TC.3000

Panel Carrier

INSTRUCTION MANUAL

Attention: Read the instruction manual before using the appliance.

1

Instruction Manual

• Do not overreach on the equipment. Maintain

balance and feet in comfortable position at all times.

Important information you should know:

• The images in this manual are illustrative and are

meant to demonstrate the correct operation of your

product, there may be small changes in relation to the

images.

Online Support: Visit our YouTube

Channel to nd several videos

that will assist you with Maksiwa

machines. Use the QRCode.

READ ALL INSTRUCTIONS

CAUTION:

If maintenance is required, replace only with identical

parts. Also, repair or replace faulty wiring.

SAFETY INSTRUCTIONS

FOR ALL EQUIPMENT

WARNINGS

• Keep a clean work surface. Cluttered areas and work

surfaces invite accidents.

• Do not use the Panel Carrier in hazardous

environments. Do not use the machine in damp or

wet locations or areas that are exposed to rain. Keep

in a well-lit work area.

• Keep children away from machines. Visitors should

be kept at a safe distance from the work area.

• Keep all tools in order. Keep tools sharp and clean for

better and safer performance. Follow the instructions

for lubricating and changing accessories.

• Check for damaged parts before continuing the use

of Panel Carrier. Any part that is damaged should be

examined carefully to determine its proper operation

and perform its function properly. Check the alignment

of moving parts, breakage of parts, mounting and any

other condition that may aect its operation. Any

part that is damaged should be repaired or replaced

immediately.

CAUTION: Failure to heed these warnings may result

in severe injury or damage to the machine.

ALWAYS USE PROPER PROTECTIVE

EQUIPMENTS TO OPERATE THIS

MACHINE.

• Always use safety glasses. Also use face or dust mask

if cutting operation is dusty. Everyday eyeglasses only

have impact resistant lenses, they are NOT safety

glasses.

• Make sure that the knobs and screws are properly

tightened and safe before starting any operation.

WARNING: Some dust created by the act of sanding,

cutting, grinding, drilling and other constructionrelated activities contains chemicals that can cause

cancer, birth defects or other reproductive harm.

Some examples of these products are: Lead-based

paint; crystal silica bricks, concrete and other masonry

products; and arsenic and chromium from chemically

treated wood.

• Make the workplace childproof making use of

padlocks.

• Do not force tools. Tools should be used for the

intended use only.

• Use appropriate equipment. Do not wear loose

clothing, jewelry, or other accessories that could get

caught in moving parts.

• It is recommended wearing shoes with non-slip soles.

Use protection for the hair in order to hold them.

• Always wear safety glasses. Also use hearing

protection.

Do not operate the machine unless the guards are in

their proper places. Always use protective goggles.

Familiarization

Use the pictures and read the descriptions carefully

to familiarize yourself with its components. The next

section will deal with the necessary adjustments for

the proper functioning of the machine. You should

know these parts and where they belong.

Specications

The TC.3000 Panel Carrier was made to facilitate

the day-to-day tasks of the modern woodworker.

Its durable structure and 4-wheels allow anyone to

2

easily carry up to 2 full sheets of wood at once. It

has an adjustable height mechanism making it easy to

work in conjunction with virtually any woodworking

equipment you have, such as panel and table saws.

With a carrying capacity of up to 254 pounds, this will

help you increase productivity, reduce injuries from

carry heavy loads, and it only requires one person to

operate it.

Minimum table height: 33”

Maximum table height: 37”

Equipment dimension: 43” x 49” x 28”

Maximum capacity: 254 Lbs

Maximum panel size: 108” x 1” x 72”

Weight: 70.5 Lbs

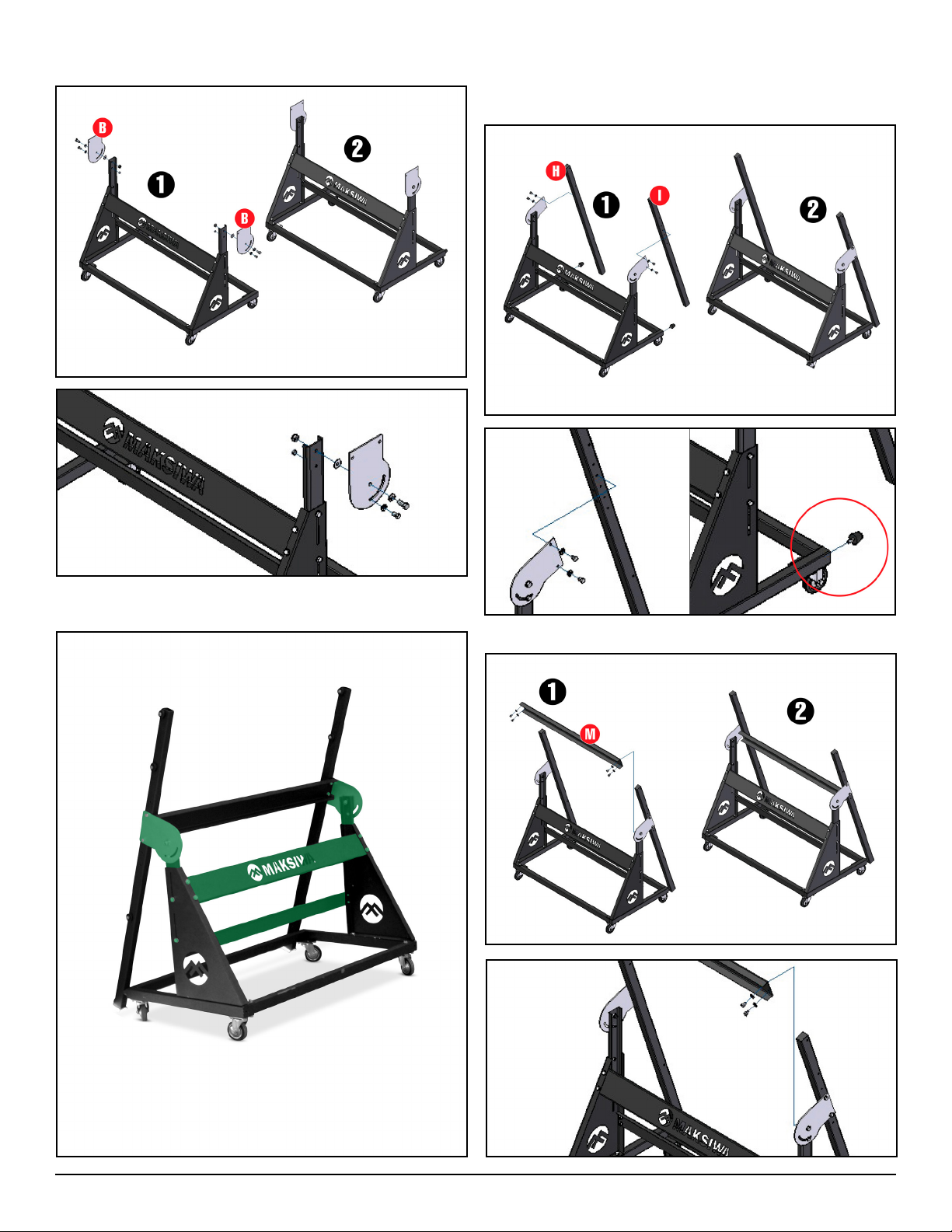

H - Left bar panel support;

I - Right bar panel support;

J - Support panel section set;

K - Support height regulation;

L - Structure cross reinforcement;

M - Top reinforcement;

N - Structure upper reinforcement.

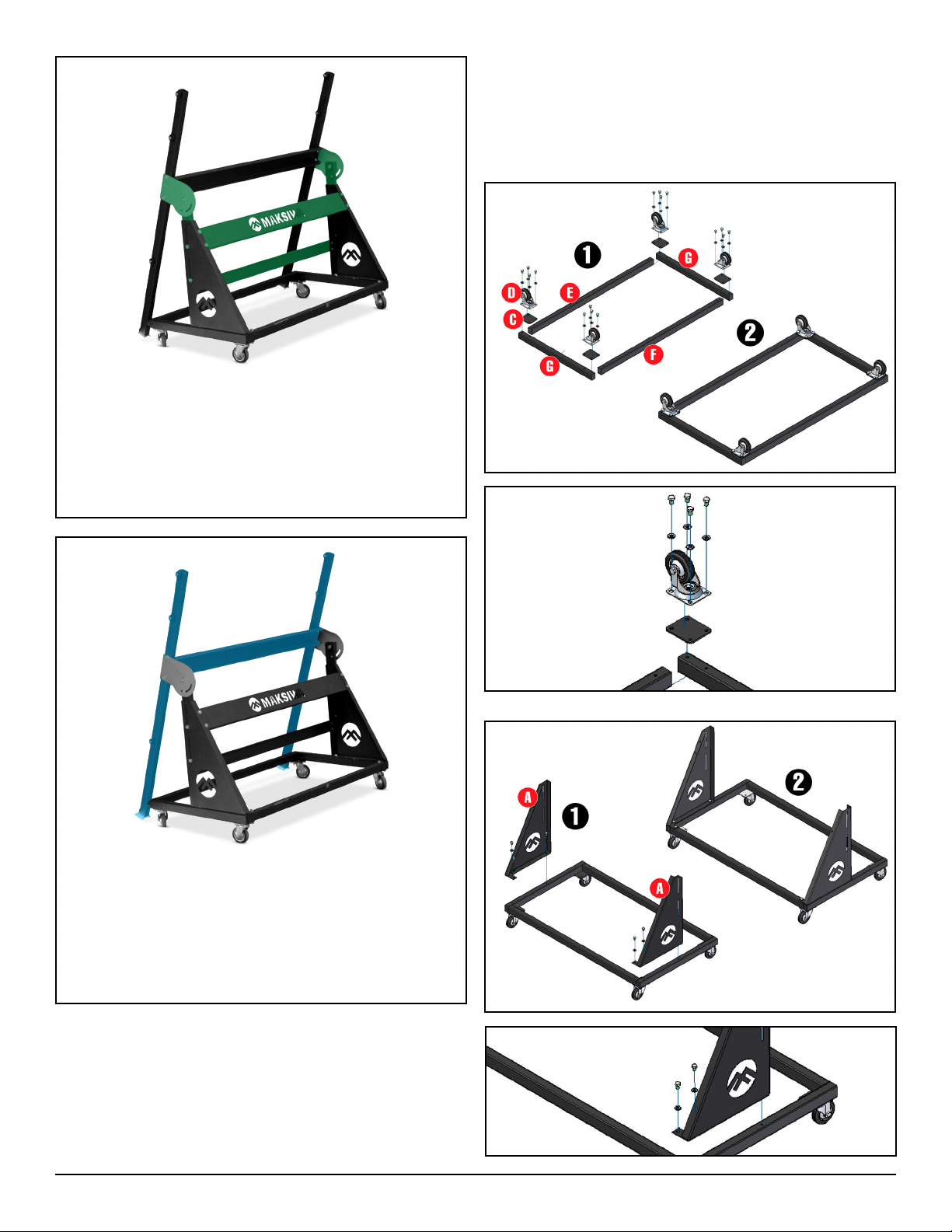

ASSEMBLY

Transport and Installation

By ergonomic issues, this equipment must be carried

by at least two people.

For packaging purposes, the machine is not fully

assembled. If you notice any damage caused by

transportation, while you open the package, notify

your supplier immediately. Do not operate the

machine.

Please dispose the packaging in an environmental

friendly way.

CONTENTS

You will receive the pieces in 3 kits with their respective

screws.

Kit 1:

- Left and right structures

- Crossbar rear structure

- Front structure

- Side structure crossbar assembly

- Base structure wheels

- Mobile rubber wheels 3”

- Screws, nuts, washers, and bolts

A - Left and right structures;

B - Support panel;

C - Base structure wheels;

D - Mobile rubber wheels 3”;

E - Crossbar rear structure;

F - Front structure;

G - Side structure crossbar assembly;

3

Kit 2:

- Support panel

- Support height regulation

- Structure upper reinforcement

- Structure cross reinforcement

- Screws, nuts, washers, and bolts

First, assemble the kit 1:

1) Mount the panel carrier base with the drive wheels.

Take the structures and align them at the vertices of

the base. After that, place the drive wheels and screw

them.

Detail

Kit 3:

- Left bar panel support

- Right bar panel support

- Top reinforcement

- Support panel section set

- Screws, nuts, washers, and bolts

2) Mount the left and right structures.

Detail

4

Ready! Kit 1 is properly mounted.

2) Mount the structure upper reinforcement.

Detail

Now, assemble the pieces of Kit 2:

1) Mount the structure cross reinforcement.

3) Mount the side structure crossbar assembly.

Detail

Detail

5

4) Mount the support panel.

Finally, assemble Kit 3:

1) Mount the left and right bar panel support.

Detail

Detail

Ready! Kit 2 is properly assembled.

2) Mount the structure cross reinforcement.

Detail

6

3) Mount the support panel section set.

Kit 3 is assembled.

4) Install all pulleys.

Ready! The TC.3000 Panel Carrier is subject to

assembly. Before using, remember all safety and

installation regulations.

Detail

7

WARRANTY TERMS

MAKSIWA assures the owner that their equipment,

identied by the Serial number issued on the Warranty

Terms.

The equipment under warranty, for two (2) years, is

as followed:

g) Damage caused by bad weather (oods, ooding,

lightning, power outages etc.).

For your safety, trust the repairs, maintenance and

adjustments (including inspection and replacement)

for technical assistance recommended by MAKSIWA,

always use genuine spare parts and accessories,

reassembling to its original machine the same way.

1. The warranty period begins on the date of the

Warranty Terms below.

2. Within the warranty period, the manual labor and

the components replaced by manufacturing defect

will be provided for free as long as duly proved by

Maksiwa Service.

3. Third-party manufacturing equipment that makes

up the MAKSIWA equipment (such as motors,

electrical equipment, belts etc.) are subject to the

terms and conditions of warranty of their respective

manufacturers.

4. In case an exchange of machine is needed, please

return the defective part or machine to MAKSIWA.

5. All workplace adaptations for the equipment are

under the responsibility of the machine owner.

6. If you notice any defect or malfunction when

receiving the equipment, get in touch immediately

with the manufacturer or Dealer. Do not turn it on.

7. Not included in this warranty is any technical visits

aimed at cleaning or adjustments caused by wear,

resulting from normal use of the equipment.

Maksiwa International Inc.

4100 N Powerline Rd, Suite D1

Pompano Beach - Florida - USA

ZIP CODE: 33073

www.maksiwa.com

8. The warranty does not cover problems caused by

mistreatment, carelessness, misuse or inappropriate

use of the functions designed for this equipment in

this manual, as well as poorly executed operations by

untrained operators to operate it.

9. MAKSIWA is not responsible for lost productivity,

direct or indirect damages caused to the owner of the

equipment or to third parties, or any other expense,

including lost prots.

10. Even under warranty, you may lose its validity as

follows:

a) Application of non-original components;

b) Alteration of its original features;

c) Lack of proper maintenance;

d) Improper use of the equipment;

e) Change in equipment or electronic connections;

f) Damage caused by mechanical shock or exposure to

unsuitable conditions (humidity, salt spray, corrosive

agents, etc.);

8

16

19

15

20

26

27

17

28

18

25

24

22

21

23

3

3

2

10

13

12

11

1

8

14

4

5

6

7

9

28 HEX SCREW M8X16 ZB 2

27 SCREW M10X25 ZB 2

26 FLAT WASHER M10 ZB 2

25 SCREW AUTO PILOT PARLOCK M10 2

24 FLAT WASHER 3/8 ZB 2

23 SCREW M8 X 20 ZB 2

22 SUPPORT PANEL 2

21 SCREW AUTO PILOT PARLOCK M8 8

20 PA 6.6 BLACK 8X9X30 12

19 SCREW M8 X 60 ZB 6

18 SUPPORT PANEL SECTION SET 1

17 LEFT BAR PANEL SUPPORT 1

16 RIGHT BAR PANEL SUPPORT 1

15 TOP REINFORCEMENT 1

14 FRONT SUSPENSION LOWER TRAY BRACKET 2

13 STRUCTURE UPPER REINFORCEMENT 1

12 STRUCTURE CROSS REINFORCEMENT 1

11 LEFT STRUCTURE 1

10 RIGHT STRUCTURE 1

9 FRONT STRUCTURE 1

8 CROSSBAR REAR STRUCTURE 1

7 HEX SCREW M8X12 ZB 40

6 FLAT WASHER M8 ZB 52

5 MOBILE RUBBER WHEELS 3” 4

4 BASE STRUCTURE WHEELS 4

3 HEX SCREW M8 ZB 12

2 SUPPORT HEIGHT REGULATION 2

1 SIDE STRUCTURE CROSSBAR ASSEMBLY 2

Nº REF. NAME QTY.

PANEL CARRIER

1

9

Loading...

Loading...