluid or approved equivalent

(reservoir capacity is approximately 26 gallons/98.4 liters). Jack plunger must be fully retracted before

filling reservoir. Replace filler cap.

3. Open release valve and operate hand pump a few strokes to bleed all air trapped under hand pump.

4. Close release valve and operate hand pump to raise plunger approximately 1 inch.

5. Open release valve to retract plunger fully to bleed all air trapped under jack plunger. Close release

valve.

6. If jack is equipped with hydraulic casters, perform the following procedure:

a. Remove the elbow/breather located on top of the reservoir.

b. Open release valve and fully retract caster plunger.

c. Fill reservoir to the top with MIL-H-5606 hydraulic fluid or approved equivalent. Replace

elbow/breather.

d. Open release valve and operate hydraulic caster hand pump a few strokes to bleed all air trapped

under hand pump.

e. Close release valve and operate hand pump to extend caster approximately 1 inch.

f. Open release valve to retract caster fully to bleed all air trapped under plunger. Close release

Property of American Airlines

valve.

g. Repeat for other hydraulic casters.

7. If jack is equipped with shock absorbers for the hydraulic casters, remove valve cap at end of unit and

charge with nitrogen gas to 275 psig (19.3 kg/sq cm) using accumulator test gauge assembly (P/N

872845).

8. If jack is equipped with electric motor operated hydraulic pump, note factory wired for 460V. Internal

wiring changes are required for 230V.

- 2 -

PRE-OPERATION INSPECTION:

Each time the jack is to be used, inspect the following:

1. Check the tripod structure for rigidity. Make sure all bolts are tightened.

2. Check hydraulic line connections for leaks. Tighten as required.

3. Check for hydraulic fluid leaks around the base, reservoir, tripod head, hand pump, air pump (if so

equipped), hydraulic casters (if so equipped) and shock absorber (if so equipped).

4. Check hand pumps for proper operation.

5. Check swivel casters for proper operation.

6. Check jack reservoir fluid level with plunger fully retracted.

7. Check hydraulic caster reservoir fluid levels with caster plungers fully retracted (if so equipped).

8. Check nitrogen charge in shock absorbers (if so equipped).

OPERATION:

CAUTION: PRIOR TO TOWING, ENGAGE THE TWO TRAILING SWIVEL CASTER

LOCKS. ON JACKS EQUIPPED WITH ADJUSTABLE SWIVEL FOOT,

ALWAYS FULLY RETRACT THE FOOTPADS BEFORE MOVING OR

TOWING THE JACK. ON JACKS WITH HYDRAULIC CASTERS, FULLY

EXTEND CASTERS BEFORE MOVING OR TOWING JACK.

1. Position the jack under the jacking pad of the aircraft. For maximum maneuverability, verify all swivel

caster locks are disengaged.

2. Raise the extension screw by turning counterclockwise until the ship adapter contacts the jacking pad

or as far as the screw will travel (24 inches maximum).

3. Verify the jack is leveled (shim footpads if necessary). The jack plunger should be plumb during

lifting. On jacks equipped with adjustable swivel foot, check level using the bubble level mounted on

the jack. Adjust the footpads to contact the ground and plumb the jack. The footpads are adjusted by

standing on the footpad and adjusting the footpad locknut as required to extend the footpad. One end

of the pump handle fits the footpad locknut for final adjusting. On jacks equipped with hydraulic

casters, operate hydraulic caster hand pumps to extend casters to plumb the jack and then adjust the

footpads to contact the ground.

CAUTION: OPEN HYDRAULIC CASTER RELEASE VALVES TO ENSURE THE

WEIGHT IS TAKEN THROUGH THE FOOTPADS

CAUTION: ON JACKS EQUIPPED WITH AIR PUMP, AIR RELIEF VALVE MUST

BE INSTALLED AT ALL TIMES. IF AIR RELIEF VALVE IS REMOVED,

IT IS POSSIBLE TO OVER PRESSURIZE THE PNEUMATIC SYSTEM

WHICH COULD CAUSE EQUIPMENT FAILURE AND POSSIBLE

BODILY INJURY.

4. On jacks equipped with air pump, connect air supply (90-110 psig) to the 1/2 NPT air inlet at the air

valve (a minimum of 56 scfm is required). Air relief valve must be properly installed. Do not attempt to

remove air relief valve.

CAUTION: LOCKNUT MUST BE INSTALLED AND OPERABLE ON JACK AT ALL

Property of American Airlines

TIMES. ALWAYS MAINTAIN LESS THAN 2 INCHES BETWEEN THE

LOCKNUT AND THE TRIPOD HEAD IN ALL PHASES OF LOAD

RAISING AND LOWERING.

5. On jacks equipped with electric motor operated hydraulic pump, connect power supply (230/460V,

60 hertz) to the switch box. Note: Factory wired for 460V. Internal wiring changes required for

230V.

- 3 -

6. To raise the load manually:

a. The jack is equipped with an adjustable hand pump. The hand pump handle length can be varied

by inserting the quick release pin through the clamp and appropriate hole along the handle (see

figure 4). A longer handle length provides greater pumping leverage for high pressure pump

operation. A shorter handle will increase the plunger stroke and allow more oil pumped per stroke.

This permits a more rapid raising of the jack plunger under a light or no load.

b. Close release valve located on the panel.

c. Operate the air valve or electric motor or hand pump until the ship adapter contacts the jacking

pad. Insure the ship adapter and the jacking pad are correctly mated. The load may now be raised

by operating the air valve or electric motor or hand pump.

d. Do not lift a load greater than the rated capacity of 100 tons.

e. Do not attempt to raise the plunger beyond the rated hydraulic lift (72 inches maximum).

f. Avoid lifting with excessive side load on the jack.

g. Spin the locknut down to the tripod head, as plunger is extending.

h. Keep the release valve closed at all times.

7. To lower the load:

a. Operate the air valve or electric motor or hand pump to relieve pressure on the locknut.

b. Spin the locknut out of the way.

c. Slowly open the release valve located on the panel to lower the load. The speed of lowering is

controlled by the amount the release valve is opened.

d. Close release valve after the plunger is fully retracted.

e. Lower the extension screw by turning clockwise.

f. Fully retract the adjustable footpads (if so equipped).

g. Fully extend hydraulic casters (if so equipped).

h. Cover the jack when not in use to prevent entrance of contaminants and water into the cylinder.

SERVICING:

Servicing the jack consists primarily of the following:

1. When in use, the jack and hydraulic caster (if so equipped) reservoirs should be kept at the proper

level with hydraulic fluid MIL-H-5606 or approved equivalent. Always check fluid levels with jack and

hydraulic caster plungers fully retracted.

2. When in use, the nitrogen precharge in the hydraulic caster shock absorbers (if so equipped) should

be maintained at 275 psig (19.3 kg/sq cm).

3. Grease the swivel casters.

4. Lubricate hand pump pivot pins.

5. Fill pump lubricator with SAE #10 oil.

6. If the jack has been put into storage or has not been used, the plunger must be fully extended and

retracted every 90 days to exercise the seals. A portion of the lift should be operated by the air pump

(if so equipped) and a portion by the hand pump. Also, the hydraulic caster plungers must be fully

extended and retracted by operating the hydraulic caster hand pumps and release valves.

DISASSEMBLY INSPECTION:

CAUTION: THE JACK THERMAL RELIEF VALVE AND SYSTEM RELIEF VALVE,

LOCATED IN THE JACK VALVE BLOCK ASSEMBLY, SHOULD NOT

BE REMOVED UNLESS ABSOLUTELY NECESSARY. THE JACK

THERMAL RELIEF VALVE IS SET TO BY-PASS HYDRAULIC FLUID

Property of American Airlines

BACK TO THE RESERVOIR AT 20-25% ABOVE THE RATED

CAPACITY OF 100 TONS. THE JACK SYSTEM RELIEF VALVE IS SET

TO BY-PASS HYDRAULIC FLUID BACK TO THE RESERVOIR AT 510% ABOVE THE RATED CAPACITY OF 100 TONS. IF ADJUSTMENT

IS REQUIRED, SEE PROCEDURE UNDER TESTING (SEE SHEET 5).

CAUTION: THE HYDRAULIC CASTER RELIEF VALVES (IF SO EQUIPPED),

- 4 -

LOCATED IN THE HYDRAULIC CASTER VALVE BLOCK

ASSEMBLIES, SHOULD NOT BE REMOVED UNLESS ABSOLUTELY

NECESSARY. THE HYDRAULIC CASTER RELIEF VALVES ARE SET

TO BY-PASS HYDRAULIC FLUID BACK TO THE RESERVOIRS AT 900

± 20 psig (63.3 ± 1.4 kg/sq cm) IF ADJUSTMENT IS REQUIRED, SEE

PROCEDURE UNDER TESTING (SEE SHEET 5).

When necessary to disassemble the jack and/or the hydraulic casters (if so equipped), open all release

valves, drain all hydraulic fluid from reservoirs and carefully inspect the following:

1. Inspect interior walls of cylinders for smoothness and freedom from rust, nicks, scratches and

excessive wear.

2. Check plungers, extension screw, cylinders, tripod head, etc., for corrosion, wear and condition of

threads.

3. Verify that the extension screw has a positive stop to prevent it from being extended beyond its safe

thread engagement.

4. Inspect packings, seals, gaskets and wipers in the cylinder assembly, hand pumps and hydraulic

caster assemblies for cuts, scratches, deterioration and distortion.

5. Inspect upper and lower bearings for excessive scoring and/or wear.

6. Check oil screen located in the valve block for cleanliness.

7. Inspect valves and valve seats in the hand pump bodies and valve blocks for scratches, dents and

proper seating of the balls.

8. Inspect all pivot pins for wear, cracks, pits or evidence of damage or pending damage.

9. Check tripod structure for damages.

10. Inspect all areas for excessive dirt, oil, dust and chips.

REPAIR AND REPLACEMENT:

No definite time schedule can be established for the overhaul of the jack for replacement of the various

moving parts. The number of times the jack is raised and lowered and the amount of load raised at each

operation materially affect the life of the working parts. Do not overload the jack. Overloading is

dangerous, will hasten the need for overhaul and may damage the jack. During overhaul, replace all parts

that do not pass disassembly inspection requirements. Regardless of apparent condition, replace all parts

marked with (♦) and (✚) in the parts breakdown. A repair parts kit (P/N 795PK) which contains all of the

parts marked with (♦) and a hydraulic caster repair parts kit (P/N 8818PK) which contains all of the parts

marked with (✚) are available and recommended to keep on hand at your facility. Coat all O-rings and

back-up rings with hydraulic fluid MIL-H-5606 prior to assembly. Clean all metal parts with clean solvent

and dry with compressed air. Lubricate all threads. Use teflon tape carefully on all pipe threads. Remove

excess tape because it can clog valves and passages. If ball valves, located in valve blocks, do not seat

properly, they may need to be reseated by tapping the ball into the valve seat with a brass rod cupped at

one end.

TESTING:

Place jack in a load indicating test fixture. Make sure the test adapter is 1 1/4 inch female spherical

radius. Operate jack hand pump to extend plunger against the test adapter. Make sure ship adapter and

test adapter are correctly mated. Load test the jack at rated capacity of 100 tons. If the jack fails to

operate properly, check for trouble as indicated in the Trouble Shooting Chart (see sheet 12). With the

plunger extended and supporting the capacity load, allow the jack to stand for 10 minutes. Any excess

settling indicates leakage in the hand pump, check valves or jack packing seals. Check for hydraulic fluid

leaks and replace all defective parts.

If adjustment is required for the jack thermal relief valve, perform the following procedure:

1. Remove plug (figure 3, item 8) to expose thermal relief valve. Close release valve (figure 3, item 2).

2. Place jack in a load indicating test fixture. Make sure the test adapter is 1 1/4 inch female spherical

radius. Operate hand pump to extend plunger against the test adapter. Make sure ship adapter and

test adapter are correctly mated.

Property of American Airlines

- 5 -

3. While operating the hand pump, adjust set screw (figure 3, item 9) until the thermal relief valve bypasses hydraulic fluid back to the reservoir at 120.0 to 125.0 tons.

4. Replace plug (figure 3, item 8). Once more operate hand pump to verify correct setting.

5. Open release valve to relieve pressure.

If adjustment is required for the jack system relief valve, perform the following procedure:

1. Remove plug (figure 3, item 8) to expose system relief valve. Close release valve (figure 3, item 2).

2. Place jack in a load indicating test fixture. Make sure the test adapter is 1 1/4 inch female spherical

radius. Operate hand pump to extend plunger against the test adapter.

3. While operating the hand pump, adjust set screw (figure 3, item 9) until the system relief valve bypasses hydraulic fluid back to the reservoir at 105.0 to 110.0 tons.

4. Replace plug (figure 3, item 8). Once more operate hand pump to verify correct setting.

5. Open release valve to relieve pressure.

If adjustment is required for the hydraulic caster relief valves (if so equipped), perform the following

procedure:

1. Remove plug (figure 11, item 12) to expose relief valve. Close release valve (figure 11, item 6).

2. Remove plug (figure 11, item 33) and install a 0-1000 psig test gauge.

3. Operate the hydraulic caster hand pump (figure 11, item 17) to fully extend caster. Continue to

operate hand pump until the relief valve by-passes hydraulic fluid back to the reservoir at 900 ± 20

psig (63.3 ± 1.4 kg/sq cm).

4. Replace plug (figure 11, item 12). Once more operate hand pump to verify correct setting.

5. Open release valve to relieve pressure, remove test gauge and replace plug (figure 11, item 33).

6. Repeat for other hydraulic casters.

SPECIAL TOOLS:

The following special tools are necessary to disassemble/reassemble the cylinder assembly, the hydraulic

casters (if so equipped) and the shock absorber assembly (if so equipped). These tools may be

purchased upon request:

Part No. Description Qty

79588 Spanner wrench, retaining nut---------------------------------------------------------------------- 1

490-028 Spanner wrench, hydraulic caster cap------------------------------------------------------------ 1

78957 Lifting tool, extension screw ------------------------------------------------------------------------- 1

79589 Lifting tool, plunger------------------------------------------------------------------------------------- 1

78956 Lifting tool, tripod head-------------------------------------------------------------------------------- 1

78955 Lifting tool, cylinder

872845 Accumulator test gauge assembly, 0-300 psig------------------------------------------------- 1

------------------------------------------------------------------------------------- 1

RECOMMENDED SPARE PARTS:

The following spare parts are recommended and available upon request.

Part No. Description Qty

Standard Spare Parts

795PK Repair parts kit ------------------------------------------------------------------------------------------ 1

56010-1 Valve block assembly --------------------------------------------------------------------------------- 1

79366 Release valve knob

79365 Release valve stem ------------------------------------------------------------------------------------ 1

65228 Release valve lockscrew ----------------------------------------------------------------------------- 1

55155 Safety pop-off valve assembly---------------------------------------------------------------------- 2

79571-1 Hand pump assembly

55762-7 Pump handle--------------------------------------------------------------------------------------------- 1

76347 Reservoir gasket---------------------------------------------------------------------------------------- 1

79562 Filler cap with dipstick--------------------------------------------------------------------------------- 1

424-005 Drain cock valve

Property of American Airlines

------------------------------------------------------------------------------------ 1

--------------------------------------------------------------------------------- 1

---------------------------------------------------------------------------------------- 1

- 6 -

55991-14 Placard, tonnage, 100 ton---------------------------------------------------------------------------- 1

79596 Placard, instruction------------------------------------------------------------------------------------- 1

55998 Sticker, Malabar----------------------------------------------------------------------------------------- 2

55994 Sticker, fluid ---------------------------------------------------------------------------------------------- 1

75940 Sticker, towing

79536A Spring loaded swivel caster with swivel lock---------------------------------------------------- 3

79307 Lower bearing-------------------------------------------------------------------------------------------- 1

79619 Upper bearing-------------------------------------------------------------------------------------------- 1

79386 Ship adapter

79595 Rain hat---------------------------------------------------------------------------------------------------- 1

441-001 Air pump--------------------------------------------------------------------------------------------------- 1

441-030 Seal kit, air pump

421-004 Air valve --------------------------------------------------------------------------------------------------- 1

425-001 Air relief valve-------------------------------------------------------------------------------------------- 1

471-001 Lubricator ------------------------------------------------------------------------------------------------- 1

499-001 Muffler

481-001 Oil screen ------------------------------------------------------------------------------------------------- 1

431-010 Electric motor -------------------------------------------------------------------------------------------- 1

440-055 Hydraulic gear pump----------------------------------------------------------------------------------- 1

432-020 Flexible coupling---------------------------------------------------------------------------------------- 1

79368 Load gauge----------------------------------------------------------------------------------------------- 1

424-001 Shutoff valve --------------------------------------------------------------------------------------------- 1

------------------------------------------------------------------------------------------------------ 1

------------------------------------------------------------------------------------------- 1

---------------------------------------------------------------------------------------------- 1

Air Pump Kit Spare Parts

--------------------------------------------------------------------------------------- 1

Electric Motor - Hydraulic Pump Spare Parts

Load Gauge Kit Spare Parts

Adjustable Foot Kit Spare Parts

75941 Sticker, footpad------------------------------------------------------------------------------------------ 3

79225 Level assembly------------------------------------------------------------------------------------------ 1

Hydraulic Caster Kit Spare Parts

8818PK Hydraulic caster repair parts kit--------------------------------------------------------------------- 3

881802-1 Swivel caster--------------------------------------------------------------------------------------------- 1

881802-2 Swivel caster with swivel lock----------------------------------------------------------------------- 2

483-006 Breather --------------------------------------------------------------------------------------------------- 3

79366 Release valve Knob

79365 Release valve stem ------------------------------------------------------------------------------------ 3

65228 Release valve lockscrew ----------------------------------------------------------------------------- 3

881816 Safety pop-off valve assembly---------------------------------------------------------------------- 3

490-029 Shock Absorber ----------------------------------------------------------------------------------------- 3

MS28778-6 O-ring------------------------------------------------------------------------------------------------------- 6

76378 Safety chain assembly -------------------------------------------------------------------------------- 1

421-004 Air valve --------------------------------------------------------------------------------------------------- 1

85416 Release valve-------------------------------------------------------------------------------------------- 1

76158 Placard, caution----------------------------------------------------------------------------------------- 2

Property of American Airlines

------------------------------------------------------------------------------------ 3

Shock Absorber Kit Spare Parts

Ladder Assembly Kit Spare Part

Remote Control Kit Spare Parts

- 7 -

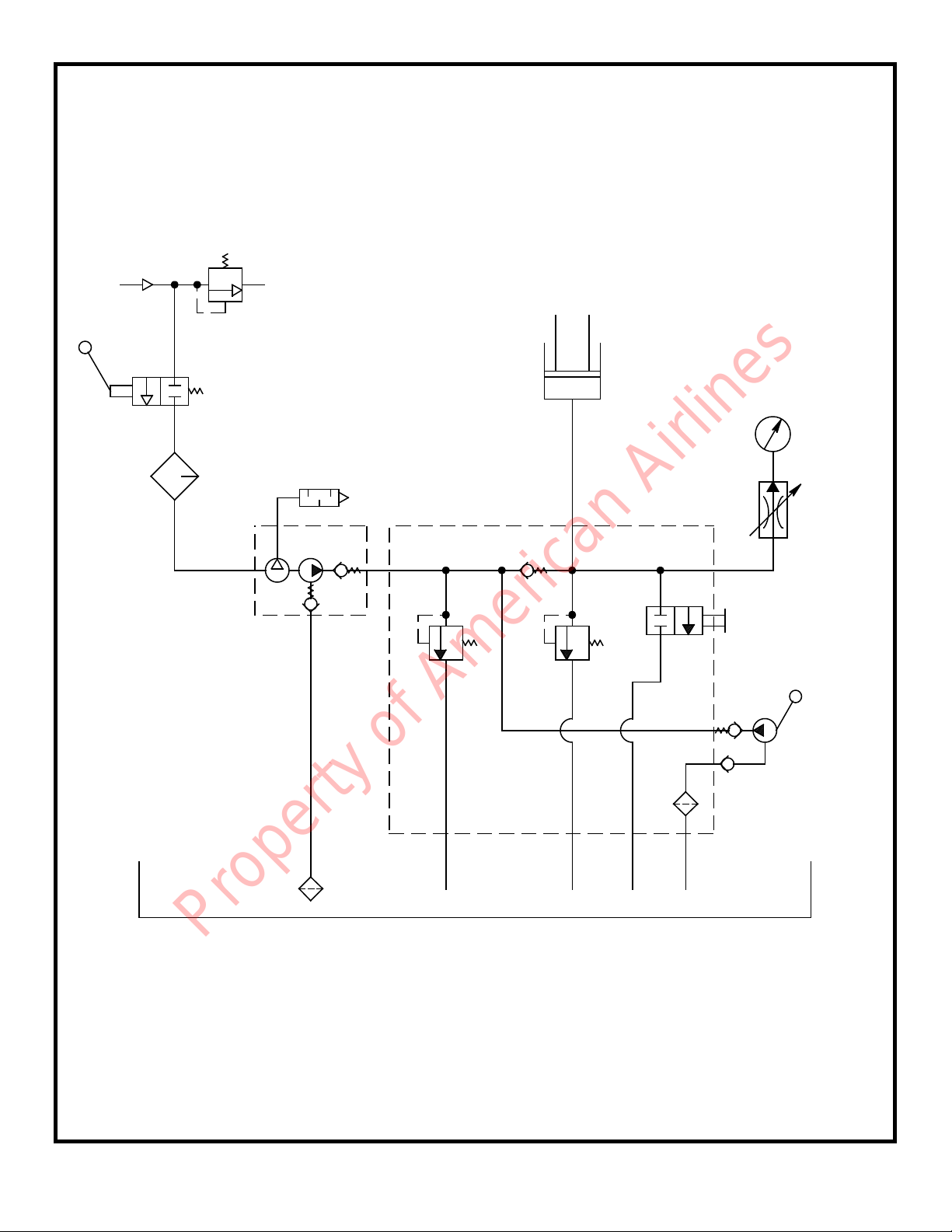

AIR INLET

PNEUMATIC / HYDRAULIC DIAGRAM

A

B

C

D

E

H

G

K

L

M

J

F

N

P

A

- AIR RELIEF VALVE

B

- AIR VALVE

C

- LUBRICATOR

D

- AIR PUMP

E

- MUFFLER

F

- OIL SCREEN

G

- VALVE BLOCK

F

Property of American Airlines

RESERVOIR

H

- SYSTEM RELIEF VALVE

J

- THERMAL RELIEF VALVE

K

- CYLINDER ASSEMBLY

L

- LOAD GAUGE

M

- SHUTOFF VALVE

N

- RELEASE VALVE

P

- HAND PUMP

- 8 -

Loading...

Loading...