Makita TD0101F, TD0101 User Manual

T

ECHNICAL INFORMATION

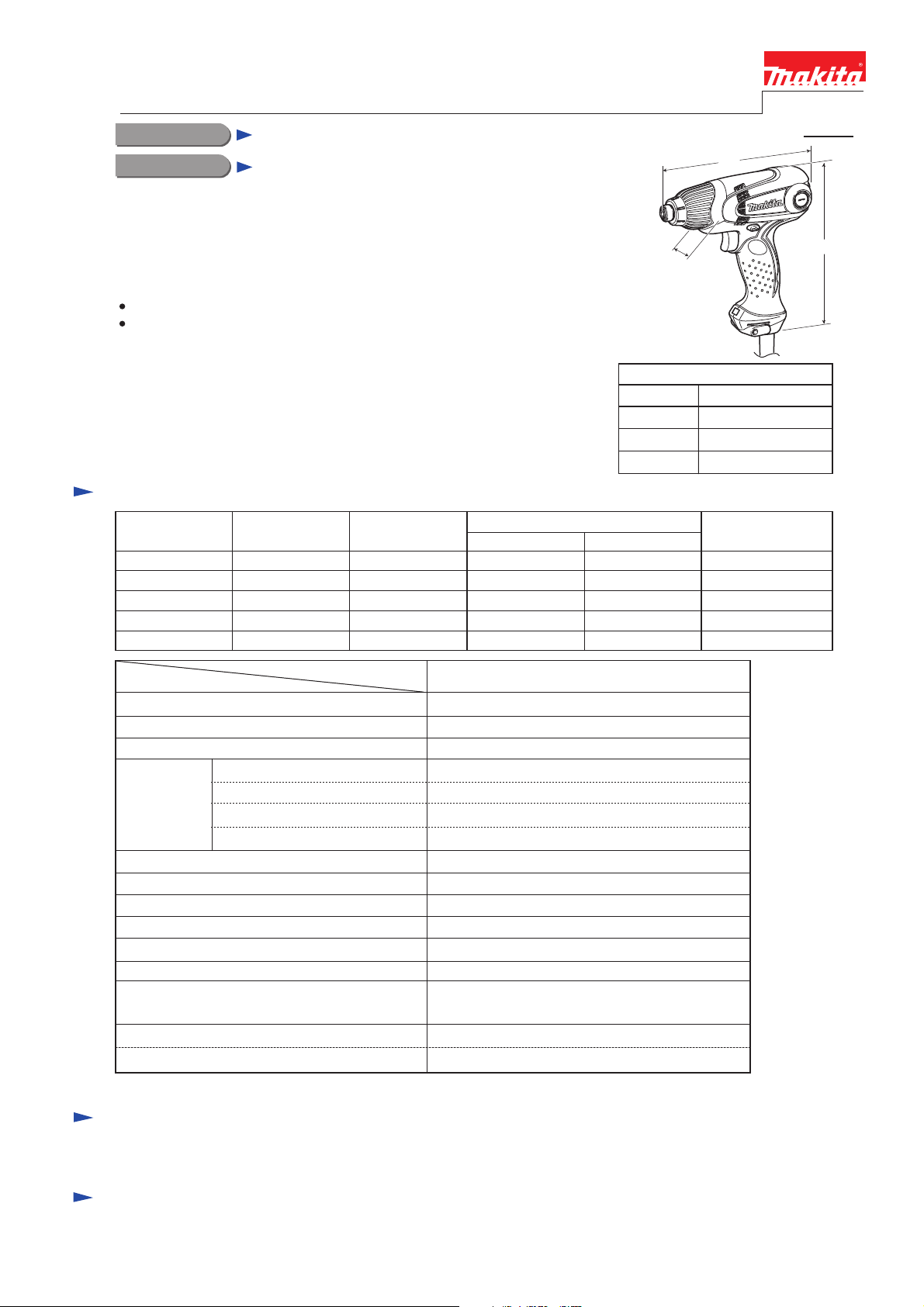

Models No.

Description

TD0101, TD0101F

Impact Driver

CONCEPT AND MAIN APPLICATIONS

Models TD0101 and TD0101F are cost-competitive

100N.m-class impact driver developed as the entry model

of Makita impact driver series.

Its main features are:

Compact design with an overall length of 184mm (7-1/4")

Lightweight at only 0.99kg (2.2lbs)

PRODUCT

P 1/ 14

L

H

W

The only difference between TD0101 and TD0101F is:

TD0101: Without LED job light

TD0101F: With LED job light

Specification

Voltage (V) Cycle (Hz)

110

120

220

230

240

Impacts per min.: min-1=ipm

Driving shank: mm (")

Capacities

Electric brake

Variable speed control by trigger

Reverse switch

Protection against electric shock

Power supply cord: m (ft)

Net weight: kg (lbs)

Current (A)

2.2

1.7

1.1

1.0

1.0

Machine screw

Standard bolt

High tensile bolt

Coarse thread screw

50/60

50/60

50/60

50/60

50/60

Model

Dimensions: mm (")

TD0101, TD0101F

Length (L) 184 (7-1/4)

Width (W)

Height (H)

Continuous Rating (W)

Input Output

230

---

230

230

230

TD0101/ TD0101FSpecifications

0 - 3,600No load speed: min-1 = rpm

0 - 3,200

6.35 (1/4) Hex

M4 - M8 (5/32 - 5/16")

M5 - M14 (3/16 - 9/16")

M5 - M10 (3/16 - 3/8")

22 - 90mm (7/8 - 3-1/2")

100 [1,020] (885)Max. fastening torque*: N.m [kgf.cm] (in.lbs)

No

Yes

Yes

No/ YesLED job light

Double insulation

Australia, New Zealand, Brazil, Chile: 2.0 (6.6)

Other countries: 2.5 (8.2)

0.99 (2.2)

0.99Weight according EPTA-Procedure 01/2003: kg

90

90

90

90

90

Max. Output (W)

67 (2-5/8)

192 (7-9/16)

140

140

140

140

140

*torque at 3 seconds after seating when fastening M12 high tensile bolt

Standard equipment

Phillips bit ......................... 1 pc

Note: The standard equipment for the tool shown above may differ by country.

Optional accessories

Phillips bits, Square bits, Socket bits, Drill chucks, Hex shank auger bits,

Bit piece, Adjustable locator

P 2/ 14

R

epair

CAUTION: Unplug the tool and remove the bit from the machine for safety before repair/

maintenance in accordance with the instruction manual!

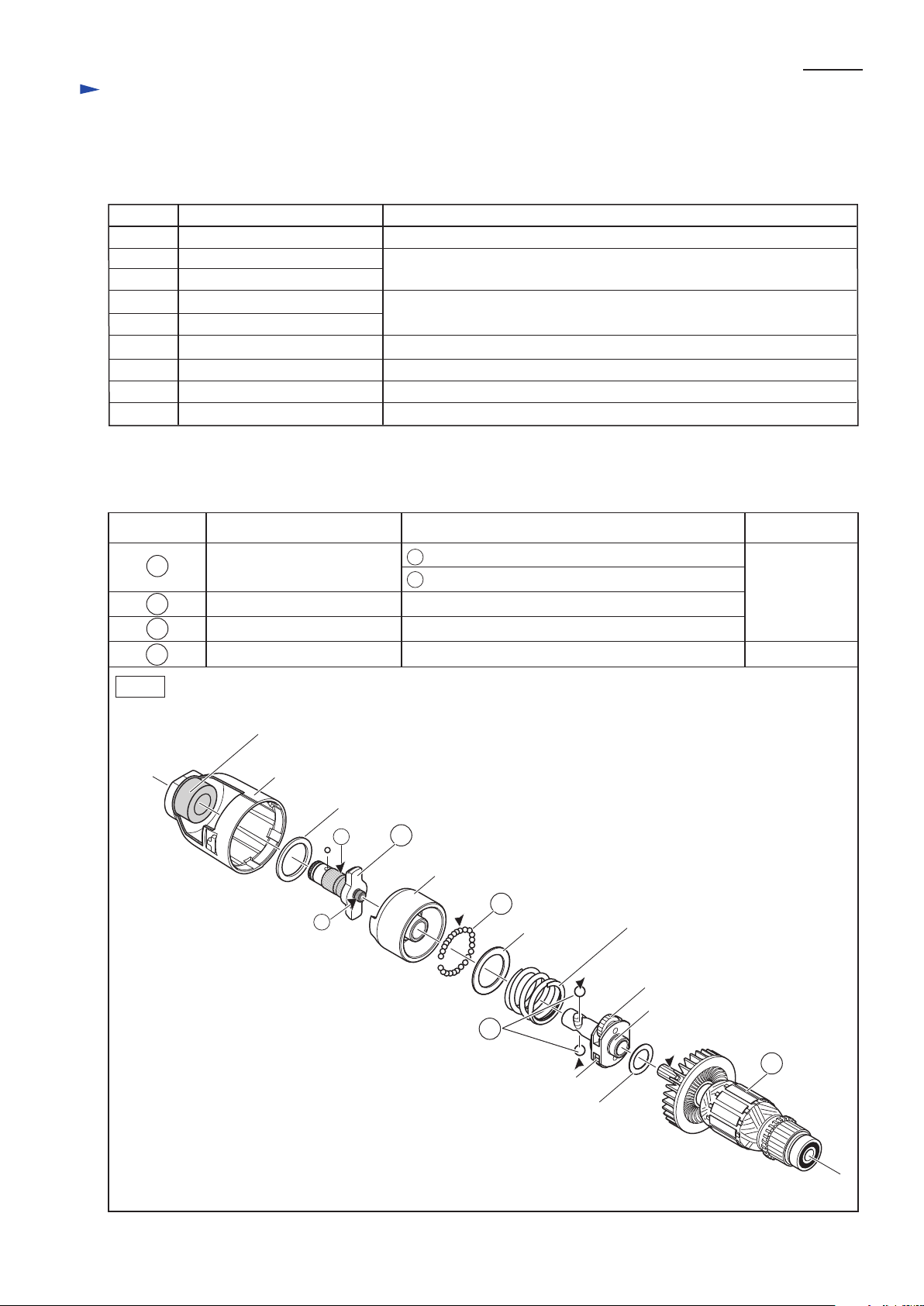

[1] NECESSARY REPAIRING TOOLS

[2] LUBRICATIONS

Fig. 1

Code No.

1R041 Vise plate Disassembling Hammer case complete

1R045 Gear Extractor (large)

Disassembling Hammer

1R223 Torque wrench shaft 20-90N.m

Disassembling Hammer case complete

1R224 Ratchet head 12.7 for 1R223

1R232 Pipe 30 Supporting jig when disassembling Bit sleeve

1R288 Screwdriver magnetizer Magnetizing Screwdriver for removing Steel balls

1R291 Retaining ring S and R pliers Disassembling / Assembling Ring spring 10

1R346 Center attachment for 1R045

134844-7 Socket 27-50 Disassembling Hammer case complete

Description

Use for

Item No.

Apply Makita grease FA.No.2 to the following portions designated with the black triangle to protect parts

and product from unusual abrasion.

Description Amount

approx. 1g

a little

Portion to lubricate

Sleeve 12

Flat

washer 20

Flat washer 12

Compression

spring 21

Hammer

Spur gear 17

Spindle

Spur gear 17

Hammer case complete

Nylon washer 20

13

15

19

28

a

b

13

Anvil

a Drum portion where Sleeve 12 contacts

b Small drum portion which is inserted into Spindle

Steel ball 3 (24 pcs.)

Steel ball 4.8 (2 pcs.)

Armature

Gear teeth for smooth engaging with Spur gear 17

whole portion

whole portion

15

19

28

P 3/ 14

R

epair

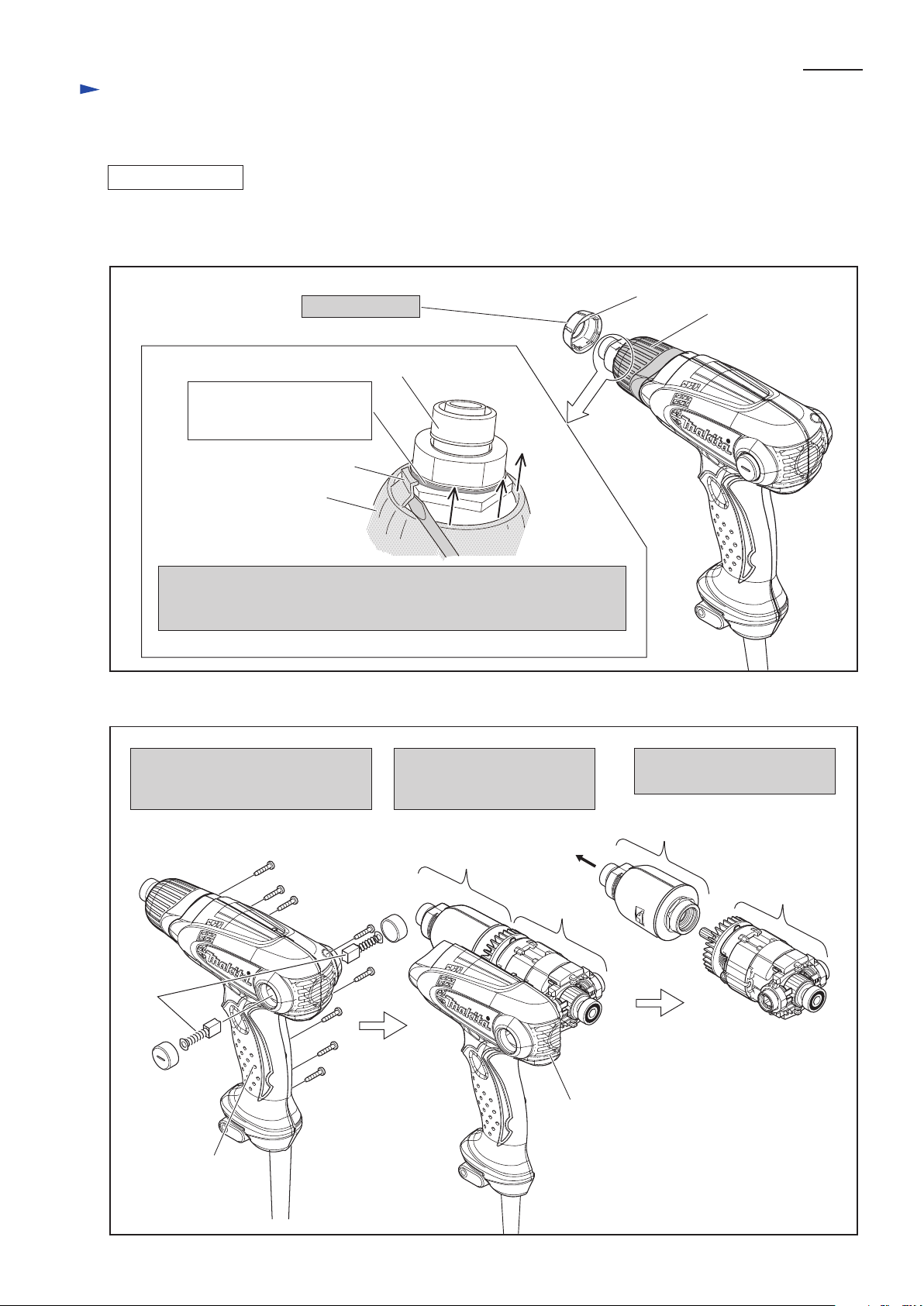

[3] DISASSEMBLY/ASSEMBLY

[3]-1. Hammer Case Section

DISASSEMBLING

(1) Remove Hammer case section from the machine as illustrated in Figs. 2, 3.

Hammer

case cover

Hammer

case cover

Groove of Hammer case for

accepting the hook of

Hammer case cover

Degrooving the hooks of Hammer case cover from the groove of Hammer

case complete, slide Hammer case cover toward Bit sleeve side.

Hammer case cover can be removed from Hammer case complete.

Remove bumper.

Separate Hammer case section

from Motor section.

hook

Bit sleeve

Bumper

Housing set (L)

Fig. 2

Fig. 3

Housing set (L)

Carbon

brush

3x16 Tapping screw

(8pcs.)

Hammer case

section

Hammer case section

Motor

section

Motor section

Remove Carbon brush and then,

disassemble Housing set (R) by

unscrewig 3x16 Tapping screws.

Remove Motor and Hammer

section in a set from Housing

set (L).

P 4/ 14

R

epair

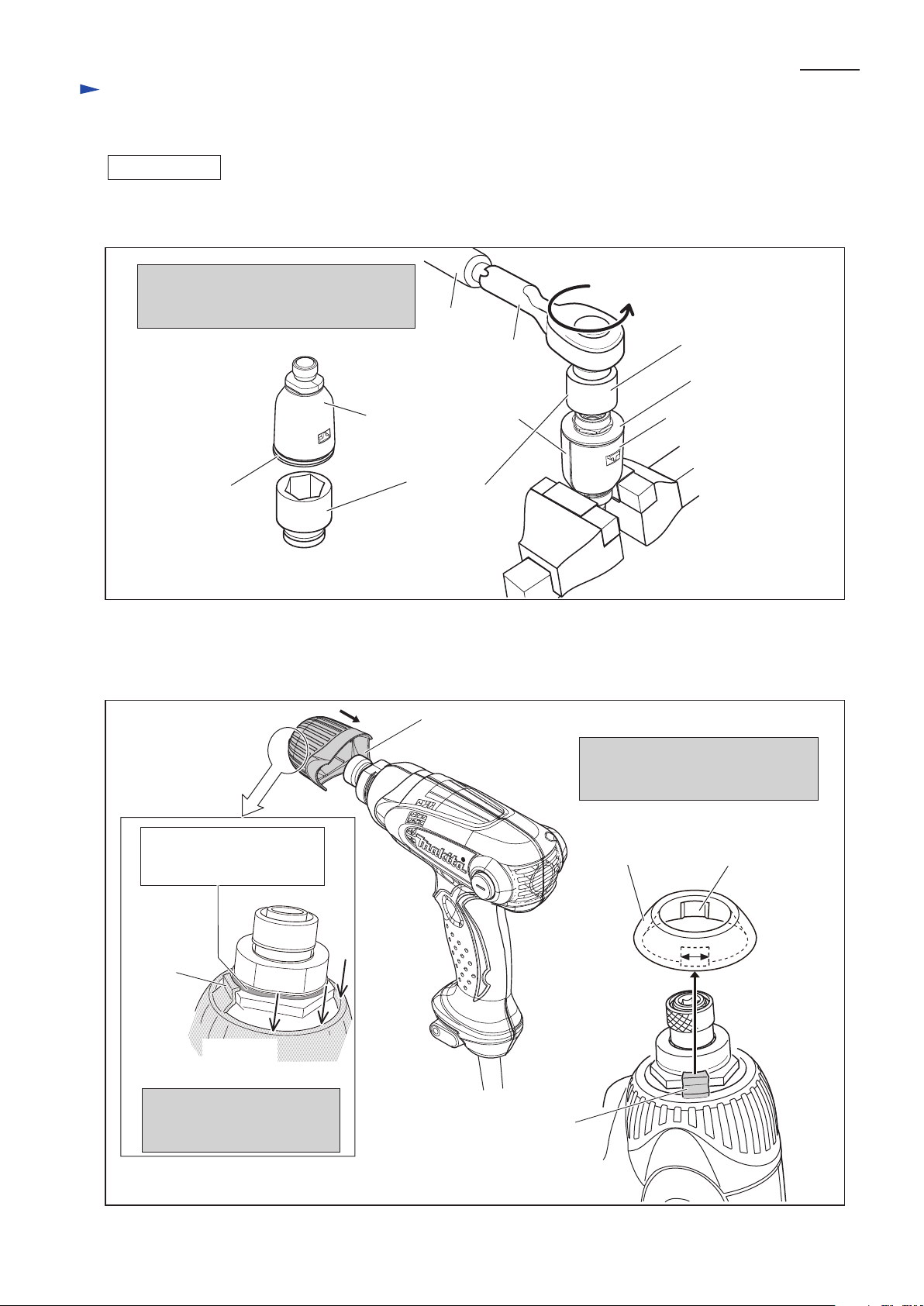

[3] DISASSEMBLY/ASSEMBLY

[3]-1. Hammer Case Complete

DISASSEMBLING

ASSEMBLING

Spur gear 17

Assemble Hammer section

while engaging Spur gear 17

with Internal gear 43.

Assemble Hammer case complete

to Bearing box while aligning the

hollows of Bearing box to the

projections of Internal gear 43.

Then turn Hammer case complete

counterclockwise by hand and

tighten as firm as possible.

Set Bearing box to 134847-1 held with vise.

And then insert the ring portion of Internal

gear 43 into Bearing box.

Internal

gear 43

Vise

1R041

flat portions

Bearing box

Hammer case

complete

Hold the flat portion of Hammer

case complete in vise with 1R041.

Hammer case complete can

be disassembled as illustrated

below.

Vise

134847-1

Attach 134847-1 and 1R224 to 1R223,

and fit 134847-1 to the hex portion of

Bearing box.

Then turn 1R223 clockwise.

1R224

1R223

Bearing box

Hammer

Internal gear 43

Fig. 4

Fig. 5

(2) The removed Hammer case section is disassembled as illustrated in Fig. 4.

Hammer

section

Hammer case

complete

Hammer case

complete

Bearing box

(1) Use 134847-1 as a supporting jig for Bearing box and assemble Hammer case complete as illustrated in Fig. 5.

Internal

gear 43

hollow (6 pcs.)

projections (6pcs.)

134847-1

Bearing

box

Bearing

box

Internal gear 43

ring portion

Hammer

case cover

Bumper

Assemble Bumper while fitting

the hollows to the hooks of Hammer

case cover.

P 5/ 14

R

epair

[3] DISASSEMBLY/ASSEMBLY

[3]-1. Hammer Case Complete

ASSEMBLING

Bearing box

Bearing box

Hammer case complete

Vise

134847-1

1R224

1R223

134847-1

Hammer case complete

Assemble Hammer case complete

by turning Bearing box counter clockwise.

The fastening torque is 25 - 30 N.m.

(2) Set the assembled Hammer case complete in the same position as disassembling. And assemble as illustrated

in Fig 6.

Fig 6

(3) Join Motor section with Hammer case complete. And assemble them to Housing set (L). Refer to Fig. 3.

(4) Assemble Brush holder and Carbon brush. And then, assemble Housing set (R). Refer to Fig. 3.

(5) Assemble Hammer case cover and Bumper as illustrated in Fig. 7.

Groove of Hammer case for

accepting the hooks of

Hammer case cover

Fit the hooks of Hammer case

cover to the groove of Hammer

case complete.

hook

hook

hollows for fitting

to hooks of Hammer

case cover

Hammer

case cover

Fig. 7

Loading...

Loading...