Page 1 of 13

PPH MAKOT

ul. Przewóz 34/304

30-716 Kraków | Poland

www.makot.pl

+ 48 537 872 522 (Sales Department)

+ 48 602 260 992 (Technical Department)

biuro@makot.pl (Sales Department)

dt@makot.pl (Technical Department)

1. DESCRIPTION.

Temperature regulators of SMT series are a microprocessor-based, programmable

temperature controllers, intended for use i.a. in milk coolers and all types of dryers.

The series includes the following regulators:

− SMT-01,

− SMT-02,

− SMT-02H,

− SMT-03.

Individual types differ from each other in the way of output of control inputs and

outputs. The casing of regulators in this series are adapted for panel mounting.

2. TECHNICAL DATA.

temperature measuring range

between -40 OC and +120 OC

control temperature range

between -40 OC and +120 OC

(decreased by a set hysteresis)

measuring resolution of the

temperature measurer (resolution

of control temperature settings)

1 OC for the range below -9,9 OC

0,2 OC for the range from -10 OC to +100 OC

1 OC for the range over +100 OC

control hysteresis

[programmable parameter]

between 0,2 OC and 10 OC for the range from -10 OC to +100 OC

between 1 OC and 10 OC for the range <-10 OC and >+100 OC

working time of the stirrer

(ventilator)

[programmable parameter]

between 1 min. and 60 min.

standstill time of the stirrer

(ventilator)

[programmable parameter]

between 1 min. and 60 min.

temporary work time of the stirrer

(ventilator)

[programmable parameter]

between 1 min. and 60 min.

time delay for switching the unit /

stirrer on after the regulator is

between 1 s. and 999 s.

Page 2 of 13

turned on or the power supply

decay occurs

length of control sensors

5 m

type of temperature sensor

thermistor NTC

type of temperature measurer

digital LED

load capacity of relay contacts

controlling the unit (heating system)

30 A 250 V AC

load capacity of relay contacts

controlling the stirrer (ventilator)

10 A 250 V AC

power supply

230 V AC 50 HZ

protection class

IP 55

safety class

CE

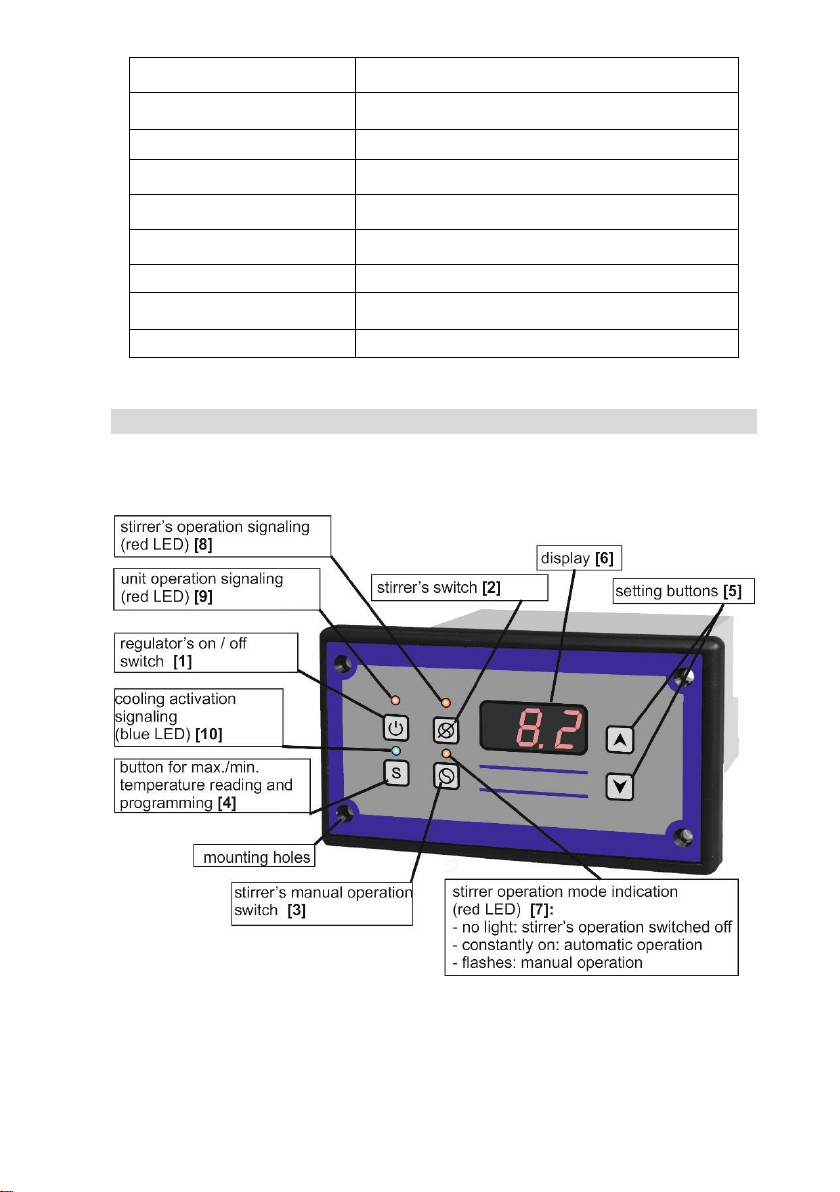

3. CONSTRUCTION.

Regulator SMT is placed in a compact casing, including all control and executive

elements:

The regulator is equipped with:

✓ button for switching the regulator on and off [1],

✓ button disabling automatic stirrer (fan) operation [2],

✓ button enabling manual operation of the stirrer (fan) [3],

✓ digital temperature meter allowing for current temperature control, independently

from switching on or off the regulator [6],

Page 3 of 13

✓ LEDs signaling the current operating status of the cooling (heating) unit and the

stirrer (fan) [7] [8] [9] [10]

✓ input for connecting the limit switch,

✓ control outputs, that is:

− unit control output (heating system),

− stirrer (fan) control output.

In the figure above, the types of outputs and inputs are shown, depending on the type

of regulator.

The regulator SMT-02H v. 3, apart from cable entry through glands, has a sealing

connection of the front part of the casing with its back, which ensures splash-proofness.

ATTENTION

The blue LED indicates the activation of the cooling (heating) mode. If the LED is off,

and the regulator is connected to the mains, it means the cooling (heating) operation

of the regulator is switched off. However, you can switch on the stirrer’s manual

operation by pressing the button [3].

Page 4 of 13

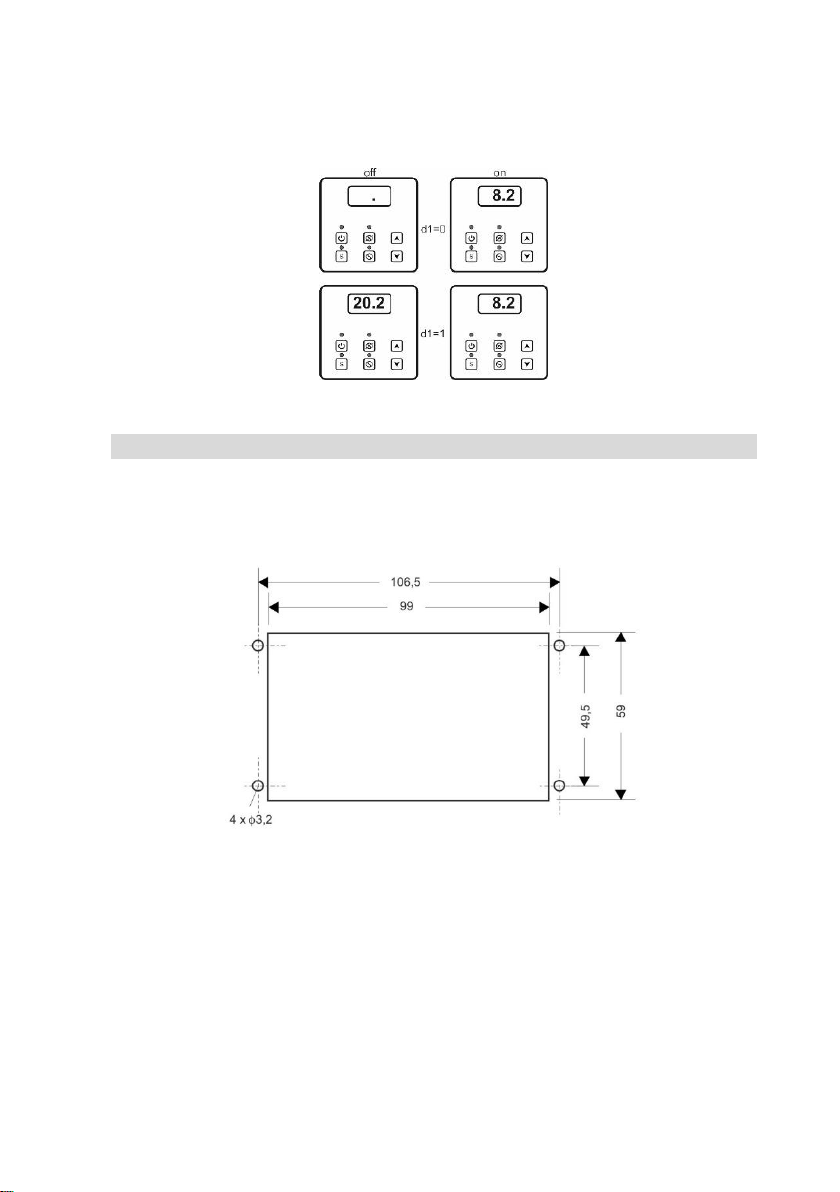

If the regulator’s control operation is switched off, a dot is displayed on the regulator's

display (factory settings). By changing the parameter d1 (see 6. PROGRAMMING) from

the value 0 for value 1, when the regulator is switched off, the display will show the

current measured temperature.

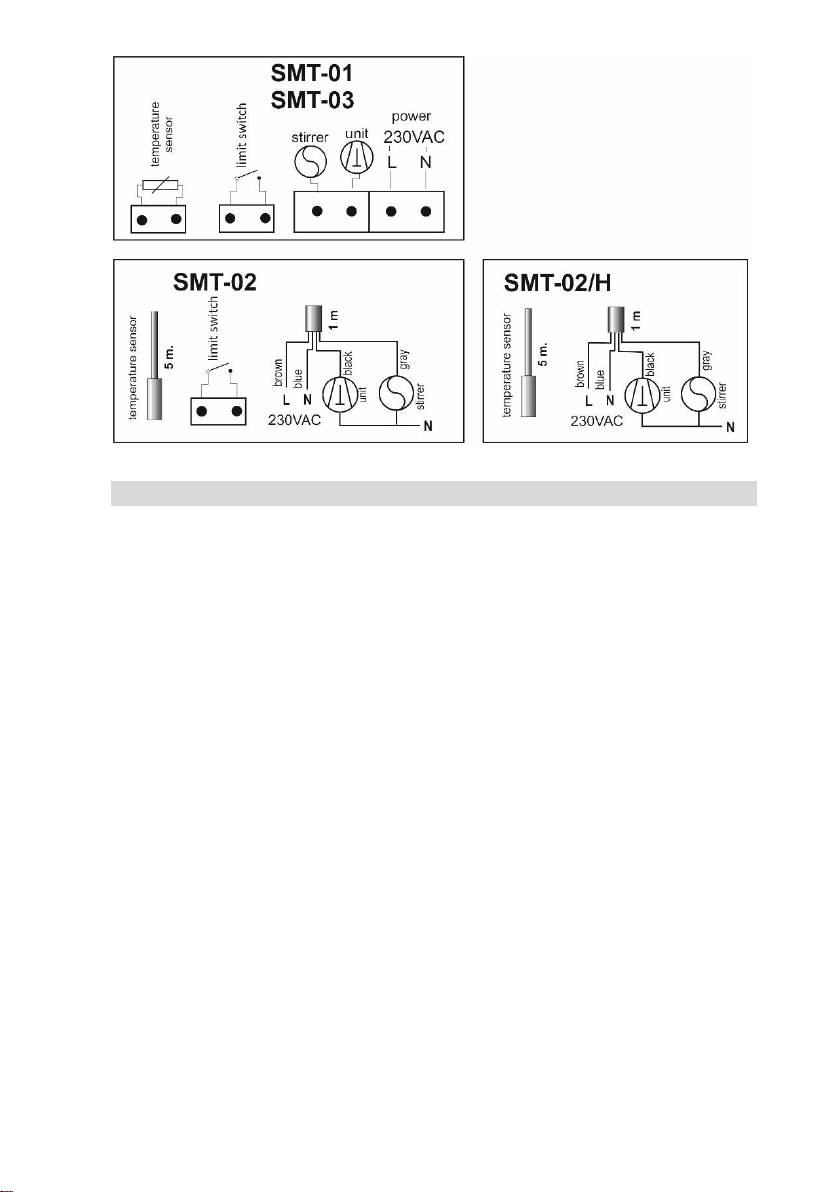

4. SCHEME OF CONNECTION OF THE REGULATOR.

In order to connect the regulator to the device with which it is to be controlled,

the following should be done:

✓ prepare the hole in the refrigeration device to install the regulator

✓ place the regulator in the prepared hole and screw it in properly,

✓ place the temperature sensor inside the cooling chamber in the most convenient

place for temperature measurement and at the same time shielded from accidental

damage,

✓ connect the regulator to the outputs located on the rear wall of the casing, according

to the following scheme:

Page 5 of 13

5. REGULATOR FUNCTIONS.

The regulator is equipped with a number of functions that, together with the possibility

of creating your own program, enable adjusting the regulator's work to the individual

needs of the user. Some of the functions listed below are activated after the appropriate

programming of the regulator (see 6. PROGRAMMING and 9. SETTING TABLE).

1. Continuous temperature measurement function, regardless of whether

the regulator is on (regulator must be connected to the power supply) – parameter

d1 is set to 1.

2. The function of controlling the refrigeration system (unit), depending on the

measured temperature – parameter C9 is set to the value 0.

3. Light signaling function for switching on the cooling (heating) operation – blue LED

is on.

4. Control function of the heating system, depending on the measured temperature –

parameter C9 is set to 1.

5. The stirrer or fan control function enabling the implementation of the following

variants of this control – depending on the F0 parameter settings:

a. automatic operation:

− cyclic operation of the stirrer (fan), independent of the operating condition

of the unit (heating system),

− stirrer operates continuously during the operation of the unit, when the unit

is switched off, the stirrer goes into cyclic operation,

− stirrer (fan) works only when the unit (heating system) is switched on,

− continuous stirrer (fan) operation while the regulator's operation is on (main

application in dryers),

Page 6 of 13

− switched off stirrer (fan) operation,

b. operation triggered manually:

− switching on continuous stirrer (fan) operation, regardless of whether

the control operation of the regulator is switched on; in order to end

the stirrer (fan) operation, press the button [3],

− switching on the stirrer (fan) operation for a strictly defined time, regardless

of whether the control work of the regulator is switched on.

6. Blocking function of the stirrer and the unit when the flap of the milk cooler tank

opens (actuation of the limit switch) – parameter AF. In dryers it can be used to turn

off the fan, e.g. when the door is opened.

7. Defining the operation of the limit switch as negative or positive – parameter UU.

8. The unit operation supervision function, consisting in the possibility of setting

the maximum and minimum working time of the unit, as well as the minimum

standstill time of the unit – parameters E1 and E2.

9. The function of registering the maximum and minimum temperature values

throughout the regulator's working cycle. This function is connected with

the possibility of temporally delaying the recording of temperature data to the

regulator's memory since its activation – parameter AA.

10. The function of alarm signaling (visual and audible) of exceeding the set temperature

range – parameters HA and HE. This function is connected with the possibility

of delaying the time of switching on the alarm system of the regulator from

the moment of its activation.

11. Monitoring and signaling function of the damage to the temperature sensor – in such

case the letters ACU appear on the display.

12. Function of adjustable delay time for switching on the unit and stirrer after decay

and re-switching on the voltage – parameter dE.

6. PROGRAMMING.

In order to ensure the correct working cycle of the regulator, it is necessary to program

its operating parameters accordingly. By default, the controller is programmed

for standard operating conditions for the purpose of controlling the milk cooler.

In order to change the factory setting, enter the setting mode. This is done by holding

the button marked with the letter S for approx. 17 seconds. After entering the setting

mode UCO appears on the display. The next pressing of the S button confirms

the willingness to make changes. Then press the ▲ key to enter the access code and

confirm with the S button. After correct entry into the setting mode, the ▲ and ▼

buttons are used to select the desired parameter. The entry to the parameter settings is

made by pressing the S button. The change of the parameter value is made using the ▲

and ▼ buttons; for the change to be saved, confirm with the button S. The exit from

Page 7 of 13

the setting mode is made by setting the EE parameter and confirmation with the S button

or automatically after 17 seconds of inactivity. The following figure illustrates

the programming procedure:

7. THE REGULATOR’S WORK CYCLE.

When the regulator is connected to the mains and its operation is switched on with

the button [1], the regulator – after the delay set in parameter dE – goes to the control

phase.

The regulator controls two control circuits:

a. control circuit for the refrigeration (heating) unit;

b. control circuit for the stirrer’s (fan’s) motoreducer.

The work for the control settings of the refrigeration system will be discussed below.

ATTENTION

Parameter dE is the delay of switching on the unit and the stirrer after switching on

the regulator's work or after the supply voltage decay – default value is set to 5 sec.

7.1. Control of the refrigeration unit.

The temperature control value (within the range specified in parameters b1 and b2) is

set by pressing the buttons marked with the symbols ▲ and ▼, while short pressing any

of these buttons displays the currently set value, while only the next pressing causes

the change of this value. Transition on the display from reading the measured

temperature to the reading of the set control temperature is signaled by the flashing

of digits / numbers.

Page 8 of 13

The unit control in the cooling phase takes place depending on the temperature present

in the refrigeration chamber. The regulator can control the cooling temperature in the

range of -40 OC up to +120 OC. In order to limit the scope of the control so as to prevent

the user of the cooling device from setting the temperature outside this range, set the

proper parameters: b1 (limitation of the lower control temperature range) and b2

(limitation of the upper control temperature range).

ATTENTION

Temperatures specified in parameters b1 and b2 do not indicate control points

for switching off and switching on the operation of the unit.

Setting b1 = b2 blocks the possibility of changing the programmed temperature

by means of the ▲ and ▼ buttons. It is not allowed to set b1 > b2.

The change in the value of b1 or b2 can be blocked by the currently set control

temperature.

In the event of such a situation, change the control temperature settings and then

change parameters b1 and / or b2.

It is also important to set the control hysteresis correctly – parameter HI. The control

hysteresis is a parameter that determines the temperature difference at which

the switching off occurs and then the unit is switched on. For example, if the control

temperature is set to + 4 OC and hysteresis to 2 OC, then the unit will be switched off

after reaching 4 OC, while its re-activation will occur after the temperature has risen

to 4+2 = 6 OC.

The regulator allows to set the hysteresis of the control in the range of 0.2 OC to 10 OC,

every 0.2 OC.

ATTENTION

If the regulator is set in heating mode, the hysteresis operation has the opposite

character, i.e. the heating system is switched off after the temperature has dropped

below the set value, taking into account the value of the programmed hysteresis.

7.2. Control of the stirrer’s motoreducer.

The working status of the stirrer is signaled by two red LED (see 3. CONSTRUCTION):

− signaling of switching on the stirrer’s motoreducer [8],

− indication of the stirrer operation mode [7].

The regulator has two modes of stirrer operation, i.e. automatic or manual, which are

described in detail below.

7.2.1. Automatic stirrer operation.

In this mode, depending on the settings of parameters F0, E1 and E2, the stirrer may be

connected to the operation of the unit or completely independent of the operation

of the unit (see 9. TABLE OF SETTINGS).

The stireer operation setting in the automatic mode is signaled by the continuous

lighting of the red LED [7].

Page 9 of 13

The stirrer's operation can be switched off at any time by means of the [2] button

(see 3. CONSTRUCTION), except when the F0 parameter is set to 2 or 3.

Switching off the regulator by pressing the [1] button also turns off the stirrer operation.

7.2.2. Manually triggered stirrer operation.

The manual stirrer operation can be initiated by pressing the button marked by symbol

[3] (see 3. CONSTRUCTION); at this point, the automatic operation of the stirrer stops

and the manual operation starts. Manual operation of the stirrer is also possible when

the regulator is switched off (button [1]) or stirrer operation switched off (button [2]).

The manual operation of the stirrer is not interrupted when the regulator is switched off

manually by pressing the [1] button.

The setting of the stirrer operation in manual mode is signaled by a flashing red LED [7].

The stirrer operation in this mode can be interrupted at any time by pressing the button

again. The manual stirrer operation can take place in two variants, depending on the

CP parameter settings:

− setting the value 0 means continuous stirrer operation,

− setting the value >0 means that the stirrer works for the set number of minutes; after

the set time elapses, the manual operation of the stirrer is switched off.

ATTENTION

No light signaling of the stirrer operation [7] [8] when the regulator is switched off

means that the automatic stirrer operation has been switched off, at the same time

the manual operation has not been switched on.

8. ADDITIONAL FUNCTIONS.

Below, some specific functions of the regulator will be described, enabling the regulator

to be used for various applications.

8.1. Limit switch of the flap.

The regulator is equipped with the possibility of connecting the external limit switch

of the tank flap. The principle of operation of this input consists in immediately switching

off the stirrer's operation at the moment of shorting or opening of this input (depending

on the UU parameter setting), made by the connected limit switch of the flap. The return

of the stirrer operation (after being interrupted by the limit switch) follows after

the disappearance of the flap opening signal with a delay of 5 seconds.

At the same time, depending on the AF parameter settings made, it is possible to disable

the unit operation. The unit operation is switched off with a set delay in relation to the

opening signal of the flap, so that the momentary opening does not immediately stop

the operation of the unit. The unit returns to work after the flap opening signal

disappears, taking into account the programmed minimum standstill time of the unit.

Page 10 of 13

8.2. The function of registering the minimum and maximum temperatures.

The SMT regulator has the function of recording in its internal memory the values

of maximum and minimum temperatures that occur throughout the regulator's

operating cycle. This function makes it possible to check whether the milk is stored under

the correct temperature conditions.

When the device is switched on, after the end of the programmed delay (parameter AA

– see 9. TABLE OF SETTINGS), the temperature values are recorded to the regulator's

memory. The programmable delay time of enabling this function allows for pre-cooling

of the milk after the start of cooling and thus not taking into account the maximum

temperature when the device is started. This time should be selected by the user for the

type of tank and the actual operating conditions of the device.

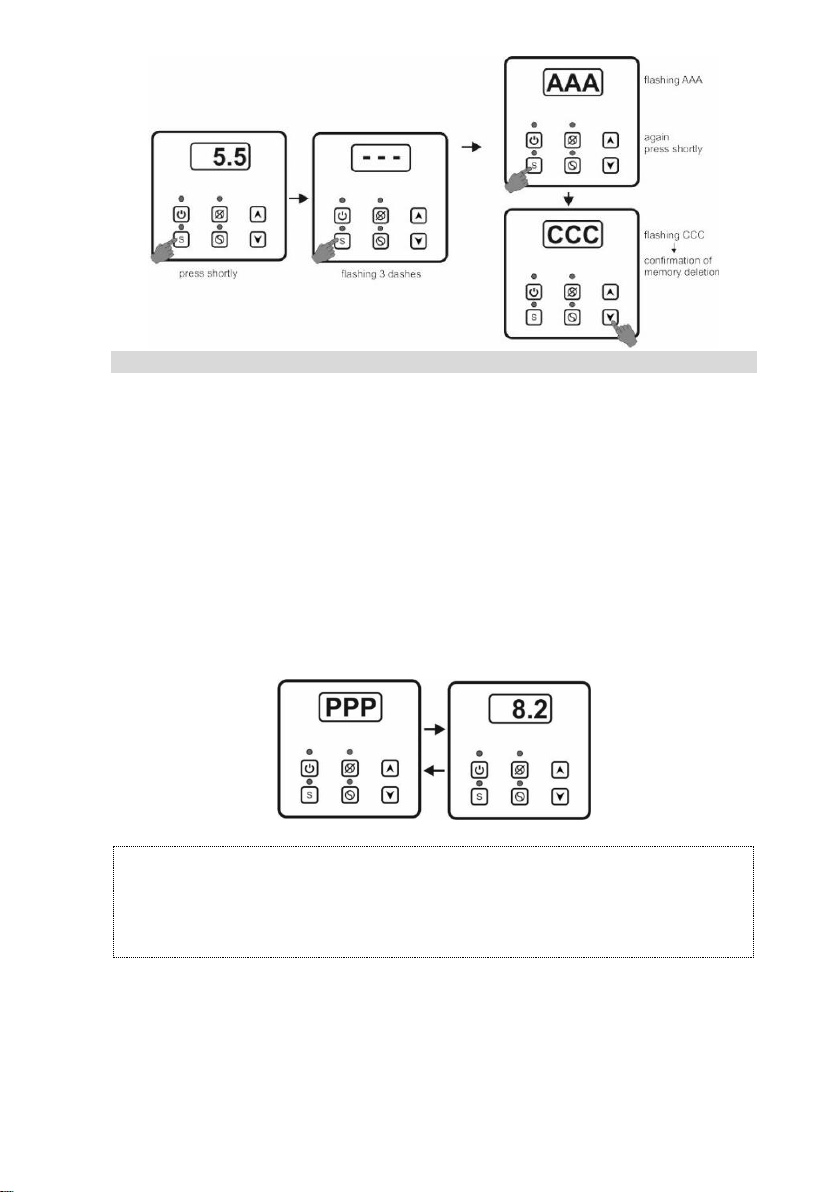

At any time, the user can read the maximum and minimum temperaturę values presently

available. The following figure illustrates reading:

ATTENTION

1. In the absence of entries of maximum and minimum temperatures in the regulator's

memory, the symbol --- is displayed.

2. Power supply loss causes the regulator's memory to be cleared.

At any time, you can manually delete the current maximum and minimum values.

The following figure illustrates manual memory erasing:

Page 11 of 13

8.3. The function of alarm signaling the exceeding of the correct temperature range.

The regulator has the function of signaling the exceeding of the set temperature range.

In order for the function to work properly, the appropriate temperature range must first

be programmed, this is: parameter A1 – temperature below which the alarm will be

activated and parameter A2 – temperature above which the alarm will be triggered

(see 9. TABLE OF SETTINGS).

The third parameter to be defined is the time delay of switching on the alarm function

from the moment the regulator’s operation is switched on – parameter AA. This delay

eliminates the triggering of an alarm in the initial cooling phase.

Exceeding the set temperature range is signaled visually and sound. In the event

of activation of the alarm, the buzzer is triggered cyclically every 1 minute for 5 seconds,

and at the same time letters PPP and the temperaturę value are displayed.

ATTENTION

The parameter AA is identical to the delay specified in the maximum and minimum

temperature recording function. In other words, the delay value set in the parameter

AA will be the same for recording max. and min. temperature and for parameters A1

and A2.

The audible alarm can be turned off by setting the HE parameter to 1 (see 9. TABLE

OF SETTINGS). In this case, exceeding the set temperature range is signaled only visually,

as shown in the figure above. The alarm system (audible and visual) can also be turned

off completely by changing the HA parameter to 1 (see 9. TABLE OF SETTINGS).

Page 12 of 13

8.4. Temperature sensor damage indication.

If the regulator etects damage to the temperature sensor, the letters ACU appears

on the display, and at the same time the audible alarm signal is activated. The operation

of the unit and the stirrer is interrupted until the failure is removed.

ATTENTION

Sensor damage indication also occurs if the range of temperatures measured by the

regulator is exceeded.

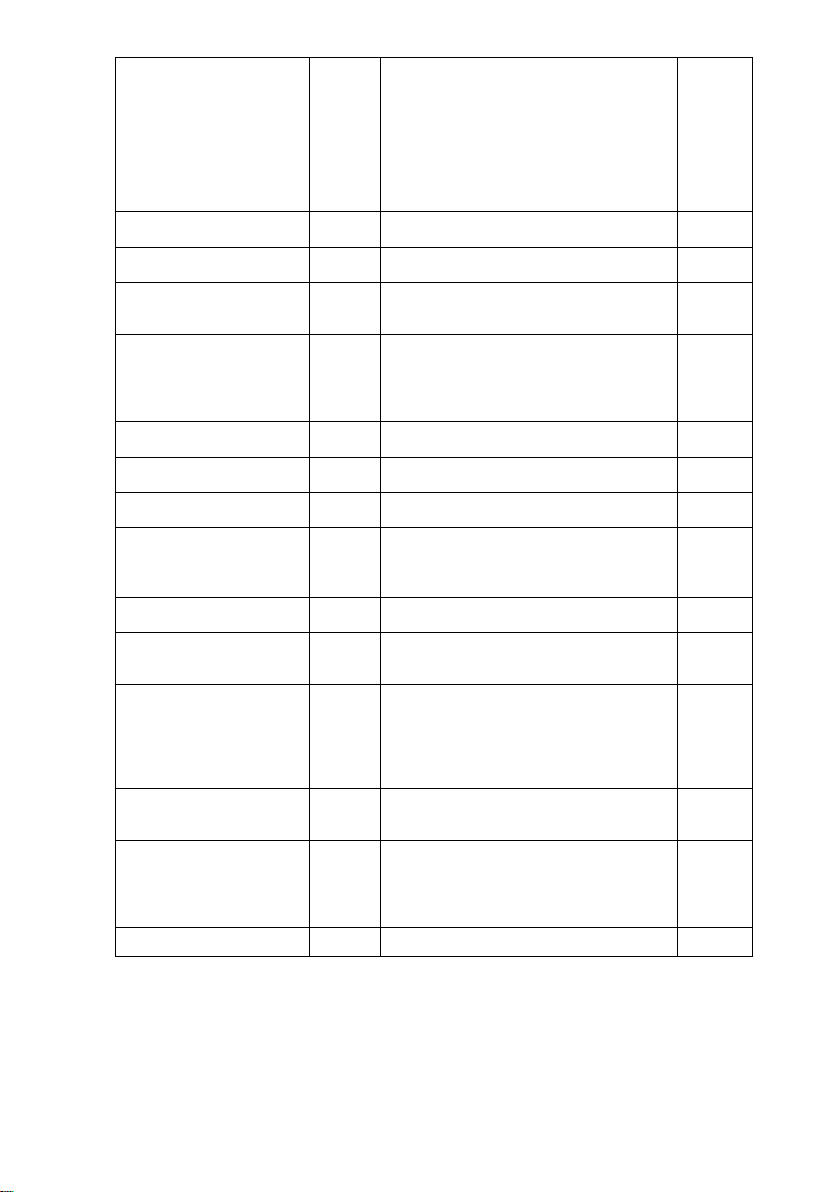

9. TABLE OF SEETINGS.

DESCRIPTION OF THE

PARAMETER

SYMBOL

SETTING RANGE

FACTORY

SETTING

accessing the settings

UC0

access code

1.2

regulator operation mode

C9

0 – cooling

1 – heating

0

limitation of the lower value

for the control temperature

range

b1

the possibility of setting the temperature from

-40 OC to +120 OC, every 1.0 OC

2 (OC)

limitation of the upper value

for the control temperature

range

b2

the possibility of setting the temperature from

-40 OC to +120 OC, every 1.0 OC

10 (OC)

control hysteresis

HI

the possibility of setting the temperature:

• from 0.2 OC to 10 OC, every 0.2 OC – for the

range from -10 OC to +100 OC and

• from 1.0 OC to 10 OC, every 1.0 OC – for the

range of <-10 OC and > + 100 OC

2 (OC)

minimum working time of the

unit

CA

0 – off

1 – on: the possibility of setting the time from

1 min. to 60 min., every 1 min.

0

maximum working time of the

unit

CC

0 – off

1 – on: the possibility of setting the time from

0,5 h to 9,5 h, every 0,5 h

0

minimum standstill time of

the unit (standby)

CF

0 – off

1 – on: the possibility of setting the time from

1 min. to 60 min., every 1 min.

0

time after which the unit is

turned off after the flap of the

milk tank

is opened

AF

0 – off

1 – on: the possibility of setting the time from 0,1

min. (6 s.) to 15 min., every 0,1 min. (6 s.)

0,1

(min.)

[= 6 s.]

stirrer operation mode

F0

0 – operation according to the times set in

the parameters E1 and E2, regardless of the

operation of the unit

1 – continuous operation while the unit is

running; when the unit is on standby, the stirrer

operates according to the times set in the

1

Page 13 of 13

parameters E1 and E2

2 – as in setting 1, but disabling with the

stirrer's working button causes its operation

only during the operation of the unit

3 – as in setting 1, but the button that disables

the stirrer operation is inactive

4 – continuous operation, regardless of the

operation of the unit and times set in the

parameters E1 and E2

standstill time of the stirrer

E1

the possibility of setting the time from 1 min.

to 60 min., every 1 min.

15 (min.)

working time of the stirrer

E2

the possibility of setting the time from 1 min.

to 60 min., every 1 min.

2 (min.)

manual stirrer operation

mode

CP

0 – continuous work

>0 – stirrer operation for a specified time in the

range of from 1 min. to 60 min., every 1 minute

5 (min.)

delay of registering of the

max. / min. values

of temperature and delay

of activation of the

temperature alarm

AA

the possibility of setting the time from 0 h to

24 h, every 0,1 h

2 (h)

lower temperature of the

alarm

A1

the possibility of setting the temperature from

-40 OC to +120 OC, every 1.0 OC

2 (OC)

upper temperature of the

alarm

A2

the possibility of setting the temperature from

-40 OC to +120 OC, every 1.0 OC

12 (OC)

sound of the alarm

HE

0 – on

1 – off

0

visual and sound alarm

of exceeding the set

temperature range

(parameters A1 and A2)

HA

0 – on

1 – off

0

scaling the control sensor**

CU

every 0,2 OC

scalable

value

setting the operation of the

limit switch of opening the

tank’s flap

UU

0 – closing the limit switch: raising the flap

1 – opening the limit switch: raising the flap

0

delay of switching on the unit

and the stirrer after

connecting

the regulator to the mains or

when power supply decay

occurs

dE

from 1 s. to 999 s., every 1 s.

5 (s.)

display status when the

control is switched off

d1

0 – the dot is displayed

1 – the currently measured temperature is

displayed

0

return to factory settings

FA

0

1 – after setting "1" and turning off the

regulator from the power supply, switching on

again restores the factory settings and the

parameter value goes back to "0"

0

leaving the settings

EE

** set at the manufacturing stage (do not change without obvious need)

Loading...

Loading...