Page 1

Automatic

INSTRUCTION MANUAL

Drapery Opener

MODEL ZZCMlOl (CMlOl)

With receiving unit

MODEL ZZCM301 (CM301)

Without receiving unit

c

-

SPEC

Maximum

rod

length

20

I

F

ft.

I

CAT1

0

Maximum weight

60

N

S

of drapery

Ibs.

per mdtor

1I

\

a

7

Track speed of remote

50

ft. per minute

Minimum width

Single Double control unit

5

"

of

valance

8

"

Operating range

32.8

ft.

Page 2

WARNING:

Polarized

Plugs

To reduce the risk of electric shock, the motor has a polarized plug (one blade

a

than the other). This plug will fit in

fit fully in the outlet, reverse the plug. If

trician to install the proper outlet.

Rod

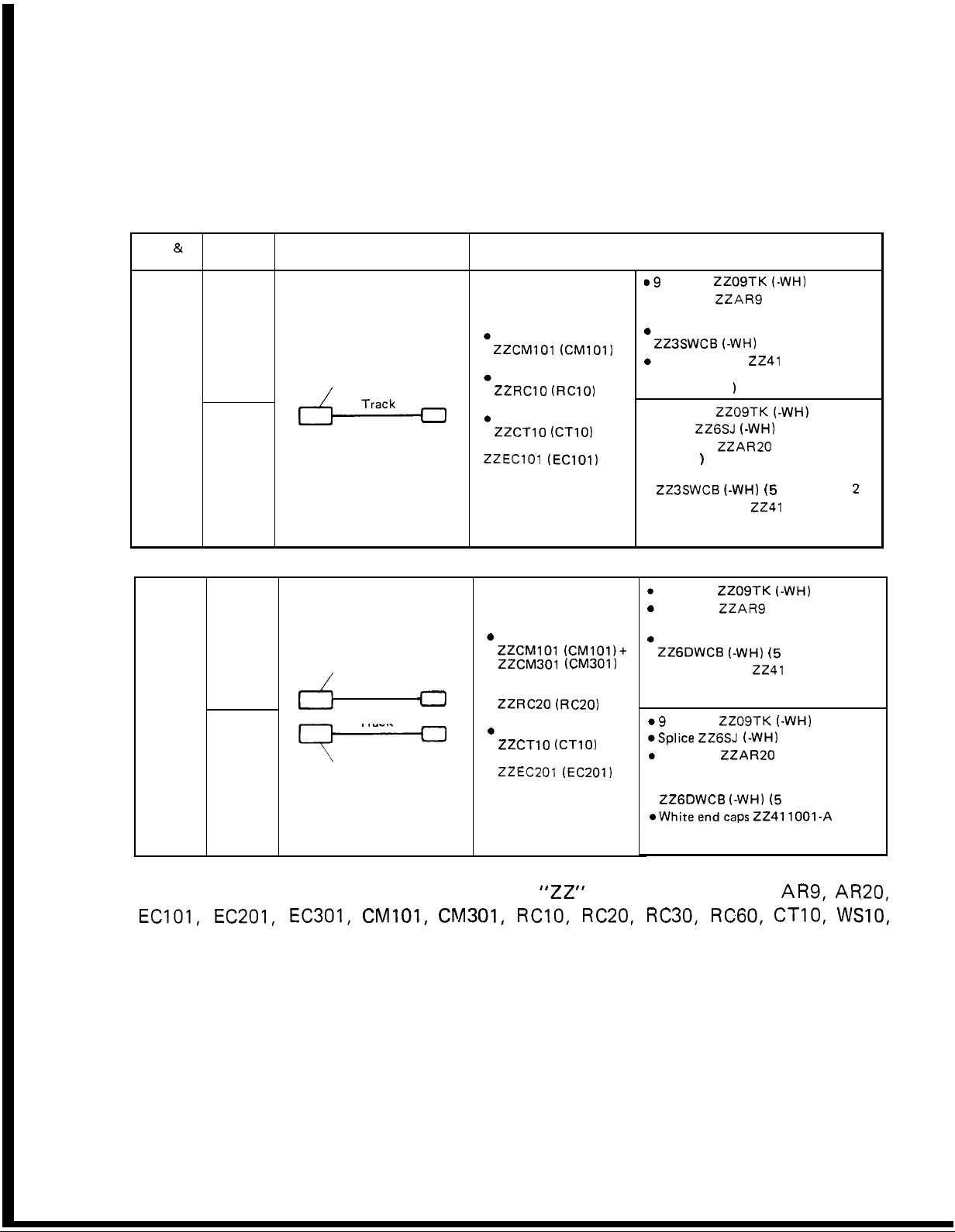

&

Motor

1

Rod

1 Motor

Rod

length

9

FT

18 FT

Assembly chart

Motor

Track

L

polarized outlet only one way. If the plug does not

it

still does not fit, contact a qualified elec

Do

not change the plug in any way.

Components

e9

ft track ZZOSTK (-WH)

0

Rod assy. ZZAR9 (with 32

carriers)

0

0

Motor model

ZZCM101 (CM101)

0

Remote controller:

ZZRClO (RC10)

0

Timer:

ZZCT10 (CT10)

ZZEC101 (EC101)

contains items listed

a

bove

.

:

Universal mounting brackets

ZZ3SWCB (-WH)

White end caps 2241 1001 -A

(For use with white track and

components.

0

9

ft track ZZOSTK (-WH)

0

Splice ZZ6SJ (-WH)

0

Rod assy. ZZAR20 (with 64

carriers

0

Universal mounting brackets

ZZ3SWCB (-WH)

0

White end caps 2241 1001

(For use with white track

and components.)

1

(5

per pack)

(5

per pack) x 2

is

x

2

-

A

wider

-

9

9

FT

Motor

2 Rods

2 Motors

7

18 FT

To

the following product labels, the letters

Track

Track

Motor

0

Motor model

ZZCM101 (CM101)+

ZZCM3Ol (CM301)

0

Remote controller:

ZZRC20 (RC20)

0

Timer:

ZZCT10 (CT10)

ZZEC201 (EC201)

contains items listed

above.

"ZZ"

:

may not be affixed:

ft track ZZOSTK (-WH)

0

Rod assy. ZZAR9 (with 32

carriers)

0

Universal mounting brackets

ZZ6DWCB (-WH)

0

White end caps 2241 1001-A

(For use with white track

and components.)

09

.Splice ZZ6SJ (-WH) x 2

0

Rod assy. ZZAR2O (with 64

carriers)

0

Universal mounting brackets

ZZGDWCB (-WH)

~Whiteendcaps ZZ411001-A

(For use with white track

and components.)

x

2

(5

ft track ZZOSTK (-WH) x 4

x

2

x

per pack)

x

2

(5

per pack) x 2

x

2

AR9,

2

AR20,

EC101, EC201, EC301, CM101, CM301, RC10, RC20, RC30, RC60, CT10, WSIO,

W S20, W S30.

2

Page 3

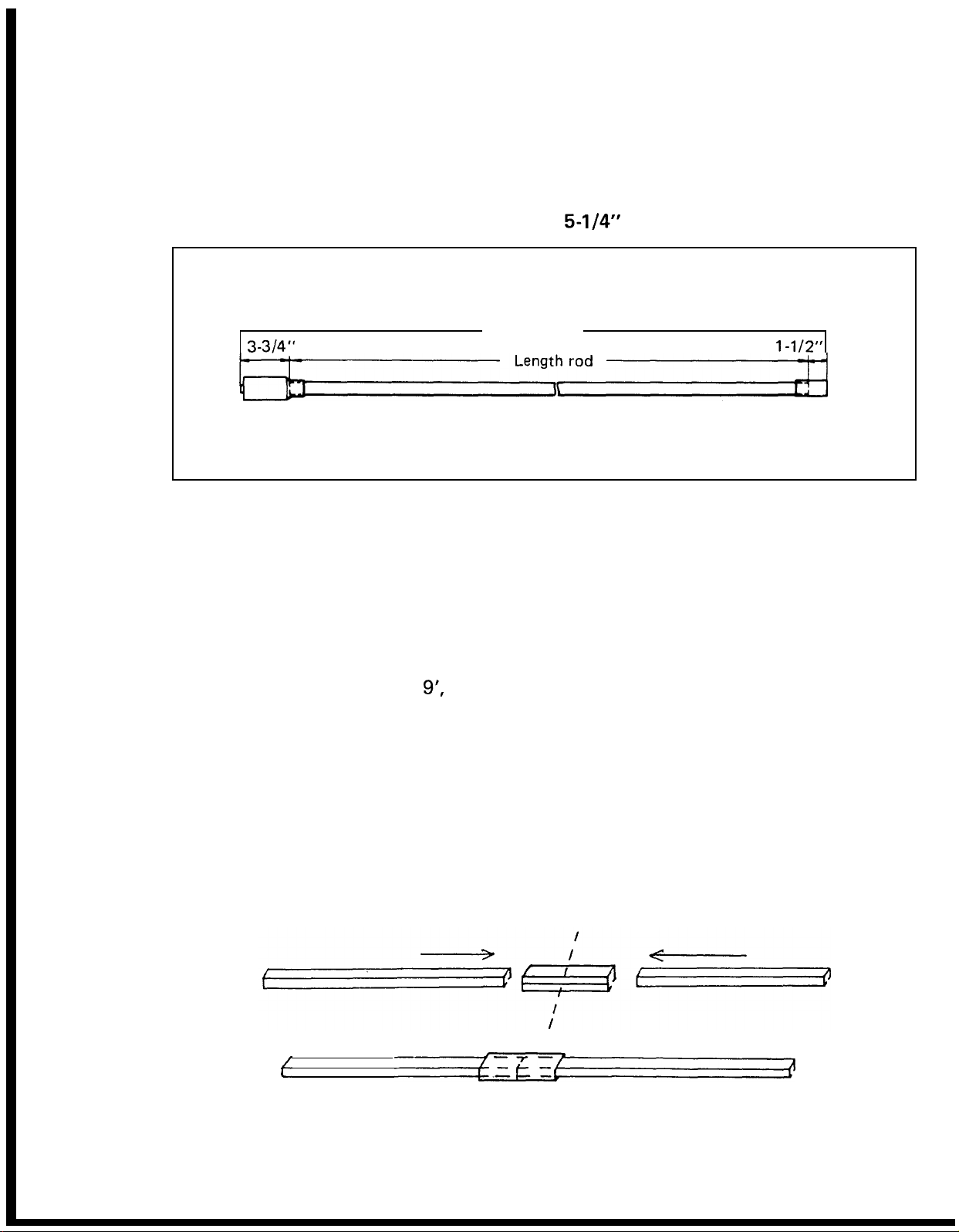

Cutting Track to Size

The

desired overall length of the rod should be determined and the aluminum track cut

according to the following equation prior to attaching the end and motor pulley housings.

Length

The purpose of the equation

of

aluminum track = overall length

3-314''

is

to offset for the length that the end and motor pulley

housings add to the overall length.

90

make

important for one

degree cuts and remove any burrs that may affect smooth operation; this

-

way applications.

Splicing Tracks

Center opening

less

5-1/4"

Total length

A

hack saw can be used to cut the track. Use care to

1-1

12"

is

most

For applications larger than

9',

two tracks must be spliced together using the supplied

splice. Tracks should be cut equal in length to ensure the splice will be centered in the

rod.

One-way

For one-way operations, cut only one track to adjust length.

Place

splice furthest away

from motor end.

NOTE

Insert tracks equally into

:

slice

butting them together. (Fig.

1

)

Fig.

1

Page 4

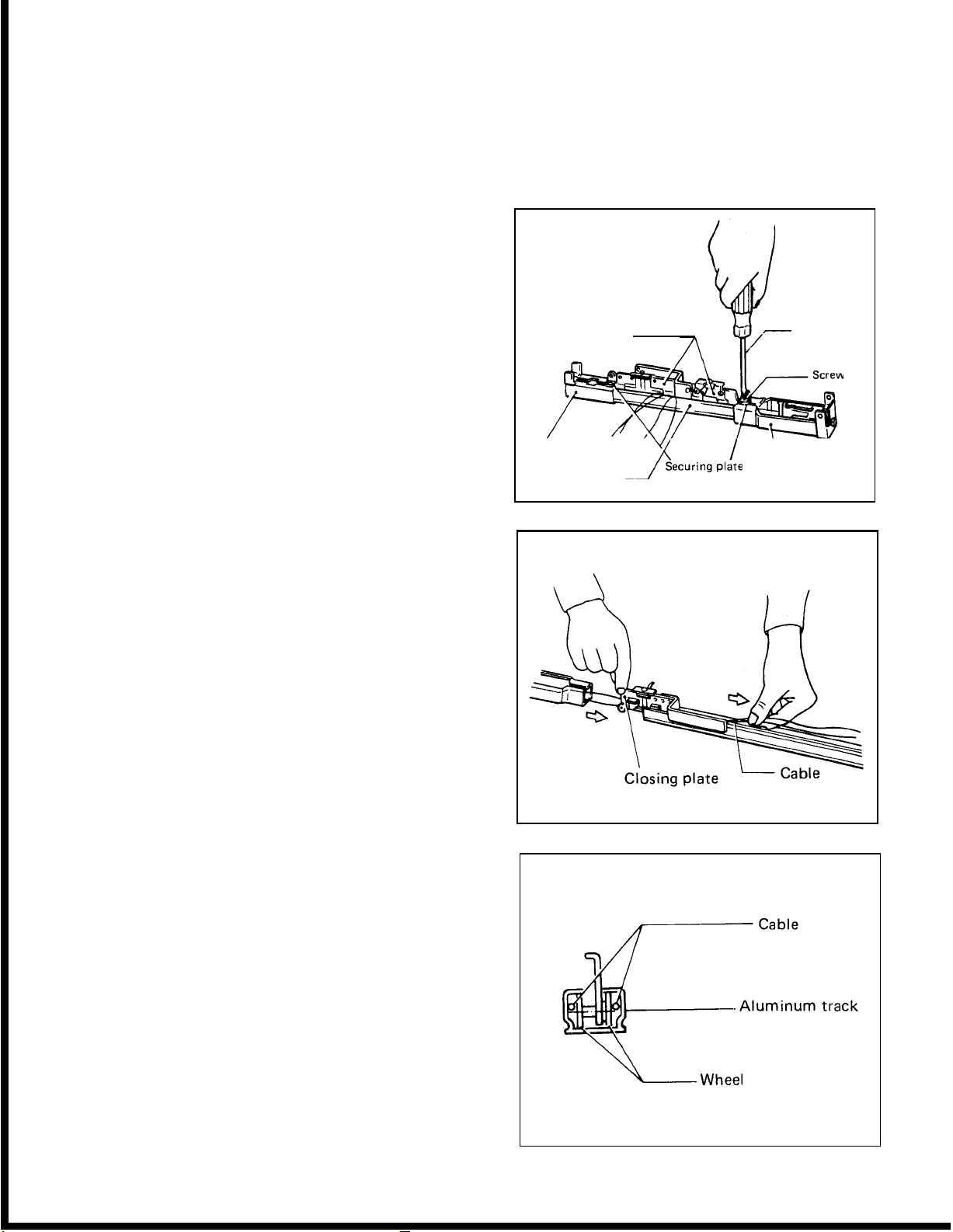

Rod

Assembly for Center Opening Applications

Allow yourself ample working area. Depending on the model of rod assembly and the

provided cable length, the end and motor pulley covers can be

assembly

1.

Remove twist

.

ties

from cable and care

-

as

far

as

20'

apart during

fully uncoil to prevent tangles.

2.

Loosen screws and remove securing

plates from each end of the temporary

(Fig.

track.

3.

Detach end and motor pulley housings

2)

Closing plates

A

Screwdriver

from temporary track.

4.

Remove closing plates from temporary

track. Discard temporary track.

5.

Stretch end and motor pulley housings

out to the fullest distance the cable will

allow. Make sure the cable

is

not tangled.

Position each closing plate near

its

re

Enb pulley housing

Temporary track

-

/

Motbr pulley housing

Fig.

2

spective pulley housing.

6.

Starting

at

the motor pulley housing

end, lay the cable into the aluminum

track about

making sure

it

4

"

twisted. While gently applying tension

(pulling) on the cable, insert the closing

3)

plate into the track. (Fig.

Be

keep the cable on the outside of the

4)

wheels. (Fig.

Attach the motor pulley

housing to the track. Make sure the

track is butted up to the stop inside the

cover. Repeat operation

again making sure wire

at

other end,

is

not twisted or

crossed. Reinstall securing plates to

motor pulley and end pulley housings.

is

not

sure to

Fig.

3

4

LWheei

of

closing

plate

Fig.

4

Page 5

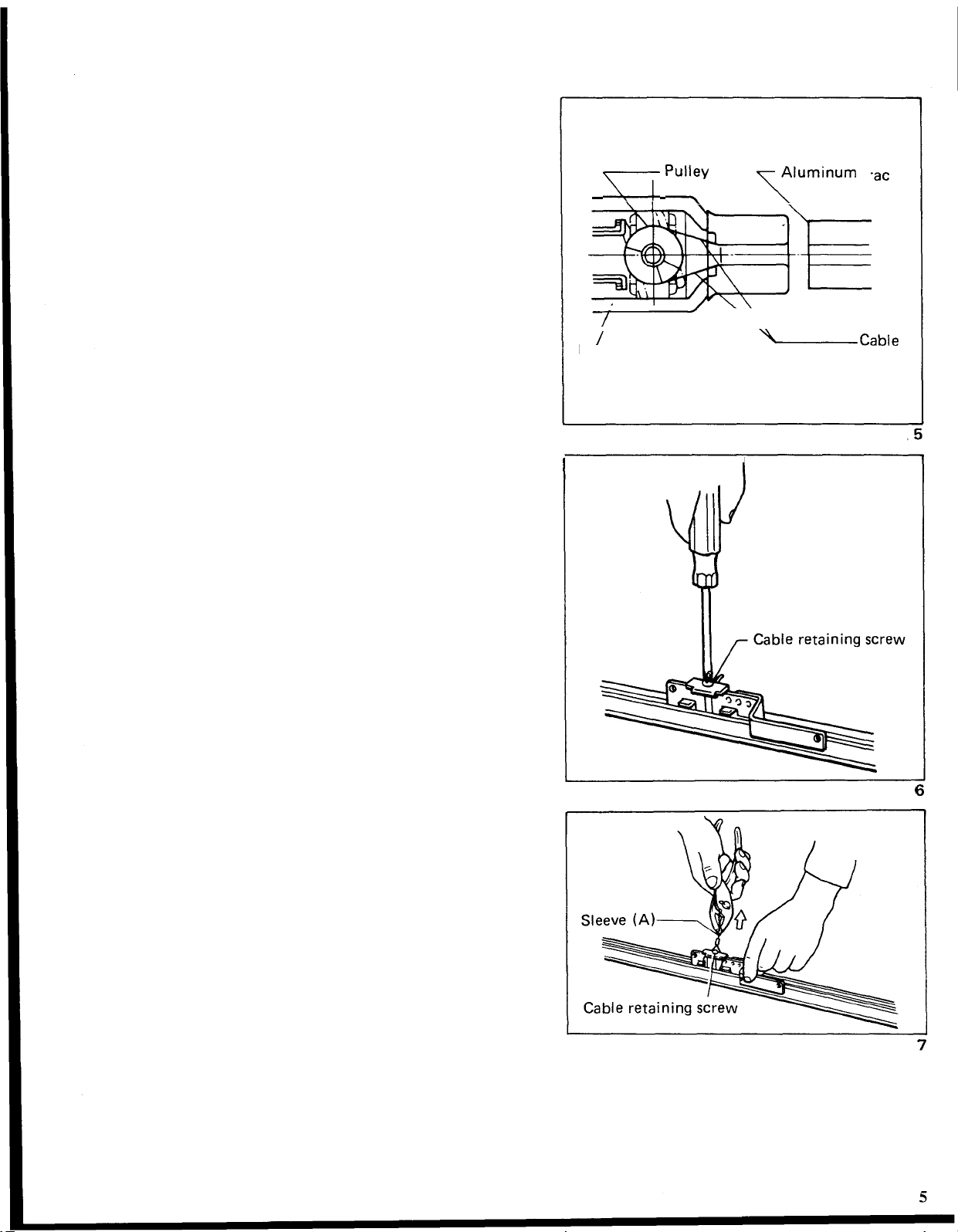

NOTE

:

When inserting the closing plates into

the aluminum track, make sure the

cable stays on the outside of the wheels.

4)

(Fig.

the

in

housings. (Fig.

7.

Loosen the cable retaining screw on the

Also check that the cable rides

groove of the pulley in both

5)

top of the closing plate that has the

overlap arm. The screw

need

only be

loosened; be careful not to remove

completely. (Fig.

6)

it

Motor

I

/

\I

I

/

Pul:y

pulley

housing

\Aluminum

tt

.ac

\\

LCable

Fig.

I

k

8.

With pliers grab

all

pull

excess cable. (Fig.

keeping tension on the cable, re

the

screw. Check

sleeve

that

(A)

and gently

7)

-

the cable rides

in the groove of the pulley in both

If

housings.

7

and

8.

not, realign and repeat steps

Move the closing plate by hand

to make sure that the movement

smooth.

by:

cable

pulley wheel, or

any of these are the

If

it

is

not,

it

can be caused

(1)

The cable

is

not properly routed around the

is

twisted,

(3)

The cable

case,

make appropriate corrections.

(2)

is

Fig.

While

tighten

is

The

Fig.

not riding correctly in the groove of the pulley. If

1

'

Page 6

9.

Adjust center-position of draperies by

loosening the cable retaining screw on

the closing plate without the overlap

8)

The

arm. (Fig.

loosened; be careful not to remove it

completely. This will let the closing

plate slide on the cable allowing adjust

ment to achieve center (or desired

position). Some resistance will be felt

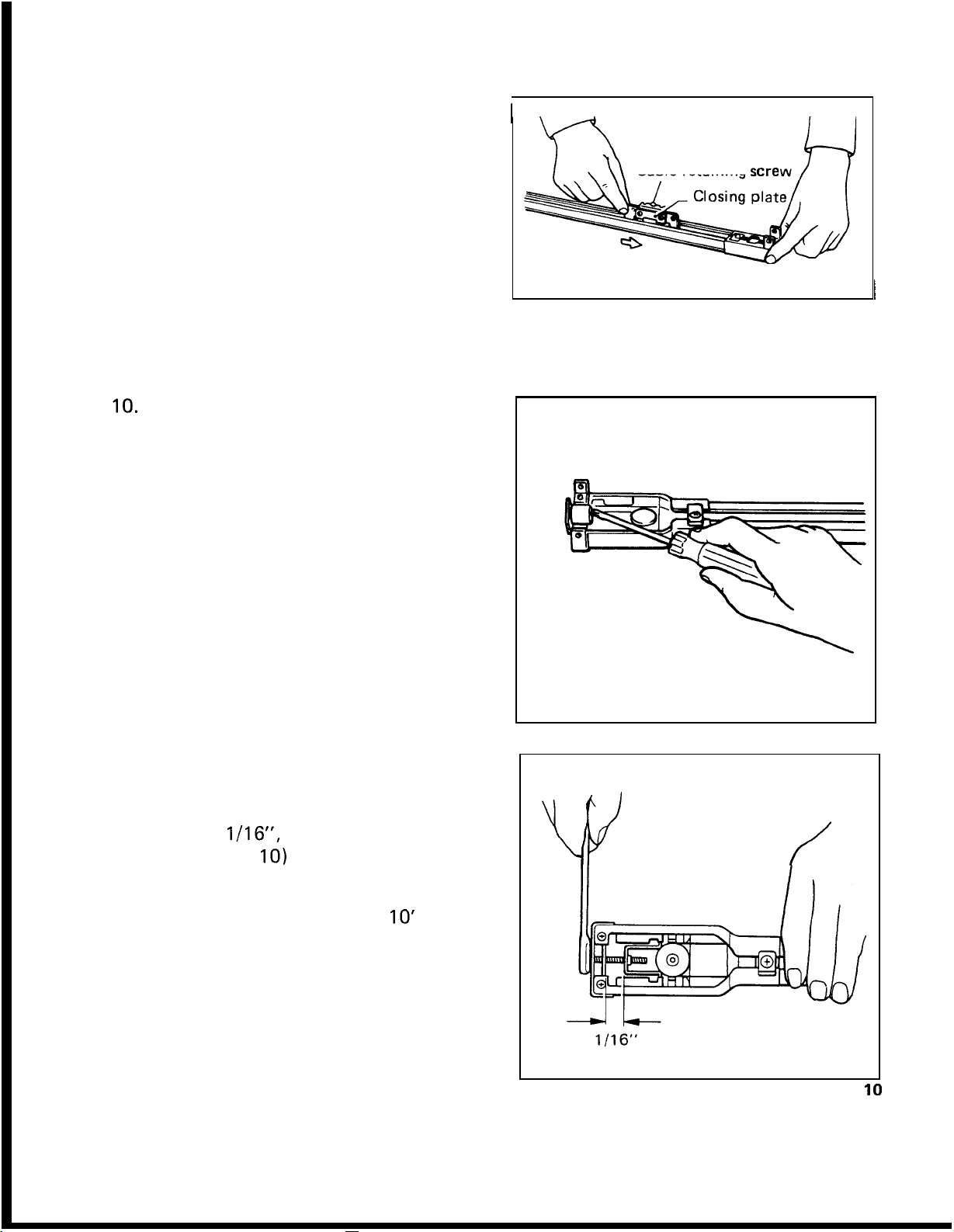

IO.

Using a screwdriver or the handle end

of

the provided wrench, lift out and

remove the temporary

the motor pulley housing and discard.

(Fig.

9)

screw need only be

steel

spacer from

as

I

-

\

Cable retaining scre

I

I

I

11.

With the provided wrench turn the ten

sion-adjusting bolt clockwise leaving

gap between tension plates of approxi

mately

nickel. (Fig.

NOTE

Rod lengths in

quire more tension

of the cable on the pulley wheels.

1/16",

:

or the thickness of

IO)

excess

of

IO'

to

prevent slipping

may

re

-

a

a

-

-

\

"V

Fig.

Fig.

9

10

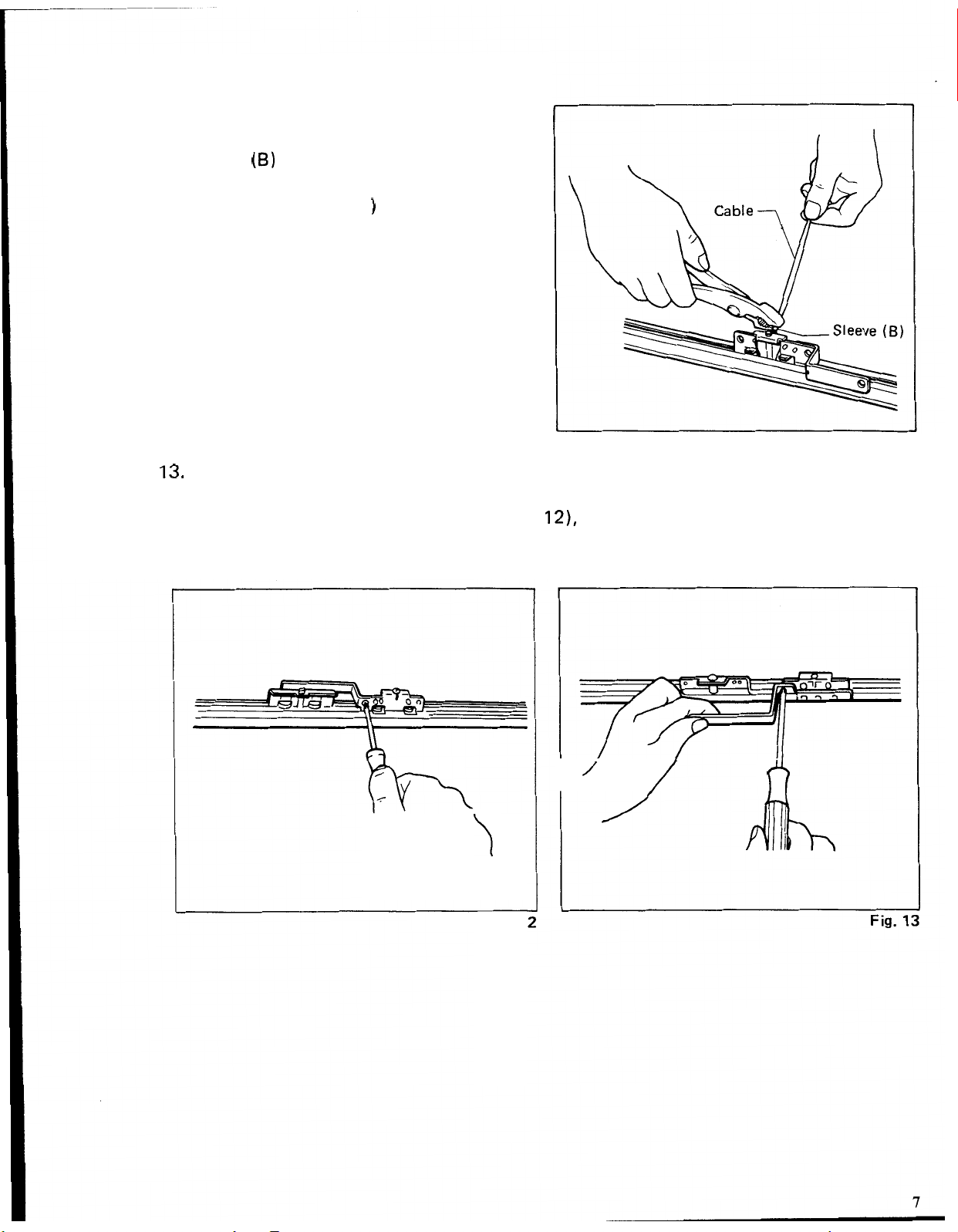

Page 7

12.

After again making sure the movement

is

of the closing plates

sleeve

pliers, crimp the

excess cable. (Fig.

13.

The rod assembly comes

However,

fasten the arm to the closing plate (Fig.

same side, (on the same closing plate). (Fig.

so

(6)

up to the closing plate. With

sleeve

11

it

can just

as

to project toward the interior of the room once the rod has been mounted.

smooth, move

and cut off the

)

set

up to have the motor mounted on the right side of the rod.

as

easily be placed

at

the left side by removing the two screws that

12),

reversing the arm and reattaching to the

13)

The overlap arm should be attached

Fig.

11

\

>

Fig.

12

’/

n

Page 8

Rod

Assembly for One-way Operations

Allow yourself ample working area. Depending on the model of rod assembly and the

provided cable length, the end and motor pulley covers can be

assembly

.

as

far

as

20'

apart during

1. Follow steps

FOR CENTER OPENING APPLICA

1

-

5 of

ROD

ASSEMBLY

-

TIONS.

2.

Loosen and remove the screw from the

closing plate that does not have the

overlap arm. This will release the clos

ing plate from the cable. Discard closing

plate. (Fig. 14)

3.

Starting

4" making sure

at

the motor pulley housing end, lay the cable into the aluminum track about

it

is not twisted. While gently applying tension (pulling) on the cable,

insert the closing plate into the track. (Fig. 15) Be sure to keep the cable on the out

side of the wheels. (Fig. 16) Attach motor and end pulley housings to ends of track.

Make sure the track

is

butted up to the stops inside the housings. Reinstall securing

plates to motor pulley and end pulley housings.

Fig.

14

-

Cable

Alum

i

nu

m

track

Wheel

I

Fig.

15

&

1

of

closing plate

Fig.

16

8

Page 9

4.

Loosen the cable retaining screw on the

top of the remaining closing plate (with

overlap arm). The screw need only be

loosened; be careful not to remove

completely.

(Fig.

17)

it

sleeve

5.

With pliers gr

pull

all

excess cable. (Fig.

b

keeping tension on the cable, re

(A)

and gently

18)

While

-

tighten

the screw. Check that the cable rides in

the groove

ings.

and

If not, realign and repeat steps

5.

to make sure that the movement

smooth.

(1)

The cable

of

the pulley in both hous

4

Move the closing plate by hand

is

If

it

is

not,

it

can be caused by:

is

twisted,

(2)

The cable is

-

not properly routed around the pulley wheel, or

the groove of the pulley. If any

6.

Using a screwdriver or the handle end of

the provided wrench, lift out and re

move the temporary

steel

of

these are the

spacer from

-

the motor pulley housing and discard.

(Fig.

19)

I

I

Cable

(3)

case,

retaining

The cable

s

is

not riding correctly in

make appropriate corrections.

Fig.

Fig.

1

1,

Fig.

19

I

9

Page 10

7.

With the provided \ lrench turn the ten

sion-adjusting bolt clockwise leaving

gap between tension plates of approxi

mately

nickel. (Fig.

1/16",

20)

or the thickness of

-

a

-

a

NOTE

Rod lengths in excess of

quire more tension to prevent slipping

of the cable on the pulley wheels.

8.

After again making sure the movement

of the closing plate

sleeve

pliers, crimp the

excess cable. (Fig.

:

10'

is

smooth, move

(9)

up to the closing plate. With

sleeve

and cut off the

21)

may re

-

_I&

1

I1

6

"

Fig.

21

9.

The motor

the draperies will stack when open (right or left). The rod assembly comes

right stacking draperies. For left stacking draperies

lap arm on the closing plate. Remove the two screws that fasten the arm to the closing

plate (Fig.

motor to be on the left side of the track behind the draperies when open.

is

designed to be hidden behind the drapery stack. Determine on which side

set

it

is

necessary to reverse the over

22),

switch

it

to the opposite side and reattach. (Fig.

23)

This allows the

n

/7

Fig.

2:

Fig.

21

up for

Fig.

23

-

10

Page 11

Installation

Chart

Motor(s) may be attached on the right or left

01

rod, 1 motorsystem

02

rods, 2 motors system

using

the same components.

I

Double mounting bracket

I

I.

11

Page 12

Mounting

Rod

Supplied brackets will accommodate either wall or ceiling mount applications. Due to the

various building materials used in construction,

i.e.,

concrete, drywall or wood, we do not

supply fasteners. Your local hardware store can help you in choosing the proper fastener

for your needs.

1.

Attach appropriate brackets (ceiling or wall) to the rod approximately every 24".

Make sure to place

a

bracket close to each end since this

is

where the most weight

is

placed when the draperies are open.

NOTE

:

When mounting rod to wall or ceiling allow extra space to accommodate for the neces

sary floor and track clearance. Typical allowance will be 1-1/2" to 2" greater than

drapery length. This will prevent the draperies from dragging across the floor while

allowing the draperies to be hung below the rod for smooth operation.

2.

Position rod in desired location and

mark bracket mounting holes on wall or

ceiling depending on your specific appli

cation.

ing dimensions.) It

(See

Fig. 24 for bracket mount

is

important for

-

-

NSTALLATION CHART:

in the right

or

left

using

DOUBLE CEILING MOUNT APPLICATION

Motorts) may be attached

the same components.

proper operation to mount the rod

straight and

level.

ceiling will not be straight or true.

mount brackets have the ability to

adjust for this. Once the rod

loosen the screw that attaches the

Many times walls and

Wall

is

up,

ceil

-

I

Minimum Mlnlmum

DOUBLE WALL MOUNT APPLICATION

ing clip to the wall bracket. This will

allow the rod to relax to

its

natural

straight shape. Retighten the screws. In

case

the

of ceiling mount,

it

may be

necessary to place shims between the

bracket and ceiling in order to make the

rod straight and

3.

Detach brackets from rod, drill marked

holes to

size

level.

for the fasteners chosen

and attach brackets.

SINGLE WALL MOUNT

1

9/16"

-

SINGLE CEILING MOUNT

4

t

I

""

Minimum

-

12

Fig.

24

Page 13

4.

Starting

rod into brackets. (Fig.

fully attach rod into bracket; a snap or

click can be felt and heard when proper

ly engaged.

at

the center of the rod, snap

25)

Be

sure

to

-

/

Fig.

2!

Loading

After installing the rod, remove securing

plates and load carriers

ends of the rod. In the

applications, carriers would be loaded from

motor pulley housing end only. Load the

proper amount

specific drapery

cable on outside

carriers. Reinstall securing plates

time.

Stop

The stop

position options for attaching draperies.

Tighten securing plate

Leave motor pulley securing plate (with re

turn arms and extra pinning holes) loose

since

to attach the motor. After motor is

tached to the motor pulley housing, slide

the securing plate back until

over rubber section and tighten.

Carriers

(Fig.

26)

into both

case

of

one-way

of

carriers based on your

size.

Be

careful to keep

of

wheels when loading

at

(Optional)

is

designed to

it

must be slid down the track in order

give

more pinning

at

end pulley only.

it

is

centered

this

at

-

-

\

\

\\

Fig.

26

I

Fig.

2'

13

Page 14

Attaching

Motor

One Motor, One

Track

System

With rod mounted to either wall or ceiling, attach the motor to the rod.

1.

Holding the motor

at

45 degree angle to

the track, push down on the lever on

the

motor, insert the shaft into the hole

the

in

parallel to the track. (Fig.

motor gear and turn the motor

28)

Release

the lever and the motor will lock into

the motor pulley housing. Without

pushing the lever, gently try to twist the

motor to ensure

(Fig.

29)

some play will be

it

is

securely attached.

felt,

however

the motor should not release.

2.

Slide back the under cover from the

motor to expose the female modular

1

connecting ports.

3.

Connect timer to modular port labeled

"

Timer". The timer comes with Velcro

We

for attaching to the wall.

mend

draperies where

TIMER

it

be put behind the stack of the

it

will out of view.

section for instructions on how

recom

-

See

to program.

otor

pulley

housing

Fig.

28

4. Return under cover to original position.

5. Position the infrared receiving eye

as

to have the black part facing the

so

room without any obstructions.

6.

Hang draperies. Remember to adjust pins

the bottom of the rod.

7.

Plug motor into standard

NOTE

:

The infrared receiving eye

120 V polarized receptacle.

is

designed to receive the signal through most draperies and be

hidden from view. However, some black

these

cases

the receiving eye must be exposed.

Fig.

so

the top of the draperies ride just below

-

out type draperies can impede the signal.

29

In

14

Page 15

Two Motors, Two Tracks System

1.

Follow step 1 of

TRACK

closest to window.

SYSTEM

ONE

MOTOR,

starting with rod

ONE

~

,

ZZCM301

(without receiving

(No.2)

unit)

NOTE

With the two motor system (over and

under draperies), the

(ZZCNllOl)

most rod (room side), and the "kid

motor should be on the rod closest to

the window. (Fig.

2.

Slide back the under cover from both

motors to expose the female modular

connecting ports.

3.

Connect provided modular connecting

wire from port labeled number

the

(Fig.

tion clips on the side of the motor. (Fig.

32)

and prevent the wire from interfering

with the draperies.

:

"

parent" motor

should be on

the

30)

"2"

"

parent" motor to the "kid" motor.

31)

Route wire through the reten

This will

give

a

more finished

inner

on

look

"

-

~

-

Receiving nut

Inside

ZZCMIOI

(with receiving

ZZCM301

ZZCMIOI

(No.

1)

unit)

Fig.

(No.

(No.

30

2)

1)

4.

Connect timer to modular port labeled

"

Timer" on "parent" motor. The timer

comes with Velcro for attaching to the

wall.

the stack of

out of view.

instructions on how to program.

5.

6.

Position the infrared receiving eye

to

without any obstructions.

7.

Hang draperies. Remember to adjust

pins

below the bottom of the rod.

8.

NOTE

The infrared receiving eye

hidden from view. However, some black out

these

We

recommend

the

See

Reinstall under cover on both motors.

have

the black part facing

so

the top of the draperies ride just

Plug motors into standard

:

cases

the receiving eye must be exposed.

it

be put behind

draperies where

TIMER

section for

the

120

V polarized receptacle.

is

designed to receive the signal throuqh most draperies and be

it

will

so

room

as

'

Fig.

Fig.

-

type draperies can impede the signal. In

31

I

32

15

Page 16

Remote control unit

Point the remote control unit in the direction of the receiving unit. The operating range

is

of the remote control unit

Button indicated above opens the drapery.

Button indicated above closes the drapery.

4

I

STOP

Button indicated above stops the drapery

in any position.

Push button slightly. One push of the

button

drapery fully open or fully closed, there

is

no need to operate the

because

drapery

I

is

sufficient. When you want the

it

will automatically stop when the

is

fully open or fully closed.

32.8 ft.

button,

ORAPERY REMOTE

CONTROLLER

E10

STOP

88

STOP

on

NOTE

When the motor

the button to move in the same direction,

In

ZZCM301

control unit, respectively

the

:

is

stopped

case

of ZZCMlOl (CM101) + ZZCM301 (CM301

(CM301) (No. 2) can be operated by No. 1 and No. 2 buttons on the remote

at

the fully open or fully closed position, and you then push

.

ZZCM301 (CM301)

(NO.

2)

v

A*

LZZCM1O1 (CM101)

(No.

1)

it

will not operate.

),

ZZCMlOl (CM101)

(No.

1) and

16

Page 17

24

Hour

Timer

-

4

Memory

Timer Disl )lay

Functions

I

TIME

!

ON/OFF

E3

CAUTION

.Do not install in locations where temperatures exceed 50°C

sunlight can strike the timer.

The LCD (liquid crystal display) can be damaged by excessive heat.

Avoid locations where temperatures may become excessively low. LCD response time

may be slowed or the time may become inoperative. These low temperature symptoms

are not permanent. Normal functions will return after the timer warms up.

:

Time

I

Timer

OpedClose Button

Memory Clear Button

Memory Display Button

Minute

Hour

Set

Button

ON/OFF

Set

Button

Set

Button

(122°F)

Button

or where direct

0

Do not drop or impact the timer, Do not attempt to disassemble or damage may result.

17

Page 18

Installing timer

Connect the timer cord to the connecting jack marked "TIMER" on

receiving unit). Use

the appropriate location.

Setting

Entire display flickers when the power

comes

.When

the

dicators light up steadily. The display will

return to the flickering status after about

15

.Adjustment to the correct present time

can be made using the

tons. Adjusting past

advance the

mode, the colon

and minute digits will keep lighting up

steadily.

pressed and held, the "Hour" or "Minute

indicator will continue to advance.

for

present time

ON.

the

-1

"

Hour", "Minute" and "AM-PM" in

seconds, if

"

If

either

Velcro tape provided on the back of

button

left

as

is.

Hour" indicator. During this

If : I'

the

is

pushed, only

jHi

and

/MI

60

minutes does not

between the hour

(HI

or

(Mi

button

but

-

-

is

"

the

timer to attach the timer

Time Adjust Mode

1

No.

1

I

1

motor (with

+

!

In 15seconds

i

In 15 seconds

to

0

About

the

automatically. During the "Present Time

mode, the colon

.To

exact moment when the minute changes. The time will begin from that moment from

"00"

0

After setting the time,

button to change modes from the "Present Time" to the "Time Adjust". Then adjust

the time according to the previous instructions.

15

seconds after setting the time,

display will turn to the "Present Time

''

:

If

will keep flickering.

adjust the time to the nearest second, push the button and release

seconds.

if

you wish to readjust the present time, first push the

"

"

Present Time Mode

it

at

I

TIME

the

18

Page 19

Setting

for

open/close time

*Push

the

open/close indicator will flicker. This

indicates that the timer

"

The open/close indicator can be changed

to

merely pushing the

Adjust

by using the and

ture

display after adjustment for drapery

opening

@By

more, the

flicker. Follow the previous procedures to

set

and

the

F]

"

Timer

Timer

Set

"

"

open mode" or "close mode" by

the "open" time

at

right shows an example of the

at

7

:

pushing the

open/close time in memories

4.

button to change to

Set

"

mode. The left side

is

now in the

mode for memory

open/close button.

or

"

close" time

/Mi

buttons. The pic

00

a.m.

-1

open/close indicator will

button once

No.

I

No.

2,

1.

-

HM

""

3

elf you wish to erase the memory, push

the-] button to flicker the desired

memory

IhA/c]

open/close indicator will disappear from

the display.

No.

1,

2,

3

or

4.

Then push the

button to erase. The appropriate

I

-:

-\I/.

I

19

Page 20

Timer function

To actuate the timer, push the

button. The open/close indicator will

appear.

0

To

turn the timer off, push the

button again. The open/close indicator

will disappear from the display.

Confirming open/close time

1

ON/OFF

ONIOFF

,

-_

ON’OFF

r

AM

I

I

I

I

-,\

I

/

=

.

-11

L7.T-I

I

9

.

tzf

Timer Function

1-1

Timer Function

(OFF)

(ON)

To confirm the open/close time, push the

button, the

whenever necessary.

Note

:

Memories

programmed

necessarily sequential

The operating time for opening or closure

tion time, remote control operation

0

If the motor

reprogram memory

Maintenance

Wipe the timer with a soft, dry cloth. Do not use alcohol, benzene or thinner type pro

ducts, or damage to the timer may result.

set

times for memory

No.

1

-

4

need not relate to the exact sequence

into the timer. Memories can be

I

y

.

is

unplugged or electric failure happens, memory will be lost. You must

as

previously explained. The present time also needs to be re-set.

No.

[MEMO]

1,

2,

is

isnot possible.

button. Each time you push

3

and 4 will be displayed.

set

approximately 6 seconds. During this opera

them,

Reset

of

functions that you have

independently of each other: not

the memory

-

-

20

Page 21

OPT

ION A L

ACC

E

SSO

R

I

ES

WALL SWITCH

Wall

switch can only

Model

for

ZZWSIO (WSIO)

one

motor

i

(For

class

be

used

2

wiring only)

in conjunction with ZZCM101 (CM101).

Model

for

ZZWS20 (WS20)

two motors.

21

Page 22

MAINTENANCE

Test

operat

After assembling the complete system, connect to the power supply. Test the manual

and automatic operation to be sure the system functions properly. In

check the following

ion

"

Trouble Shooting Chart".

case

of a problem,

Trouble

Problem

Remote control unit

does not operate.

Motor does not stop

matically

fully closed positions,

Can operate

(No. 1 ) but cannot operate

ZZCM301 (CM301) (No.

ZZCM301 (CM301)

Drapery automatically stops

without pushing button

before drapery

or fully closed.

Cannot open and close Assembly of drapery track

drapery

at

fully open and

ZZCM101 (CM101)

~~

by hand.

auto-

(No.

is

fully open

2)

or

3).

Power plug

properly. power receptacle properly.

Battery in remote control Replace battery in remote

unit

Receiving unit

Not enough tension on the

cable. by turning tension adjusting

Cord on motor (with receiv-

ing unit)

properly.

Interference with movement

of d rapery

is

incorrect. to instructions in this manual.

Shooting

Cause Solution

is

not engaged Plug power supply cord into

is

dead. control unit.

is

not ccnnected

Chart

is

obstructed. Remove interferring object.

.

Increase tension of the cable

hex. bolt.

Reconnect cord accroding to

instructions in this manual.

Remove object which restricts

drapery.

-

assemble track according

Re

I

maintain product SAFETY and RELIABILITY, repairs should

To

be performed by

Makita Authorized or Factory Service Centers, always using Makita replacement parts.

22

Page 23

..............................................

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

MAKITA LIMITED THREE YEAR WARRANTY

Warranty Policy

Every Makita motor is thoroughly inspected and tested before leaving the factory. It is warranted to

of

be free

of

original purchase. Should any trouble develop during this three-year period, return the COMPLETE

motor, freight prepaid,

the trouble is caused by defective workmanship or material, Makita will repair (or at our option, replace)

without charge.

This Warranty does not apply where:

repairs have been made or attempted by others:

repairs are required because of normal wear and tear:

The motor has been abused, misused or improperly maintained;

*alterations have been made to the motor.

.The battery has not been charged immediately after purchase.

IN NO EVENT SHALL MAKITA BE LIABLE FOR ANY INDIRECT, INCIDENTAL

DAMAGES FROM THE SALE

DURING AND AFTER THE TERM OF THIS WARRANTY.

MAKITA DISCLAIMS LIABILITY FOR ANY IMPLIED WARRANTIES, INCLUDING IMPLIED WAR

RANTIES OF “MERCHANTABILITY” AND “FITNESS

THREE

This Warranty gives you specific legal rights, and you may also have other rights which vary from

state to state. Some states do not allow the exclusion or limitation of incidental or consequential

damages,

on how long an implied warranty lasts,

defects from workmanship and materials for the period of THREE YEAR from the date

to

one of Makita’s Factory or Authorized Service Centers.

OR

USE OF THE PRODUCT. THIS DISCLAIMER APPLIES BOTH

FOR

A SPECIFIC PURPOSE,” AFTER THE

-

YEAR TERM OF THIS WARRANTY.

so

the above limitation or exclusion may not apply to you. Some states do not allow limitation

so

the above limitation may not apply to you.

If

inspection shows

OR

CONSEQUENTIAL

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

-

*

*

*

*

*

8

*

*

...............................................

Loading...

Loading...