Page 1

INSTRUCTION MANUAL

MANUAL DE INSTRUCCIONES

Battery Powered Wheelbarrow

Carretilla Propulsada a Batería

XUC01

IMPORTANT: Read Before Using.

IMPORTANTE: Lea antes de usar.

Page 2

ENGLISH (Original instructions)

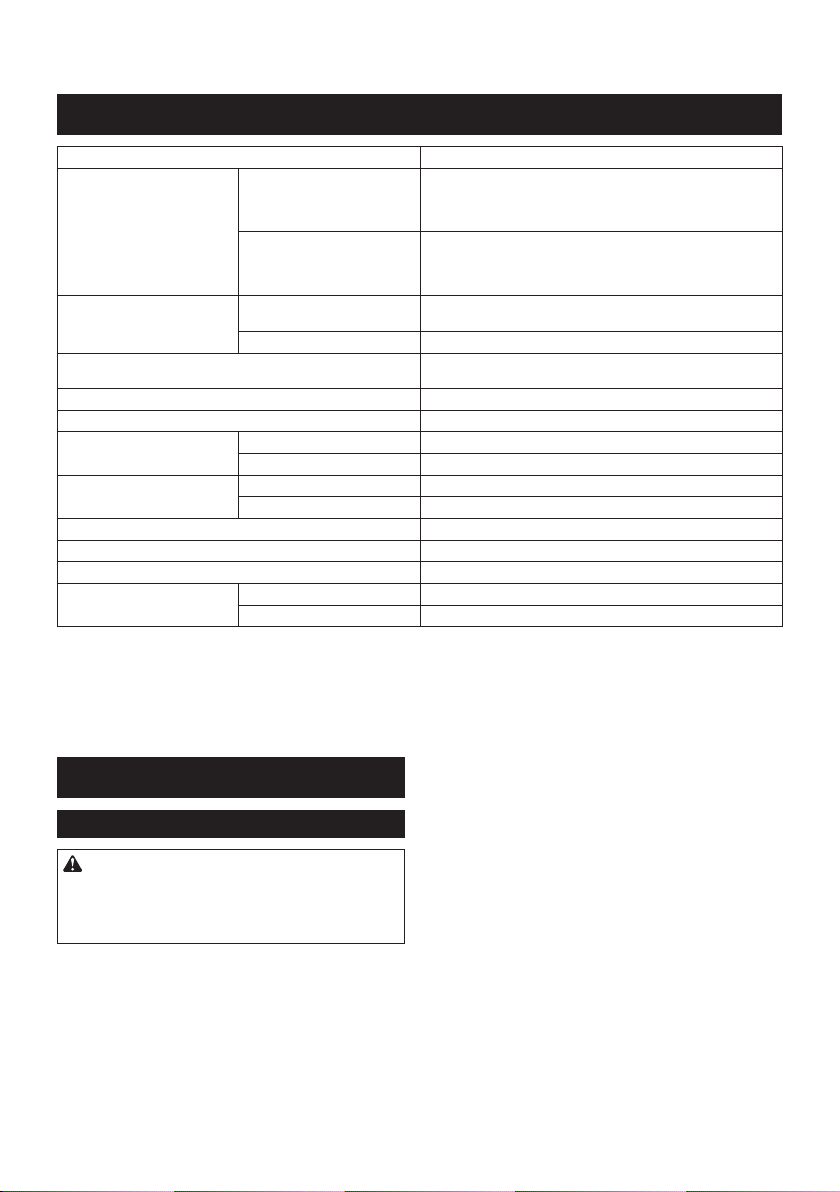

SPECIFICATIONS

Model: XUC01

Dimensions

(L x W x H)

Traveling speed Forward 1.5 or 3.5 km/h (0.9 or 2.2 mile/h)

Minimum turning radius 1,075 mm (1.2 yard)

Maximum climbing capacity 12°

Maximum load capacity 130 kg (287 lbs)

Brake Front wheel Disc brake with wire

Tire Front wheel Tubeless tire

Rated voltage D.C. 18 V

Standard battery cartridge

Charger DC18RC / DC18RD / DC18SD / DC18SE / DC18SF

Net weight When carrier is installed 45 kg (99 lbs)

• Due to our continuing program of research and development, the specications herein are subject to change

without notice.

• Specications and battery cartridge may differ from country to country.

• The weight may differ depending on the attachment(s), including the battery cartridge. The lightest and heavi-

est combination, according to EPTA-Procedure 01/2014, are shown in the table.

When carrier is installed During operation: 1,560 mm x 1,060 mm x 900 mm

When bucket is installed During operation: 1,310 mm x 790 mm x 900 mm

Reverse 1.0 km/h (0.6 mile/h)

(Outer diameter when turning with front wheel as axis)

Rear wheel Fixed with pedal

Rear wheel Self-sealing tire

BL1815N / BL1820B / BL1830 / BL1830B / BL1840B / BL1850B / BL1860B

When bucket is installed 39 - 40 kg (86 - 88 lbs)

(61-1/2″ x 41-3/4″ x 35-1/2″)

When stored: 1,110 mm x 670 mm x 820 mm

(43-3/4″ x 26-3/8″ x 32-1/4″)

(51-1/2″ x 31-1/8″ x 35-1/2″)

When stored: 1,110 mm x 590 mm x 820 mm

(43-3/4″ x 23-1/4″ x 32-1/4″)

SAFETY WARNINGS

General power tool safety warnings

WARNING: Read all safety warnings, instruc-

tions, illustrations and specications provided

with this power tool. Failure to follow all instructions

listed below may result in electric shock, re and/or

serious injury.

Save all warnings and instructions for future reference.

The term "power tool" in the warnings refers to your

mains-operated (corded) power tool or BATTERYoperated (cordless) power tool.

Work area safety

1. Keep work area clean and well lit. Cluttered or

dark areas invite accidents.

2. Do not operate power tools in explosive atmo-

spheres, such as in the presence of ammable

liquids, gases or dust. Power tools create sparks

which may ignite the dust or fumes.

3. Keep children and bystanders away while

operating a power tool. Distractions can cause

you to lose control.

Electrical Safety

1. Power tool plugs must match the outlet. Never

modify the plug in any way. Do not use any

adapter plugs with earthed (grounded) power

tools. Unmodied plugs and matching outlets will

reduce risk of electric shock.

2. Avoid body contact with earthed or grounded

surfaces, such as pipes, radiators, ranges and

refrigerators. There is an increased risk of elec-

tric shock if your body is earthed or grounded.

3. Do not expose power tools to rain or wet conditions. Water entering a power tool will increase

the risk of electric shock.

2 ENGLISH

Page 3

4. Do not abuse the cord. Never use the cord for

carrying, pulling or unplugging the power tool.

Keep cord away from heat, oil, sharp edges

or moving parts. Damaged or entangled cords

increase the risk of electric shock.

5. When operating a power tool outdoors, use an

extension cord suitable for outdoor use. Use of

a cord suitable for outdoor use reduces the risk of

electric shock.

6. If operating a power tool in a damp location is

unavoidable, use a ground fault circuit interrupter (GFCI) protected supply. Use of a GFCI

reduces the risk of electric shock.

7. Power tools can produce electromagnetic

elds (EMF) that are not harmful to the user.

However, users of pacemakers and other similar

medical devices should contact the maker of their

device and/or doctor for advice before operating

this power tool.

Personal Safety

1. Stay alert, watch what you are doing and use

common sense when operating a power tool.

Do not use a power tool while you are tired or

under the inuence of drugs, alcohol or medication. A moment of inattention while operating

power tools may result in serious personal injury.

2. Use personal protective equipment. Always

wear eye protection. Protective equipment such

as dust mask, non-skid safety shoes, hard hat, or

hearing protection used for appropriate conditions

will reduce personal injuries.

3. Prevent unintentional starting. Ensure the

switch is in the off-position before connecting

to power source and/or BATTERY pack, picking up or carrying the tool. Carrying power tools

with your nger on the switch or energising power

tools that have the switch on invites accidents.

4. Remove any adjusting key or wrench before

turning the power tool on. A wrench or a key left

attached to a rotating part of the power tool may

result in personal injury.

5. Do not overreach. Keep proper footing and

balance at all times. This enables better control

of the power tool in unexpected situations.

6. Dress properly. Do not wear loose clothing or

jewellery. Keep your hair, clothing and gloves

away from moving parts. Loose clothes, jewel-

lery or long hair can be caught in moving parts.

7. If devices are provided for the connection of

dust extraction and collection facilities, ensure

these are connected and properly used. Use of

dust collection can reduce dust-related hazards.

8. Do not let familiarity gained from frequent use

of tools allow you to become complacent and

ignore tool safety principles. A careless action

can cause severe injury within a fraction of a

second.

9. Always wear protective goggles to protect

your eyes from injury when using power tools.

The goggles must comply with ANSI Z87.1 in

the USA.

It is an employer's responsibility to enforce

the use of appropriate safety protective equipments by the tool operators and by other persons in the immediate working area.

Power tool use and care

1. Do not force the power tool. Use the correct

power tool for your application. The correct

power tool will do the job better and safer at the

rate for which it was designed.

2. Do not use the power tool if the switch does

not turn it on and off. Any power tool that cannot

be controlled with the switch is dangerous and

must be repaired.

3.

Disconnect the plug from the power source and/

or remove the BATTERY pack, if detachable,

from the power tool before making any adjust

ments, changing accessories, or storing power

tools. Such preventive safety measures reduce the

risk of starting the power tool accidentally.

4. Store idle power tools out of the reach of chil-

dren and do not allow persons unfamiliar with

the power tool or these instructions to operate

the power tool. Power tools are dangerous in the

hands of untrained users.

5. Maintain power tools and accessories. Check

for misalignment or binding of moving parts,

breakage of parts and any other condition that

may affect the power tool’s operation. If damaged, have the power tool repaired before use.

Many accidents are caused by poorly maintained

power tools.

6. Keep cutting tools sharp and clean. Properly

maintained cutting tools with sharp cutting edges

are less likely to bind and are easier to control.

7. Use the power tool, accessories and tool bits

etc. in accordance with these instructions, taking into account the working conditions and

the work to be performed. Use of the power tool

for operations different from those intended could

result in a hazardous situation.

8. Keep handles and grasping surfaces dry,

clean and free from oil and grease. Slippery

handles and grasping surfaces do not allow for

safe handling and control of the tool in unexpected

situations.

9. When using the tool, do not wear cloth work

gloves which may be entangled. The entanglement of cloth work gloves in the moving parts may

result in personal injury.

BATTERY tool use and care

1. Recharge only with the charger specied by

the manufacturer. A charger that is suitable for

one type of BATTERY pack may create a risk of

re when used with another BATTERY pack.

2.

Use power tools only with specically designated BATTERY packs. Use of any other

BATTERY packs may create a risk of injury and re.

3.

When BATTERY pack is not in use, keep it

away from other metal objects, like paper clips,

coins, keys, nails, screws or other small metal

objects, that can make a connection from one

terminal to another. Shorting the BATTERY termi-

nals together may cause burns or a re.

4. Under abusive conditions, liquid may be

ejected from the BATTERY; avoid contact. If

contact accidentally occurs, ush with water.

If liquid contacts eyes, additionally seek med-

ical help. Liquid ejected from the BATTERY may

cause irritation or burns.

3 ENGLISH

-

Page 4

5. Do not use a BATTERY pack or tool that is

damaged or modied. Damaged or modied

batteries may exhibit unpredictable behaviour

resulting in re, EXPLOSION or risk of injury.

6. Do not expose a BATTERY pack or tool to re

or excessive temperature. Exposure to re or

temperature above 130 °C may cause explosion.

7. Follow all charging instructions and do not

charge the BATTERY pack or tool outside the

temperature range specied in the instructions. Charging improperly or at temperatures

outside the specied range may damage the

BATTERY and increase the risk of re.

Service

1. Have your power tool serviced by a qualied

repair person using only identical replacement

parts. This will ensure that the safety of the power

tool is maintained.

2. Never service damaged BATTERY packs.

Service of BATTERY packs should only be performed by the manufacturer or authorized service

providers.

3. Follow instruction for lubricating and changing accessories.

Battery powered wheelbarrow safety

warnings

1. This machine cannot be used on the public

road.

2. While operating the machine, always wear

non-slip and protective footwear. Non-skid,

closed-toed safety boots and shoes will reduce the

risk of injury.

3. Inspect pathway before hauling objects/mate-

rials. Familiarizing yourself with the pathway and

ensuring it is wide enough to safely navigate the

machine under load will help reduce losing control

of the machine.

4. Use extreme caution on slippery, loose and

unstable terrain. Wet and slippery surfaces, such

as wet grassy areas, snow or ice, and loose and

unstable terrain, such as sand or gravel surfaces,

may cause the machine to lose traction and may

adversely affect steering, braking and stability.

5. Do not operate the machine on excessively

steep slopes. This reduces the risk of loss of

control, slipping and falling which may result in

personal injury. Slopes greater than the maximum recommended grade and side grades may

increase the risk of instability and may adversely

affect the ability to stop safely.

6. When working on slopes, always be sure of

your footing, always work across the face

of slopes, never up or down, and exercise

extreme caution when changing direction. This

reduces the risk of loss of control, slipping and

falling which may result in personal injury.

7. Whenever possible, use level areas for stopping, loading and unloading and never leave

machine unattended on a slope. The machine is

more unstable when resting on a slope than when

resting on a level surface.

8. When stopping on slopes, face the machine

uphill or downhill and block unbraked wheels.

The machine is less stable when facing across a

slope. Unbraked wheels, especially those of the

castor-type, can potentially turn and roll downhill

even while the front wheel parking brake is set.

9. When leaving the machine unattended, set

parking brake once the machine is located in a

safe stopping area. The parking brake prevents

unwanted movement of the front wheel and can

improve stability.

10. Ensure that ramps are clean, strong and

secure. In order to reduce the risk of injury, all

ramps must be clear of loose debris and strong

enough to withstand the weight of anticipated

loads that will be moved over them. They must

have adequate blocking underneath and to both

sides to eliminate deections and side-to-side

movement under load. All ramps must be wide

enough to have sure footing while hauling loads

across them.

11. Avoid extending ramps without toe boards

or railings over open spaces. Elevated open

spaces and open trenches invite accidental falls

and increase the potential for serious injury. Use

toe boards or railings on ramps over open spaces

to prevent driving the machine off the ramp.

12. Ensure all locking screws are tightly secure

before using. Locking screws on the rear wheels

and open-type carrier front and side walls must be

secure to prevent unwanted movement of these

adjustable parts of the machine.

13. Never operate the machine in an overloaded

condition. Make sure the machine has the proper

capacity rating for the objects or materials that

have to be hauled. Excessive loads will make

the machine more difcult to maneuver and stop,

will increase stopping time and distance, and will

increase the risk of instability.

14. Never operate your machine in an over stacked

condition. Stacking material above the tray rim or

over the sides of the tray can cause the machine

to be uncontrollably out of balance and control.

15. Use containers and tie-downs to secure loads.

Loose and/or insecure loads are more likely

to shift which can result in loss of stability and

control.

16. Always maintain a rm grip on handles. Loss of

control can increase the risk of personal injury.

17. Remove safety key when not in use. The safety

key prevents unwanted, powered use of the

machine, such as by children or other untrained

or unauthorized persons. Without the key, electric

power cannot be turned “on”.

18. Use a sturdy plate with anti-slip and detach-

ment prevention function when loading and/

or unloading this machine for transportation,

or moving this machine between different

levels. Make sure the plate inclination does not

exceed 12°, and operate the machine slowly

and carefully. Unstable and quick operation

may result in overturn and/or falling.

19. Do not disassemble, repair, or modify this

machine.

4 ENGLISH

Page 5

Operation

1. When operating the machine, stand behind the

machine and hold the handles rmly.

2. Do not operate the machine while riding on the

machine.

3. Do not allow others to ride on the machine.

4. When operating the machine in reverse and

walking backward, watch behind you and be

careful not to slip or trip.

5. Do not use the machine when visibility is poor

because there is a risk of striking obstacles.

6. When operating the machine on rough ground,

decrease speed and exercise caution.

7. When using the machine, avoid soft ground

to prevent overturn due to the shoulder of the

road collapsing.

8. Do not operate the machine on upward slopes

greater than 12°.

9. If you nd an abnormality, stop the machine

on at ground. Before inspecting the machine,

pull the brake lever and lock the brake, and

then turn the power off.

10.

Before operating the machine, make sure that

the lock lever is fully pulled down and com-

pletely locked. If the lock is incomplete, there is a

risk of accident or injury as the carrier or bucket may

be tilted and the objects fall when going downhill.

11. Be careful not to entangle the cords with the

load or obstacles.

Operation on slopes

1. Do not cross on slopes.

2.

Be sure to decrease speed and exercise caution.

3. Exercise caution when starting or stopping the

machine on slopes.

4. As the loads become less stable on slopes,

rmly secure the loads with ropes.

5. As the machine becomes unstable depending

on the condition of the road, keep the load to a

minimum.

6. As the view is obscured on slopes, keep the

height of the load to a minimum.

7.

Never park the machine on steep slopes. Park

the machine on at ground, pull the brake lever

and lock the brake, and then turn the power off.

8. Do not change the direction or speed mode on

steep slopes.

9. Do not release the switch trigger on upward

slopes. The machine may go in reverse and

cause an accident.

10.

Make sure that the remaining battery capacity

is enough before operating on slopes. If the

remaining battery capacity is not enough, charge

the battery or replace it with a charged one.

Loading objects

1. Do not overload objects. When loading

objects, be sure to follow the instructions and

load limits in the manual.

2. Firmly secure the objects with ropes.

3. Load the objects within the carrier or bucket.

If the objects protrude from the carrier or bucket,

there is a risk of accidents due to the objects

falling or contact obstacles such as walls.

4. Be sure that loaded objects are below eye

level. If the load is too high, it is dangerous

because the view is obscured. Also, there is a risk

of overturning and injury because the load is likely

to be unbalanced.

5. Load the objects on the carrier or bucket

evenly. If the objects are loaded unevenly, there is

a risk of overturning and injury because the load is

likely to be unbalanced.

6. Before loading the objects or operating the

machine, make sure that the lock lever is fully

pulled down and completely locked.

7. Be sure to load heavy objects rst to keep

balance.

8. Do not extend the front and side rails on steep

slopes. Extend the side rails when lightweight

objects are loaded.

9. When extending the front and side rails, do not

extend them over the extension limit. Be sure

to extend the side rails so that the right and

left sides are the same length, and load objects

evenly.

10. Load and unload objects on at ground.

11. When lifting and tilting the carrier or bucket,

hold the handles and frame rmly, and work in

a stable posture.

Maintenance

1. Always be sure to park the machine on at

ground and lock the brake lever before storage or attempting to perform inspections or

maintenance.

SAVE THESE INSTRUCTIONS.

WARNING: DO NOT let comfort or familiarity

with product (gained from repeated use) replace

strict adherence to safety rules for the subject

product. MISUSE or failure to follow the safety

rules stated in this instruction manual may cause

serious personal injury.

Symbols

The followings show the symbols used for tool.

volts

direct current

Important safety instructions for

battery cartridge

1. Before using battery cartridge, read all instruc-

tions and cautionary markings on (1) battery

charger, (2) battery, and (3) product using

battery.

2. Do not disassemble battery cartridge.

3. If operating time has become excessively

shorter, stop operating immediately. It may

result in a risk of overheating, possible burns

and even an explosion.

5 ENGLISH

Page 6

4. If electrolyte gets into your eyes, rinse them

out with clear water and seek medical attention right away. It may result in loss of your

eyesight.

5. Do not short the battery cartridge:

(1) Do not touch the terminals with any con-

ductive material.

(2) Avoid storing battery cartridge in a con-

tainer with other metal objects such as

nails, coins, etc.

(3) Do not expose battery cartridge to water

or rain.

A battery short can cause a large current

ow, overheating, possible burns and even a

breakdown.

6. Do not store the tool and battery cartridge in

locations where the temperature may reach or

exceed 50 °C (122 °F).

7. Do not incinerate the battery cartridge even if

it is severely damaged or is completely worn

out. The battery cartridge can explode in a re.

8. Be careful not to drop or strike battery.

9. Do not use a damaged battery.

10. The contained lithium-ion batteries are subject

to the Dangerous Goods Legislation requirements.

For commercial transports e.g. by third parties,

forwarding agents, special requirement on packaging and labeling must be observed.

For preparation of the item being shipped, consulting an expert for hazardous material is required.

Please also observe possibly more detailed

national regulations.

Tape or mask off open contacts and pack up the

battery in such a manner that it cannot move

around in the packaging.

11. Follow your local regulations relating to dis-

posal of battery.

SAVE THESE INSTRUCTIONS.

CAUTION: Only use genuine Makita batteries.

Use of non-genuine Makita batteries, or batteries that

have been altered, may result in the battery bursting

causing res, personal injury and damage. It will

also void the Makita warranty for the Makita tool and

charger.

Tips for maintaining maximum

battery life

1. Charge the battery cartridge before completely

discharged. Always stop tool operation and

charge the battery cartridge when you notice

less tool power.

2. Never recharge a fully charged battery cartridge. Overcharging shortens the battery

service life.

3. Charge the battery cartridge with room tem-

perature at 10 °C - 40 °C (50 °F - 104 °F). Let

a hot battery cartridge cool down before

charging it.

4. Charge the battery cartridge if you do not use

it for a long period (more than six months).

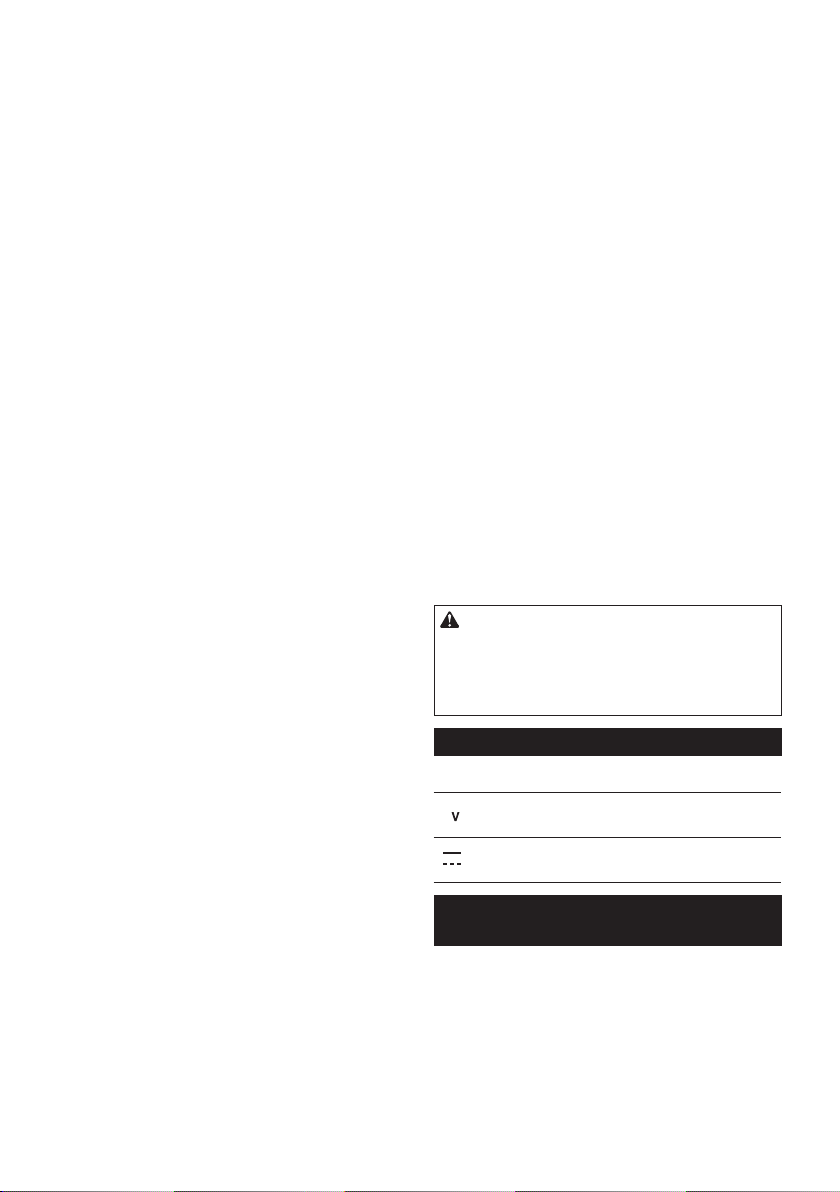

PARTS DESCRIPTION

Parts description (when the carrier

is installed)

1 2

4

10

5

6

7

9 8 6

1 Control panel 2 Handle

3 Switch trigger 4 Battery box

5 Brake lever for front

wheel

7 Brake pedal for rear

wheel

9 Front wheel 10 Carrier

Parts description (when the bucket

is installed)

10

9 8 6

1 Control panel 2 Handle

3 Switch trigger 4 Battery box

5 Brake lever for front

wheel

7 Brake pedal for rear

wheel

9 Front wheel 10 Bucket

6 Rear wheel

8 Lamp

1 2

4

5

6

7

6 Rear wheel

8 Lamp

3

2

3

2

6 ENGLISH

Page 7

ASSEMBLY

CAUTION: Always be sure that the machine is

switched off and the battery cartridge is removed

before carrying out any work on the machine.

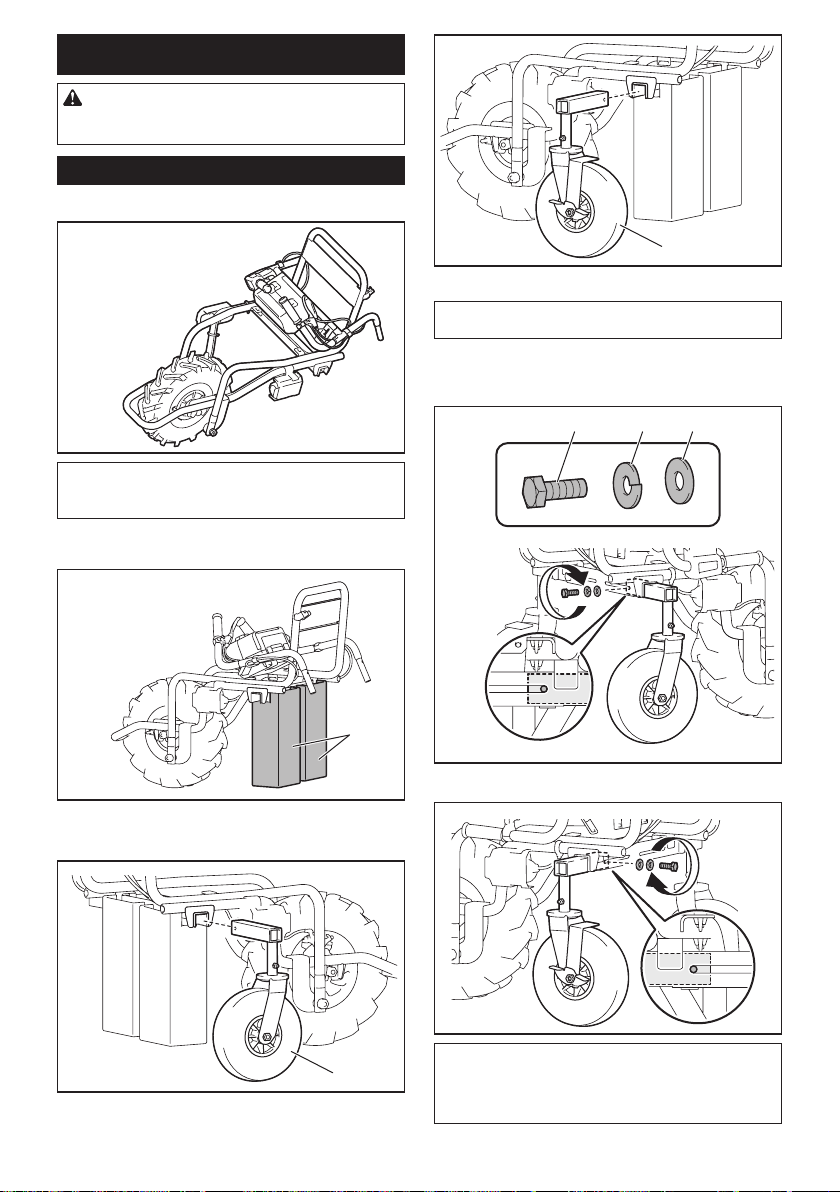

Assembling main unit

1. Take out the base unit and handles from the box.

NOTICE: Be sure to take out the base unit and

handles together, so that excessive force is not

applied to the cords.

2. Place the packing material under the rear side of

the base unit.

1

► 1. Rear wheel

NOTE: The support legs can be attached instead of

the rear wheels.

4. Attach the spring washer and the washer to the

short hexagonal bolt, and then tighten them using the

wrench included in the package.

231

► 1. Packing material

3. Insert the rear wheels into the frame.

► 1. Rear wheel

1

► 1. Short hexagonal bolt 2. Spring washer 3. Washer

NOTICE: Be sure to use the short hexagonal

1

bolts to tighten the rear wheels.

NOTICE: Fix the rear wheels at the same position

on both sides.

7 ENGLISH

Page 8

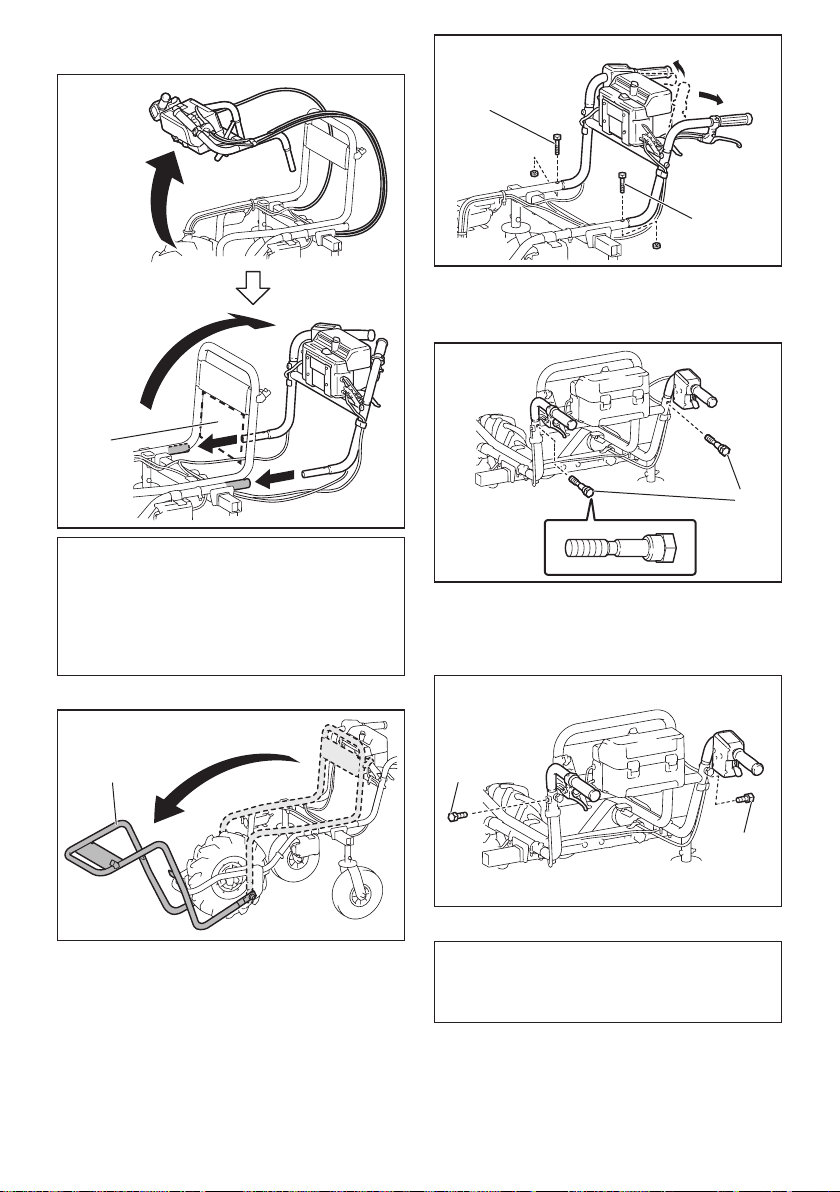

5. Raise the handles, and then insert them into the

base unit.

A

1

1

► 1. Long hexagonal bolt

8. Tighten the shoulder bolts from the rear using the

wrench included in the package.

1

NOTICE:

in the gure. Long objects may be entangled with the

cords and cause accidents.

Do not allow the cords inside area "A"

NOTICE: Do not apply excessive force to the

cords when raising and inserting the handles.

NOTICE: Be sure to raise the handles with both

hands.

6. Open the carrier frame toward the front.

1

► 1. Carrier frame

7. Unfold the handles, then insert the long hexagonal

bolts into the base unit, and then tighten the nuts with

the wrench included in the package.

► 1. Shoulder bolt

9. Tighten the short hexagonal bolts from both sides

using the wrench included in the package to x the

handles.

1

1

► 1. Short hexagonal bolt

NOTICE: Do not tighten the short hexagonal

bolts with excessive force. Tighten them with

proper force so that the handles are stably xed.

NOTICE: Do not pinch the cords with the bolts.

10. Fix the cords with the clamps.

8 ENGLISH

Page 9

CAUTION: If the rear wheels are installed,

press the brake pedal for the rear wheel to lock

the rear wheel.

13. Hook the carrier lock, and then pull down the lock

lever to lock the carrier.

1

1

2

1

► 1. Clamp

11. Fold the carrier frame.

1

► 1. Carrier frame

12. Press the lock button while pulling the brake lever

to lock the brake.

1

2

► 1. Carrier lock 2. Lock lever

NOTICE: Make sure that the lock lever is locked

securely.

NOTICE: Do not pinch the cords with the lock

lever.

NOTE: If you attach the support legs instead of the

rear wheels, remove the rear wheels from the frames,

and then attach the support legs to the frames.

1

2

► 1. Rear wheel 2. Support leg

► 1. Lock button 2. Brake lever

9 ENGLISH

Page 10

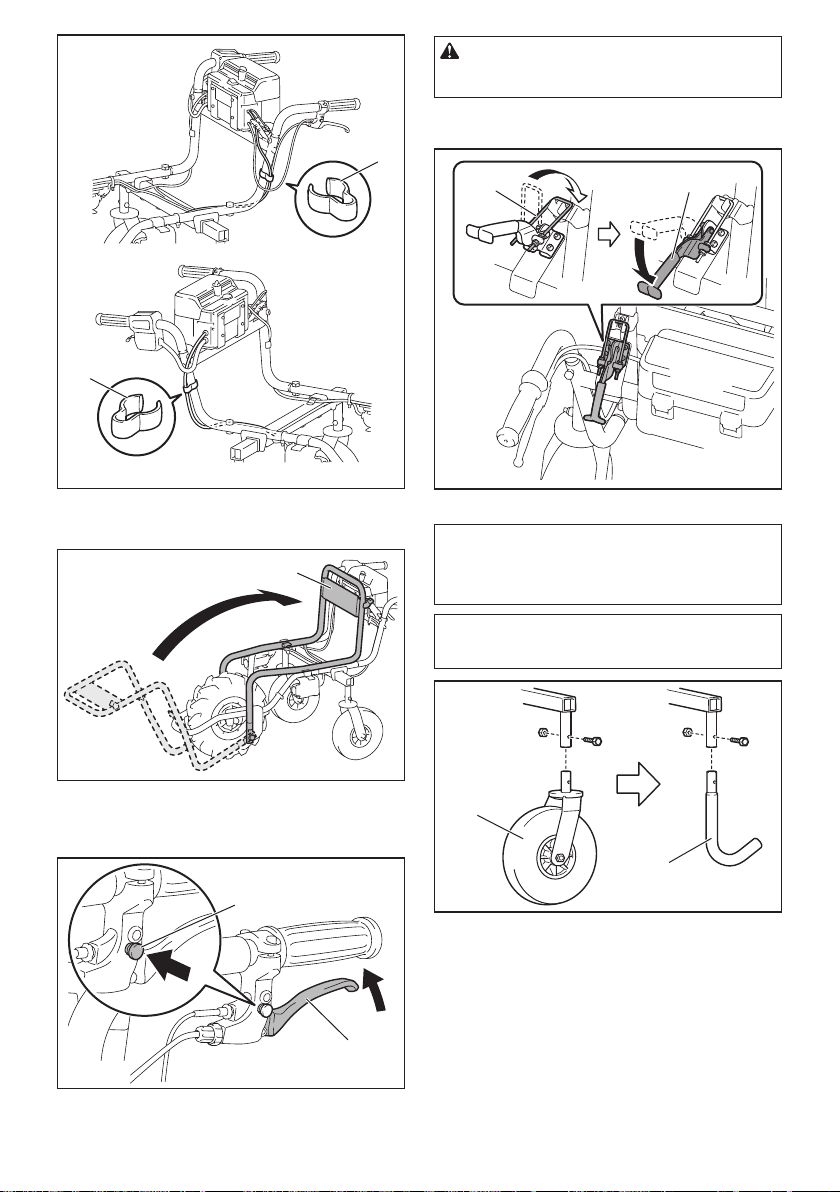

Assembling and installing carrier

Optional accessory

1. Take out the carrier from the box, attach the front

and side rails to the base frame, and then tighten the

thumb nuts to x the rails.

1

1

► 1. Thumb nut

2. Place the carrier on the base unit, and then insert

the hexagonal bolts and washers into the frames from

the top. Tighten the washers and spring washers and

buttery nuts from the bottom to x the carrier.

1

2

3

3

4

5

► 1. Long hexagonal bolt 2. Short hexagonal bolt

3. Washer 4. Spring washer 5. Buttery nut

NOTICE: Use the long bolts for the front, and the

short bolts for the rear.

Installing bucket

Optional accessory

Place the bucket on the base unit, insert the hexagonal bolts

into the frames, and then tighten the washers and spring

washers and buttery nuts from the bottom to x the bucket.

1

1

2

3

4

►

1. Hexagonal bolt 2. Washer 3. Spring washer 4. Buttery nut

10 ENGLISH

Page 11

FUNCTIONAL

DESCRIPTION

Installing or removing battery

cartridge

CAUTION: Always switch off the machine

before installing or removing of the battery

cartridge.

CAUTION: Make sure that you lock the battery

cover before use. Otherwise, mud, dirt, or water may

cause damage to the product or the battery cartridge.

CAUTION: Always install the battery cartridge

fully until the red indicator cannot be seen. If not,

it may accidentally fall out of the machine, causing

injury to you or someone around you.

CAUTION: Do not install the battery cartridge

forcibly. If the cartridge does not slide in easily, it is

not being inserted correctly.

CAUTION: Do not use the high-temperature

battery cartridge. When the high-temperature battery cartridge is used, the machine stops automatically before a short beep sound is emitted, and may

cause an injury.

Installing the battery cartridge

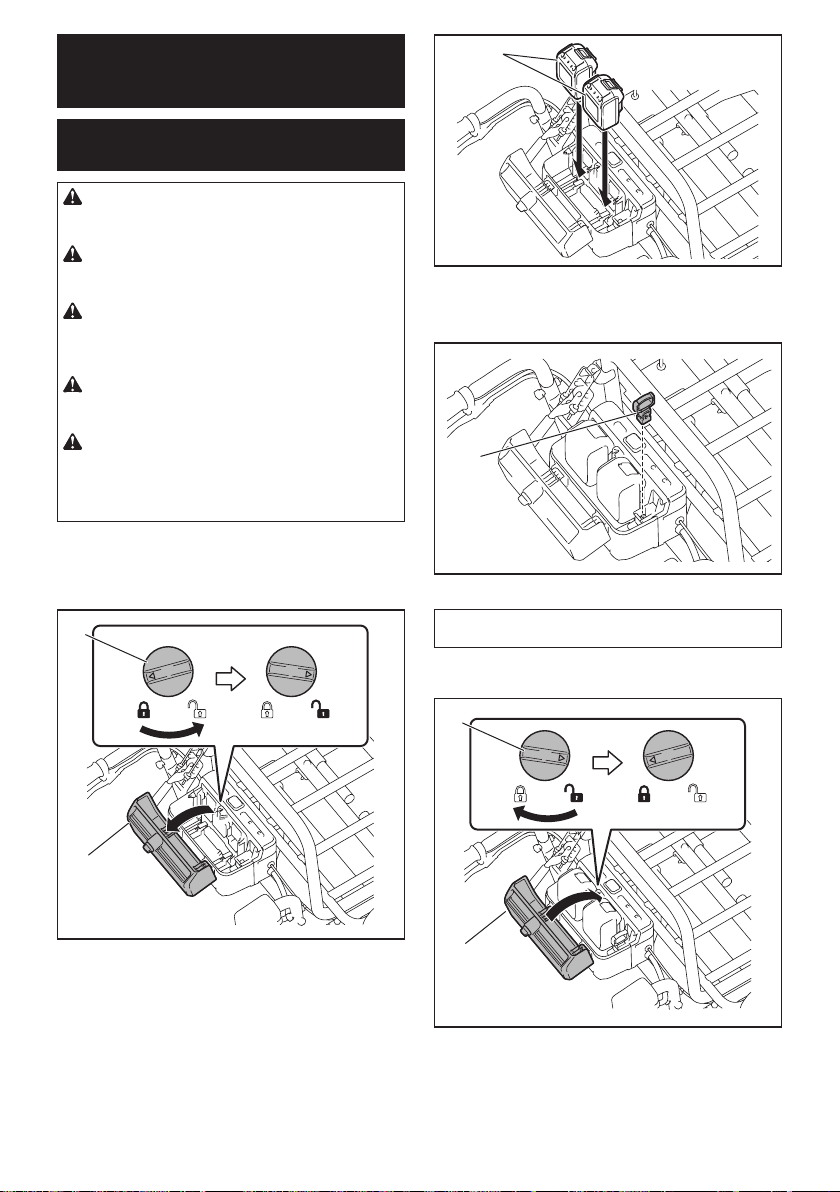

1. Rotate the lock lever, and then open the cover of

the battery box.

1

1

► 1. Battery cartridge

3. Insert the lock key in the place shown in the gure

as far as it will go.

1

► 1. Lock key

NOTE: If the lock key is not inserted completely, the

machine does not work.

4. Close the cover of the battery box, and then rotate

the lock lever.

2

► 1. Lock lever 2. Cover

2. Align the tongue on the battery cartridge with the

slot on the battery box, and then slide the cartridge until

it locks in place with a little click. If you can see the red

indicator on the upper side of the button, battery cartridge is not locked completely.

1

2

► 1. Lock lever 2. Cover

11 ENGLISH

Page 12

Removing the battery cartridge

11

1. Rotate the lock lever, and then open the cover of

the battery box.

2. Pull out the battery cartridge from the battery box

while sliding the button on the front of the cartridge.

1

► 1. Button

3. Pull out the lock key.

4. Close the cover of the battery box, and then rotate

the lock lever.

Machine / battery protection system

The machine is equipped with a machine/battery

protection system. This system automatically cuts off

power to the motor to extend machine and battery life.

The machine will automatically stop during operation

if the machine or battery cartridge is under one of the

following conditions. A short beep sound is emitted

before the machine stops automatically. The battery

indicators and LED indicators blink while the beep

sound is emitted.

Overload protection

When the machine is operated in a manner that causes

it to draw an abnormally high current, the machine automatically stops without any indication. In this situation,

turn the machine off and remove the cause of overload,

and then turn the machine on to restart.

Overheat protection

When the machine is overheated, the machine stops

automatically. Let the machine cool down before turning

the machine on again. The overheat protection is likely

to work under high temperature environment.

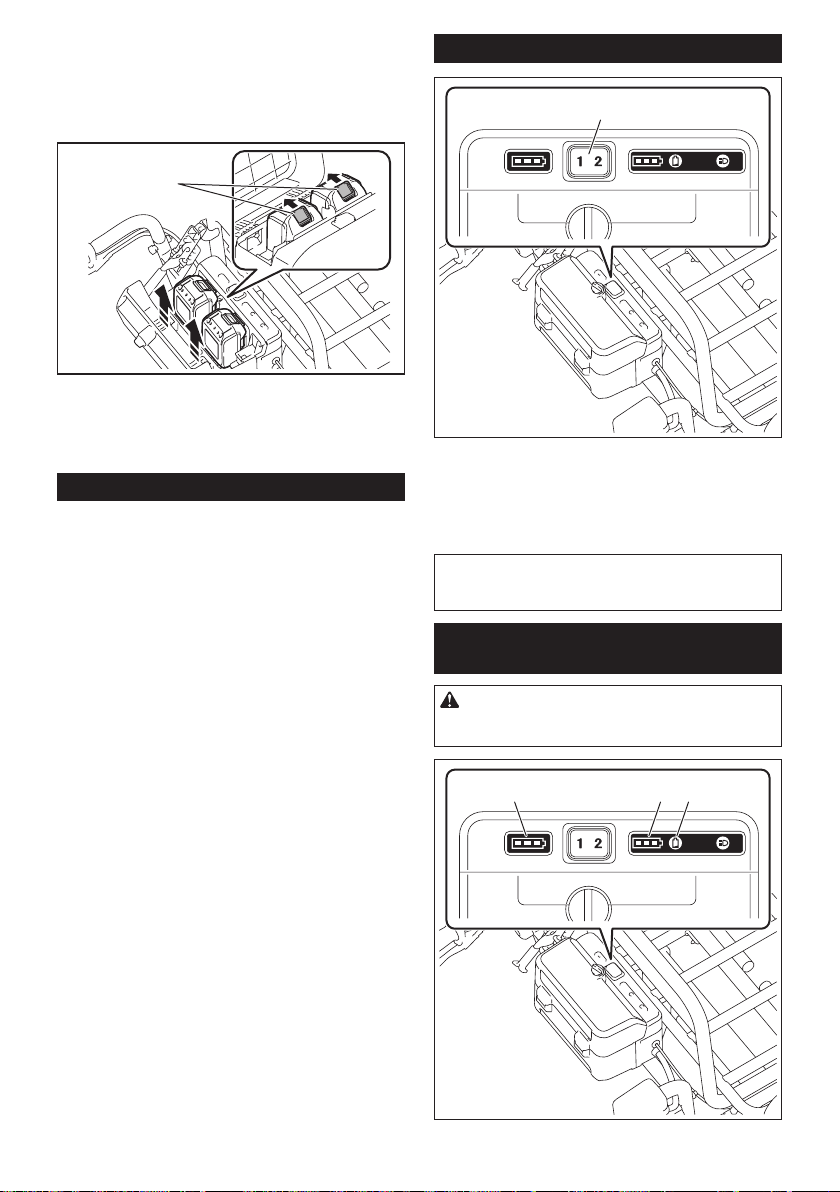

Switching the battery cartridge

1

► 1. Battery selection switch

Up to two battery cartridges can be installed in the

battery box, although the machine uses one battery

cartridge for operation. Before operating the machine,

select the battery cartridge used for operation by pressing the number on the battery selection switch.

NOTICE: If only one battery cartridge is installed in

the battery box, be sure to select the battery box in

which the battery cartridge is installed.

Indicating the remaining battery

capacity on the battery box

CAUTION: Before checking the remaining

battery capacities or switching the battery car-

tridge, be sure to stop the machine.

2

Overdischarge protection

When the battery capacity becomes low, the machine

stops automatically. If the machine does not operate

even when the switches are operated, remove the

battery cartridge and charge it.

► 1. Battery indicator 2. Check button

12 ENGLISH

Page 13

Press the check button to indicate the remaining battery

capacities. The battery indicators correspond to each

battery.

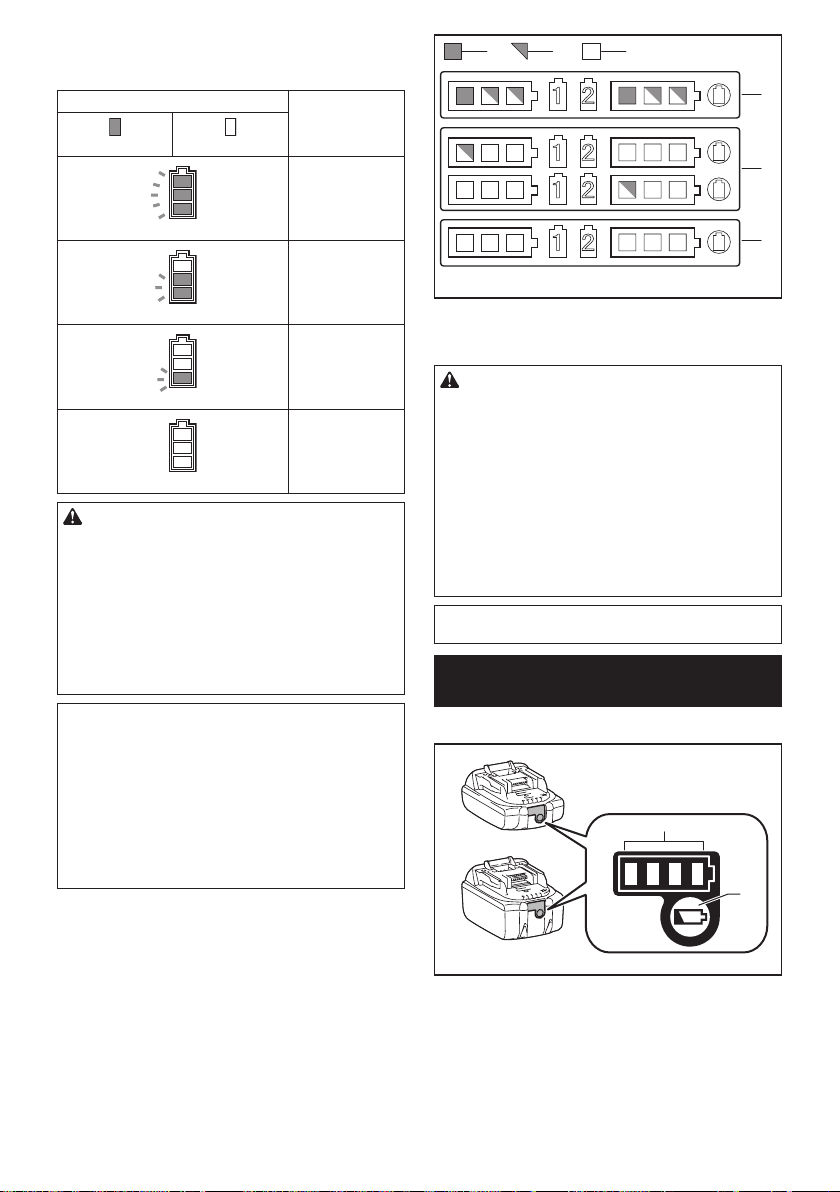

Battery indicator status

On

Off

Remaining battery

capacity

50% - 100%

20% - 50%

0% - 20%

Battery not

installed

CAUTION: When the battery capacity

becomes low, a short beep sound is emitted.

If you continue to operate the machine at low

battery capacity, a long beep sound is emitted

and the machine automatically stops. When you

hear the short beep sound, pull the brake lever

and lock the brake, and then switch the battery

cartridge to a charged one or charge the battery

cartridge. When the remaining battery capacity runs

out, the machine suddenly stops automatically and

this may cause an injury.

NOTE: If you continue to pull the switch trigger even

if you hear the short beep sound, the machine stops

automatically. After the machine stops automatically,

the beep sound continues and the support brake

(electric brake) is enabled. To cancel the beep sound

and release the support brake, pull the brake lever

and release the switch trigger. Do not push the

machine forcibly without releasing the support brake.

After releasing the support brake, you can tell which

battery protection system is working by checking the

battery indicator status.

1 23

4

5

6

► 1. Lighting 2. Blinking 3. Turned off 4. Overheat

protection 5. Overdischarge protection 6. Overload

protection

CAUTION: If the beep sound is emitted while

operating on slopes or the machine stops automatically on slopes, move the machine to a safe

place, lock the brake, and then switch the battery

cartridge to a charged one or charge the battery

cartridge.

If the load is large, and the beep sound is emitted while operating on slopes or the machine

stops automatically on slopes, do not move the

machine forcibly. Lock the brake, pay attention to

safety and switch the battery cartridge to a charged

one, and then move the machine to a safe place.

Reduce the load before operating the machine again.

NOTE: You can check the remaining battery capacity

even if the lock key is not inserted.

Indicating the remaining battery

capacity

Only for battery cartridges with the indicator

1

2

► 1. Indicator lamps 2. Check button

Press the check button on the battery cartridge to indicate the remaining battery capacity. The indicator lamps

light up for a few seconds.

13 ENGLISH

Page 14

Indicator lamps Remaining

23

Lighted Off Blinking

NOTE: Depending on the conditions of use and the

ambient temperature, the indication may differ slightly

from the actual capacity.

capacity

75% to 100%

50% to 75%

25% to 50%

0% to 25%

Charge the

battery.

The battery

may have

malfunctioned.

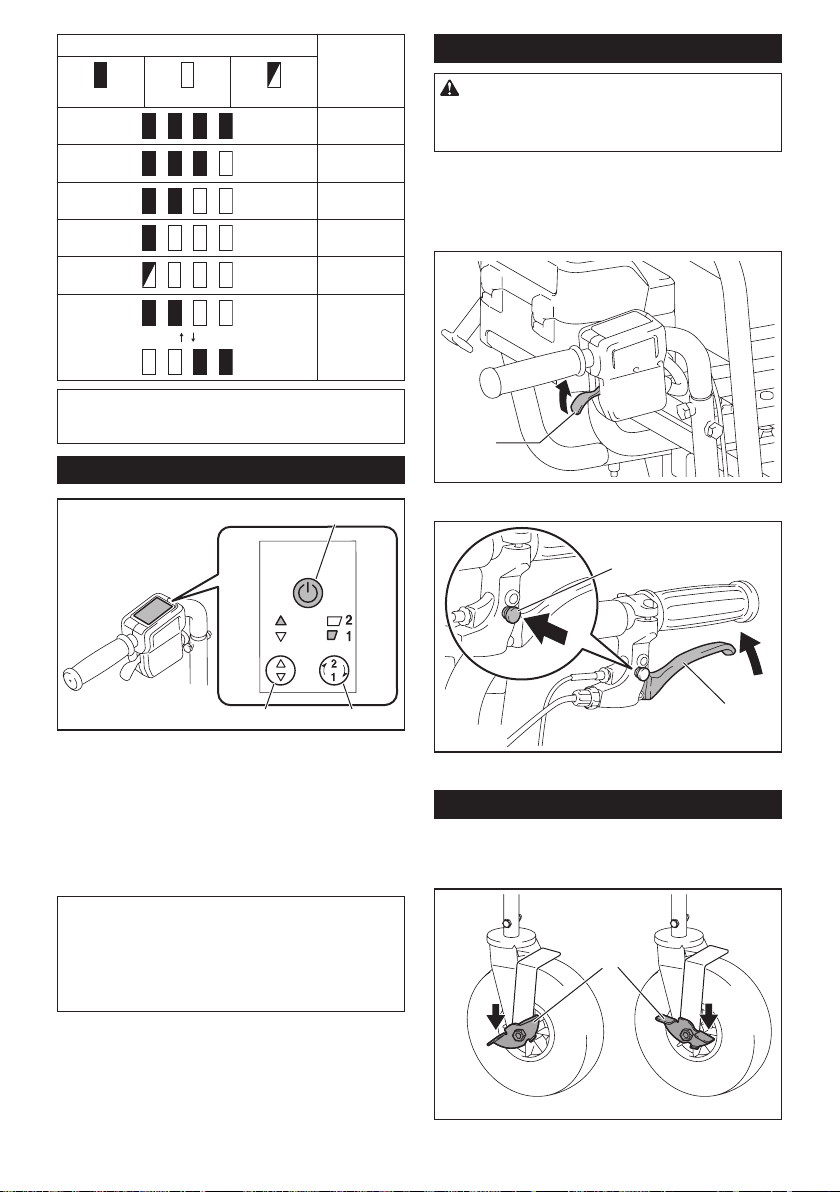

Control panel

1

Switch and brake action

WARNING: Before installing the battery car-

tridge into the machine, always check to see that

the switch trigger actuates properly and returns

to the "OFF" position when released.

To start the machine, pull the switch trigger. To stop the

machine, release the switch trigger and pull the brake

lever. To lock the brake lever, press the lock button

while pulling the brake lever. To release the lock, pull

the brake lever.

1

► 1. Switch trigger

1

► 1. Power button 2. Forward/reverse button 3. Speed

button

To turn the power on, press the power button for a few

seconds. Press the forward/reverse button to switch

between the forward mode and reverse mode. Press

the speed button to switch between low speed and high

speed. When the power is turned on, the forward mode

and low speed are set. To turn the power off, press the

power button for a few seconds.

NOTE: The forward/reverse button is not available

while pulling the switch trigger.

NOTE: A short beep sound comes out when operating the machine in reverse.

NOTE: The speed button is not available when operating the machine in reverse.

2

► 1. Lock button 2. Brake lever

Rear wheel brake

The rear wheel on the left side is equipped with a brake.

Press the brake pedal toward the front to lock the brake. To

release the brake, press the brake pedal toward the rear.

1

► 1. Pedal

14 ENGLISH

Page 15

Lighting up the front lamps

Press the lamp button on the battery box to light up

the lamps. To turn off the lamps, press the lamp button

again.

1

1

2

2

2

► 1. Lamp button 2. Lamp

NOTE: The lamps go off if the machine is left unat-

tended for approximately 10 minutes.

NOTE: The lamps go off when the power is turned off.

NOTE: You can light up the lamps even if the lock key

is not inserted.

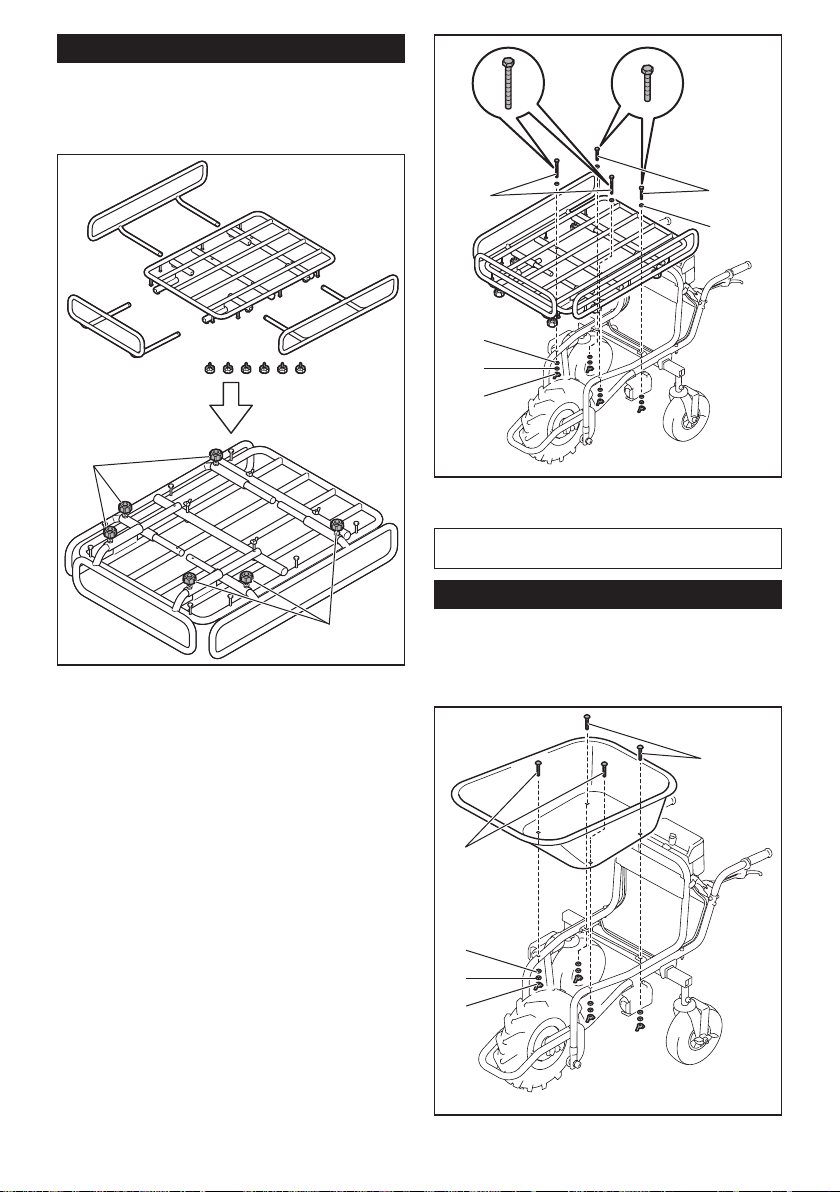

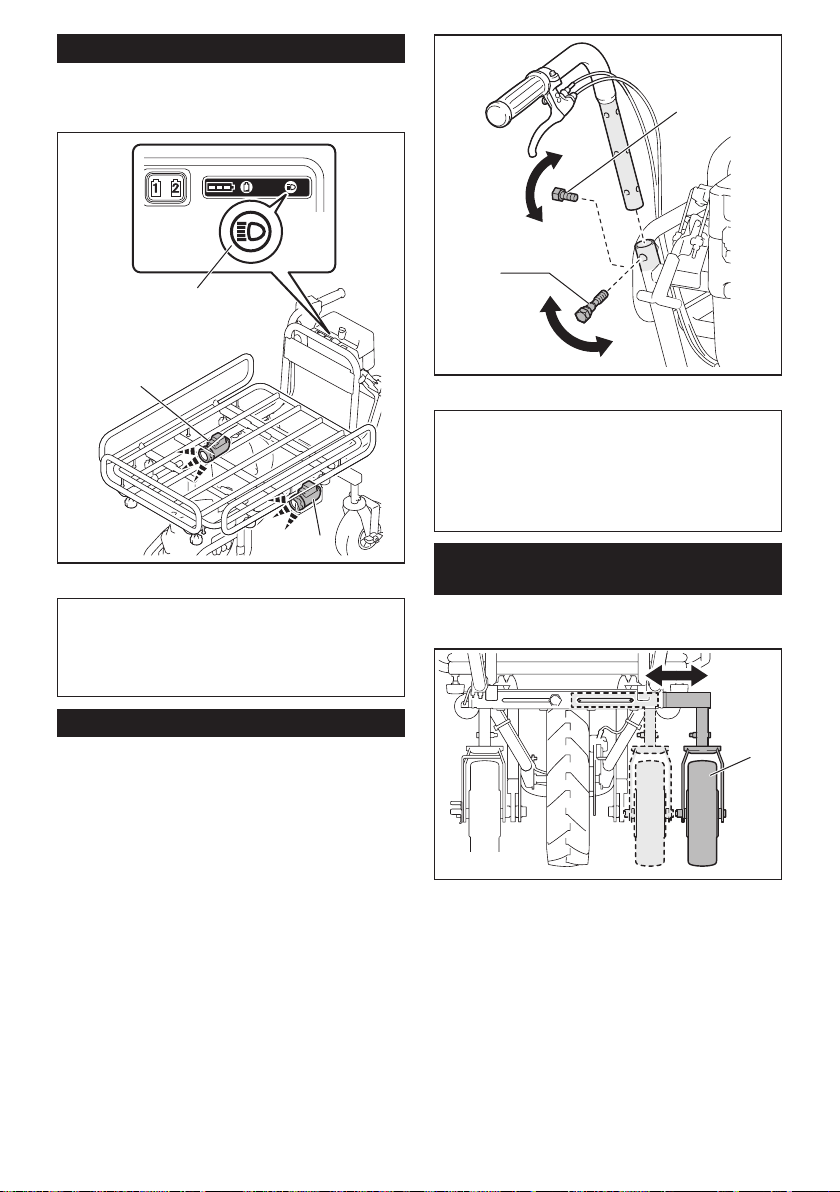

Adjusting the handle height

Remove the short hexagonal bolts and shoulder bolts

using the wrench included in the package, and then

adjust the handle height. The height can be adjusted to

three levels. Tighten the shoulder bolts and short hex-

agonal bolts to x the handle.

► 1. Short hexagonal bolt 2. Shoulder bolt

NOTICE: Fix the left and right handles at the

same height.

NOTICE: Do not tighten the short hexagonal

bolts with excessive force. Tighten them with

proper force so that the handles are stably xed.

NOTICE: Do not pinch the cords with the bolts.

Adjusting the width of the rear

wheels

Loosen the short hexagonal bolts using the wrench

included in the package, and then slide the rear wheels.

1

► 1. Rear wheel

Tighten the short hexagonal bolts using the wrench

included in the package to x the wheels.

15 ENGLISH

Page 16

1

► 1. Short hexagonal bolt

CAUTION: Extend the rear wheels to the max-

imum to keep balance. When the rear wheels are

not extended, keep the load to a minimum.

NOTICE: Fix the rear wheels at the same position

on both sides.

Adjusting the width of the carrier

Loosen the 6 thumb nuts, and then slide the front and

side rails. Tighten the thumb nuts to x the front and

side rails.

1

2

OPERATION

Operating the machine

NOTICE: The front wheel is driven by battery

power in this machine. Use this machine to assist

with carrying operations.

NOTICE: Be sure to insert the lock key in the bat-

tery box before the operation. If the lock key is not

inserted, a short beep sound is emitted when you pull

the switch trigger. The beep sound stops by releasing

the switch trigger and pulling the brake lever.

1. Select the battery cartridge with the battery selection switch.

2. Press the power button on the control panel for a

few seconds to turn the power on.

1

► 1. Power button

1

1

► 1. Thumb nut 2. Rail

CAUTION: Do not slide the rails beyond the

limit mark.

1

3. Pull the brake lever to release the lock of the

brake lever.

1

2

► 1. Lock button 2. Brake lever

NOTE: Release the rear wheel brake if the rear

wheels are installed.

4. Hold the handles rmly with both hands.

16 ENGLISH

Page 17

5. Pull the switch trigger.

CAUTION: Be sure to load objects so that

they are below eye level. If the load is too high, it is

dangerous because the view is obscured. Also, there

is a risk of overturning and injury because the load is

likely to be unbalanced.

1

► 1. Switch trigger

Loading objects

CAUTION: Before loading objects on the

machine, make sure that the power is off and the

brake lever is locked.

CAUTION: If the rear wheels are installed,

make sure that the rear wheel brake is locked

before loading objects on the machine.

CAUTION: Before loading objects on the

machine, make sure that the carrier or bucket is

locked.

CAUTION: Be sure to load objects within the

carrier or bucket. If objects are sticking out of the

carrier or bucket, they may fall or collapse if they

touch obstacles.

When loading objects on the carrier, secure the objects

with ropes and tie them down to the rope hooks.

17 ENGLISH

Page 18

Dumping objects

CAUTION: Lift the carrier or bucket on at

and stable ground. Operation on unstable ground

my cause an accident or injury.

You can dump the objects by lifting and tilting the carrier

or bucket.

1. Stop the machine, and then lock the brakes.

NOTICE: It is recommended to block the front

wheel to stabilize the machine.

2. Release the lock lever.

3. Stand at the side of the machine, hold the handle

with one hand, and then lift and tilt the carrier or bucket

by pushing up the carrier frame with the other hand.

Periodic checks

• Check that the bolts and nuts are tightened rmly.

• Check that the carrier is locked when the lock

lever is fully pulled down.

CAUTION: Hold the handle and carrier frame

rmly, and work in a stable posture.

CAUTION: Keep the load to a minimum. If the

load is large, do not try to lift the carrier. Reduce

the load, and then lift the carrier.

CAUTION: After dumping the objects, be sure

to lock the carrier or bucket.

MAINTENANCE

CAUTION: Always be sure to park the

machine on at ground and lock the brake lever

before storage or attempting to perform inspections or maintenance.

CAUTION: If the rear wheels are installed,

make sure that the rear wheel brake is locked

before storage, inspections, or maintenance.

CAUTION: Always be sure that the lock

key and battery cartridge are removed from

the machine before storage, inspections, or

maintenance.

CAUTION: Always remove the lock key when

the machine is not in use. Store the lock key in a

safe place out of reach of children.

1

► 1. Carrier lock 2. Lock lever

• Check that the brake lever works properly.

2

1

► 1. Brake lever

18 ENGLISH

Page 19

WARNING: If the brake lever reaches the han-

dle when you fully pull the lever, the brake is not

working properly. Adjust the brake, or ask your

local Makita Service Center for repairs.

• Check to see if the front wheel is not damaged or

at.

Cleaning the machine

NOTICE: Never use gasoline, benzine, thinner,

alcohol or the like. Discoloration, deformation or

cracks may result.

NOTICE: Pour the water below the carrier or

bucket when cleaning the machine with running

water. Do not use the high pressure washer for

cleaning.

Remove mud, dirt, and the like from the machine. Clean

the machine with running water. After the cleaning, wipe

the machine with a dry cloth.

Storage

Remove the lock key. Store the machine in a safe place

out of the reach of children.

When storing the machine, the handles can be turned

toward the front. Remove the short hexagonal bolts

and shoulder bolts using the wrench included in the

package. Turn the handles toward the outside, and then

rotate the handles to the front. Tighten the shoulder

bolts and short hexagonal bolts to x the handles.

1

► 1. Carrier frame

2. Pull the brake lever to release the lock button of

the brake lever.

1

2

► 1. Lock button 2. Brake lever

3. Loosen the adjusting sleeve and xing nut.

2

1

► 1. Shoulder bolt 2. Short hexagonal bolt

NOTICE: Do not tighten the short hexagonal

bolts with excessive force. Tighten them with

proper force so that the handles are stably xed.

NOTICE: Do not pinch the cords with the bolts.

Adjusting the brake

CAUTION: If the rear wheels are installed, be

sure to lock the rear wheel brake before adjusting

the brake.

1. Remove the carrier or bucket, and then open the

carrier frame.

2

12

► 1. Adjusting sleeve 2. Fixing nut

4. Tighten the xing nut only.

19 ENGLISH

Page 20

1

1

► 1. Fixing nut

5. Loosen the adjusting sleeve and xing nut.

12

► 1. Adjusting sleeve 2. Fixing nut

6. Tighten the xing nut only.

► 1. Fixing nut

7. Make sure that the brake lever is in the halfway

position when it is fully pulled. If the brake lever is in the

halfway position, go to step 13. If the brake lever is not

in the halfway position, go to step 8.

1

► 1. Brake lever

8. Loosen the xing nut only.

20 ENGLISH

Page 21

1

1

► 1. Fixing nut

9. Tighten the xing nut and adjusting sleeve

together.

12

► 1. Adjusting sleeve 2. Fixing nut

10. Loosen the xing nut only.

► 1. Fixing nut

11. Tighten the xing nut and adjusting sleeve

together.

12

► 1. Adjusting sleeve 2. Fixing nut

12. Make sure that the brake lever is in the halfway

position when it is fully pulled.

21 ENGLISH

Page 22

1

► 1. Brake lever

13. Fold the carrier frame, and then attach the carrier

or bucket.

1

► 1. Carrier frame

OPTIONAL

ACCESSORIES

CAUTION: These accessories or attachments

are recommended for use with your Makita tool

specied in this manual. The use of any other

accessories or attachments might present a risk of

injury to persons. Only use accessory or attachment

for its stated purpose.

If you need any assistance for more details regarding these accessories, ask your local Makita Service

Center.

• Carrier

• Bucket

• Makita genuine battery and charger

NOTE: Some items in the list may be included in the

tool package as standard accessories. They may

differ from country to country.

MAKITA LIMITED ONE YEAR

WARRANTY

Warranty Policy

Every Makita tool is thoroughly inspected and tested

before leaving the factory. It is warranted to be free of

defects from workmanship and materials for the period

of ONE YEAR from the date of original purchase.

Should any trouble develop during this one year period,

return the COMPLETE tool, freight prepaid, to one

of Makita’s Factory or Authorized Service Centers. If

inspection shows the trouble is caused by defective

workmanship or material, Makita will repair (or at our

option, replace) without charge.

This Warranty does not apply where:

• repairs have been made or attempted by others:

• repairs are required because of normal wear and

tear:

• the tool has been abused, misused or improperly

maintained:

• alterations have been made to the tool.

IN NO EVENT SHALL MAKITA BE LIABLE FOR ANY

INDIRECT, INCIDENTAL OR CONSEQUENTIAL

DAMAGES FROM THE SALE OR USE OF THE

PRODUCT. THIS DISCLAIMER APPLIES BOTH

DURING AND AFTER THE TERM OF THIS

WARRANTY.

MAKITA DISCLAIMS LIABILITY FOR ANY IMPLIED

WARRANTIES, INCLUDING IMPLIED WARRANTIES

OF "MERCHANTABILITY" AND "FITNESS FOR A

SPECIFIC PURPOSE," AFTER THE ONE YEAR TERM

OF THIS WARRANTY.

This Warranty gives you specic legal rights, and you

may also have other rights which vary from state to

state. Some states do not allow the exclusion or limitation of incidental or consequential damages, so the

above limitation or exclusion may not apply to you.

Some states do not allow limitation on how long an

implied warranty lasts, so the above limitation may not

apply to you.

22 ENGLISH

Page 23

ESPAÑOL (Instrucciones originales)

ESPECIFICACIONES

Modelo: XUC01

Dimensiones

(La x An x Al)

Velocidad de recorrido Hacia adelante 1,5 km/h o 3,5 km/h (0,9 mile/h o 2,2 mile/h)

Radio de giro mínimo 1 075 mm (1,2 yard)

Capacidad máxima para subir pendientes 12°

Capacidad máxima de carga 130 kg (287 lbs)

Freno Rueda delantera Freno de disco con cable

Neumático Rueda delantera Neumático sin cámara

Tensión nominal 18 V c.c.

Batería estándar

Cargador DC18RC / DC18RD / DC18SD / DC18SE / DC18SF

Peso neto Con la cesta instalada 45 kg (99 lbs)

• Debido a nuestro continuo programa de investigación y desarrollo, las especicaciones aquí incluidas están

sujetas a cambio sin previo aviso.

• Las especicaciones y el cartucho de batería pueden variar de país a país.

• El peso puede variar en función de los accesorios, incluido el cartucho de batería. En la tabla se muestra la

combinación de peso más ligero y más pesado conforme al procedimiento 01/2014 de EPTA.

Con la cesta instalada Durante la operación: 1 560 mm x 1 060 mm x 900 mm

Durante el almacenamiento: 1 110 mm x 670 mm x 820 mm

Con la canasta instalada Durante la operación: 1 310 mm x 790 mm x 900 mm

Durante el almacenamiento: 1 110 mm x 590 mm x 820 mm

Hacia atrás 1,0 km/h (0,6 mile/h)

(Diámetro exterior al girar con la rueda delantera como eje)

Rueda trasera Fijo con pedal

Rueda trasera Neumático autosellable

BL1815N / BL1820B / BL1830 / BL1830B / BL1840B / BL1850B / BL1860B

Con la canasta instalada 39 kg - 40 kg (86 lbs - 88 lbs)

(61-1/2″ x 41-3/4″ x 35-1/2″)

(43-3/4″ x 26-3/8″ x 32-1/4″)

(51-1/2″ x 31-1/8″ x 35-1/2″)

(43-3/4″ x 23-1/4″ x 32-1/4″)

ADVERTENCIAS DE

SEGURIDAD

Advertencias generales de

seguridad para herramientas

eléctricas

ADVERTENCIA: Lea todas las advertencias

de seguridad, instrucciones, ilustraciones y espe-

cicaciones suministradas con esta herramienta

eléctrica. El no seguir todas las instrucciones indicadas a continuación podría ocasionar una descarga

eléctrica, incendio y/o lesiones graves.

Conserve todas las advertencias

e instrucciones como referencia

en el futuro.

En las advertencias, el término “herramienta eléctrica”

se reere a su herramienta eléctrica de funcionamiento

con conexión a la red eléctrica (con cableado eléctrico)

o herramienta eléctrica de funcionamiento a batería

(inalámbrica).

Seguridad en el área de trabajo

1. Mantenga el área de trabajo limpia y bien ilu-

minada. Las áreas oscuras o desordenadas son

propensas a accidentes.

2. No utilice las herramientas eléctricas en

atmósferas explosivas, tal como en la presencia de líquidos, gases o polvo inamables. Las

herramientas eléctricas crean chispas que pueden

prender fuego al polvo o los humos.

3. Mantenga a los niños y curiosos alejados

mientras utiliza una herramienta eléctrica. Las

distracciones le pueden hacer perder el control.

23 ESPAÑOL

Page 24

Seguridad eléctrica

1.

Las clavijas de conexión de las herramientas

eléctricas deberán encajar perfectamente en la

toma de corriente. No modique nunca la clavija

de conexión de ninguna forma. No utilice ninguna

clavija adaptadora con herramientas eléctricas

que tengan conexión a tierra (puesta a tierra). La

utilización de clavijas no modicadas y que encajen

perfectamente en la toma de corriente reducirá el

riesgo de que se produzca una descarga eléctrica.

2.

Evite tocar con el cuerpo supercies conectadas a tierra o puestas a tierra tales como tubos,

radiadores, cocinas y refrigeradores. Si su cuerpo

es puesto a tierra o conectado a tierra existirá un

mayor riesgo de que sufra una descarga eléctrica.

3. No exponga las herramientas eléctricas a la

lluvia ni a condiciones húmedas. La entrada de

agua en una herramienta eléctrica aumentará el

riesgo de que se produzca una descarga eléctrica.

4. No maltrate el cable. Nunca utilice el cable

para transportar, jalar o desconectar la herramienta eléctrica. Mantenga el cable alejado del

calor, aceite, objetos cortantes o piezas móvi-

les. Los cables dañados o enredados aumentan

el riesgo de sufrir una descarga eléctrica.

5.

Cuando utilice una herramienta eléctrica en

exteriores, utilice un cable de extensión apro-

piado para uso en exteriores. La utilización de un

cable apropiado para uso en exteriores reducirá el

riesgo de que se produzca una descarga eléctrica.

6. Si no es posible evitar usar una herramienta

eléctrica en condiciones húmedas, utilice un

alimentador protegido con interruptor de cir-

cuito de falla a tierra (ICFT). El uso de un ICFT

reduce el riesgo de descarga eléctrica.

7.

Las herramientas eléctricas pueden producir campos electromagnéticos (CEM) que no son dañinos

para el usuario. Sin embargo, si los usuarios tienen

marcapasos y otros dispositivos médicos similares,

deberán consultar al fabricante de su dispositivo y/o a

su médico antes de operar esta herramienta eléctrica.

Seguridad personal

1. Manténgase alerta, preste atención a lo que

está haciendo y utilice su sentido común

cuando opere una herramienta eléctrica. No

utilice una herramienta eléctrica cuando esté

cansado o bajo la inuencia de drogas, alcohol o medicamentos. Un momento de distracción

mientras opera las herramientas eléctricas puede

terminar en una lesión grave.

2. Use equipo de protección personal. Póngase

siempre protección para los ojos. El equipo

protector tal como máscara contra el polvo, zapatos de seguridad antiderrapantes, casco rígido y

protección para oídos utilizado en las condiciones

apropiadas reducirá el riesgo de lesiones.

3. Impida el encendido accidental. Asegúrese

de que el interruptor esté en la posición de

apagado antes de conectar a la alimentación

eléctrica y/o de colocar el cartucho de batería,

así como al levantar o cargar la herramienta.

Cargar las herramientas eléctricas con su dedo

en el interruptor o enchufarlas con el interruptor encendido hace que los accidentes sean

comunes.

4. Retire cualquier llave de ajuste o llave de

apriete antes de encender la herramienta. Una

llave de ajuste o llave de apriete que haya sido

dejada puesta en una parte giratoria de la herra-

mienta eléctrica puede ocasionar alguna lesión.

5.

No utilice la herramienta donde no alcance.

Mantenga los pies sobre suelo rme y el equilibrio

en todo momento. Esto permite un mejor control de

la herramienta eléctrica en situaciones inesperadas.

6.

Use una vestimenta apropiada. No use ropa suelta

ni alhajas. Mantenga el cabello, la ropa y los guantes alejados de las piezas móviles. Las prendas de

vestir holgadas, las alhajas y el cabello largo suelto

podrían engancharse en estas piezas móviles.

7.

Si dispone de dispositivos para la conexión de

equipos de extracción y recolección de polvo,

asegúrese de conectarlos y utilizarlos debida

mente. Hacer uso de la recolección de polvo puede

reducir los riesgos relacionados con el polvo.

8.

No permita que la familiaridad adquirida debido

al uso frecuente de las herramientas haga que se

sienta conado e ignore los principios de seguridad de las herramientas. Un descuido podría oca-

sionar una lesión grave en una fracción de segundo.

9. Utilice siempre gafas protectoras para prote-

ger sus ojos de lesiones al usar herramientas

eléctricas. Las gafas deben cumplir con la

Norma ANSI Z87.1 en EUA.

Es responsabilidad del empleador imponer

el uso de equipos protectores de seguridad

apropiados a los operadores de la herramienta

y demás personas cerca del área de trabajo.

Mantenimiento y uso de la herramienta eléctrica

1. No fuerce la herramienta eléctrica. Utilice la

herramienta eléctrica correcta para su aplicación. La herramienta eléctrica adecuada hará un

mejor trabajo y de forma más segura a la velocidad para la que ha sido fabricada.

2.

No utilice la herramienta eléctrica si el interruptor no la enciende y apaga. Cualquier herramienta

eléctrica que no pueda ser controlada con el interruptor es peligrosa y debe ser reemplazada.

3.

Desconecte la clavija de la fuente de alimentación y/o retire la batería de la herramienta eléctrica, en caso de ser removible, antes de realizar

ajustes, cambiar accesorios o almacenar las

herramientas eléctricas. Tales medidas de segu-

ridad preventivas reducirán el riesgo de poner en

marcha la herramienta eléctrica de forma accidental.

4. Guarde la herramienta eléctrica que no use

fuera del alcance de los niños y no permita

que las personas que no están familiarizadas

con ella o con las instrucciones la operen. Las

herramientas eléctricas son peligrosas en manos

de personas que no saben operarlas.

5. Dé mantenimiento a las herramientas eléctri-

cas y los accesorios. Compruebe que no haya

piezas móviles desalineadas o estancadas,

piezas rotas y cualquier otra condición que

pueda afectar al funcionamiento de la herramienta eléctrica. Si la herramienta eléctrica

está dañada, haga que la reparen antes de

utilizarla. Muchos de los accidentes son ocasio-

nados por no dar un mantenimiento adecuado a

las herramientas eléctricas.

24 ESPAÑOL

-

Page 25

6. Mantenga las herramientas de corte limpias

y losas. Si recibe un mantenimiento adecuado

y tiene los bordes alados, es probable que la

herramienta se atasque menos y sea más fácil

controlarla.

7. Utilice la herramienta eléctrica, los accesorios

y las brocas de acuerdo con estas instrucciones, considerando las condiciones laborales

y el trabajo a realizar. Si utiliza la herramienta

eléctrica para realizar operaciones distintas de

las indicadas, podrá presentarse una situación

peligrosa.

8. Mantenga los mangos y supercies de asi-

miento secos, limpios y libres de aceite o

grasa. Los mangos y supercies de asimiento

resbalosos no permiten una manipulación segura

ni el control de la herramienta en situaciones

inesperadas.

9. Cuando vaya a utilizar esta herramienta, evite

usar guantes de trabajo de tela ya que éstos

podrían atorarse. Si los guantes de trabajo de

tela llegaran a atorarse en las piezas móviles,

esto podría ocasionar lesiones personales.

Uso y cuidado de la herramienta a batería

1. Recargue sólo con el cargador especicado

por el fabricante. Un cargador que es adecuado

para un solo tipo de batería puede generar riesgo

de incendio al ser utilizado con otra batería.

2. Utilice las herramientas eléctricas solamente

con las baterías designadas especícamente

para ellas. La utilización de cualquier otra batería

puede crear un riesgo de lesiones o incendio.

3. Cuando no se esté usando la batería, manténgala alejada de otros objetos metálicos, como

sujetapapeles (clips), monedas, llaves, clavos,

tornillos u otros objetos pequeños de metal

los cuales pueden actuar creando una cone-

xión entre las terminales de la batería. Originar

un cortocircuito en las terminales puede causar

quemaduras o incendios.

4. En condiciones abusivas, podrá escapar

líquido de la batería; evite tocarlo. Si lo toca

accidentalmente, enjuague con agua. Si hay

contacto del líquido con los ojos, busque asistencia médica. Puede que el líquido expulsado

de la batería cause irritación o quemaduras.

5. No utilice una herramienta ni una batería que

estén dañadas o hayan sido modicadas. Las

baterías dañadas o modicadas podrían ocasionar una situación inesperada provocando un

incendio, explosión o riesgo de lesiones.

6. No exponga la herramienta ni la batería al

fuego ni a una temperatura excesiva. La exposición al fuego o a una temperatura superior a los

130 °C podría causar una explosión.

7. Siga todas las instrucciones para la carga y

evite cargar la herramienta o la batería fuera

del rango de temperatura especicado en

las instrucciones. Una carga inadecuada o a

una temperatura fuera del rango especicado

podría dañar la batería e incrementar el riesgo de

incendio.

Servicio

1. Haga que una persona calicada repare la

herramienta eléctrica utilizando sólo piezas de

repuesto idénticas. Esto asegura que se mantenga la seguridad de la herramienta eléctrica.

2. Nunca dé servicio a baterías que estén daña-

das. El servicio a las baterías solamente deberá

ser efectuado por el fabricante o un agente de

servicio autorizado.

3. Siga las instrucciones para la lubricación y

cambio de accesorios.

Advertencias de seguridad para la

carretilla propulsada a batería

1. Esta máquina no puede ser usada en la vía

pública.

2. Cuando opere la máquina use siempre calzado

de protección con suela antiderrapante. Los

zapatos y botas de seguridad cerrados con suela

antideslizante reducen el riesgo de lesiones.

3.

Inspeccione el camino antes de acarrear objetos

o materiales. Familiarizarse con el camino y ase-

gurarse de que éste sea lo sucientemente ancho

para conducir la máquina bajo carga de forma

segura ayudará a minimizar la pérdida de control.

4. Tenga extrema precaución en terrenos res-

balosos, sueltos o inestables. Las supercies

mojadas y resbalosas, tales como áreas pastosas

húmedas, nieve o hielo, así como los terrenos

sueltos e inestables como supercies con arena

o grava podrían causar que la máquina perdiera

tracción afectando adversamente la conducción,

el frenado y la estabilidad.

5. No opere la máquina sobre pendientes excesi-

vamente pronunciadas. Esto reducirá el riesgo

de pérdida de control, resbalones y caídas que

podrían causar lesiones personales. Las pendientes con una inclinación superior al máximo

recomendado y los desniveles laterales podrían

incrementar el riesgo de inestabilidad y afectar

adversamente la capacidad para detener la

máquina de forma segura.

6. Cuando trabaje en pendientes, asegúrese

siempre de pisar rmemente y de frente

a éstas, nunca arriba ni abajo, y de tener

extrema precaución al cambiar de dirección.

Esto reducirá el riesgo de pérdida de control,

resbalones y caídas que podrían causar lesiones

personales.

7. Cuando sea posible, use las áreas niveladas

para detenerse, cargar y descargar, y nunca

deje la máquina desatendida sobre una pendiente. La máquina es más inestable cuando está

sobre una pendiente que cuando está sobre una

supercie nivelada.

8. Cuando se detenga sobre pendientes, colo-

que la máquina orientada hacia arriba o hacia

abajo y bloquee las ruedas que no tengan el

freno. La máquina es menos estable cuando está

orientada de frente a una pendiente. Las ruedas

sin freno, en especial aquellas de tipo giratorio,

pueden girar de repente y rodar hacia abajo

incluso si el freno de estacionamiento de la rueda

delantera está puesto.

25 ESPAÑOL

Page 26

9. Cuando vaya a dejar la máquina desaten-

dida, ponga el freno de estacionamiento una

vez que la máquina se encuentre en un área

segura para detenerse. El freno de estacionamiento evita el movimiento no intencional de la

rueda delantera y puede mejorar la estabilidad.

10.

Asegúrese de que las rampas estén despejadas

y que sean resistentes y seguras. A n de reducir

el riesgo de lesiones, todas las rampas deberán ser

despejadas de residuos sueltos y lo sucientemente

resistentes para soportar el peso de las cargas previstas que serán transportadas sobre éstas. Éstas debe-

rán tener un bloqueo adecuado por debajo y a ambos

lados para evitar las desviaciones y los movimientos

laterales bajo la carga. Todas las rampas deberán ser

lo sucientemente anchas para asegurar una pisada

rme al acarrear las cargas a través de éstas.

11.

Evite extender las rampas sin usar tablones de

pie o cercos sobre espacios abiertos. Los espa-

cios abiertos elevados y las zanjas son propensos

a caídas por accidente e incrementan la probabilidad de lesiones personales. Utilice tablones de pie

o cercos sobre los espacios abiertos a n de evitar

que la máquina se desvíe fuera de la rampa.

12. Asegúrese de que todos los tornillos de

bloqueo estén rmemente apretados antes

del uso. Los tornillos de bloqueo en las ruedas

traseras así como en la parte delantera y paredes

laterales de la cesta de tipo abierta deberán asegurarse para evitar un movimiento no intencional

de estas piezas ajustables de la máquina.

13.

Nunca opere la máquina en condiciones de

sobrecarga. Asegúrese de que la máquina tenga la

medida de capacidad adecuada para los objetos o

materiales que se van a acarrear. Las cargas excesivas harán que la máquina sea más difícil de maniobrar y detener, incrementarán el tiempo de parada y

la distancia, y aumentarán el riesgo de inestabilidad.

14. Nunca opere la máquina en condiciones de

apilamiento excesivo. Apilar material sobre el

borde de la caja o los lados de la caja puede causar que la máquina pierda el equilibrio y el control

de forma incontrolable.

15. Utilice anclajes para sujetar las cargas. Las

cargas sueltas y/o no aseguradas tienen mayor

probabilidad de desplazarse y ocasionar la pérdida de estabilidad y control.

16. Mantenga siempre una sujeción rme en los

mangos. La pérdida de control puede incrementar

el riesgo de lesiones personales.

17. Retire la llave de seguridad cuando no vaya a

utilizar la máquina. La llave de seguridad evita

el uso accionado de manera accidental de la

máquina, por ejemplo por niños u otras personas

no capacitadas ni autorizadas. Sin la llave, la

alimentación eléctrica no podrá activarse.

18. Utilice una placa resistente que funcione para

evitar un deslizamiento o desenganche al

cargar y/o descargar esta máquina para transporte, o al moverla entre diferentes niveles.

Asegúrese de que la inclinación de la placa no

exceda de 12° y use la máquina lenta y cuidadosamente. Una operación inestable y rápida

podría ocasionar una volcadura y/o una caída.

19. No desarme, repare ni modique esta

máquina.

Operación

1. Cuando opere la máquina, párese detrás de

ésta y sujete los mangos rmemente.

2. No opere la máquina mientras esté montado

sobre ella.

3. No permita que otras personas se monten

sobre la máquina.

4. Cuando opere la máquina en reversa o camine

hacia atrás, vea detrás suyo y tenga cuidado

de no resbalarse o tropezarse.

5. No utilice la máquina cuando no tenga buena

visibilidad ya que existe riesgo de golpear

contra obstáculos.

6. Cuando opere la máquina sobre un suelo irre-

gular, reduzca la velocidad y tenga cuidado.

7.

Evite usar la máquina sobre suelo blando para evitar una volcadura debido a un colapso del arcén.

8. No opere la máquina sobre pendientes elevadas con una inclinación mayor a 12°.

9. En caso de observar alguna anormalidad,

detenga la máquina sobre suelo plano. Antes

de inspeccionar la máquina, jale la palanca

del freno y bloquee el freno, luego apague la

máquina.

10. Antes de operar la máquina, asegúrese de

que la palanca de bloqueo haya sido jalada

completamente hacia abajo y esté totalmente

bloqueada. Si ésta no está totalmente bloqueada,

puede haber riesgo de accidente o lesión debido a

que la cesta o canasta podrían inclinarse y hacer

que los objetos se caigan al ir cuesta abajo.

11. Tenga cuidado de que los cables no se enreden con la carga o los obstáculos.

Operación en pendientes

1. No cruce a través de pendientes.

2. Asegúrese de reducir la velocidad y tener

cuidado.

3. Tenga precaución al arrancar o detener la

máquina en pendientes.

4. Asegure rmemente las cargas con cuerdas

ya que éstas pueden perder estabilidad en

pendientes.

5. Procure que la carga siempre sea mínima ya

que la máquina puede volverse inestable en

función de la condición de la carga.

6. Procure que la carga tenga la altura mínima

posible ya que ésta podría tapar la vista en

pendientes.

7. Nunca estacione la máquina en pendientes

pronunciadas. Estacione la máquina sobre

suelo plano, jale la palanca del freno y bloquee

el freno, luego apague la máquina.

8. No cambie el modo de dirección ni de veloci-

dad en pendientes pronunciadas.

9. No suelte el gatillo interruptor en pendientes

hacia arriba. La máquina podría irse en reversa y

provocar un accidente.

10. Asegúrese de que la capacidad restante de

la batería sea suciente antes de operar la

máquina en pendientes. Si la capacidad restante de la batería no es suciente, cargue

la batería o reemplácela con una que esté

cargada.

26 ESPAÑOL

Page 27

Carga de objetos

1. Evite cargar la máquina con demasiados obje-

tos. Al cargar objetos, asegúrese de seguir las

instrucciones y los límites de carga indicados

en el manual.

2. Asegure rmemente los objetos con cuerdas.

3. Cargue los objetos dentro de la cesta o

canasta. Si los objetos sobresalen de la cesta o

canasta existe riesgo de accidentes debido a que

los objetos pueden caerse o golpear contra obstáculos tales como paredes.

4. Asegúrese de que los objetos cargados estén

por debajo del nivel de los ojos. Si la carga es

demasiado alta, la vista podría taparse y resultar

peligroso. Asimismo, podría haber riesgo de volcadura y lesiones debido a la probabilidad de que

la carga pierda el equilibrio.

5. Cargue los objetos dentro de la cesta o

canasta de manera uniforme. Si los objetos no

se cargan uniformemente, podría haber riesgo de

volcadura y lesiones debido a la probabilidad de

que la carga pierda el equilibrio.

6. Antes de cargar los objetos u operar la

máquina, asegúrese de que la palanca de

bloqueo haya sido jalada completamente hacia

abajo y esté totalmente bloqueada.

7. Asegúrese de cargar los objetos pesados

primero para mantener el equilibrio.

8. No extienda las barras delantera y laterales en

pendientes pronunciadas. Extienda las barras

laterales cuando cargue objetos ligeros.

9. Cuando extienda las barras delantera y

laterales, no rebase el límite de extensión.

Asegúrese de extender las barras laterales

de manera que los lados derecho e izquierdo

tengan la misma longitud y cargue los objetos

uniformemente.

10. Cargue y descargue los objetos sobre suelo

plano.

11. Cuando levante o incline la cesta o canasta,

sujete los mangos y el bastidor rmemente

y colóquese en una postura estable para

trabajar.

Mantenimiento

1. Asegúrese siempre de estacionar la máquina

sobre suelo plano y bloquee la palanca

del freno antes de almacenar la máquina o

intentar realizar una inspección o tarea de

mantenimiento.

GUARDE ESTAS

INSTRUCCIONES.

ADVERTENCIA: NO DEJE que la comodidad

o familiaridad con el producto (a base de utilizarlo

repetidamente) evite que siga estrictamente las

normas de seguridad para dicho producto. El

USO INCORRECTO o el no seguir las normas de

seguridad indicadas en este manual de instrucciones puede ocasionar lesiones graves.

Símbolos

A continuación se muestran los símbolos utilizados

para la herramienta.

volts o voltios

corriente directa o continua

Instrucciones importantes de

seguridad para el cartucho de batería

1.

Antes de utilizar el cartucho de batería, lea todas

las instrucciones e indicaciones de precaución

en el (1) el cargador de batería, (2) la batería, y (3)

el producto con el que se utiliza la batería.

2. No desarme el cartucho de batería.

3. Si el tiempo de operación se ha acortado en

exceso, deje de operar de inmediato. Podría

correrse el riesgo de sobrecalentamiento,

posibles quemaduras e incluso explosión.

4. En caso de que ingresen electrolitos en sus

ojos, enjuáguelos bien con agua limpia y consulte de inmediato a un médico. Esto podría

ocasionar pérdida de visión.

5. Evite cortocircuitar el cartucho de batería:

(1) No toque las terminales con ningún mate-

rial conductor.

(2) Evite guardar el cartucho de batería en un

cajón junto con otros objetos metálicos,

tales como clavos, monedas, etc.

(3) No exponga el cartucho de batería al

agua o la lluvia.

Un cortocircuito en la batería puede causar un ujo

grande de corriente, sobrecalentamiento, posibles

quemaduras e incluso una descompostura.

6. No guarde la herramienta ni el cartucho de

batería en lugares donde la temperatura pueda

alcanzar o exceder los 50°C (122°F).

7. Nunca incinere el cartucho de batería incluso

en el caso de que esté dañado seriamente o

ya no sirva en absoluto. El cartucho de batería

puede explotar si se tira al fuego.

8.

Tenga cuidado de no dejar caer ni golpear la batería.

9. No use una batería dañada.

10.

Las baterías de ión de litio están sujetas a los requisitos reglamentarios en materia de bienes peligrosos.

Para el trasporte comercial, por ej., mediante

terceros o agentes de transporte, se deben tomar

en cuenta los requisitos especiales relativos al

empaque y el etiquetado.

Para efectuar los preparativos del artículo que se

va a enviar, se requiere consultar a un experto en

materiales peligrosos. Si es posible, consulte además otras regulaciones nacionales más detalladas.

Pegue o cubra con cinta adhesiva los contactos

abiertos y empaque la batería de manera que ésta

no pueda moverse dentro del paquete.

11. Siga las regulaciones locales relacionadas al

desecho de las baterías.

GUARDE ESTAS INSTRUCCIONES.

27 ESPAÑOL

Page 28

PRECAUCIÓN: Utilice únicamente baterías

originales de Makita. El uso de baterías no originales de Makita, o de baterías alteradas, puede ocasionar que las baterías exploten causando un incendio,

lesiones personales y daños. Asimismo, esto invalidará la garantía de Makita para la herramienta y el

cargador Makita.

Consejos para alargar al máximo

la vida útil de la batería

1. Cargue el cartucho de batería antes de que

se descargue completamente. Pare siempre la operación y cargue el cartucho de

batería cuando note menos potencia en la

herramienta.

2. No cargue nunca un cartucho de batería que

esté completamente cargado. La sobrecarga

acortará la vida de servicio de la batería.

3. Cargue el cartucho de batería a una tempera-

tura ambiente de 10 °C - 40 °C (50 °F - 104 °F).

Si un cartucho de batería está caliente, déjelo

enfriar antes de cargarlo.

4. Cargue el cartucho de batería si no va a utili-

zarlo durante un período prolongado (más de

seis meses).

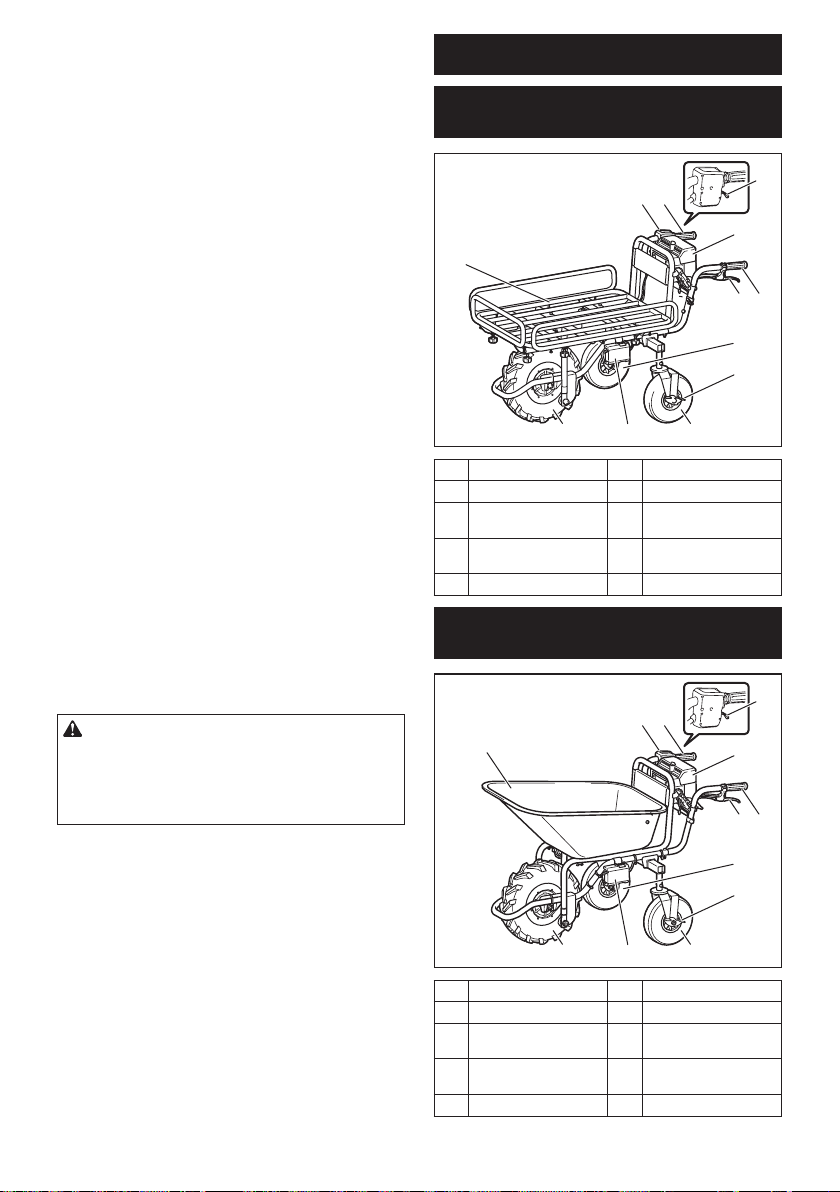

DESCRIPCIÓN DE LAS

PIEZAS

Descripción de las piezas (con la

cesta instalada)

3

1 2

4

10

Descripción de las piezas (con la

canasta instalada)

1 2

10

9 8 6

1 Panel de control 2 Mango

3 Gatillo interruptor 4 Caja de batería

5 Palanca del freno para

la rueda delantera

7 Pedal del freno para la

rueda trasera

9 Rueda delantera 10 Canasta

6 Rueda trasera

8 Lámpara

3

4

5

2

6

7

MONTAJE

PRECAUCIÓN: Asegúrese siempre de que

la máquina haya sido apagada y el cartucho de

batería extraído antes de realizar cualquier tra-

bajo en la máquina.

Ensamble de la unidad principal